Page 1

Flow Sensors

Insert Style Flow Sensors

SDI Series

DESCRIPTION

The Data Industrial SDI Series insert flow sensors from

Badger Meter offer accurate liquid flow measurement in closed

pipe systems in an easy to install economical package. Impeller

sensors offer a quick response to changes in flow rate and are well

suited to flow control and batch type applications in addition to

flow monitoring. The four-bladed impeller design is rugged,

non-fouling and does not require custom calibration. Coupled

with the proprietary patented digital detection circuit, the sensor

measures flows from under 0.5 ft/sec (0.15 m/sec) to more than

20 ft/sec (6.1 m/sec) regardless of the conductivity or turbidity

of the liquid. The standard frequency output produces a low

impedance square wave signal proportional to flow rate that may

be transmitted up to 2000 ft (610 m) without amplification. The

SDI Series includes:

• Single direction powered insert with raw, scaled pulse and

analog output

• Bidirectional powered insert with analog and scaled

pulse output

• Battery powered insert with a local or remote display and

scaled pulse output

HOT TAP SENSORS OPTIONAL

APPLICATIONS

SDI insert style flow sensors are intended for general clean liquid

flow measurement applications. They are available in either brass

or stainless steel construction.

FUNCTIONALITY

These insert style sensors are intended for direct installation into

pipelines through a 1 in. (25 mm) tap. The pipeline must be out

of service and not under pressure at the time of installation. For

any pipeline that is in service at the time of installation or cannot

be de-pressurized and drained for service, the SDI hot tap model

equipped with isolation valves is recommended.

Three different stem lengths in both the direct insert and hot tap

versions accommodate pipe diameters 1-1/2…36 in. (38…914 mm)

depending on the pipe material and tapping methods. Larger sizes

usually require the use of hot tap models.

In pipe sections with at least 10 diameters of straight pipe

upstream of the sensor and 5 diameters of straight pipe

downstream, accuracies of ±1% of rate may be achieved when

the flow sensor is installed at the correct insertion depth and

properly aligned.

Hot tap sensors feature an isolation valve and mounting hardware

to install or remove the sensor from a pipeline that would be

difficult to shut down or drain. In a true hot tap installation the

sensor is mounted in the pipe under pressure by attaching a service

saddle or weld-on fitting to the pipe and mounting the isolating

valve to the threaded connection. A hole is then cut in the wall of

the pipe through the valve using a commercial tapping machine

with a 1 in. size cutter. Once the hole is cut, the tapping machine

is removed and the valve is shut. Then the sensor assembly is

mounted to the isolation valve and extended into the pipeline

to measure flow. Even in new construction a hot tap sensor may

be appropriate for service considerations. The hot tap sensor is

constructed of 316 stainless steel and is rated for service to 1000

psi at 70° F (21° C) (see “Maximum Pressure Rating for SST Stem” on

page 4). The sensor installs in a 1 in. NPT tap for both wet and

dry installations. The small stem diameter allows the sensor to be

inserted into the pressurized pipeline by hand without the need for

an installation tool. Mounting hardware holds the sensor firmly in

place at the correct depth and alignment.

BATTERY POWERED SENSORS OPTIONAL

Battery powered versions are complete flow measuring systems

providing a local or remote programmable display of rate, total

or both, powered by a C size lithium battery that has a five year

life span.

SEN-DS-01382-EN-07 (May 2017)

Product Data Sheet

Page 2

Flow Sensors, Insert Style Flow Sensors

OUTPUT CONFIGURATIONS

Standard Frequency

Sensor output is a pulse proportional to flow. The signal is similar to all 200 Series flow sensors and will interface with all existing Data

Industrial transmitters and monitors. The power supply to the sensor and the output signal from the sensor is carried on the same two wires.

Wire connections are made at screw terminals on removable headers inside the NEMA 4X housing.

Analog Output

The sensor is also available with a two-wire loop powered 4…20 mA output. The analog output is produced by an onboard

micro-controller for precise, drift-free signals. Sensors may be preprogrammed at the factory or field programmed using the a computer

with the programming kit and Windows® based software program. All information is stored in the flow sensor nonvolatile memory.

Scaled Pulse Output

The scaled pulse is produced by an onboard micro-controller for precise, accurate outputs. This option may be programmed to produce an

isolated solid state contact closure scaled to any number of engineering units of measure. Sensors may be preprogrammed at the factory

or field programmed using the a computer with the programming kit and Windows® based software program. All information is stored in

nonvolatile memory in the flow sensor. This is a four-wire option.

Bidirectional Flow, Analog Output

This option provides a programmable 4…20 mA signal proportional to flow rate and a contact closure to indicate the direction of flow. The

unit may be preprogrammed at the factory or field programmed using a computer with the programming kit and Windows® based software

program. The user can program the unit for pipe size, flow scale and the direction of flow. This is a six-wire option.

Bidirectional Flow, Scaled Pulse Output

This option provides the user with a choice of outputs. In one case the sensor provides an output scaled to the required number of

engineering units on one set of terminals and a contact closure to indicate the direction of flow on another. The other choice provides

two isolated scaled pulse outputs, one for each direction. Programming the output choice, pipe size, output scale and direction of flow by

the user are also accomplished by using a computer with the programming kit and Windows® based software program. This option also

requires six wires.

Display Options

All models except the standard frequency output version may also be equipped with a display. Integrated into the NEMA 4X housing, the

eight digit LCD may be programmed to show rate of flow, flow total or toggle between the two. Bidirectional models also show

flow direction.

The eight character 3/8 in. LCD is mounted on the sensor visible through a lens at the top of the electronics housing.

For battery powered versions only, an optional remote display is available where the LCD is located in a wall mount NEMA 4 enclosure. The

remote may be connected to the flow sensor up to a maximum of 50 ft (15 m) away using extension cables.

Page 2 May 2017

SEN-DS-01382-EN-07

Page 3

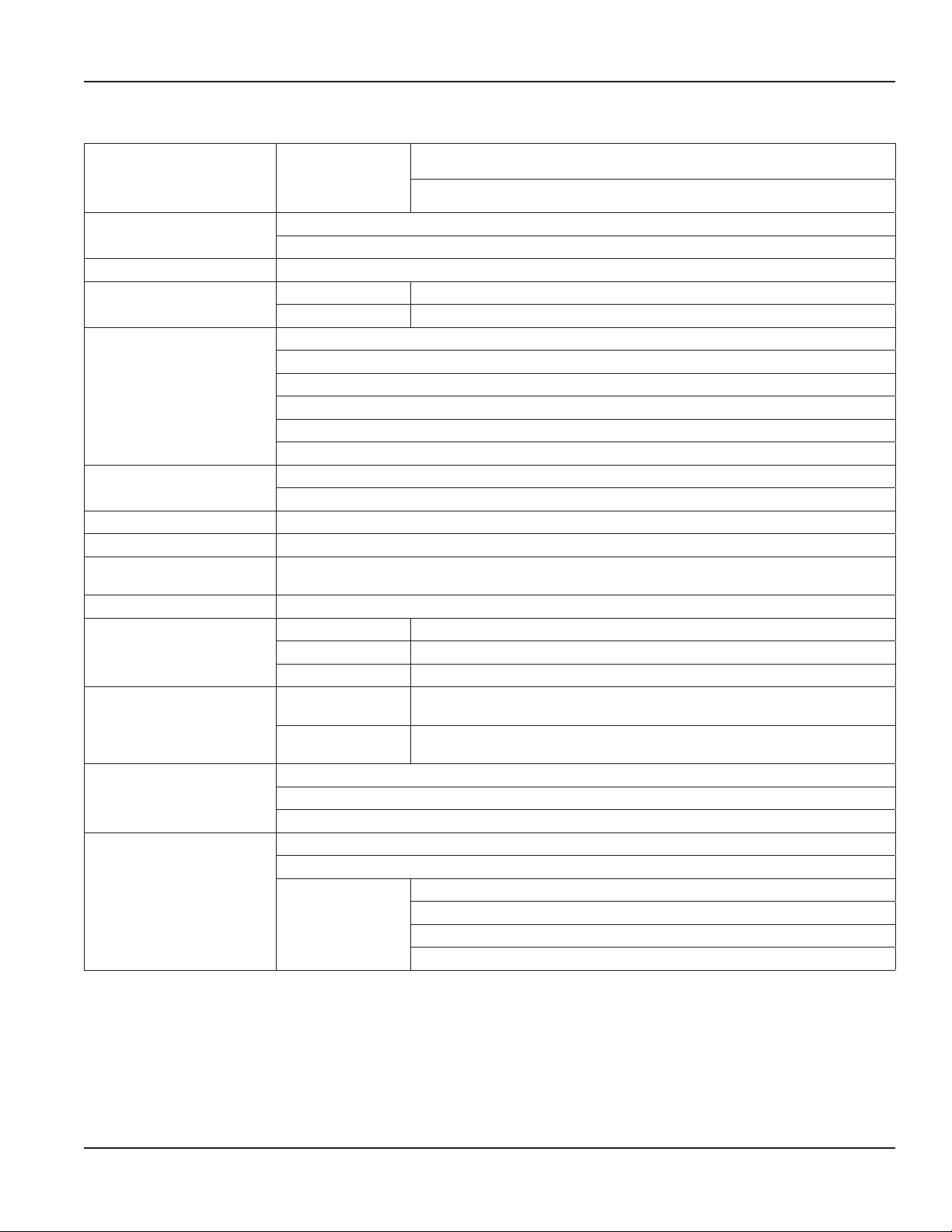

SPECIFICATIONS

Product Data Sheet

Sensor stem,

Wetted Materials

Sensor Tip

O-rings, Bearings, Shaft See ordering matrix

Operating Temperature

Maximum Pressure Rating

Stainless Steel (Non Shock)

Optimum Design Flow

Range

Pressure Drop 0.5 psi or less at 10 ft/sec (3 m/sec.) for all pipe sizes 1.5 in. (38 mm) diameter and up

Accuracy Standard: to ±1% of rate over optimum flow range

Straight Pipe Requirement

Repeatability ±0.5%

Enclosure

Programming

Display (Optional)

Accessories

mounting adapter,

isolation valve,

and nipple:

Polyphenylene sulfide (PPS)

Polyetheretherketone (PEEK)

Electronics 14…150° F (–10…65° C)

LCD –4…150° F (–20…65°C)

1000 psi (68.9 bar) @ 70° F (21° C)

900 psi (62 bar) @ 100° F (37.8° C)

670 psi (46.1 bar) @ 140° F (60° C)

225 psi (15.5 bar) @ 180° F (82° C)

600 psi (41.3 bar) @ up to 140° F (60° C)

225 psi (15.5 bar) @ 180° F (82° C)

1…20 ft/sec. (0.30…6 m/sec.)

Extended flow range < 0.5…20 fps

Install sensor in straight pipe section with a minimum distance of 10 diameters upstream and

5 diameters downstream to any bend, transition, or obstruction.

Sensor- battery Polypropylene with Viton® sealed acrylic cover. Meets NEMA 6P specifications

Sensor Polypropylene with Viton® sealed acrylic cover. Meets NEMA 4X specifications

Remote Polycarbonate w/ Neoprene® sealed cover. Meets NEMA 4X specifications.

Battery powered

version

Bidirectional, pulse,

and analog versions

8 character, 3/8 in. (10 mm) LCD

STN (Super Twisted Nematic) display

Annunciators for rate, total, totalizer multipliers, low battery, flow direction

USB to DIC converter programming kit (840134-0002)

ASDIB-20 programming kit- battery powered A-301 connector cable or USB

Battery powered

version

316 Stainless steel

Brass, B16, UNS C36000

A-303 connector cable and SDI Series software

USB to DIC converter programming kit (840134-0002)

07101 5 ft (1.5 m) extension cable

07108 10 ft (3 m) extension cable

07102 20 ft (6 m) extension cable

07109 50 ft (15 m) extension cable

SEN-DS-01382-EN-07

Page 3 May 2017

Page 4

Flow Sensors, Insert Style Flow Sensors

PSIG

• 225 PSI up to 180°F

Power Specications

Unidirectional Bidirectional Battery

Raw Pulse

Option 0

Number of Wire Connections

Operating Voltage 8…35V DC n/a

Overvoltage

Protection

Quiescent Current

Draw

@ 12V DC or 24V AC

Pulse

Units

Analog

Units

The battery operated version is powered by a C size lithium battery with a five year life span

Short Circuit Current 50 mA typical n/a > 100 mA

Output Frequency 800 Hz max n/a

Output Pulse Width

Output Isolation n/a n/a Opto-isolated Opto-isolated Opto-isolated Opto-isolated

Operating Voltage n/a 8…25V DC n/a 8…25V DC n/a n/a

Output Response

Time

2 2 4 6 6 2

30V AC

± 40V DC

330 µA typical

5 mS below

100 Hz

n/a

Analog Loop

Option 1

± 40V DC

Software-controlled

current of

3.5…20.5 mA

n/a

Varies with

programmable filter

Scaled Pulse

Option 2

12…30V AC

12…35V DC

30V AC

± 40V DC

< 2.0 mA < 5.0 mA < 5.0 mA n/a

For direction >

Scaled by

customer

Adjustable

50 mS to 5.0

seconds in

50 mS

increments

n/a

programmable

Analog Loop

Option 5

12…30V AC

12…35V DC

30V AC

± 40V DC

100 mA

n/a

n/a

Varies with

filter

Operated

Scaled Pulse

Option 6

12…30V AC

12…35V DC

30V AC

± 40V DC

> 100 mA > 100 mA

Scaled by

customer

Adjustable

50 mS to 5.0

seconds in

50 mS

increments

n/a n/a

Scaled Pulse

Option 2

n/a

n/a

Scaled by

customer

Selectable

50 mS

100 mS

250 mS

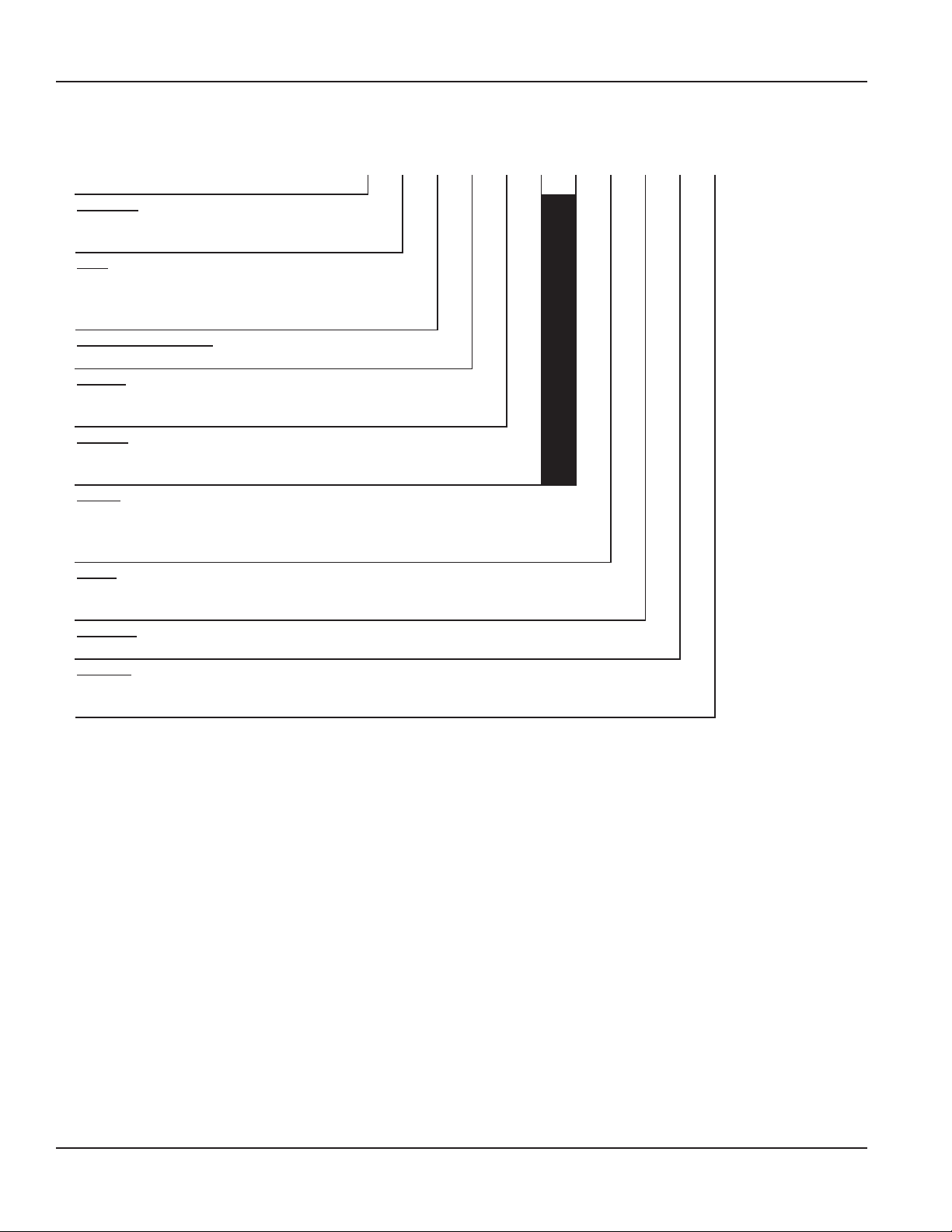

Maximum Pressure Rating for SST Stem

(Note: PPS or PEEK Tip)

1000

900

800

700

600

500

400

300

200

100

Pressure vs. Temp [non-shock]

PEEK*

PPS*

70 100 140 180 220 260 300

* Max. Pressure Temp. Ratings for Brass:

• 600 PSI up to 140°F

Page 4 May 2017

SEN-DS-01382-EN-07

Page 5

ORDERING MATRIX

SDI Series Single Direction Insert Powered Version Ordering Matrix

SDI 0 H1 N 0 0 - 0 2 0 0

MATERIAL

Stainless Steel / PPS Tip 0

Brass / PPS Tip (not available with hot tap)

Stainless Steel / Peek Tip 2

TYPE

Direct Insert for Pipe 1½" - 10" * D1

Direct Insert for Pipe 12" - 36" * D2

Direct Insert 36" and UP* D3

Hot Tap for Pipe 1½" - 10" * H1

Hot Tap for Pipe 12" - 36" * H2

Hot Tap for Pipe 36" and UP * H3

ELECTRONIC HOUSING

NEMA 4X N

OUTPUT

Standard Frequency Pulse 0

Analog 4-20mA 1

Scaled Pulse 2

DISPLAY

No Display 0

LCD Option (requires output option 1 or 2)

O-RING

Viton® 0

EPDM 1

AFLAS 2

SHAFT

Tungsten Carbide [Standard] 2

Hastelloy®C-276 [optional - consult factory] 1

IMPELLER

Stainless Steel 0

BEARING

®

Torlon

Ketron 2

1

Product Data Sheet

1

0

* Pipe size is for reference only. Depending on pipe size, tapping saddle or existing hardware, longer sensor length may be required. Consult the factory. For

material details, consult the factory.

SEN-DS-01382-EN-07

Page 5 May 2017

Page 6

Flow Sensors, Insert Style Flow Sensors

1

Torlon

0

SDI Series Bidirectional Insert Powered Ordering Matrix

SDI 0 H1 N 5 0 - 0 2 0 0

MATERIAL

Stainless Steel / PPS Tip 0

Stainless Steel / PEEK Tip 2

TYPE

Hot Tap for Pipe 1½" - 10" * H1

Hot Tap for Pipe 12" - 36" * H2

Hot Tap for Pipe 36" and up* H3

ELECTRONIC HOUSING

NEMA 4X N

OUTPUT

Bi-Directional 4-20mA + Direction 5

Bi-Directional Scaled Pulse 6

DISPLAY

No Display 0

LCD Option 1

O-RING

Viton® 0

EPDM 1

AFLAS 2

SHAFT

®

Hastelloy

IMPELLER

Stainless Steel 0

BEARING

Ketron 2

C-276 [optional - consult factory]

®

2Tungsten Carbide [Standard]

* Pipe size is for reference only. Depending on pipe size, tapping saddle or existing hardware, longer sensor length may be required. Consult the factory. For

material details, consult the factory.

Page 6 May 2017

SEN-DS-01382-EN-07

Page 7

SDI Series Battery Powered Ordering Matrix

Brass / PPS Tip (not available with hot tap) 1

1

Torlon

®

0

MATERIAL

Stainless Steel / PPS Tip 0

Stainless Steel / PEEK Tip 2

TYPE

Direct Insert for Pipe 1-1/2" thru 10" * D1

Direct Insert for Pipe 12" thru 36" * D2

Direct Insert 36" and UP* D3

Hot Tap for Pipe 1-1/2" thru 10" * H1

Hot Tap for Pipe 12" thru 36" * H2

Hot Tap for Pipe 36" and UP * H3

ELECTRONIC HOUSING

Battery Powered/NEMA 6 B

OUTPUT

No Output N

Scaled Pulse 2

2 Pulse Output 9

DISPLAY

LCD Option 1

Remote Display/NEMA 4X 2

O-RING

Viton® 0

EPDM 1

AFLAS 2

SHAFT

®

Hastelloy

IMPELLER

Stainless Steel 0

BEARING

C-276 [optional - consult factory]

Product Data Sheet

SDI 0 D1 B N 1 - 0 2 0 0

2Tungsten Carbide [Standard]

* Pipe size is for reference only. Depending on pipe size, tapping saddle or existing hardware, longer sensor length may be required. Consult the factory. For

material details, consult the factory.

SEN-DS-01382-EN-07

Page 7 May 2017

Page 8

Flow Sensors, Insert Style Flow Sensors, SDI Series

Control. Manage. Optimize.

Data Industrial is a registered trademark of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities. Due to continuous

research, product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the extent an

outstanding contractual obligation exists. © 2017 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Eastern Europe Branch Oce (for Poland, Latvia, Lithuania, Estonia, Ukraine, Belarus) | Badger Meter Europe | ul. Korfantego 6 | 44-193 Knurów | Poland | +48-32-236-8787

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 21-06 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | 7-1202 | 99 Hangzhong Road | Minhang District | Shanghai | China 201101 | +86-21-5763 5412

Switzerland | Badger Meter Swiss AG | Mittelholzerstrasse 8 | 3006 Bern | Switzerland | +41-31-932 01 11

Legacy Document Numbers: DTB-001-05-EN, DTB-002-04-EN, DTB-066-03-EN

Loading...

Loading...