Page 1

Transit Time Ultrasonic Flow Meters

TFX-5000 Meter Modbus RTU Protocol

TTM-UM-03073-EN-01 (August 2019)

User Manual

Page 2

Transit Time Ultrasonic Flow Meters, TFX-5000 Meter Modbus RTU Protocol

CONTENTS

Supported Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Communication Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Registers/Starting Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Function Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Word Order/Endian . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Modbus Registers and Coils. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Flow Meter Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Energy Meter Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Enumerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Warning and Alarm Message Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Failure Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Check Function Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Out-of-Specication Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Informational Events Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Page ii August 2019TTM-UM-03073-EN-01

Page 3

Supported Features

SUPPORTED FEATURES

TFX-5000 meters include an EIA-485 port that is selectable for Modbus RTU or BACnet MS/TP protocol. The meter can be

wired on a single daisy chain network and be queried for flow rate and totalizer readings along with diagnostic and

other information.

For further information on the proper installation of the transmitter, see the TFX-5000 user manual.

EIA-485 port on the TFX-5000 automatically detects which lines are A and B for transmitting and receiving. The hardware

automatically corrects for the RS485 negative and positive connections being swapped.

WIRING

RS485 Output

The RS485 feature allows up to 126 transmitters to be placed on a single three-wire cable up to 4000 feet. All transmitters are

assigned a unique numeric address that allows all of the transmitters on the cable network to be independently accessed.

Either Modbus RTU or BACnet MS/TP protocol is used to interrogate the transmitters.

Flow rate and total can be monitored over the digital communications bus.

When a USB programming cable is connected, the RS485 and frequency outputs are disabled.

Terminator Resistors

(Enabled through Parameter Setting)

60.4 Ohms

60.4 Ohms

A B

Figure 1: Typical RS485 interface

TB700

3

4

External Equipment

RS485 +

RS485 −

COMMUNICATION SETTINGS

To set up the meter for Modbus RTU:

1. Go to Main Menu > System Setup > Communications menu.

2. Select Modbus RTU.

3. Set the address (1…127).

4. Check that the baud rate, parity, stop bits and word order (endian) match the master device.

5. Enable the terminating resistor if the meter is the last device in the network. TFX-5000 meters have a built-in resistor that

can be selected through the communication setting.

6. Select the master timeout. TFX-5000 meters can display a warning when the master device does not send a packet within

the specified time. Setting the master timeout to 0 disables the warning.

7. Select which parameters the master device can write to:

a. All coil outputs and read/write holding registers

b. Coil outputs only (resets)

c. None (read only).

Page 3 August 2019 TTM-UM-03073-EN-01

Page 4

Registers/Starting Address

REGISTERS/STARTING ADDRESS

It is important to know whether the master device uses starting addresses or registers/coils as these numbers are offset by 1.

For example, holding output coil 00001 is starting address 00 (hex).

Function Codes

TFX-5000 transmitters support the following function codes, as applicable:

01 (0x01 hex) Read Coils

03 (0x03 hex) Read Holding Registers

04 (0x04 hex) Read Input Registers

05 (0x05 hex) Write Single Coil

06 (0x06 hex) Write Single Register

16 (0x10 hex) Write Multiple Registers

Word Order/Endian

Each Modbus holding register represents a 16-bit integer value (2 bytes). The official Modbus standard defines Modbus as a

‘big-endian’ protocol where the most significant byte of a 16-bit value is sent before the least significant byte. For example,

the 16-bit hex value of ‘1234’ is transferred as ‘12’ ‘34’.

Beyond 16-bit values, the protocol itself does not specify how 32-bit (or larger) numbers that span over multiple registers

should be handled. It is very common to transfer 32-bit values as pairs of two consecutive 16-bit registers in little-endian word

order. For example, the 32-bit hex value of ‘12345678’ is transferred as ‘56’ ‘78’ ‘12’ ‘34’. The register bytes are still sent in bigendian order per the Modbus protocol, but the 16-bit registers are sent in little-endian order. Alternatively, some devices store

and transfer the Modbus registers in big-endian word order. For example, the 32-bit hex value of ‘12345678’ is transferred as

‘12’ ‘34’ ‘56’ ‘78’.

As long as the transferring and receiving device transmit the data in the same manner, it does not matter in which order the

words are sent. The word order is selectable in the TFX-5000 meter. This option is useful in applications where the Modbus

master cannot be configured for endianness.

Page 4 August 2019TTM-UM-03073-EN-01

Page 5

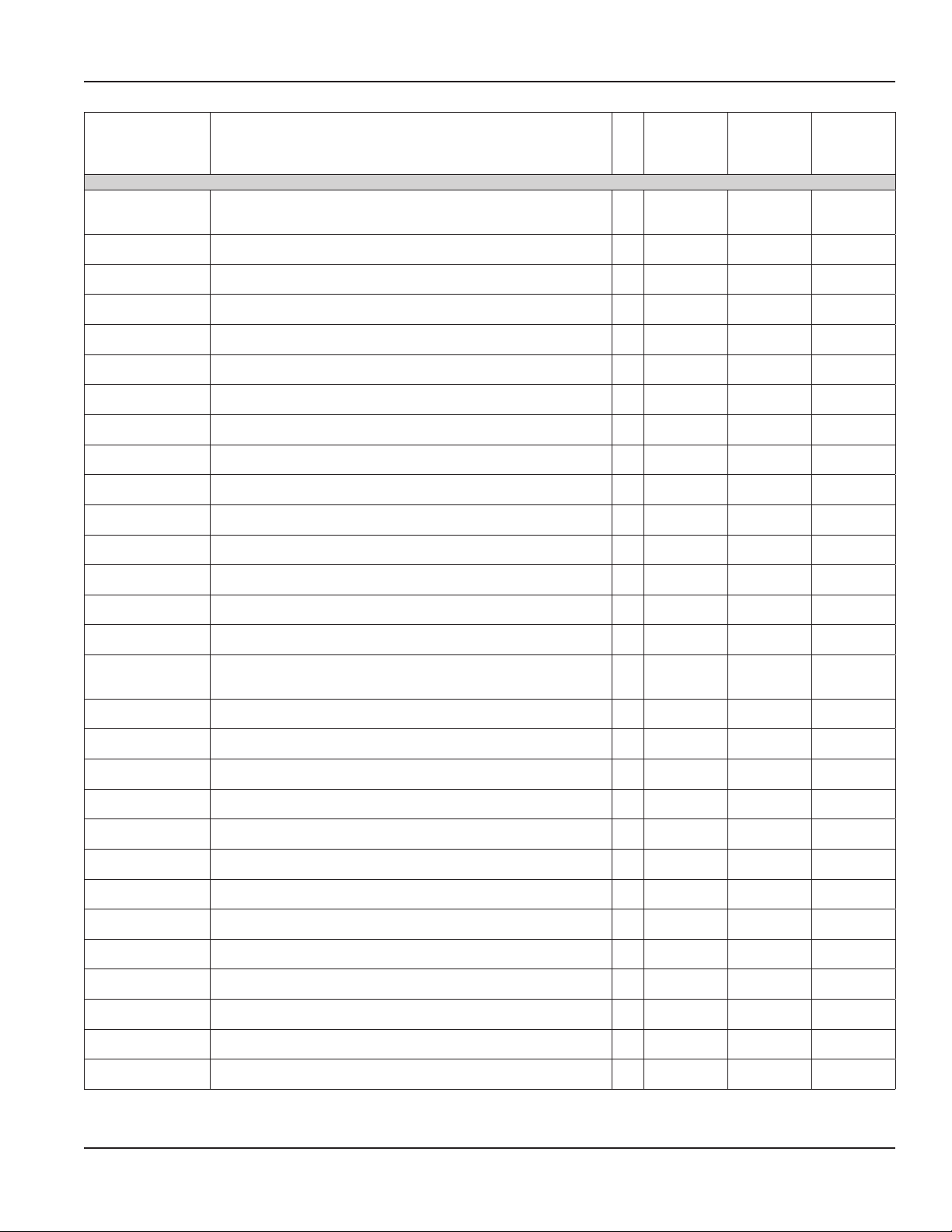

MODBUS REGISTERS AND COILS

Flow Meter Registers

Modbus Registers and Coils

Descriptive Name Description

READINGS

Flow Rate on Screen

Velocity on Screen

Delta Time Filtered (ns)

Flow Rate (gal/min) Flow rate in gallons/minute. R 40201-40202 40801-40802 41401-41404

Velocity (ft/sec) Fluid velocity in feet/second. R 40203-40204 40803-40804 41405-41408

Flow Rate (l/min) Flow rate in liters/minute. R 40401-40402 41001-41002 41601-41604

Velocity (m/sec) Fluid velocity in meters/second. R 40403-40404 41003-41004 41605-41608

TOTALS

Net Flow Totalizer

(home screen units)

Positive Flow Totalizer

(home screen units)

Negative Flow Totalizer

(home screen units)

Gross Flow Totalizer

(home screen units)

Flow Totalizer

Overflow Counter

(Net)

Flow Totalizer

Overflow Counter

(Positive)

Flow Totalizer

Overflow Counter

(Negative)

Flow Totalizer

Overflow Counter

(Gross)

Net Flow Totalizer (gal)

Positive Flow Totalizer

(gal)

Negative Flow Totalizer

(gal)

Gross Flow Totalizer

(gal)

Totalizer Overflow

Counter (Net)

Totalizer Overflow

Counter (Positive)

Totalizer Overflow

Counter (Negative)

Totalizer Overflow

Counter (Gross)

Net Flow Totalizer

(liters)

Positive Flow Totalizer

(liters)

Negative Flow Totalizer

(liters)

Gross Flow Totalizer

(liters)

Flow rate displayed on home screen. Unit is based on selection for

home screen.

Fluid velocity displayed on home screen. Unit is based on selection for

home screen.

Time of flight difference between upstream and downstream used to

calculated the flow rate. Units are nanoseconds.

Total volume as forward flow minus reverse flow. A negative total results

when reverse flow is greater than forward flow. Unit is based on selection for

home screen.

Total volume of flow in forward direction. Reverse flow is not accounted for

in the total. Unit is based on selection for home screen.

Total volume of flow in reverse direction. Forward flow is not accounted for

in the total. Unit is based on selection for home screen.

Total volume of forward and reverse flow. Unit is based on selection for

home screen.

Number of times the net flow total overruns. R 42009-42010 — —

Number of times the positive flow total overruns. R 42011-42012 — —

Number of times the negative flow total overruns. R 42013-42014 — —

Number of times the gross flow total overruns. R 42015-42016 — —

Total volume as forward flow minus reverse flow. A negative total results

when reverse flow is greater than forward flow.

Total volume of flow in forward direction. Reverse flow is not accounted for

in the total.

Total volume of flow in reverse direction. Forward flow is not accounted for

in the total.

Total volume of forward and reverse flow. R 42107-42108 42407-42408 42713-42716

Number of times the net flow total overruns. R 42109-42110 — —

Number of times the positive flow total overruns. R 42111-42112 — —

Number of times the negative flow total overruns. R 42113-42114 — —

Number of times the gross flow total overruns. R 42115-42116 — —

Total volume as forward flow minus reverse flow. A negative total results

when reverse flow is greater than forward flow.

Total volume of flow in forward direction. Reverse flow is not accounted for

in the total.

Total volume of flow in reverse direction. Forward flow is not accounted for

in the total.

Total volume of forward and reverse flow. R 42207-42208 42507-42508 42813-42816

Integer and

Long Integer

Access

Network

R 40001-40002 40601-40602 41201-41204

R 40003-40004 40603-40604 41205-41208

R 40005-40006 40605-40606 41209-41212

R 42001-42002 42301-42302 42601-42604

R 42003-42004 42303-42304 42605-42608

R 42005-42006 42305-42306 42609-42612

R 42007-42008 42307-42308 42613-42615

R 42101-42102 42401-42402 42701-42704

R 42103-42104 42403-42404 42705-42708

R 42105-42106 42405-42406 42709-42712

R 42201-42202 42501-42502 42801-42804

R 42203-42204 42503-42504 42805-42808

R 42205-42206 42505-42506 42809-42812

Single

Precision

32-bit

floating point

Double

Precision

64-bit

floating point

Page 5 August 2019 TTM-UM-03073-EN-01

Page 6

Modbus Registers and Coils

Descriptive Name Description

Integer and

Long Integer

Access

Network

Single

Precision

32-bit

floating point

Double

Precision

64-bit

floating point

TOTALS (continued)

Totalizer Overflow

Counter (Net)

Totalizer Overflow

Counter (Positive)

Totalizer Overflow

Counter (Negative)

Totalizer Overflow

Counter (Gross)

Number of times the net flow total overruns. R 42209-42210 — —

Number of times the positive flow total overruns. R 42211-42212 — —

Number of times the negative flow total overruns. R 42213-42214 — —

Number of times the gross flow total overruns. R 42215-42216 — —

HOME SCREEN UNITS

Flow Rate Units Flow rate units on home screen as defined in parameter settings. R 43001 — —

Flow Rate Decimal

Number of digits after the decimal of flow rate on home screen. Use with

long integer format.

R 43002 — —

Velocity Units Velocity units on home screen as defined in parameter settings. R 43003 — —

Flow Total Units Total volume units on home screen as defined in parameter settings. R 43004 — —

Flow Total Decimal

Number of digits after the decimal of flow total on home screen. Use with

long integer format.

R 43005 — —

SETUP

Low Flow Cutoff

Low Signal Cutoff

High Signal Cutoff

Setting to display flow rate as zero & stop totalizing when flow rate goes

below this value.

Setting to display flow rate as zero & stop totalizing when signal strength

goes below this value and trigger a low signal error message.

Setting to display flow rate as zero & stop totalizing when signal strength

goes above this value and trigger an oversaturate error message.

R/W — 44001-44002 —

R/W 44003 — —

R/W 44004 — —

DIAGNOSTICS ALARMS

Active Failed

Conditions

Message code corresponds to the bit (for example, F02 is bit 02). R 45001-45007 — —

Active Out of

Specification

Message code corresponds to the bit (for example, S02 is bit 02). R 45008-45014 — —

Conditions

Active Check Function

Conditions

Message code corresponds to the bit (for example, C02 is bit 02). R 45015-45021 — —

45033-45288

Alarm History Individual registers per buffer. R

Array of

100 single

— —

registers

DIAGNOSTICS

Signal Strength Indicates the strength of the ultrasonic signal. R 45501 — —

Current Output #1

Source

Parameter assigned to Current Output #1.

Current Output #1 Current in mA of Current Output #1. R — 45602-45603 —

Output #1 Mode Operation mode of Digital Output #1.

Output #1 Source Parameter assigned to Digital Output #1.

Output #1 Status Status of Digital Output #1.

1

Output #2 Mode Operation mode of Digital Output #2.

Output #2 Source Parameter assigned to Digital Output #2.

Output #2 Status Status of Digital Output #2.

1

Aux Output Mode Operation mode of Auxiliary Output.

Aux Output Source Parameter assigned to Auxiliary Output.

Aux Output Status Status of Digital Auxiliary.

Input Mode Operation mode of Digital Input.

Input Active State Indicates the voltage level to make the input active.

Input Status Status of Digital Input.

1

See “Enumerations” on page 12.

2

Use only if auxiliary output card is installed.

1, 2

1

1

1

1

1

1

1

1, 2

1, 2

R 45601 — —

R 45701 — —

R 45702 — —

R 45703 — —

R 45704 — —

R 45705 — —

R 45706 — —

R 45801 — —

R 45802 — —

R 45803 — —

1

R 45901 — —

R 45902 — —

R 45903 — —

Page 6 August 2019TTM-UM-03073-EN-01

Page 7

Modbus Registers and Coils

Descriptive Name Description

Integer and

Long Integer

Access

Network

Single

Precision

32-bit

floating point

Double

Precision

64-bit

floating point

COMMUNICATION

Modbus Access Modbus Access Type. R 46001 — —

Modbus Active

Timeout

Termination Resistor

Defines the maximum time that master will poll the meter. If the meter

does not see any communication from the master in the time specified, a

message will trigger.

Selection to enable or disable the internal termination resistor (RS485

devices only).

R/W 46002 — —

R/W 46003 — —

IDENTIFICATION

Tag Identification String setting to identify the meter. R 47001 — —

Part Number Part number of the meter. (String) R 47065 — —

Serial Number Serial number of the meter. (String) R 47129 — —

Firmware Version Firmware version of the meter. (String) R 47193 — —

Calibration Date Date the meter was last calibrated at factory. (String) R 47257 — —

Date Code Date the meter was manufactured. (String) R 47321 — —

Coils

Descriptive Name Description

ACTIONS

Reset Totalizers Resets all flow totals in meter to zero.

Unlatch Alarms Unlatches outputs in alarm latched state.

Clear Alarm History Clears all errors, alarms and event codes from alarm history.

Reboot Device Reboots the meter.

1

See “Enumerations” on page 12.

1

1

1

Network

W 00001

1

W 00002

W 00003

W 00004

Coil

Access

Page 7 August 2019 TTM-UM-03073-EN-01

Page 8

Modbus Registers and Coils

Energy Meter Registers

Descriptive Name Description

READINGS

Flow Rate on Screen

Velocity on Screen

Delta Time Filtered (ns)

Energy/BTU Rate

Temperature #1

Temperature #2

Delta Temperature

Flow Rate (gal/min) Flow rate in gallons/minute. R 40201-40202 40801-40802 41401-41404

Velocity (ft/sec) Fluid velocity in feet/second. R 40203-40204 40803-40804 41405-41408

Energy Rate (kBTU) Energy rate in kBTU. R 40205-40306 40805-40806 41409-41412

Flow Rate (l/min) Flow rate in liters/minute. R 40401-40402 41001-41002 41601-41604

Velocity (m/sec) Fluid velocity in meters/second. R 40403-40404 41003-41004 41605-41608

Energy Rate (kWH) Energy rate in kWH. R 40405-40406 41005-41006 41609-41612

TOTALS

Net Flow Totalizer

(home screen units)

Positive Flow Totalizer

(home screen units)

Negative Flow Totalizer

(home screen units)

Gross Flow Totalizer

(home screen units)

Flow Totalizer

Overflow Counter

(Net)

Flow Totalizer

Overflow Counter

(Positive)

Flow Totalizer

Overflow Counter

(Negative)

Flow Totalizer

Overflow Counter

(Gross)

Energy/BTU Net Total

(home screen units)

Energy/BTU Positive

Total (home screen

units)

Energy/BTU Negative

Total (home screen

units)

Energy/BTU Gross Total

(home screen units)

Energy/BTU Totalizer

Overflow Counter

(Net)

Energy/BTU Totalizer

Overflow Counter

(Positive)

Energy/BTU Totalizer

Overflow Counter

(Negative)

Flow rate displayed on home screen. Unit is based on selection for

home screen.

Fluid velocity displayed on home screen. Unit is based on selection for

home screen.

Time of flight difference between upstream and downstream used to

calculated the flow rate. Units are nanoseconds.

Energy rate displayed on home screen. Unit is based on selection for

home screen.

Temperature #1 displayed on home screen. Unit is based on selection for

home screen.

Temperature #2 displayed on home screen. Unit is based on selection for

home screen.

Delta temperature displayed on home screen. Order of operation and unit is

based on selection for home screen.

Total volume as forward flow minus reverse flow. A negative total results

when reverse flow is greater than forward flow. Unit is based on selection for

home screen.

Total volume of flow in forward direction. Reverse flow is not accounted for

in the total. Unit is based on selection for home screen.

Total volume of flow in reverse direction. Forward flow is not accounted for

in the total. Unit is based on selection for home screen.

Total volume of forward and reverse flow. Unit is based on selection for

home screen.

Number of times the net flow total overruns. R 42009-42010 — —

Number of times the positive flow total overruns. R 42011-42012 — —

Number of times the negative flow total overruns. R 42013-42014 — —

Number of times the gross flow total overruns. R 42015-42016 — —

Total energy as positive energy rate minus negative energy rate. A negative

total results when reverse flow is greater than positive energy rate. Unit is

based on selection for home screen.

Total energy of flow in forward direction, such as heating. Negative energy

rate is not accounted for in the total. Unit is based on selection for

home screen.

Total energy of flow in reverse direction, such as cooling. Positive energy rate

is not accounted for in the total. Unit is based on selection for home screen.

Total energy of forward and negative energy rate (all energy to heat and

cool). Unit is based on selection for home screen.

Number of times the net energy total overruns. R 42025-42026 — —

Number of times the positive energy total overruns. R 42027-42028 — —

Number of times the negative energy total overruns. R 42029-42030 — —

Integer and

Long Integer

Access

Network

R 40001-40002 40601-40602 41201-41204

R 40003-40004 40603-40604 41205-41208

R 40005-40006 40605-40608 41209-41216

R 40009-40010 40609-40610 41217-41218

R 40011-40012 40611-40612 —

R 40013-40014 40613-40614 —

R 40015-40016 40615-40616 —

R 42001-42002 42301-42302 42601-42604

R 42003-42004 42303-42304 42605-42608

R 42005-42006 42305-42306 42609-42612

R 42007-42008 42307-42308 42613-42616

R 42017-42018 42317-42318 42633-42636

R 42019-42020 42319-42320 42637-42640

R 42021-42022 42321-42322 42641-42644

R 42023-42024 42323-42324 42645-42648

Single

Precision

32-bit

floating point

Double

Precision

64-bit

floating point

Page 8 August 2019TTM-UM-03073-EN-01

Page 9

Modbus Registers and Coils

Descriptive Name Description

TOTALS (continued)

Energy/BTU Totalizer

Overflow Counter

(Gross)

Net Flow Totalizer (gal)

Positive Flow Totalizer

(gal)

Negative Flow Totalizer

(gal)

Gross Flow Totalizer

(gal)

Totalizer Overflow

Counter (Net)

Totalizer Overflow

Counter (Positive)

Totalizer Overflow

Counter (Negative)

Totalizer Overflow

Counter (Gross)

Energy/BTU Net Total

(kBTU)

Energy/BTU Positive

Total (kBTU)

Energy/BTU Negative

Total (kBTU)

Energy/BTU Gross Total

(kBTU)

Net kBTU Totalizer

Overflow Counter

Positive kBTU Totalizer

Overflow Counter

Negative kBTU

Totalizer Overflow

Counter

Gross kBTU Totalizer

Overflow Counter

Net Flow Totalizer

(liters)

Positive Flow Totalizer

(liters)

Negative Flow Totalizer

(liters)

Gross Flow Totalizer

(liters)

Totalizer Overflow

Counter (Net)

Totalizer Overflow

Counter (Positive)

Totalizer Overflow

Counter (Negative)

Totalizer Overflow

Counter (Gross)

Energy Net Total (kWh)

Energy Positive Total

(kWh)

Energy Negative Total

(kWh)

Energy Gross Total

(kWh)

Number of times the gross energy total overruns. R 42031-42032 — —

Total volume as forward flow minus reverse flow. A negative total results

when reverse flow is greater than forward flow.

Total volume of flow in forward direction. Reverse flow is not accounted for

in the total.

Total volume of flow in reverse direction. Forward flow is not accounted for

in the total.

Total volume of forward and reverse flow. R 42107-42108 42407-42408 42713-42716

Number of times the net flow total overruns. R 42109-42110 — —

Number of times the positive flow total overruns. R 42111-42112 — —

Number of times the negative flow total overruns. R 42113-42114 — —

Number of times the gross flow total overruns. R 42115-42116 — —

Total energy as positive energy rate minus negative energy rate. A negative

total results when reverse flow is greater than positive energy rate.

Total energy of flow in forward direction, such as heating. Negative energy

rate is not accounted for in the total.

Total energy of flow in reverse direction, such as cooling. Positive energy rate

is not accounted for in the total.

Total energy of forward and negative energy rate (all energy to heat

and cool).

Number of times the net energy total overruns. R 42125-42126 — —

Number of times the positive energy total overruns. R 42127-42128 — —

Number of times the negative energy total overruns. R 42129-42130 — —

Number of times the gross energy total overruns. R 42131-42132 — —

Total volume as forward flow minus reverse flow. A negative total results

when reverse flow is greater than forward flow.

Total volume of flow in forward direction. Reverse flow is not accounted for

in the total.

Total volume of flow in reverse direction. Forward flow is not accounted for

in the total.

Total volume of forward and reverse flow. R 42207-42208 42507-42508 42813-42816

Number of times the net flow total overruns. R 42209-42210 — —

Number of times the positive flow total overruns. R 42211-42212 — —

Number of times the negative flow total overruns. R 42213-42214 — —

Number of times the gross flow total overruns. R 42215-42216 — —

Total energy as positive energy rate minus negative energy rate. A negative

total results when reverse flow is greater than positive energy rate.

Total energy of flow in forward direction, such as heating. Negative energy

rate is not accounted for in the total.

Total energy of flow in reverse direction, such as cooling. Positive energy rate

is not accounted for in the total.

Total energy of forward and negative energy rate (all energy to heat

and cool).

Integer and

Long Integer

Access

Network

R 42101-42102 42401-42402 42701-42704

R 42103-42104 42403-42404 42705-42708

R 42105-42106 42405-42406 42709-42712

R 42117-42118 42417-42418 42733-42736

R 42119-42120 42419-42420 42737-42740

R 42121-42122 42421-42422 42741-42744

R 42123-42124 42423-42424 42745-42748

R 42201-42202 42501-42502 42801-42804

R 42203-42204 42503-42504 42805-42808

R 42205-42206 42505-42506 42809-42812

R 42217-42218 42517-42518 42833-42836

R 42219-42220 42519-42520 42837-42840

R 42221-42222 42521-42522 42841-42844

R 42223-42224 42523-42524 42845-42848

Single

Precision

32-bit

floating point

Double

Precision

64-bit

floating point

Page 9 August 2019 TTM-UM-03073-EN-01

Page 10

Modbus Registers and Coils

Descriptive Name Description

TOTALS (continued)

Net kWh Totalizer

Overflow Counter

Positive kWh Totalizer

Overflow Counter

Negative kWh Totalizer

Overflow Counter

Gross kWh Totalizer

Overflow Counter

HOME SCREEN UNITS

Flow Rate Units Flow rate units on home screen as defined in parameter settings. R 43001 — —

Flow Rate Decimal

Velocity Units Velocity units on home screen as defined in parameter settings. R 43003 — —

Flow Total Units Total volume units on home screen as defined in parameter settings. R 43004 — —

Flow Total Decimal

Energy Rate Units Energy rate units on home screen as defined in parameter settings. R 43006 — —

Energy Rate Decimal

Temperature Units Temperature units on home screen as defined in parameter settings. R 43008 — —

Energy Total Units Energy total units on home screen as defined in parameter settings. R 43009 — —

Energy Total Decimal

SETUP

Low Flow Cutoff

Low Signal Cutoff

High Signal Cutoff

DIAGNOSTICS ALARMS

Active Failed

Conditions

Active Out of

Specification

Conditions

Active Check Function

Conditions

Alarm History Individual registers per buffer. R

1

See “Enumerations” on page 12.

Number of times the net energy total overruns. R 42225-42226 — —

Number of times the positive energy total overruns. R 42227-42228 — —

Number of times the negative energy total overruns. R 42229-42230 — —

Number of times the gross energy total overruns. R 42231-42232 — —

Number of digits after the decimal of flow rate on home screen. Use with

long integer format.

Number of digits after the decimal of flow total on home screen. Use with

long integer format.

Number of digits after the decimal of energy rate on home screen. Use with

long integer format.

Number of digits after the decimal of energy total on home screen. Use with

long integer format.

Setting to display flow rate as zero & stop totalizing when flow rate goes

below

this value.

Setting to display flow rate as zero & stop totalizing when signal strength

goes below this value and trigger a low signal error message.

Setting to display flow rate as zero & stop totalizing when signal strength

goes above this value and trigger an oversaturate error message.

Message code corresponds to the bit (for example, F02 is bit 02). R 45001-45007 — —

Message code corresponds to the bit (for example, S02 is bit 02). R 45008-45014 — —

Message code corresponds to the bit (for example, C02 is bit 02). R 45015-45021 — —

Integer and

Long Integer

Access

Network

R 43002 — —

R 43005 — —

R 43007 — —

R 43010 — —

R/W — 44001 —

R/W 44003 — —

R/W 44004 — —

45033

Array of

100 single

registers

Single

Precision

32-bit

floating point

— —

Double

Precision

64-bit

floating point

Page 10 August 2019TTM-UM-03073-EN-01

Page 11

Modbus Registers and Coils

Descriptive Name Description

Integer and

Long Integer

Access

Network

Single

Precision

32-bit

floating point

Double

Precision

64-bit

floating point

DIAGNOSTICS

Signal Strength Indicates the strength of the ultrasonic signal. R 45501 — —

Current Output #1

Source

Parameter assigned to Current Output #1.

1

R 45601 — —

Current Output #1 Current in mA of Current Output #1. R — 45602-45603 —

Current Output #2

Source

Parameter assigned to Current Output #2.

1

R 45604 — —

Current Output #2 Current in mA of Current Output #2. R — 45605-45606 —

Current Output #3

Source

Current Output #3 Current in mA of Current Output #3.

Output #1 Mode Operation mode of Digital Output #1.

Output #1 Source Parameter assigned to Digital Output #1.

Output #1 Status Status of Digital Output #1.

Output #2 Mode Operation mode of Digital Output #2.

Output #2 Source Parameter assigned to Digital Output #2.

Output #2 Status Status of Digital Output #2.

Output #3 Mode Operation mode of Digital Output #3.

Output #3 Source Parameter assigned to Digital Output #3.

Output #3 Status Status of Digital Output #3.

Aux Output #1 Mode Operation mode of Auxiliary Output #1.

Aux Output #1 Source Parameter assigned to Auxiliary Output #1.

Aux Output #1 Status Status of Digital Auxiliary #1.

Aux Output #2 Mode Operation mode of Auxiliary Output #2.

Aux Output #2 Source Parameter assigned to Auxiliary Output #2.

Aux Output #2 Status Status of Digital Auxiliary #2.

Input Mode Operation mode of Digital Input.

Input Active State Indicates the voltage level to make the input active.

Input Status Status of Digital Input.

Parameter assigned to Current Output #3. R 45607 — —

1

1

1

1

1

1

1

1

1

1

1, 2

1, 2

1, 2

1, 2

1, 2

1, 2

1

1

1

R — 45608-45609 —

R 45701 — —

R 45702 — —

R 45703 — —

R 45704 — —

R 45705 — —

R 45706 — —

R 45707 — —

R 45708 — —

R 45709 — —

R 45710 — —

R 45711 — —

R 45712 — —

R 45713 — —

R 45714 — —

R 45715 — —

R 45901 — —

R 45902 — —

R 45903 — —

COMMUNICATION

Modbus Access Modbus Access Type. R 46001 — —

Modbus Active

Timeout

Termination Resistor

Defines the maximum time that master will poll the meter. If the meter

does not see any communication from the master in the time specified, a

message will trigger.

Selection to enable or disable the internal termination resistor (RS485

devices only).

1

R/W 46002 — —

R/W 46003 — —

IDENTIFICATION

Tag Identification String setting to identify the meter. (String) R 47001 — —

Part Number Part number of the meter. (String) R 47065 — —

Serial Number Serial number of the meter. (String) R 47129 — —

Firmware Version Firmware version of the meter. (String) R 47193 — —

Calibration Date Date the meter was last calibrated at factory. (String) R 47257 — —

Date Code Date the meter was manufactured. (String) R 47321 — —

1

See “Enumerations” on page 12.

2

Use only if auxiliary output card is installed.

Coils

Descriptive Name Description

ACTIONS

Reset Totalizers Resets all flow totals in meter to zero.

Unlatch Alarms Unlatches outputs in alarm latched state.

Clear Alarm History Clears all errors, alarms and event codes from alarm history.

Reboot Device Reboots the meter.

1

See “Enumerations” on page 12.

1

1

1

Coil

Access

Network

W 00001

1

W 00002

W 00003

W 00004

Page 11 August 2019 TTM-UM-03073-EN-01

Page 12

Enumerations

ENUMERATIONS

Parameter Enumeration Value

UNITS OF MEASURE

Flow Rate Units Liters per second 0

Velocity Units Meters per second 0

Flow Total Units Liters 0

Energy Rate

Units

Temperature

Units

Energy Total

Units

Liters per minute 1

Liters per hour 2

Cubic meters per second 3

Cubic meters per minute 4

Cubic meters per hour 5

Cubic feet per second 6

Cubic feet per minute 7

Cubic feet per hour 8

Gallons per second 9

Gallons per minute 10

Gallons per hour 11

Mega gallons per day 12

United Kingdom gallons per second 13

United Kingdom gallons per minute 14

United Kingdom gallons per hour 15

Barrels per minute 18

Mega United Kingdom gallons per day 19

Barrels per day 20

Acre feet per day 21

Fluid barrels per day 22

Imperial barrels per day 23

Custom flow rate 24

Feet per hour 11

Hectoliters 1

Cubic meters 2

Cubic feet 3

Gallons 4

Mega gallons 5

United Kingdom gallons 6

Acre feet 9

Oil barrel 10

Mega United Kingdom gallons 11

Liquid barrel 12

Feet 13

Meters 14

Kilograms 15

Custom 16

Custom 0

Watts 1 - W

Kilowatts 2 - kW

Mega Watts 3 - mW

British thermal units per hour 4 - btu/h

Thousand British thermal units per hour 5 - kbtu/h

Million British thermal units per hour 6 - mbtu/h

KiloJoule per hour 7 - kJ/h

Mega Joule per hour 8 - mJ/h

Kilocalorie per hour 9 - kcal/h

Megacalorie per hour 10 - mcal/h

Ton of refrigeration 11 - ton/RT

Degrees Celsius 0

Degrees Fahrenheit 1

Degrees Kelvin 2

Custom 0

British thermal units 1

Thousand British thermal units 2

Million British thermal units 4

Ton 5

KiloJoule 6

Mega Joule 7

Kilowatt hours 8

Mega kilowatt hours 9

Thousand calories 10

Mega calories 11

Parameter Enumeration Value

INPUTS/OUTPUTS

Current Output

Source

Digital Output

Mode

Digital Output

Source

Digital Output

Status

Aux Output

Mode

Aux Output

Source

Aux Output

Status

Input Mode Disabled 0

Input Active

State

Input Status Inactive 0

COMMUNICATION

Termination

Resistor

ACTIONS

Reset Totalizers Disabled 0

Unlatch Alarms Disabled 0

Clear Alarm

History

Reboot Device Disabled 0

Disabled 0

Flow rate 1

Velocity 2

Signal strength 3

Temperature 1 (Energy models only) 4

Temperature 2 (Energy models only) 5

Energy rate (Energy models only) 6

Test mode 7

Disabled 0

Frequency 1

Pulse totalizer 2

Direction status 3

Mode alarm 4

Disabled 0

Flow rate 1

Velocity 2

Test mode 3

Energy rate (Energy models only) 4

Off 0

On 1

Frequency 2

Pulse 3

Disabled 4

Disabled 0

Pulse totalizer 2

Direction status 3

Mode alarm 4

Disabled 0

Flow rate 1

Velocity 2

Test mode 3

Energy rate (Energy models only) 4

Off 0

On 1

Pulse 3

Disabled 4

Reset flow total 1

Unlatch alarm 2

Active high 0

Active low 1

Active 1

Disabled 0

Enabled 1

Enabled 1

Enabled 1

Disabled 0

Enabled 1

Enabled 1

Page 12 August 2019TTM-UM-03073-EN-01

Page 13

Warning and Alarm Message Codes

WARNING AND ALARM MESSAGE CODES

Failure Codes

OTE:N F01 indicates that the bootloader could not start the firmware application, so it is not possible to record this failure in

the alarm history.

Code Description

F02 ELECTRONIC ERROR Multiple watchdog timeouts occurred.

F03 ELECTRONIC ERROR Voltage levels are out of specification.

F10 LOW SIGNAL Signal strength is below cutoff.

F11 HIGH SIGNAL Signal strength is oversaturated.

F20 RTD #1 ERROR Unable to detect RTD #1.

F21 RTD #2 ERROR Unable to detect RTD #2.

Check Function Codes

Code Description

C01 CURRENT TEST Current output is in test mode.

C10 OUTPUT #1 FREQUENCY TEST Output #1 is in frequency test mode.

C11 OUTPUT #1 PULSE TEST Output #1 is in pulse test mode.

C12 OUTPUT #1 SWITCH TEST Output #1 is forced on or off.

C20 OUTPUT #2 FREQUENCY TEST Output #2 is in frequency test mode.

C21 OUTPUT #2 PULSE TEST Output #2 is in pulse test mode.

C22 OUTPUT #2 SWITCH TEST Output #2 is forced on or off.

C30 OUTPUT #3 FREQUENCY TEST Output #3 is in frequency test mode.

C31 OUTPUT #3 PULSE TEST Output #3 is in pulse test mode.

C32 OUTPUT #3 SWITCH TEST Output #3 is forced on or off.

C41 AUX #1 PULSE TEST Aux Output #1 is in pulse test mode.

C42 AUX #1 SWITCH TEST Aux Output #1 is forced on or off.

C51 AUX #2 PULSE TEST Aux Output #2 is in pulse test mode.

C52 AUX #2 SWITCH TEST Aux Output #2 is forced on or off.

C60 SIMULATION MODE Meter is running flow simulation.

Page 13 August 2019 TTM-UM-03073-EN-01

Page 14

Warning and Alarm Message Codes

Out-of-Specification Codes

Code Description Correction

S01 ELECTRONIC WARNING Fault detected and meter rebooted. Contact factory, update firmware, or repair or replace transmitter.

S02 DEFAULT FAILED Reset to factory defaults failed.

S03 LANGUAGE FILE

CORRUPT

S10 mA TOO HIGH

S11 mA TOO HIGH Flow or energy rate higher than 20 mA. Check the scaling of the Current #2 output.

S12 mA TOO HIGH Flow or energy rate higher than 20 mA. Check the scaling of the HART output.

S19 mA SUPPLY VOLTAGE

ERR

S20 FREQ HIGH Value higher than max. frequency output. Check the scaling of the frequency on Output #1.

S21 FREQ HIGH Value higher than max. frequency output. Check the scaling of the frequency on Output #2.

S22 FREQ HIGH Value higher than max. frequency output. Check the scaling of the frequency on Output #3.

S30 PULSE HIGH Pulse output is too fast for the pulse width. Check the scaling factor, units and pulse width of the pulse on Output #1.

S31 PULSE HIGH Pulse output is too fast for the pulse width. Check the scaling factor, units and pulse width of the pulse on Output #2.

S32 PULSE HIGH Pulse output is too fast for the pulse width. Check the scaling factor, units and pulse width of the pulse on Output 3.

S33 PULSE HIGH Pulse output is too fast for the pulse width.

S34 PULSE HIGH Pulse output is too fast for the pulse width.

S40 HIGH FLOW Flow rate is above high flow alarm setting. Check flow rate and Set High setting for Output #1.

S41 HIGH FLOW Flow rate is above high flow alarm setting. Check flow rate and Set High setting for Output #2.

S42 HIGH FLOW Flow rate is above high flow alarm setting. Check flow rate and Set High setting for Output #3.

S43 HIGH FLOW Flow rate is above high flow alarm setting. Check flow rate and Set High setting for Aux Output #1.

S44 HIGH FLOW Flow rate is above high flow alarm setting. Check flow rate and Set High setting for Aux Output #2.

S45 LOW FLOW Flow rate is below low flow alarm setting. Check flow rate and Set Low setting for Output #1.

S46 LOW FLOW Flow rate is below low flow alarm setting. Check flow rate and Set Low setting for Output #2.

S47 LOW FLOW Flow rate is below low flow aram setting. Check flow rate and Set Low setting for Output #3.

S48 LOW FLOW Flow rate is below low flow aram setting. Check flow rate and Set Low setting for Aux Output #1.

S49 LOW FLOW Flow rate is below low flow aram setting. Check flow rate and Set Low setting for Aux Output #2.

S50 TOTAL OVERFLOW

S60 COMM TIMEOUT

S61 MODULE TIMEOUT Network timeout. Check communication settings and wiring.

S62 DISCONNECTED Bluetooth connection timed out. —

S63 BLUETOOTH FAIL Unable to initialize Bluetooth. Update firmware. If error repeats, repair or replace transmitter.

S64 MODULE FAILED Unable to initialize module. Reseat module and reboot trnasmitter. If error repeats, replace module.

S65 MODULE MISMATCH Module installed does not match settings. Replace module with correct module. Check card type settings.

S67 DATA LOG ERROR SD micro card is missing or full. Check SD micro card. If data logging is not required, disable data logging.

S70 TEMP #1 LOW Temp. #1 is below low alarm setting. Check fluid temperature and RTD #1. Check alarm settings for Output #1.

S71 TEMP #1 LOW Temp. #1 is below low alarm setting. Check fluid temperature and RTD #1. Check alarm settings for Output #2.

S72 TEMP #1 LOW Temp. #1 is below low alarm setting. Check fluid temperature and RTD #1. Check alarm settings for Output #3.

S73 TEMP #2 LOW Temp. #1 is below low alarm setting. Check fluid temperature and RTD #1. Check alarm settings for Aux Output #1.

S74 TEMP #2 LOW Temp. #1 is below low alarm setting. Check fluid temperature and RTD #1. Check alarm settings for Aux Output #2.

S75 TEMP #1 HIGH Temp. #1 is above high alarm setting. Check fluid temperature and RTD #1. Check alarm settings for Output #1.

S76 TEMP #1 HIGH Temp. #1 is above high alarm setting. Check fluid temperature and RTD #1. Check alarm settings for Output #2.

S77 TEMP #1 HIGH Temp. #1 is above high alarm setting. Check fluid temperature and RTD #1. Check alarm settings for Output #3.

S78 TEMP #1 HIGH Temp. #1 is above high alarm setting. Check fluid temperature and RTD #1. Check alarm settings for Aux Output #1.

S79 TEMP #1 HIGH Temp. #1 is above high alarm setting. Check fluid temperature and RTD #1. Check alarm settings for Aux Output #2.

S80 HIGH ENERGY RATE Flow rate is above high flow alarm setting. Check energy flow rate and Set High setting for Output #1.

S81 HIGH ENERGY RATE Flow rate is above high flow alarm setting. Check energy flow rate and Set High setting for Output #2.

S82 HIGH ENERGY RATE Flow rate is above high flow alarm setting. Check energy flow rate and Set High setting for Output #3.

S83 HIGH ENERGY RATE Flow rate is above high flow alarm setting. Check energy flow rate and Set High setting for Aux Output #1.

S84 HIGH ENERGY RATE Flow rate is above high flow alarm setting. Check energy flow rate and Set High setting for Aux Output #2.

S85 LOW ENERGY RATE Flow rate is above low flow alarm setting. Check energy flow rate and Set Low setting for Output #1.

S86 LOW ENERGY RATE Flow rate is above low flow alarm setting. Check energy flow rate and Set Low setting for Output #2.

S87 LOW ENERGY RATE Flow rate is above low flow alarm setting. Check energy flow rate and Set Low setting for Output #3.

S88 LOW ENERGY RATE Flow rate is above low flow alarm setting. Check energy flow rate and Set Low setting for Aux Output #1.

S89 LOW ENERGY RATE Flow rate is above low flow alarm setting. Check energy flow rate and Set Low setting for Aux Output #2.

S90 TEMP #2 LOW Temp. #2 is below low alarm setting. Check fluid temperature and RTD #2. Check alarm settings for Output #1.

S91 TEMP #2 LOW Temp. #2 is below low alarm setting. Check fluid temperature and RTD #2. Check alarm settings for Output #2.

S92 TEMP #2 LOW Temp. #2 is below low alarm setting. Check fluid temperature and RTD #2. Check alarm settings for Output #3.

English only. Update firmware.

Flow or energy rate higher than flow rate at 20

mA output.

Supply voltage out of range for 4-20 mA

outputs.

Accumulated flow total is greater than

viewable digits.

Modbus master or BACnet device

communication packet.

Check calibration. If it does not match the calibration settings on the

transducer serial tag, enter field calibration settings. Return to the

Home Screen and continue to operate (if the reset to factory defaults is

through the transmitter).

Check the scaling of the Current #1 output.

Check wiring.

Check the scaling factor, units and pulse width of the pulse on Aux Output #1

dry contact.

Check the scaling factor, units and pulse width of the pulse on Aux Output #2

dry contact.

Check the totalizer units or reset the flow total to clear the overflow counter.

Check master device poll rate and offline status. Check wiring and termination

resistor setting.

Page 14 August 2019TTM-UM-03073-EN-01

Page 15

Warning and Alarm Message Codes

Code Description Correction

S93 TEMP #2 LOW Temp. #2 is below low alarm setting. Check fluid temperature and RTD #2. Check alarm settings for Aux Output #1.

S94 TEMP #2 LOW Temp. #2 is below low alarm setting. Check fluid temperature and RTD #2. Check alarm settings for Aux Output #2.

S95 TEMP #2 HIGH Temp. #2 is above high alarm setting. Check fluid temperature and RTD #2. Check alarm settings for Output #1.

S96 TEMP #2 HIGH Temp. #2 is above high alarm setting. Check fluid temperature and RTD #2. Check alarm settings for Output #2.

S97 TEMP #2 HIGH Temp. #2 is above high alarm setting. Check fluid temperature and RTD #2. Check alarm settings for Output #3.

S98 TEMP #2 HIGH Temp. #2 is above high alarm setting. Check fluid temperature and RTD #2. Check alarm settings for Aux Output #1.

S99 TEMP #2 HIGH Temp. #2 is above high alarm setting. Check fluid temperature and RTD #2. Check alarm settings for Aux Output #2.

Informational Events Codes

Information events are only displayed in the ALARM HISTORY and not on the Home Screen.

I01 POWER ON Power on or rebooted.

I11 ZERO Meter zeroed.

I12 FACTORY CALIBRATION Calibration changed from Field to Factory.

I13 FIELD CALIBRATION Calibration changed from Factory to Field.

I21 FIRMWARE CHANGED Firmware updated.

I31 FLOW TOTAL RESET Flow total reset to zero.

I41 NO SD CARD Micro SD card not installed.

Page 15 August 2019 TTM-UM-03073-EN-01

Page 16

Transit Time Ultrasonic Flow Meters, TFX-5000 Meter Modbus RTU Protocol

TROUBLESHOOTING

Code Description Recommended Action

S60 MODBUS TIMEOUT Modbus

master device communication

packet.

Symptoms Possible Causes Recommended Action

No communication Transmit and receive are wired incorrectly. Check the network wiring from the meter.

Intermittent communication Cable is not properly shielded. Communication cables must have shielding to protect the quality of the

Unable to read specific

parameters correctly

Unable to write specific

parameters

Check master device poll rate and offline

status.

Baud rate does not match master. Check the baud rate of the master and ensure the baud rate of the meter

Parity and stop bits do not match the

master.

Slave address is not unique. Another device

is on the network with the same address.

Cable is not terminated properly. For Modbus RTU on EIA-485 network, devices can be daisy chained

Cable or chain longer than 4000 feet. For Modbus RTU on EIA-485 network, the full length of the network cannot

Cable routed near power cables such a

variable frequency drives.

Cable is not terminated properly. For Modbus RTU on EIA-485 network, devices can be daisy chained

Cable or chain longer than 4000 feet. For Modbus RTU on EIA-485 network, the full length of the network cannot

Word order (endian) or data type/format In Modbus RTU, floating point, long integers and string character registers

Transmitter is set up for read only or is set

up for read and write only to resets

Word order (endian) or data type/format In Modbus RTU, floating point, long integers and string character registers

Check the recommended actions listed for no communication symptom.

If the master device communicates less frequently, change the Master

Timeout to a larger time period.

matches the master. The master is often a PLC or BAS. If it does not match,

change the Baud Rate setting in the Modbus RTU Communication menu.

Check that the settings are compatible with the master. If it does not match,

change the Parity or Stop Bit setting in the Modbus RTU

Communication menu.

Check the addresses of the other devices on the network. Check that the

slave address is not 1.

together. The two devices on the end of the chain need to have terminated

resistors. Terminating resistors can be enabled through the Modbus RTU

Communication menu.

exceed 4000 feet. Check the length of the cabling.

communication signals from electromagnetic interference (EMI). Check that

the cable has a shield. Typically, one end of the shield drain is connected

to a clean ground to dissipate EMI and prevent ground loops. However,

depending on the ground quality, cable length and type of interference,

other methods can be employed.

Cables carrying high currents cause a high degree of electromagnetic

interference that can interfere with the quality of the communication signals.

Route signal cables away from power cables.

together. The two devices on the end of the chain need to have terminated

resistors. Terminating resistors can be enabled through the Modbus RTU

Communication menu.

exceed 4000 feet. Check the length of the cabling.

may have the word order (endian) swapped. Check the data type and endian

of the master and verify that the register in the meter matches the matches.

If it does not match, change the Word Order setting in the Modbus RTU

Communication menu.

These settings are commonly used to prevent accidental or unauthorized

changes to the a device over a network. Check the Access setting in the

Modbus RTU menu.

may have the word order (endian) swapped. Check the data type and endian

of the master and verify that the register in the meter matches the matches.

If it does not match, change the Word Order setting in the Modbus RTU

Communication menu.

Control. Manage. Optimize.

Dynasonics, AquaCUE and SoloCUE are registered trademarks of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities. Due

to continuous research, product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the extent

an outstanding contractual obligation exists. © 2019 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Eastern Europe Branch Oce (for Poland, Latvia, Lithuania, Estonia, Ukraine, Belarus) | Badger Meter Europe | ul. Korfantego 6 | 44-193 Knurów | Poland | +48-32-236-8787

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 19-07 Parkway Parade | Singapore 449269 | +65-63464836

Switzerland | Badger Meter Swiss AG | Mittelholzerstrasse 8 | 3006 Bern | Switzerland | +41-31-932 01 11

Loading...

Loading...