Page 1

Industrial Process Controller

Model PC200

DESCRIPTION

The Badger Meter® Model PC200 is a microprocessor-driven

instrument designed for batching and filling both small and large

quantities, as well as displaying total, accumulated total and flow

rate. Designed to interface with our complete line of industrial flow

meters, it totalizes, indicates and controls fluid flows. Many years

of experience in the industrial market has allowed Badger Meter

to incorporate features indispensable in the liquid batching and

control operations.

OPERATION

Input signals in the form of pulses from open collector transistors

or dry contact closures can be scaled to any unit of measure for

totalization, instantaneous rate of flow indication and bidirectional

batch counting. At the preset quantity, a relay signal output can

be initiated to control valves, motors, alarms and other process

control devices.

FEATURES

This product is designed with a focus on:

• Ease-of-use with the numerical keyboard.

• Ruggedness for its application with a robust enclosure, keyboard

and proper mechanical relays.

• Clear operator information: all relevant data can be monitored in

one glance.

• User-friendly installation with quality plug-and-play terminals;

suitable for both AC and DC applications (standard).

• A wide range of inputs, outputs and functions for a broad

fulfillment in many applications.

OPERATOR ALARMS

No Flow Alarm

The PC200 offers a no-flow monitoring feature: if the flow meter fails

to generate a signal during a certain period of time, the unit shuts

off the control outputs and brings the batch controller into HOLD

and alarm mode. A “NO FLOW” alarm message displays.

Flow Rate Alarm

If, during a batch process, the actual flow rate is outside the allowed

range, a “LO RATE”, or “HI RATE” alarm message displays, indicating

the type of alarm: “LO RATE”, “HI RATE”.

FLEXIBILITY

• Count up or count down with end of batch at zero or at batch

preset value.

• Presettable set point and signal length for pre-warn output to

control valve’s first stage, sound alarm or control

injection pumps.

• Non-volatile memory preserves all programmed information

during power failure.

• DC input for mobile installations or backup power.

• Field-replaceable keyboard.

SERVICE

• Front panel or optional enclosure provides NEMA 4X (watertight

and corrosion-proof) protection.

• Self test alerts of any internal failure.

• Default sets all functions to factory programmed values.

• Plug-in output relays.

CTL-DS-00491-EN-05 (December 2017)

Product Data Sheet

Page 2

Industrial Process Controller, Model PC200

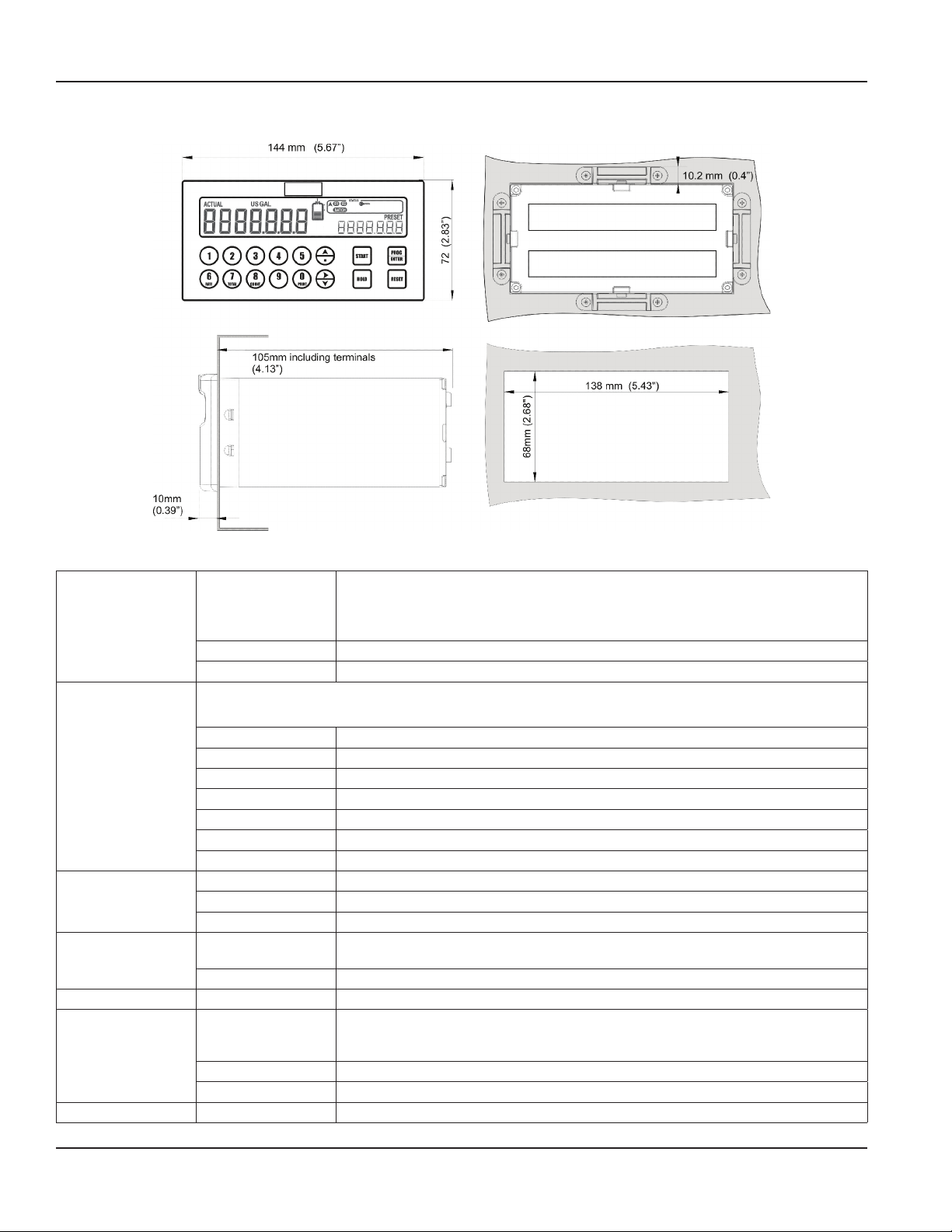

DIMENSIONS

SPECIFICATIONS

High intensity transflective numeric and alphanumeric LCD, UV-resistant

Type

Display

Digits Seven 14 mm (0.56 in.) and ten 8 mm (0.3 in.); various symbols and measuring units

Refresh rate User definable: 8 times/sec.

Die-cast aluminum front panel, GRP back enclosure

Polycarbonate window, silicone gasket; UV stabilized and flame retardant material

Keypad Sixteen industrial micro-switch keys; UV-resistant silicone keypad; replaceable front

Painting UV-resistant 2-component industrial painting

Enclosure

Environment

Power

Terminal Connections Type Removable plug-in terminal strip; wire max. 2.5 mm2 (0.1 in.2)

Data Protection

Environment EMC Compliant ref: EN 61326 (1997), EN 61010-1 (1993). CE and FPP certified

Dimension 144 × 72 × 110 mm (5.67 × 2.83 × 4.33 in.), W x H x D

Classification IP65 / NEMA4X at the front side

Panel cutout 138 × 68 mm (5.43 × 2.68 in.) W x H

Weight 650 gram / 1.7 lb

Panel thickness Max. 6 mm (0.25 in.)

Operation –20…60° C (–4…140° F)

Storage –40…80° C (–40…176° F)

Humidity 85% non-condensing, relative

Type PG

Sensor excitation 8.2 / 12 or 24V DC selectable; max. 50 mA

Type

Passcode Configuration settings and control keys can be passcode protected

Lock function Complete keyboard can be locked with external input (for example, key lock or PLC)

White LED backlight. Intensity adjustable from 0…100% in steps of 20%

Good readings in full sunlight and darkness

85…265V AC. Power consumption max. 15 Watt

24V DC + 10%. Power consumption max. 15 Watt

EEPROM backup of all setting

Backup of running totals

Data retention at least 10 years

Page 2 December 2017CTL-DS-00491-EN-05

Page 3

Flow Meter Inputs

Control Inputs

Control Outputs

Operator Functions

Preset / Total

Accumulated Total

Flow Rate

NPN, open collector, reed-switch, active pulse signals 8, 12 and 24V

• Minimum 0 Hz, maximum 7 kHz for total and flow rate

Frequency

K-Factor 0.000010…9,999,999 with variable decimal position

Low-pass filter Available for all pulse signals

Low Level 0…2V DC max.

High Level 8…20V DC max.

Impedance 4.7 kOhm pull-up to 12V DC

VDC Current 2.5 mA steady state

Function Six remote inputs: START, HOLD, RESET, total reset, counter reset, lock keyboard

Frequency DC to 20 Hz typical

Type Current sinking

Logic Level sensitive

Low Level 0… 2V DC max

High Level 8…20V DC max

Impedance 4.7 kOhm pull-up to 12V DC

Current 2.5 mA steady state

Response 100 ms make and break time

Function

Scaled pulse output Max. frequency 500 Hz. Pulse length user-definable 0.001…2 seconds

Mechanical relays Two mechanical relay outputs; max. switch power 230V AC…3A

Transistors Three passive transistor outputs, not isolated; load max. 50V DC…300 mA

• Enter a preset value

• Start / interrupt and stop the batch process

• Total can be reset to zero

• Batch counter can be reset to zero

Displayed information

Additional functions

Digits 7 digits

Units L, m3, USGAL, IGAL, ft3, bbl, kg, ton, US ton, lb

Decimals 0, 1, 2 or 3

Note Total can be reset to zero.

Digits 10 digits

Units/decimals According to selection for preset.

Digits 7 digits

Units L, m3, USGAL, IGAL, ft3, bbl, kg, ton, US ton, lb

Time unit sec, min, hour, day

Decimals 0, 1, 2 or 3

• Maximum frequency depends on signal type and internal low-pass filter

• Example: Reed switch with low-pass filter: max. frequency 120 Hz

• One batch output (always a mechanical relay)

• Four user-defined outputs (one mechanical relay and three transistor):

• Batch, two-stage control, high flow rate alarm, low flow rate alarm, no-flow alarm, any alarm,

scaled pulse, pre-warn, end of batch signal

• Preset value

• Running batch total or remaining quantity

• Total and accumulated total

• Flow rate

• Batch counter

• Active overrun correction

• Minimum / maximum preset value

Product Data Sheet

Page 3 December 2017 CTL-DS-00491-EN-05

Page 4

Industrial Process Controller, Model PC200

Control. Manage. Optimize.

Trademarks appearing in this document are the property of their respective entities. Due to continuous research, product improvements and enhancements, Badger Meter reserves

the right to change product or system specications without notice, except to the extent an outstanding contractual obligation exists. © 2017 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Eastern Europe Branch Oce (for Poland, Latvia, Lithuania, Estonia, Ukraine, Belarus) | Badger Meter Europe | ul. Korfantego 6 | 44-193 Knurów | Poland | +48-32-236-8787

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 21-06 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | 7-1202 | 99 Hangzhong Road | Minhang District | Shanghai | China 201101 | +86-21-5763 5412

Switzerland | Badger Meter Swiss AG | Mittelholzerstrasse 8 | 3006 Bern | Switzerland | +41-31-932 01 11

Loading...

Loading...