Page 1

RUN PROGRAM

RELAY 1 RELAY 2

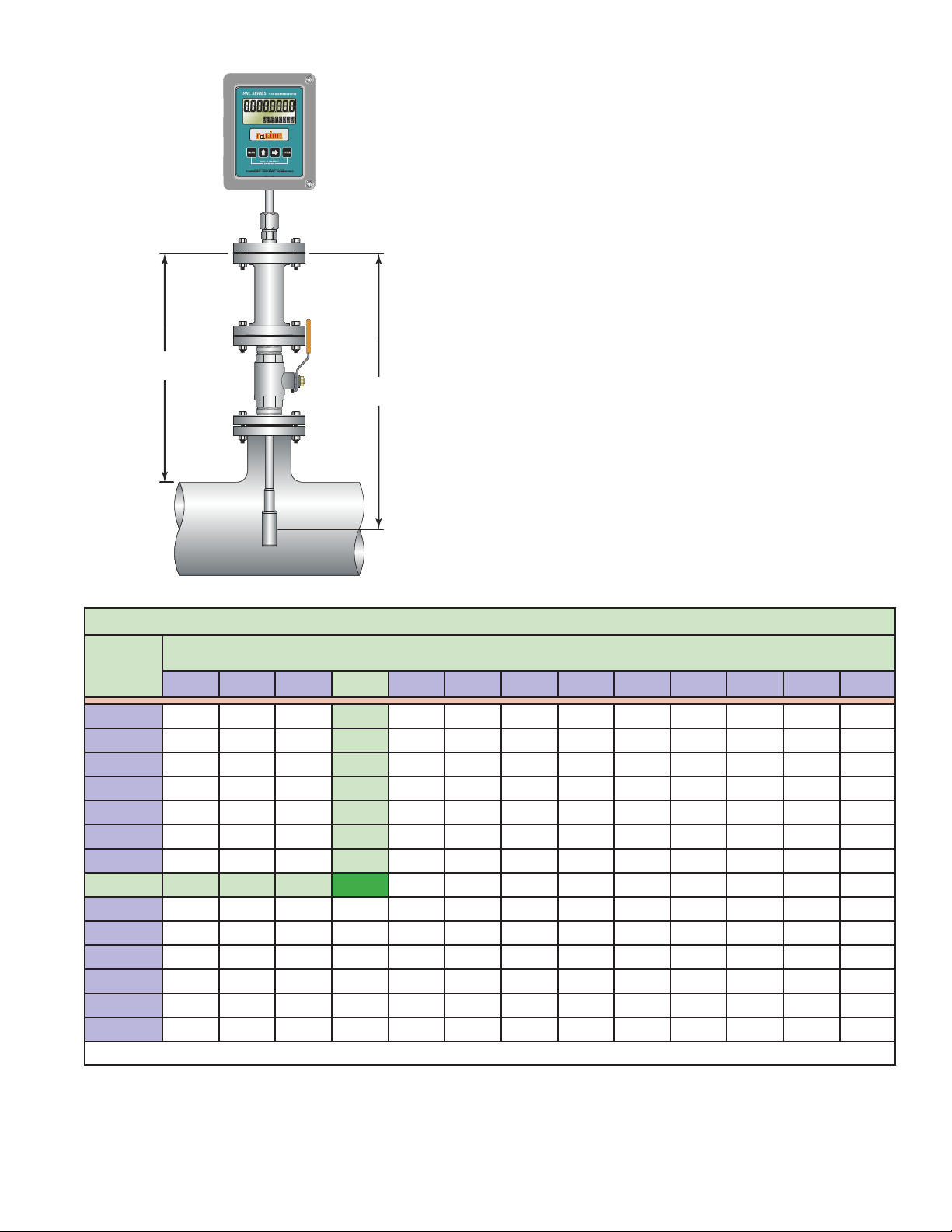

RNL Vortex Insertion

Liquid Flow Meter

Installation & Operation Manual09-VRX-UM-00408 (July 2012)

Page 2

2

09-VRX-UM-00408 07/12

Page 3

TABLE OF CONTENTS

INTRODUCTION ................................................................................................................4

INSTALLATION ...................................................................................................................5

Mechanical Installation ...........................................................................................................................5

Installation Location ............................................................................................................................................................... 5

Back Pressure Calculations .....................................................................................................................7

Electrical Installation ...............................................................................................................................9

Wiring ........................................................................................................................................................................................10

Pulse Output ........................................................................................................................................................................... 11

Cable Installation ................................................................................................................................................................... 11

+ 4-20 mA Terminals ............................................................................................................................................................. 11

OPERATING THE MONITOR ............................................................................................13

Basic Programming Mode .....................................................................................................................13

Additional Scaling Parameters .............................................................................................................15

Totalizer Functions ................................................................................................................................17

TROUBLESHOOTING .......................................................................................................18

APPENDIX ........................................................................................................................20

Additional Installation Requirements ...................................................................................................20

Introduction ............................................................................................................................................................................20

Turbulence ...............................................................................................................................................................................20

Swirl ............................................................................................................................................................................................20

Sonic Noise ..............................................................................................................................................................................21

Velocity Pro le for RNL Insertion Meters ....................................................................................................................... 21

Straight-Run Piping Considerations ................................................................................................................................21

Temperature and Pressure Tap Locations .....................................................................................................................22

RNL Insertion Style Meter Installation ............................................................................................................................22

Hot Tap Insertion Flow Meter Installation ............................................................................................22

Maximum Fluid Velocity ......................................................................................................................................................23

Flow Pro ling .........................................................................................................................................25

Reducing the Pipe Diameter ..................................................................................................................26

SPECIFICATIONS .............................................................................................................27

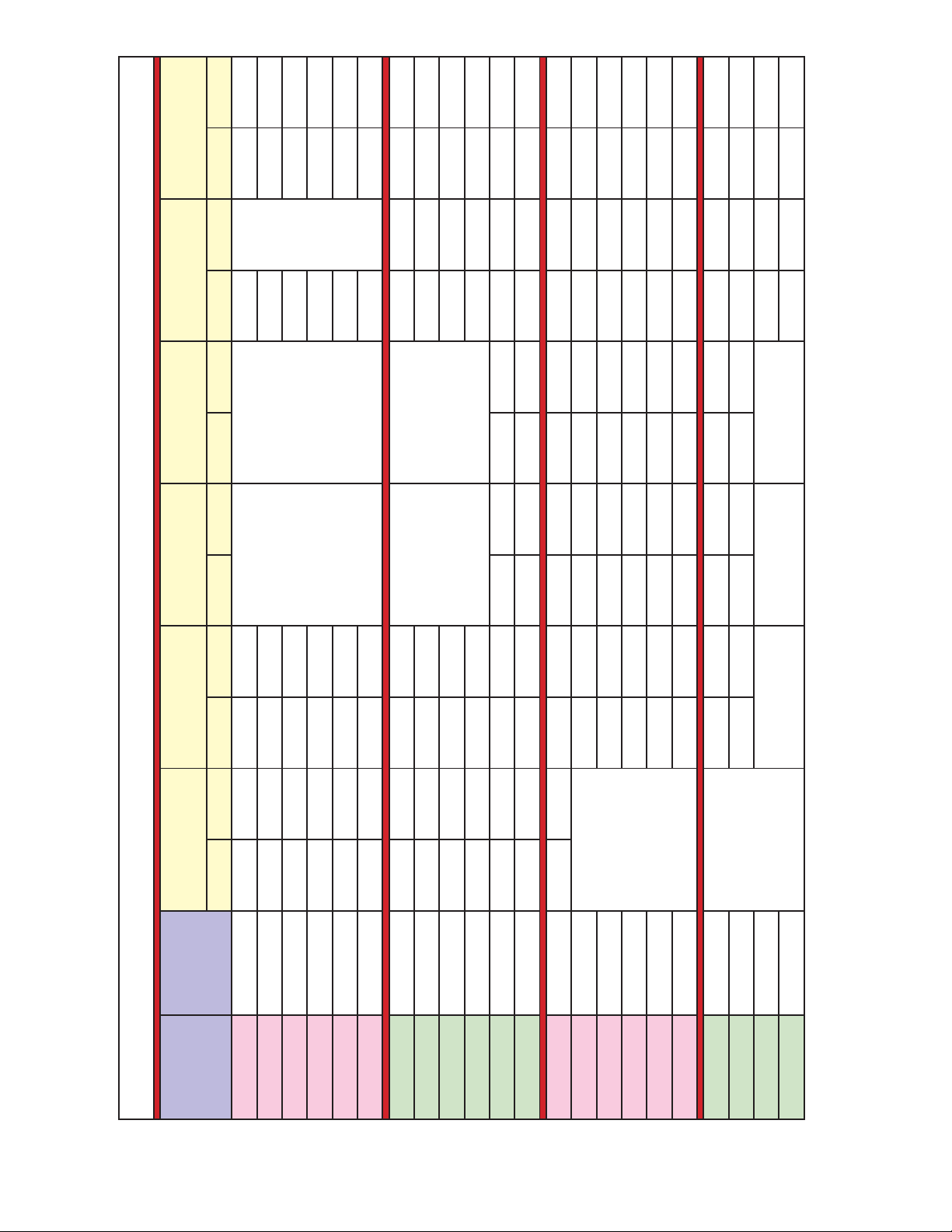

PIPE TABLES .....................................................................................................................28

WARRANTY ......................................................................................................................33

09-VRX-UM-00408 07/12

3

Page 4

FIGURES

FIGURE 1 VON KARMAN VORTEX STREET ............................................................................................4

FIGURE 2 BACK PRESSURE CALCULATIONS .........................................................................................7

FIGURE 3 OUTLINE DIMENSIONS FOR RNL SERIES .............................................................................8

FIGURE 4 FLOW METER TERMINAL FUNCTIONS .................................................................................9

FIGURE 5 LOAD RESISTANCE VS. SUPPLY VOLTAGE ..........................................................................10

FIGURE 6 DEDICATED POWER SUPPLY HOOKUP ..............................................................................11

FIGURE 7 LOOP POWER HOOKUP .......................................................................................................12

FIGURE 8 RNL SEPARATE POWER AND RECEIVER HOOKUP ............................................................12

FIGURE 9 420 mA TEST SETUP ............................................................................................................15

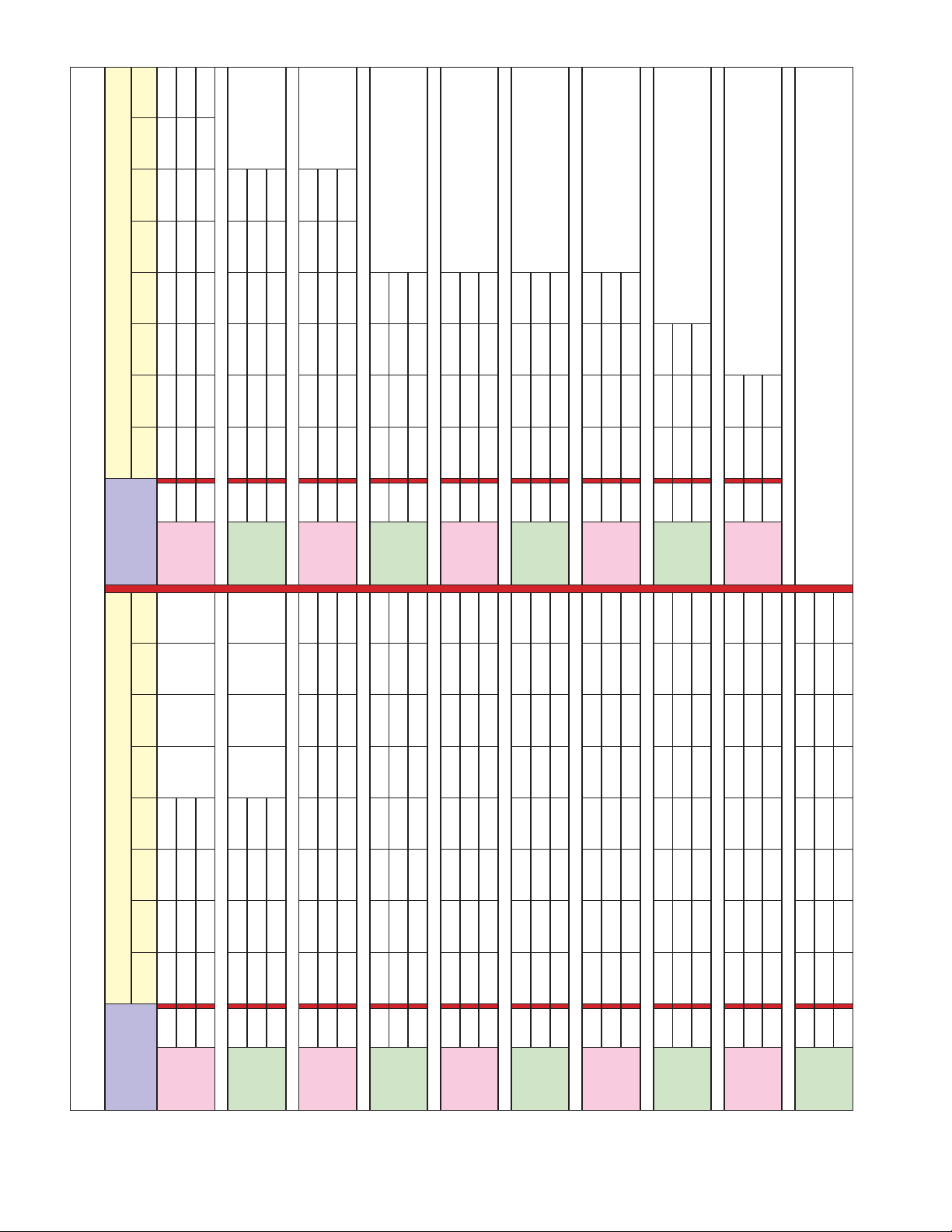

FIGURE 10 PROGRAMMING MENU MAP .............................................................................................19

FIGURE A1 TURBULENCE ......................................................................................................................20

FIGURE A2 SWIRL ..................................................................................................................................20

FIGURE A3 SONIC NOISE ......................................................................................................................21

FIGURE A4 HOT TAP CUTAWAY ............................................................................................................22

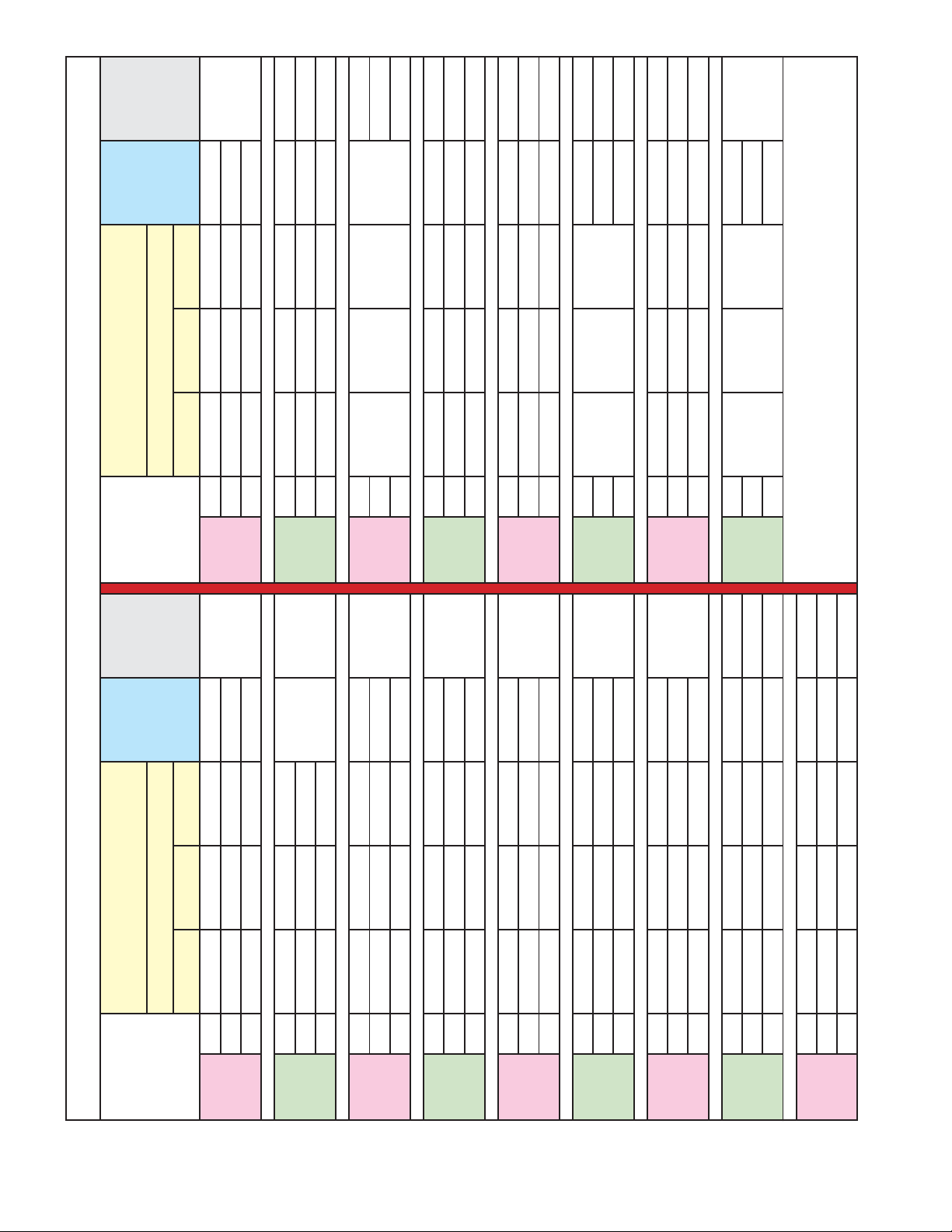

FIGURE A5 HOT TAP DIMENSIONS ......................................................................................................23

FIGURE A6 INSERTION DEPTH .............................................................................................................24

FIGURE A7 MAKING REDUCTIONS OR ENLARGEMENTS ..................................................................26

TABLES

TABLE 1 MINIMUM PIPING REQUIREMENTS ........................................................................................6

TABLE 2 FLOW RANGES ..........................................................................................................................6

TABLE 3 LINE RESISTANCE FOR CURRENT LINES ...............................................................................10

TABLE 4 EXPONENT MULTIPLIERS ......................................................................................................14

TABLE A1 INSERTION DEPTH ...............................................................................................................24

TABLE A2 FLOW PROFILE RAW DATA ...............................................................................................25

TABLE A3 FLOW PROFILE NORMALIZED DATA ................................................................................25

TABLE A4 STEEL, STAINLESS STEEL, P.V.C. PIPE STANDARD CLASSES .........................................28

TABLE A5 CAST IRON PIPE STANDARD CLASSES ............................................................................30

TABLE A6 DUCTILE IRON PIPE STANDARD CLASSES ......................................................................31

TABLE A7 TUBING SCHEDULES ...........................................................................................................32

4

09-VRX-UM-00408 07/12

Page 5

INTRODUCTION

The RNL vortex shedding ow meters are designed to provide accurate and repeatable liquid ow measurements in a variety

of common ow measurement applications. The ow meters employ a patented ultrasonic technique to measure a form of

turbulence created in the ow stream. This turbulence, know as a Von Karman Vortex Street, is related to the volumetric ow

through a full pipe.

An everyday example of a vortex shedding phenomenon is a ag waving in the breeze: the ag waves due to the vortices

shed by air moving across the

agpole.

Within the ow meter, as a uid

moves across a strut or “blu body”,

vortices are also shed but on a

smaller scale. The vortices form

alternately, from one side to the

other, causing pressure uctuations.

The alternating pressure changes are

detected by the piezoelectric crystals

in the sensor tube, and are converted

to an analog signal or pulse output.

The frequency of the vortices is

directly proportional to the ow. This

results in extremely accurate and

repeatable measurements with no troublesome moving parts (see Figure 1).

Bluff

Body

Ultrasonic

Beam

Transmitter

T

R

Receiver

FIGURE 1 VON KARMAN VORTEX STREET

Counter

The ow meters primary output is a 4-20 milliampere (mA) current. The value of the current output is proportional to the ow

rate. The secondary output is a pulse train whose frequency is directly proportional to the ow.

Each RNL ow meter is calibrated against ow standards traceable to NIST (National Institute of Standards and

Technology).

The RNL ow meter is an insertion style retractable ow meter, for pipe sizes 4 inches (102 mm) and larger. The meter is

usually installed through a 2 inch full port isolation valve (See Figure A4), which permits the meter to be retracted or inserted

without shutting down the system.

The RNL series ow meters are calibrated in actual volumetric ow rates, such as gallons per minute (GPM) and comes with a

standard rate and total display.

09-VRX-UM-00408 07/12

5

Page 6

INSTALLATION

MECHANICAL INSTALLATION

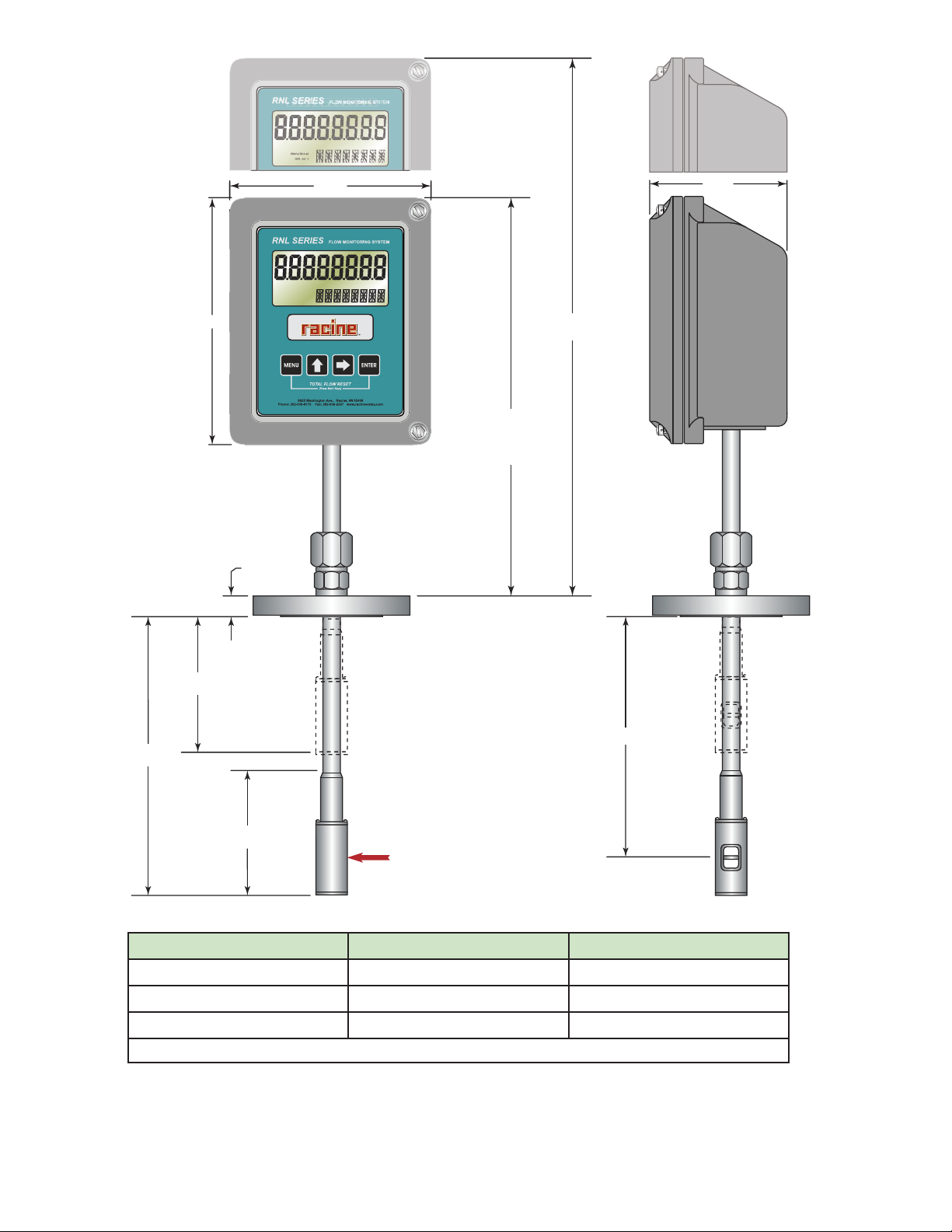

The ow meter is shipped completely assembled, tested and ready to install and operate in its permanent location. See Figure

3 for the applicable outline dimensions for the ow meter. See the Appendix for additional installation information.

Installation Location

The RNL series ow meters use a combination of ultrasonic and vortex shedding technologies to measure volumetric ow. An

ultrasonic noise source can interfere with this technique, therefore the meter should not be installed near high intensity ultrasonic

noise sources. Common ultrasonic noise sources include the following:

» Slightly open valves operating with large pressure drops.

» Small pipe leaks in high pressure systems.

» Venturis operating at near-sonic ow rates.

» Sonic nozzles.

If these ultrasonic noise sources cannot be eliminated, the meter should be mounted with at least one elbow between the ow

meter and the noise source remembering to keep in mind the straight pipe run requirements as described next.

The sensor should be installed with at least 20 pipe diameters of straight pipe upstream and 10 pipe diameters downstream.

This condition provides a fully developed, symmetrical ow pro le that is necessary to obtain accurate and repeatable results.

Shorter upstream/downstream piping may be used, although a shift in calibration may occur. If severe turbulence or distorted

ow pro les are present, ow straighteners should be used. Consult factory for shorter upstream/downstream con gurations.

When installing the ow meter in a newly constructed process line, a strainer should be installed upstream of the meter to

prevent foreign material from damaging the meter strut or obstructing the ow. Damage to the strut could a ect the accuracy

of the meter.

In order to prevent cavitation, it is important that the required back pressure be maintained. The minimum required back pressure

varies with temperature. See the back pressure calculations in Figure 2. The sensor should be installed using the minimum piping

requirements indicated in Table 1.

Maximum volumetric ows are determined by the inside diameter of the pipe and the velocity of the uid being measured.

Calculations of minimum and maximum ow ranges are based on the pipe being full at all times. See Table 2 for ow ranges in

common pipe sizes.

BACK PRESSURE CALCULATIONS

At high ow rates, cavitation may occur, causing a ow meter to be inaccurate. Cavitation can be prevented by increasing the

back pressure. The following equation determines the minimum back pressure required to prevent cavitation:

P1 = PVP + 0.03 V

where: P1 = line pressure at the meter PSIA

P

V = line velocity FPS

EXAMPLE: In water at 65° F owing with a speed of 25 fps, the vapor pressure is 0.3 PSIA.

P1 = 0.3 + 0.03 (25)2 = 19.05 PSIA If atmospheric pressure is 14.69 PSIA,:

Then P1 = 19.05 PSIA - 14.69 PSIA = 4.36 PSIG

= vapor pressure of the liquid PSIA

VP

²

Maintaining a back pressure of 5 PSIG or greater will prevent cavitation.

FIGURE 2 BACK PRESSURE CALCULATIONS

6

09-VRX-UM-00408 07/12

Page 7

Upstream Obstruction

90° Elbow 10

Two 90° Elbows, Same Plane 15

Two 90° Elbows, Di erent Planes 20

Flow Straightener

(recommended when ever an axial swirl exists in the ow stream)

Fully Open Shut-o Valve 5

Minimum Required Straight-run Pipe

Diameters Upstream from Meter

10

Downstream Obstruction

Control Valve 5

Minimum Required Straight-run Pipe

Diameters Downstream from Meter

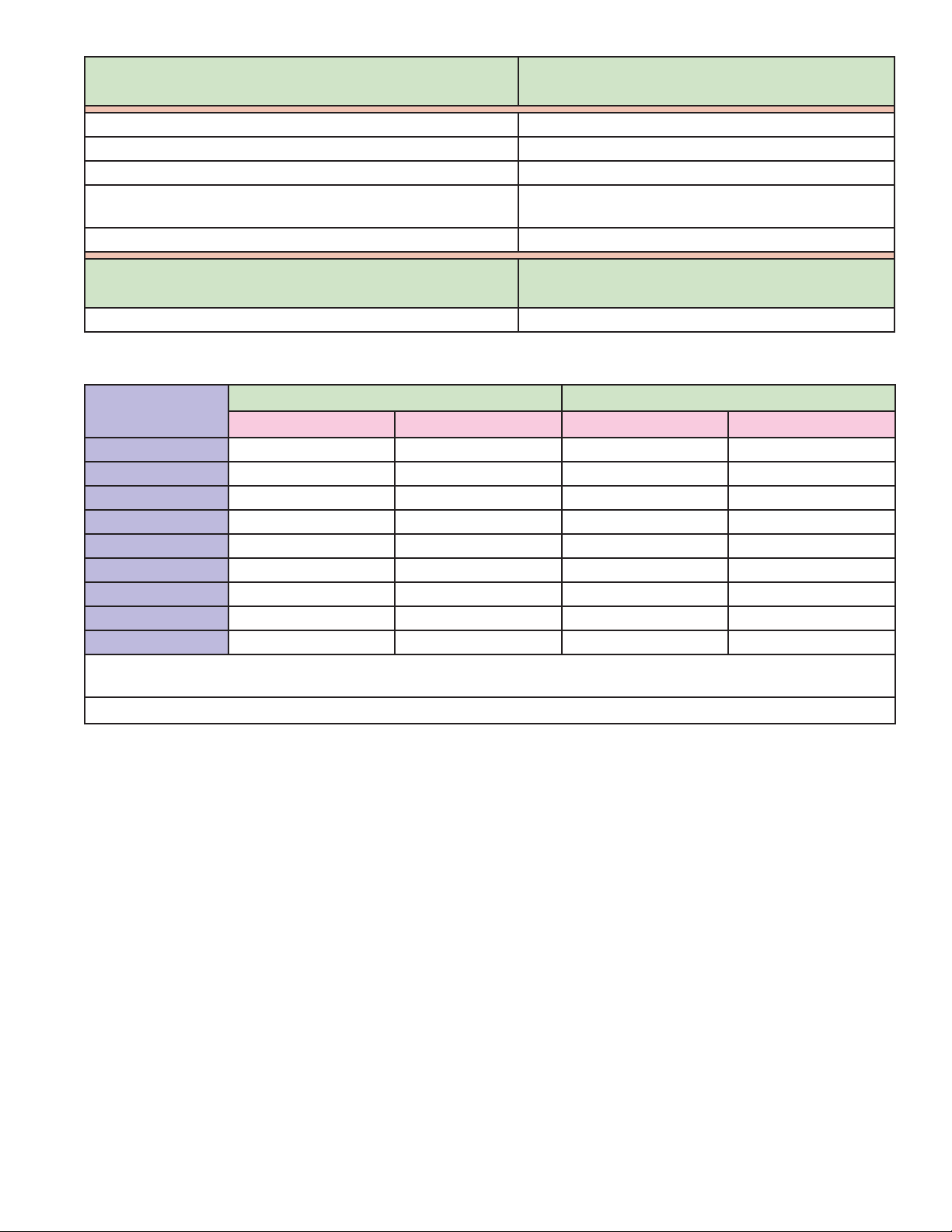

TABLE 1 MINIMUM PIPING REQUIREMENTS

NOMINAL SIZE

INCH (mm)

4.0 (100) 79 635 300 2,403

6.0 (152) 180 1441 682 5,454

8.0 (203) 312 2,495 1,181 9,444

10.0 (254) 492 3,933 1,861 14,886

12.0 (305) 698 5,582 2,641 21,130

14.0 (356) 843 6,746 3,192 25,537

16.0 (406) 1,102 8,813 4,170 33,360

18.0 (457) 1,394 11,155 5,278 42,226

20.0 (508) 1,733 13,864 6,560 52,481

Based on water at 1 centistoke at 73° F, schedule 40 pipe 1 to 20 fps (0.3 to 6 mps). For reference only, consult sizing

program for temperature and pressure conditions other than those listed here.

GALLONS PER MINUTE (gpm) LITERS PER MINUTE (lpm)

Minimum Flow Maximum Flow Minimum Flow Maximum Flow

TABLE 2 FLOW RANGES

09-VRX-UM-00408 07/12

7

Page 8

RUN

R

ELAY

1

7.00"

.75"

RUN PROGRAM

RELAY 1 RELAY 2

5.75"

9.75" Maximum

at Maximum

Insertion

C Maximum

Retracted

3.93"

4.00" Maximum

Retracted

B Maximum

Insertion

4.50"

Maximum

ABC

12.00 (305) 13.125 (333) 18.83 (478)

24.00 (610) 25.125 (638) 30.83 (783)

36.00 (914) 37.125 (943) 42.83 (1088)

All dimensions are in inches (mm)

FIGURE 3 OUTLINE DIMENSIONS FOR RNL SERIES

A

Flow

8

09-VRX-UM-00408 07/12

Page 9

The RNL Series ow meters are designed to mount on a standard ANSI 150 lb., 2” pipe ange. It is recommended that the customer

conduct a ow pro le survey and place the probe at the optimum point. The labeling of the ow direction on the sensor should

be aligned with the ow in the pipe. Maximum insertion depth is a product of pipe size and uid velocity, see Appendix Table

A1 for Insertion Depth Chart.

CAUTION: Avoid bending the vortex strut or damaging the transducers during installation. The torque value for

the Conax tting is 90-100 ft. lbs.

NOTE: See Appendix for further information on installation.

ELECTRICAL INSTALLATION

TP1

TP2

TP3

TRANSDUCER

CONNECTIONS

White

Green

Black

Green

White

Black

Label Denoting

Receiving

XMIT

RECV

4-20 Pulse

Transducer Cable

PULSE

OUTPUT

LOOP POWER

R

CONNECTIONS

FIGURE 4 FLOW METER TERMINAL FUNCTIONS

Electrical connections for the ow meter are made using screw-type terminals located inside the electronics enclosure. To

expose these terminals, open the cover. The functions of these terminals are illustrated in Figure 4.

09-VRX-UM-00408 07/12

9

Page 10

Wiring

A two conductor cable of 16 to 24 AWG solid or stranded wire is required to make connections to the ow meter. It is recommended

that a shielded interconnecting cable be used. The maximum cable length for the power depends on the supply voltage lines

required to drive the ow meter and the current meter being used to monitor the current output of the ow meter. The maximum

length of the cable is determined by using Figure 5 to calculate the maximum load (resistance in Ohms) that can be driven using

the known power supply voltage. In determining this value the voltage drop across the meter being used to monitor the current

output of the ow meter must be considered. After this value has been found, Table 3 can be used to calculate the resistance in

the cable being used and adjust the input voltage as required.

Ohms/Ft Related to Wire Size (AWG)

16 AWG = 0.00420 Ohm/Ft

18 AWG = 0.00651 Ohm/Ft

20 AWG = 0.01035 Ohm/Ft

22 AWG = 0.01310 Ohm/Ft

24 AWG = 0.02620 Ohm/Ft

TABLE 3 LINE RESISTANCE FOR CURRENT LINES

Loop Voltage - 7 VDC

0.02

= Maximum Loop Resistance

1200

1100

1000

900

800

700

600

500

Loop Load (Ohms)

400

300

Operate in the

Shaded Regions

200

100

10 12 14 16 18 20 22 24 26 28 30

Loop Voltage (VDC)

10

FIGURE 5 LOAD RESISTANCE VS. SUPPLY VOLTAGE

09-VRX-UM-00408 07/12

Page 11

Pulse Output

The pulse output is a secondary output and is not intended for long transmission. The load on the line must be 50 kilohm

minimum and 1,000 picofarads (pf) maximum.

The maximum length of shielded cable that can be attached to this output is 100 feet.

Cable Installation

To install the cable in the ow meter, route the cable through the cable gland located on the electronics enclosure.

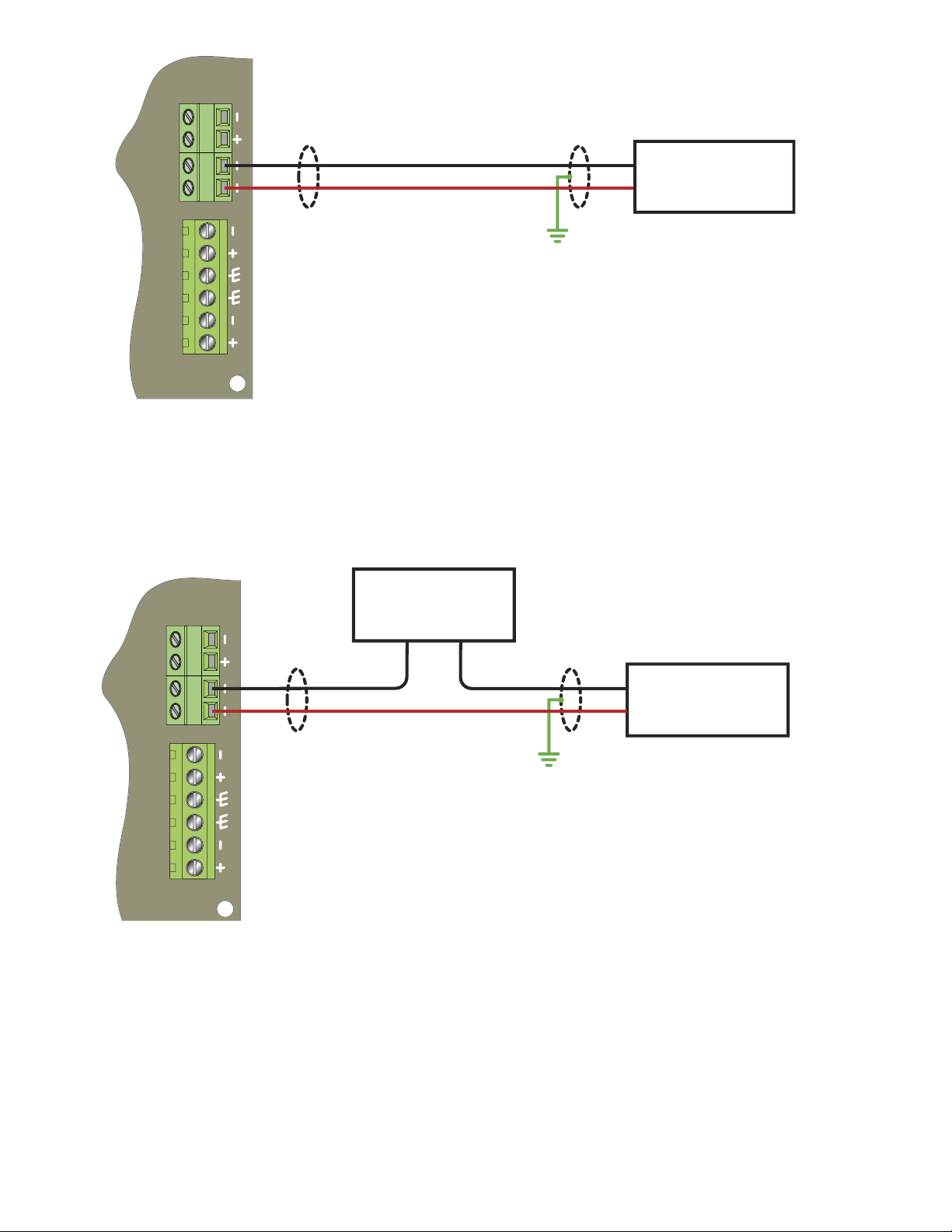

The wiring of the other end of the cable will vary depending on the speci c installation requirements. Figures 6, 7, and 8 show

the wiring diagram for variations of ow meter installation.

The ow meter’s 4 position terminal strip provides all the connections needed to operate the ow meter.

+ 4-20 mA Terminals

The + 4-20 mA terminals are used for the ow meter’s power supply. This power supply should be 10 to 30 Volt DC and be capable

of supplying 25 Milliamp to the ow meter. Because this meter has a built-in display no additional wiring is necessary for basic

operation (See Figure 6).

Pulse

-

4-20

+

2 CONDUCTOR

SHIELDED CABLE

RECV

XMIT

FIGURE 6 DEDICATED POWER SUPPLY HOOKUP

CURRENT OUTPUT 2 WIRE HOOKUP

STAND ALONE POWER SUPPLY

-

10-30 VDC

POWER SUPPLY

+

09-VRX-UM-00408 07/12

11

Page 12

Pulse

-

RECEIVER

+

4-20 mA

4-20

RECV

XMIT

-

+

2 CONDUCTOR

SHIELDED CABLE

CURRENT OUTPUT 2 WIRE HOOKUP

RECEIVER AND POWER SUPPLY COMBINED

FIGURE 7 LOOP POWER HOOKUP

If the current loop is used to transmit data the receiving device may also be the current source for the instrument (See Figure 7).

Finally the device used to measure the current can be installed in series with the return line as illustrated in Figure 8. This output

is a standard 4 to 20 Milliamp output, where 4 Milliamp corresponds to no ow and 20 Milliamp indicates 100% (full scale) ow.

4-20 mA

RECEIVER

Pulse

+

-

-

-

10-30 VDC

4-20

RECV

XMIT

+

2 CONDUCTOR

SHIELDED CABLE

POWER SUPPLY

+

CURRENT OUTPUT 2 WIRE HOOKUP

SEPARATE RECEIVER AND POWER SUPPLY

FIGURE 8 RNL SEPARATE POWER AND RECEIVER HOOKUP

If the pulse output function is to be used the receiving device must conform to the output parameters as described in the

speci cations section. Attach a cable as describe in to the Pulse output terminal and terminate the other end of the cable at the

desired location.

12

09-VRX-UM-00408 07/12

Page 13

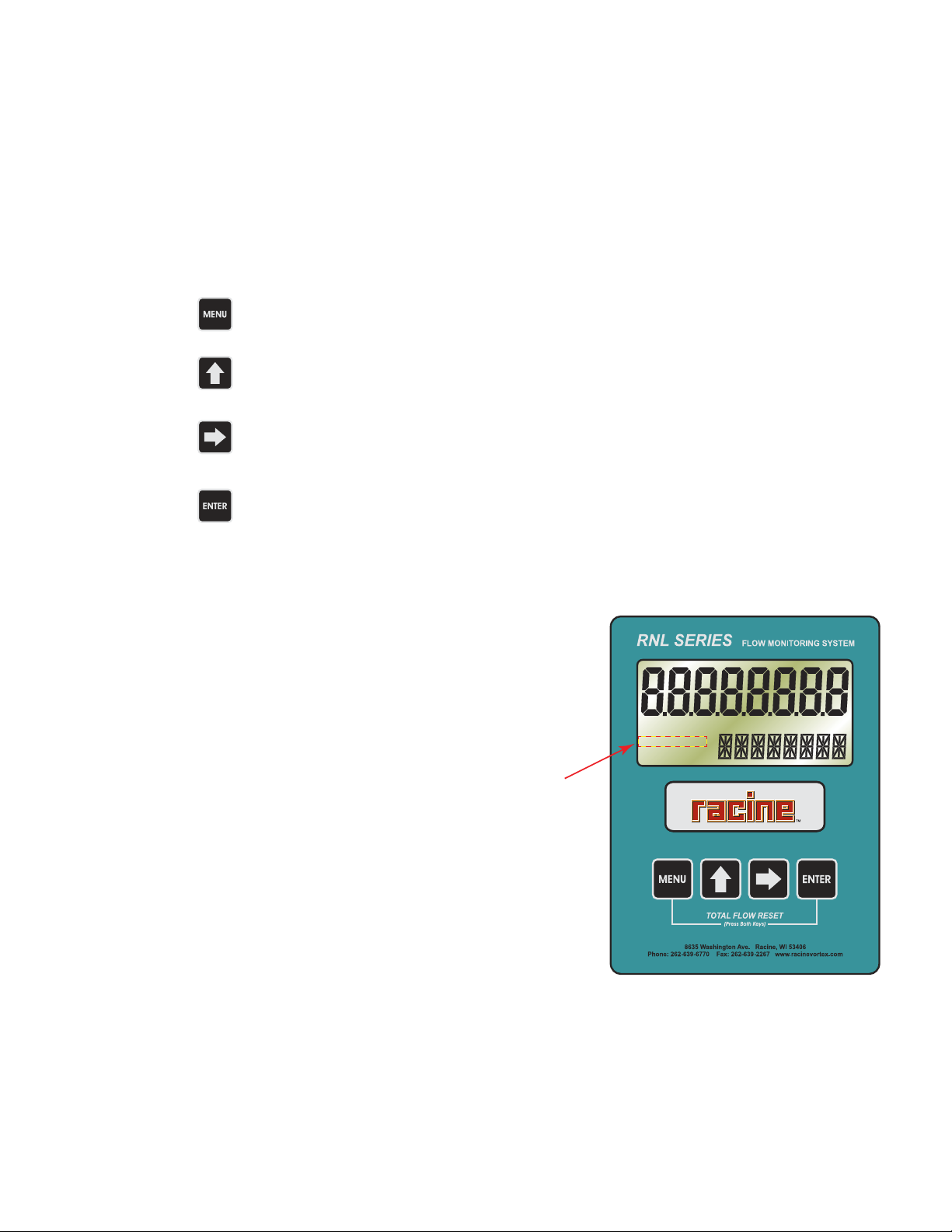

OPERATING THE MONITOR

The monitor has two modes of operation, referred to as the RUN mode and the PROGRAM mode. Both the run mode and the

program mode display screen enunciators con rming the state of the monitor. A quick glance at the lower left hand corner of

the LCD screen will con rm operating status. Normal operation will be in the run mode. To access the programming mode, press

the MENU key once. The programming indicator will appear signaling that the display is ready to accept programming inputs.

After programming the display with the necessary information, a lock out feature can be turned on to prevent unauthorized

access or changing the meter's setup parameters.

BASIC PROGRAMMING MODE

Keys:

MENU - Switches to PROGRAMMING mode.

Up Arrow - Scrolls forward through the parameters choices and increments

numeric variables.

Right Arrow - Scrolls backward through the parameters choices and moves the

active digit to the right.

ENTER - Used to save programming information, advance to the next programming

parameter, and in the reset process.

Modes:

RUN – Normal operating mode.

PROGRAM – Used to program variables into

the display

Entering Programming Mode – Change to programming

mode by pressing the MENU key once. The mode indicator

will change from RUN to PROGRAM.

RUN

and

Select The ID Unit – At the ID UNIT prompt press the

ENTER key once. The current ID (inside diameter) unit

will begin to ash. Using the arrow keys choose INCH for

US measurements or MM for metric measurements. Press

ENTER once to save the meters ID Unit choice and advance

to the pipe ID selection.

Select The Pipe ID – At the ID prompt press the ENTER key once. The current

meter ID (inside diameter) will begin to ash. Using the arrow keys enter the

pipe inside diameter. Press ENTER once to save the pipe ID.

PROGRAM

Indicators

RUN PROGRAM

RELAY 1 RELAY 2

NOTE: Speci cation charts for common types of pipes can be found in the appendix of this manual.

09-VRX-UM-00408 07/12

13

Page 14

Select The Display Function – The monitor can display RATE or TOTAL or alternate between BOTH rate and total. At the DISPLAY

prompt press the ENTER key once. The monitor now shows the display mode currently in e ect. If the current selection is correct,

press the ENTER key to advance to the next parameter. To change to an alternate display mode, use the arrow keys to scroll to

the desired display mode and press ENTER to save the choice.

A TEST function is also available in the Display Function sub-menu. With the test function selected the display acts like a frequency

counter and displays the raw input frequency being supplied to the frequency input terminals. The second line of the test screen

shows transducer signal strength.

Velocity*

Select The Rate Unit – The monitor can display rate in any of

the units listed at the right.

Feet VEL FEET

Meters VEL MTRS

Volumetric

If the current selection is correct, press the ENTER key to

advance to the next parameter. To change to an alternate rate

unit, use the arrow keys to scroll to the desired display units

and press ENTER to save the choice.

Gallons GALLONS

Liters LITERS

Millions of Gallons MGAL

Cubic Feet CUBIC FT

Select The Rate Interval – The monitor can display rate

Million Cubic Feet M CU FT

Cubic Meters CUBIC ME

Interval Displayed as

Seconds SEC

Minutes MIN

Hours HOUR

Days DAY

interval in any of the units listed below.

Million Liters MEGLTRS

Acre Feet ACRE FT

Oil Barrels (42 GAL) OIL BARR

Liquid Barrels (31.5 GAL) LIQ BARR

Mass**

Kilograms KGS

Pounds LBS

* - Velocity measurements not available as totalizer units.

If the current selection is correct, press the ENTER key to

** - Mass units require entry of speci c gravity.

advance to the next parameter. To change to rate interval,

use the arrow keys to scroll to the desired interval and press

ENTER to save the choice.

Select the Totalizer Units - The ow totalizer unit is used

to set the ow totalizer exponent. This feature is useful for

accommodating a very large accumulated ow. The exponent

is a x10n multiplier, where “n” can be from -1 (x0.1) to +6

(x1,000,000). Table 4 should be referenced for valid entries

and their in uence on the display.

If the current selection is correct, press the ENTER key to

advance to the next parameter. To change to rate interval, use

the arrow keys to scroll to the desired interval and press ENTER

to save the choice.

This completes the basic setup for the meter.

14

Exponent Display Multiplier

E-1 x 0.1

E0 x 1 (no multiplier)

E1 x 10

E2 x 100

E3 x 1,000

E4 x 10,000

E5 x 100,000

E6 x 1,000,000

TABLE 4 EXPONENT MULTIPLIERS

09-VRX-UM-00408 07/12

Page 15

ADDITIONAL SCALING PARAMETERS

4-20 Pulse

XMIT

RECV

+

-

10-30 VDC

POWER SUPPLY

10A MAX

FUSED

400mA

FUSED

CAT III

1000V

HOLD MIN MAX REL

Hz % ms RANGE

AutoHOLD FAST MI N M X LOGGING YES

CANCEL SAVE NO

SETUP

μA

mA

A

W

V

TEMPERATURE

COM

OFF

nS

W

VIEW MEM

CLEAR MEM

V

dB

mV

dB

ac+dc

V

ac+dc

A

mA

mV

ac+dc

mA

A

μA

ac+dc

μA

°C

°F

AC+DC

00

Speci c Gravity (SP GRAV)- The speci c gravity for the uid being measured must be entered if mass readings are desired. The

SP GRAV (speci c gravity) prompt will only be displayed when one of the mass Rate Units is chosen.

Low Flow Cuto (FL C OFF) - The low ow cuto is entered as an actual ow value between maximum ow and minimum ow

and in uences how the ow meter will act at ows very near zero. Generally, an entry of 2% of the maximum ow provides for

a stable zero indication. When the ow rate drops below the entered value, the meters’ display will read zero.

Damping (DAMPING) - The damping value is increased to increase stability of the ow rate readings. Damping values are

decreased to allow the ow meter to react faster to changing ow rates.

Flow 4 mA Setting (FLOW 4MA) - If the 4-20 mA analog output is to be used the ow rate that corresponds to 4 mA must be

set. If the current selection is correct, press the ENTER key once to advance to the next parameter. If adjustment is required, use

the arrow keys to input the correct 4 mA setting. The arrow key moves the active digit one place to the right for each press of

the key. The arrow key increments the active digit one integer for each press of the key. When the correct 4 mA ow rate has

been entered press ENTER once to store this value and move to the next parameter.

Flow 20 mA Setting (FLOW20MA) - If the 4-20 mA analog output is to be used the ow rate that corresponds to 20 mA must

be set. If the current selection is correct, press the ENTER key once to advance to the next parameter. If adjustment is required,

use the arrow keys to input the correct 20 mA setting. The arrow key moves the active digit one place to the right for each

press of the key. The arrow key increments the active digit one integer for each press of the key. When the correct 20 mA ow

rate has been entered press ENTER once to store this value and move to the next parameter.

4-20 mA Calibration (4-20CAL?) - The 4-20 mA calibration menu allows the ne adjustment

of the 4-20 mA output. The 4 mA setting is typically between 35 and 50. To set the 4 mA value,

connect an ammeter in series with the loop power supply. At the 4-20CAL? prompt press ENTER

once. The display will now show a steady NO indication. Press the arrow key to change to a

YES display. Press ENTER once to access the 4 mA ne adjustment.

4 mA Adjustment (4MA OUT) - While monitoring the ammeter, adjust the

4 mA value to obtain a 4 mA reading. The arrow key increments the value

and the arrow key decrements the value. When a steady 4 mA reading is

obtained on the ammeter press the Enter key to lock in this value and move

to the 20 mA adjustment.

20 mA Adjustment (20MA OUT) - The 20 mA adjustment is preformed using

the same procedure as the 4 mA adjustment.

While monitoring the ammeter, adjust the 20 mA value to obtain a 20 mA

reading. The arrow key increments the value and the arrow key decrements

the value. When a steady 20 mA reading is obtained on the ammeter press the

Enter key to lock in this value and move to the next parameter.

4-20 mA Test (4-20TEST)- The monitor contains a diagnostic routine that allows

the simulation of mA values between 4 and 20 to check output tracking. At the

4-20TEST prompt the arrow keys change the simulated mA output in increments

of 1 mA. The ammeter should track the simulated mA output. If a 4-20 mA test is

not necessary press MENU once to move to the next parameter.

FIGURE 9 420 mA TEST SETUP

Password (PASSWORD) - Password protection prevents unauthorized users from changing programming information. Initially

the password is set to all zeros. To change the password press ENTER once at the password prompt. The rst digit of the password

value will begin to ash. Using the arrow keys as previously described enter the password value. Pressing ENTER will store the

password and exit to run mode.

09-VRX-UM-00408 07/12

15

Page 16

Advanced Setup (ADV STUP) - The advances setup menu allows access to entries for applying scaling factors, enabling or

disabling the pulse output, and adding linearization points.

At the ADV STUP prompt press ENTER once. The display will now show a steady NO indication. Press the arrow key to change

to a YES display. Press ENTER once to access the rst parameter.

Scale Factor (SCALE F) - At the SCALE F prompt press the ENTER key once. The current scale factor will begin to ash. If the

current selection is correct, press the ENTER key to advance to the next parameter.

The scale factor is used to force a global change to all variables. For example, under operating conditions the display is reading a

consistent 3% below the expected values at all ow rates. Rather than changing all parameters individually the scale factor can

be used to compensate for the 3% o set. The scale factor would be set to 1.03 to correct the readings.

The range of scale factors is from 0.5 to 1.5. The default scale factor is 1.00. A scale factor is used to correct (correlation adjustment)

or change the ow value displayed on the LCD.

A correlation adjustment allows the user to “force” the display to read a ow value di erent from the factory calibrated value.

This procedure is only valid for an “o set” di erence. In other words the readings must be o by a constant value or percentage

for the entire measurement range.

Totalizer Pulse Output (PULS OUT) - The pulse output parameter can be either enabled or disabled. When enabled this output

generates a 20 mS duration pulse for every time the least signi cant digit of the totalizer increments. The amplitude of the pulse

is dependent on the voltage level of the supply connected to the pulse output and is limited to a maximum 30 VDC.

Linearization (LINEAR) - Enhanced accuracy can be obtained by linearization of the display. The linearization routine will accept

a maximum of ten points. Linearization requires additional calibration data from the sensor to be used with the monitor. Typically

calibration information is obtained for three, ve, or ten points.

Number of Points - At the LINEAR prompt press ENTER once. The rst display number will begin to ash. Again the arrow

key increments the value and the arrow moves the cursor between digits. Enter the number of linear points to be used.

When the number of points has been input press the ENTER key once to move to the rst linear segment.

Press the ENTER key once and the rst linear point's frequency input will begin to ash FREQ 1. Enter the frequency for the

rst linear point using the arrow keys. When the frequency value input is completed, press ENTER once again to change to

the coe cient value for the rst linear point.

At the COEFF 1 prompt enter the coe cient that corresponds to the frequency value previously entered. Press ENTER once

to move to the next scaling point.

Continue entering pairs of frequency and coe cient points until all data has been entered.

TOTALIZER FUNCTIONS

Reset Total - To reset the monitor total display, in run mode press MENU and ENTER simultaneously until TOTAL RST starts to

ash. The TOTAL RST will stop ashing and the display will return to run mode at the conclusion of the reset procedure.

Store Total - The current total can be manually stored in the monitors ash memory. Press and hold the ENTER key for 2 seconds.

The display will respond with a ashing TOTALSVD and then start a display test. At the end of the test the instrument will return

to run mode.

Automatic Store Total - The monitor is equipped with a store total feature that works automatically saving the current total to

ash memory once every ten minutes.

16

09-VRX-UM-00408 07/12

Page 17

TROUBLESHOOTING

The RNL series ow meters are designed to ensure long term accuracy and reliability. The material used for construction and

self-cleaning strut are speci cally designed to withstand the rigors of industrial environments.

As a result, periodic adjustments or re-calibration is not required. The following section is intended as a guide to eliminating

common problems found with the installation of the ow meters. Technical assistance is also available directly from Badger

Meter, who also provides complete re-calibration and repair service for the RNL series ow meter at nominal cost.

1) Is the ow meter cable installed correctly?

2) Is the proper power supplied to the correct terminals?

3) Is the ow meter installed with the ow direction arrow aligned with ow in the pipe?

4) For insertion style ow meters has the sensor head been inserted to the optimum depth?

09-VRX-UM-00408 07/12

17

Page 18

Totalizer Units

Not Available as

OR

Note: Only available when either

KGS or LBS are Selected

See Note

18

For INCHES For mm

FIGURE 10 PROGRAMMING MENU MAP

09-VRX-UM-00408 07/12

Page 19

APPENDIX

RUN PROGRAM

RELAY 1 RELAY 2

ADDITIONAL INSTALLATION REQUIREMENTS

Introduction

Installing a ow meter is something which requires careful consideration. It cannot just be placed in a line somewhere and be

expected to ful ll its purpose adequately. The geometry and condition of the pipe runs in the area of the installation must be

considered to ensure the best and most accurate operation of the ow-meter. This appendix provides suggestions for optimum

installations.

Most flow meter manufacturers define installation conditions in terms of upstream and

downstream straight pipe lengths from the point of installation. Unfortunately this is not the

only requirement, and one needs to consider other peripheral conditions, such as proximity and

style of bends, and other equipment installed in the line. By doing this, problems of turbulence,

swirl, and sonic noise may be avoided.

Turbulence

Turbulence is a disturbance of the ow caused by bends and

obstructions in the ow stream (it is this phenomenon which

makes the vortex ow meter work). Fortunately turbulence dies

out fairly quickly, so by positioning the ow meter well away from

bends and obstructions this potential problem of measuring ow

in turbulent conditions is overcome (See Figure A1).

FIGURE A1 TURBULENCE

Swirl

Unlike turbulence, swirl will not die away. Once created it will

continue until dissipated on the next pipe bend in

the system. Swirl occurs after two bends, in close

proximity, which are at an angle to each other.

When designing an installation, keep the ow

meter out of any line which has two adjacent

bends upstream. (See Figure A2).

Sonic Noise

Sonic noise is created by valves (either ow control or pressure control valves)

which are slightly open. Like swirl, sonic noise will only dissipate on a

bend so it is important to install ow meters out of line of sight of

valves. Sonic noise is caused by liquid obtaining sonic velocities

through a slightly open valve which has a pressure di erence

across it. This noise travels both up and down stream from

the valve therefore the ow meter must be installed well

away from the valve, preferably around a bend (See Figure

A3).

FIGURE A2 SWIRL

FIGURE A3 SONIC NOISE

09-VRX-UM-00408 07/12

19

Page 20

Velocity Pro le for RNL Insertion Meters

When using an RNL series insertion ow meter, it is necessary to consider the e ects of the velocity pro le across the pipe or

duct to optimize accuracy.

In large pipes, the ow moves slowly at the pipe walls but is at maximum velocity in the center of the pipe creating a continuously

variable velocity across the pipe. This velocity variation is called the velocity pro le of the pipe, and can be measured and plotted

by using the insertion ow meter to measure velocities at various noted positions across the pipe. As the maximum velocity is

in the center of the pipe, it follows that if the ow meter is positioned in the center, it will not measure average ow. The “rule

of thumb” position is 25% of the pipe ID into the pipe, but the optimum position can only be obtained by measuring the pro le

and working out the correct position from that.

Straight-Run Piping Considerations

The sensor should be installed with 20 diameters, or more, of straight, unobstructed, full area pipe upstream of the ow meter

installation and 10 diameters, or more, downstream. This condition provides a fully developed, symmetrical ow pro le that is

necessary to obtain accurate and repeatable results. The rst obstruction up and downstream should be a full area elbow. If the

minimum straight run is not possible, the general rule is to have 80% of the straight run upstream and 20% downstream from

the ow meter installation.

High intensity ultrasonic noises should not be located upstream or downstream from the sensor. Common ultrasonic noise

sources include the following:

● Slightly cracked valves operating with large pressure drops.

● Small pipe leaks in high pressure systems.

● Venturies operating at near-sonic fl ow rates.

● Sonic nozzles.

If these ultrasonic noise sources cannot be eliminated, the meter should be mounted with at least one elbow between the ow

meter and the noise source.

Temperature and Pressure Tap Locations

User supplied pressure and temperature sensors should be mounted downstream from the ow meter. The pressure sensor

should be approximately 3-5 pipe diameters and the temperature sensor approximately 4-8 pipe diameters downstream.

RNL Insertion Style Meter Installation

The RNL series ow meter is shipped completely assembled, tested and ready to install and operate in its permanent location.

If the main line can be depressurized easily without undue user inconvenience, then a simple installation, consisting of a 2 inch

(51 mm) nozzle and a standard ANSI 150 pound, 2 inch pipe ange may be used. This permits the shortest shaft length to be used,

which keeps clearance space requirements for insertion and removal to a minimum. Gaskets (not provided) are necessary between

the sensor and ANSI ange. It is recommended that the customer conduct a ow pro le survey prior to installing ow meter.

DANGER - Caution should be used when inserting or retracting at pressures exceeding 60 PSIG (4.14 BARg).

20

09-VRX-UM-00408 07/12

Page 21

HOT TAP INSERTION FLOW METER INSTALLATION

Where de-pressurizing the line for ow meter maintenance is impossible or undesirable, the “hot tap” method of installation is

used. This method involves inserting the ow meter through a 2 inch (50.76 mm) spool piece and a 2 inch (50.76 mm) full port

valve and will require a longer shaft length as well as greater clearance space for removal and installation.

DANGER - Caution should be used when inserting or retracting at pressures exceeding 60 PSIG (4.14 BARg).

Figure A4 shows the cutaway of a typical hot tap installation.

Coupler

6” x 2” Nipple with

2” Full Port

Ball Valve

3” x 2” Nipple

FIGURE A4 HOT TAP CUTAWAY

Pressure Port

09-VRX-UM-00408 07/12

21

Page 22

Figure A5 shows a sample hot tap installation. With the exception of the spool piece, which must be a minimum of 6 inches

10.75" Maximum

at Maximum

Insertion

4.50" Maximum

Retracted

Standard ANSI

2 Inch 150 Lb. Flange

Determined

By Stem

Length

Determined

By Stem

Length

2" Full Port

Valve

Flow

4.50"

Maximum

Spool Piece

4.00" Minimum

RUN PROGRAM

RELAY 1 RELAY 2

5.75"

7.00"

RUNP

R

1

R

(152 mm) in length, all of the dimensions are suggestions only. Actual dimensions may vary depending on customer’s own hot

tap con guration.

To calculate the required insertion ow meter stem

length for the installation:

For pipe diameters less than 24 inches (609 mm):

ROGRAM

ELAY

Calculate the distance from the center line of

ELAY 2

the pipe to the top of the ow meter mounting

ange.

For pipe diameters greater than 24 inches (609 mm):

Calculate the distance from the top of the ow

meter ange to a point ¼ of the pipe diameter.

Where a flow profile is desirable, calculate the

distance from the bottom of the pipe to the top

of the ow meter mounting ange and subtract 2

inches (50.76 mm). Round this distance up to the

next largest 12 inches (305 mm) increment. This is

the stem length that should be ordered.

DANGER - Caution should be used

when inserting or retracting at

pressures exceeding 60 PSIG (4.14

BARg).

22

FIGURE A5 HOT TAP DIMENSIONS

09-VRX-UM-00408 07/12

Page 23

Maximum Fluid Velocity

L2

RUN PROGRAM

RELAY 1 RELAY 2

L1

Insertion meters are subject to damage from bending if the uid velocity

exceeds a speci c value. The threshold velocity where damage may occur is

found in a lookup table (See Table A1) and the depth the meter stem

extends into the pipe (See Figure A6).

L1 = Distance from bottom of ow meter ange to center of vortex strut.

L2 = Distance from bottom of ow meter ange to top inside wall of pipe

1) Find the appropriate L1 distance for your application in the rst

column.

2) Once the L1 distance is identi ed, move across the row until the

appropriate L2 distance is located for the application. The resulting

number is the maximum uid velocity.

EXAMPLE: L1 length = 24, and L2 length = 12.

Using Table A1 follow the 24” (L1) row until it intersects the 12” (L2)

column. L1 and L2 intersect at 13 ft/sec. Exceeding the maximum

uid velocity of 13 ft/sec risks bending the meter stem.

FIGURE A6 INSERTION DEPTH

L1

Inches

10 26 28

12 22 24 25

14 20 21 22 24

16 18 18 19 20 22

18 16 16 17 18 19 21

20 15 15 15 16 17 18 20

22 13 14 14 15 15 16 17 19

24 13 13 13 13 14 15 15 16 18

26 12 12 12 12 13 13 14 15 16 17

28 11 11 11 12 12 12 13 13 14 15 17

30 10 10 11 11 11 11 12 12 13 14 15 16

32 10 10 10 10 10 11 11 11 12 12 13 14 15

34 9 9 10 10 10 10 10 11 11 11 12 13 14

36 9 9 9 9 9 9 10 10 10 11 11 12 12

NOTE: Operating at velocities higher than the values listed in the table may result in bending the stem of the insertion meter.

6 8 10 12 14 16 18 20 22 24 26 28 30

L2 (INCHES)

09-VRX-UM-00408 07/12

TABLE A1 INSERTION DEPTH

23

Page 24

FLOW PROFILING

If the purchased ow meter is long enough to be inserted to the far side of the pipe, the ow through the pipe may be pro led

at various ow rates. The goal is to nd a point in the pipe that remains a consistent percentage of the average ow rate over a

wide range of ow. A sample ow pro le is shown in Table A2. In this example, the ow rate of a 48 inch pipe is measured every

six inches across the diameter of the pipe beginning and ending 3 inches from the near and far sides of the pipe. The distance

in inches from the nearside of the pipe is shown. Measurements are taken at a low, medium and high average ow. In Table

A3 the ow rate at each measurement point has been converted to a percentage of the average ow. It can be seen that point

number three (15 inches from the near side of the pipe) reads a consistent 102 percent of the average ow. The meter should

be placed in this position and the output should be divided by 1.02 to obtain the correct reading. Flow pro ling should be done

for all insertion meter installations.

FLOW

FLOW RATE AT MEASUREMENT POINT (F/S)

12345678 AVERAGE (ft/s)

LOW FLOW 1.90 2.00 2.04 2.06 2.06 2.04 2.00 1.90 2.0

MEDIUM FLOW 5.58 5.91 6.12 6.21 6.24 6.18 6.06 5.70 6.0

HIGH FLOW 10.92 11.70 12.24 12.48 12.60 12.48 12.18 11.40 12.0

DISTANCE

3 9 15 21 27 33 39 45 INCHES

TABLE A2 FLOW PROFILE RAW DATA

FLOW

LOW FLOW 95.0 100.0 102.0 103.0 103.0 102.0 100.0 95.0

MEDIUM FLOW 93.0 98.5 102.0 103.5 104.0 103.0 101.0 95.0

HIGH FLOW 91.0 97.5 102.0 104.0 105.0 104.0 101.5 95.0

FLOW RATE AT MEASUREMENT POINT (%)

12345678

TABLE A3 FLOW PROFILE NORMALIZED DATA

REDUCING THE PIPE DIAMETER

To decrease the variation of ow pro le, the piping can be narrowed at the ow meter as shown in Figure A7. This will smooth

the ow and increase the e ectiveness of ow pro ling. Nearly any angle can be used on the down-stream side of the meter to

restore the original pipe diameter. However, if the angle of piping is seven degrees or less, nearly all the pressure drop caused

by the narrow pipe section will be recovered.

RUN PROGRAM

RELAY 1 RELAY 2

FIGURE A7 MAKING REDUCTIONS OR ENLARGEMENTS

Flow

7°3d 1d

09-VRX-UM-00408 07/12

24

D

30°

d

Page 25

SPECIFICATIONS

MEASURED Liquids

MINIMUM PIPE SIZE 4 inches (102 mm)

FLOW RATE MEASURED 2...18 fps (0.6...5.5 mps)

PROCESS TEMPERATURE -20° F...300° F (-28° C...148° C)

PROCESS PRESSURE -5...250 PSIG (-0.3...17 BARg)

MINIMUM BACK PRESSURE See Figure 2 - BACK PRESSURE CALCULATIONS

MAXIMUM VISCOSITY 10 centistokes - Consult factory for higher viscosities

ACCURACY ±2.0% of reading

REPEATABILITY ±0.5% of reading

RESPONSE TIME 1 second

INPUT POWER 4-20 mA 2 Wire Current Loop Powered; +10 to +30 VDC, 25 mA max

4-20 mA Current Loop

ANALOG OUTPUT

PULSE OUTPUT

PROCESS CONNECTION

ENVIRONMENTAL

DISPLAY

ENCLOSURE NEMA 4X (IP66) Polycarbonate

Resolution 1:4000

Transient Over-voltage: Category 3, in accordance with IEC 664

Outputs one pulse for each increment of totalizers least signi cant digit

Pulse Type: Opto-Isolated open collector transistor

Maximum Voltage: 30 VDC

Pulse Width ON State: 20 ms / Max pulse rate 25 Hz

Current ON State: 0.9 V drop @ 5.0 mA

or 0.7 V drop @ 0.1 mA

Stainless steel w/PPS transducer assembly

Standard: 2” ANSI 150 lb ange

Optional: 300 lb ange or ¾ NPT x 2 NPT Bushings

Ambient Temperature: -20 °F to 110 °F (-30 °C to 43 °C)

Humidity: 0-90% Non-condensing

Flow Rate and Total

8 digit, .75” high numeric display; 8 character, .38” high alphanumeric

4-20 mA Loop Powered; +10 to +30 VDC, 25 mA max

09-VRX-UM-00408 07/12

25

Page 26

SCH 20 SCH 30 STD SCH 40

SCH 10

(Lt Wall)

26

TABLE A4 STEEL, STAINLESS STEEL, P.V.C. PIPE STANDARD CLASSES

SCH 5

ID Wall ID Wall ID Wall ID Wall ID Wall ID Wall

Outside

Diameter

Inches

Nominal

Pipe Size

1 1.315 1.185 0.065 1.097 0.109 1.049 1.049 0.133

1.25 1.660 1.53 0.065 1.442 0.109 1.380 1.380 0.140

2 2.375 2.245 0.065 2.157 0.109 2.067 2.067 0.154

1.5 1.900 1.77 0.065 1.682 0.109 1.610 1.610 0.145

3 3.500 3.334 0.083 3.260 0.120 3.068 3.068 0.216

2.5 2.875 2.709 0.083 2.635 0.120 2.469 2.469 0.203

4 4.500 4.334 0.083 4.260 0.120 4.026 0.237 4.026 0.237

3.5 4.000 3.834 0.083 3.760 0.120 3.548 3.548 0.226

5 5.563 5.345 0.109 5.295 0.134 5.047 0.258 5.047 0.258

6 6.625 6.407 0.109 6.357 0.134 6.065 0.280 6.065 0.280

8 8.625 8.407 0.109 8.329 0.148 8.125 0.250 8.071 0.277 7.981 0.322 7.981 0.322

10 10.75 10.482 0.134 10.42 0.165 10.25 0.250 10.13 0.310 10.02 0.365 10.02 0.365

12 12.75 12.42 0.165 12.39 0.180 12.25 0.250 12.09 0.330 12.00 0.375 11.938 0.406

14 14.00 13.50 0.250 13.37 0.315 13.25 0.375 13.25 0.375 13.124 0.438

16 16.00 15.50 0.250 15.37 0.315 15.25 0.375 15.25 0.375 15.000 0.500

18 18.00 17.50 0.250 17.37 0.315 17.12 0.440 17.25 0.375 16.876 0.562

20 20.00 19.50 0.250 19.25 0.375 19.25 0.375 19.25 0.375 18.814 0.593

24 24.00 23.50 0.250 23.25 0.375 23.25 0.375 23.25 0.375 22.626 0.687

30 30.00 29.37 0.315 29.00 0.500 29.00 0.500 29.25 0.375 29.25 0.375

36 36.00 35.37 0.315 35.00 0.500 35.00 0.500 35.25 0.375 35.25 0.375

42 42.00 41.25 0.375 41.25 0.375

48 48.00 47.25 0.375 47.25 0.375

09-VRX-UM-00408 07/12

Page 27

STEEL, STAINLESS STEEL, P.V.C. PIPE (STANDARD CLASSES)

SCH 60 X STG. SCH 80 SCH 100 SCH 120/140 SCH 180

ID Wall ID Wall ID Wall ID Wall ID Wall ID Wall

Outside

Diameter

Nominal

09-VRX-UM-00408 07/12

Pipe Size

Inches

1 1.315 0.957 0.179 0.957 0.179 0.815 0.250

1.25 1.660 1.278 0.191 1.278 0.191 1.160 0.250

2 2.375 1.939 0.218 1.939 0.218 1.687 0.344

1.5 1.900 1.500 0.200 1.500 0.200 1.338 0.281

3 3.500 2.900 0.300 2.900 0.300 2.624 0.438

2.5 2.875 2.323 0.276 2.323 0.276 2.125 0.375

4 4.500 3.826 0.337 3.826 0.337 3.624 0.438 3.438 0.531

3.5 4.000 3.364 0.318 3.364 0.318

5 5.563 4.813 0.375 4.813 0.375 4.563 0.500 4.313 0.625

6 6.625 5.761 0.432 5.761 0.432 5.501 0.562 5.187 0.719

8 8.625 7.813 0.406 7.625 0.500 7.625 0.500 7.437 0.594 7.178 0.719 6.183 1.221

10 10.75 9.750 0.500 9.75 0.500 9.562 0.594 9.312 0.719 9.062 0.844 8.500 1.125

12 12.75 11.626 0.562 11.75 0.500 11.37 0.690 11.06 0.845 10.75 1.000 10.12 1.315

14 14.00 12.814 0.593 13.00 0.500 12.50 0.750 12.31 0.845 11.81 1.095 11.18 1.410

16 16.00 14.688 0.656 15.00 0.500 14.31 0.845 13.93 1.035 13.56 1.220 12.81 1.595

18 18.00 16.564 0.718 17.00 0.500 16.12 0.940 15.68 1.160 15.25 1.375 14.43 1.785

20 20.00 18.376 0.812 19.00 0.500 17.93 1.035 17.43 1.285 17.00 1.500 16.06 1.970

24 24.00 22.126 0.937 23.00 0.500 21.56 1.220 20.93 1.535 20.93 1.535 19.31 2.345

30 30.00 29.00 0.500

36 36.00 35.00 0.500

42 42.00 41.00 0.500

48 48.00 47.00 0.500

27

Page 28

Class

TABLE A5 CAST IRON PIPE STANDARD CLASSES

Size

(Inches)

Class

25.80 25.80 26.32 26.32 26.90 26.90 27.76 27.76

O.D.

0.76 0.98 1.05 1.16 1.31 1.45 1.75 1.88

24”

24.28 24.02 24.22 24.00 24.28 24.00 24.26 24.00

31.74 32.00 32.40 32.74 33.10 33.46

O. D.

0.88 1.03 1.20 1.37 1.55 1.73

Wall

30”

29.98 29.94 30.00 30.00 30.00 30.00

I.D.

37.96 38.30 38.70 39.16 39.60 40.04

O.D.

0.99 1.15 1.36 1.58 1.80 2.02

Wall

36”

35.98 36.00 35.98 36.00 36.00 36.00

I.D.

44.20 44.50 45.10 45.58

O.D.

1.10 1.28 1.54 1.78

Wall

42”

42.00 41.94 42.02 42.02

I.D.

50.55 50.80 51.40 51.98

O.D.

1.26 1.42 1.71 1.99

Wall

48”

47.98 47.96 47.98 48.00

I.D.

56.66 57.10 57.80 58.40

O.D.

1.35 1.55 1.90 2.23

Wall

54”

53.96 54.00 54.00 53.94

I.D.

62.80 63.40 64.20 64.28

O.D.

1.39 1.67 2.00 2.38

Wall

60”

60.02 60.06 60.20 60.06

I.D.

75.34 76.00 76.88

O.D.

1.62 1.95 2.39

Wall

72”

72.10 72.10 72.10

I.D.

87.54 88.54

O.D.

1.72 2.22

Wall

84”

84.10 84.10

I.D.

28

ABCDEFGH ABCDEFGH

Size

(Inches)

O.D. 3.80 3.96 3.96 3.96

Wall 0.39 0.42 0.45 0.48 Wall

3”

I.D. 3.02 3.12 3.06 3.00 I.D.

O.D. 4.80 5.00 5.00 5.00

Wall 0.42 0.45 0.48 0.52

4”

I.D. 3.96 4.10 4.04 3.96

O.D. 6.90 7.10 7.10 7.10 7.22 7.22 7.38 7.38

Wall 0.44 0.48 0.51 0.55 0.58 0.61 0.65 0.69

6”

I.D. 6.02 6.14 6.08 6.00 6.06 6.00 6.08 6.00

O.D. 9.05 9.05 9.30 9.30 9.42 9.42 9.60 9.60

Wall 0.46 0.51 0.56 0.60 0.66 0.66 0.75 0.80

8”

I.D. 8.13 8.03 8.18 8.10 8.10 8.10 8.10 8.00

O.D. 11.10 11.10 11.40 11.40 11.60 11.60 11.84 11.84

Wail 0.50 0.57 0.62 0.68 0.74 0.80 0.86 0.92

10”

I.D. 10.10 9.96 10.16 10.04 10.12 10.00 10.12 10.00

O.D. 13.20 13.20 13.50 13.50 13.78 13.78 14.08 14.08

Wall 0.54 0.62 0.68 0.75 0.82 0.89 0.97 1.04

12”

I.D. 12.12 11.96 12.14 12.00 12.14 12.00 12.14 12.00

O.D. 15.30 15.30 15.65 15.65 15.98 15.98 16.32 16.32

Wall 0.57 0.66 0.74 0.82 0.90 0.99 1.07 1.16

14”

I.D. 14.16 13.98 14.17 14.01 14.18 14.00 14.18 14.00

O.D. 17.40 17.40 17.80 17.80 18.16 18.16 18.54 18.54

Wall 0.60 0.70 0.80 0.89 0.98 1.08 1.18 1.27

16”

I.D. 16.20 16.00 16.20 16.02 16.20 16.00 16.18 16.00

O.D. 19.50 19.50 19.92 19.92 20.34 20.34 20.78 20.78

Wall 0.64 0.75 0.87 0.96 1.07 1.17 1.28 1.39

I.D. 18.22 18.00 18.18 18.00 18.20 18.00 18.22 18.00

18”

09-VRX-UM-00408 07/12

O.D. 21.60 21.60 22.06 22.06 22.54 22.54 23.02 23.02

Wall 0.67 0.80 0.92 1.03 1.15 1.27 1.39 1.51

20”

I.D. 20.26 20.00 20.22 20.00 20.24 20.00 20.24 20.00

Page 29

Lining

Mortar

Class

Dbl. 0.375

Std . 0.1875

Dbl. 0.375

Std . 0.1875

Dbl. 0.375

Std . 0.1875

Dbl. 0.500

Std. 0.250

Dbl. 0.500

Std. 0.250

Dbl. 0.500

Std. 0.250

Dbl. 0.500

Std. 0.250

Dbl. 0.500

Std. 0.250

TABLE A6 DUCTILE IRON PIPE STANDARD CLASSES

Size

(Inches)

Lining

Mortar

Class

Wall 0.35 0.38 0.41 0.44 0.47 0.50 0.53

O.D. 19.50 19.50 19.50 19.50 19.50 19.50 19.50

18”

Dbl. 0.250

Std. 0.123

I.D. 18.80 18.74 18.68 18.62 18.56 18.50 18.44

O.D. 21.60 21.60 21.60 21.60 21.60 21.60 21.60

20”

Dbl. 0.250

Std. 0.123

0.38 0.41 0.44 0.47 0.50 0.53 0.56

25.80 25.80 25.80 25.80 25.80 25.80 25.80

Wall

O.D.

24”

Dbl. 0.250

Std. 0.123

25.04 24.98 24.92 24.86 24.80 24.74 24.68

I.D.

0.39 0.43 0.47 0.51 0.55 0.59 0.63

32.00 32.00 32.00 32.00 32.00 32.00 32.00

Wall

O. D.

30”

Std. 0.123

31.22 31.14 31.06 30.98 30.90 30.82 30.74

I.D.

Dbl. 0.250

0.43 0.48 0.62 0.58 0.45 0.68 0.73

38.30 38.30 38.30 38.30 38.30 38.30 38.30

Wall

O.D.

36”

Dbl. 0.250

Std. 0.123

37.44 37.34 37.06 37.14 37.40 36.94 36.48

I.D.

0.47 0.53 0.59 0.65 0.71 0.77 0.83

44.50 44.50 44.50 44.50 44.50 44.50 44.50

Wall

O.D.

42”

Dbl. 0.250

Std. 0.123

43.56 43.44 43.32 43.20 43.08 42.96 42.84

I.D.

0.51 0.58 0.65 0.72 0.79 0.86 0.93

50.80 50.80 50.80 50.80 50.80 50.80 50.80

Wall

O.D.

48”

Dbl. 0.375

Std . 0.1875

49.78 49.64 49.50 49.36 49.22 49.08 48.94

I.D.

0.57 0.65 0.73 0.81 0.89 0.97 1.05

57.10 57.10 57.10 57.10 57.10 57.10 57.10

Wall

O.D.

54”

Dbl. 0.375

Std . 0.1875

55.96 55.80 55.64 55.48 55.32 55.16 55.00

I.D.

09-VRX-UM-00408 07/12

50 51 52 53 54 55 56 50 51 52 53 54 55 56

Size

(Inches)

O.D. 3.96 3.96 3.96 3.96 3.96 3.96

Wall 0.25 0.28 0.31 0.34 0.37 0.41

3”

I.D. 3.46 3.40 3.34 3.28 3.22 3.14

O.D. 4.80 4.80 4.80 4.80 4.80 4.80

Wall 0.26 0.29 0.32 0.35 0.38 0.42 Wall 0.36 0.39 0.42 0.45 0.48 0.51 0.54

4”

I.D. 4.28 4.22 4.16 4.10 4.04 3.93 I.D. 20.88 20.82 20.76 20.70 20.64 20.58 20.52

O.D. 6.90 6.90 6.90 6.90 6.90 6.90 6.90

Wall 0.25 0.28 0.31 0.34 0.37 0.40 0.43

6”

I.D. 6.40 6.34 6.28 6.22 6.16 6.10 6.04

O.D. 9.05 9.05 9.05 9.05 9.05 9.05 9.05

Wall 0.27 0.30 0.33 0.36 0.39 0.42 0.45

8”

I.D. 8.51 8.45 8.39 8.33 8.27 8.21 8.15

O.D. 11.10 11.10 11.10 11.10 11.10 11.10 11.10

Wail 0.39 0.32 0.35 0.38 0.41 0.44 0.47

10”

I.D. 10.32 10.46 10.40 10.34 10.28 10.22 10.16

O.D. 13.20 13.20 13.20 13.20 13.20 13.20 13.20

Wall 0.31 0.34 0.37 0.40 0.43 0.46 0.49

12”

I.D. 12.58 12.52 12.46 12.40 12.34 12.28 12.22

O.D. 15.30 15.30 15.30 15.30 15.30 15.30 15.30

Wall 0.33 0.36 0.39 0.42 0.45 0.48 0.51

14”

I.D. 14.64 14.58 14.52 14.46 14.40 14.34 14.28

O.D. 17.40 17.40 17.40 17.40 17.40 17.40 17.40

Wall 0.34 0.37 0.40 0.43 0.46 0.49 0.52

16”

I.D. 16.72 16.66 16.60 16.54 16.48 16.42 16.36

29

Page 30

ALUMINUM

Copper &

Brass Pipe

COPPER TUBING

O D 8.125 8.125 8.125 8.625 8 000

8”

0. D. 10 000

10”

Nominal

Diameter

ALUMINUM

O. D. 3.625 3.625 3.625 4.000

3½”

O. D. 4.125 4.125 4.125 4.500 4.000

4”

O D. 5.000

4-½”

0. D. 5.125 5.125 5.125 5.563 5.000

5”

0. D. 6.125 6.125 6.125 6.625 6.000

6”

O. D 7.625 7.000

7”

TABLE A7 TUBING SCHEDULES

Copper &

Brass Pipe

Type Type

30

COPPER TUBING

KLM KLM

I.D. 0.527 0.545 0.569 0.625 I.D. 3.385 3.425 3.459 3.500

Wall 0.049 0.040 0.028 0.108 Wall 0.120 0.100 0.083 0.250

O. D. 0.625 0.625 0.625 0.840

Nominal

Diameter

1/2”

O. D. 0.750 0.750 0.750

Wall 0.049 0.042 0.030 Wall 0.063 0.134 0.110 0.095 0.250

5/8”

I.D. 0.652 0.666 0.690 I. D. 3 874 3.857 3.905 3.935 4.000

O. D. 0.875 0.875 0.875 1.050

Wall 0.065 0.045 0.032 0.114 Wall 0.250

3/4”

I.D. 0.745 0.785 0.811 0.822 I. D. 4.500

O. D. 1.125 1.125 1.125 1.315

Wall 0.065 0.050 0.035 0.127 Wall 0.160 0.125 0.109 0.250 0.063

1”

I.D. 0.995 1.025 1.055 1.062 I. D. 4.805 4.875 4.907 5.063 4.874

O. D. 1.375 1.375 1.375 1.660

Wail 0.065 0.055 0.042 0.146 Wall 0.192 0.140 0.122 0.250 0.063

1-¼”

I.D. 1.245 1.265 1.291 1.368 ID. 5.741 5.845 5.881 6.125 5.874

O. D. 1.625 1.625 1.625 1.900

Wall 0.072 0.060 0.027 0.150 Wall 0.282 0.078

1-½”

I.D. 1.481 1.505 1.571 1.600 I. D. 7.062 6.844

O. D. 2.125 2.125 2.125 2.375

Wall 0.083 0.070 0.058 0.157 Wall 0,271 0.200 0.170 0.313 0.094

2”

I.D. 1.959 1.985 2.009 2.062 I. D. 7.583 7.725 7.785 8.000 7.812

I.D. 2.435 2.465 2.495 2.500 2.400 I. D. 9.812

Wall 0.095 0.080 0.065 0.188 0.050 Wall 0.094

O. D. 2.625 2.625 2.625 2.875 2.500

2 ½”

09-VRX-UM-00408 07/12

O. D. 3.125 3.125 3.125 3.500 3.000

Wall 0.109 0.090 0.072 0.219 0.050

3”

I.D. 2.907 2.945 2.981 3.062 2.900

Page 31

Badger Meter Warranty

Series RNL Insertion Liquid

PRODUCTS COVERED

The Badger Meter warranty shall apply to the Racine

Vortex RNL Series Insertion Liquid Flow Meter

(“Product”).

MATERIALS AND WORKMANSHIP

Badger Meter warrants the Product to be free from

defects in materials and workmanship for a period

of 12 months from the original purchase date.

PRODUCT RETURNS

Product failures must be proven and verified to

the satisfaction of Badger Meter. The Badger Meter

obligation hereunder shall be limited to such

repair and replacement and shall be conditioned

upon Badger Meter receiving written notice of

any asserted defect within 10 (ten) days after its

discovery. If the defect arises and a valid claim is

received within the Warranty Period, at its option,

Badger Meter will either (1) exchange the Product

with a new, used or refurbished Product that is

at least functionally equivalent to the original

Product, or (2) refund the purchase price of the

Product. DO NOT RETURN ANY PRODUCT UNTIL

YOU HAVE CALLED THE BADGER METER CUSTOMER

SERVICE DEPARTMENT AND OBTAINED A RETURN

AUTHORIZATION.

Product returns must be shipped by the Customer

prepaid F.O.B. to the nearest Badger Meter factory

or distribution center. The Customer shall be

responsible for all direct and indirect costs associated

with removing the original Product and reinstalling

the repaired or replacement Product. A replacement

Product assumes the remaining warranty of the

original Product or ninety (90) days from the date of

replacement, whichever provides longer coverage.

LIMITS OF LIABILITY

This warranty shall not apply to any Product

repaired or altered by any Product other than

Badger Meter. The foregoing warranty applies

only to the extent that the Product is installed,

serviced and operated strictly in accordance with

Badger Meter instructions. The warranty shall not

apply and shall be void with respect to a Product

exposed to conditions other than those detailed

in applicable technical literature and Installation

and Operation Manuals (IOMs) or which have been

subject to vandalism, negligence, accident, acts

of God, improper installation, operation or repair,

alteration, or other circumstances which are beyond

the reasonable control of Badger Meter.

With respect to products not manufactured by

Badger Meter, the warranty obligations of Badger

Meter shall in all respects conform and be limited

to the warranty extended to Badger Meter by the

supplier.

THE FOREGOING WARRANTIES ARE EXCLUSIVE

AND IN LIEU OF ALL OTHER EXPRESS AND

IMPLIED WARRANTIES WHATSOEVER, INCLUDING

BUT NOT LIMITED TO IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE (except warranties of title).

Any description of a Product, whether in writing

or made orally by Badger Meter or its agents,

specifications, samples, models, bulletins, drawings,

diagrams, engineering sheets or similar materials

used in connection with any Customer’s order are

for the sole purpose of identifying the Product

and shall not be construed as an express warranty.

Any suggestions by Badger Meter or its agents

regarding use, application or suitability of the

Product shall not be construed as an express

warranty unless confirmed to be such, in writing, by

Badger Meter.

EXCLUSION OF CONSEQUENTIAL DAMAGES AND

DISCLAIMER OF OTHER LIABILITY

Badger Meter liability with respect to breaches of

the foregoing warranty shall be limited as stated

herein. Badger Meter liability shall in no event

exceed the contract price. BADGER METER SHALL

NOT BE SUBJECT TO AND DISCLAIMS: (1) ANY

OTHER OBLIGATIONS OR LIABILITIES ARISING OUT

OF BREACH OF CONTRACT OR OF WARRANTY, (2)

ANY OBLIGATIONS WHATSOEVER ARISING FROM

TORT CLAIMS (INCLUDING NEGLIGENCE AND

STRICT LIABILITY) OR ARISING UNDER OTHER

THEORIES OF LAW WITH RESPECT TO PRODUCTS

SOLD OR SERVICES RENDERED BY BADGER METER,

OR ANY UNDERTAKINGS, ACTS OR OMISSIONS

RELATING THERETO, AND (3) ALL CONSEQUENTIAL,

INCIDENTAL AND CONTINGENT DAMAGES

WHATSOEVER.

09-VRX-UM-00408 07/12

Badger Meter Warranty

31

Page 32

Trademarks appearing in this document are the property of their respective entities.

Due to continuous research, product improvements and enhancements, Badger Meter reserves the right to change produc t or system speci cations without notice, except to the extent an outstanding

contractual obligation exists. © 2012 Badger Meter, Inc. All rights reserved.

info@racinevortex.com | www.racinevortex.com | www.badgermeter.com

Phone: 262-639-6770 | Fax: 262-417-1155

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuffen | Germany | +49-7025-9208-0

Czech Republic | Badger Meter Czech Republic s.r.o. | Maříkova 2082/26 | 621 00 Brno, Czech Republic | +420-5-41420411

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacific | Badger Meter | 80 Marine Parade Rd | 21-04 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | Rm 501, N° 11 Longyue Apartment | N° 180 Longjin Rd, Jiuting Songjiang District | Shanghai, China | 201615 | +86-21-5763 5412

Loading...

Loading...