Page 1

Recordall® Combo Meter

Lead-Free Bronze Alloy, Size 8"

NSF/ANSI Standards 61 and 372 Certied

DESCRIPTION

The Badger Meter Recordall Combo meters meet or exceed the

most recent revision of AWWA Standard C700 and are available

in a lead-free bronze alloy. The Combo meters comply with the

lead-free provisions of the Safe Drinking Water Act, are certified to

NSF/ANSI Standards 61 and 372 (Trade Designation: Combo-01)

and carry the NSF-61 mark on the housing. All components of the

lead-free bronze alloy meter (housing, measuring element, seals,

and so on) comprise the certified system.

The Combo meter combines two metering technologies in one

innovative package. A positive displacement chamber measures

low flow, while a turbine chamber records high flow.

The 8-inch Combo meter features:

• Spring-loaded check valve to facilitate one-way water flow

through appropriate measurement chambers, in line

with demand.

• Permanently sealed, tamper-resistant register or encoder.

• Meters and encoders that are compatible with Badger Meter

AMR/AMI systems and other approved reading technologies

Badger Meter ORION® and GALAXY® AMR/AMI meter reading

systems are available for all Combo meters. Itron® ERT reading

systems are also available. An optional summator can be provided

as an integral part of the register assembly. All register options are

removable from the meter without disrupting water service.

TAMPERPROOF FEATURES

Unauthorized removal of the register or encoder is inhibited by

the use of an optional tamper detection seal wire screw, TORX®

tamper-resistant seal screw or the proprietary tamper-resistant

keyed seal screw. Each can be installed at the meter site or at

the factory.

Rotor and disc movements are transmitted by magnetic drive

couplings to individual register odometers. The direct magnetic

drive provides a positive, reliable and dependable register coupling

for straight-reading or remote reading options. The self-lubricating

thermoplastic register gearing is designed to minimize friction and

provide long life.

OPERATING PERFORMANCE

The Recordall Combo meter meets or exceeds registration accuracy

for low, normal operating, maximum continuous operation, and

changeover flow rates as specified in AWWA Standard C702.

CONSTRUCTION

The Recordall Combo meter’s construction complies with ANSI and

AWWA C702 standards. It consists of a stainless steel spool with

bypass port, turbine measuring chamber, a check valve with bypass

piping, a disc measuring chamber, valve assembly, and sealed

direct reading registers. To simplify maintenance, the registers and

measuring elements can be removed without removing the meter

housing from the line.

APPLICATIONS

Use the Recordall Combo meter for measuring potable cold

water in commercial and industrial applications where flow is in

one direction only. The meter is an ideal choice for facilities that

experience rapid and wide fluctuations in water demand, such as

hospitals, universities, residential complexes and manufacturing or

processing facilities.

OPERATION

As water enters the meter at low flow rates, a spring-loaded

check valve on the downstream side holds the clapper assembly

in a closed position. Water is diverted through a bypass to the

disc measuring chamber. As the flow rate increases, a pressure

differential is created that opens the check valve and allows water

to flow through the turbine chamber. A small amount of water will

continue to flow through the bypass when the clapper assembly is

fully open.

RCO-DS-00079-EN-02 (October 2013)

METER INSTALLATION

The meter is designed for installations where flow is in one

direction only. A separate strainer is required to ensure optimum

flow conditioning and protection of the measuring element.

Companion flanges for installation of meters on various pipe types

and sizes are available in cast iron or NL bronze as an option.

Product Data Sheet

Page 2

Recordall® Combo Meter, Size 8"

REGISTERS / ENCODERS

Standard—Sweep-Hand Registration

The standard register is a straight-reading, permanently sealed magnetic drive register. Dirt, moisture, tampering and lens fogging

problems are eliminated. The register has a six-odometer wheel totalization display, 360° test circle with center sweep hand, and flow finder

to detect leaks. Register gearing is made of self-lubricating engineered polymer, which minimizes friction and provides long life. The multiposition register simplifies meter installation and reading. The register capacity is 100,000,000 gallons (10,000,000 ft3, 1,000,000 m3).

Optional—Encoders for AMR/AMI Reading Solutions

AMR/AMI solutions are available for all Recordall Combo meters. All reading options can be removed from the meter without disrupting

water service. Badger Meter encoders provide years of reliable, accurate readings for a variety of applications and are also available prewired to Badger Meter approved AMR/AMI solutions. See details at www.badgermeter.com.

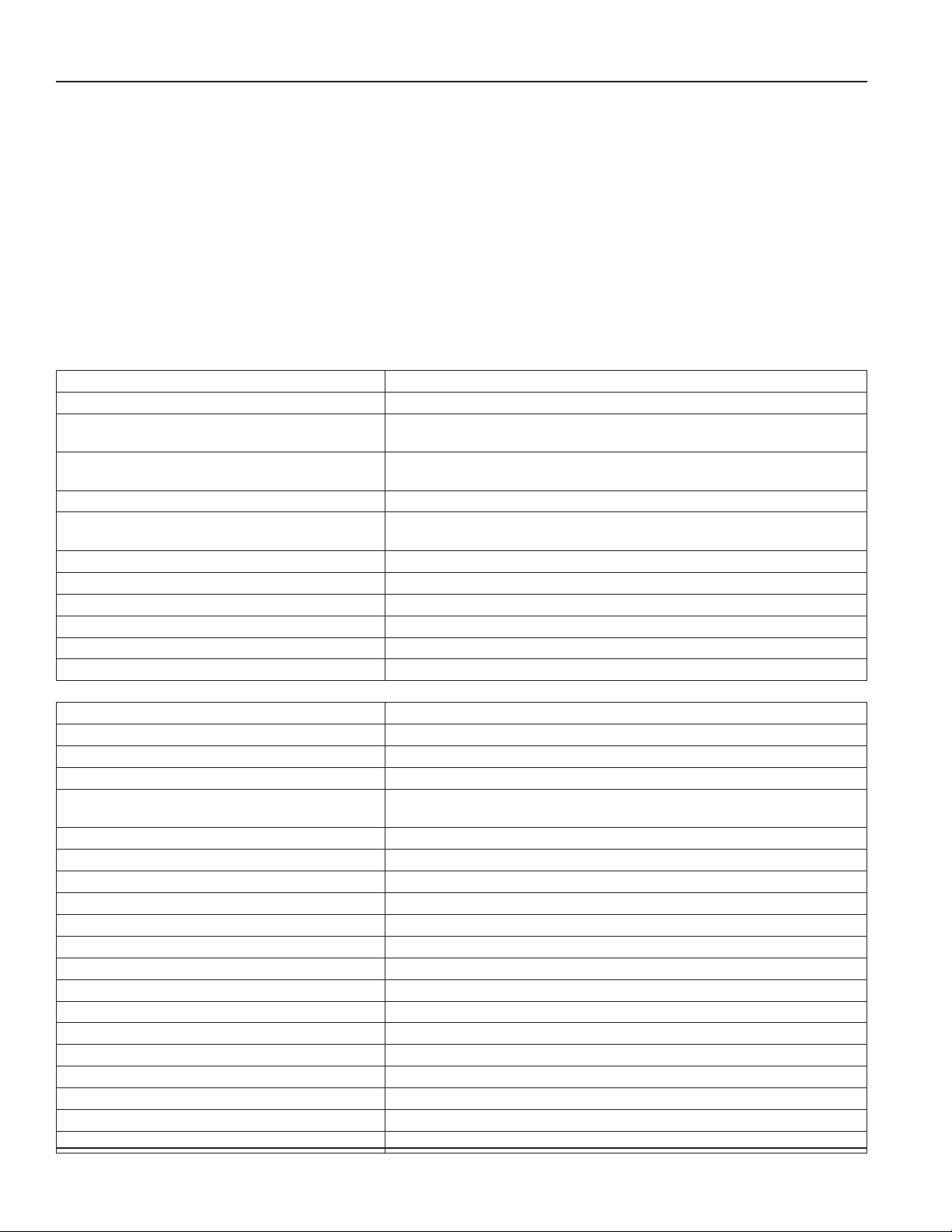

SPECIFICATIONS

Combo Meter Model 8" Model (200 mm)

Meter Flange, AWWA Class D (C-207) 8" (200 mm)

Typical Operating Range

(100% ± 1.5%)

Low Flow Registration

(95% minimum)

Maximum Continuous Flow 3500 gpm (795 m3/h)

Pressure Loss at Maximum Continuous Flow 6.3 psi at 3500 gpm

Pressure Loss at Crossover 2 psi (0.138 bar)

Minimum Crossover Accuracy 90%

Maximum Operating Pressure 150 psi (10 bar)

Maximum Operating Temperature 105° F (40° C)

Check Valve Conforms to UL 312 and FM 1045

Bypass Line Specify right-facing (standard, as shown) or left-facing assembly

Materials

Meter Housing Fusion-bonded epoxy coated ductile cast iron

Bypass Meter Housing Lead-free bronze alloy

Bypass Measuring Chamber Injection-molded thermoplastic

Bypass Brass piping conforming to AWWA C800, NSF 61 & 372 compliant

Spool Body Stainless steel, with stainless steel bypass port.

Nose Cone & Straightening Vanes Thermoplastic

Rotor Thermoplastic

Rotor Radial Bearings Lubricated thermoplastic

Rotor Thrust Bearing Sapphire jewels

Rotor Bearing Pivots Passivated 316 stainless steel

Calibration Mechanism Stainless steel & thermoplastic

Magnet Ceramic

Clapper Assembly (clapper, spring, hinge & pins) Stainless steel

Clapper Seal Elastomeric, EPDM

Valve Seat Stainless steel

Valve Body & Cover Plate Fusion-bonded epoxy coated steel

Valve Cover Plate Gasket Elastomeric sheet

Register Housing & Cover Thermoplastic or bronze

Trim Zinc-plated stainless steel or (optional) all stainless steel.

Test Plug, 2" Stainless steel or lead-free bronze

2.5…4500 gpm

(0.56…1022 m3/h)

1.25 gpm (0.28 m3/h)

(0.43 bar at 795 m3/h)

Standard steel flange connections with zinc chromate plating.

Page 2 October 2013

Page 3

PHYSICAL DIMENSIONS

B

CENTER LINE

OF MAINLINE

Product Data Sheet

C

A

Combo Meter Model 8" Model (200 mm)

Meter & Pipe Size 8" (200 mm)

Shipping Weight (fully assembled) 357 lb (162 kg)

Length (A) 41-7/8" (1063 mm)

Height (B ) 19-1/2" (495 mm)

Height (C) 6-3/4" (171 mm)

Width (D) 23-3/4" (603 mm)

Width (E) 17" (732 mm)

D

E

Page 3 October 2013

Page 4

PRESSURE LOSS CHART

1

10

100

1000

10000

1 10 100 1000 10000

Rate of flow in gallons per minute (gpm)

2468

25

20

15

PSI

10

Pressure Loss

5

0

ACCURACY CHART

Rate of flow in gallons per minute (gpm)

2468 20

10

20 40 60 80 200

40 60 80

200 400 800

400 600 800

600

2000 4000 6000 8000

2000 4000 6000 8000

5

Over

Register

+

0

-

5

Accuracy Percent

10

Under

Register

15

GALAXY, ORION, and Recordall are registered trademarks of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities.

Due to continuous research, product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the

extent an outstanding contractual obligation exists. © 2013 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Czech Republic | Badger Meter Czech Republic s.r.o. | Maříkova 2082/26 | 621 00 Brno, Czech Republic | +420-5-41420411

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 21-04 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | 7-1202 | 99 Hangzhong Road | Minhang District | Shanghai | China 201101 | +86-21-5763 5412 Legac y Document Number: RCM-T-08

Loading...

Loading...