Page 1

Recordall® Turbo Series Meters

Models 160 (1-1/2 in.), 200 (2 in.), 450 (3 in.), 1000 (4 in.),

2000 (6 in.), 3500 (8 in.), 5500 (10 in.) and 6200 (12 in.)

NSF/ANSI Standards 61 and 372 Certied

DESCRIPTION

Recordall Turbo Series meters meet or exceed the most recent

revision of AWWA Standard C701 Class II Standards and are

available in a lead-free bronze alloy for sizes 1-1/2 in. through 10 in.

and cast iron for 12 in. meters. Turbo Series meters comply with the

lead-free provisions of the Safe Drinking Water Act. Sizes

1-1/2 in. through 10 in. meters are also certified to NSF/ANSI

Standards 61 and 372 (Trade Designation: Turbo Series LL-NS)

and carry the NSF-61 mark on the housing. All components of the

lead-free alloy meter (housing, measuring element, seals and so on)

comprise the certified system.

Models 160 through 6200 are designed for 1-1/2 in. through

12 in. applications. These meters feature:

• Direct coupled turbine based on an exclusive in.floating rotor

in. design that reduces bearing friction—and associated wear

and tear.

• Low pressure loss for improved system efficiency.

• Exceptional registration accuracy across low flow rate, normal

operating flow rate and maximum continuous operation flow.

• Permanently sealed, tamper-resistant register or encoder.

• Integral strainer option for sizes 1-1/2 in. through 4 in.

help protect your system from damaging debris and

related downtime.

• Meters and encoders are compatible with Badger Meter

AMR/AMI meter reading systems and other approved

reading technologies.

Applications: Recordall Turbo Series meters are designed for

cold water, commercial and industrial applications where flows

are consistent medium to high flows. Applications include hotels,

apartment buildings, irrigations centers and manufacturing and

processing plants. Turbo Series meters help reduce

day-to-day maintenance costs while delivering accurate and

efficient performance.

Operation & Performance: Direct magnetic drive is achieved

when the magnet carrier is driven by a gear train coupled to

the rotor. The gear train consists of two sets of gears connected

by a vertical transmission shaft. One gear set is at the magnet

carrier, the other is a worm gear set at the rotor shaft. When

water flows into the Turbo Series meter measuring element, it

contacts the multi-vaned rotor. The resulting rotor rotation is

then transmitted by magnetic coupling to a sealed register or

encoder. The direct magnetic drive is built to provides a reliable

meter-to-registration coupling.

Tamper-Proof Features: Unauthorized removal of the register

or encoder is inhibited by the option of a tamper detection seal

wire screw, TORX® tamper-resistant seal screw or the proprietary

tamper-resistant keyed seal screw. Each can be installed at the

meter site or at the factory.

Construction: The Recordall Turbo Series meter is constructed in

compliance with ANSI and AWWA C701 standards. It consists of

the following basic components: meter housing, interchangeable,

unitized measuring element and permanently sealed direct

reading registers or encoders.

The measuring element consists of the transmission coupling,

rotor, inlet and outlet straightening vanes with nose cones, and

calibration ring assembly. The unique inlet and outlet straightening

vanes minimize swirl from piping arrangements upstream as well

as downstream.

A strainer is recommended to help ensure optimal flow

conditioning and protection for the measuring element. An

integral strainer is available as an option for 1-1/2 in. through 4 in.

meter sizes. The stainless steel strainer is built into the inlet end and

includes a removable cover plate to permit easy access for routine

cleaning. External strainers are available in sizes 2 in. through 12 in.

To simplify maintenance, the registers or encoders and measuring

elements can be removed without removing the meter housing.

Interchangeability of certain parts between meters also minimizes

spare parts inventory investment.

Meter Installation: The meter is designed for installations where

flow is in one direction only. Companion flanges for installation of

meters on various pipe types and sizes are available in cast iron or

NL bronze as an option. See the "Recordall Turbo Series Meters User

Manual" for specific instructions.

RTS-DS-00320-EN-06 (November 2016)

Product Data Sheet

Page 2

Recordall® Turbo Series Meters

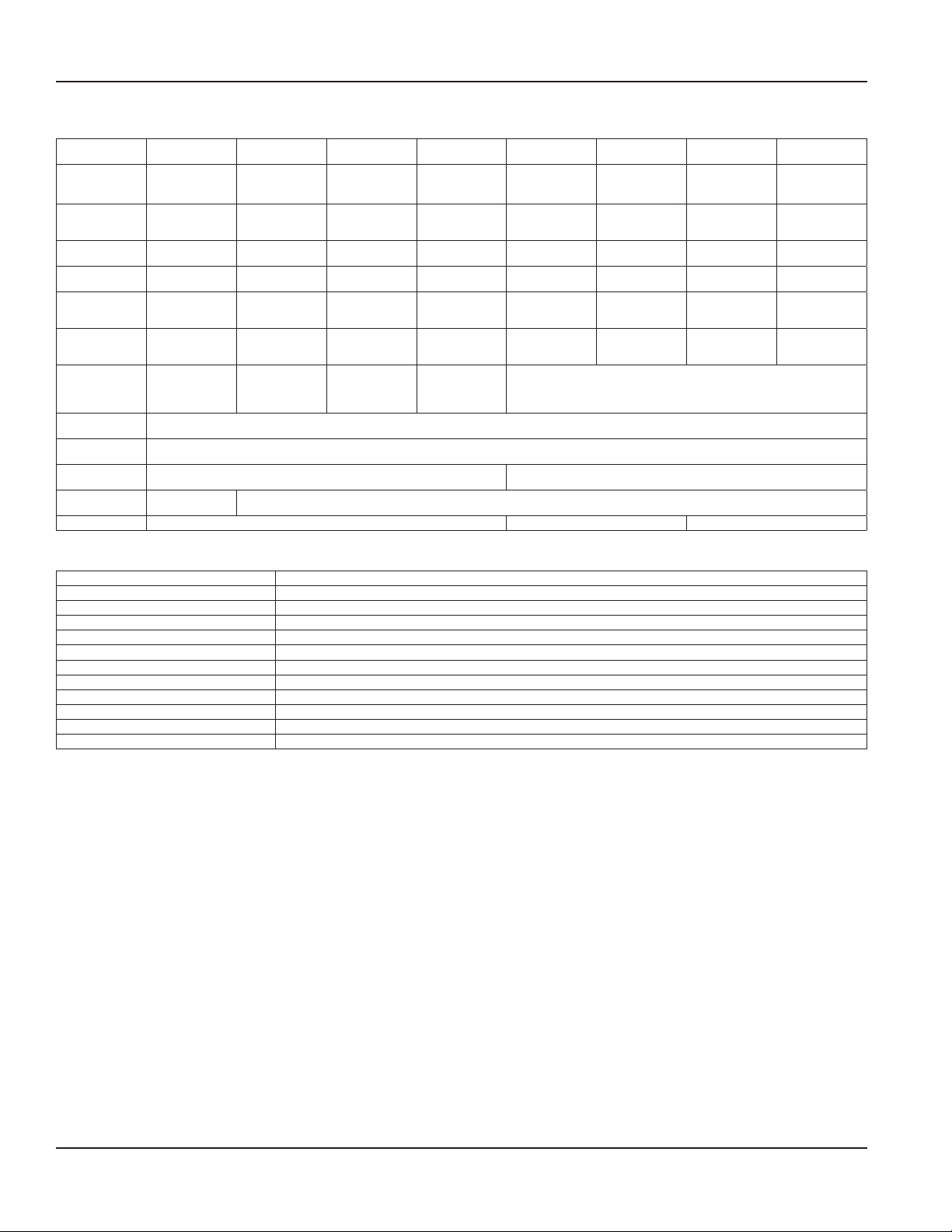

SPECIFICATIONS

Turbo Series

Model

Meter Flanges

AWWA 125

Pound Class

Typical

Operating Range

(100% ± 1.5%)

Typical Low Flow

(95% min.)

Max. Continuous

Flow

Maximum

Intermittent

Flow

Pressure Loss at

Max. Continuous

Flow

Pressure Loss at

Max. Continuous

Flow: With

Integral Strainer

Max. Operating

Pressure

Max. Operating

Temperature

Optional Integral

Strainer

Optional

External Strainer

Test Plug Standard with integral strainer; optional for other models. Optional for Models 2000 and 3500. —

160

1-1/2 in. (40 mm)

Elliptical Elliptical or Round Round Round Round Round Round

4…200 gpm

(0.9…45.4 m3/h)

2.5 gpm (0.6 m3/h) 2.5 gpm (0.6 m3/h) 4 gpm (0.9 m3/h) 6 gpm (1.4 m3/h) 12 gpm (2.7 m3/h) 20 gpm (4.5 m3/h) 30 gpm (6.8 m3/h)

160 gpm

(36 m3/h)

200 gpm

(45.4 m3/h)

3.8 psi (0.26 bar) 3.1 psi (0.21 bar) 1.8 psi (0.12 bar) 7.3 psi (0.50 bar) 4.8 psi (0.33 bar) 2.5 psi (0.17 bar) 1.6 psi (0.11 bar) 0.8 psi (0.05 bar)

9.9 psi (0.68 bar) 8.3 psi (0.57 bar) 5 psi (0.43 bar) 17.8 psi (1.2 bar) —

Removable cover plate permits access to strainer for cleaning.

— Available for Models 200, 450, 1000, 2000, 3500, 5500 and 6200.

200

2 in. (50 mm)

4…310 gpm

(0.9…70.4 m3/h)

200 gpm

(45.4 m3/h)

310 gpm

(70.4 m3/h)

Built into inlet end.

450

3 in. (80 mm)

5…550 gpm

(1.1…124.9 m3/h)

450 gpm

(102.2 m3/h)

550 gpm

(124.9 m3h)

1000

4 in. (100 mm)

10…1250 gpm

(2.3…284 m3/hr)

1000 gpm

(227.1 m3/h)

1250 gpm

(284 m3h)

150 psi (10 bar)

120° F (49° C)

2000

6 in. (150 mm)

20…2500 gpm

(4.5…568 m3/h)

2000 gpm

(454 m3/h)

2500 gpm

(568 m3/h)

3500

8 in. (200 mm)

30…4500 gpm

(6.8…1022 m3/h)

3500 gpm

(795 m3/h)

4500 gpm

(1022 m3/h)

5500

10 in. (250 mm)

50…7000 gpm

(11.4…1590 m3/h)

5500 gpm

(1250 m3/h)

7000 gpm

(1590 m3h)

—

6200

12 in. (300 mm)

Round

AWWA 125 lb

class

90…8800 gpm

(20.5…1998 m3/h)

65 gpm

(14.8 m3/h)

6200 gpm

(1408 m3/h)

8800 gpm

(1988 m3/h)

MATERIALS

Meter Housing Lead-free alloy (EXCEPTION: Model 6200 meter housing is blue epoxy-coated cast iron)

Turbo Head Lead-free alloy

Nose Cone & Straightening Vanes Thermoplastic

Rotor Thermoplastic

Rotor Radial Bearings Lubricated thermoplastic

Rotor Thruster Bearing Sapphire jewels

Rotor Bearing Pivots Passivated 316 stainless steel

Calibration Mechanism Stainless steel & thermoplastic

Magnet Ceramic

Trim Stainless steel

Register Housing & Cover Thermoplastic or bronze

Optional Strainer and Trim Stainless steel

Page 2 November 2016RTS-DS-00320-EN-06

Page 3

Product Data Sheet

0

0,1

0,4

0,5

0,6

0,7

0,8

0,9

0,2

0,3

Badger Meter

®

64085-009

®

T-160

Recordall

m

3

1-1/2"

0

1

4

5

6

7

8

9

2

3

Badger Meter

®

64085-023

®

T-2000

Recordall

m

3

6"

0

1

4

5

6

7

8

9

2

3

Badger Meter

®

64085-045

®

T-6200

Recordall

m

3

12"

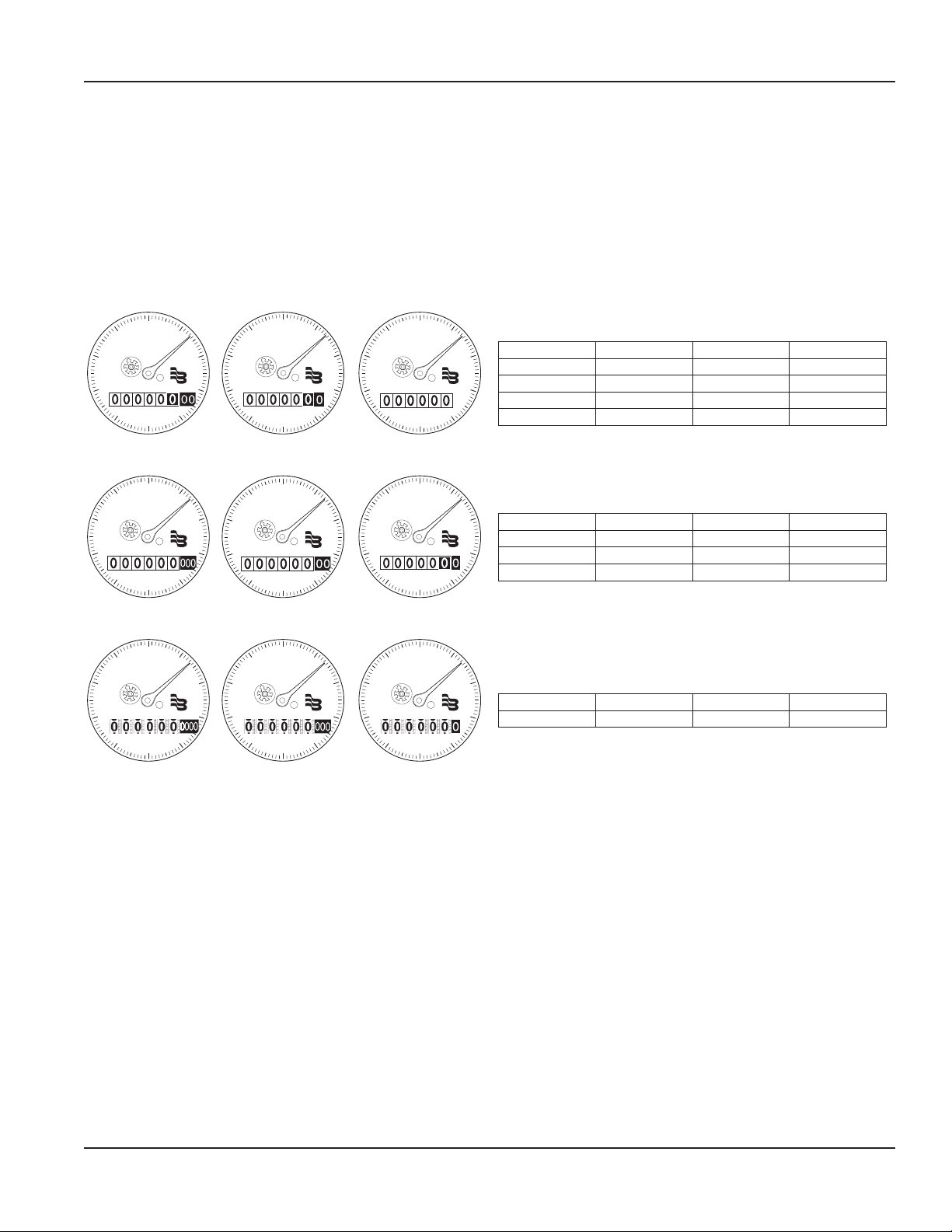

REGISTERS / ENCODERS

Standard—Sweep-Hand Registration

The standard register is a straight-reading, permanently sealed magnetic drive register. Dirt, moisture, tampering and lens fogging

problems are eliminated. The register has a six-odometer wheel totalization display, 360° test circle with center sweep hand, and flow finder

to detect leaks. Register gearing is made of self-lubricating engineered polymer, which minimizes friction and provides long life. The multiposition register simplifies meter installation and reading. The register capacity for the 1-1/2 in., 2 in., 3 in. and 4 in. meters is 100,000,000

gallons (10,000,000 ft3, 1,000,000 m3). The register capacity for the 6 in., 8 in., and 10 in. meters is 1,000,000,000 gallons (100,000,000 ft3,

10,000,000 m3). The high-flow register capacity for the 12 in. meter is 10,000,000,000 gallons (1,000,000,000 ft3, 10,000,000 m3).

Registers for 1-1/2 in., 2 in., 3 in. and 4 in. Meters

9

6

0

Recordall

T-160

1-1/2"

Cubic Feet

5

1

®

Badger Meter

®

4

80

64085-001

70

0

Recordall

1-1/2"

Gallons

T-160

50

10

®

8

20

Badger Meter

®

64085-005

30

7

40

90

60

Registers for 6 in., 8 in. and 10 in. Meters

800

64085-017

700

900

600

Recordall

T-2000

6"

Gallons

500

0

100

®

200

300

80

64085-020

70

Badger Meter

®

400

90

60

0

Recordall

T-2000

6"

Cubic Feet

50

10

®

Badger Meter

®

40

Registers for 12 in. Meters

8000

64085-043

7000

9000

6000

Recordall

T-6200

12"

Gallons

5000

0

1000

®

Badger Meter

®

®

2000

3000

800

64085-044

700

4000

900

600

0

Recordall

T-6200

12"

Cubic Feet

500

100

®

Badger Meter

®

400

200

300

Sweep Hand Revolution

2

3

Meter Model Gallon Cubic Feet Cubic Meter

160 100 10 1

200 100 10 1

450 100 10 1

1000 100 10 1

Sweep Hand Revolution

20

30

Meter Model Gallon Cubic Feet Cubic Meter

2000 1000 100 10

3500 1000 100 10

5500 1000 100 10

Sweep Hand Revolution

Meter Model Gallon Cubic Feet Cubic Meter

6200 10000 1000 10

Optional—Encoders for AMR/AMI Reading Solutions

AMR/AMI solutions are available for all Recordall Disc Series meters. All reading options can be removed from the meter without

disrupting water service. Badger Meter encoders provide years of reliable, accurate readings for a variety of applications and are also

available pre-wired to Badger Meter approved AMR/AMI solutions. See details at www.badgermeter.com.

Page 3 November 2016 RTS-DS-00320-EN-06

Page 4

Recordall® Turbo Series Meters

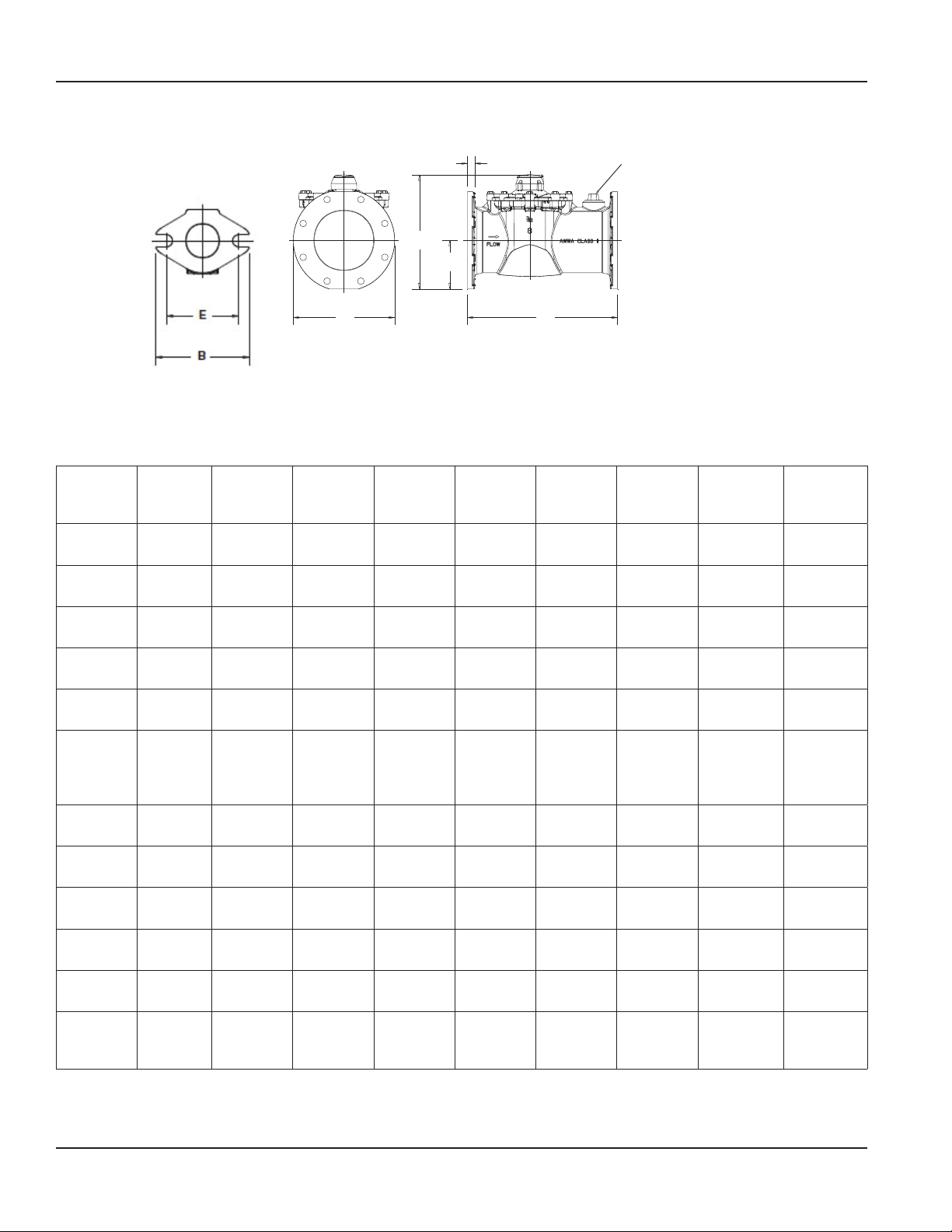

PHYSICAL DIMENSIONS OF METERS WITHOUT STRAINER

Turbo

Series

Model

Meter

Flanges

Meter &

Pipe Size

Net

Weight

Shipping

Weight

Qty. of

Bolts

NPT Test

Port &

Test Plug

(optional)

Length

(A)

Width

(B )

Height

(C)

Flange

(D)

Bolt Circle

(E)

Centerline

(F)

D

NPT Test Port & Test Plug

(1-1/2 . . . 8”)

C

F

B A

Figure 1: Sample Illustration from 8 in. Model 3500

160 200 200 450 1000 2000 3500 5500 6200

1-1/2 in.

Elliptical

1-1/2 in.

(40 mm)

14.3 lb

(6.5 kg)

16.8 lb

(7.6 kg)

2 2 4 4 8 8 8 12 12

1 in.

(25.4 mm)

13 in.

(330 mm)

5-7/32 in.

(133 mm)

6-9/32 in.

(159 mm)

51/64 in.

(20 mm)

4 in.

(102 mm)

1-27/32

in.

(47 mm)

2 in.

Elliptical

2 in.

(50 mm)

14.9 lb

(6.8 kg)

16.4 lb

(7.4 kg)

1-1/2 in.

(40 mm)

10 in.

(254 mm)

5-27/32 in.

(148 mm)

6-1/2 in.

(165 mm)

25/32 in.

(20 mm)

4-1/2 in.

(114 mm)

2-1/16 in.

(52 mm)

2 in. Round 3 in. Round 4 in. Round 6 in. Round 8 in. Round

2 in.

(50 mm)

17.4 lb

(7.9 kg)

18.9 lb

(8.6 kg)

1-1/2 in.

(40 mm)

10 in.

(254 mm)

6 in.

(152 mm)

7-3/32 in.

(180 mm)

5/8 in.

(16 mm)

4-3/4 in.

(121 mm)

2-5/8 in.

(67 mm)

3 in.

(80 mm)

31 lb

(14.1 kg)

34 lb

(15.4 kg)

2 in.

(50 mm)

12 in.

(305 mm)

7-1/2 in.

(191 mm)

8-11/16 in.

(220 mm)

3/4 in.

(19 mm)

6 in.

(152 mm)

3-11/32 in.

(85 mm)

4 in.

(100 mm)

40 lb

(18.1 kg)

45 lb

(20.4 kg)

2 in.

(50 mm)

14 in.

(356 mm)

9 in.

(229 mm)

9-21/32 in.

(245 mm)

13/16 in.

(21 mm)

7-1/2 in.

(191 mm)

4-5/16 in.

(109 mm)

6 in.

(150 mm)

77 lb

(35 kg)

89 lb

(40.4 kg)

2 in.

(50 mm)

18 in.

(457 mm)

11 in.

(280 mm)

13-5/16 in.

(338 mm)

7/8 in.

(22 mm)

9-1/2 in.

(241 mm)

5-1/4 in.

(133 mm)

8 in.

(200 mm)

123 lb

(55.7 kg)

147 lb

(66.6 kg)

2 in.

(50 mm)

20 in.

(508 mm)

13-1/2 in.

(343 mm)

15-3/16 in.

(385 mm)

1 in.

(25 mm)

11-3/4 in.

(298 mm)

6-3/8 in.

(162 mm)

10 in.

Round

10 in.

(250 mm)

210 lb

(95.3 kg)

235 lb

(106.6 kg)

— —

26 in.

(660.4 mm)

16 in.

(406.4 mm)

17-15/32 in.

(443 mm)

1-1/16 in.

(27 mm)

14-1/4 in.

(362 mm)

7-7/8 in.

(199.4 mm)

19-11/16 in.

19-11/16 in.

12 in.

Round

12 in.

(300 mm)

262 lb

(118.8 kg)

286 lb

(129.7 kg)

(500 mm)

19 in.

(482 mm)

(500 mm)

1.26 in.

(32 mm)

17 in.

(432 mm)

8-7/8 in.

(226 mm)

Page 4 November 2016RTS-DS-00320-EN-06

Page 5

Product Data Sheet

PHYSICAL DIMENSIONS OF METERS WITH INTEGRAL STRAINER

Figure 2: Physical dimensions

Turbo Series Model 160 200 200 450 1000

Meter Flanges Elliptical Elliptical Round Round Round

Meter & Pipe Size 1-1/2 in. (40 mm) 2 in. (50 mm) 2 in. (50 mm) 3 in. (80 mm) 4 in. (100 mm)

Net Weight 14.3 lb (6.5 kg) 24 lb (11 kg) 26 lb (12 kg) 49 lb (22 kg) 60 lb (27.22 kg)

Shipping Weight 16.8 lb (7.6 kg) 28 lb (13 kg) 30 lb (14 kg) 55 lb (25 kg) 70 lb (31.75 kg)

Number of Bolts 2 2 4 4 8

NPT Test Port

& Test Plug

(Standard)

Length (A) 13 in. (330 mm) 17 in. (432 mm) 17 in. (432 mm) 19 in. (483 mm) 23 in. (584 mm)

Width (B ) 5-7/32 in. (133 mm) 5-27/32 in. (148 mm) 6 in. (152 mm) 7-1/2 in. (191 mm) 9 in. (229 mm)

Height (C) 6-9/32 in. (159 mm) 6-1/2 in. (165 mm) 7-3/32 in. (180 mm) 8-15/16 in. (227 mm) 9-21/32 in. (245 mm)

Flange (D) 51/64 in. (20 mm) 27/32 in. (47 mm) 5/8 in. (16 mm) 27/32 in. (21 mm) 13/16 in. (21 mm)

Bolt Circle (E) 4 in. (102 mm) 4-1/2 in. (114 mm) 4-3/4 in. (121 mm) 6 in. (152 mm) 7-1/2 in. (191 mm)

Centerline (F) 1-27/32 in. (47 mm) 2-1/16 in. (52 mm) 2-5/8 in. (67 mm) 3-19/32 in. (91 mm) 4-5/16 in. (109 mm)

1 in. (25.4 mm) 1-1/2 in. (40 mm) 1-1/2 in. (40 mm) 2 in. (50 mm) 2 in. (50 mm)

Page 5 November 2016 RTS-DS-00320-EN-06

Page 6

Recordall® Turbo Series Meters

Pressure Loss

PSI

1 10 100 1000 10000

25

20

15

10

5

0

1.5 in.

2 in.

3 in.

4 in.

6 in.

8 in.

10 in.

12 in.

PRESSURE LOSS CHART FOR METERS WITHOUT STRAINER

Rate of flow in gallons per minute (gpm)

PRESSURE LOSS CHART FOR METERS WITH INTEGRAL STRAINER

Rate of flow in gallons per minute (gpm)

2 4 6 8 20 40 60 80 200 800600400

25

20

15

P.S.I.

10

Pressure Loss

5

0

10 100 10001

1.5”

1.5”

2”

4”

3”

Page 6 November 2016RTS-DS-00320-EN-06

Page 7

ACCURACY CHARTS FOR METERS WITHOUT STRAINER

Accuracy Per Cent

1

100

100010

Under

1

100

100010

110100 1000 10000

Rate of flow in gallons per minute (gpm)

Product Data Sheet

1-1/2 in. Meter

2 in. Meter

10

5

Over

Register

+

0

-

5

10

Under

Register

15

10

5

Over

Register

+

0

-

5

Accuracy Per Cent

10

Register

15

2468 20 40 60 80

2468 20 40 60 80

200 400 600 800

200 400 600 800

3 in. Meter

4 in. Meter

2648 20 40 60 80 200400 800 2000600 3000 8000

10

5

Over

Register

+

0

-

5

10

Accuracy Per Cent

Under

Register

15

Page 7 November 2016 RTS-DS-00320-EN-06

Page 8

Recordall® Turbo Series Meters

100

10

10000

1000

Accuracy Per Cent

Register

Under

ACCURACY CHARTS FOR METERS WITHOUT STRAINER CONTINUED

Rate of flow in gallons per minute (gpm)

6 in. Meter

Over

Register

Accuracy Per Cent

Undar

Register

8 in. Meter

10 in. Meter

12 in. Meter

1 10 100 1000 10000

10

5

Over

Register

+

0

-

5

Accuracy Per Cent

10

Under

Register

15

10

5

Register

Over

+

0

-

5

10

15

4 6 8 20 40 60 80 200 4002 600 800 2000 4000 6000 8000

80604020

800600400200

8000600040002000

Page 8 November 2016RTS-DS-00320-EN-06

Page 9

ACCURACY CHARTS FOR METERS WITH INTEGRAL STRAINER

100 10001 10

Accuracy Per Cent

Rate of flow in gallons per minute (gpm)

Product Data Sheet

1-1/2 in. Meter

2 in. Meter

10

5

Over

Register

+

0

-

5

10

Accuracy Per Cent

Under

Register

15

1 100 100010

10

5

Over

Register

+

0

-

5

10

Under

Register

15

2 4 6 8 20 40 60 80 200 400 600 800

2 4 6 8 20 40 60 80 2OO 400 600 800

3 in. Meter

4 in. Meter

Page 9 November 2016 RTS-DS-00320-EN-06

Page 10

Recordall® Turbo Series Meters

INTENTIONAL BLANK PAGE

Page 10 November 2016RTS-DS-00320-EN-06

Page 11

INTENTIONAL BLANK PAGE

Product Data Sheet

Page 11 November 2016 RTS-DS-00320-EN-06

Page 12

Recordall® Turbo Series Meters

Making Water Visible®

MAKING WATER VISIBLE and RECORDALL are registered trademarks of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities.

Due to continuous research, product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the

extent an outstanding contractual obligation exists. © 2016 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Czech Republic | Badger Meter Czech Republic s.r.o. | Maříkova 2082/26 | 621 00 Brno, Czech Republic | +420-5-41420411

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 21-04 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | 7-1202 | 99 Hangzhong Road | Minhang District | Shanghai | China 201101 | +86-21-5763 5412

Switzerland I Badger Meter Swiss AG I Mittelholzerstrasse 8 I 3006 Bern I Switzerland I +41-31-932 01 11 Legacy Document Numbers: RTS-T-1-1/2. 3. 4. 6. 8. 10 and 12; RTS-T-I 1-1/2, 2, 3, and 4

Loading...

Loading...