Page 1

Vortex Flow Meter

RVL Series

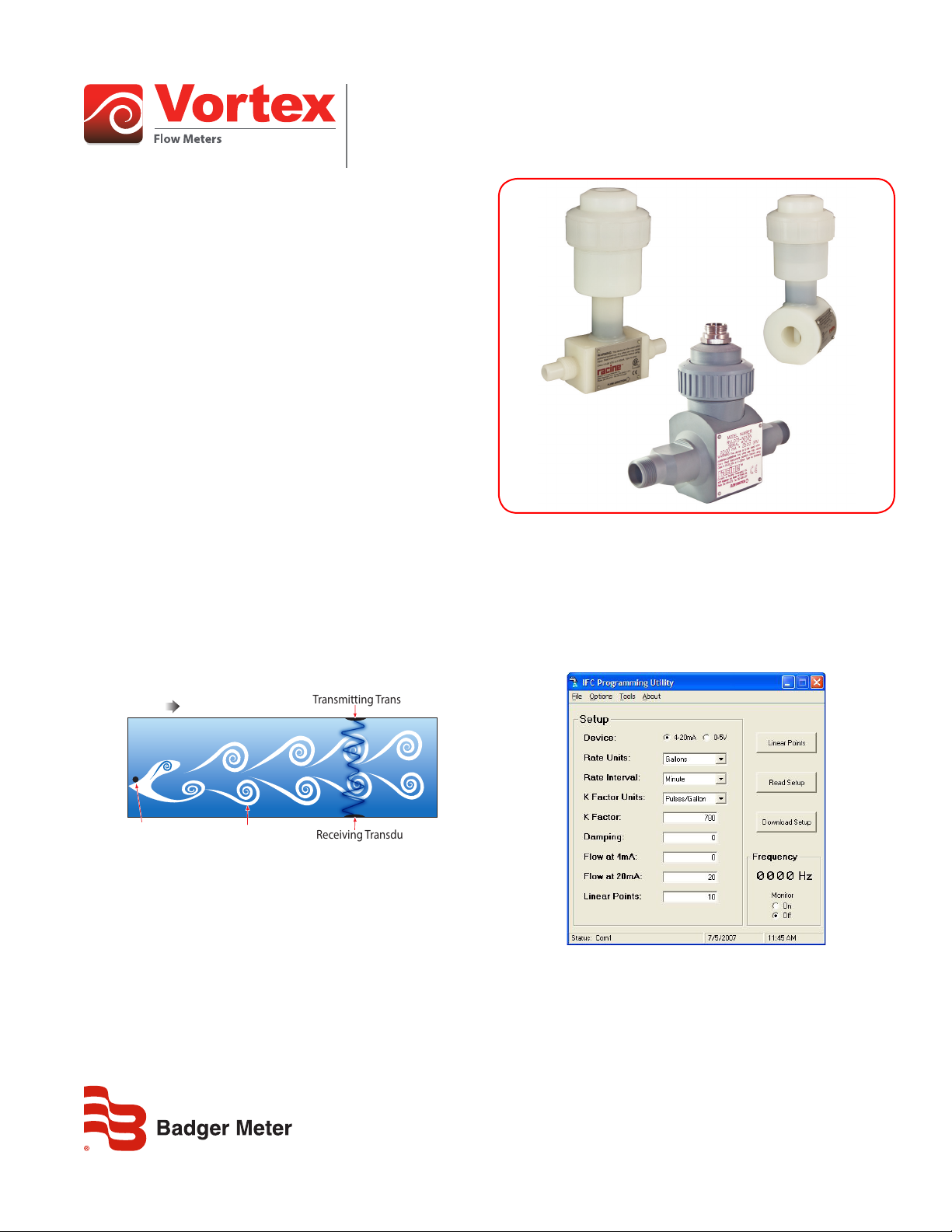

DESCRIPTION

The RVL liquid flow meter uses vortex-shedding technology with

embedded piezoelectric pressure sensors. The meter has no moving

parts, and any potential for fluid contamination is eliminated by the

non-metallic corrosion-resistant body materials. The meter includes

a compact plug-in transmitter module with two-wire 4…20 mA or

three-wire pulse output. All electronics are housed in a corrosionresistant enclosure. Units can be recalibrated and reprogrammed in

the field.

APPLICATION

The RVL is perfect for aggressive or easily contaminated fluids.

• Ultra-pure water distribution

• RO/DI skids

• Cooling water

• Chemical injection

• Nonabrasive slurries

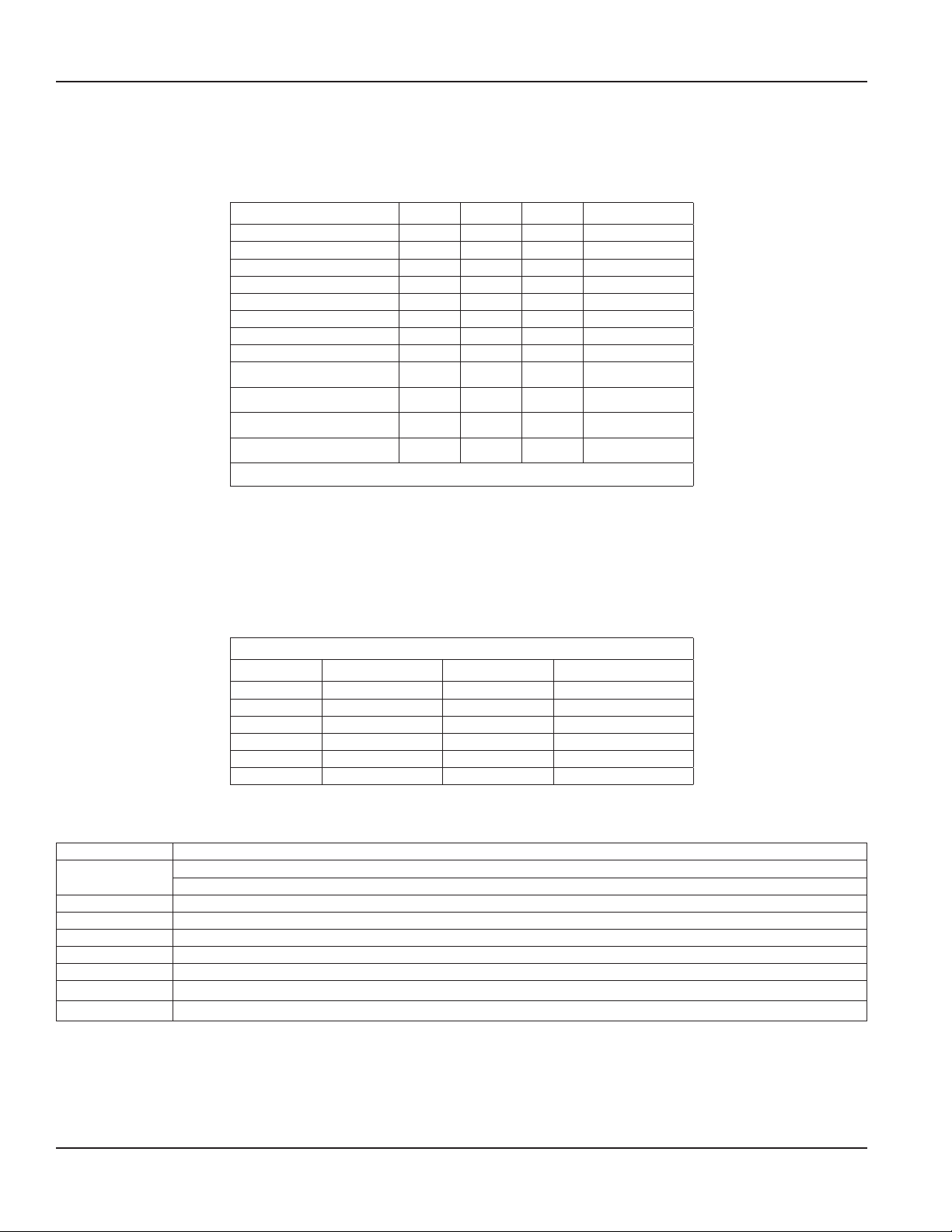

OPERATING PRINCIPLE

Operation of the RVL vortex flow meter is based on the vortex

shedding principle. As fluid moves around a strut, vortices (eddies)

are formed and move downstream. They form alternately, from

one side to the other, causing pressure fluctuations that are sensed

by a piezoelectric crystal in the sensor tube. The frequency of the

vortices is directly proportional to the flow rate.

FLOW

Small Strut

Shed Vortices

Transmitting Transducer

Receiving Transducer

CONSTRUCTION

The precision machined bodies provide quality end fittings, while

avoiding ionic contamination. There are no metallic wetted parts,

gaskets or elastomers in the meter. The body material selected is

homogeneous throughout the flow path.

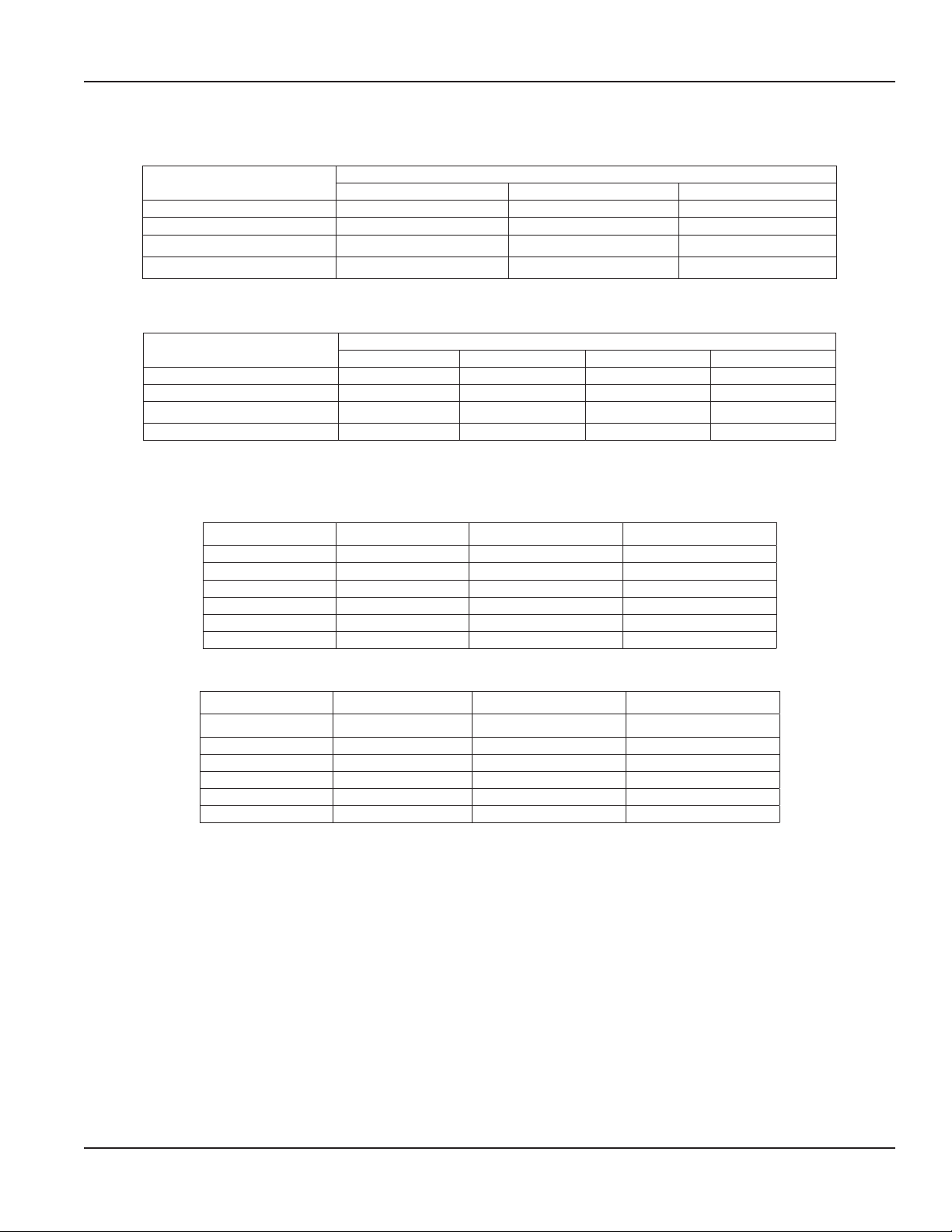

OPTIONAL SOFTWARE

An optional software utility kit is available to configure the RVL

4…20 mA output. (The pulse output is not field configurable.) Part

number RVS220-954 contains a RS232 nine-pin cable, software

CD, TTL to RS232 converter and a board interface cable. The

program enables easy configuration of span, damping and units of

measurement.

VRX-DS-01586-EN-08 (April 2019)

Product Data Sheet

Page 2

Material Selection

MATERIAL SELECTION

When choosing the best flow meter for a process, review the concentration, operating temperatures and operating pressure of the fluid

being measured. In a thermoplastic piping system, choose the same material for the meter and the pipe wherever possible to maintain fluid

compatibility and aid in bonding the materials. The table below shows the compatibility of fluid types with thermoplastic materials.

Chemical PVC PVDF CPVC Polypropylene

Aluminum Hydroxide A A A A

Chlorine Water A B A D

Fuel Oils A B — A

Hydraulic Oil A A — D

Hydrochloric Acid 37% B A A C

Hydrochloric Acid 20% B A C A

Isopropyl Alcohol A — C A

Nitric Acid (Concentrated) B A D D

Phosphoric Acid (>40%) B B A A

Potassium Hydroxide A A A A

Propylene Glycol C — C A

Sulfuric Acid (10…75%) A A A A

A= Excellent B= Good C= Fair D= Severe effect

FLUID CONSIDERATIONS

In vortex flow meters, fluids with high viscosities tend to dampen the formation of vortices and reduce the effective range. Viscosities above

1 cSt raise the minimum readable flow rate, reducing rangeability. The effect is linear to viscosity. Particles and internal bubbles do not

usually affect vortex meters. In slurry services, PVDF models typically work very well. Slurries containing grit can wear down the bluff body

over a period of time and long fibers can catch and build up on the bluff, decreasing accuracy.

Liquids with specific gravities higher than 2.0 adversely affect the permissible amount and duration of over-flow range.

Reduction of Range Based on Viscosity

Viscosity Minimum Maximum Flow Range

1 cSt 1 12 12:1

2 cSt 2 12 6:1

3 cSt 3 12 4:1

4 cSt 4 12 3:1

5 cSt 5 12 2.4:1

6 cSt 6 12 2:1

Meters are calibrated with tap water at 1 cSt (32 SSU) at ambient temperature

SPECIFICATIONS

Measured Fluids Liquids

Connections

Accuracy ±1% of full scale, 4…20 mA; ±2% of full scale, frequency pulse

Repeatability ±0.25% actual flow

Response Time 2 seconds minimum, step change in flow

Input Power 13…30V DC

Signal Output 4…20 mA or frequency pulse (source–sink driver; 1A source/1.5A sink; typical output resistance 10 Ω)

Enclosure NEMA 4X (IP 66)

Certifications CE: EN50082-1:1992

Butt or NPT thread

Wafer (mounted between flanges)

Page 2 April 2019

VRX-DS-01586-EN-08

Page 3

Pressure vs Temperature Ratings

NPT/Butt End Fittings

Maximum Fluid Temperature

203° F (95° C)* — 24 psig (1.6 bar) 40 psig (2.7 bar)

150° F (66° C) — 63 psig (4.3 bar) 130 psig (8.9 bar)

100° F (38° C) 93 psig (6.4 bar) 120 psig (8.3 bar) 150 psig (10.3 bar)

70° F (21° C) 150 psig (10.3 bar) 150 psig (10.3 bar) 150 psig (10.3 bar)

Wafer End Fittings

Maximum Fluid Temperature

203° F (95° C) — — 24 psig (1.6 bar) 40 psig (2.7 bar)

150° F (66° C) — 90 psig (6.2 bar) 100 psig (6.9 bar) 130 psig (8.9 bar)

100° F (38° C) 130 psig (8.9 bar) 130 psig (8.9 bar) 130 psig (8.9 bar) 150 psig (10.3 bar)

70° F (21° C) 150 psig (10.3 bar) 150 psig (10.3 bar) 150 psig (10.3 bar) 150 psig (10.3 bar)

FLOW RANGES

NPT/Butt End Fittings

Flow Ranges

Maximum Operating Pressure

PVC CPVC PVDF

*Reduces low ow rate on 1/4 in. (6 mm) meter

Maximum Operating Pressure

PVC PP CPVC PVDF

Wafer End Fittings

Meter Size Minimum Flow Maximum Flow Turndown Ratio

1/4 in. (6.3 mm) 0.6 gpm (2.3 lpm) 5 gpm (19 lpm) 8:1

1/2 in. (12.7 mm) 1.5 gpm (5.7 lpm) 15 gpm (56.8 lpm) 10:1

3/4 in. (19.1 mm) 2.5 gpm (9.5 lpm) 25 gpm (94.6 lpm) 10:1

1 in. (25.4 mm) 5.0 gpm (18.9 lpm) 50 gpm (189 lpm) 10:1

1-1/2 in. (38.1 mm) 10.0 gpm (37.9 lpm) 100 gpm (379 lpm) 10:1

2 in. (50.8 mm) 20.0 gpm (75.7 lpm) 200 gpm (757 lpm) 10:1

Meter Size Minimum Flow Maximum Flow Turndown Ratio

1/2 in. (12.7 mm) 1.5 gpm (5.7 lpm) 15 gpm (56.8 lpm) 10:1

3/4 in. (19.1 mm) 2.5 gpm (9.5 lpm) 25 gpm (94.6 lpm) 10:1

1 in. (25.4 mm) 5.0 gpm (18.9 lpm) 50 gpm (189 lpm) 10:1

1-1/2 in. (38.1 mm) 10.0 gpm (37.9 lpm) 100 gpm (379 lpm) 10:1

2 in. (50.8 mm) 20.0 gpm (75.7 lpm) 200 gpm (757 lpm) 10:1

3 in. (76.2 mm) 30.0 gpm (113.6 lpm) 300 gpm (1136 lpm) 10:1

VRX-DS-01586-EN-08

Page 3 April 2019

Page 4

1/2" NPT Female

1/2" NPT Female

C D

Dimensions

DIMENSIONS

NPT/Butt End Fittings

Conduit Connection

A

NPT/Butt End

B

C D

Meter Size

A B C D A B C D

PVC/CPVC in. (mm) PVDF (Butt) in. (mm)

1/4 in. (6.3 mm) 3.81 (97) 1.75 (45) 5.25 (133) 2.5 (64) 5.9 (150) 0.63 (16) 4.87 (124) 1.31 (33)

1/2 in. (12.7 mm) 3.81 (97) 1.75 (45) 7.13 (181) 2.5 (64) 5.75 (146) 0.78 (20) 4.87 (124) 1.31 (33)

3/4 in. (19.1 mm) 3.81 (97) 1.75 (45) 7.63 (194) 2.5 (64) 5.75 (146) 0.94 (24) 4.87 (124) 1.44 (37)

1 in. (25.4 mm) 3.92 (100) 1.75 (45) 8.03 (204) 2.5 (64) 5.88 (149) 1.19 (30) 5.09 (129) 2 (51)

1-1/2 in. (38.1 mm) 3.9 (99) 2 (51) 8.37 (213) 2.5 (64) 6.21 (158) 1.50 (38) 6.24 (158) 2.50 (64)

2 in. (50.8 mm) 4.31 (109) 2 (51) 8.37 (213) 2.5 (64) 6.6 (168) 1.88 (48) 6.77 (172) 3 (76)

Wafer End Fittings

Conduit Connection

A

B

Meter Size

A B C D

1/2 in. (12.7 mm) 5.85 in.(149 mm) 0.78 in. (20 mm) 2.03 in. (52 mm) 1.75 in. (44 mm)

3/4 in. (19.1 mm) 5.90 in. (150 mm) 0.94 in. (24 mm) 2.03 in. (52 mm) 2.13 in. (54 mm)

1 in. (25.4 mm) 5.69 in. (145 mm) 1.19 in. (30 mm) 2.25 in. (57 mm) 2.47 in. (63 mm)

1-1/2 in. (38.1 mm) 6.00 in. (152 mm) 1.50 in. (38 mm) 2.63 in. (67 mm) 3.25 in. (83 mm)

2 in. (50.8 mm) 6.37 in. (162 mm) 1.88 in. (48 mm) 3.22 in. (82 mm) 4.00 in. (102 mm)

3 in. (76.2 mm) 6.88 in. (175 mm) 2.50 in. (64 mm) 4.25 in. (108 mm) 5.24 in. (133 mm)

PVDF

Page 4 April 2019

VRX-DS-01586-EN-08

Page 5

PART NUMBER CONSTRUCTION

Options

1

2

3

and Display Mounting must be m arked as "N" for none.

Model

Line Size

Body Style

Body Material

Output

Options

1

2

3

Display Mounting

1.)

2.)

3.)

NPT End Fittings

RVL Piezoelectric Vortex Flow Meter

for Liquids (NPT Fittings)

Model

Piezoelectric Vortex Flow Meter for Liquids (In-Line) RVL

Line Size

1/4 Inch | 5 gpm (19 lpm) Maximum Flow Rate 025

1/2 Inch | 15 gpm (56.8 lpm) Maximum Flow Rate 050

3/4 Inch | 25 gpm (94.6 lpm) Maximum Flow Rate 075

1 Inch | 50 gpm (189 lpm) Maximum Flow Rate 100

1-1/2 Inch | 100 gpm (379 lpm) Maximum Flow Rate 150

2 Inch | 200 gpm (757 lpm) Maximum Flow Rate 200

Body Style

NPT (Male) Thread N

Body Material

PVC 1

CPVC 2

PVDF 4

Output

4 … 20 mA X

Rate Frequency Pulse | Not Available with Display

None N

High Temperature Rated: 203° F (95° C)

Stainless Steel Tags S

3-Pin (male) Output Connector

Display Mounting

None N

Top Mount 1

Right Mount 3

-

P

Part Number Construction

H

3

1.) Multiple Options may be listed in series on the part number - add as necessary

High Temperature option ONL Y available with Body Material options "2" and "4"

2.)

3.) When selecting Option 3, 3-Pin (male) Output Connector, a display cannot be mounted o n the meter

Butt End Fittings

RVL Piezoelectric Vortex Flow Meter

for Liquids (Butt End Fittings)

Piezoelectric Vortex Flow Meter for Liquids (In-Line) RVL

1/2 Inch | 15 gpm (56.8 lpm) Maximum Flow Rate 050

3/4 Inch | 25 gpm (94.6 lpm) Maximum Flow Rate 075

1 Inch | 50 gpm (189 lpm) Maximum Flow Rate 100

1-1/2 Inch | 100 gpm (379 lpm) Maximum Flow Rate 150

2 Inch | 200 gpm (757 lpm) Maximum Flow Rate 200

Butt End Connection B

PVDF 4

4 … 20 mA X

Rate Frequency Pulse | Not Available with Display

None N

High Temperature Rated: 203° F (95° C)

Stainless Steel Tags S

3-Pin (male) Output Connector

None N

Top Mount 1

Right Mount 3

Multiple Options may be listed in series on the part number - add as necessary

High Temperature option ONL Y available with Body Material option "4"

When selecting Option 3, 3-Pin (male) Output Connector, a display cannot be mounted o n the meter

and Display Mounting must be mar ked as "N" for none.

-

P

H

3

VRX-DS-01586-EN-08

Page 5 April 2019

Page 6

Not Available with Display

Options

1

2

and Display Mounting must be marked as "N" for none..

Part Number Construction

Wafer End Fittings

RVL Piezoelectric Vortex Flow Meter

-

for Liquids (Wafer End Fittings)

Model

Piezoelectric Vortex Flow Meter for Liquids (Wafer) RVL

Line Size

1 Inch | 50 gpm (189 lpm) Maximum Flow Rate 100

1-1/2 Inch | 100 gpm (379 lpm) Maximum Flow Rate 150

2 Inch | 200 gpm (757 lpm) Maximum Flow Rate 200

3 Inch | 300 gpm (1136 lpm) Maximum Flow Rate 300

Body Style

Wafer W

Body Material

PVC 1

CPVC 2

Polypropylene 3

PVDF 4

Output

4 … 20 mA X

Rate Frequency Pulse |

None N

High Temperature Rated: 203° F (95° C)

Stainless Steel Tags S

3-Pin (male) Output Connector³ 3

Display Mounting

None N

Top Mount 1

Right Mount 3

1.) Multiple Options may be listed in series on the part number - add as necessary

High Temperature option ONLY available with Body Material options "2" and "4"

2.)

3.) When selecting Option 3, 3-Pin (male) Output Connector, a display cannot be mounted on the meter

P

H

Page 6 April 2019

VRX-DS-01586-EN-08

Page 7

PRESSURE DROP VS FLOW RATE

PRESSURE DROP (psid)

PRESSURE DROP

FLOW (gpm) FLOW (lpm)

PRESSURE DROP (psid)

PRESSURE DROP

FLOW (gpm) FLOW (lpm)

NPT/Butt End Fittings

Wafer End Fittings

Pressure Drop vs Flow Rate

(Millibar)

(Millibar)

VRX-DS-01586-EN-08

Page 7 April 2019

Page 8

Vortex Flow Meter, RVL Series

Control. Manage. Optimize.

Trademarks appearing in this document are the property of their respective entities. Due to continuous research, product improvements and enhancements, Badger Meter reserves

the right to change product or system specications without notice, except to the extent an outstanding contractual obligation exists. © 2019 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Eastern Europe Branch Oce (for Poland, Latvia, Lithuania, Estonia, Ukraine, Belarus) | Badger Meter Europe | ul. Korfantego 6 | 44-193 Knurów | Poland | +48-32-236-8787

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 19-07 Parkway Parade | Singapore 449269 | +65-63464836

Switzerland | Badger Meter Swiss AG | Mittelholzerstrasse 8 | 3006 Bern | Switzerland | +41-31-932 01 11

Legacy Document Number: 09-VRX-BR-00365-EN RVL-0001

Loading...

Loading...