Page 1

Industrial Meters

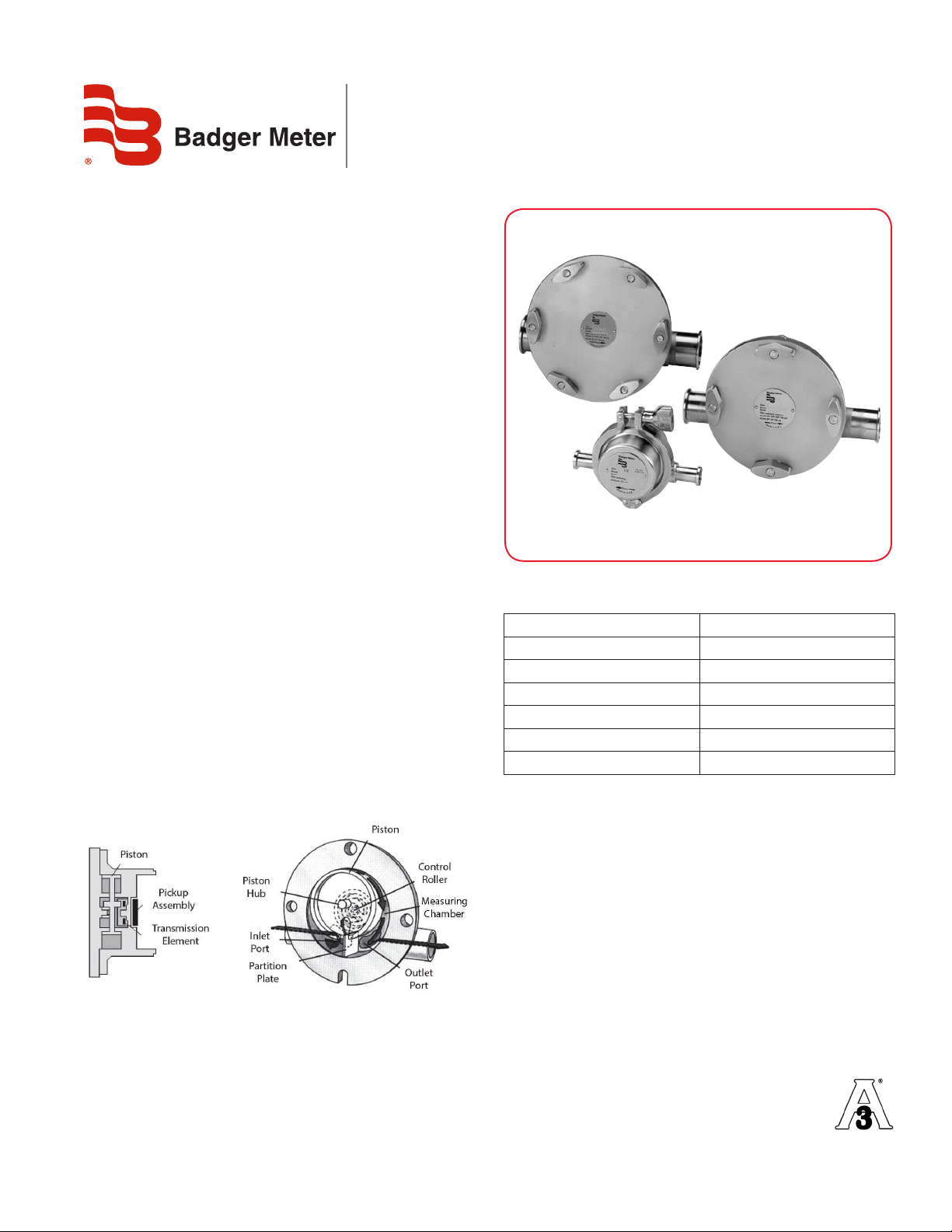

Oscillating Piston Model OP Sanitary, 3A Approved

Sizes 1/2", 1", 2"

DESCRIPTION

The Badger Meter positive displacement meter, Model OP, is one

of the most cost effective methods for metering process fluids in

the chemical, pharmaceutical and food industries. The simple but

efficient design of the OP meter generates high accuracy

and repeatability over the entire meter flow range. Magnetic,

through-the-wall transmission prevents operator exposure to

corrosive fluids and protects the fluid from external contamination.

Offered in three sizes, 1/2", 1" and 2", for flows up to 100 gpm,

these meters are extremely rugged, reliable and need little

maintenance and calibration. With only three internal moving

parts, maintenance is seldom required. If necessary, it takes but a

few minutes.

All parts are designed and built of materials recommended for your

application, providing you with a long life, trouble-free, precision

flow meter. The meter’s compact design and mode of operation

allows for installation in tight spaces and in any position.

To complement the OP meter line, Badger Meter offers a

complete line of accessories that includes mechanical, pneumatic,

electromechanical and electronic transmitters, totalizers, indicators

and batch/process controllers.

MATERIALS OF CONSTRUCTION

OPERATION

The meter function is based on the continuous filling and

discharging of the measuring chamber (positive displacement).

Controlled clearances between the piston and the chamber

provide minimum gap leakage for precise measurement of each

volume cycle. As the piston oscillates, its center hub rotates a

magnet. The movement is sensed through the meter wall by

electromagnetic sensors or by a follower magnet. Each revolution

of the magnet is equivalent to a fixed volume of fluid, which is

converted to any engineering unit of measure for totalization,

indication or process control.

All Meter Sizes Sanitary Model

Housing Materials 316 Stainless Steel

Piston Materials Ultem

O-Ring Materials Teflon

Bushing Material Rulon (white)

Magnet Casing Alloy 20

Control Roller Alloy 20

OPM-DS-01066-EN-01 (June 2015)

Product Data Sheet

Page 2

Industrial Meters, Oscillating Piston Model OP Sanitary, 3A Approved

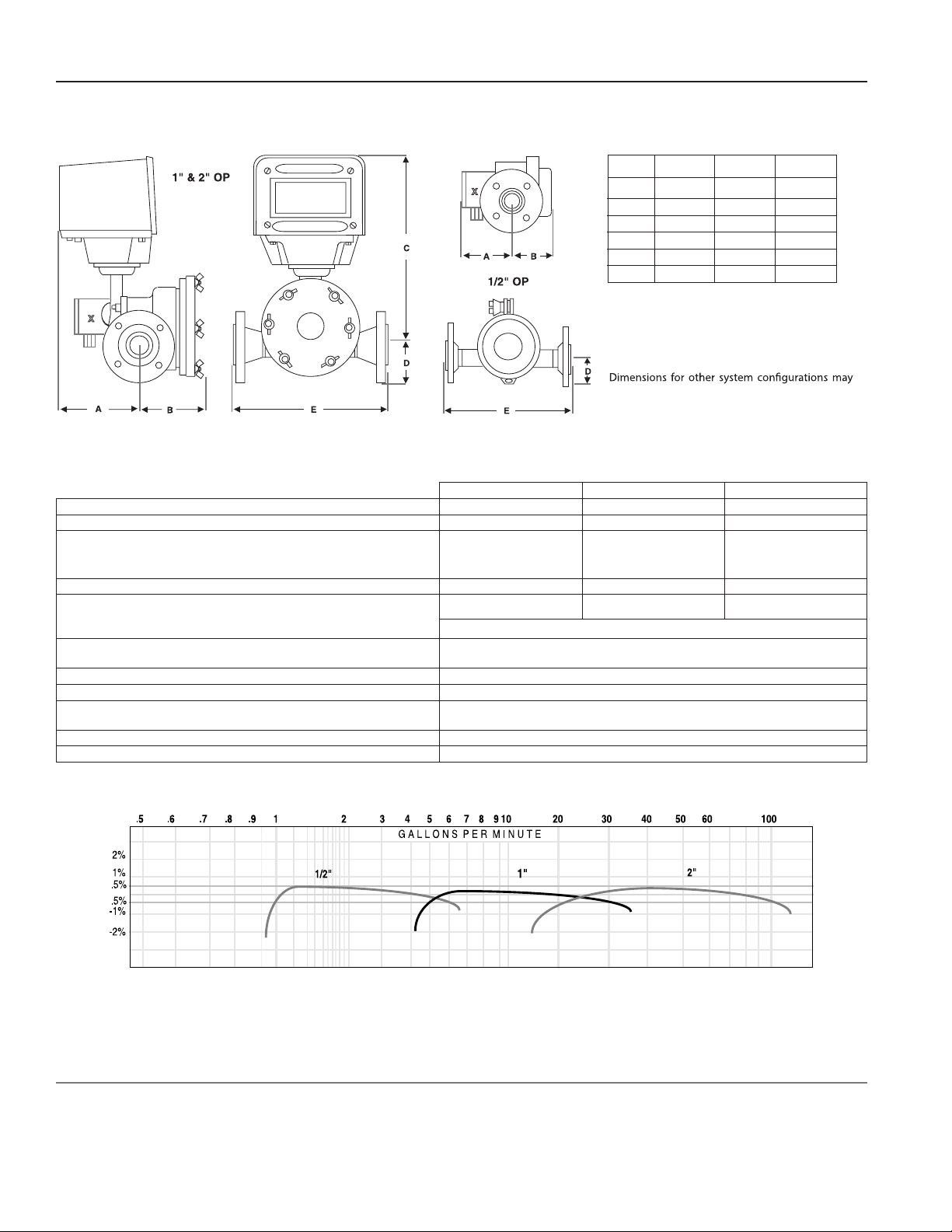

DIMENSIONS

1/2" 1" 2"

A 4.31" 6.16" 6.63"

B 2.32" 3.81" 5.56"

C 15.83" 16.21"

D 1.75" 2.13" 3.00"

E 6.75" 11.00" 12.62"

E* 6.75" 11.00" 11.81"

* Tri-Clamp

Dimensions shown are of meter with angle drive and

PC meter mount or with rear drive and transmitter.

vary slightly. Please consult with factory

SPECIFICATIONS

1/2" 1" 2"

Minimum Flow Rate, Q Minimum 1.5 gpm 5.5 gpm 25 gpm

Continuous Operating Maximum Rate 4 gpm 20 gpm 65 gpm

Short Duration Maximum Flow, Q Maximum

Continuous operation is acceptable at these rates, but accelerated wear of the

piston and/or bushings may occur.

Standard Connections Tri-Clamp Tri-Clamp Tri-Clamp

Pressure Drop at

Maximum Continuous Operating Flow

(@ viscosity & specic gravity of water)

Maximum Viscosity Limit

Maximum Operating Pressure 150 psi

Maximum Operating Temperature 250 °F

Minimum Operating Temperature**

**Minimum temperature for stated accuracy.

Accuracy ± 0.5% over entire meter flow range

Repeatability ± 0.2% or better under similar repeatable batch operations

6 gpm 30 gpm 100 gpm

1.8 psi 6.3 psi 10.6 psi

Pressure loss increases with fluid viscosity

10,000 cps (flow range is decreased as viscosity increases).

Contact factory for higher viscosities

40 °F

Metric Conversion: psi x 0.0703 = bars gpm x 3.785 = liters per minute ° F - 32 x 0.555 = ° C

ACCURACY CURVES: Accuracy tested in ambient temperature on water. Higher accuracy may be achieved with more viscous uids.

Control. Manage. Optimize.

Trademarks appearing in this document are the property of their respective entities. Due to continuous research, product improvements and enhancements, Badger Meter reserves

the right to change product or system specications without notice, except to the extent an outstanding contractual obligation exists. © 2015 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Czech Republic | Badger Meter Czech Republic s.r.o. | Maříkova 2082/26 | 621 00 Brno, Czech Republic | +420-5-41420411

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 21-06 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | 7-1202 | 99 Hangzhong Road | Minhang District | Shanghai | China 201101 | +86-21-5763 5412 Legacy Document Numbers: OPM-DS-00292-EN-02

Loading...

Loading...