Page 1

Series 9000

RESEARCH® CONTROL

Valves

Installation &

Operation Manual

BadgerMeter,Inc.

®

940467

1-02

Page 2

TABLE OF CONTENTS

Page

General .............................................................................................................................................. 1

Installation ......................................................................................................................................... 1

Disassembly and Reassembly ........................................................................................................... 1

Replacing Trim Sets ........................................................................................................................... 1

Installing Trim Sets ............................................................................................................................. 2

Lapping Sequence ............................................................................................................................. 3

Assembly ........................................................................................................................................... 3

Stroke Adjustment and Pressure Test ................................................................................................ 4

Packing, Chevron Ring ....................................................................................................................... 5

Braided Teflon and Graphoil Packing .................................................................................................. 5

Bellows .............................................................................................................................................. 7

General ............................................................................................................................................ 7

Removal of Assembly from Valve .................................................................................................... 7

Removing lnnervalve from Bellows Assembly & Seat from Body .................................................... 8

Installing Bellows Seal Assembly, Innervalve & Seat....................................................................... 8

Valve Positioners ............................................................................................................................... 9

General ............................................................................................................................................ 9

Integral Mounting ............................................................................................................................. 9

Range Springs ................................................................................................................................. 9

Top Loading, Air-to-Close ................................................................................................................. 9

Bottom Loading, Air-to-Open .......................................................................................................... 10

Adjusting Zero ............................................................................................................................... 10

Servicing........................................................................................................................................ 10

Terminology ...................................................................................................................................... 11

Notes ............................................................................................................................................... 12

Special Information .......................................................................................................................... 13

Page 3

General

The purpose of these instructions is to supply pertinent

information for installation of original equipment, repair,

adjustments, retrimming, repacking and other information necessary to achieve the best possible service

from Research Control Valves.

Research Control Valves are engineered, designed, and

manufactured with the end user in mind. Most parts are

interchangeable with any other like assembly. The inner

components (spare trims) are available in 39 different

flow coefficient (Cv) sizes and in many different materials compatible with most process conditions.

Installation

After inspecting the valve (or valves) and determining

that the valve (or valves) meets the specifications, install as follows:

1. Normal installation is directly into any 1/4", 1/2",

3/4", or 1” piping system with flow direction arrow on

body pointing downstream. This allows the stem packing to see the lowest pressure conditions after the

pressure drop occurs. It should be noted that chevron

ring stem packing is a dynamic seal that needs pressure to be energized.

2. Valves, especially plastic, should be bracket mounted

in high vibration areas or where they may be subjected

to damage from shock. If necessary, provide as required,

bypass, manual block valve, filters, etc. When installing valves that have the Low Flow “P” Series innervalves,

small micron filters should be used where process permits.

to hold unbalance created by higher pressure on actual

application. It should be noted that on air-to-close valves

with no pressure, the travel indicator will show over travel.

With 3 PSIG to actuator, the indicator will be very close

to the open position.

Disassembly and Reassembly

(Best done at instrument shop bench)

For the purpose of these instructions, consider the

topworks or actuator as a complete sub-assembly not

to be dismantled except for replacing diaphragms or

topworks packing. The only necessary topworks adjustment is made with the spring adjuster and/or the

zero adjustment on positioner-equipped valves (see

paragraph on Positioners). To position the stem, travel

in relation to the 3-15, 3-9, 9-15 PSIG etc. instrument

signal operating the valve.

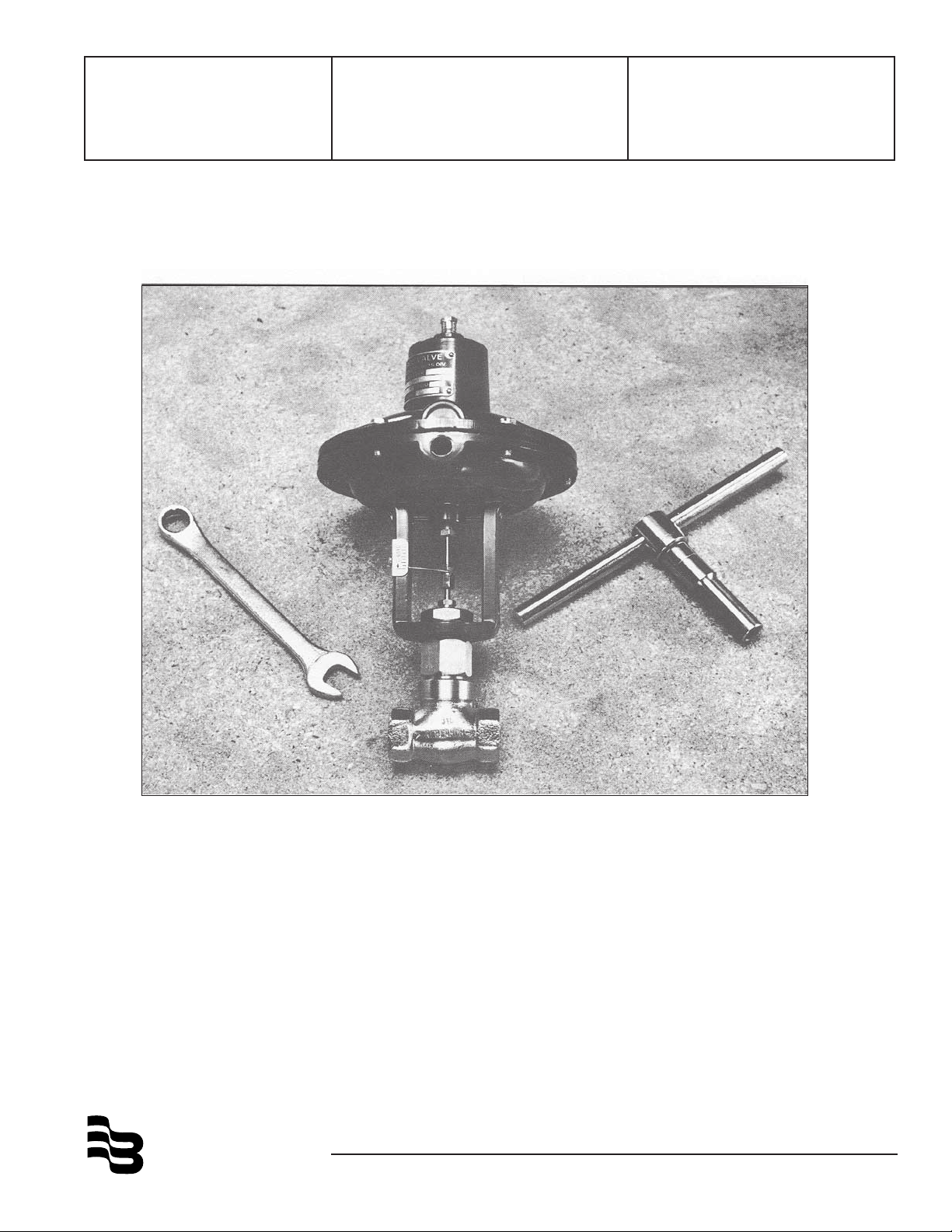

Replacing Trim Sets

Installing innervalve trim sets is accomplished with the

body and bonnet subassembly separated from the

topworks using appropriate wrenches. (Tool kits are

available at a nominal cost for 1/4”, 1/2”, 3/4”, and 1”

valves.) To separate the body bonnet assembly from

the topworks on ATO valves, apply 6-9 PSIG instrument air to the operator, lifting innervalve off seat to

prevent damage to the valve seating surfaces. (Not

necessary for ATC valves.)

3. Connect instrument air supply to diaphragm case

using appropriate NPT fittings (1/8" NPT for 1/4" valves

and 1/4" NPT for 1/2", 3/4", and 1” valves) to the desired tubing size adaptor (normally 1/4” tube fittings).

All connections to standard positioners, Moore products or Badger

®

, are 1/4" NPT. (For positioner data, see

paragraph under Positioners.)

4. All standard production valves as shipped are adjusted and preset at the factory with 90 PSIG air piped

to the inlet port of the body. Air-to-open valves are adjusted to come off seat at approximately 3.25 PSIG

instrument signal and be fully opened at 15 PSIG. Airto-close valves are set to close when signal is at 14.75

PSIG and be fully open at 3 PSIG. Process conditions

may dictate additional adjustment of the spring adjuster

FIG. 1

1

Page 4

1 .With innervalve off seat, use two open-end wrenches

(1/4" for 1/4" valves and 3/8" for 1/2", 3/4", and 1”

valves), one holding the stem connector in position,

and with the other loosen the topworks stem nut above

travel pointer; remove travel pointer.

2. With valve body in vise (clamp on ends), loosen the

yoke to bonnet locknut (yoke locknut) with a slotted

end wrench (7/8" boxed end for 1/4" valves, 1-1/8" for

1/2", 3/4" and 1" valves), and unscrew completely.

3. With the open-end wrench, turn the stem connector

counterclockwise (right hand threads), unscrewing from

the topworks stem completely. (Fig. 1)

4. Remove topworks from body bonnet assembly.

5. With the valve body in vise, loosen and unscrew

bonnet from body using open-end or crescent wrench.

Installing Trim Sets

(Matching pairs do not separate)

With all parts cleaned in an appropriate solvent, install

desired trim set in body bonnet assembly as follows:

FIG. 3

1. With trim as shown in Figure 3, apply a coating of

Neolube (graphite dry film lubricant), process permitting,

to the threads and seating surfaces of the seat. Air dry

for 30 seconds. Do not use any thread sealing

compounds containing metal particles. NOTE: New

replacement innervalves, come pre-coated with NeoLube

except those specially cleaned.

FIG. 2

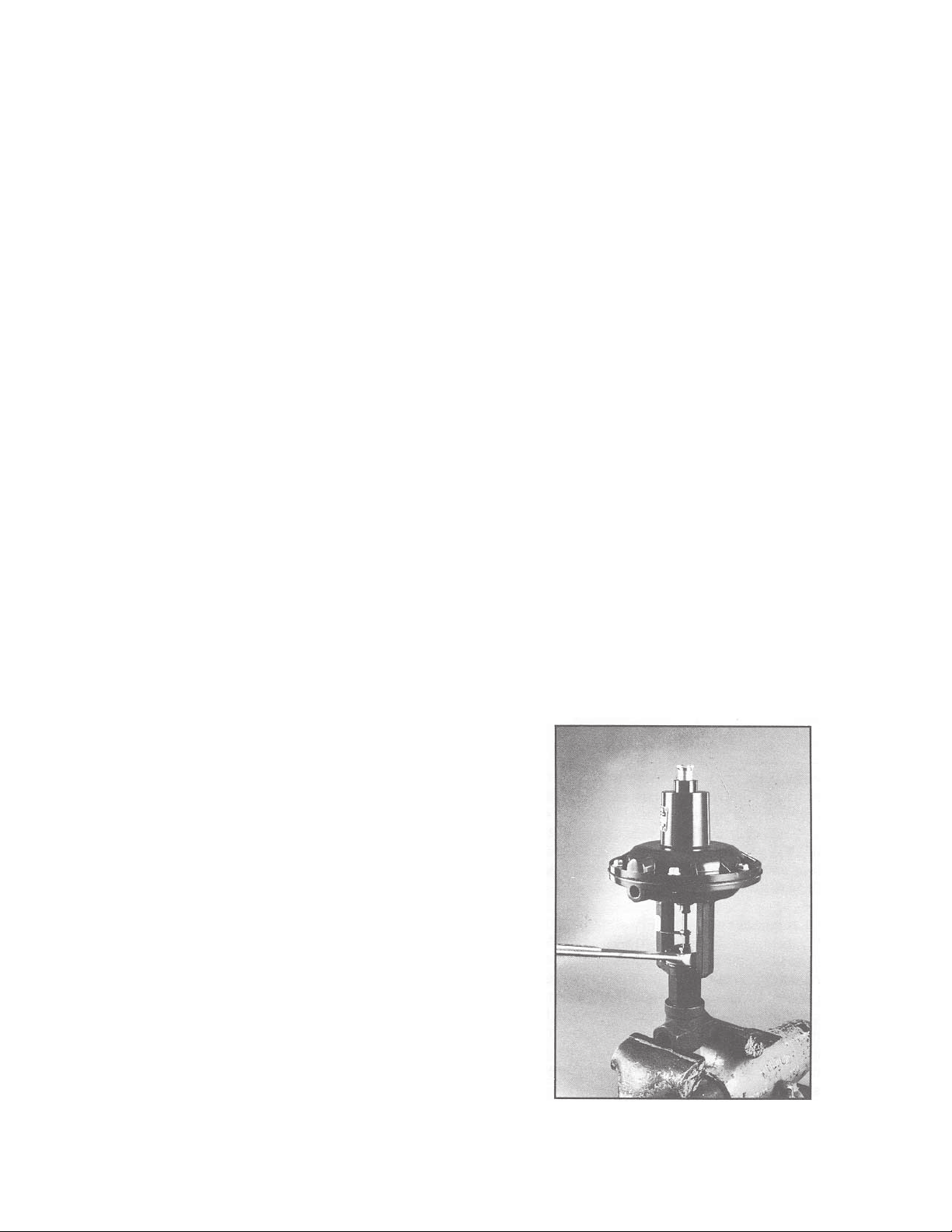

6. Remove seat from body using a deep thin wall socket

and T-handle assembly (3/8" hexagon for 1/4" valves,

5/8" hexagon for 1/2", 3/4" hexagon for 3/4"valves, and

15/16" hexagon for 1” valves).

Some purchased long set sockets

(heavyduty) will not fit body cavity without turning

O.D. to fit past body threads.

(Fig. 2)

7. Most standard innervalves “K” through “P18” in 1/4"

valves and “F” through the “P” series trim in 1/2" valves

can be removed upward from the bonnet through the

packing, all others by removing stem connector and

withdrawing downward through the packing. When

removing the larger trims down through packing, it is

best to withdraw stems until threaded portion is in

contact with packing and then rotate stem and allow

the threads to screw through the packing area.

2. Remove seat from innervalve and place hex first into

the long set socket wrench and T-handle assembly.

NOTE: Tissue paper can be stuffed into the socket to

prevent seat from falling through.

FIG. 4

3. With body inverted in palm of hand as shown in

Figure 4, start seat threads into body, invert body and

tighten seat. Do not over-torque. Standard torque figures

using new parts at the factory are: 10/11 ft/pounds on

“P” trim seats, 8.5 ft/pounds on other 1/4" seats, 35 ft/

pounds on 1/2", 3/4" and 1” seats. It should be noted

that torque figures are applicable to new parts and may

not be the same for used parts. For longest service life,

on new or used parts, it’s best to use procedure detailed

in paragraph 4.

2

Page 5

4. Torque seat firmly into body with the short T- handle

assembly. Check seat to body seal, by making body a

bubble chamber, using a pointed plastic plug in seat to

seal as shown in Figure 5 with downstream port plugged

and 50 psi air pressure upstream, check for leak. If

leak exists, re-torque seat and recheck until bubbletight seal is accomplished. On smaller letter or “P” series

trim sets, over-torquing seat in the body can reduce the

orifice size to where interference between innervalve

and seat can cause a premature mechanical failure

(galling) when stroking valve.

FIG. 6

clockwise, counterclockwise motion between the thumb

and forefinger, lifting the innervalve off seat and

repositioning periodically to achieve a uniform lap ring.

After each lapping operation, remove bonnet from body

and clean innervalve and seat from body. Clean seat by

submerging body in solvent and swabbing orifice with

wetted pipe cleaner and blow dry with air. After cleaning,

reassemble and check leak rate as shown in Figure 7.

Caution should be taken to not overlap.

FIG. 5

5. With body in vise, again clamping across ends of

body not sides of body, place body bonnet gasket in

place. (Process permitting, coat each side of gasket

with lubricant such as Dow Corning or Dupont Krytox

valve seal.) With the stem section of the trim set

installed in the bonnet, coat the bonnet threads (body

end) with lubricant.

6. Screw bonnet into body and tighten with open-end or

crescent wrench. Apply the proper torque to bonnet/

body joint as listed on the back side of individual

technical briefs.

7. Stroke innervalve manually to check for misalignment. Should misalignment exist, check straightness

of innervalve or packing. (See Packing Installation.)

NOTE: All replacement trim sets have been prelapped

at the factory. When installed per instructions, trims

should leak no more than 1/10 of one percent of

maximum flow for the given size, (ANSI Class III). If

necessary, with care, bubble-tight shutoff can normally

be achieved by lapping in seating surfaces with the

innervalve set installed in the body bonnet assembly

using lapping compound (white aluminum oxide 38-1000

grit) with the packing removed, using the packing glands

as the upper guide (brass lap bushing available at

factory). See Figure 6. Lapping should be done with a

FIG. 7

Lapping Sequence

Lap for about 30 seconds, clean and check leak rate;

repeat sequence until desired shutoff is achieved. If

after lapping three or four times leak still exists, check

the seating surfaces of both innervalve and seat for

excess nicks, scratches, or indication of galling if the

trim has previously been in service. Do not lap for

shutoff any of the “P” series trims.

Assembly

1. With body in vise, place topworks yoke on bonnet

with yoke locknut slipped over the stem connector and

down on bonnet threads (6-9 PSIG air on air-to-open

topworks).

2. With topworks in correct position relative to the

centerline of the body, tighten yoke locknut using a

boxed-end (slotted) wrench.

3

Page 6

3. Raise innervalve and screw the stem connector on

topworks stem until the two stems are butted together.

4. Install travel pointer between stem connector and

locknut on topworks stem. Hold stem connector in place

and tighten topworks stem nut against the travel pointer

positioned 1/32" to 1/16" away from travel scale.

Stroke Adjustment and Pressure Test

1. With valve completely assembled and with a manually

regulated supply (3-15 PSIG) to the topworks, adjust

with spring adjuster until valve stroke is corresponding

to the normal 3-15 PSIG instrument signal. To set this

precisely, pipe 90 PSIG air to the upstream port and

with rubber tubing piped from downstream port, bubble

check shutoff point. (Fig. 8)

2. Set air-to-open valves to open at 3-1/4" PSIG.

valve open. Using a plastic squeeze bottle filled with a

soapy water solution, flood each joint and inspect for

leaks. Check and tighten packing just until no leak is

visible. Do not over-tighten. (Fig. 9)

FIG. 8

3. Set air-to-close valves to close at 14-3/4" PSIG.

4. Nominal stem travel of 7/16" for 1/4" valves and

9/16" for 1/2", 3/4", and 1” valves is fixed in the topworks

spring rate for a 12 PSIG span. If valve has been set

with a high bench setting because of pressure, full travel

may not occur at 15 PSIG.

5. If necessary, reposition travel scale relative to stroke.

FIG. 9

7. Normal hysteresis (dead band) in valve stroke should

be no more than 1/4 PSIG instrument signal. This can

be checked by placing the thumb and forefinger on the

valve stem in contact with the packing gland and

regulating manually the 3-15 PSIG instrument signal

(gauge in line), visually watching gauge and feeling

movement. (Fig. 10)

6. Pressure test all seals with 90 PSIG air piped to the

upstream port, downstream port plugged with

FIG. 10

4

Page 7

Packing, Chevron Ring

1. Proceed with disassembly of body-bonnet assembly as in changing trims.

2. Remove the packing gland and all components from

within the cavity. If the Teflon packing follower has been

damaged due to over tightening and extruded into the

threads of the packing cavity, a standard screwdriver

can be driven into the teflon to unscrew the follower. ln

this case, the packing follower needs to be replaced.

3. Clean and inspect cavity and parts for damage.

4. Place packing adaptor in the cavity making sure the

flat side is down and in place.

5. Place the first ring into the cavity at a 90 degree

angle to its seated position. When the ring is at the

bottom of the cavity, tip it over with the cup side down

using a small plastic or wooden probe. Continue this

procedure with the two additional rings. This method

prevents the threads of the cavity from damaging the

lips of the rings.

6. Place the packing follower on top of the rings, making

sure the inverted “V” is down. (The arrangement for

reversed Cv ring vacuum packing requires special parts.)

7. Replace the packing gland. Tighten until contact is

made with the packing follower.

8. If the plug portion of the trim is machined integral on

the stem, the stem connector should be tightened onto

the stem before insertion into the bonnet and may be

inserted through the packing from the top of the bonnet.

If the plug portion of the trim is screwed onto the stem,

the stem should be placed through the packing from

the bottom of the bonnet by gently screwing the stem

threads through the packing. The stem connector can

then be tightened onto the stem.

psi). If packing leaks, tighten gland just until leak stops.

Excess torque can damage Teflon components. Once

this procedure is complete, the valve can be tested at

higher pressures.

CAUTION: Do not tighten gland more than is necessary

to stop leaks.

NOTE: On valves supplied prior to October 1993, the

packing follower on all valves was virgin Teflon and

packing adaptor was the same metal material as valve.

To improve on the total packing function in regard to

sealing and replacement, both the follower and adaptor

materials have been changed to now available, Teflon

PFA. This denser Teflon material allows the guide

diameter to be closer for better alignment and solves

the cold flow problem of the original virgin Teflon follower.

Braided Teflon and Graphoil

The original packing for Research Control Valves was

braided Teflon which used a smaller gland nut. After

molded chevron rings became available and for a period

of time, there was a difference between the bonnet

packing cavity, depending on type of packing used. The

components parts were not interchangeable until the

current design was introduced in 1972, standard 1981,

using a common cavity for all types packing.

1. Braided Teflon is available and used in current packing

cavity by putting in a dummy stem to fit the packing

over as shown in Figure 11. Fill the cavity

9. Retract the stem sufficiently to keep the trim from

seating and screw the bonnet into the body. Be sure to

install gasket.

10. Apply the proper torque to bonnet/body joint as listed

on the back side of individual technical briefs under

pressure/temperature ratings.

11. Proceed with assembly and adjustments per Page

3.

12. Test packing by tightening gland 1/4 turn past

fingertight. Do initial test with low pressure (80 to 100

FIG. 11

with sock or rope type packing, tamping into the cavity

with a packing tool or piece of appropriate size copper

tubing as shown in Figure 12, until cavity is full with a

couple threads showing. Screw gland in and tighten to

compress packing.

5

Page 8

FIG. 12

FIG. 13

Remove gland and blow or pick out any small pieces

that may be in the threads. (Fig. 13) Replace gland finger

tight and remove dummy stem Figure 14 and replace

with new innervalve and stem. Tighten packing gland

and test seal at final assembly the same as with chevron

ring packing.

FIG. 14

2. Graphoil Packing

Depending on the application, graphoil packing is

available in preformed rings to fit standard packing

cavities for all Research Control Valves. When a process

must run hot to prevent material from solidifying or for

other purposes where finned bonnets are used to

dissipate heat to protect the packing are not applicable,

graphoil may be the solution. If the application is quick

opening (on-off) and graphoil packing is used, the

standard actuator will work with higher operating pressure.

If application is to control, a positioner should be used

to overcome additional drag, or hysteresis, created by

graphoil making stem seal, especially on high pressure

gases.

6

Page 9

Bellows

General

On applications involving toxic gases, radioactive

materials and others where the primary seal at the valve

stem is critical, a metal bellows stem seal can be used

to preclude leakage as long as the integrity of the

bellows remains intact. Extreme care should be

exercised in removing and/or installing the Bellows Seal

Assembly to preclude damage. The metal thickness of

the low pressure bellows is only 0.005” to 0.007” thick,

and excess torsion will twist and deform the convolutions,

damaging the assembly.

FIG. 15

FIG. 17

FIG. 16

FIG. 18

Removal of Assembly from Valve

1. Remove the valve from the process line and hold

valve in a bench vise clamped on the body ends.

2. On air-to-open valves apply air pressure to diaphragm

to raise innervalve off seat. (Not necessary for air-to close valves).

7

Page 10

3. Loosen stem connector locknut above travel indicator.

4. Loosen yoke nut holding topworks to bonnet.

NOTE: If the above procedure is being done because of

bellows failure, it is not necessary to be concerned

about damage to the bellows.

5. Rotate entire topworks counterclockwise; top-works

stem will unscrew from stem connector.

CAUTION - Unscrew straight up or stem could be bent.

6. Finish unscrewing yoke nut and lift off topworks.

7. Loosen and unscrew bonnet assembly from body.

(Fig. 16)

8. Loosen and unscrew bonnet cap and bellows

assembly from bonnet. (Fig. 17)

9. Grasp bonnet stem located immediately under

connector with sharp nose pliers and remove connector

without allowing stem to turn.

10. Remove the bellows from the bonnet cap. At times

it is necessary to cut and fish out the Teflon bellows

gasket in order to free up the bellows assembly for

removal.

Removing lnnervalve from Bellows Assembly and

Seat from Body

1. Hold stem of bellows in a lathe collet or suitable

holding device (1/8" for 1/4" valves or 3/16" for 1/2",

3/4", and 1” valves) and gently unscrew innervalve

counterclockwise using a small end wrench fitting the

flats on the innervalve. Avoid any side motion or bending.

If the bellows stem threads unscrews before the

innervalve unscrews, make a strap wrench by cutting a

strip of 80 grit emery paper the width of the bellows

length and roll about three revolutions clockwise around

the bellows assembly with the coarse side against the

bellows. Grasp the emery paper by hand and with the

wrench on the innervalve flats, remove the innervalve

from the bellows. Normally this procedure prevents

damaging the bellows because the emery paper wrapped

around the bellows gives it more support transferring

the twisting forces to where the bellows is welded to

the lower end plate.

2. Do not try to remove stem from bellows assembly.

3. Do not grasp the bellows in any manner other than

above nor allow it to twist.

4. Unscrew seat from body with a long set socket

wrench.

Installing Bellows Seal Assembly, lnnervalve and

Seat

Generally the foregoing steps are the reverse of

disassembly, but best results will be experienced by

processing in the following sequence:

1. Screw innervalve into bellows assembly only hand

tight.

2. If the secondary packing in bonnet cap has not been

damaged, proceed; otherwise, remove old packing but

do not replace until later.

3. Place bellows-bonnet gasket carefully over bellows

to flange.

4. Insert stem into bonnet cap, carefully turning in a

clockwise direction until flange is seated all the way

into bonnet cap.

5. Be sure gasket is home and not damaged.

6. With bellows upward, carefully screw bonnet into

bonnet cap by hand until it is seated.

7. Holding bonnet in a vise, screw bonnet cap home

firmly with a wrench.

8. At this point install new secondary packing if

necessary, tightening gland firmly by finger tight as with

a standard packed valve. (See paragraph on packing.)

9. Remove from vise and hand-install connector by hand.

10. With small wrenches on connector and flats on the

innervalve, tighten firmly but prevent using any side

motion.

11. With body held in a vise as instructed, screw the

bonnet, bellows seal and innervalve assembly into the

body.

12. When body bonnet assembly is complete, the

innervalve should be off seat with the bellows in its free

state and should move approximately 1/8" when pushed

down before touching seat.

8

Page 11

13. CAUTION - With valves having “P” trims, be sure

the plug enters the seat before starting the bonnet

threads into the body.

14. Assemble the topworks to the body-bonnet assembly

in the exact reverse order from dismantiling. On air-to

open topworks remember to have air on the diaphragm,

rotating the topworks until the topworks and bellows

stem butts together in the middle of the connector. Use

Valve Positioners

General

Badger’s valve positioners use the full force of the air

supply pressure to drive the diaphragm or piston of the

pneumatic actuator to a position corresponding to the

pneumatic instrument signal output from a controller

(pressure, temperature, flow, etc.) and hold that position,

regardless of the forces which tend to change valve

position.

two wrenches to tighten travel indicator lock nut to

preclude twisting the bellows. If the topworks is not in

the correct position with the stems butted together in

the middle of the connector, rotate the topworks

counterclockwise to the correct position before locking

down the stem locknut. Do not rotate more than 90°

15. See stroke adjustment and pressure test.

Like all valve positioners, Badger’s have a feedback

circuit which measures position of the actuator’s

diaphragm or piston. The built-in valve positioner

supplies or vents air in response to the control-instrument

signal stroking the valve to the required position.

Integral Mounting

Badger’s compact valve positioners incorporate a single

axis force-balance principal of operation to insure

accurate and stable positioning of Research Control

Valves. The positioners become an integral part of the

valve actuator. In all cases, including bottom loading

applications, the built-in valve positioner is mounted

directly on the topworks with no external piping or other

exposed mechanisms.

Range Springs

The position of the diaphragm or piston in the valve

actuator is sensed by the amount of compressive force

exerted by the range spring on the valve actuator

diaphragm assembly. Standard strokes are 7/16" and

9/16". Standard signal ranges are 3-15, 3-9, 9-15, and

6-30 PSIG. Consult the factory for other ranges.

Top Loading, Air-to-Close

Air pressure from the control instrument is exerted

between the two lower diaphragms. Because of the

difference in the two diaphragm areas, the resultant force

is exerted in an upward direction. In balance condition,

the pneumatic force on the diaphragm plus

9

Page 12

the upward force exerted by the range spring is balanced

by the downward force of the zero adjustment spring. In

balance condition, positioner vents to atmosphere.

When control-instrument pressure increases, the

diaphragm assembly will move upward closing the

exhaust port and opening the pilot valve allowing supply

air to pass directly to the actuator diaphragm. The supply

air will drive the actuator downward. As the actuator

moves down, the range spring relaxes until its force

decreases enough to offset the increase in controlinstrument pressure, allowing the pilot valve to close

and exhaust to open. On air-to-close valves with

positioners, the supply pressure should be sufficient

for function, but never excessive. For function the

positioner supply pressure needs to be a minimum of 3

PSIG above instrument signal. Excessive supply

pressure can result in damage to trims when the

innervalve touches the seat and the signal continues

down. The positioner sees this as resistance and reacts,

causing the full supply pressure to be applied to the

main diaphragm in the actuator.

ATO valves with type BLRA or Moore 73B positioners,

zero adjustment is made with 3 psi instrument air to the

positioner, turning zero adjustment screw until valve

seats at 3 psi. Full travel within tolerances governed by

the range spring should occur on ATO or ATC valves

using the standard 3-15, 3-9, 9-15, etc. instrument signal.

NOTE: Factory zero adjustments are made on Research

Control Valves with positioners, using 90 PSIG air

pressure piped to the upstream valve port, connecting

a Tygon or rubber tubing to the downstream port and

immersing the end in a water filled container to detect

any leakage across the seat during zero adjustment.

Servicing

Badger’s valve positioners must be isolated from the

system before service or removal can be accomplished.

(Recommended procedure is to move complete valve

with positioner to instrument repair bench where

necessary tools and manual set air regulators are

available.)

Bottom Loading, Air-to-Open

Air pressure from control instrument is inserted between

the dual upper diaphragms and the center diaphragm.

Because of the difference in the two diaphragm areas,

the resultant force is exerted in a downward direction.

In balance condition, the pneumatic force on the

diaphragm, plus the downward force exerted by the zero

adjustment spring, is balanced by the upward force of

the range spring. In balance condition, positioner vents

to atmosphere.

When control-instrument pressure increases, the

diaphragm assembly will move downward allowing the

spool valve to close the exhaust port and allow the

supply air to pass through interior porting to the bottom

side of the diaphragm or piston in the actuator. The

supply air will drive the actuator upward. As the actuator

moves up, the range spring will compress until its force

increases enough to offset the increase in controlinstrument pressure causing the spool valve to move,

shutting off supply air to the actuator and opening

exhaust.

Adjusting Zero

To clean pilot or spool valve, remove brass hex head

sealing screw under top cap and with small sharp nose

pliers, tweezers or other device, remove and clean pilot

or spool valve and replace. On air-to-close TLDA and

Moore 73N positioners, the pilot is a one piece unit that

seldom fails due to dirty air or material such as Teflon

tape getting into the pilot and causing malfunction. On

air-to-open BLRA and Moore 73B positioners, the

functional clearances around the spool valve is very

close and more likely to fail due to dirty air or Teflon

tape. Clearance is a function of bleed and must be close

as possible, but large enough to function. To replace

the diaphragm assembly, it is necessary to unscrew

the six screws holding the positioner to the adaptor and

remove the positioner assemble. Invert positioner and

remove the two assembly screws in the bottom ring.

When assembling the positioner diaphragm assembly

to the main housing, make sure to align index grooves.

Positioners must be correctly assembled in order to

function. Individual sub-assemblies such as the

diaphragm assembly should be replaced as one unit.

For ATC valves with type TLDA or Moore 73N12F

positioners, zero adjustment is made with 15 psi

instrument air (for 12 psi span) to the positioner, turning

zero adjustment screw until valve seats at 15 psi. For

10

Page 13

TERMINOLOGY

PCV -

Pressure Control Valve

LCV -

Level Control Valve

TCV -

Temperature Control Valve

FCV -

Flow Control Valve

Topworks (Actuator) -

Positioner -

ATO -

ATC -

F/O -

N/O -

F/C -

N/C -

Body Bonnet Assy -

Instrument added or attached to topworks for more precise control

Air to Open. Increasing air signal opens valve

Air to Close. Increasing air signal closes valve

(Fail Open) Valve opens on air failure

(Normally Open) Valve opens on air failure

(Fail Close) Valve closes on air failure

(Normally Close) Valve closes on air failure

The assembly that provides force

That assembly consisting of body, bonnet, gasket, innervalve, stem, seat, packing,

gland and yoke nut

Trim Set -

=% -

Lin. -

Q.O. -

P1 -

P2 -

HP -

The interchangeable components in a set consisting of innervalve, stem and seat

Equal Percentage. Lift versus flow characteristic

Linear lift versus flow characteristics

Opening - ON-OFF service

lnlet pressure to valve

Downstream pressure from valve

Delta P - Pressure drop across valve

Cv -

Flow Coefficient - Water flow at 1 PSI pressure drop

Chevron Rings -

Braid Tef. -

Packing, molded V-rings (normally 3 per set)

Packing, rope-type braided Teflon with Teflon suspensoid lubricant

11

Page 14

Notes

12

Page 15

Special Information

Use this page for recording special operator information not included in the preceding (i.e., internal and supplier phone

numbers, addreses, etc.)

13

Page 16

Please see our website at

www.badgermeter.com

for specific contacts.

Copyright © Badger Meter, Inc. 2002. All rights reserved, all data subject to change without notice.

Due to continuous research, product improvements and enhancements,

Badger Meter reserves the right to change product or system specifications

without notice, except to the extent an outstanding bid obligation exists.

BadgerMeter,Inc.

6116 E. 15th Street, Tulsa, Oklahoma 74112

(918) 836-8411 / Fax: (918) 832-9962

®

www.badgermeter.com

Loading...

Loading...