Page 1

CRL-AS-00091-EN-01 (August 2014)

RCT 1000 Coriolis Meter

Application Data Sheet

Date

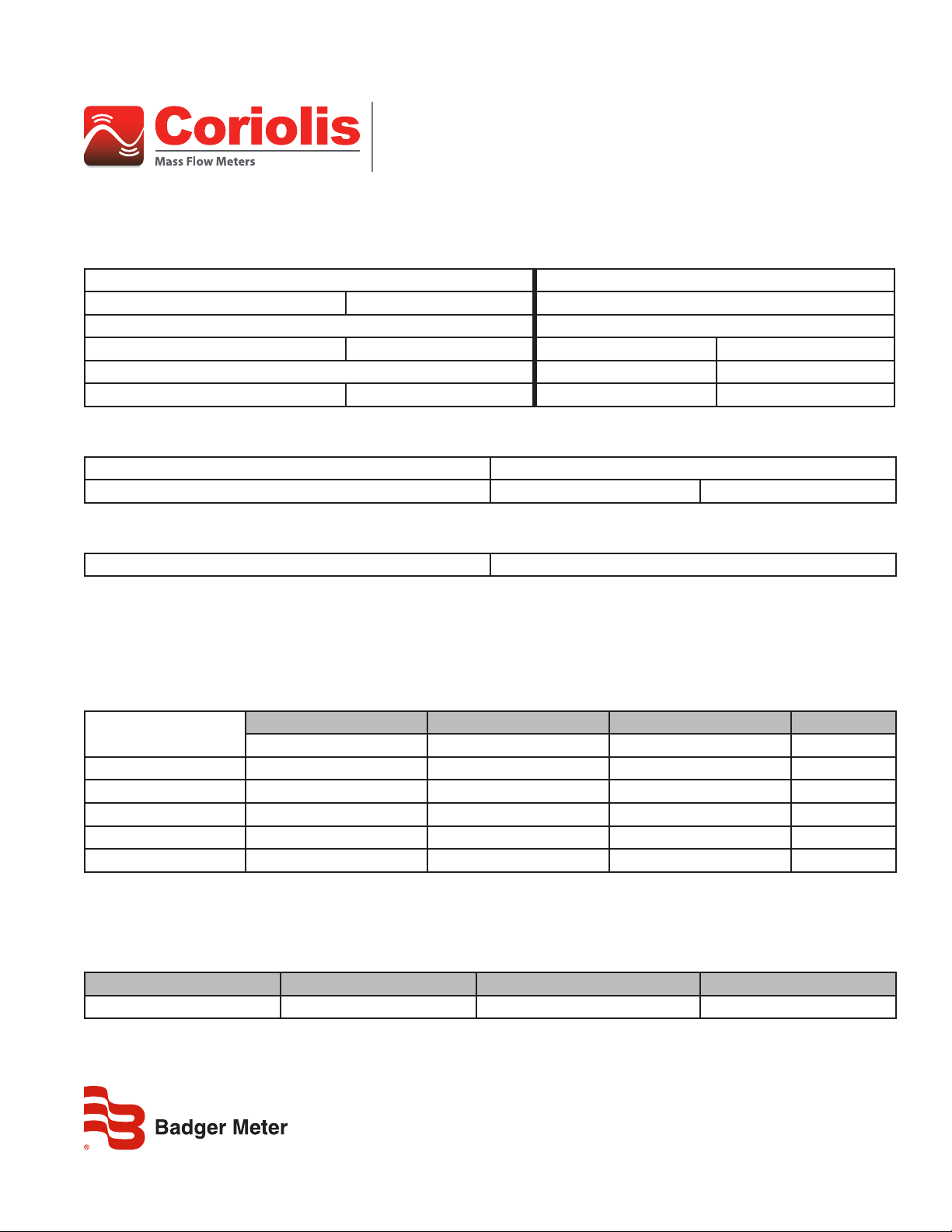

CUSTOMER CONTACT INFORMATION

Customer Contact: Company:

Email: Phone: Address 1:

Additional Contact: Address 2:

Email: Phone: City: State:

Additional Contact: Country: Zip/Postal Code:

Email: Phone: Phone: Fax:

REPRESENTATIVE/DISTRIBUTOR CONTACT INFORMATION

Company: Contact Name:

Location: Email: Phone:

CUSTOMER PROJECT IDENTIFICATION

Project Name: Subsystem:

OPERATING CHARACTERISTICS

Fluid Name Fluid Type Process Conditions

Technical

Trade Name

Minimum Nominal Maximum Units

Flow Rate

Line Pressure

Viscosity

Density

Temperature

Vapor Pressure

__________________________________________________________________________________________________________________

** All items above this line must be completely filled out prior to receiving a quote **

** If fluid is a slurry or suspension **

Carrier Fluid Name Solid Material Name Percent Solid Concentration (Est.) Particle Size

%

** For percent mass measurement, please contact Badger Meter technical support for percent mass worksheet **

Page 2

Coriolis Mass Meter Application Data Sheet

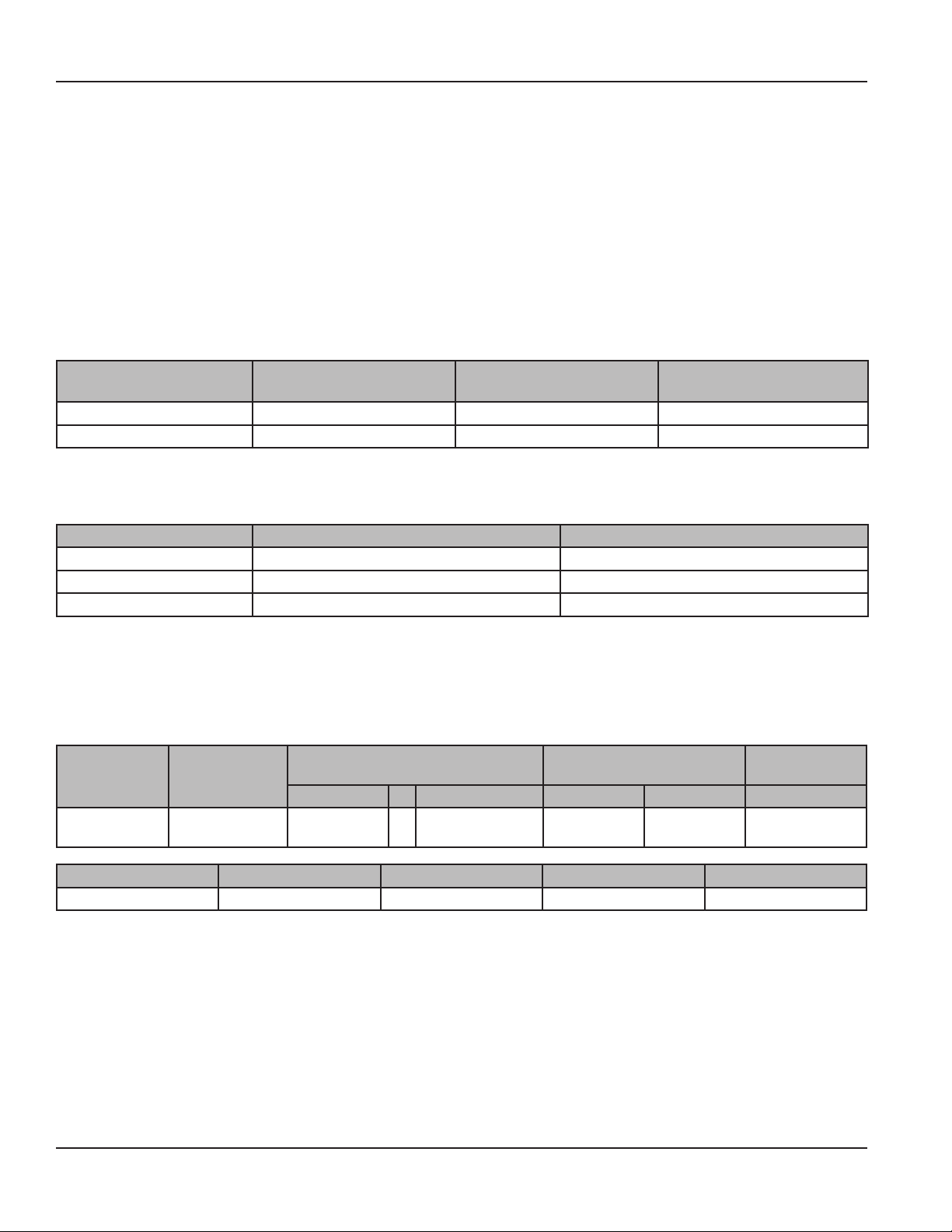

SENSOR/TRANSMITTER LOCATION

Sensor Transmitter

Process Connection Mounting Style

Indoor Horizontal Piping Orientation Cable Length (Remote Mount)

Outdoor Vertical Piping Orientation Cable Type (Remote Mount)

Area Classification Area Classification

INPUT REQUIREMENTS*

Analog Parameter and Spanning Information

(In Addition to Integral Temperature Sensor)

Analog Input Parameter Units Span

Example (0-100 psi)

Analog Input 1 (0-5V DC/mA)

Analog Input 2 (0-5V DC/mA)

OUTPUT REQUIREMENTS*

Analog Parameter and Spanning Information

Analog Output Parameter Spanning Information

Analog 1 (4-20 mA)

Analog 2 (4-20 mA)

Analog 3 (4-20 mA)

* Factory settings will be used, unless specified.

FREQUENCY/PULSE

Select One: Frequency Mode, Scaled Pulse or Pulse Width Modulation

Assign to Flow Rate, Total, Temperature, Density, Concentration, etc...

Isolated Open

Collector

Frequency/Pulse

Output

PID Control Device Parameter Low Nominal High

Assigned

Variable

Frequency Mode

Choose Hz and Value Ranges

0 Hz/Max Hz = 0 Value/Max Value Pulse per Unit Pulse Width On 1kHz Carrier

=

Scaled Pulse Mode Pulse Width

COMMUNICATION OPTIONS

(One RS485 Connector is Standard)

Modulation

Page 2 August2014

Page 3

Coriolis Mass Meter Application Data Sheet

DESCRIBE APPLICATION/SPECIAL REQUIREMENTS

FOR BADGER METER PERSONNEL AND AUTHORIZED REPS ONLY

PART NUMBER SELECTION REQUIRED FOR ORDERS

Sensor

Sensor Size Wetted

RCS

—

Material

S

Process

Connection

— —

Electronic

Mounting

R

Area

Cert.

—

G

*Leave blank for non-custom orders

Transmitter

Enclosure

Type

RCT N

Transmitter

Options

—

Area

Certification

K

—

D2

—

Electronic

Mounting

R

Communication

Protocol

— —

*Leave blank for non-custom orders

Cable

BADGER METER PERSONNEL ONLY

Badger Meter Order Number:

Calibration/

Uncertainty

— —

Reserved Specials*

—

N

Sensor

Connection

N

Specials*

(fill in)

—

(fill in)

Note: for orders with multiple meter configurations, fill out a new sheet for the Part Number Selection section, but use the same

Order Number.

Page 3 July 2014

Loading...

Loading...