Page 1

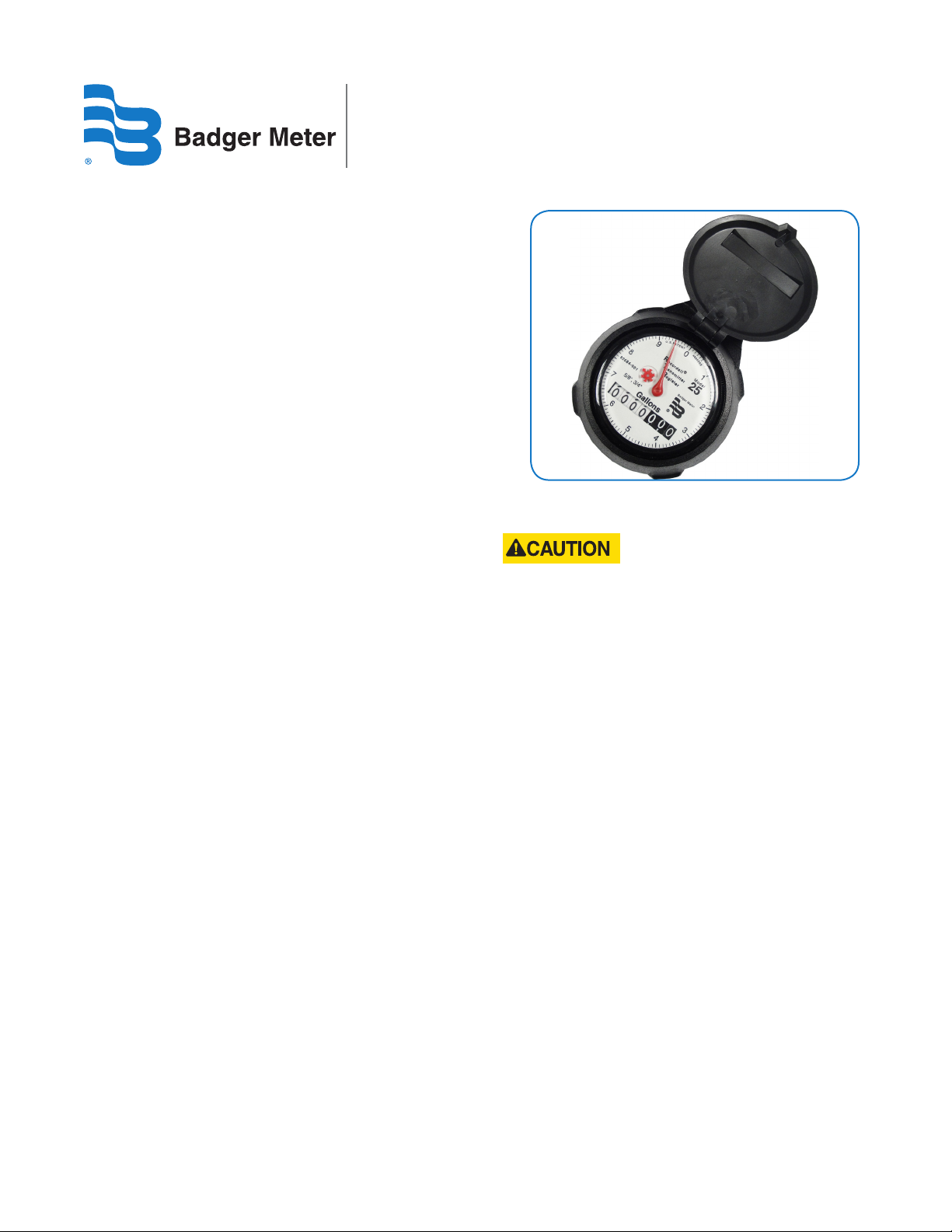

Recordall®

Transmitter Register (RTR®)

INTRODUCTION

Product Inspection and Unpacking

Upon opening the shipping container, visually inspect the product

and applicable accessories for any physical damage such as

scratches, loose or broken parts, or any other sign of damage that

may have occurred during shipment.

OTE:N If damage is found, request an inspection by the carrier’s

agent within 48 hours of delivery and file a claim with the

carrier. A claim for equipment damage in transit is the sole

responsibility of the purchaser.

PRODUCT OVERVIEW

Description

Recordall Transmitter Registers from Badger Meter communicate

through a patented piezo-electric, solid-state switch to provide

digital output. It features a non-proprietary protocol and very low

power requirements. The RTR with glass lens is available factory

pre-wired to Badger Meter AMR/AMI products, or may be spliced

to other devices following the instructions. The RTR is permanently

sealed to eliminate the intrusion of moisture, dirt, or other

contaminants, and is suitable for installation in all environments,

including meter pits subject to continuous submergence.

Compatibility

The RTR is designed for use with all current Badger Meter Recordall®

Disc, Turbo Series, Compound Series, Combo Series and Fire Service

meters and assemblies. Each RTR is clearly identified on the face

of the dial with an assembly number, unit of measure and meter

model. The RTR provides connectivity with Badger Meter ORION®

fixed network, migratable and classic AMR/AMI endpoints, GALAXY®

AMR/AMI endpoints, and other AMR/AMI technology solutions

approved by Badger Meter.

CONNECTING A RTR TO AN ENDPOINT

THE RTR SHOULD ONLY BE CONNECTED TO A PRODUCT

APPROVED BY BADGER METER. CONNECTION TO AN

UNAPPROVED PRODUCT WILL VOID THE RTR WARRANTY.

Badger Meter RTRs have a factory installed three-conductor cable

(brown) for connection to the endpoint. If the wire is cut or broken

and requires a field splice after the initial installation, connect likecolor wires to maintain proper installation. Badger Meter wiring

standards use the black wire as the negative (–) conductor and the

red as the positive (+) conductor.

Before proceeding with the installation, be certain that the

meter type and size correspond, and that the proper encoder

configuration has been supplied for the application.

REG-UM-01090-EN-07 (August 2014)

Installation Manual

Page 2

Splicing Considerations

Splice connections made in pit environments require a pit field

splice kit (62084-001), which can be ordered separately. See the

Field Splice Kit Installation Instructions available on our website.

ORION endpoints shipped factory pre-wired to a Badger Meter RTR

require no splicing. All you do is mount the RTR to the meter and

tighten the seal screw.

Wire Connections

The RTR is available factory pre-wired to Badger Meter

AMR/AMI products. The RTR is permanently sealed to eliminate the

intrusion of moisture, dirt, or other contaminants, and is suitable

for installation in all environments, including meter pits subject to

continuous submergence.

The RTR is also available with potted, pre-sized wire harness

available for connection to endpoints in the field. Standardized lead

lengths are 3, 10, 25, and 75 feet.

In-line Connector

An in-line connector is an optional feature that allows connectivity

to AMR/AMI devices without the need for a field splice kit.

TESTING

After all connections are complete, test the entire installation

including the RTR, the wiring and the endpoint for proper operation

in accordance with the instructions supplied with

the endpoint.

SPECIFICATIONS

Transmitter/Register

Unit of Measure

Number Wheels

Test Circle

Weight

Humidity

Temperature

Signal Characteristics

Visual Resolution

Electronic Resolution

Typical Signal Duration

On State Resistance

Power Source

Maximum Switching

Straight reading, permanently sealed,

magnetic drive

U.S. gallons, cubic feet, cubic meters,

clearly identified on register face

Six with 3/16” high numerals font type

360° circle with ten major increments

with ten divisions each

9 ounces

0…100% condensing

–40…49° C (–40…120° F)

Open Drain (FET)

1/100th of Test Circle

1/10th of Test Circle

15…75 ms @ 25° C (77° F) 8…75 ms

over operating temperature range at

67 µA

7.5 Ohms @ 25° C (77° F)

External

30V DC @ 1 mA @ 25° C (77° F)

INSTALLING THE RTR

Bayonet Mount

The bayonet mount positions the encoder in any of four

orientations for visual reading convenience. The RTR can be

removed from the meter without disrupting water service.

Install the RTR on the water meter and secure it using the tamperproof screw provided.

Making Water Visible®

MAKING WATER VISIBLE, ORION, GALAXY, and RECORDALL are registered trademarks of Badger Meter, Inc. Other trademarks appearing in this document are the property of their

respective entities. Due to continuous research, product improvements and enhancements, Badger Meter reserves the right to change product or system specications without

notice, except to the extent an outstanding contractual obligation exists. © 2014 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Czech Republic | Badger Meter Czech Republic s.r.o. | Maříkova 2082/26 | 621 00 Brno, Czech Republic | +420-5-41420411

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 21-06 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | 7-1202 | 99 Hangzhong Road | Minhang District | Shanghai | China 201101 | +86-21-5763 5412 Legacy Document Number: RTR-I-05-EN 62935-002

Loading...

Loading...