Page 1

Valve Positioners

RCV SRD991 Intelligent Positioner

POS-UM-00010-EN-03 (August 2014)

User Manual

Page 2

Valve Positioners, RCV SRD991 Intelligent Positioner

Page ii August 2014POS-UM-00010-EN-03

Page 3

User Manual

CONTENTS

Device Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

With Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Without Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Common Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Unpacking & Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Accident Prevention. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Electrical Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Summary – Hart and 4-20 mA without Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Mounting to Actuator (Valve) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Connection and Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

System Conguration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Summary – Foundation Fieldbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Connection and Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Bus Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

System Integration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Summary – Probus-PA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Mounting to Actuator (Valve) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Connection and Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Bus Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

System Integration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Summary – FoxCom (Digital) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Mounting to Actuator (Valve) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connection and Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

System conguration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Method of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Initialize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Device Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Page iii August 2014 POS-UM-00010-EN-03

Page 4

Valve Positioners, RCV SRD991 Intelligent Positioner

In Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Failsafe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Out of Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Calibrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Simulate (Foundation Fieldbus Version Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Functional Designations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

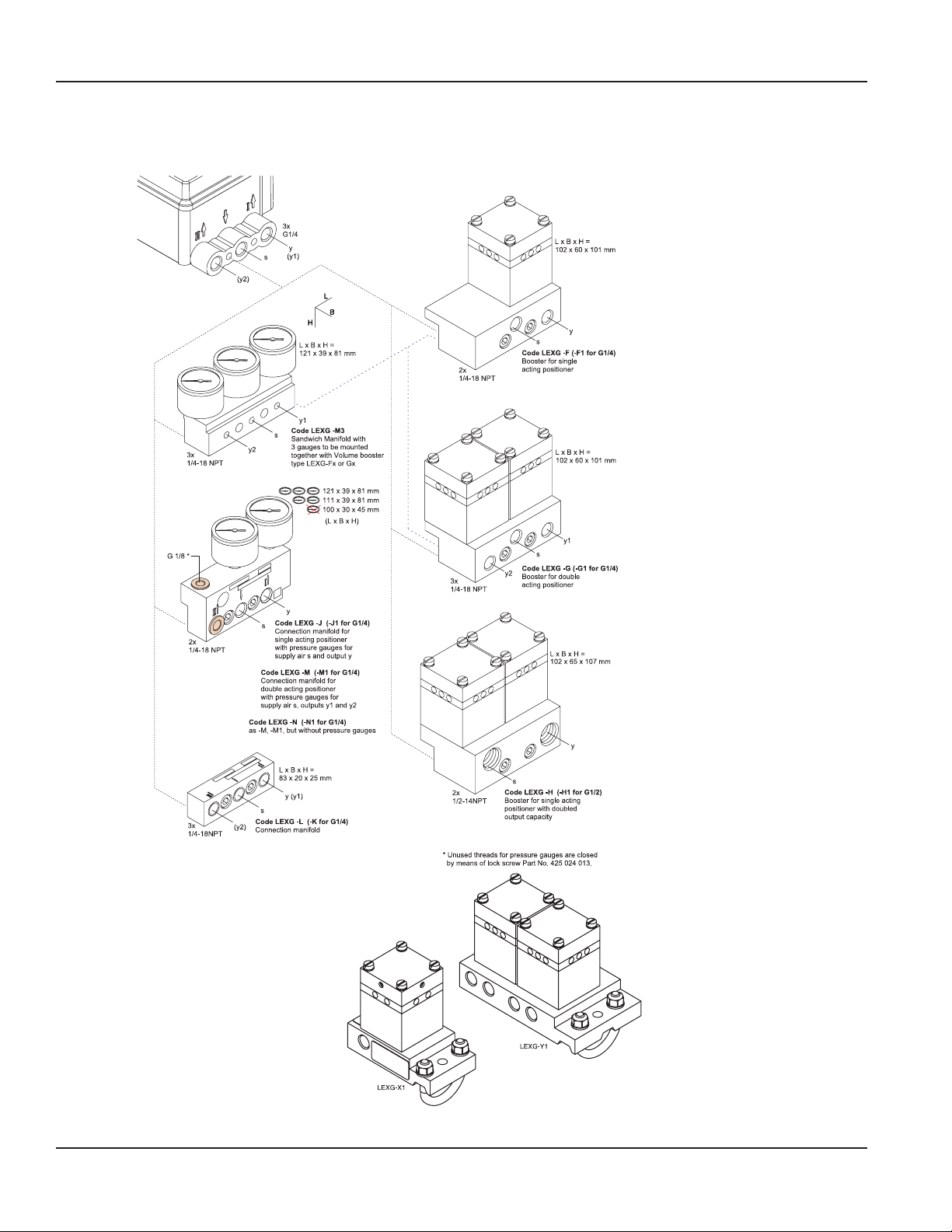

Pneumatic Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

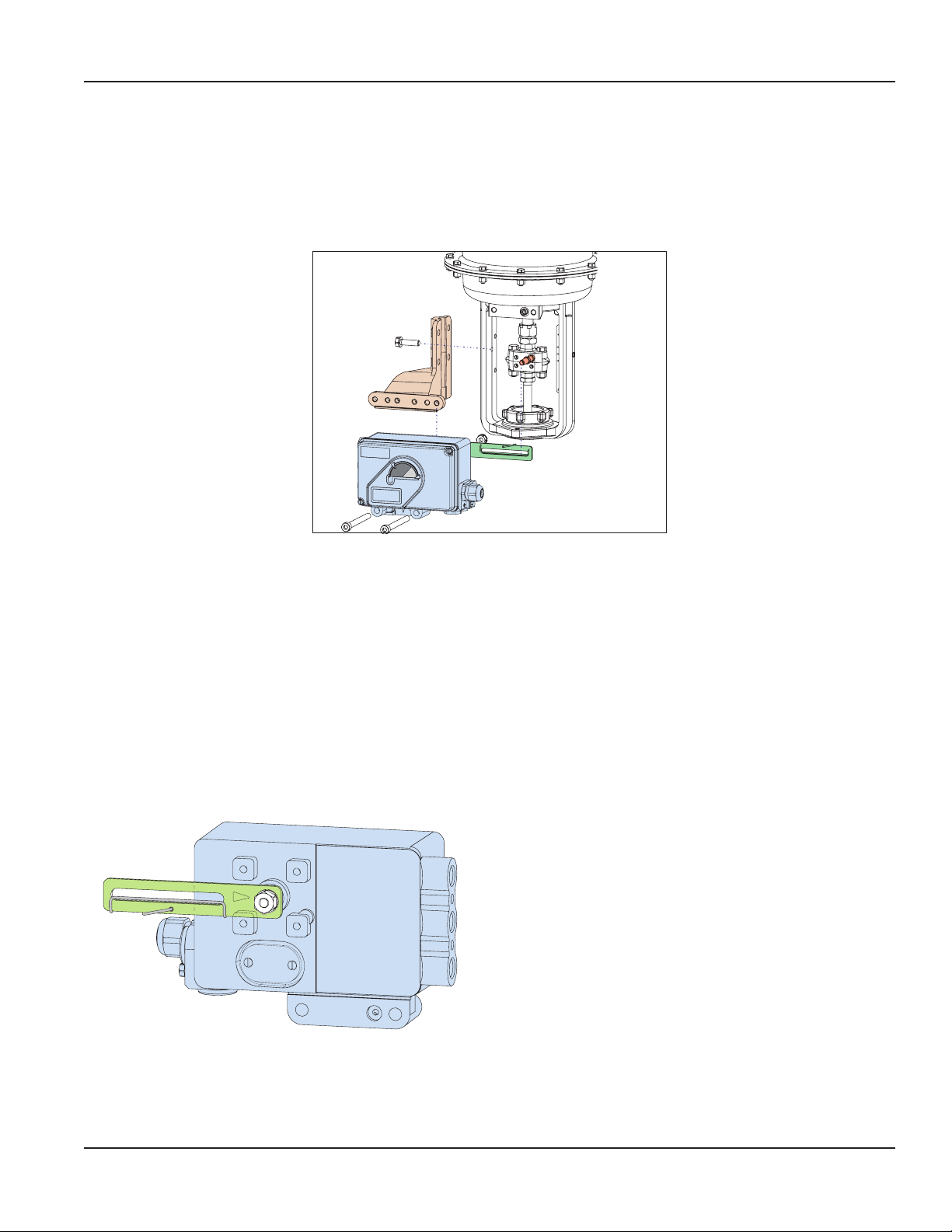

Mounting to Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

NAMUR Mounting Linear Actuator, Left Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

NAMUR Mounting Linear Actuator, Right Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Linear Actuator, Direct Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Mounting to Rotary Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Pneumatic Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Limit Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Additional Inputs / Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Built-in Pressure Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Setting by Means of Local Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

After Power ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

In Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Operation with Local Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Menu Structure for SRD991 / SRD960 with LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Conguration of 0 and 100% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Description of Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Setting the Travel Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Selecting Gear Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Exchange of Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Service Plug and IrCom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Page iv August 2014POS-UM-00010-EN-03

Page 5

User Manual

Supply Filter Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Removing the Electronics Unit* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Troubleshooting Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Errors Detected During Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Errors Detected During Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Diagnosis without LED or LCD Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Safety Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

EMC and CE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Explosion Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

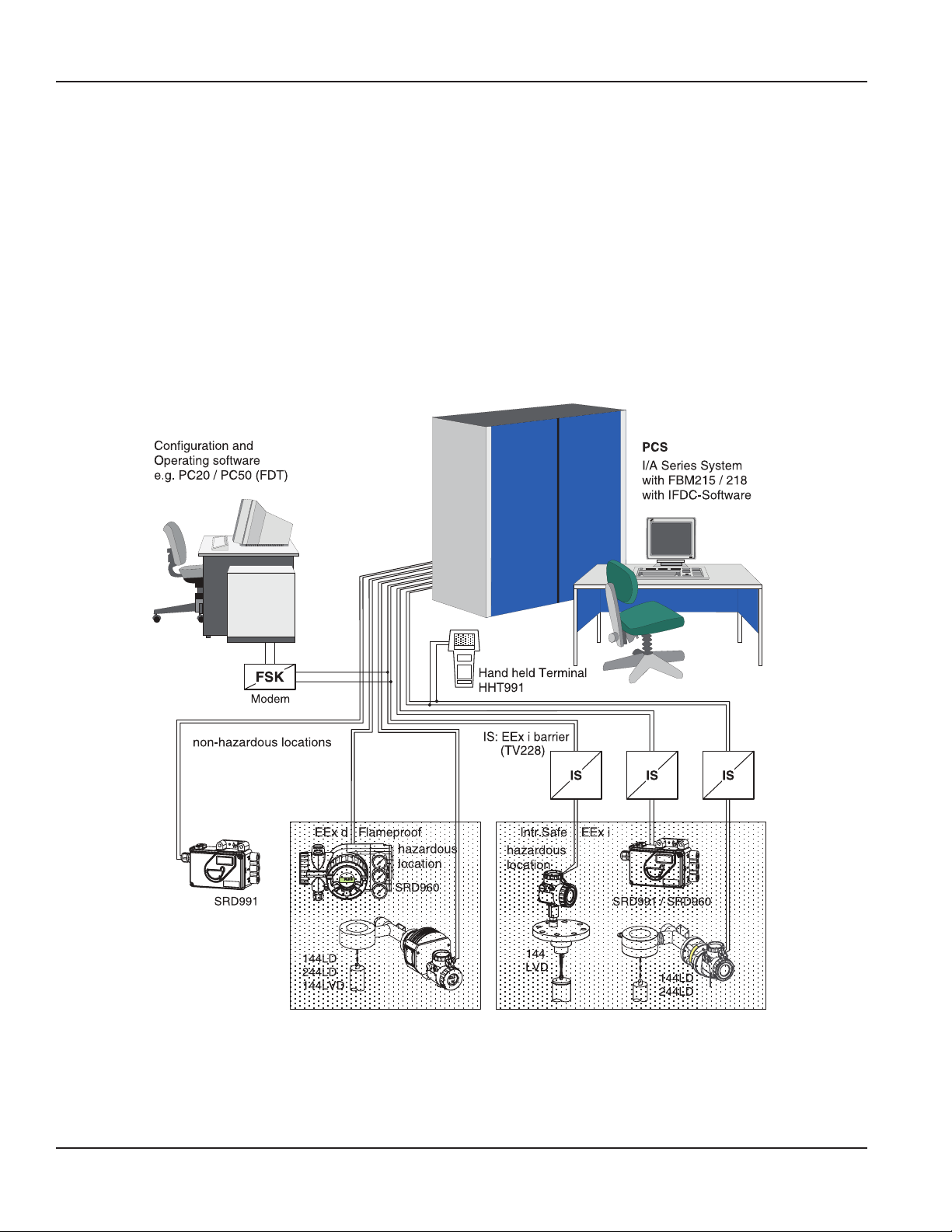

System Conguration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

HART Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

FoxCom Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

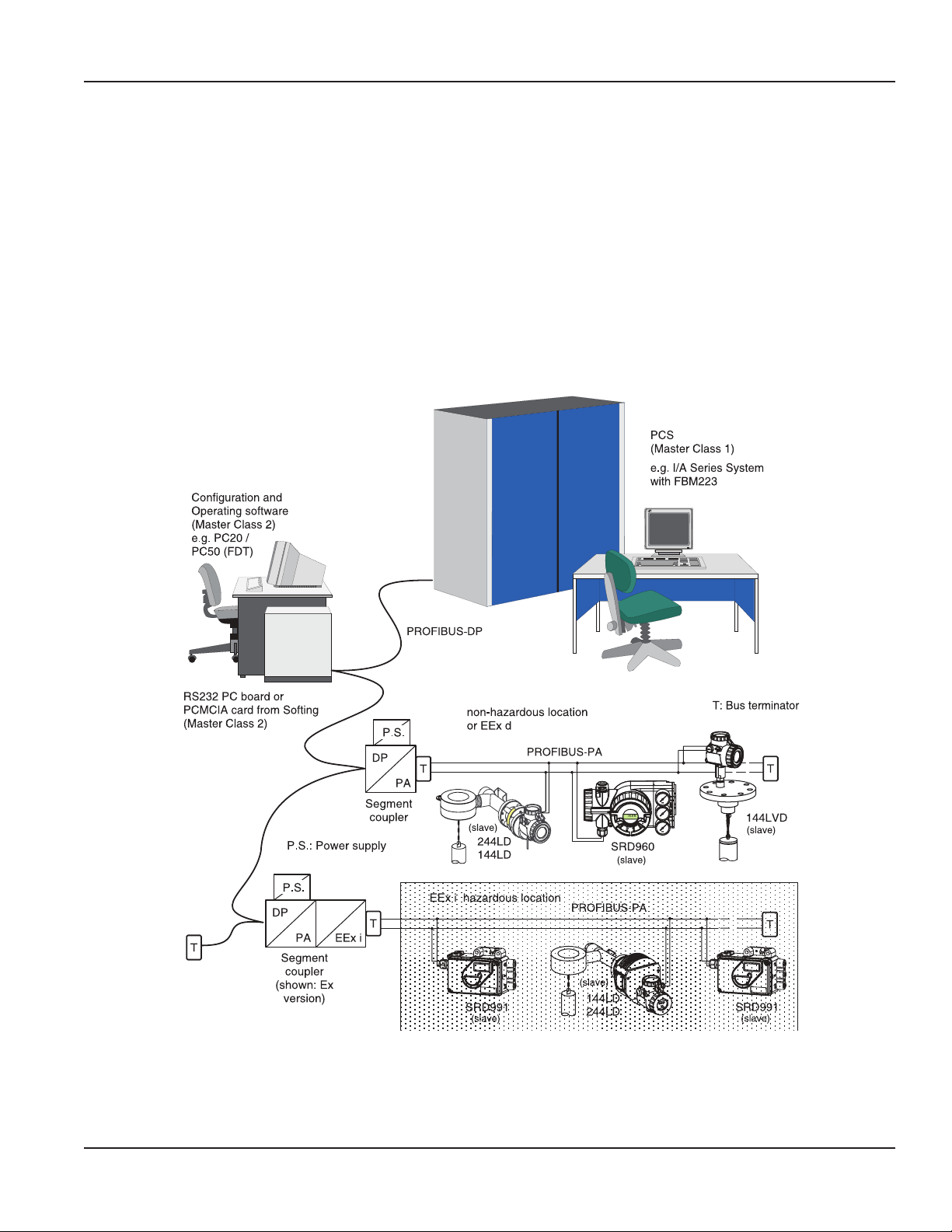

With Communication PROFIBUS-PA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

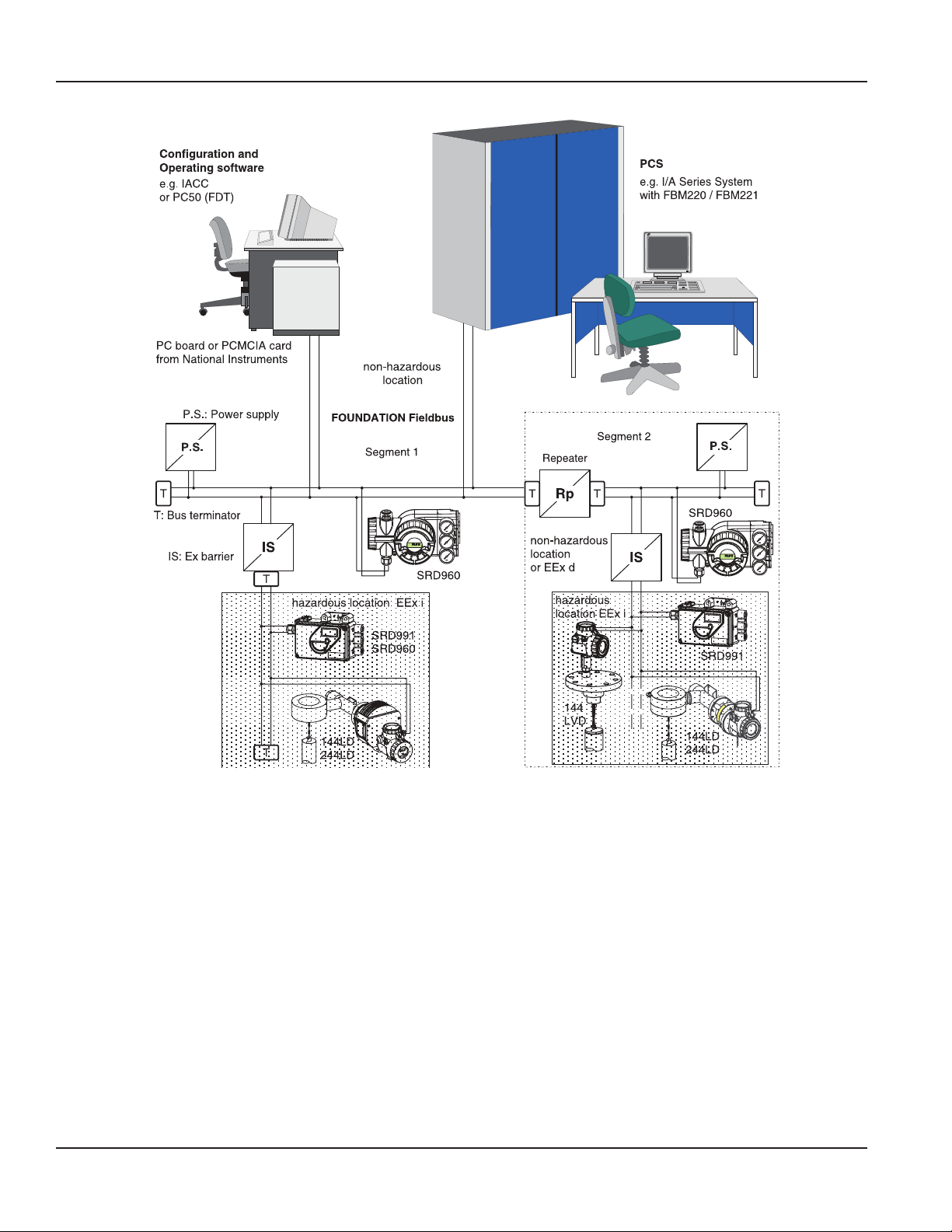

With Communication FOUNDATION Fieldbus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

System Conguration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Dimensions INOX SRD991 in Stainless Steel Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Page v August 2014 POS-UM-00010-EN-03

Page 6

Valve Positioners, RCV SRD991 Intelligent Positioner

Page vi August 2014POS-UM-00010-EN-03

Page 7

Device Features

The intelligent positioner SRD991 is designed to operate pneumatic valve actuators and can be operated from control

systems, controllers or PC-based configuration and operational tools, such as FDT/DTM Software. The positioner is available

with different communication protocols. The multi-lingual full text graphical LCD in connection with the three push-buttons

allows a comfortable and easy local configuration and operation as well as the display of valve specific data, and status and

diagnostic messages.

DEVICE FEATURES

• Autostart with self-calibration

• Self diagnostics, status and diagnostic messages

• Easy operation with three keys

• Multi-Lingual full text graphical LCD, or LEDs

• VALcare or Valve Monitor DTM for valve diagnostics and predictive maintenance

With Communication

• HART, FOUNDATION Fieldbus H1, PROFIBUS-PA, FoxCom

• Configuration by means of local keys, handheld terminal (HART), PC or I/A Series system or with a infrared interface by

means of IRCOM

Without Communication

• Input signal 4…20 mA

Common Features

• Stroke 8…260 mm (0.3…10.2 in.) with standard lever; larger stroke with special lever

• Angle range up to 95° (up to 300° on request)

• Supply air pressure up to 6 bar (90 psig), with spool valve up to 7 bar (105 psig)

• Single or double-acting

• Mounting on linear actuators according to NAMUR

◊ IEC 50534-6-1

◊ VDI/VDE 3847

• Mounting on rotary actuators according to VDI/VDE 3845 or IEC60534-6-2

• Protection class IP 66 and NEMA 4X

• Approved for SIL applications

• Explosion protection: Intrinsic safety according to ATEX and FM/CSA

Repair and maintenance operations must be carried out by qualified personnel!

Page 7 August 2014 POS-UM-00010-EN-03

Page 8

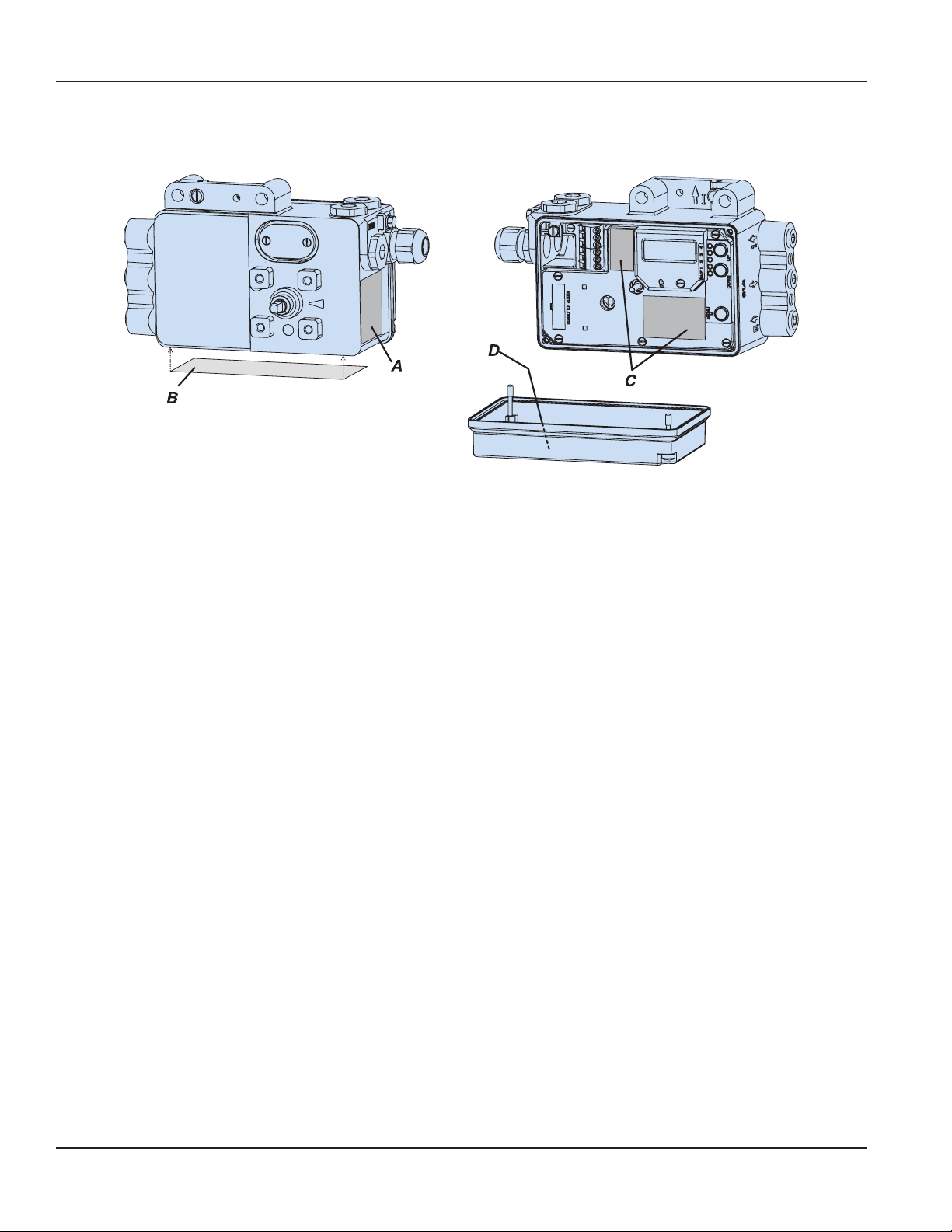

Labels

LABELS

A Nameplate

B Nameplate

C Warning labels, terminal wiring,key and

LED-designation

D Brief description inside cover

Page 8 August 2014POS-UM-00010-EN-03

Page 9

Unpacking & Inspection

UNPACKING & INSPECTION

Upon opening the shipping container, visually inspect the product and applicable accessories for any physical damage such

as scratches, loose or broken parts, or any other sign of damage that may have occurred during shipment.

OTE:N If damage is found, request an inspection by the carrier’s agent within 48 hours of delivery and file a claim with the

carrier. A claim for equipment damage in transit is the sole responsibility of the purchaser.

Installation and startup of instrument to be carried out only by qualified personnel, familiar with installation and start-up

procedures and operation of this product!

SAFETY INFORMATION

The installation of this product must comply with all applicable federal, state, and local rules, regulations, and codes.

Failure to read and follow these instructions can lead to misapplication or misuse of the product, resulting in personal injury

and damage to equipment.

Accident Prevention

The connected instrument contains mechanically moved parts, such as feedback levers, which could cause injuries. The

operators have to be instructed accordingly.

Electrical Safety

• This instrument satisfies the conditions for safety class III, overvoltage category I according to EN 61010-1 or IEC1010-1.

• Any work on electrical parts must be done by qualified personnel if any supply is connected to the instrument. The

instrument must be used for its designated purpose and connected in accordance with its connection diagram.

• Locally applicable installation regulations for electrical equipment must be observed, e.g. in the Federal Republic of

Germany DIN VDE 0100 resp. DIN VDE 0800.

• The instrument must be operated with safety extra low voltage SELV or SELV-E.

• Safety precautions taken in the instrument may be rendered ineffectual if the instrument is not operated in accordance

with the Master Instructions.

• Limitation of power supplies for fire protection must be observed due to EN 61010-1, appendix F or IEC 1010-1.

SUMMARY HART AND 4…20 MA WITHOUT COMMUNICATION

Mounting to Actuator (Valve)

The SRD991 can be mounted to linear or rotary actuators.

Connection and Startup

When connecting the supply air and applying a current source to the input terminals, pay attention to polarity. An initial

startup required no additional equipment.

Use the local push-buttons to change basic parameters such as type of actuator, side of installation, valve opens/closes with

increasing setpoint value, and characteristics curve of the valve (values set ex-factory: stroke actuator, mounting side: left,

valve opens with increasing setpoint value, linear characteristics curve).

Thereafter, an AUTOSTART can be performed during which the SRD991 determines independently the geometric data of the

actuator as well as control parameter, to ensure an optimized operation with the attached valve.

HART version:

The positioner can be operated either locally or via handheld terminal or PC (via modem).

Page 9 August 2014 POS-UM-00010-EN-03

Page 10

Summary – Hart and 4…20 mA without Communication

System Conguration

Version 4…20 mA without communication: Connection as traditional point-to-point connection according to the known

regulations of the measuring & control techniques.

HART version: When using ‘Communication’ (an AC signal which modulates on the 4-20 mA signal), make sure the

connected outputs, buffer amplifier and barriers are compatible with the frequency ranges used. In addition to the load,

the AC impedance requirements must be met. Therefore, it is recommended that only the specified amplifier, barrier and

configuration device be used.

To prevent crosstalk between lines and reduce disturbances through electromagnetic influences, use twisted-pair shielded

lines with a diameter of AWG 22…14 (0.3…2.5 mm2) and a maximum capacity of 100 pF/m.

The line capacities and connected devices may not exceed the maximum values listed for a particular HART protocol.

All components that are connected to the SRD in an explosion hazardous area require an Ex-Approval. The applicable limit

values must not be exceeded. Comply with the limit values when connecting additional capacitances, inductances, voltage or

current sources.

Page 10 August 2014POS-UM-00010-EN-03

Page 11

Summary – Foundation Fieldbus

SUMMARY FOUNDATION FIELDBUS

Mounting to Actuator (Valve)

The SRD991 can be mounted to linear or rotary actuators.

Connection and Startup

When connecting the supply air and applying a current source to the input terminals, pay attention to polarity. An initial

startup required no additional equipment.

Use the local push-buttons to change basic parameters such as type of actuator, side of installation, valve opens/closes with

increasing setpoint value, and characteristics curve of the valve (values set ex-factory: stroke actuator, mounting side: left,

valve opens with increasing setpoint value, linear characteristics curve).

Thereafter, an AUTOSTART can be performed during which the SRD991 determines independently the geometric data of the

actuator as well as control parameter, to ensure an optimized operation with the attached valve.

Bus Connection

The SRD 991 in the version FOUNDATION Fieldbus is bus compatible, which means that to a 2-core lead, the instruments have

to be attached in parallel according to IEC 1158-2. The lead serves as voltage feeder as well as for digital communication.

A FOUNDATION Fieldbus can consist of one or several segments, each with an individual length of up to 1900 meters. An

Ex-barrier should not be further than 100 meters from a bus terminal. To a segment up to 32 instruments can be attached.

A maximum of up to 240 instruments can be addressed (including repeater = connector of segments). To activate each

instrument individually, an individual address has to be entered.

From the factory, the address 29h (41) is always stored. This address can be changed automatically with the NI-Configurator.

System Integration

With the NI-Configurator changes in the configuration of the SRD991 can be carried out. The required files (*.FFO, *.SYM,

*.CFF) can be downloaded from the Internet by path

http://www.foxboro-eckardt.com/products/srd991_en.html.

Page 11 August 2014 POS-UM-00010-EN-03

Page 12

More informations about FOUNDATIONFieldbus seewww.fieldbus.org

Summary – Probus-PA

SUMMARY PROFIBUSPA

Mounting to Actuator (Valve)

The SRD991 can be mounted to linear or rotary actuators.

Connection and Startup

When connecting the supply air and applying a current source to the input terminals, pay attention to polarity. An initial

startup required no additional equipment.

Use the local push-buttons to change basic parameters such as type of actuator, side of installation, valve opens/closes with

increasing setpoint value, and characteristics curve of the valve (values set ex-factory: stroke actuator, mounting side: left,

valve opens with increasing setpoint value, linear characteristics curve).

Thereafter, an AUTOSTART can be performed during which the SRD991 determines independently the geometric data of the

actuator as well as control parameter, to ensure an optimized operation with the attached valve.

Page 12 August 2014POS-UM-00010-EN-03

Page 13

More informations about PROFIBUS see www.profibus.com

1)

Summary – Probus-PA

Bus Connection

The SRD 991 PROFIBUS-PA version is bus compatible, which means that to a 2-core lead the instruments have to be attached

in parallel according to IEC 1158-2. The lead serves as voltage feeder as well as for digital communication. To activate each

instrument individually, an individual address has to be entered.

From the factory the address 126 is always stored 1); Since this address cannot be used during operation, a new address has to

be entered in every instrument. This can be done via the local keys, with the FDT/DTM software or a commercial configurator.

To a PROFIBUS-PA-segment with a length of up to 1900 meters, up to 32 instruments can be attached. A maximum of up to

126 instruments can be addressed with PROFIBUS.

System Integration

During operation the SRD991 will communicate with a PROFIBUS master class 1. The required GSD-file (“instrument-specific

dates”) can be downloaded from the Internet by path

http://www.foxboro-eckardt.com/products/srd991_en.html.

as per profile 3.0

Page 13 August 2014 POS-UM-00010-EN-03

Page 14

Summary – FoxCom (Digital)

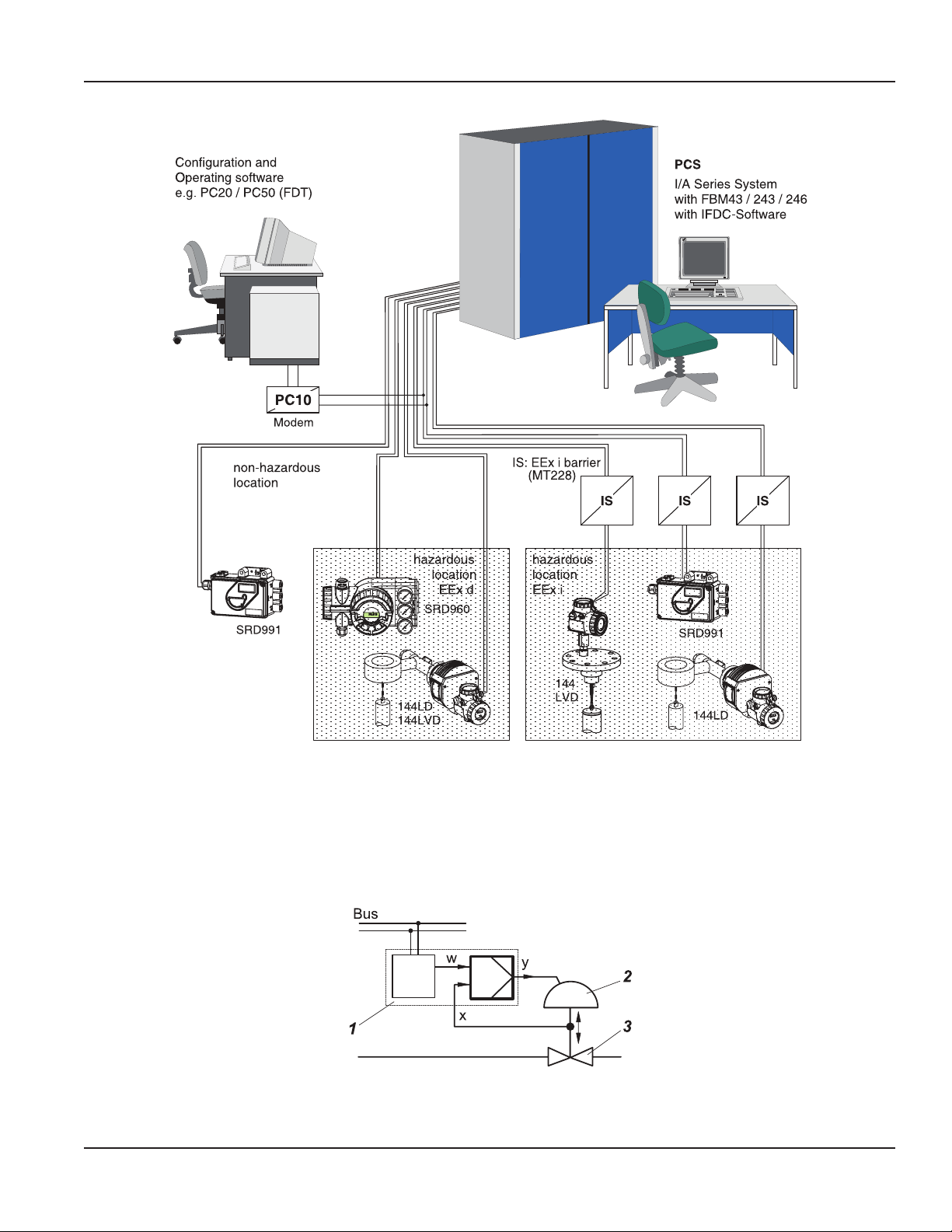

SUMMARY FOXCOM DIGITAL

Mounting to Actuator (Valve)

The SRD991 can be mounted to linear or rotary actuators.

Connection and Startup

When connecting the supply air and applying a current source to the input terminals, pay attention to polarity. An initial

startup required no additional equipment.

Use the local push-buttons to change basic parameters such as type of actuator, side of installation, valve opens/closes with

increasing setpoint value, and characteristics curve of the valve (values set ex-factory: stroke actuator, mounting side: left,

valve opens with increasing setpoint value, linear characteristics curve).

Thereafter, an AUTOSTART can be performed during which the SRD991 determines independently the geometric data of the

actuator as well as control parameter, to ensure an optimized operation with the attached valve.

FoxCom version:

The positioner can be operated either locally, via PC, or via I/A Series System (FoxCom).

System conguration

When using ‘Communication’ (a digital signal with constant amplitude), make sure the connected outputs, buffer amplifier

and barriers are compatible with the frequency ranges used. In addition to the load, the AC impedance requirements must be

met. Therefore, use only the specified amplifier, barrier and configuration device.

To prevent crosstalk between lines and reduce disturbances through electromagnetic influences, use twisted-pair shielded

lines with a diameter of AWG 22–14 (0.3…2.5 mm2) and a maximum capacity of 100 pF/m.

The line capacities and connected devices may not exceed the maximum values listed for a particular FoxCom protocol.

All components connected to the SRD in an explosion hazardous area require an Ex-Approval. The applicable limit values

must not be exceeded. Comply with the limit values when connecting additional capacitances, inductances, voltages

and currents.

Page 14 August 2014POS-UM-00010-EN-03

Page 15

Method of Operation

METHOD OF OPERATION

General

The intelligent positioner SRD991 1 and the pneumatic actuator 2 form a control loop with the setpoint value w (from master

controller or control system), the output pressure y and the position x of the actuator on valve 3.

Figure 1: Fieldbus version

For the supply air, use a filter regulator.

Page 15 August 2014 POS-UM-00010-EN-03

Page 16

sAir supply 1.4... 6 bar (20... 90 psig)

Method of Operation

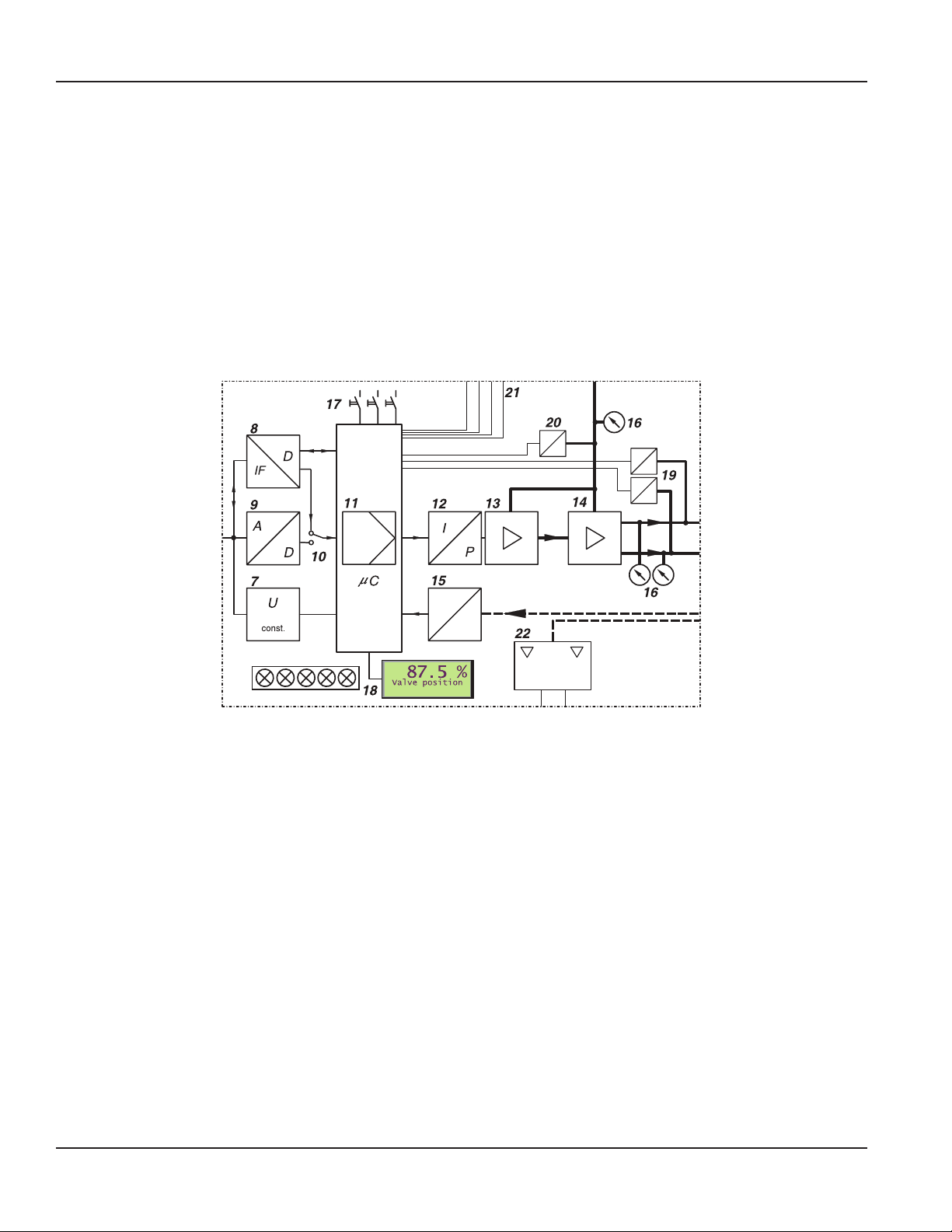

The positioner can be attached to both linear and rotary actuators.

Actuators with spring force are controlled by a single acting positioner. Actuators without spring force are controlled by a

double acting positioner.

HART or FoxCom version:

The positioner can be operated locally by means of local keys or a handheld terminal, or remotely via PC-based configuration

or a corresponding control system.

PROFIBUS-PA or FOUNDATION Fieldbus version:

The positioner can be operated locally by means of local keys, remotely via a corresponding control system, or can be

operated via PC-based configuration and operating tools.

Block Diagram

Input (w) each

acc.to version:

Analog operation

•

4...20mA

(+FSK)

• Digital operation

FSK

13...36 VDC

• Bus input

y

1

y

2

Output

pressure

to actuator

xPosition

of actuator

Operation

With the intelligent positioner with input signal 4-20 mA or superimposed HART signal, the supply takes place via the power

signal adjacent to the input.

By means of voltage converter 7, derivation of the internal supply of the electronics takes place. The power value is measured,

in A/D transformer 9 converted, and directed via switch 10 to digital controller 11.

With PROFIBUS-PA or FOUNDATION Fieldbus, the SRD is powered by means of the bus cable. The positioner is operated

from a control system by sending a setpoint (setpoint value) to the positioner. The digital signal is directed via the interface

component 8 to the digital controller 11. By means of the voltage converter 7 the internal supply of the electronics is

established, fed via the bus cable.

With FoxCom digital operation, a DC voltage is provided at input w. On this voltage an FSK signal is modulated. The

modulation contains information, such as setpoint value, sent digitally to the control unit 11 across the FSK unit 8.

The output of controller 11 drives the electro-pneumatic converter (IP-module) 12, controlling a pre-amplifier 13, the

single acting (or double acting) pneumatic power amplifier 14. The output of the amplifier 14 is the output pressure y to

the actuator.

The pneumatic amplifiers are supplied with supply air 1.4…6 bar (20…90 psig).

The position x of the actuator is sent to the control unit 11 by the position sensor (conductive plastic potentiometer) 15.

Optional gauges 16 , pressure sensors 19 , 20 , inputs / outputs 21 (two binary outputs; a 4…20 mA output and alarm;

control inputs for ‘Open/Close’ and ‘Hold last value’) enable additional diagnostic indications and possible intervention. The

mechanical limit switch 22 (optional) enables independent alarm signals.

Page 16 August 2014POS-UM-00010-EN-03

Page 17

Operating Modes

Adjusting and startup of the positioner, as well as the demand for internal information, can be made using the local keys 17

with indication given by LCD, 18 or LEDs.

OPERATING MODES

Operation of the positioner is divided into individual operating modes. Operating modes may change depending on, for

example, key commands or internal calculations. The different operating modes are described in abbreviated form below.

Initialize

Upon powerup or reset (pressing the 3 keys simultaneously), several self-tests are conducted. Individual steps in the self-test

process are indicated by the LCD or green LEDs.

If no error occurs, the device moves to OUT OF SERVICE, if it is still in a delivery condition; AUTOSTART has to be performed. If

AUTOSTART was done already, the device will go to IN OPERATION.

If faults are detected, the code of the faulty self-test will remain. If error occurs again after reset, the device is probably

defective and should be sent in for repair.

Device Fault

In the event that the LCD shows a message (or red LED lights up constantly and all green LEDs are off), a device fault is

signaled. These faults are detected during cyclical self-test.

The device can no longer be operated. This could be caused by a jammed menu key or defective program memory.

If a device error occurs repeatedly, the device should be sent in for repair.

In Operation

After performing an AUTOSTART, the device moves to IN OPERATION and will always, even after restarting or resetting, move

back to the safety position (de-energized valve position) or FAILSAFE. If setpoint values are fed via communication, the SRD

will go to IN OPERATION.

Failsafe

With FF H1 and Profibus PA Communication

Positioner carries out actions as configured in menu “failure handling”. Additionally, the cyclical self-diagnosis takes place.

If the instrument is IN OPERATION, but no setpoint values arrive via communication, the SRD will go to FAILSAFE mode, after a

defined time period; either with

• maintaining last value

• output pressureless, or

• with predetermined position.

As soon as setpoint values arrive via communication again, the instrument is immediately back IN OPERATION.

Out of Service

The SRD991 as delivered is configured to remain OUT OF SERVICE after powerup until moving to IN OPERATION via the

manually initiated function AUTOSTART.

In the device state OUT OF SERVICE, the menu entering mode remains active at all times. If a device has been IN OPERATION

already and is removed from an actuator and mounted to another, it is recommended to take the device out of operation via

RESET CONFIG (Menu 9.1) prior to disconnecting the device from the first actuator.

This enables the next actuator to be started in the delivered condition (see “Startup”).

Calibrate

During an AUTOSTART function the device is in condition CALIBRATION. The actuator is moved up- and downward several

times, and the device could be busy for a few minutes. Subsequently, the device moves to IN OPERATION.

Page 17 August 2014 POS-UM-00010-EN-03

Page 18

Operating Modes

Message

The SRD991 continuously supervises important device functions. In the event that limit values are exceeded or operational

problems occur, messages are signaled via the LCD or the special LED blinking mode.

The message with the highest priority will be indicated first. With key DOWN additional messages can be called up, with

key UP the measuring values can be retrieved. It is possible at all times to reach the menu by pressing the menu keys to

possibly eliminate the problem by performing suitable menu functions. Further references may be found in chapter “Troubleshooting”.

Simulate (Foundation Fieldbus Version Only)

During function IN OPERATION, the valve position queried via the communication, can be simulated with a value that has

been entered via communication into the instrument during position SIMULATION. Thereby the positioner continues with

normal operation and regulates to the ”accurate” set value.

For the SRD, this function has to be additionally released or blocked via menu 10.

LCD description, definition of the LEDs and possible operator interventions are described in “Startup” on page 39.

Page 18 August 2014POS-UM-00010-EN-03

Page 19

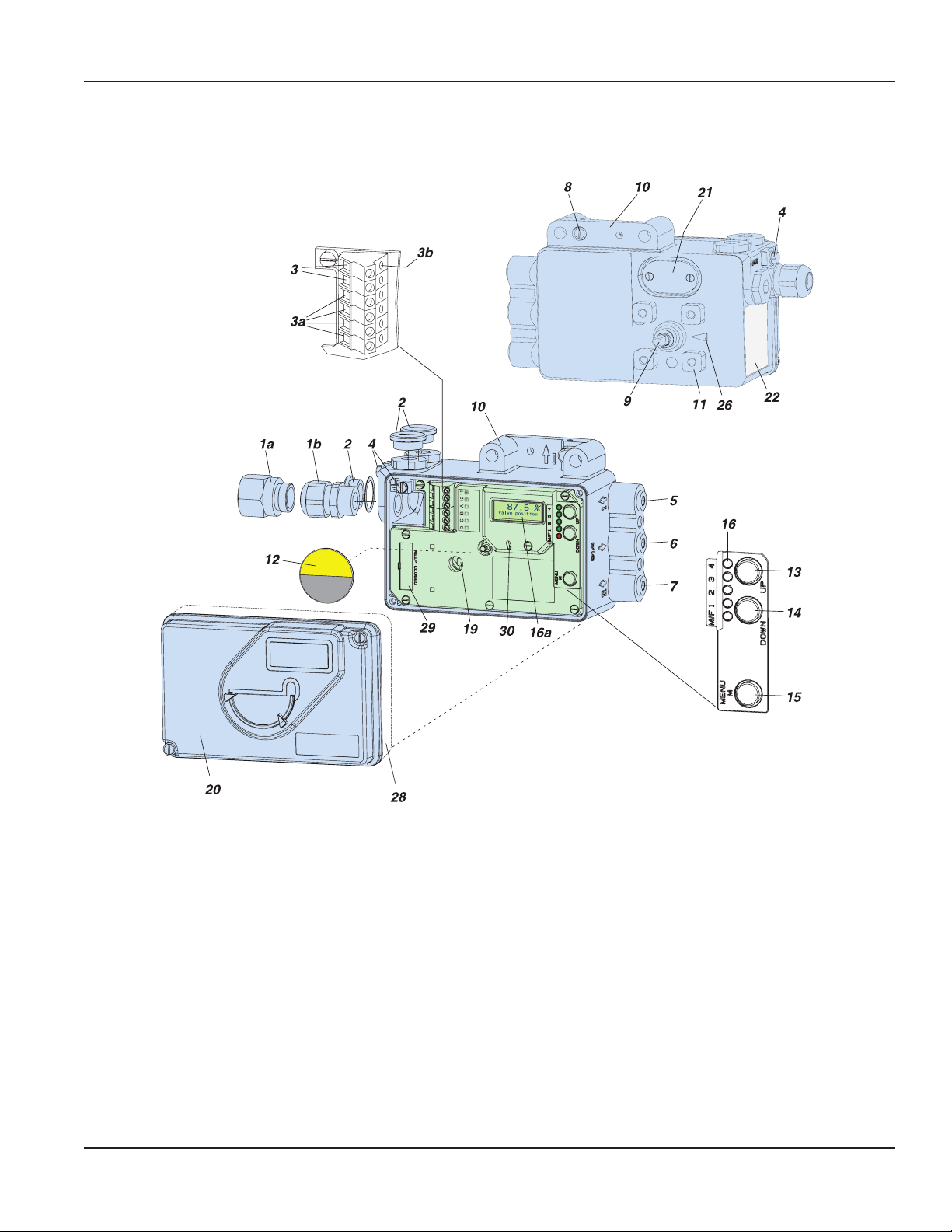

FUNCTIONAL DESIGNATIONS

10

11

12

13

14

15

4) Depending on theversion,the device is equipped with or withoutLEDs

Functional Designations

1a Adapter, eg. 1/2”-14 NPT

1b Cable gland

2 Plug, interchangeable withPos.1

3

Screw terminals1)(11 / 12) for input (w)or

for bus connectionIEC 1158-2

3)

3a Screw terminals1)for additional inputs/outputs

3b Test socketsØ2mm, integrated in terminalblock

4 Ground connection

5 Female threadG)1/4 -18 NPT or outputI(y1)

6 Female threadG)1/4 -18 NPT for air supply (s)

7 Female thread

G)

1/4 -18 NPT or outputII (y2)

8 Direct attachment holefor outputI(y1)

9 Feedback shaft

Connection manifold forattachment to stroke actuators

(not withVDI/VDE 3847 version)

Connection base forattachment to rotary actuators

Travel indicator

Key UP

Key DOWN

Key M (Menu)

16 Status display(1red LED, 4 green LEDs)

16a LCD withtruetext in 3different languages

19 Fixing shaftfor limit switch

20 Coverwith window to 12

Air vent, dust and water protected

21

22 Data label

23 Tipjacks

2)

Ø2mm forcurrent measurement

24 Switch2)for currentmeasurement

25 Tipjacks2)Ø2mm forcommunication

26 Arrow is perpendicular to shaft 9 at angle 0 degree

27 Ball valvefor protection class NEMA 4X

28 High cover withbuilt-in limit switch

29 Plug for service connector

3)

30 IrCom interface

G) With marked letter "G"inthe housing the pneumatic connecting threads

arecut as G1/4 instead of 1/4-18 NPT

1) Alternatively Cageclamps(WAGO) instead of screwterminals

2) Only with FoxCom version

3) Not with FoxCom version

Page 19 August 2014 POS-UM-00010-EN-03

Page 20

T

LEXG-F1:

LEXG-G1:

LEXG-H1:

Alternative:

Amplifier,

(Connection

LEXG-X1:

LEXG-Y1:

LEXG-Z1:

When mounting, check theproper seating of theO-rings

Functional Designations

Pneumatic Accessories

andbolt on theaccessorieswiththe twoM8 bolts. Unused

outputs are closed by meansof plastic plugs.

ypes withG-threads instead of standard NPT-threads:

As LEXG-F, however withthread G1/4

As LEXG-G, however withthread G1/4

As LEXG-H, however withthread G1/2

independent of positioner:

from positioner to amplifier with tubes)

As LEXG-F1, however externally mounted

As LEXG-G1, however externally mounted

As LEXG-H1, however externallymounted

Page 20 August 2014POS-UM-00010-EN-03

Page 21

Mounting to Actuators

MOUNTING TO ACTUATORS

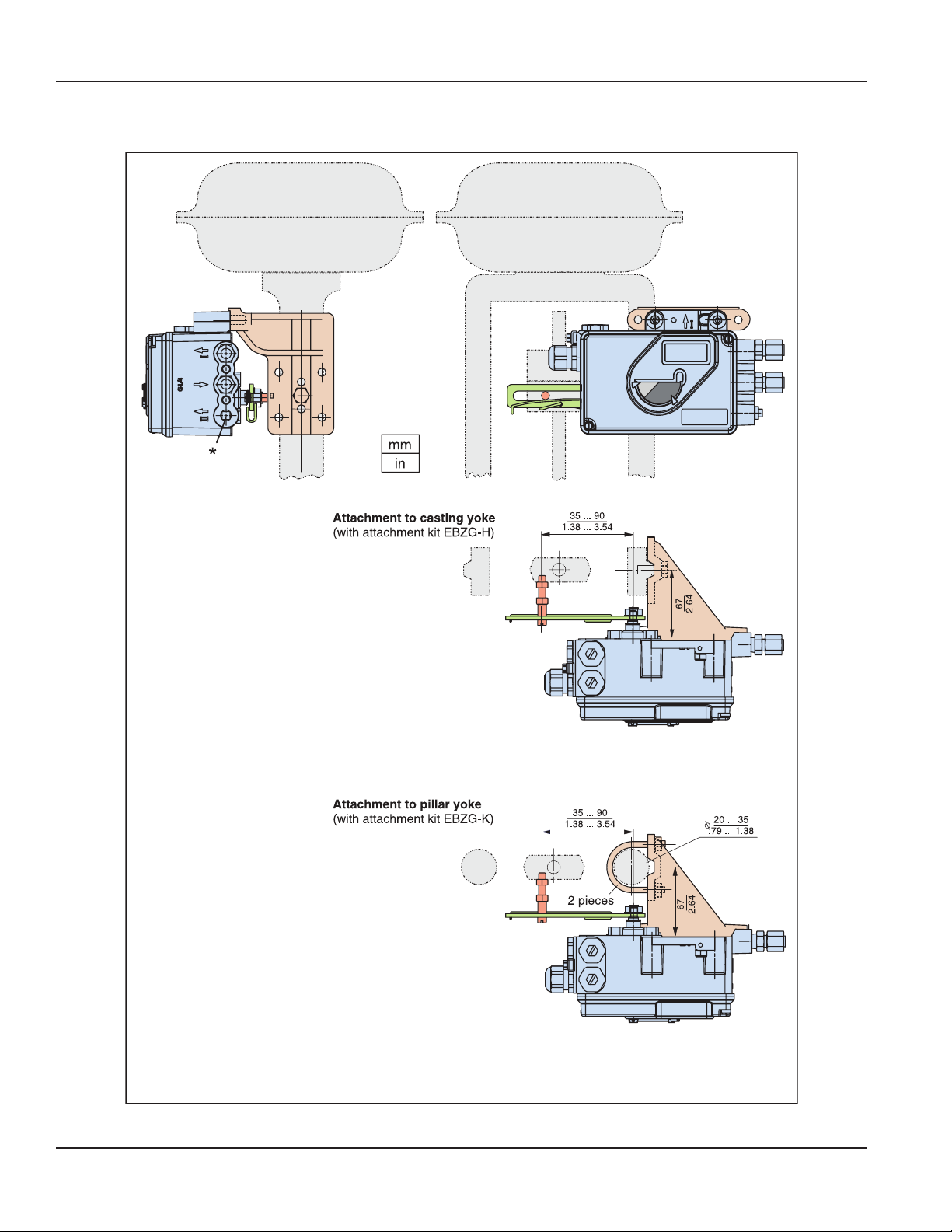

NAMUR Mounting Linear Actuator, Left Side

Applicable to actuators with cast yoke or pillar yoke according to NAMUR (DIN IEC 534-6).

Mounting the positioner with pneumatic connections on the left side and electrical connections on the lower right side.

Figure 2: NAMUR mounting, left side

Attachment of the positioner to the actuator is made to the left using the mounting bracket and feedback lever for a NAMUR

mount. Use:

attachment kit EBZG -H for a cast yoke, or

attachment kit EBZG -K for a pillar yoke.

The side outputs I (or I and II) are used. The rear output I is closed by means of a lock screw 522 588 013.

Pneumatic connections: Do not use Teflon tape for sealant. The fine fibers could disturb the function of the SRD. Apply only

Loctite® #243 sealant to the male thread.

Screw-type glands for electrical connections are positioned on the lower or right side. Any unused threaded holes are closed

by plugs.

If housing cover has an air vent, this air vent must facedown when mounted.

Preparing the Positioner

Rotate the shaft stub of shaft 9 so that the flat on the shaft stub

is perpendicular to the arrow 26 on the housing at mid travel

range (detail see “Mounting Dimensions for Direct Mounting”).

Fasten the feedback lever A to the shaft by means of spring

washer and nut M8.

Figure 3: Feedback lever

Page 21 August 2014 POS-UM-00010-EN-03

Page 22

Mounting to Actuators

Preparing the Actuator

Screw the carrier bolt to the stem connector and lock it by means of a counter nut.

A carrier bolt with an adjustable length is used to be able to screw on various coupling pieces.

Figure 4: Carrier bolt

It consists of a stud S, which is screwed into the coupling piece K (with 3 mm Allen key) and locked with a lock nut M6. The

threaded sleeve H is screwed onto it and locked with a lock nut M6. Make sure that the bolt is adjusted to the right length!

Fasten the mounting bracket to the left side of the yoke. For a cast yoke use a screw M8 x 30, for a pillar yoke use two U-bolts

and four nuts.

Mounting of the Positioner

Fasten the positioner to the mounting bracket using two spring washers and two screws M8 x 80.

Note, the carrier bolt B is in the slot of the feedback lever A and the compensating spring F touches the carrier bolt.

Figure 5: Feedback lever

For optimum use of the positioner operating range, it is recommended that the arrangement is adjusted according to the

following procedure before fixing. At an actuator position in the middle of travel range, the feedback lever position should be

perpendicular to the actuator stem and the angle range should be between −10…10° and −45…45°.

Fasten the positioner to the mounting bracket so that a suitable angle range is selected.

It is recommended that the pneumatic and electrical connections are made after adjusting the position.

Page 22 August 2014POS-UM-00010-EN-03

Page 23

NAMUR Mounting Dimensions – Left Side

LCD orientation canbe

changed by means of local

push buttons under Menu

9.9.2to„flipped“,to ensure

acorrect orientation of the

display.

Mounting to Actuators

Page 23 August 2014 POS-UM-00010-EN-03

Page 24

Mounting to Actuators

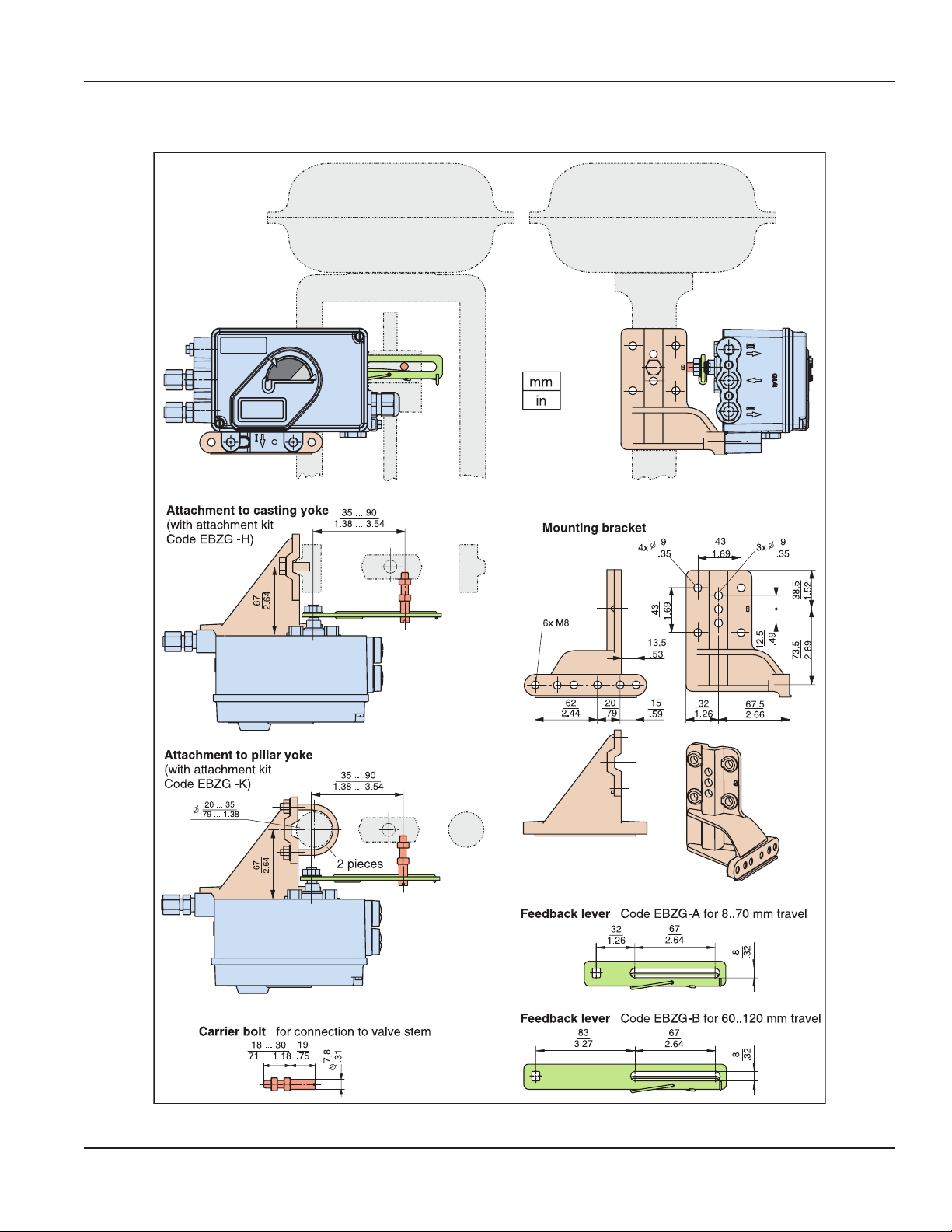

NAMUR Mounting Linear Actuator, Right Side

Right-side mounting is done if left-side mounting is not possible for structural reasons.

Applicable to actuators with cast yoke or pillar yoke according to NAMUR (DIN IEC 534-6).

Mounting the positioner with pneumatic connections on the right side and electrical connections on the left side.

Figure 6: NAMUR mounting, right side

Attachment of the positioner to the actuator is made to the right using the mounting bracket and feedback lever for a

NAMUR mount. Use:

attachment kit EBZG -H for a cast yoke, or

attachment kit EBZG -K for a pillar yoke.

The side outputs I (or I and II) are used. The rear output I is closed by means of a lock screw 522 588 013.

Pneumatic connections: Do not use Teflon tape for sealant. The fine fibres could disturb the function of the SRD. Apply only

Loctite® #243 sealant to the male thread.

Screw-type glands for electrical connections are positioned on the left side. Any unused threaded holes are closed by plugs.

If housing cover has an air vent, this air vent must facedown when mounted.

Preparing the Positioner

Rotate the shaft stub of shaft 9 so that the flat on the shaft stub

is perpendicular to the arrow 26 on the housing at mid travel

range (detail see “NAMUR Mounting Dimensions – Right Side”).

Fasten the feedback lever A to the shaft by means of spring

washer and nut M8.

Figure 7: Feedback lever

Page 24 August 2014POS-UM-00010-EN-03

Page 25

Mounting to Actuators

Preparing the Actuator

Screw the carrier bolt to the stem connector and lock it by means of a counter nut.

A carrier bolt with an adjustable length is used to be able to screw on various coupling pieces.

Figure 8: Carrier bolt

It consists of a stud S, which is screwed into the coupling piece K (with 3 mm Allen key) and locked with a lock nut M6. The

threaded sleeve H is screwed onto it and locked with a lock nut M6. Make sure that the bolt is adjusted to the right length!

Fasten the mounting bracket to the left side of the yoke. For a cast yoke use a screw M8 x 30, for a pillar yoke use two U-bolts

and four nuts.

Mounting the Positioner

Fasten the positioner to the mounting bracket using two spring washers and two screws M8 x 80.

Note, the carrier bolt B is in the slot of the feedback lever A and the compensating spring F touches the carrier bolt.

Figure 9: Feedback lever

For optimum use of the positioner operating range, it is recommended the arrangement be adjusted according to the

following procedure before fixing. At an actuator position in the middle of travel range, the feedback lever position should be

perpendicular to the actuator stem and the angle range should be between −10…10° and −45…45°.

Fasten the positioner to the mounting bracket so that a suitable angle range is selected.

It is recommended that the pneumatic and electrical connections are made after adjusting the position.

Page 25 August 2014 POS-UM-00010-EN-03

Page 26

Mounting to Actuators

NAMUR Mounting Dimensions – Right Side

Mounting bracket,feedback lever and

carrier bolt

Page 26 August 2014POS-UM-00010-EN-03

Page 27

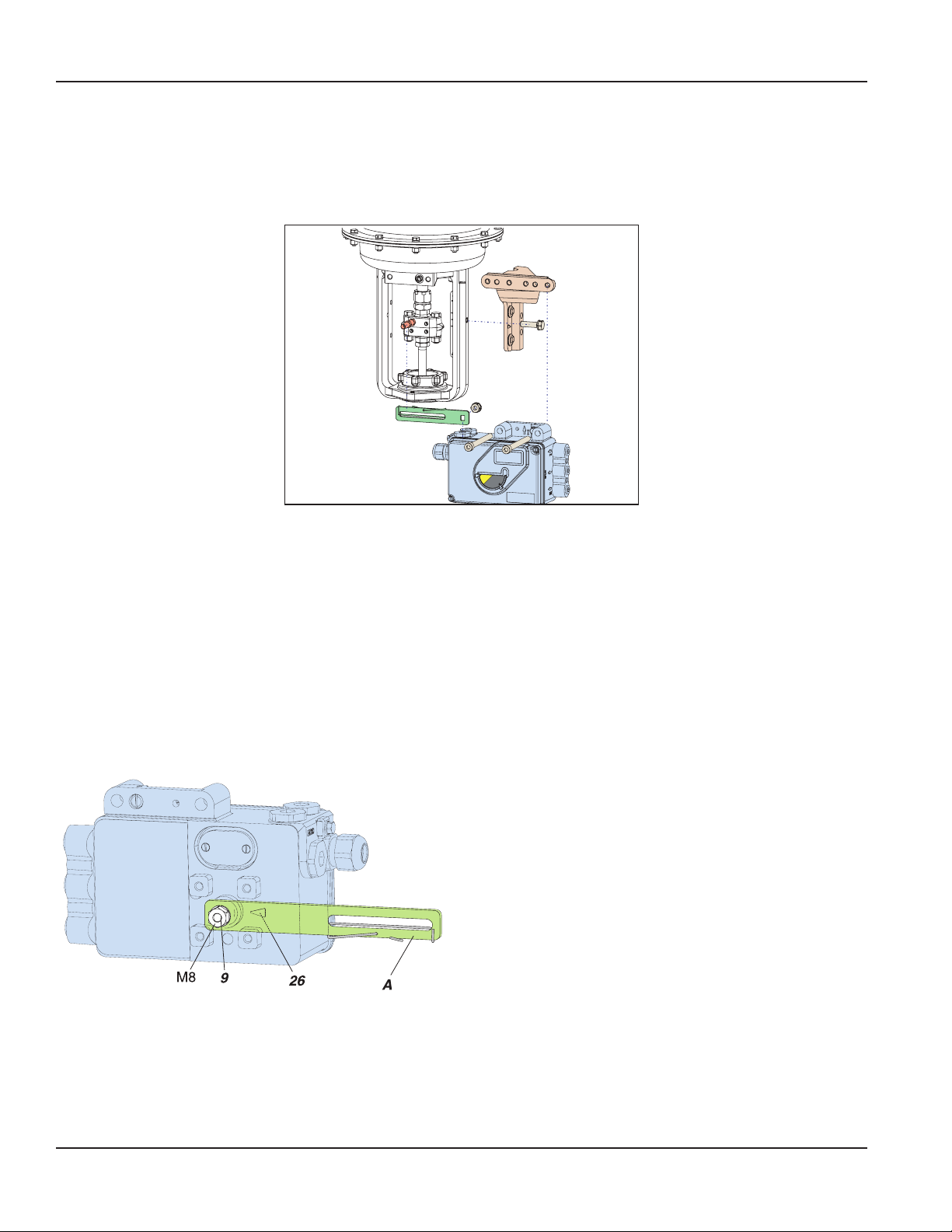

Mounting to Actuators

Linear Actuator, Direct Mounting

Actuators with appropriately prepared yoke (PA200, PA350) enable mounting of the SRD991 directly to the actuator yoke.

Figure 10: Direct mounting

Bolt the positioner directly to the actuator yoke using the feedback lever for a direct mount (with attachment kit EBZG -D).

The rear output I and the side outputs I and II are used as follows:

• Actuator single acting, spring force closes:

The rear output I is used (remove lock screw in hole D ).

The side output I is closed by means of a lock screw.

• Actuator single acting, spring force opens:

The side output I is used.

The rear output I is closed by means of a lock screw.

• Actuator double acting:

The rear output I and the side output II is used.

The side output I is closed by means of a lock screw.

Pneumatic connections: Do not use Teflon tape for sealant. The fine fibers could disturb the function of the SRD. Apply only

Loctite® #243 sealant to the male thread.

Screw-type glands for electrical connections are positioned on the side. Any idle female threads are closed by means of plugs.

If housing cover has an air vent, this air vent must facedown when mounted.

Page 27 August 2014 POS-UM-00010-EN-03

Page 28

M6

B

R

Mounting to Actuators

Preparing the Positioner

Figure 11: Feedback lever

Preparing the Actuator

Rotate the shaft stub of shaft 9 so that the flat on the shaft stub

is perpendicular to the arrow 26 on the housing at mid travel

range (detail see “Mounting Dimensions for Direct Mounting”).

Fasten the feedback lever A to the shaft by means of spring

washer and nut M8.

Screw in the carrier bolt B on the coupling piece K on the drive

spindle S at the lower left and lock it by means of a nut M6.

Figure 12: Carrier bolt

Mounting the Positioner

Figure 13: Feedback lever

KS

Fasten the positioner to the upper part of the yoke using 2

spring washers and 2 screws M8 x 80, as shown above. The rear

output I of positioner has contact to the air duct R in the yoke.

Note the correct position of the O-ring on the yoke for the rear

connection I!

Note, the carrier bolt B is in the slot of the feedback lever A and

the compensating spring F touches the carrier bolt.

Page 28 August 2014POS-UM-00010-EN-03

Page 29

Mounting Dimensions for Direct Mounting

Mounting to Actuators

Page 29 August 2014 POS-UM-00010-EN-03

Page 30

Mounting to Actuators

Mounting to Rotary Actuators

Applicable to rotary actuators that meet the VDI/VDE 3845 standard for mounting. Installation position of positioner: Mount

the positioner so that the pneumatic connections are in the same direction as the longitudinal drive axis of the actuator as

shown in the photograph below.

Figure 14: Mounting to rotary actuator

The feedback shaft 9 of the SRD has no mechanical stop, therefore may spin 360°. The permissible rotation angle

range is between 50…–50° around the arrow at the housing concerning the flat area of the feedback shaft (also see

“Mounting Dimensions for Direct Mounting” bottom). Since a rotary actuator has a rotary angle of about 90°, the mounting as

described in the following must be carried out very precisely.

Attachment of the positioner to the actuator is made by using the rotary adaptor kit EBZG -R.

Either the side outputs I (or I and II) are used and the rear output I is closed by means of the lock screw 522 588 013.

Pneumatic connections: Do not use Teflon tape for sealant. The fine fibers could disturb the function of the SRD. Apply only

Loctite® #243 sealant to the male thread.

Screw-type glands for electrical connections are used as needed. Any unused threaded holes are closed by plugs.

PREVENT ACCUMULATION OF WATER IN THE INSTRUMENT IN THIS MOUNTING POSITION BY SEALING CABLE ENTRY

AGAINST WATER. PROVIDE A CONTINUOUS SUPPLY OF DRY INSTRUMENT AIR.

Preparing the Positioner

Valve must be in failsafe position and the direction of rotation of the actuator drive shaft must be known. These items are

extremely important for proper functioning. These items can be checked as follows in case they are not clear:

• In the single-acting actuator the force of the installed spring closes. The pressure-less actuator is in failsafe position.

Through manually feeding compressed air it can be seen whether the actuator drive shaft rotates to the left or to the right.

• In the double-acting actuator (without spring reset) both air chambers are basically equal. Failsafe position can be either

“open” or “close”. Therefore, indication of the failsafe position has to be determined by engineering. Then the direction of

rotation may be determined by manual feeding of compressed air.

Bolt 2 is screwed into actuator drive shaft 1 for subsequent centering of the rotary adaptor 3. The attachment console is

mounted to the stroke actuator (see illustration).

Page 30 August 2014POS-UM-00010-EN-03

Page 31

Figure 15: Attachment diagram for bracket

Mounting to Actuators

Figure 16: Rotary adaptor

Preparing the Actuator

Prepare the rotary adapter:

• For attachment to a counter-clockwise or left turning actuator, secure the stud screw 4 in the threaded hole “L” of the

rotary adaptor; hole “R” remains open.

• For attachment to a clockwise or right turning actuator secure the stud screw 4 in the threaded hole “R” of the rotary

adaptor; hole “L” remains open. Stud screw should always be tightened into the flat on the on the feedback shaft 9.

Place the rotary adaptor 3 with two washers 5 on the feedback shaft 9 of the positioner against the stop.

OTE:N When the product temperature rises, the drive shaft 1 becomes longer. Therefore, mount the rotary adaptor 3 with

approximately 1 mm (0.04 in.) of clearance between the drive shaft 1 and the rotary adaptor 3. Add washers 5 on the

feedback shaft stub 9 before attaching the rotary adaptor. Two washers should result in a clearance of 1 mm.

Screw and tighten the bolt in the coupling against the flat part of the feedback shaft (do not screw against thread!).

Turn the feedback shaft so that the arrow of the coupling points to the arrow of the SRD housing. Beginning and end

positions of the actuator drive shaft 1 and feedback shaft 9 are marked by arrows for the respective direction of rotation.

The feedback shaft is now in the normal position corresponding to the failsafe position of the actuator.

Page 31 August 2014 POS-UM-00010-EN-03

Page 32

Mounting to Actuators

Mounting the Positioner

SRD and actuator are in failsafe position.

Attach the SRD on the console in such a way that the catch of coupling 3 is guided into the groove of shaft 1. Use bolt 2 to

center and align the positioner to the actuator. Be careful not to shift shafts 1 and 9 and that both shafts are exactly flush.

Fasten the positioner to the bracket by means of 4 lock washers and 4 screws M6 x 12.

SRD

Direction

of rotation

0 → 100 %

of feedback

9

shaft

SRD

Direction

of rotation

0 → 100 %

of actuator

1

Rotary actuator

Page 32 August 2014POS-UM-00010-EN-03

shaft

Rotary actuator

Page 33

PNEUMATIC CONNECTIONS

FRS923 filter regulator.

Supply

Supply air pressure .......1.4 to 6bar (20 to 90 psig)

Air supply ...............accordingto ISO 8573-1

- Solid particle size and density class2

-Oil rate ..............class3

- Pressure dew point 10 K under ambient temperature

For air supply, we recommend the FOXBORO ECKARDT

Pneumatic Connections

W ARNING

To avoid anypersonal injury resulting from burstingofparts,do

not exceedmaximum supply pressure of positionerand actuator.

To avoid anypersonal injury or propertydamage fromsuddenor

fast movement, during airconnection:

Do not put your fingerorother part at anytime insidethe valveor

in anymoving part of theactuator. Do not put your fingerorother

part at anytimeinthe feedback levermechanism. Do nottouchthe

rear part of thepositioneratany time.Connect airsupply only after

connection Y1 andY2 (fordoubleacting)are done.

Following alignment and mounting of thepositioner to the

valve, pneumatic tubing has to be provided.

Explanationofabbreviatons:

s Supply air

y1-d Output 1for direct mounting,depressurizedat

currentless electronics.When using this output

has to be closed by meansofhex.screw.

y1 Output1,depressurized at currentlesselectronics.

When usingthisoutput,

means of sealing screw and O-ring.

y2 Output2fordouble-actingactuator. Full pressure at

currentless electronics. Closedatsingle-acting

actuator.

n1 Hex. Screw with NPTthread

Part No.522 588 013 (stainless steel)

Part No.556 446 016 (plastic)

n2 Sealingscrew with O-ring

Unused pneumatic connectionsmust be closed off.

FAIL SAFE POSITION FOR DOUBLE ACTING

Fail safe position of the double acting valveis given by the

fail safe action of the pneumaticofthe positione ritself.

In case positioner is de-energized:

Output Y1 is 0

Output Y2 is 100% of airsupply pressure

Thereforedopneumatic piping of Y2 to the chamber of the

actuator that should be pressurized to do the requested fail safe.

In any caseput air supply only when theoutput Y2 is connected.

y1-d has to be closed by

y1

Page 33 August 2014 POS-UM-00010-EN-03

Page 34

Electrical Connection

ELECTRICAL CONNECTION

TO AVOID ANY ELECTRICAL SHOCK, RESPECT THE MAXIMUM INPUT SUPPLY VOLTAGE FOR THE DEVICE AND OPTIONS.

TO AVOID ANY PERSONAL INJURY OR PROPERTY DAMAGE FROM SUDDEN OR FAST MOVEMENT, DURING ELECTRICAL

CONNECTION: DO NOT PUT YOUR FINGER OR OTHER PART AT ANY TIME INSIDE THE VALVE OR IN ANY MOVING PART

OF THE ACTUATOR. DO NOT PUT YOUR FINGER OR OTHER PART AT ANY TIME IN THE FEEDBACK LEVER MECHANISM.

DO NOT TOUCH THE REAR PART OF THE POSITIONER AT ANY TIME.

Unused cable glands should be closed off.

Feed in the bus cable through the gland 1. The gland is suitable for cable diameters of 6…12 mm (0.24…0.47 in). Observe the

tightness of the cable entry.

Make the electrical connection of the input line at the screw terminals 3b, whereby with fieldbus devices no polarity has to be

observed. The terminals are suitable for wire cross-sections of 0.3…2.5 mm2 (22 -14 AWG).

The shield of the bus connection is

• with conductive cable glands (recommended) directly connected with the housing

• with non-conductive cable glands to be placed onto the inner screw terminal 4.

OTE:N When connecting shielded cable, connect the cable shield on both sides (on the positioner as well as on the system

side). For selection of cable, see recommendation for cable types according to IEC 1158-2.

For connection to a local ground, use the internal and external ground terminal 4.

Test sockets for measuring purposes are integrated into the connecting terminals. With version HART or FoxCom at clamps

11+ and 12– a handheld terminal or modem for communication can be attached.

Page 34 August 2014POS-UM-00010-EN-03

Page 35

Electrical Connection

Page 35 August 2014 POS-UM-00010-EN-03

Page 36

Options

OPTIONS

Limit Switch

TO AVOID ANY PERSONAL INJURY DO NOT TOUCH CONTROL

VANES DURING OPERATION.

Remove three screws A including tooth lock washer from

plastic cover.

Attach limit indicator B so that the flattened shaft end 19

contacts the groove of the limit indicator shaft in the positioner.

Attach limit indicator by means of three longer screws C

and washers.

Test: the coupling shaft at back of positioner should easily be

turnable, thereby also moving the vanes of the limit indicator. If

this is not the case, loosen screws C and flush-align the shafts of

positioner and limit switch (turn coupling shaft several times).

Replace short travel indicator 12 by long travel indicator.

Screw high cover 28 (or standard cover with insert frame) on

housing.

Figure 17: Limit switch

Figure 18: Switch functions

Switch Functions

Feedback lever, feedback shaft and the control vanes are all

connected to each other, without an intermediate transmission.

The control vanes are therefore moving simultaneously with the

same angle rate as the feedback lever.

The length of the control vane corresponds with the swing angle

of 120°.

Both control vanes are located on different planes. Each control

vane can be seen independently from the other, because each

has its own sensor.

By adjusting the screws, the control vanes can be adjusted

relatively to the angle rate, so that, for example, one vane dives

into and another dives out of the sensor (see illustration).

Page 36 August 2014POS-UM-00010-EN-03

Page 37

Setting Limit Switch Trigger Points

First loosen screw S until disc D is no longer blocked by bolt B.

Then turn disc by 90°, until set screws 1 and 2 are accessible.

Set trigger point switch GW1:

Turn screw 1 at mark (•), until desired switch behavior is reached.

Set trigger point switch GW2:

Turn screw 2 at mark (• •), until desired switch behavior

is reached.

To fix switch points turn disc again by 90°, until the bolt catches,

then fasten tight the center screw S.

Figure 19: Levels of control vanes (illustration without cover)

Additional Inputs / Outputs

General

All versions of the SRD991 are prepared to retrofit this option.

Take current off SRD and turn off the supply air. Unscrew cover and remove electronics unit 40.

Attach option board 8 to connection ledge (observe orientation, see illustration). Refasten electronics unit 40.

After initialization, acknowledge message 10 by simultaneous pressing keys UP + DOWN.

Options

Option “Position Feedback and Alarm”

The analog output for position feedback indicates the valve position 0…100% as current signal 4…20 mA 1). Signal range is

3.8…20.5 mA, at fault approx. 0.5 mA.

1)

The direction of action of the position response message is set: valve position 0% = 4 mA; valve position 100% = 20 mA

The binary output for Alarm will be activated in the following cases (see “Messages”):

• Calibration error

(for example due to break-up of calibration) Message 3

• Output outside of limits determined during Autostart

(Check mounting of feedback lever) Message 5

• Circuit to potentiometer is disturbed

(cable plugged?) Message 5

• Circuit to IP module is disturbed

(cable plugged?) Message 6

• No actuator movement; Message 7

• Remaining control deviation (packing is too tight?)

Message 11

Signal range: 1 mA resp. 4…6 mA, at fault < 50 A.

In the event of disturbances in the electronics of the SRD, the Watchdog circuit is activated. The binary output for alarm

signalizes this as “cable failure”.

Page 37 August 2014 POS-UM-00010-EN-03

Page 38

Options

Figure 20:

Option “Two Binary Outputs”

Both binary outputs AB1 resp. AB2 switch to high current as soon as the valve position is below resp. exceeds the associated

limit value. If the binary outputs AB1 resp. AB2 are to be inverted (higher current no alarm, lower current alarm), the

association upper/ lower alarm have to be exchanged.

Signal range 1 mA resp. 5…6 mA, at fault < 50 A.

Option “Binary Inputs”

The binary inputs EB1 and EB2 for two external switches resp. sensors initiate the following actions:

EB1 EB2 Action

2)

2)

closed closed IN SERVICE

open closed Position to be operated

full power to 0%

closed open Position to be operated

full power to 100 %

open open Hold last value

2)

Factory setting. Via communication actions may be turned off or used otherwise. EB1 and EB2 can thus also be used as

diagnostics inputs.

An input not used is to be short-circuited (wire bridge between + and –).

Attention: Even if opening limit or closing limit are set: these actions are superimposed, and the actuator actually moves to

0 % resp. 100%.

Built-in Pressure Sensors

The pressure sensors 50 are part of the electronics 40 , therefore, the electronics has to be exchanged for conversion to

this option.

Disconnect electric power and air supply. Remove cover and electronic unit 40.

Remove, if present, the M3 bolts with sealing washers from both chimneys 52. Press in a sealing plug 51 Part No. 534 346 013

into the top of each chimney 52 until the collar makes contact. DO NOT GREASE!

To install an electronics unit with pressure sensors, carefully guide the tubes 50 of the pressure sensors vertically into the

sealing plugs 51. Do not twist or tilt the unit. Fasten screws on the electronics unit.

Page 38 August 2014POS-UM-00010-EN-03

Page 39

Startup

Figure 21: Pressure sensors

STARTUP

TO AVOID ANY PERSONAL INJURY OR PROPERTY DAMAGE FROM SUDDEN OR FAST MOVEMENT, DURING

CONFIGURATION AND AUTOSTART:

DO NOT PUT YOUR FINGER OR OTHER PART AT ANY TIME INSIDE THE VALVE OR IN ANY MOVING PART OF THE

ACTUATOR. DO NOT PUT YOUR FINGER OR OTHER PART AT ANY TIME IN THE FEEDBACK LEVER MECHANISM. DO NOT

TOUCH THE REAR PART OF THE POSITIONER AT ANY TIME.

ENSURE YOU THAT PNEUMATIC CONNECTION IS MADE ACCORDING TO “PNEUMATIC CONNECTIONS”.

General

Check the nameplate with respect to indications referring to Ex / non- Ex, input signal, communication, output signal, single /

double acting, additional inputs / outputs.

Setting by Means of Local Keys

The SRD991 can be adjusted by means of a local keypad when the cover is off.

M (Menu) start menu / end menu

UP / DOWN counting up/down of menu numbers resp. parameter numbers

UP + DOWN simultaneously: confirm at start, or when entering, storing, or verifying

M + UP + DOWN simultaneously: Reset = new start of SRD, thereafter initialization

1)

The stored data of the positioner is not affected, and remains unchanged.

1)

Page 39 August 2014 POS-UM-00010-EN-03

Page 40

MDOWN UP

M1 234

1c

¼f

¾f

½f

–OFF

Operation

Indication with LCD

In totally intuitive text:

Before starting the positioner, mount the SRD to the actuator; connect power and air supply. The supply air connection must

have sufficient capacity and pressure of 1.4…6 bar (20…90 psig) and should not exceed the maximum operating pressure of

the actuator.

OTE:N Configuration using local keys or the communication interface may interfere with operation of the actual process!

During configuration it is recommended that there is no flow through the valve.

Figure 22: Local keys

If there is no response using the local keypad (message 1 appears), make sure that the Write Protection is not set. Remove the

write protection using the FDT/DTM configuration software.

Indication with LEDs

The LEDs serve as indication in the following methods:

½½ ---Mand LED1flash

onstant light,ON

lashing: shortON, long OFF

lashing: long ON,short OFF

lashing: ON andOFF same duration

OPERATION

After Power ON

INIT: After power on of the input signal, or after reset, the SRD initializes, and the various components of the electronics are

checked and started. (The stored data of the positioner not affected, and remains unchanged).

The current status is stated on the LCD in clear text or indicated as LED code.

Initialization after positioner startup takes approx. 3 sec, then the SRD goes

• Into operation (Autostart has already been done) or

• To configuration, Menu 9.9 (with LCD, select the text language).

Page 40 August 2014POS-UM-00010-EN-03

Page 41

...

...

Select with keys

(together)

½=ON and OFF flashing same duration

UP or DOWN and confirm

with UP+DOWN

and the display orientation is selected ...

then automatically continued to configuration:

Configuration

MENU: The various specifications for configuration are arranged in menus:

LEDsflash

red green

M 1234

Menu

½½ 1

½½ 2

Description

Actuator system,

mounting side

Autostart,

ShortAutostart

Operation

½½3

½½4

½½½ 5

½½ ½ 6

½½ ½ 7

½½½ 8

½½½9

½½½ 10

1)

Versions without LCD: This menu can be configured only with version HART or version “without communication”.

Valve function

Characteristic of setpoint

Limits and Alarms

1)

Parameterfor

position controller

Manual setting of

pneumatic output

Manual setting of

valve position

Calibrationfunctions

for workshop

PROFIBUS-PA:BusAddress

FOUNDATION F.:Simulate

In Operation

After an autostart, the SRD automatically goes IN OPERATION. (Additional parameters can be configured by pressing the

menu key M.)

Page 41 August 2014 POS-UM-00010-EN-03

Page 42

Operation

87.5 %

On the LCD display the process variable is indicated.

(With LED version, all LEDs are off during operation.)

Through pressing of keys UP or DOWN, additional information

can be retrieved from the SRD:

(Certain data is available only with the corresponding options.)

Manual Operation

Press UP+DOWN together to put the SRD into manual operation mode, where the valve position can be set manually. Press M

twice to exit the menu.

Diagnostics During Operation

If the diagnostics determines an occurrence, this is indicated in

87.5 %

MESSAGE: The SRD recognizes an occurrence which the user must eliminate by taking suitable steps in order to continue

with operation. This can be e.g. a wrong configuration or missing supply air.

ERROR: During self-testing the SRD recognized an error and is no longer operable.

the bottom line: (resp. blinking code with LEDs).

Page 42 August 2014POS-UM-00010-EN-03

Page 43

Operation with Local Keys

Operation

With LCD

• Press M to enter the Menu mode. Menu 1 appears.

• Press UP or DOWN to select the desired Menu item Each press of the key moves one menu item forward (or back).

• Press UP+DOWN together to confirm the selected menu item and enter the Parameter change mode for the selected

menu item.

• To exit the Menu mode, press M again.

If the device remains in the Menu mode, it still is OUT OF SERVICE and AUTOSTART has to be initiated.

If the device is IN OPERATION, the display with the valve position appears.

If you select a menu but press no other keys for a few moments, the SRD switches automatically back to operation.

With LED

• Press M to enter the Menu mode. The red LED flashes alternately with the green LED1, which indicates the Menu item 1.

• Press UP or DOW to select the desired Menu item Each press of the key moves one menu item forward (or back).

The flashing green LEDs indicate the selected menu item.

LED test before configuration: Move from menu item 1 to 4 and inspect that each LED lights.

• Press UP+DOWN together to confirm the selected menu item and enter the Parameter change mode for the selected

menu item.

The red LED goes off and the remaining green LED indicates the parameter or state to be set.

• To exit the Menu mode, press M again.

Red and green LEDs extinguish when device is IN SERVICE. If device remains in Menu mode, it still is OUT OF SERVICE and

AUTOSTART has to be initiated.

If you select a menu but press no other keys for a few moments, the SRD switches automatically back to operation.

1)

Exception in Menu 6 (and at PROFIBUS Menu 10). No parameter indicated at rst, but ashing rhythm with long green and short red phases. This points to a sub-menu. Then entry

into parameter selection as described.

Page 43 August 2014 POS-UM-00010-EN-03

Page 44

Operation

Menu Structure for SRD991 / SRD960 with LCD

Page 44 August 2014POS-UM-00010-EN-03

Page 45

Additional Parameters

nO

The following parameters are accessible via communication only:

Control difference limit value 5%

Control difference response time 1 min

Parameter write protectio

Alarm limit fortotal strokes 90 Mio.

Alarm limit fortotal cycles 90 Mio.

Dead band for valve cycles 1%

Set value source: Model CodexFxx digital

Set value source: all others analog

Hysteresis for position alarms 0.5%

For the complete parameter list, see the FDT/DTM Software.

Operation

yrotcafxeretemaraP

%5.0siseretsyhgnilaeS

FFOnoitkA-efasliaF

ECIVRESNInoitcapu-rewoP

FF

%001mrala-erpreppU

%0mrala-erprewoL

Page 45 August 2014 POS-UM-00010-EN-03

Page 46

Operation

Conguration of 0 and 100%

Valid for single and double acting

Configuration requested

MENU 1:

"Mounting"

1.11.2 1.31.4 3.1 3.2

MENU3:

"Valve Action"

Configuration of0and 100%

Input Signal

Range

4mA=0%

20 mA = 100%

4mA=100%

20 mA =0%

4mA=0%

20 mA = 100%

4mA=100%

20 mA =0%

Linear

Left

Linear

Right

Rot

cclockw

Rot

clockwise

Direct Reverse

4mA=0%

20 mA = 100%

4mA=100%

20 mA =0%

4mA=0%

20 mA = 100%

4mA=100%

20 mA =0%

Page 46 August 2014POS-UM-00010-EN-03

Page 47

Valid for single and double acting

13

Configuration requested

MENU 1:

"Mounting"

1.11.2 1.3 1.4 3.

Operation

MENU 3:

"Valve Action"

.2

Configuration of 0and 100% Request Action

4mA=0%

20 mA = 100%

4mA=100%

20 mA =0%

4mA=0%

20 mA = 100%

4mA=100%

20 mA =0%

Linear

Left

Linear

Right

cclockw

Rot

Rot

clockwise

Direct Reverse

4mA=0%

20 mA = 100%

4mA=100%

20 mA =0%

4mA=0%

20 mA = 100%

4mA=100%

20 mA =0%

Page 47 August 2014 POS-UM-00010-EN-03

Page 48

Confirm

Operation

Description of Menus

Menu 1: Actuator System, Mounting Side

withkeys UP+DOWN

W ARNING

To avoid anypersonalinjuryorpropertydamagefromsuddenor fast

movement, during configuration:

Do not put your finger or otherpartatany time inside thevalve or in

anymoving part of the actuator.Do not putyourfinger or otherpart

at anytimeinthe feedback lever mechanism. Do nottouch therear

part of thepositioneratany time.

M 1234

½½ ---Mand LED1flash

Foranoptimal actuator adaptation theSRD hastobeconfigured whether it

isarotaryoralinear actuator.

The positioner of the rotary actuator can work directly with thelinearposition sensorvalue. In case of a stroke actuator an error tan(α )arises due

to the angle of theresultingin1%non-linearityattravelof 30°. The SRD

is able to correct thetravel viathe tanfunction and thus avoid bigger linearity errors.

The rotationdirectionofthe adaptershaft forthe tapchangesdepending

on the mountingsideofthe stroke actuator. “Valve closed” in one case

means “Valve open” in another one.

There are rotary actuator typesopening in thecounter clockwise direction

and othersopening in theclockwise direction. This also has to be signaled

to theSRD so that 0% “Valve closed” and100% “Valve open” arecorrectly

assigned.

(Further with UP key:)

-1--- LED 1lightsup

Forstroke actuators mountedleft of thespindle resp. directly mounted.

--1-- LED 2lightsup

For stroke actuators mountedright of thespindle.

---1- LED 3lightsup

For rotaryactuators opening thevalve during counter clockwise (left)rotation.

----1 LED4lightsup

For rotaryactuators openingthe valve during clockwise (right)rotation.

Page 48 August 2014POS-UM-00010-EN-03

Page 49

Menu 2: Autostart

M123 4

Selection betweendifferent Autostart modes

(change withkey UP or DOWN):

Autostart:

To automatically adapt the positioner to the valve. Geometric dataofthe

actuator is determined and optimally assignedtocontrol parameters. If the

"Standard" Autostart does not resultinstableregulation, another Autostart

mode-depending upon actuator-shouldbeselected. At initialstart-up,

an Autostart should always be performed.

2.2 Ready for"Standard"Autostart:

With keyUPorDOWN to other Autostart modes:

2.1 Ready for "End points" Autostart:

Serves for automatic adjustment of the SRD to the mechanicalend points.

2.3 Ready for "Enhanced" Autostart:

To the optimizationofthe controllerparametersinrelationtostandard mode:

2.4 Ready for "Smoothresponse" Autostart:

Extended, damped controllerparameters fore.g. smaller drives

2.5 Ready for "Fastresponse" Autostart:

Extended, undamped controllerparameters fore.g.largerdrives

Operation

½-½- -MandLED 2flash

Attention:Autostart overwrites previouscontrol parameters!

-1--1 LED1andLED 4lightsup

--11-LED 2 and LED 3lightsup

- -1-1LED 2and LED4lights up

-1-1-LED 1and LED3lights up

-11--LED 1 and LED 2lightsup

W ARNING

To avoidany personalinjuryorpropertydamage from sudden or fast

movement, duringautostart:

Do not put your fingerorother part at anytimeinside the valve or in

anymovingpart of theactuator. Do not put your fingerorother part

at anytimeinthe feedback lever mechanism. Do not touchthe rear

part of the positioneratany time.

After selection andstart

taking severalminutes canbefollowedatLCD or thegreen LEDs .

Durationonavalve positioncan take some time depending on actuator

volume, air supply,pressure, etc.

-1--- LED1lights up

Moving direction, mechanical startingand ending positions are determined

by one or several passagesofvalve position range.

- -1- -LED 2lightsup

Ramps areentered and controlsystemparameter is determined(ratio

position/valvesize).

---1-LED 3lightsup

Jumps are entered for determination of control parameters.

----1LED 4lightsup

Determinationof positioning speeds.

----- AllLEDs are off

Determined values aresaved;previous valuesare superscribed. The

SRD is IN SERVICE againwiththe detected new parameters.

(bypressing theUP+DOWN keys)the function

Page 49 August 2014 POS-UM-00010-EN-03

Page 50

M1 234

Operation

Menu 3: Mode of Action of SRD and Additional Position Feedback

½- -½-MandLED3flash

Function of the positioner is setat:

It will set themodeof actionofthe positioner and theoptionally present

feedback. Without thecard“position feedback”, themenuitem“Feedback”

is not displayed.

3.1Select “SRD”:

¼¾ ---Mshort flash, LED1long flash

-1--- LED1lights up

3.1.1“Normal”if increasing inputsignal is to initiateincreasing output

signal.

----1 LED4lightsup

3.1.2“Reverse”ifincreasing input signal is to initiatedecreasing output

signal.

3.2Select “Feedback”: (if present)

¼-¾- -Mshortflash,LED 2 longflash

-1--- LED1lights up

3.2.1“Normal”for increasing current with increasing valve position.

----1 LED4lightsup

3.2.2“Reverse”for decreasing current with increasing valve position.

Page 50 August 2014POS-UM-00010-EN-03

Page 51

Menu 4: Characteristic of Setpoint

M 1234

-

½- --½MandLED4flash

A relationship between theinput signal and valveposition is set.

-1--- LED 1lightsup

4.1 “Linear”.See Fig. 4.1

--1-- LED 2lightsup

4.2 “Equalpercentage”: Resultsinanequal percentage characteristicline

withaposition ratio of 1:50 foravalveoflinear characteristic.

See Fig. 4.2

---1- LED 3lightsup

4.3“Inverse equal perc.”:Resultsinaninverselyequal percentagecharac

teristic line with a positionratio of 50:1for a valve of linear characteristic.

See Fig. 4.3

Operation

----1LED 4light sup

“User definedcharacteristic”:

Acharacteristic line entered via

communication (not via local keys) with

2to22supportingpoints)isactivated.

A linear characteristic is factoryset.

3.4.giF2.4.giF1.4.giF

Page 51 August 2014 POS-UM-00010-EN-03

Page 52

Note:

inversely equal percentage characteristic

Operation

Menu 5: Limit and Alarms of Valve

With versionswithLCD,the values canbeadjusted stepwiselocallyin

“clear text” withkeysUPorDOWN.

With versionswithLED andHARTor“withoutcommunication”, the

corresponding currentofthe valveisrated via analog output and entered

with keys UP+DOWN.

With versionsLED andfieldbus, thevalues can be entered only via

communication.

With versionswithcommunication, thevaluescan be configured also with

corresponding software.