Page 1

Coriolis Flow Meter

RCT1000 with RCS005 and RCS008 Sensors

DESCRIPTION

The RCT1000 Coriolis mass flow meter identifies flow rate by

directly measuring mass flow and density of fluids over a wide

range of process temperatures with a high degree of accuracy. For

homogenous fluids consisting of two components like sugar and

water, the RCT1000 Coriolis system can derive the concentration

and mass of each component based on fluid properties and density

measurement. Furthermore, the unobstructed, open flow design

makes it suitable for a variety of fluids such as slurries and other

viscous, nonconductive fluids that are difficult to measure with

other technologies.

APPLICATIONS

The Coriolis design and measurement principle allows the meter to

be an exceptional device in measuring:

• Adhesives, glues or binding materials

• Coatings and hardeners

• Dyes, fragrances, vitamins and other additives

• Homogeneous suspensions

• Vegetable oils and fats

OPERATION

Coriolis flow meters simultaneously measure mass flow rate,

density and temperature. As fluid flows through the vibrating

sensor tube, forces induced by the flow cause the tube to twist

slightly. These small deflections are measured by carefully placed

detectors. A phase shift occurs between detector signals that is

directly proportional to mass flow rate. As the fluid density varies,

the resonant frequency at which the tube vibrates changes, which

is also measured by the detectors. Temperature is measured by

an internal RTD in order to calculate thermal effects on the tube

vibrating frequency and can be used as a measurement output.

CONTROLS SYSTEM INTEGRATION

RCT1000 transmitters provide a variety of means to integrate the

meter’s output into new and existing operations. The batch and

PID functionality enables direct control of devices, such as valves,

by use of digital or analog outputs. Additionally, programmable

digital outputs can indicate low and high alarm conditions. Network

options are available including EtherNet/IP, Modbus TCP/IP and

Modbus RTU.

MAINTENANCE

With no internal moving parts, the vibrating tube design has little

impact on mechanical wear, resulting in a longer life expectancy

and in fewer repairs than many other flow technologies.

FLUID DIAGNOSTICS

RCT Console software offers much more than configuration features.

Users can obtain advanced data logging and performance trending

analysis, as well as system verification provided by the unique

HealthTrack feature, which captures critical operation parameters.

ADVANTAGES

• Highly accurate direct measurement of:

◊ Mass flow

◊ Density

• Derive concentration of homogenous liquids containing

two components

• Open flow path

• No straight-run requirements

• Low maintenance operation

• Flexible integration options

• Advanced fluid diagnostic software

CRL-DS-01550-EN-01 (April 2016)

Product Data Sheet

Page 2

Coriolis Flow Meter, RCT1000 with RCS005 and RCS008 Sensors

SPECIFICATIONS

The complete remote mount metering system consists of the following; each component must be purchased separately:

• Sensor

• Transmitter

• Cable assembly

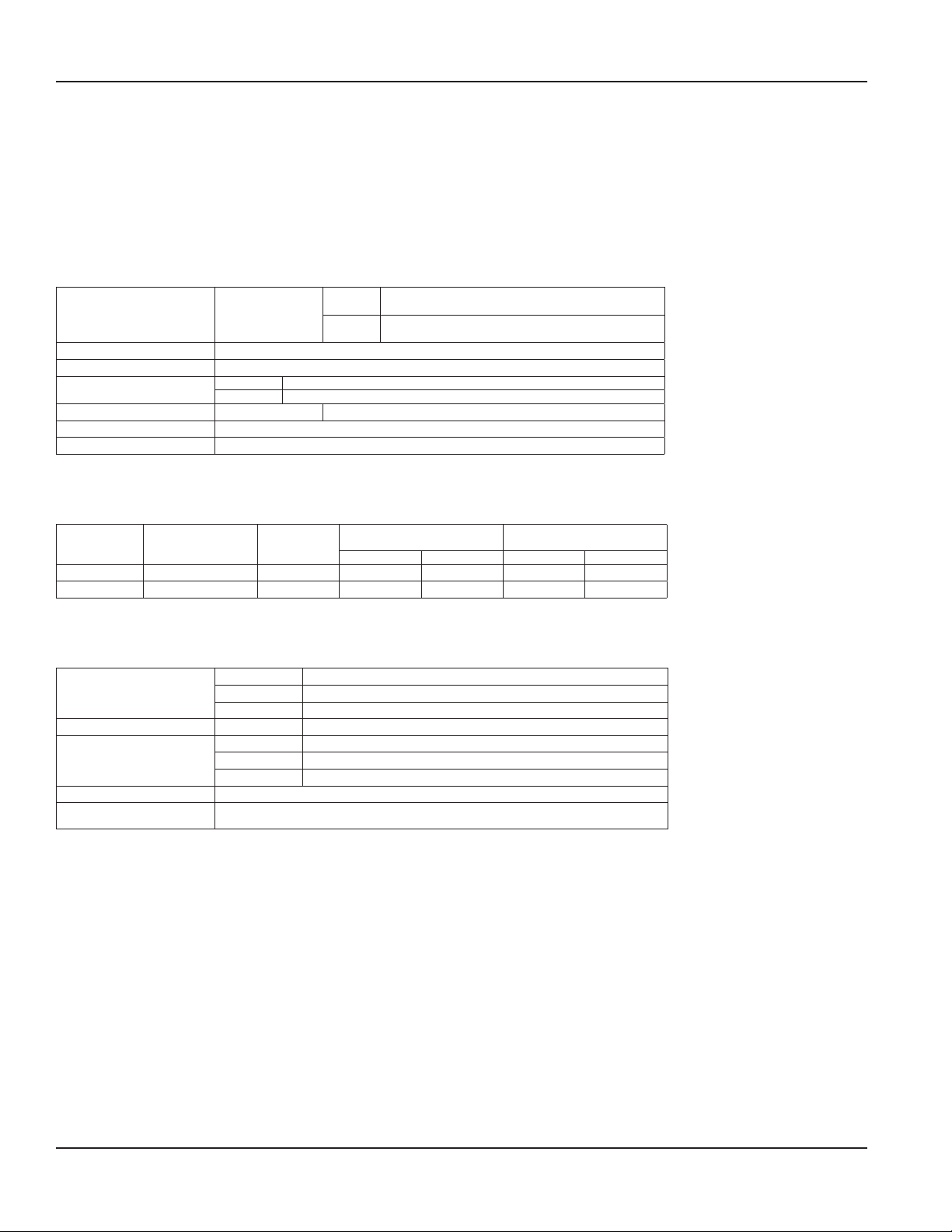

System with RCS005/RCS008 Sensors

Uncertainty

Density ±0.12486 lb/ft3 (0.002 g/cm3)

Repeatability ±0.05% of reading ± zero stability

Zero Stability

Safety Certifications Ordinary Location UL61010–1/CSA C22.2 No. 61010–1:2010

Density Measurement Flowing, referenced, API, Brix, Baume and net oil

Conformance CE

Mass Flow Rate

(Liquids)

RCS005 ±0.00005 lb/min

RCS008 ± 0.0002 lb/min

RCS005

RCS008

± 0.1% for flow rate > 0.05 lb/min

± 0.00005 lb/min for flow rate <= 0.05 lb/min

± 0.1% for flow rate > 0.2 lb/min

± 0.0002 lb/min for flow rate <= 0.2 lb/min

Flow Rate Specications

Model

RCS005 1/4 in., 1/16 in. 1 0…1.25 0…34 0.124 34

RCS008 1/4 in., 3/32 in. 1 0…2.75 0…74.8 0.274 74.8

Nominal Line and

Equivalent

Pipe Size

Number of

Flow Tubes

Flow Range

lb/min kg/hr gal/min l/h

Volumetric

Equivalent 1 g/cm

Sensors

Model Maximum Allowable Pressure

Pressure

Wetted Materials Standard 316L stainless steel

Temperature

Process Connections 1/4 in. O-ring face sealing; NPT

Conformance

RCS005 2755 psi (190 bar)

RCS008 1800 psi (124 bar)

Fluid Range –40…392° F (–40…200° C)

Accuracy ±1.8° F (1° C)

Repeatability ±0.54° F (0.3° C)

ASME B31.3 Pressure Piping Hydro Test

NACE MR0175/ISO 15156

3

Page 2 April 2016

CRL-DS-01550-EN-01

Page 3

Product Data Sheet

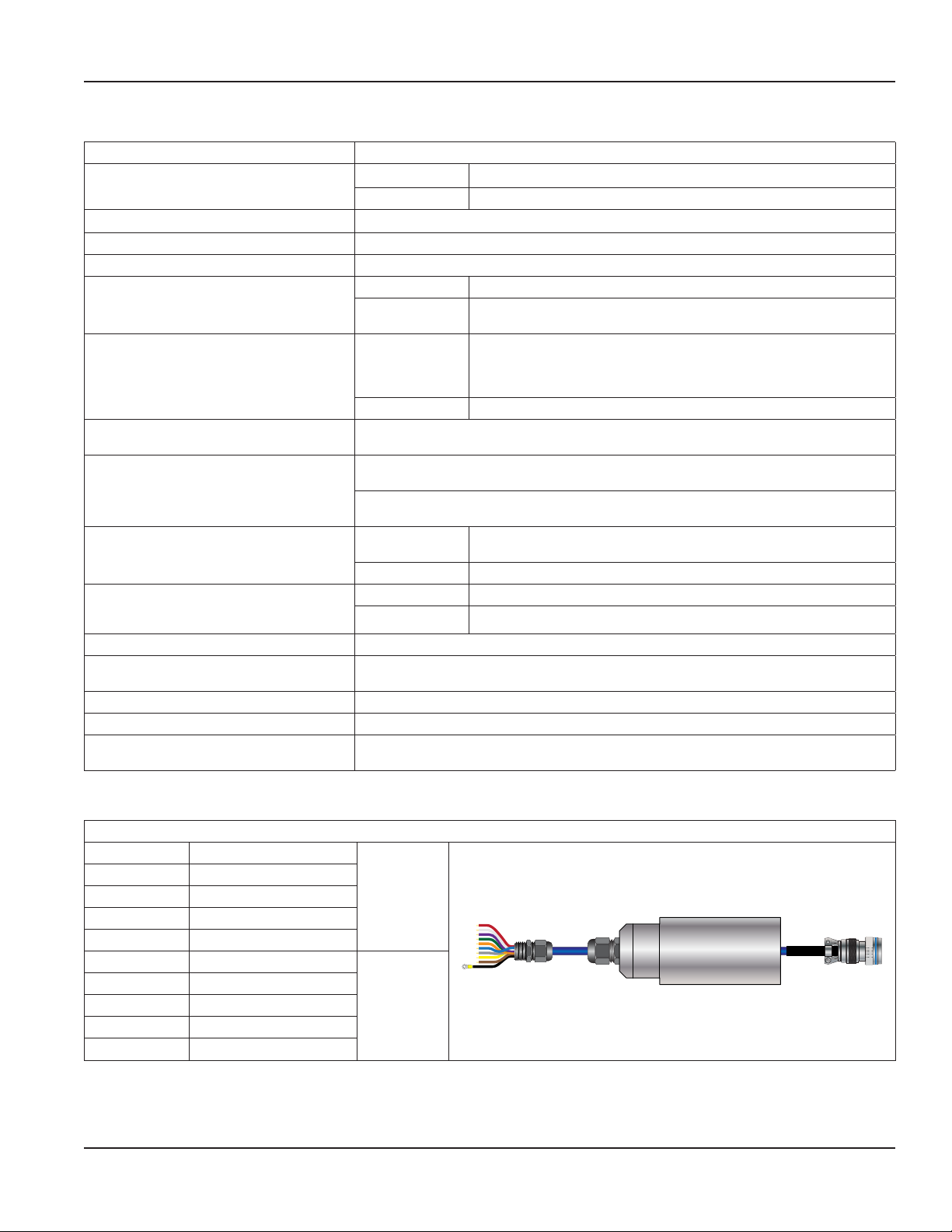

Transmitter

Enclosure NEMA 4 [IP-65]; powder coated aluminum, polycarbonate, urethane and stainless steel

Power Requirements

(Standard with Every RCTN Transmitter)

Ambient Temperature 14…158° F (–10…70° C)

Configuration Four–button HMI or RCT Console configuration

Display 4 line × 20 character; alpha-numeric; dot matrix; LED backlighting

RTD Input

Analog I/O

Auxiliary Power

Frequency/Pulse Output

Digital I/O

Industrial Communications Modular Port

Standard Configuration Port USB 2.0 interface (through a Mini–B receptacle) for RCT Console software

Alarms

Transmission Distance Up to 100 ft (30 meters); contact factory if longer length is needed

Other Functions Batch control, PID control. User configuration of all I/O functions

Measurements

115/230V AC ±15% 50/60 Hz 25 W maximum

20…28V DC 15 W maximum

Standard (1 input) Built–in 100 Ω Platinum RTD within the sensor body

Optional

(1 auxiliary input)

Outputs

Inputs Two 0…5V DC inputs. 20k Ω input impedance, approximately 12 bit resolution

Internal 24V DC supply, 100 mA maximum (for batching functions, frequency output channel

and like applications)

One open collector transistor, user configurable as rate (3 kHz max output), accumulator 0…10 Hz;

PWM with 1 kHz carrier

User assignable to rate, any totalizer, PID, temperature, density, concentration or other

similar measurements.

Outputs

Inputs Four 5…24V DC, 1 k Ω impedance

Standard Modbus RTU (EIA–485/RS485)

Optional Module Modbus TCP/IP & EtherNet/IP

Six Hi/Lo Alarms; Alarm status on display by default, assignable to digital I/O (limit 2 or 4) and available

via digital communications

Forward and reverse mass flow and total, density, temperature; concentration, volumetric flow and

total (derived)

Additional 100 Ω 3–wire Platinum RTD input for the secondary RTD is used by

customers who want to be able to calibrate their RTD

Three 4…20 mA (0…22 mA capable), maximum load 500 Ω, approximately 16

bit resolution outputs; assignable to mass flow, volume, density, temperature,

concentration, PID and similar measurements. User defined fault condition

output value anywhere in the 0…22 mA range

Four 5…28V DC, 50 mA maximum current draw (external pullup resistor

required)

CABLE KITS

The kits include the cable assembly, cable protector and sensor cable connection cover.

RC820476-20 Kit, PVC jacketed cable 20 ft

RC820476-35 Kit, PVC jacketed cable 35 ft

RC820476-50 Kit, PVC jacketed cable 50 ft

RC820476-70 Kit, PVC jacketed cable 70 ft

RC820476-100 Kit, PVC jacketed cable 100 ft

RC820477-20 Kit, FEP jacketed cable 20 ft

RC820477-35 Kit, FEP jacketed cable 35 ft

RC820477-50 Kit, FEP jacketed cable 50 ft

RC820477-70 Kit, FEP jacketed cable 70 ft

RC820477-100 Kit, FEP jacketed cable 100 ft

Temp range:

–40…176° F

(–40…80° C)

Temp range:

–94…392° F

(–70…200° C)

CRL-DS-01550-EN-01

Page 3 April 2016

Page 4

Coriolis Flow Meter, RCT1000 with RCS005 and RCS008 Sensors

DIMENSIONS

Electronics Enclosure

8.25 in. Minimum Top Clearance

RCTN

D

A

B C D E F

C

B

0.19 in. Diameter

A

Mounting Holes

F

E

9.80 in. (249.9 mm) 8.00 in. (203.2 mm) 10.30 in. (261.6 mm) 4.30 in. (109.2 mm) 3.66 in. (93.0 mm) 8.32 in. (211.2 mm)

Pipe Mount Bracket

#8-32 UNC-2B

Screws

Pipe Mount Bracket

#8-32 UNC-2B

Screws

Vertical Pipe Mount

Horizontal Pipe Mount

RCTN Pipe Mounting Options

A

B

C

D

E

F

G

H

Pipe Bracket Dimensions

A B C D E F G H

5.50 in.

(139.7 mm)

Page 4 April 2016

4.00 in.

(101.6 mm)

1.11 in.

(28.2 mm)

0.625 in.

(15.9 mm)

CRL-DS-01550-EN-01

1.25 in.

(31.8 mm)

3.80 in.

(96.5 mm)

5.25 in.

(133.6 mm)

6.00 in.

(152.4 mm)

Page 5

Product Data Sheet

Sensor Dimensions, RCS005

D

E

A

B

C

G

Sensor Nominal Size A B C D E F G

RCS005 1/4 in.

5.90 in.

(149.9 mm)

5.00 in.

(127 mm)

1.00 in.

(25.4 mm)

3.60 in.

(85.3 mm)

7.93 in.

(201.7 mm)

2.42 in.

(61.6 mm)

F

1.23 in.

(31.2 mm)

Sensor Dimensions, RCS008

Sensor

RCS008 1/4 in.

Nominal

Size

A B C D E F G H J

8.48 in.

(215.3 mm)

5.72 in.

(145.3 mm)

APPROXIMATE SHIPPING WEIGHTS

Figure 1: RCS008 dimensions

6.60 in.

(167.7 mm)

1.50 in.

(38.1 mm)

8.70 in.

(221 mm)

2.67 in.

(67.8 mm)

0.98 in.

(24.9 mm)

4.65 in.

(118 mm)

2.48 in.

(63 mm)

Model Sensor Only Model Cables Only

RCS005 5.5 lb 2.49 kg RC820***–20 6 lb 2.7 kg

RCS008 9.7 lb 4.4 kg RC820***–35 8 lb 3.6 kg

Model Transmitter Only RC820***–50 10 lb 4.5 kg

RCTN 6.5 lb 2.95 kg RC820***–70 13 lb 5.9 kg

RC820***–100 17 lb 7.7 kg

CRL-DS-01550-EN-01

Page 5 April 2016

Page 6

Coriolis Flow Meter, RCT1000 with RCS005 and RCS008 Sensors

NETWORK OPTIONS

RS-485 Network All RCT1000 meters come equipped an EIA-485 port with Modbus RTU..

10/100 Base-T Network An optional Ethernet module allows communications via Modbus TCP/IP or EtherNet/IP.

SOFTWARE UTILITY

RCT Console software is a PC-based software that can be used to configure, operate and diagnose the RCT1000 Coriolis meter. Additionally,

the software can log and graph fluid characteristics and parameters for historical comparisons. RCT Console software is included with the

RCT1000 Coriolis meter.

ACCESSORIES

Please consult the factory for the availability, pricing and delivery estimates of additional accessories.

Page 6 April 2016

CRL-DS-01550-EN-01

Page 7

SENSORS PART NUMBER CONSTRUCTION

Sensors RCS005 and RCS008 ONLY

Model

Badger Meter Coriolis Flow Meter RCS

Nominal Line and Equivalent Pipe Size

1/4 in., 1/16 in. 005

1/4 in., 3/32 in. 008

Wetted Material

316L Stainless Steel S

Process Connection Type

NPT NPT

O-Ring, Face Sealing Body, 9/16-18 Threads FSM

O-Ring, Face Sealing Gland FSF

Electronic Mounting Options

Remote Mount Transmitter R

Certications

General/Ordinary Area G

Calibration/Meter Uncertainty

Liquids (Gases)

Mass Flow: 0.1% (0.5%) ± 0.05% of FS zero stability; Density: ± 0.002 g/cm3 3

Reserved

None (Reserved) N

Specials

Special Code (leave blank for non-custom orders) XXX

Product Data Sheet

- - - - - -

TRANSMITTER PART NUMBER CONSTRUCTION

Model

Badger Meter Coriolis Transmitter RCT

Enclosure Type

NEMA 4 [IP 65] N

Transmitter Options

Display and Keyboard K

Area Classication

General Area D2

Electronic Mounting Option

Remote Mount Transmitter R

Communication Protocol

Modbus RTU & Modbus TCP/IP E

Modbus RTU (Standard on all models) M

Sensor Connection

Ordinary Areas N

Specials

3-Digit Special Code (leave blank for non-custom orders) XXX

- -

- - -

CRL-DS-01550-EN-01

Page 7 April 2016

Page 8

Coriolis Flow Meter, RCT1000 with RCS005 and RCS008 Sensors

Control. Manage. Optimize.

Trademarks appearing in this document are the property of their respective entities. Due to continuous research, product improvements and enhancements, Badger Meter reserves

the right to change product or system specications without notice, except to the extent an outstanding contractual obligation exists. © 2016 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Czech Republic | Badger Meter Czech Republic s.r.o. | Maříkova 2082/26 | 621 00 Brno, Czech Republic | +420-5-41420411

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 21-06 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | 7-1202 | 99 Hangzhong Road | Minhang District | Shanghai | China 201101 | +86-21-5763 5412 Legacy Document Number: CRL-DS-00128-EN

Loading...

Loading...