Page 1

Portable Combustion

Analyzer (PCA)

Instruction 0 0 24-9219

Operation & Maintenance

Product Leadership • Training • Service • Reliability

Rev. 10 – May 2010

Page 2

WARRANTY

Bacharach, Inc. warrants to Buyer that at the time of delivery this Product

will be free from defects in material and manufacture and will conform

substantially to Bacharach Inc.’s applicable specifications. Bacharach’s

liability and Buyer’s remedy under this warranty are limited to the repair or

replacement, at Bacharach’s option, of this Product or parts thereof returned

to Seller at the factory of manufacture and shown to Bacharach Inc.’s

reasonable satisfaction to have been defective; provided that written notice

of the defect shall have been given by Buyer to Bacharach Inc. withi n two (2)

year after the date of delivery of this Product by Bacharach, Inc. The Oxyge n

(O

) Sensor has a limited warranty of one (1) year. Routine service and/or

2

calibration are excluded from this warranty.

Bacharach, Inc. warrants to Buyer that it will convey good title to this

Product. Bacharach’s liability and Buyer’s remedy under this warranty of

title are limited to the removal of any title defects or, at the election of

Bacharach, to the replacement of this Product or parts thereof that are

defective in title.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND ARE GIVEN

AND ACCEPTED IN LIEU OF (I) ANY AND ALL OTHER WARRANT IES,

EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR

PURPOSE: AND (II) ANY OBLIGATION, LIABILITY,

RIGHT, CLAIM OR REMEDY IN CONTRACT OR TORT, WHETHER OR

ARISING FROM BACHARACH’S NEGLIGENCE, ACTUAL OR

NOT

IMPLIED. The remedies of the Buyer shall be limited to those provided

herein to the exclusion of any and all other remedies including, without

limitation incidental or consequential damages. No agreement varying or

extending the foregoing warranties, remedies or this limitation will be

binding upon Bacharach, Inc. unless in writing, signed by a duly authorized

officer of Bacharach.

To Register Your Warranty, Visit

www.mybacharach.com

Notice:

Product improvements and enhancements are continuous, therefore the specifications and information

contained in this docume nt may change w ithou t noti ce.

Bacharach, Inc. shall not be liable for errors contained herein or for incidental or consequential damages in

connection with the furnishing, performance, or use of this material.

No part of this document may be pho tocopied , reproduced , or tra nslated to another language without the prior

written consent of Bacharach, Inc.

BACHARACH® is a registered trademark of Bacharach, Inc.

All other trademarks are the property of their r espectiv e ow ners.

Copyright © 2010, Bacharach, Inc., all rights reserved.

A

Instruction 0024-9219

Page 3

PCA

Contents

1.0

INTRODUCTION

1.1 The Portable Combustion A

1.2 Displayed Data

1.3 PCA Model Configurations

2.0 TECHNICAL CHARACTERISTICS

3.0 SETTING UP THE PCA

3.1 Scope

............................................................................................ 3-1

3.2 PCA Power

3.2.1 Checking and Replacing the Batteries

3.2.2 Using the Optional Power Supply

3.3 Connecting the Probe

3.4 Configuring the PCA

4.0 OPERATION

4.1 Key Pad Functions

4.2 Sampling Hole Location

4.3 Performing a Combustion Test

4.3.1 Analyzer Turn On and Warm Up

4.3.2 Installing Probe in the Stack

4.3.3 Starting a Combustion Test

4.3.4 Ending a Combustion Test

4.3.5 Turning Off the Analyzer and Purging the CO Sensor

4.4 Differential Pressure Measurement

4.5 Warm-up Screen

4.6 Sensor Status Screen

4.7 Combustion Test Screen

4.8 Fuel Sel

4.9 Draft Screens

4.10 Memory Directory Screen

4.11 Memory to PC Screen

4.12 ID Setup Screens

4.13 Temperature Setup Screen

4.14 Draft Unit Setup S

4.15 O

4.16 Language S

4.17 Display M

4.18 Time / Dat

4.19 Printer /

4.20 Calibration / Maintenance

4.21 Maint

Instruction 0024-9219

ection Screen ............................................................... 4-11

Reference Setup Screen

2

enance Screen

............................................................................ 1-1

nalyzer

.......................................... ................................. 1-2

......................................................... 1-3

.................................................................. 3-1

..................................... ........ .......... ........ ....... .......... .. 3-1

......................................... ............... ......... 3-2

..................................... ............ ................. 3-4

..................................................................................... 4-1

...................................................................... 4-1

..................................... ..... .......... ........ . 4-2

......................................................................... 4-8

.................................................................. 4-9

........................................................... 4-10

...................................... ................. ............ ......... 4-12

.......................................... ............ 4-13

............................................................. 4-14

..................................... ...................... ......... 4-17

.......................................... .......... 4-19

creen

......................................... ............... 4-20

..................................................... 4-21

etup S

ode Setup Screen

e Setup Scr

creen

.......................................................... 4-22

.......................................... ......... 4-23

een

....................................................... 4-24

Setup Screen ............................................................ 4-25

Password Screen ........................ 4-26

....................................... ........ .......... ...... 4-27

Contents

........................................... 1-1

..................................... ........ 2-1

........................... 3- 1

.................................. 3-2

.................................................. 4-3

................................... 4-3

.......................................... 4-4

............................................ 4-5

.............................................. 4-5

. 4-6

.......................................... 4-7

i

Page 4

Contents

4.22 User Na

4.23 Saving Test Data

4.24 Printing Test Data

4.25 Clear Memory Screen

4.26 Resetting the Microprocessor

5.0 CALIBRATION

5.1 Sensor Check

5.2 Calibration Fixtures

5.3 Calibrate Menu Screen

5.4 Calibrate

5.5 Calibrate TS-Span

5.6 Calibrate TA-Zero

5.7 Calib

5.8 Calibrate NX

5.9 Calibrate

5.10 Calibrate

6.0 MAINTENANCE

6.1 Routine Maintenance

6.2 Disassembly

6.3 Cleaning the Probe

6.4 Water Trap/Fil

6.5 Replacing the Particulate Filter

6.6 Replacing the

6.7 Replacing the Nitric Oxide Sensor

6.7.1 Replacing the Nitric Oxide Sensor Filter

6.7.2 Replacing the Nitric Oxi

6.8 Replacing the Carbon Monoxide Sensor

6.8.1 Replacing the Carbon Monoxide Sensor Filter

6.9 Replacing the Pump Assembly

7.0 TROUBLESHOOTING

7.1 Analyzer Repair

7.2 Error Codes

7.3 Troubleshooting G uide

8.0 PARTS & SERVICE

8.1 Replacement Parts

8.2 Accessories

8.3 Service

APPENDIX A – Display Screen Translations

APPENDIX B – Printout Translations

ii

me Screens

.................................................................................. 5-1

................................... ........................................... 5-1

TS-Zero ....................................................................... 5-4

rate TA-Span

............................................................................... 5-8

CO ............................................................................... 5-9

Draft

................................................................................ 6-1

....................................... ....... .......... ......... ...... ........ . 6-2

Oxygen Sensor .......................... ... ....................... 6-7

................................................................................. 7-2

...................................... ........ .......... ........ ....... .......... . 8-2

Centers

......................................... ....................... 4-28

........................................ ............................ 4-29

.................................................................. 4-30

............................................................. 4-32

................................................. 4-32

................................................................... 5-2

............................................................... 5-3

.................................... ....... ........ .......... ....... .. 5-5

....................................................................... 5-6

...................................................................... 5-7

........................................................................ 5-11

......................................... ...................... .. 6-1

..................................................................... 6-4

ter Assembly Mai

..................................................................... 7-1

.......................................................................... 7-1

............................................................... 7-3

.......................................................................... 8-1

...................................................................... 8-1

........................................................................... 8-6

ntenance

..................................... ....... .... 6-6

de Sensor Bias Battery

............................................ .... 6-12

................................................. B-1

PCA

................................ 6-5

........................................ .... 6-8

....................... 6-8

........... 6-9

.................................. 6-10

............ 6-11

..................................... A-1

Instruction 0024-9219

Page 5

PCA

1.0 INTRODUCTION

Introduction

1.1 The Portable Combustion Analyzer

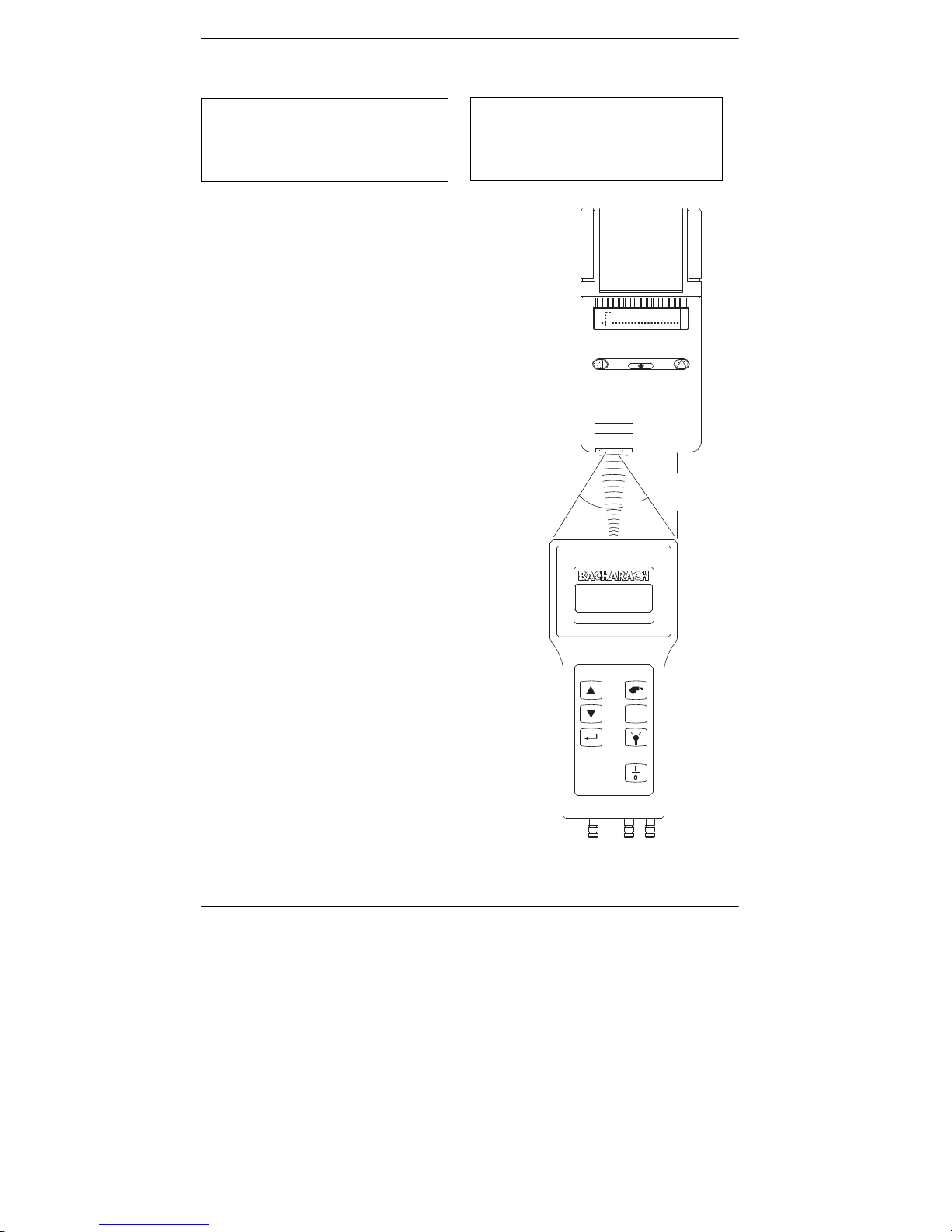

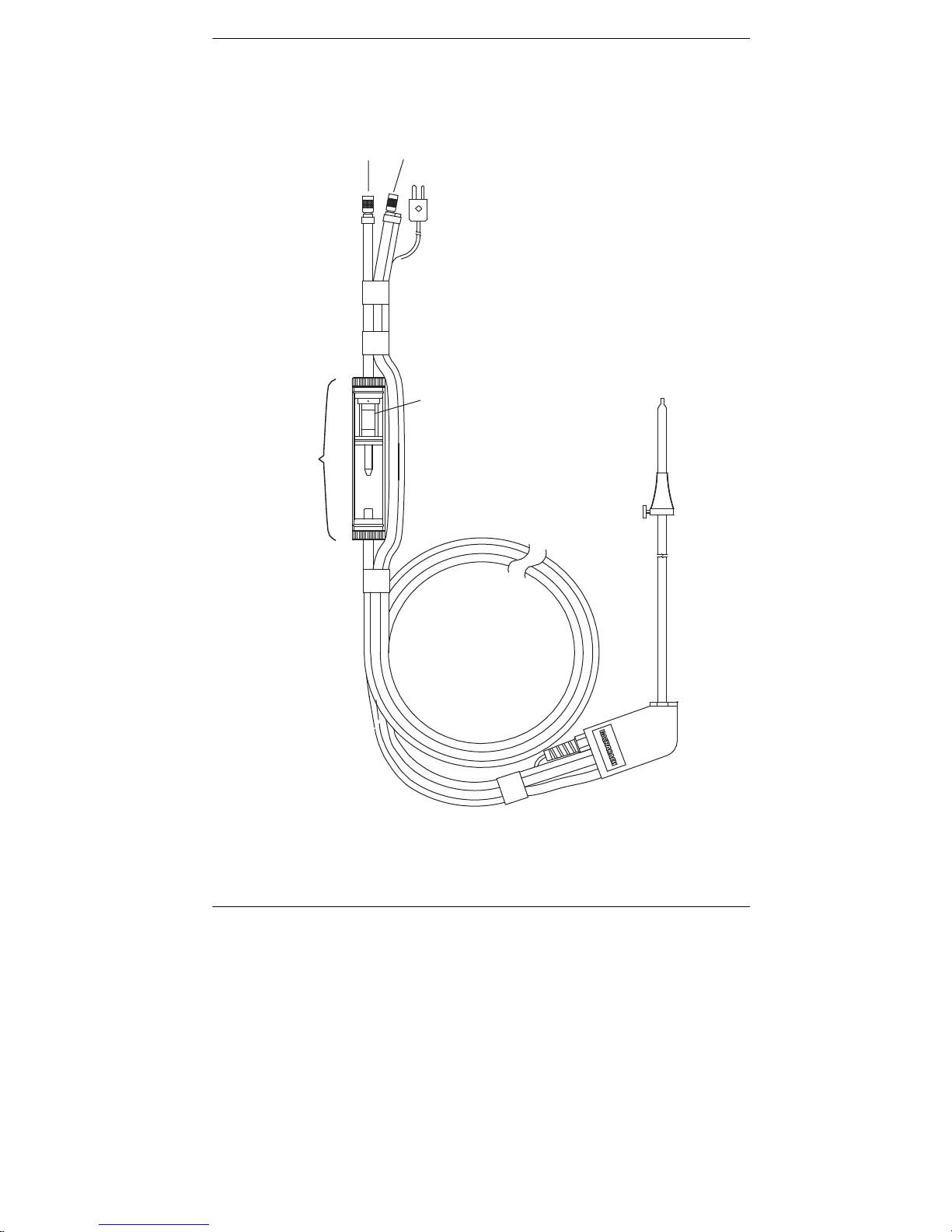

The Portable Combustion Analyzer (PCA) (Figure 1-1) is a commercial

grade, hand held, combustion efficiency analyzer that is designed for

continuous

furnaces, appliances, and boilers. The basic instrument is supplied with a

probe, instruction manual, batteries, and carrying case.

Instruction 0024-9219

(on demand) sampling of light industrial and residential

Figure 1-1. PCA

1-1

Page 6

Introduction

1.2 Displayed Data

The PCA directly measures, displays, and stores the following data:

• Room Temperature in °F or °C (Primary Air/Ambient Temperature)

• Flue Gas Oxygen Content in %

• Flue Gas Temperature in °F or °C

• Flue Gas Carbon Monoxide Content (H2 Compensated) in ppm

(For analyzers having a Carbon Monoxide sensor)

• Flue Gas Nitric Oxide content in ppm

(For analyzers having a Nitric Oxide sensor)

• Pressure/Draft in Millibars, Pascals, or Inches of Water Column

(For analyzers having a draft sensor)

• Differential Pressure in Millibars, Pascals, or Inches of Water Column

(For analyzers having a draft sensor)

The PCA will compute, display, and store the following data for any of the

seven standard fuels:

• Combustion Effi c ien cy in %

• Excess Air in %

• Flue Gas Carbon Dioxide Content in %

• Flue Gas Carbon Monoxide Content referenced to Oxygen in ppm

(For analyzers having a Carbon Monoxide sensor)

• Flue Gas Nitric Oxide Content referenced to Oxygen in ppm

(For analyzers having a Nitric Oxide sensor)

The seven standard types of fuels that can be selected are:

• Natural Gas

• Oil #2

• Oil #4

• Oil #6

•

Kerosene

• Propane

• Coal

The PCA continuously monitors flue gas exhaust conditions and updates

the above displayed values during a combustion test. If the analyzer is

equipped with an optional pressure sensor, then draft measurements can

be made simultaneously with the combustion test, or made separately.

The analyzer has the capability of storing data that was collected during

a combustion test or draft meas urem ent . The s tor ed d ata ca n then at a

later date be either viewed on the PCA’s display, printed using an optional printer, or downloaded to a computer.

1-2

Instruction 0024-9219

PCA

Page 7

PCA

1.3 PCA Model Configurations

Introduction

TABLE 1-1. PCA SENSOR CONFIGURATION S

PCA Models

Standard Advanced

PCA Part No. PCA Part No. Stack Temp., CO NX Draft

Model 24- Model 24- Air Temp. & O

10 8040 40 8140 X

15 8041 45 8141 X X

20 8042 50 8142 X X

25 8043 55 8143 X X X

30 8044 60 8144 X X X

35 8045 65 8145 X X X X

Sensors Installed

2

(

PCA 10 & 40

These basic instruments have the capability of measuring, displaying,

and storing combustion tests. They will also display flue gas Oxygen

content, flue gas Carbon Dioxid e (CO

temperature, combustion efficiency, excess air

2

) content, air temperature, flue gas

, and the current fuel

selected. The ‘standard’ PCA 1 0 stores up to 10 combusti on tests, while

the ‘advanced’ PCA 40 can store up to 100 tests.

PCA 15 & 45 with Draft

In addition to the features of the basic PCAs described above, these instruments have the added capability of measuring, displaying, and saving draft

or differential pressure in either Millibars, Pascals, or Inches-of-Water

Column.

PCA 20 & 50 with Carbon Monoxide Measurement

In addition to the features of th e basi c PCAs d escri bed ab ove, t hese

instruments have the added capability of measuring, displaying, and

saving Carbon Monoxide (CO) content, as well as calculating a CO level

that is referenced to Oxygen. T he ‘st an dard’ PC A 20 c alcula tes CO ref erenced to 0% Oxygen, while the ‘advanced’ PCA 50 calculates CO referenced to a user selected Oxygen level of between 0–15%.

PCA 25 & 55 with Draft and CO Measurement

These instruments combine the features of all the PCAs listed above.

Instruction 0024-9219

P)

1-3

Page 8

Introduction

PCA 30 & 60 with CO and Nitric Oxide Measurement

In addition to the features of the basic PCAs with CO measurement, these

instruments have the added capability of measuring, displaying, and

saving Nitric Oxide (NX) content, as well as calculating a NX level that is

referenced to Oxygen. The ‘standard’ PCA 30 calculates NX referenced to

0% Oxygen, while the ‘advanced’ PCA 60 calculates NX referenced to a

user selected Oxygen level of between 0–15%.

PCA 35 & 65 with Draft, CO & NX

These instruments are capable of measuring, displaying, and saving all

measurements as previously described.

Printout Capability

All PCAs have the ability to print the latest test data, or any of the saved

tests, to an optional printer via an infrared link.

CO Sensor Purge

On all PCAs that measure CO, if the

reading is 100 ppm or higher, the analyzer will attempt to purge itself of

CO before turning off.

ON/OFF key is pressed while the CO

Advanced PCA Model Features

‘Advanced’ models of the PCA contain the following features that are in

addition to the features of their corresponding ‘standard’ units:

• 100 memory locations

• RS232 output for transferring saved data to a personal computer

• Ability to enter three lines of user-identification information which is

printed at the top of each printout

• Ability to enter three lines of customer-identification information

which is printed with each test record

• Ability to set the Oxygen reference level from 0 to 15% for CO and NX

measurements on analyzers equi pped with a CO or NX s ensor

1-4

Instruction 0024-9219

PCA

Page 9

PCA

Technical Characteristics

2.0 TECHNICAL CHARACTERISTICS

The PCA Directly Measures and Displays:

• Oxygen content in flue gas in the r ang e of 0. 1 to 20. 9 % O

• Flue gas temperature in the range of 0 to 2192 ºF (–18 to 1200 ºC)

• Primary-air / ambient temperature is in the range of 0 to 999 ºF

(–18 to 999 ºC)

2

Optional . . .

• Differential Pressure and Draft in the range of ±28" H2O (±70.0 mb)

• Carbon Monoxide* content in flue gas in the range of 0 to 4000 ppm

• Nitric Oxide* content in flue gas in the range of 0 to 1000 ppm

The PCA Computes and Displays:

When the measured oxygen level is not above 16.0%, and the Stack (Flue

Gas) temperature is not above 1832 °F (1000 ºC)

• Efficiency in the range of 0.1 to 99.9%

• Excess Air in the range of 1 to 250%

• Carbon Dioxide content in flue gas from 0.1 to a fuel dependent

maximum value in percent

• Carbon Monoxide* content referenced to a percentage of Oxygen in

the range of 0

• Nitrix Oxide* content referenced to a percenage of Oxygen in the

range of 0 to 9,999 ppm on analyzers equipped with a NX sensor.

Standard Fuels** Available for

Combustion Calculations:

• Natural Gas

• Oil #2

• Oil #4

• Oil #6

•

Kerosene

• Propane

• Coal

* For the PCA 30, 35, 60, & 65, the display can be set up to show

either measured values of Carbon Monoxide and Nitric Oxide (C O

& NX), or show the calculated values of these gases (CF & NF)

referenced to Oxyge n. In either case, all v alues are list ed on the

printout of analzyers equipped with a printer.

** Custom fuels available upon request. Contact factory for details.

Instruction 0024-9219

to 9,999 ppm on analyzers equipped with a CO sensor.

2-1

Page 10

Technical Characteristics

Normal Operating Conditions:

Temperature:

Analyzer

Probe Tip

...................

..................

32 to 104 ºF (0 to 40 ºC)

1472 ºF (800 ºC) Max.

Humidity:

Analyzer

...................

15 to 90% Relative Humidity, Non-Condensing

Air Pressure:

Analyzer

Probe .........................

Performance:

Accuracy:

Oxygen*

Carbon Monoxide

Nitric Oxide

Flue Gas Temp.

Ambient Temp.

Pressure

...................

Atmospheric

10" H2O (25 mb) draft max at probe tip

.................... ±0.3% O

.....

±5% of reading or ±10 ppm, whichever is greater

between 0 – 2000 ppm, and ±10% of reading

between 2001 – 4000 ppm.

..............

...................

±5% of reading or ±5 ppm, whichever is greater

........

±4 ºF between 32 and 255 ºF

±6 ºF between 256 and 480 ºF

±8 ºF between 481 and 752 ºF

........

±2 ºF between 32 and 212 ºF

±2% of reading or ±0.02 inches of Water Column

(±0.05 mb), whichever is greater

2

(±2 ºC between 0 and 124 ºC)

(±3 ºC between 125 and 249 ºC)

(±4 °C between 250 and 400 °C)

(±1 °C between 0 and 100 °C)

System Flow Rate:

With

probe ................ 200

Front Panel Controls:

Seven embossed pushbutton switches with tactile feedback (refer to

Section 4.3)

Display:

20 character by 4 line alphanumeric LCD panel with a green backlight.

* Accuracy referenced in practical flue gas concentrations

(mixtures of O2, CO2 and N2)

2-2

cc/min minimum

Instruction 0024-9219

PCA

Page 11

PCA

Technical Characteristics

Power Requirements:

Four AA alkaline batteries. Battery backup for the real-time clock, RAM,

and bias voltage for the Nitric Oxide sensor is provided by internal

batteries. Optional AC Power Supplies (110 VAC & 230

available.

lithium

VAC) are also

Operating Time:

A fresh set of batteries will provide at least 8 hours of continuous opera-

tion with the pump running and the backlight turned on.

Warm Up Time:

60 seconds.

Printer Interface:

Infrared Communications (refer to Section 4.24).

Materials:

• High impact ABS plastic case

• Polycarbonate window over the display

• Nickel plated, brass quick-connect hose fitting

• Stainless steel probe

Dimensions:

Height:

Width:

Depth:

.................. 8.5

...................

................... 2

in. (215 mm)

3.8 in. (96 mm) at display (3.0 in. [75 mm] at controls)

in. (50 mm)

Weight:

With Batteries:

Instruction 0024-9219

.....

Approximately 1.5 lbs (0.7 Kg)

2-3

Page 12

Technical Characteristics

2-4

PCA

NOTES:

Instruction 0024-9219

Page 13

PCA

3.0 SETTING UP THE PCA

3.1 Scope

Before using the PCA, y ou MUS T:

• Check the batteries or plug in an Optional Power Supply (Section 3.2)

• Connect the probe to the analyzer (Section

• Check the analyzer’s config uration ( Secti on 3.4)

3.2 PCA Power

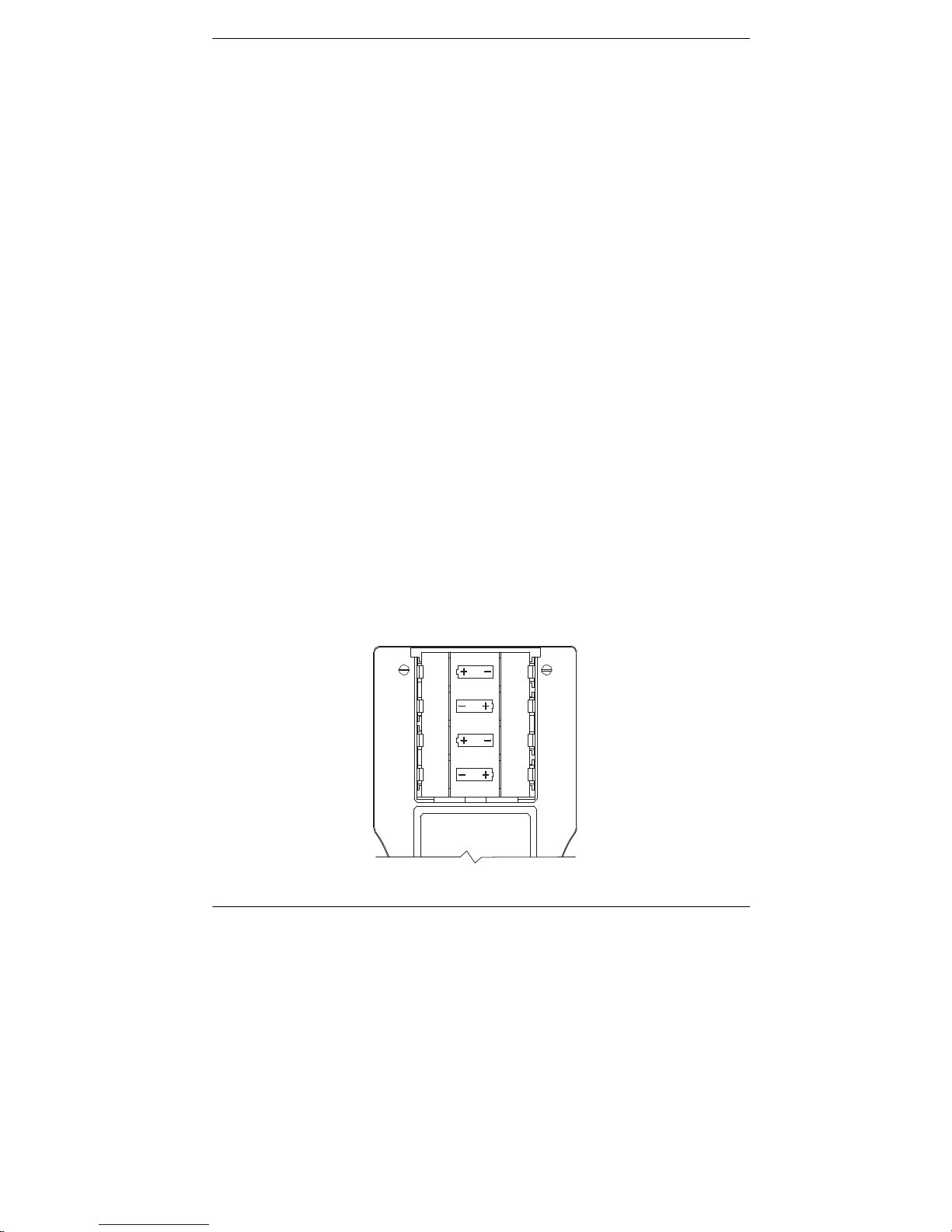

3.2.1 Checking and Replacing the Batteries

A fresh set of batteries is supplied with the PCA. Install the batteries as

described below. If a LOW BATTERY

analyzer is turned on, replace the batteries.

1.

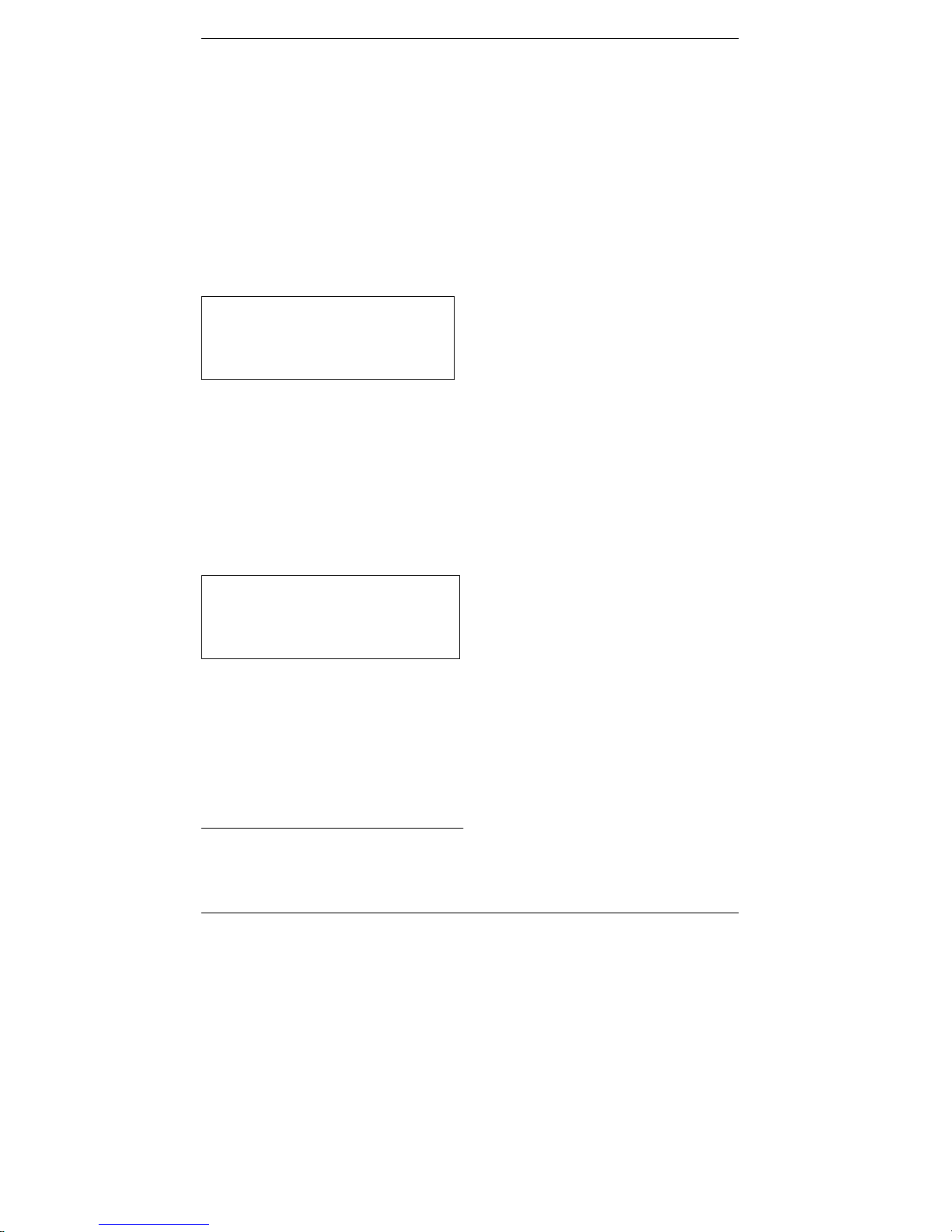

Remove the battery cover from the back of the PCA (Figure 3-1).

2.

Remove (and properly dispose of) any old batteries.

3.

Insert a fresh set of four AA alk aline b atter ies, mak ing su re to inst all

them per the “+” and “–” markings shown in the battery compartment.

4.

Replace the battery cover.

Figure 3-1. Battery Replacement

Instruction 0024-9219

3.3)

message is displayed when the

Setup

3-1

Page 14

Setup

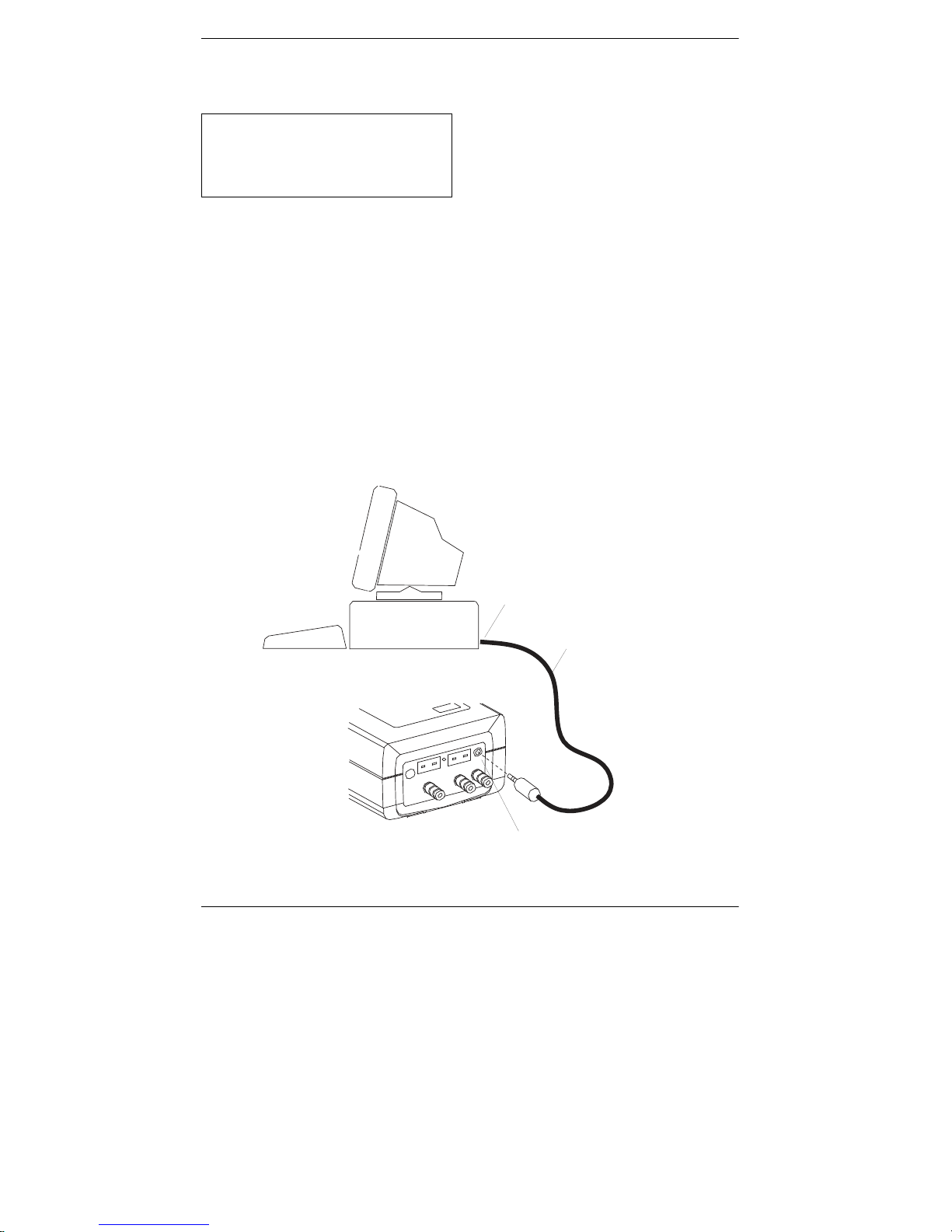

3.2.2 Using the Optional Power Supply

If an Optional Power Supply is to be used:

1.

Connect the output plug of the Optional Power Supply to the

analyzer’s power supply jack (Figure 3-2).

2.

Plug the Optional Power Supply into an appropriate AC wall outlet.

The analyzer will now operate and function normally.

3.3 Connecting the Probe

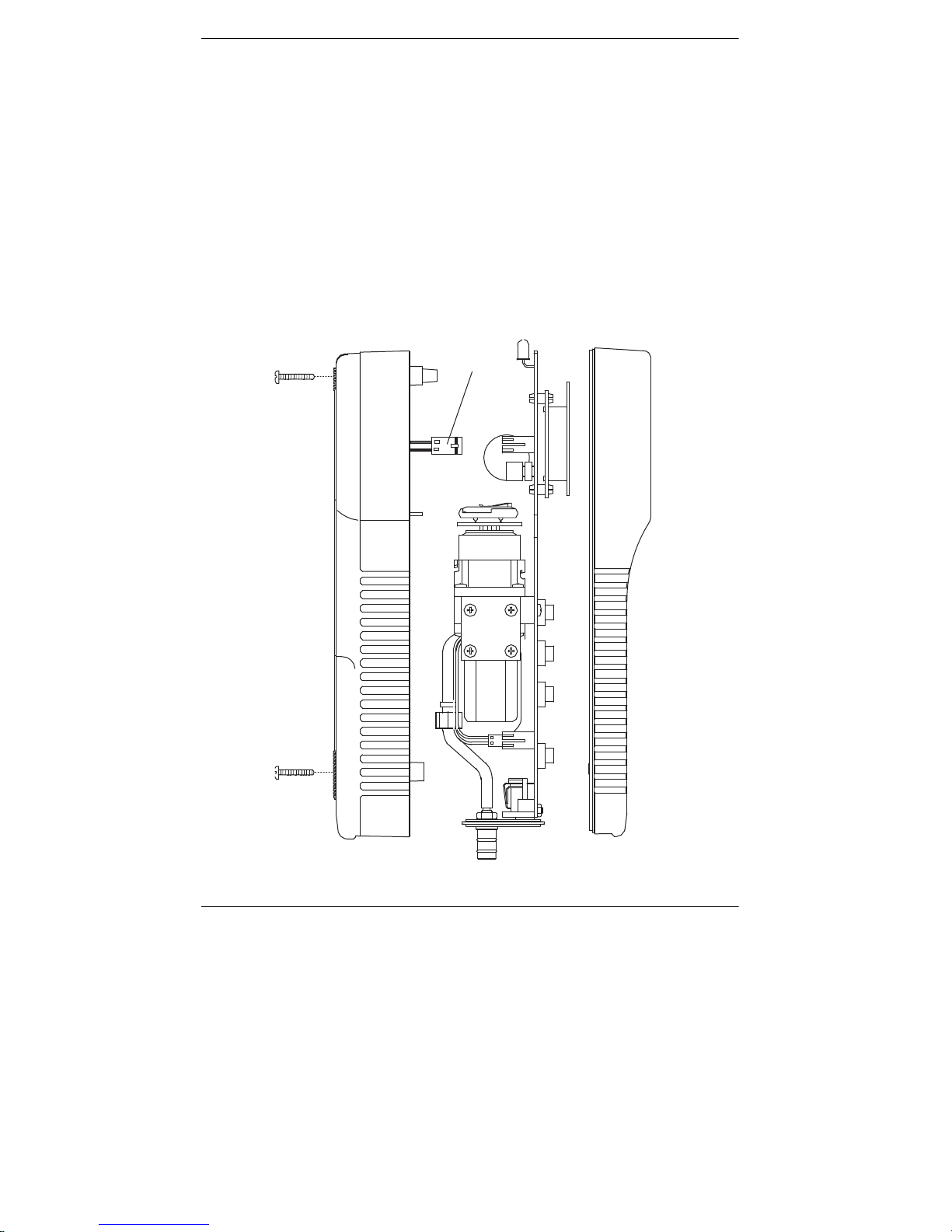

To attach the probe to the analyzer (Figure 3-2):

1.

Push the yellow-banded, quick-connect Flue Gas Hose (giving a slight

twist) onto the analyzer’s GAS sample-inlet fitting.

2.

Push the blue-banded, quick-connect Draft Hose (giving a slight twist)

onto the analyzer’s DRAFT sample-inlet fitting.

3.

Push the Flue Gas Thermocouple int o the T- ST AC K jack (c onnec tor

fits in only one way).

NOTE:

Perform Step 4 only if the Optional Room Air/Primary Air

Thermocouple is used.

The PCA has a built in room- air th ermo coup l e.

4.

Push the Optional Room Air/Primary Air Thermocouple into the

T-AIR jack (connector fits in only one way).

NOTE:

tion efficiency when the burner’s primary-air temperature is

not the same as room temperature, the primary-air tempera-

ture should be measured using the optional Primary Air

Thermocouple.

Inspect all the hoses for cracks. If any hose is defec tive, repl ace the en tire

probe assembly. Check that the water trap is empty, and the filter is not

dirty or saturated with water.

3-2

In order for the PCA to correctly calculate combus-

Instruction 0024-9219

PCA

Page 15

PCA

Power Supply

110V/60Hz

230V/50Hz

(Optional)

Instruction 0024-9219

Flue Gas

Thermocouple

Water

Trap / Filter

Assembly

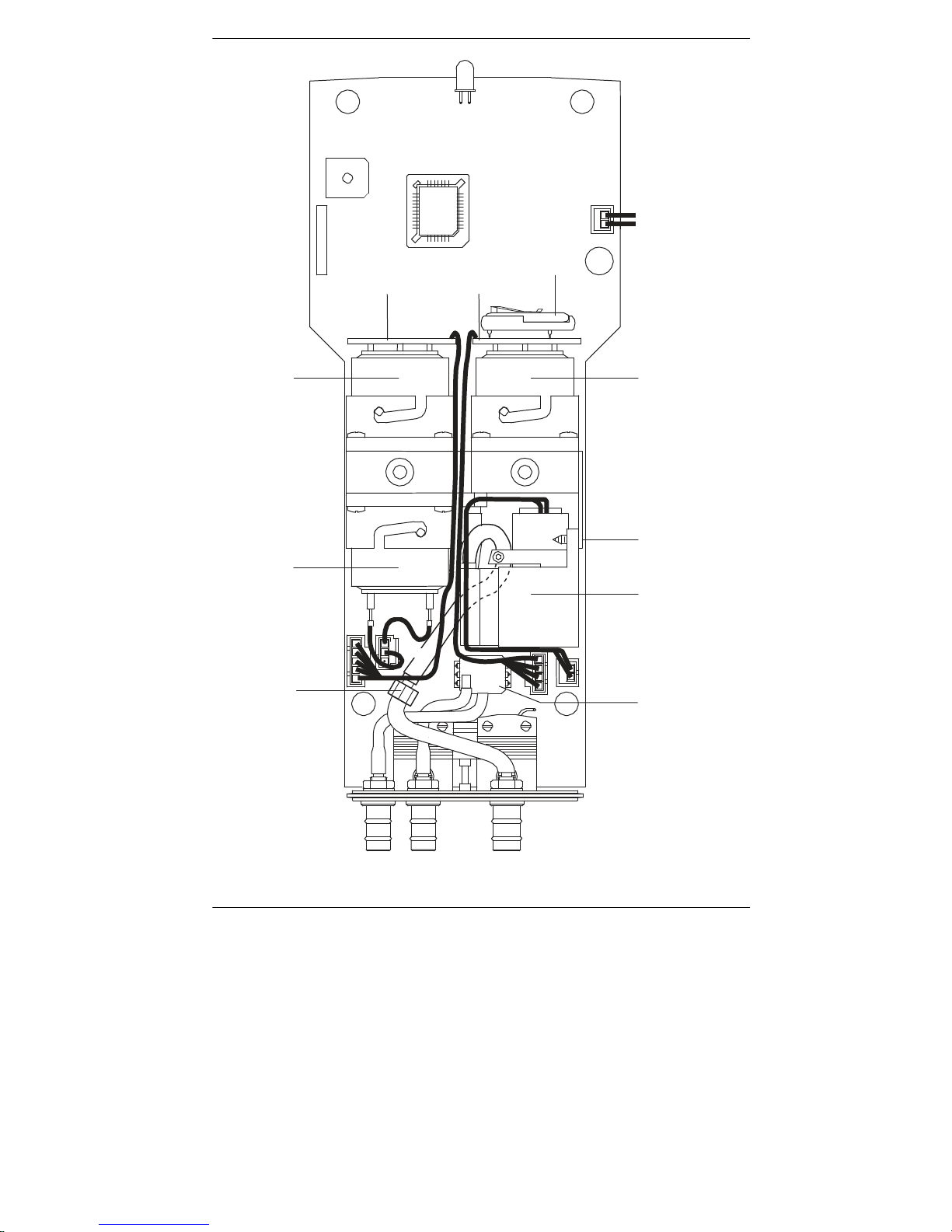

Figure 3-2. Connecting the Probe to the Analyzer

Flue Gas

Hose

Flue

Gas

Hose

Setup

Reset Button

Draft Hose

*

Present only on analyzers

equipped with a pressure

sensor.

Pressure Reference Port

(Used in the Measurement

of Differential Pressure)

*

Probe Tube

Room Air /

Primary Air

Thermocouple

(Optional)

*

Adjustable

Probe Stop

Probe

Handle

3-3

Page 16

Setup

3.4 Configuring the PCA

The PCA is configured at the factory for the parameters shown below.

These parameters, however, can be changed by following the instructions

in their associated sections.

Function

Fuel

Temperature

Draft

Oxygen Reference

Language

Display

Time

Date

3-4

0

Mode

Parameters

Natural Gas

º

C

W

C

%

English

CO & NX

HR:MIN:SEC AM/PM

MM/DD/YY

To Change,

Refer to . . .

Section

Section 4.13

Section 4.14

Section

Section 4.16

Section

Section

Section 4.18

4.8

4.15

4.17

4.18

Instruction 0024-9219

PCA

Page 17

PCA

4.0 OPERATION

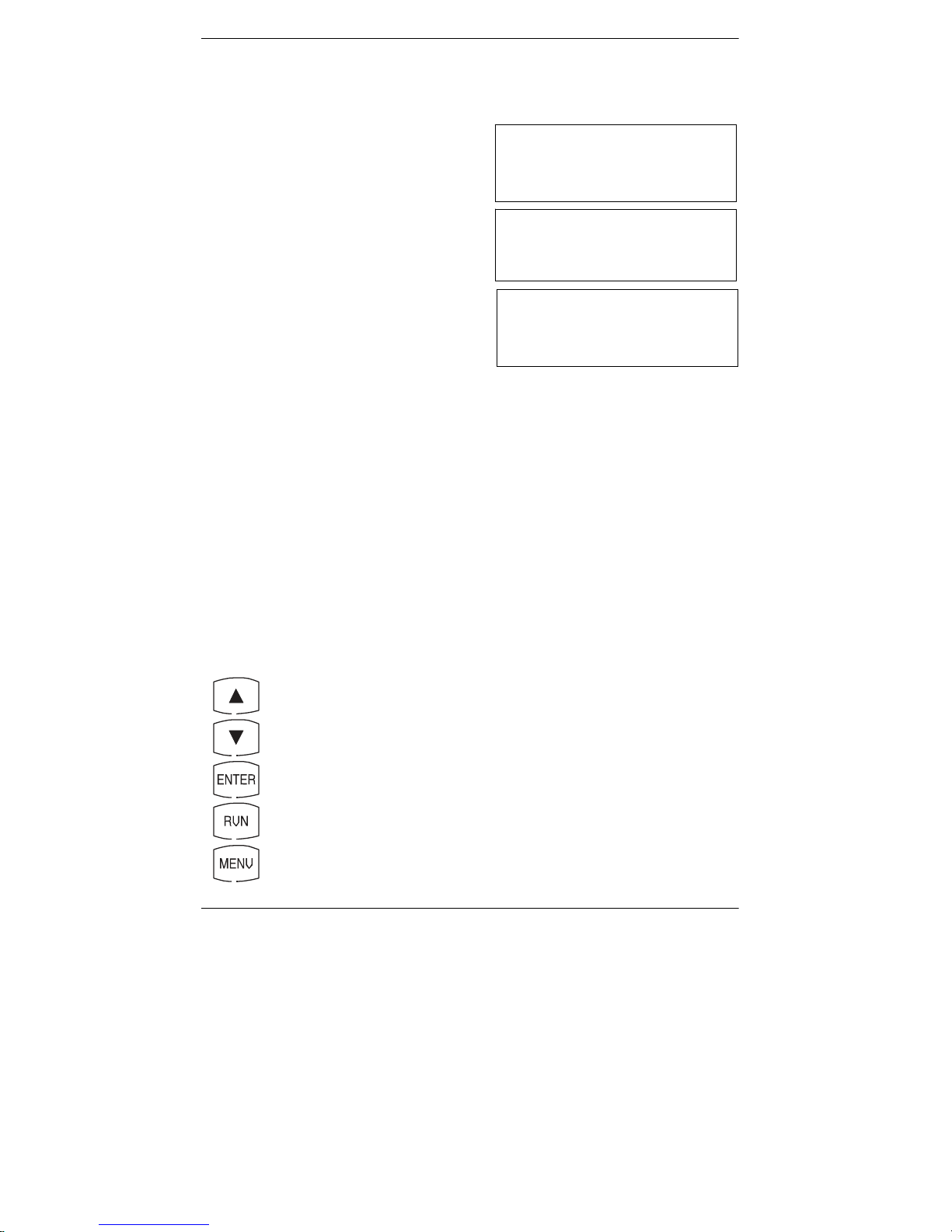

4.1 Key Pad Functions

Operation

Descriptions of the key pad functions are given below. Note that most of

the front panel key pad buttons perform multiple functions as determined

by what screen is being displayed at the time.

Turns the analyzer ON and OFF. Note tha t ther e is a 5 second

OFF-delay that allows an operator to turn the instrument back

ON by pressing the

loss of test data if the analyzer is turned OFF by mistake.

Moves the cursor [z] in front of a menu item up through the

displayed items. This key also increases alphanumeric values in

screens requiring a value change.

Moves the cursor [z] in front of a menu item down through the

displayed items. This key also decreases alphanumeric values in

screens requiring a value change.

Chooses the highlighted item (the item with the cursor [z] in front

of it) in all menus and screens. This key als o causes th e cursor t o

enter the number field in the Password Screen, and causes the

cursor to advance to the next field position in screens requiring

multiple alphanumeric entries.

Starts and stops a combustion test when the Combustion Test

Screen is displayed. Pressing this key in any other screen almost

always returns the instrument to the Combustion Test Screen.

However, there are four situations where this key behaves as an

enter key: 1)

Screen, press the RUN key to display the first calibration screen.

2)

After entering an offset or span value in any of the Calibration

Edit Screens, press the

entering a time or date value in the Time/Date Setup Screen,

press the

the left side of the display. 4)

Setup or User Name Screens, press the

Advances the display to the nex t menu scr e en.

Turns the screen’s backlight ON and OFF.

Instruction 0024-9219

RUN key to store the new values and return the cursor to

RUN

key. This feature prevents the accidental

After entering a correct password in the Password

RUN key to store the new values. 3) After

After entering text in either the ID

RUN key to store the text.

4-1

Page 18

Operation

4.2 Sampling Hole Location

The analyzer requires that a ½" diameter sampling hole be made in the

furnace stack to accommoda te t he p robe stop o n t he P robe a nd Hose

Assembly.

Locate the sampling hole downstream from the last heat exchanger,

and upstream from any source of dilution, such as a draft diverter

(Figure 4-1)

For residential and light-commercial combustion-equipment applications,

the following recommendations are applicable:

• Oil Gun Burners

stream from the furnace breaching, and at least 6 in. (15 cm) upstream

from the furnace side of the draft regulator.

• Gas Burners

at least 6 in. (15 cm) upstream from

the furnace side of the draft diverter

on gas-converted units. For gasdesigned equipment, the probe may

be inserted down into the flue

through the draft diverter or hood.

4-2

.

Important!

As the distance between the last heat exchanger

and sampling point increases, stack loss will falsely decrease

due to heat loss by convection from the flue or stack.

– Locate sampling hole at least 12 in. ( 30 cm) do wn-

– Locate sampling hole

FLUE GAS FLOW

(Downstream)

DRAFT

DIVERTER/

REGULATOR

SAMPLE

(Upstream)

FURNACE

BREECHING

Figure 4-1. Sampling Hole Location

POINT

Instruction 0024-9219

PCA

Page 19

PCA

4.3 Performing a Combustion Test

Important!

analyzer can affect its accuracy. This is important to know if

the analyzer is stored in a cold place (such as an unheated

vehicle in the winter) and then taken into a warm furnace

area. For the most accurate test results, allow the analyzer to

warm up to room temperature before use (about 10 minutes).

4.3.1 Analyzer Turn On and Warm Up

Important!

performing the following steps.

1.

Make sure that the analyzer is properly set up per Section

2.

Place probe in an area of fresh, ambient air; then press the analyzer’s

ON/OFF

key.

3.

Wait for the analyzer to countdown through its 60 second warm-up

period; then perform one of the following:

•

If no errors were detected during warm-up,

Test Screen will be displayed. Skip Step 4, and go to Section

•

If an error was detected during warm-up,

4.

If one or more errors were detected by the analyzer’s microprocessor

during warm-up, these errors will be displayed at the bottom of the

Sensor Status Screen (Section 4.6). Address any problems now per

Section 7.2; then repeat this procedure starting with Step 1.

NOTE:

instrument can still perform any test not using the function

disabled by the error.

Instruction 0024-9219

Large rapid changes in the temp er atu re of t he

Be sure the probe is at room temperature before

3.0.

the Combustion

proceed with Step

If the error detected is not critical to your test, the

Operation

4.3.2.

4.

4-3

Page 20

Operation

4.3.2 Installing Probe in the Stack

1.

After making a sampling hole in the stack (Section 4.2), and turning

on the analyzer (Section 4.3.1), screw the pro be stop supplie d with the

Probe and Hose Assembly into the sampling hole (Figure

2.

Insert the probe through the hole in the probe stop, then position the

probe tip inside the stack, near its center. Tighten the thumbscrew on

the probe stop to secure the probe.

4-2).

PROBE STOP

THUMBSCREW

Figure 4-2. Installing the Probe

4-4

Instruction 0024-9219

PCA

Page 21

PCA

4.3.3 Starting a Combustion Test

Important!

the same as the room temperature, then be sure the Optional

Room Air / Primary Air Thermocouple is installed per

Section 3.3.

1.

With the Combustio n Test S creen (Se ction 4.7) displayed and the probe

installed in the stack, press the

2.

Once all sensor readings are displa yed: A) L oosen the thum bscre w on

the probe stop. B) Move the probe in and out of the stack until the

highest stack temperature (TS) reading is obtained. C) Tighten the

thumbscrew to prevent further movement of the probe.

Alternately, the highest stack temperature can be located by displaying the Draft Screen (Section 4.9) and adjusting the probe for the

highest HOT SPOT

Note that locating the highest stack temperature is very important for

accurate combustion calculations.

3.

You can now begin burner-service procedures. The readings on the

analyzer change quickly to show changes in burner performance.

If the burner’s primary-air temperature is not

RUN

key to start a combustion test.

reading.

CAUTION

With the Water Trap / Filter Assembly stood up on its Outlet

End, do not let water condensate build up beyond the tip of

the riser tube. The sensors could be damaged if water would

enter the analyzer. Drain the water condensate after every

combustion test (refer to Section 6.4).

4.

Pressing the

while a test is in progress. Mov ing th e curs or (z) in front of the print

(

P

) function using the

current test information to an optional printer.

ENTER key

will save

s

key, and then pressing

the Combustion Test Screen readings

ENTER

will print the

4.3.4 Ending a Combustion Test

1.

Press the

stop running.

RUN

key to end a combustion test. You should hear the p ump

Instruction 0024-9219

Burn hazard! Allow a hot probe to cool before handling.

WARNING!

Operation

4-5

Page 22

Operation

CAUTION:

Do not place a hot probe inside the instrum en t’s ca rrying

case. Allow the probe to cool before storage.

2.

Loosen the thumbscrew on the probe stop; then remove the probe and

probe stop from the stack.

3.

If data was saved during the combustion test, you can turn off the

analyzer and review or print the stored data at a later time as described in Sections 4.10 and 4.23.

4.3.5 Turning Off the Analyzer and

Purging the CO Sensor

Turn off the analyzer by pressing the

If the

ON/OFF key is pressed while the CO reading is 100 ppm or higher, the

pump will automatically turn on (if not already running) to purge the

analyzer of CO.

Important!

during the purging process to allow fresh air to be drawn

through the analyzer.

The probe must be removed from the stack

ON/OFF

key.

The following message is displayed while the analyzer is being purged.

PURGING CO SENSOR

As soon as the CO level falls below 100 ppm, the pump t urns off and the

analyzer starts its normal 5 second turn-off sequence.

To abort the purging process and immediately start the analyzer’s turn-off

sequence, press the

ON/OFF key again.

NOTE:

during which time the unit can be turned on again without

any warm-up time. Press the

back on during this 5-second delay.

4-6

Turning the analyzer off initiates a 5-second delay,

RUN

key

to turn the analyzer

Instruction 0024-9219

PCA

Page 23

PCA

4.4 Differential Pressure Measurement

Operation

The difference in pressure (P) between two areas can be measured by

using the PCA’s two pressure ports and DRAFT Screen. By using Pressure

Port

2 (–)

as the reference, the pressure applie d to Port 1 (+)

displayed on the DRAFT Screen as the differential pressure b etween the

two ports.

1.

Turn on the analyzer by pressing the

cycle to complete; then press the

ON/OFF ke

MENU

key until the first DRAFT

y; wait for the warm-up

Screen is displayed (refer to Section 4.9). If a TA-SENSOR ERROR is

displayed, as the result of the probe’s thermocouple not being plugged

into the analyzer, press the

pressing the

MENU

key

RUN

key

to acknowledge the error before

.

2.

While the first DRAFT Screen is displayed, remove any hoses connected to Pressure Ports 1 and 2; then press the

these ports to atmospheric pressure.

ENTER

key to zero

3.

Connect two sampling hoses to Pressure Ports 1 and 2 (Figure 4-3).

Then place the open end of ea ch h ose in to the a reas b ein g mea sure d.

4.

The differential pressure between

the two areas is now displayed on

the third DRAFT Screen. If the

pressure at Port 1 is higher than

Port 2, then the pressure difference will be positive

. But if the

DRAFT

DRAFT

–

0.95 WC

HOT SPOT ---- °C P

«

pressure at Port #1 is lower, then the pressure difference will be

negative

pressure at Port

. The reading shown in this example indicates that the

1 is 0.95" H2O

lower than the pressure at Port

Sampling Hoses with quickconnect fittings are available

as an optional accessory.

Refer to Section 8.2 .

Pressure Port 1(+)

Pressure Port 2(–)

Reference

Figure 4-3. Differential Pressure Hose Connections

Instruction 0024-9219

will be

2.

S

4-7

Page 24

Operation

4.5 Warm-up Screen

BACHARACH, INC.

PCA xx

WARMUP yy

Where: xx = Instrument Model Number

yy = Counts down from 60 seconds

As soon as the ON/OFF

software version number are dis play ed f or ap proxi mat ely 3 s ec onds . To

continuously display these items, hold down the

The warmup cycle continues after the

The Warmup Screen is displayed during the an alyzer’s 60 second warm up

cycle, during which time the “Warmup” value (yy) counts down to zero.

After the warmup cycle is complete, (and if the unit is working correctly)

the instrument will flash NO ERRORS DETECTED

the Combustion Test Screen (Section 4.7). If there is a problem, however,

with one or more of the sensors, the Sensor Status Screen (Sect ion 4.6) is

displayed.

key is

pressed, the instrument’s serial number and

ON/OFF

ON/OFF

key is released.

key at

and go directly to

start-up.

Front Panel Key Functions:

–

No Action

–

No Action

–

No Action

–

No Action

–

No Action

Toggle Backlight ON/OFF*

–

–

Turn analyzer OFF*

* The

LIGHT

button will always turn the backlight on and off, while the

key

will always turn the analyzer on and off. These two keys will not be

mentioned in the remainder of this section.

4-8

ON/

OFF

Instruction 0024-9219

PCA

Page 25

PCA

4.6 Sensor Status Screen

BACHARACH, INC.

PCA xx

WARMUP 0

z

Where: xx = Instrument Model Number

z = Sensor(s) in error

Operation

If a problem with one or more of the sensors was detected during

warmup, the Sensor Status Screen will display an error code for those

sensors at the bottom of the screen and wait for operator intervention.

Refer to Section 7.2 for a listing and explaination of the error codes.

Note that the analyzer will not

Test Screen if a sensor error was detected. The analyzer, however, can

still be used to perform any test that does not depend on the sensor that

is in error. Press the

screen to continue using the analyzer.

RUN

Front Panel Key Functions:

automatically switch to the Combustion

key to manually enter the Combustion Test

–

No Action

–

No Action

–

No Action

–

Go to Combustion Test Screen

–

No Action

Instruction 0024-9219

4-9

Page 26

Operation

4.7 Combustion Test Screen

PCA models 10 thru 25, 40 thru 55 PCA models 30, 35, 60, & 65

O2 4.0 CO 12

C2 9.5 CF 15 NG

TA 68.0 TS 374

EF 82.6 EA 21 «S

This screen shows:

O2 ...............

C2 ...............

TA

...............

...............

EF

CO*

.............

CF*

.............

TS ...............

EA

............... Exces s a i r (%)

NX*

.............

NF*

.............

HLD/RUN

N

G ..............

P ..................

S

.................. Save

Oxygen content in flue gas (%)

Carbon Dioxide content

present in flue gas (%)

Primary/Ambient air temp. (°F)

Combustion efficiency (%)

Carbon Monoxide content in flue gas (pp m)

Carbon Monoxide content referenced to a percentage of O2 (ppm)

Stack (Flue gas) temperature (°F)

Nitric Oxide content in flue gas (ppm)

Nitric Oxide content referenced to a percentag e of O2 (ppm)

..

PCA on hold / PCA running test

Fuel code for natural gas (see Section 4.8 for other codes)

Print Data

* For PCA models 30, 35, 60 and 65, you have the option of displaying either

CO & NX, or CF & NF. Refer to Section 4.17 for setup instructions.

NOTE: Refer to Section 7.3 if stars (****) , dashes (– – –

or Xs (

Front Panel Key Functions:

Data

XXXX

) appear in the display.

–

4-10

Move cursor (z

–

Move cursor (z

Save or print screen data

–

Run test / hold test

–

–

Go to Fuel Selection Screen

HLD

P

) up

) down

O2 4.0 CO 12

C2 9.5 NX 10

TA 68.0 TS 374

EF 82.6 EA 21

- OR -

O2 4.0 CF 15 HLD

C2 9.5 NF 12 NG

TA 68.0 TS 374

EF 82.6 EA 21 «S

HL

N

«S

–) ,

Instruction 0024-9219

PCA

D

G

P

P

Page 27

PCA

4.8 Fuel Selection Screen

«NATGAS FUEL

OIL #2 KEROSENE

OIL #4 PROPANE

OIL #6 COAL

This screen is displayed by pressi ng th e

Test Screen, and is used to select the fuel being burned.

To select a fuel, first use the

desired fuel, and then press the

st

keys

ENTER

NOTE:

mains in memory after the PCA is turned off.

The fuel selected is saved as the default, and re-

MENU

key from the Combustion

to move the cursor (z) in front of the

key.

The fuel codes as displayed in the Combustion Test Screen:

NG = Natural Gas

O#2= Oil #2

O#4= Oil #4

O#6= Oil #6

Front Panel Key Functions:

KER =

Kerosene

LPG = Propane

COL = Coal

–

Move cursor

(z) up

–

Move cursor

(z) down

–

Select Fuel

–

Go to Combustion Test Screen

– Go to

Instruction 0024-9219

Draft Screen for PCAs with a pressure sensor, or the

Memory Directory Screen for PCAs without a pressure

sensor

Operation

4-11

Page 28

Operation

4.9 Draft Screens

(For PCA Models 15, 25, 35, 45, 55 & 65)

The first Draft Screen is displayed by

repeatedly pressing the

the Combustion Test Screen.

To measure draft, first zero the

analyzer’s pressure sensor to atmospheric pressure by disconnec ting th e

draft hose from the bottom of the

instrument, and then pressing the

ENTER

key. Reconnect the draft hose

after the second Draft Screen appears

(shown for 3 seconds). The third

screen shows the current values of

draft and stack temperature as

measured by the analyzer.

When using the analyzer to make a

differential pressure measurement

(Section 4.4), the differential pressure

value will appear on the third Draft

Screen.

To save (S) or print (P) the screen

data, first use the

the cursor (z) in front of the desired

function, and then press the

key.

Front Panel Key Functions:

–

4-12

Move cursor

–

Move cursor

Save or Print screen dat a

–

Go to Combustion Test Screen

–

–

Go to Memory Directory Screen

MENU

st

keys to move

(z) up

(z) down

key from

ENTER

PCA

DRAFT

DISCONNECT DRAFT

HOSE

PRESS ENTER

DRAFT

RECONNECT DRAFT

HOSE

DRAFT

DRAFT

HOT SPOT

–

0.25 XX

190 °C

Where: xx = Unit of measure.

Default is inches of water

column (WC). See Optional

Draft SETUP Screen (Section

4.14) for other choices.

Instruction 0024-9219

P

«

S

Page 29

PCA

4.10 Memory Directory Screen

Operation

‘Standard’ PCA Screen ‘Advanced’ PCA Screen

MEMORY DIRECTORY

«M8 2/24/01 3:45pm

M9 MEMORY EMPTY

CLEAR MEMORY

MEMORY DIRECTORY

«98 2/24/01 3:45pm

99 MEMORY EMPTY

CLEAR MEMORY

The Memory Directory Screen is displayed by repeatedly pressing the

MENU

key from the Combustion Test Screen

. This screen is used to select a

memory location which contains saved data that an operator can review.

NOTE:

bered M0 thru M9, while an ‘advanced’ PCA has 100 memory

locations numbered 0 thru 99.

A ‘standard’ PCA has 10 memory locations num-

To select a data-memory location, first use the

z

) in front of the desired memory location; then press the

(

saved data is now displayed in either the Combustion Test Screen

Screen, depending on whether the chosen memory location contains

combustion or draft information. To print the saved data, refer to Sec- tion

4.23.

After viewing or printing the saved data, use the

cursor (z) to the exit (E) function; then press

memory directory.

Selecting the CLEAR MEMORY

Screen from where all saved data can be erased (refer to Section

function displays the Clear Memory

st keys to move the cursor

ENTER

key. The

or Draft

st keys to move the

ENTER.

This will redisplay the

4.24).

Front Panel Key Functions:

–

Move cursor

–

Move cursor

–

Display the data saved at the chosen memory location

–

Go to Combustion Test Screen

–

Go to Memory To PC Screen for ‘Advanced’ analyzers, or the

Temperature Setup Screen for ‘Basic’ an alyzer s

Instruction 0024-9219

(z) up

(z) down

4-13

Page 30

Operation

4.11 Memory to PC Screen

MEMORY TO PC

«TRANSMIT DATA

CLEAR MEMORY

(For ‘Advanced’ PCA Models 40, 45, 50, 55, 6 0 & 65)

PCA

The Memory To PC Screen is displayed by repeatedly pressing the

from the Combustion Test Screen. Use this screen to either transmit all

stored memory locati ons to a comput er, or clear all

memory locations.

MENU

key

TRANSMIT DATA

Before data can be transmitted to a personal computer, the PCA’s RS-232

output must first be connected to an unused computer COM port using

serial data cable Part No. 24-1073 (see Figure 4-4). Also, a communications program (i.e., ProcommPlus®, Windows 3.x Terminal, or Windows 9x

Hyper Terminal) must be installed, and its communications parameters

configured for: 9600 baud, 8 data bits, 1 stop bit, no parity, and no

handshaking.

4-14

! "

" #

"$

&

' ( )*

Figure 4-4. Connecting the Seri al Dat a Cable

Instruction 0024-9219

%$

Page 31

PCA

Operation

Data is transmitted to a computer in ASCII comma-delimited

which can be captured as a text file and then opened in most commercially available spreadsheet programs. Note that e ach data rec ord consists of 20 fields, some of which may be blank for different tests and PCA

models as listed in Tables 4- 1 & 4-2.

format,

Use the communication softw are to c apt ur e and s a ve th e rec eiv ed d ata as

an ASCII text file. Consult the software’s documentation for detailed

instructions on how to perform this procedure.

To start transmitting data, first use the

in front of TRANSMIT DATA

and then press the

that as PCA downloads its data, the word TRANSMITTING…

on the display.

CLEAR MEMORY

To clear all

(

z

) in front of CLEAR MEMORY

memory locations, first use the

and then press the

Memory Screen will then appear from where all saved data can be erased

(refer to Section

4.24).

Front Panel Key Functions:

st keys to position the cursor (z)

ENTER

key. Observe

appears

st keys to position the cursor

ENTER

key. The Clear

–

Toggle cursor (z) position

–

Toggle cursor (z) position

–

Select function next to cursor

–

Go to Combustion Test Screen

–

Go to ID Setup

Instruction 0024-9219

Screen

4-15

Page 32

Operation

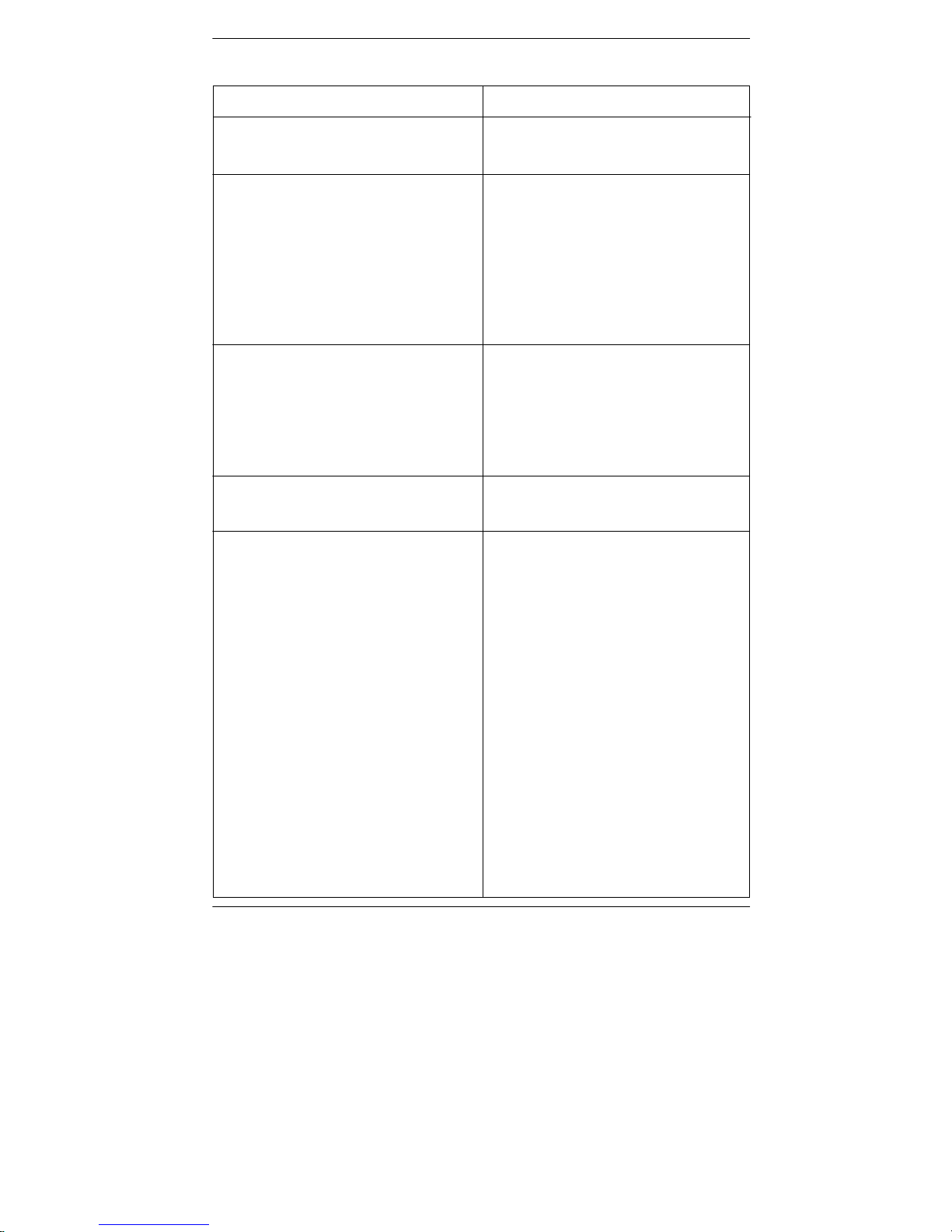

TABLE 4-1. COMMA-DELIMITED FIELDS

Field

Data Name or Value

1

2

3

4

5

6

1

7

1

8

1

9

1

10

1

11

1

12

1,2

13

1,2

14

1,3

15

1,3

16

1,2

17

1

18

1

19

20

21

1

Empty data field for draft tests

2

Empty data field for PCA Models 10, 15, 40 and 45

3

Empty data field for PCA Models 10, 15, 20, 25, 40, 45, 50, and 55

Instrument serial number

ID line 1 (up to 16 characters)

ID line 2 (up to 16 characters)

ID line 3 (up to 16 characters)

Time of test (hh:mm:ss)

Date of test (dd.mm.yyyy)

Name of fuel (up to 16 characters)

Flue gas temperature

Air temperature

Temperature unit of measure (°F or °C)

O2 concentration in %

CO2 concentration in %

CO concentration in ppm

CO referenced to nn% O2 in ppm

NO concentration in ppm

NO referenced to nn% O2 in ppm

O2 Reference used in fields 14 and 16

Combustion efficiency in %

Excess air in %

Draft measurement

Draft unit of meas

TABLE 4-2. TYPICAL SPREADSHEET FOR A PC A 65

SN ID1 ID2 ID3 TIME DATE FUEL TS TA C/F O2

AX1020 ID LINE 1 ID LINE 2 ID LINE 3 9:03:27 PM 2/24/1999 NATGAS 374 68 F 4

AX1020 ID LINE 1 ID LINE 2 ID LINE 3 9:10:35 PM 2/24/1999

C2 CO CF NX NF O2R EF EA DR MB/PA/WC

9.5 12 13 10 11 3 82.2 21 -0.25 WC

Line 1: Column Headings

Line 2: Typical Combustion Readings

Line 3: Typical Draft Readings

4-16

Label in Column

Headings

SN

ID1

ID2

ID3

TIME

DATE

FUEL

TS

TA

C/F

O2

C2

CO

C

F

NX

NF

O2R

ure

EF

EA

D

R

MB/PA/WC

-0.25 WC

Instruction 0024-9219

PCA

Page 33

PCA

4.12 ID Setup Screens

(For ‘Advanced’ PCA Models 40, 45, 50, 55, 60 & 65)

SETUP

«ID #1

ID #2

ID #3

Operation

This initial ID Setup Screen is displayed by repeatedly pressing the

key from the Combustion Test Screen. Use this screen to edit th ree lines

of customer information (e.g., the customer’s name , location, and burner

reference number).

MENU

Each ID line can be up to 16 alphanumerical characters in length. All

three lines will appear at the top of each test record for the pu rpose of

identifying individual tests.

Front Panel Key Functions for the Initial ID SETUP Screen:

–

To enter a line of text, first use the

front of the desired ID line; then press

Number Screen will then appear.

Move cursor (z) upward

–

Move cursor (z) downward

–

Select ID Number that is next to the cursor for editing

–

Go to Combustion Test Screen

–

Go to Temperature Setup Screen

st keys to position the cursor (z) in

ENTER.

The selected ID Line

SETUP

ID #1

«

Now press the

Available characters include:

st keys until the desired letter or number is displayed.

“(space)

ABCDEFGHIJKLMNOPQRSTUVWXYZ0123456789”

Instruction 0024-9219

4-17

Page 34

Operation

Press

ENTER

tion. If you make a mistake, press

to save the selected character and advance to the next posi-

ENTER

until the cursor is over the

incorrect character and make your correction by again using the

After all the desired characters have been selec ted, pres s the

save the text line and return to the initial ID SETUP Screen.

RUN

NOTE:

future test records until it is modified or deleted.

Front Panel Key Functions for the Individual ID SETUP Screens:

The entered ID information will be saved with all

–

4-18

Increment character

D

ecrement character

–

–

Select the displayed character an d a dvan ce t o th e nex t

character position

–

Save the text line and return to the initial ID SETUP Screen

Abort any changes to the text line and return to the initial

–

ID SETUP Screen

Instruction 0024-9219

PCA

st keys.

key to

Page 35

PCA

4.13 Temperature Setup Screen

SETUP

TEMPERATURE UNIT «°C

°

F

Operation

The Temperature Setup Screen is displayed by repeatedly pressing the

MENU

key from the Combustion Test Screen. Use this screen to setup the

analyzer to display temperature in either °C or °F.

To select the temperature unit-of-measure, first use the

the cursor (z) in front of °C

or °F

, and then press the

Front Panel Key Functions:

st keys to move

ENTER

key.

–

Move cursor

–

Move cursor

–

Select unit-of-measure next to cursor

–

Go to Combustion Test Screen

– Go to

sensor, or the O2 Reference Screen for ‘Advanced’ PCA s th at

have an NX and/or CO sensor, or the Language Setup Screen

for all other PCAs

Instruction 0024-9219

(z) up

(z) down

Draft Unit Setup Screen for PCAs with a pressure

4-19

Page 36

Operation

4.14 Draft Unit Setup Screen

(For PCA Models 15, 25, 35, 45, 55 & 65)

SETUP

DRAFT UNIT

The Draft Unit Setup Screen is displayed by repeatedly pressing the

key from the Combustion Test Screen. Use this scr een to setup th e

analyzer to display draft in either millibars (MB), Pascals (PA), or inchesof-water column (WC).

To select the draft unit-of-measure, first use the

cursor (z) in front of

Front Panel Key Functions:

4-20

–

–

–

–

– Go to O

M

PA

«WC

B

MENU

st keys to move the

MB, PA or WC

Move cursor

Move cursor

(z) up

(z) down

Select unit-of-measure next to cursor

Go to Combustion Test Screen

Reference Setup Screen for ‘Advanced’ PCAs that

2

, and then press the

ENTER

key.

have an NX and/or CO sensor, or the Language Setup Screen

for all other PCAs

Instruction 0024-9219

PCA

Page 37

PCA

4.15 O2 Reference Setup Screen

(For ‘Advanced’ PCA Models 50, 55, 60 and 65)

SETUP

O2 REFERENCE 0%

Operation

The O2 Reference SETUP Screen is displayed by repeatedly pressing the

MENU

key from the Combustion Test Screen. Use this screen to select the

O2 reference level that the analyzer will use to calculate the CO and NX

gas levels as referenced to Oxygen.

NOTE:

25, 30 and 35 is preset to 0% O

For PCAs with just a CO sensor, the Com bustio n Test Scr een can sh ow

both the measured level of CO, an d its calcul ate d level r efer enced t o

Oxygen displayed as CF. For PCA s with both C O and NX sensor s, the

Combustion Test Screen can only show either the measured levels of CO

and NX, or their calculated levels r efer enc ed t o Oxy gen dis play ed as CF

and NF, respectively. Refer to S ection

To select the analyzer’s Oxygen reference level, press the

the desired level is displayed, and then press the

Front Panel Key Functions:

Instruction 0024-9219

The O2 reference level for ‘standard’ PCA models 20,

and cannot be changed.

2

4.17 for set up instructions.

ENTER

key.

–

Increment O2 Reference (15% max)

–

Decrement O2 Reference (0% min)

– Select O

–

Go to Combustion Test Screen

– G

o to Language Setup Screen

Reference

2

st keys until

4-21

Page 38

Operation

4.16 Language Setup Screen

SETUP

LANGUAGE

The Language Setup Screen is displayed by repeatedly pressing the

key from the Combustion Test Screen. Use this screen to select the

language displayed on the analyzer. The languages available for selection

include English (ENG), Spanish (ESP), and French (FRA).

To select a language, first use the

of ENG, ESPor

Front Panel Key Functions:

4-22

FRA

, and then press the

–

Move cursor

–

Move cursor

–

Select Language next to cursor

–

Go to Combustion Test Screen

– Go to

Display Mode Setup Screen for PCAs that have both a

CO and NX sensor, or the Time/D ate Set up S cree n for all

other PCAs

«ENG

ESP

FRA

(z) up

(z) down

st keys

to move the cursor (z) in front

ENTER

key.

Instruction 0024-9219

MENU

PCA

Page 39

PCA

4.17 Display Mode Setup Screen

(For PCA Models 30, 35, 60 & 65)

SETUP

DISPLAY

«CO

CF NF

NX

Operation

The Display Setup Screen is displ ayed by repeate dly pressi ng the

from the Combustion Test Scree n. U se thi s scr ee n to sel ect whe ther the

Combustion Test Screen will display the measured values of Carbon

Monoxide and Nitric Oxide (CO and NX), or the calculated values of these

gases (CF and NF) referenced to Oxygen.

NOTE:

cluded on the printout and in the downloaded data of each

combustion test, regardless of what is being displayed on the

Combustion Test Screen.

The levels of CO, NX, CF and NF are always in-

MENU

To setup the display, first use the

of either

then press the

CO

NX

(measured values), or CF NF (calculated values), and

ENTER

key.

Front Panel Key Functions:

st keys to move the cursor (z) in front

–

Move cursor (z) up

–

Move cursor (z) down

–

Select Display Mode next to cursor

–

Go to Combustion Test Screen

– Go to

Instruction 0024-9219

Time/Date

Setup Screen

key

4-23

Page 40

Operation

4.18 Time / Date Setup Screen

SETUP

«

TIME

DATE

03:12:45 pm

02/24/01

The Time/Date Setup Screen is displayed by repeatedly pressing the

key from the Combustion Test Screen. Use this scree n to enter the cur-

rent time and date as follows:

Use the

field to be changed, and then press the

inside the selected field. Again press the

position to change; after which, use the

the value of that field. Continue using the

values within the chos en fi el d a re co rr ect ; t hen pre ss

values and return the cursor to the left side of the screen.

Front Panel Key Functions:

st keys to move the cursor (z) in front of the TIME

ENTER

key to move the cursor

ENTER

key to select the field

st keys to increase or decrease

ENTER

and

st keys until all

RUN

–

Move cursor (z) up, or Increase value in selected fiel d

position

or DATE

to save all field

–

Move cursor (z) down, or Decrease value in selected field

position

– Select Time or Date field to be changed as selected by the

cursor's position, and then use to move the cursor

the field positions

through

–

Go to the Combustion Test Scr een, or sav e th e ti me an d da te

values and return cursor to left side of screen

–

Go to Setup / Printer Screen, or return cursor to left side of

screen

4-24

Instruction 0024-9219

PCA

MENU

Page 41

PCA

4.19 Printer Setup Screen

SETUP

«IR - HP

IR - IRDA

RS232

PRINTER

Operation

The Printer Setup Screen is displayed by repeatedly pressing the

key from the Combustion Test Screen. Use this screen to choose the type

of connection and printer being used.

MENU

IR-HP: Infrared connection to a printer manufactured by Hewlett

Packard, which uses their proprietary infrared communications protocol

IR-IRDA: Infrared connection to a printer that uses a standard IrDA

protocol

RS232: Cable connection between the PCA and any serial printer

capable of 9600 baud operation

Use the

and printer, and then press the

return to the Combustion Test Screen.

st keys to move the cursor (z) in front of the desi r ed co nne ct i on

ENTER

key to make the selection and

Front Panel Key Functions:

–

Move cursor (z) up

–

Move cursor (z) down

–

Select connection and printer next to cursor

–

Instruction 0024-9219

Go to Combustion Test Screen

– Go to

Calibration / Maintenance Password Screen

4-25

Page 42

Operation

4.20 Calibration / Maintenance

Password Screen

PCA models 10 thru 35 PCA models 40 thru 65

CALIBRATION

«PASSWORD XXX

Where: xxx = Password number

The Calibration / Maintenance Password Screen is displayed by repeat-

edly pressing the

three-digit password must be ent ered to access the PC A 10 thr u 35’s

Calibration Menu Screen (Section 5.3), or a PCA 40 thru 65’s Maintenance Screen (Section 4.21). The password is provided on the Portable

Combustion Analyzer Calibration Password

the analyzer.

MENU

key from the Combustion Test Screen. From here a

To enter the password, first press the

the first number field; next press the

password is displayed; then pr ess

field. In a similar manner, enter the next two password digits. Then press

the

RUN

key after the correct password is entered to display either the

Calibration Menu Screen or the Maintenance Screen.

Front Panel Key Functions:

–

4-26

No action, or increase valu e in passw ord n umber f iel d

–

No action, or decrease value in password number field

–

Move cursor

–

Go to Combustion Test Screen (if cursor is on left side of

screen), or go to either the Calibration Menu or Maintenance

Screen (if the proper password was entered), or return cursor

to left side of screen (if the wrong pas swor d was ent ered)

–

Go to Combustion Test Screen (if cursor is on left side of

screen)

inside the password number field)

(z) to next position in password number field

, or return cursor to left side of screen (if cursor is

ENTER

MAINTENANCE

«PASSWORD XXX

card that was supplied with

ENTER

st keys until the first digit of the

key to move the cursor (z) into

to advance to the second number

Instruction 0024-9219

PCA

Page 43

PCA

4.21 Maintenance Screen

(For PCA Models 40, 45, 50, 55, 60 & 65)

MAINTENANCE

«CALIBRATION

USER NAME

Operation

The Maintenance Screen is displayed after entering the correct password

in the Maintenance Password Screen. Use this screen to eithe r enter the

analyzer’s Calibration Menu Scr een or User Nam e Scr een.

To enter the Calibration Menu Screen (Sec tion 5.3 ), use the

position the cursor (z) in front of CALIBRATION

ENTER

key.

, and then press the

To enter the User Name Screen (Section 4.22), use the

the cursor (

z

) in front of USER NAME, and then press the

st keys to

st keys to position

ENTER

key.

Front Panel Key Functions:

–

Toggle cursor (z) position

–

Toggle cursor (z) position

–

Select function next to cursor

–

Go to Combustion Test Screen

– No action

Instruction 0024-9219

4-27

Page 44

Operation

4.22 User Name Screens

(For PCA Models 40, 45, 50, 55, 60 & 65)

USER NAME

«LINE 1

LINE 2

LINE 3

This initial User Name Screen is displayed after selecting USER NAME

from the Maintenance Screen. Use this screen to either enter or edit three

lines of user-name information.

Each user-name line can be up to 20 alphanumerical characters in length.

All three lines will appear at the top of each printout for the purpose of

identifying the user or owner of the instrument (i.e., your company’s

name and address).

Front Panel Key Functions for Initial User Name Screen:

–

Move cursor (z) upward

–

Move cursor (z) downward

–

Select Line Number next to the cursor for editing

–

Go to Combustion Test Screen

–

Return to Maintenance Screen

To enter text, first use the

desired line number; then press

Number Screen will then appear.

st keys to position the cursor (z) in front of the

USER NAME

LINE 1

«

Now press the

Available characters include:

“(space)

4-28

st keys until the desired letter or number is displayed.

ABCDEFGHIJKLMNOPQRSTUVWXYZ0123456789”

ENTER.

The selected User Name Line

Instruction 0024-9219

PCA

Page 45

PCA

Press

ENTER

to save the selected character and advance to the next position. If you make a mistake, press

character and make your correction by again using the

ENTER

until the cursor is over the wrong

st keys.

After all the desired characters have been selec ted, press

text line and return to the initial User Name Screen.

Front Panel Key Functions for Individual User Name Screens:

RUN

–

Increment character

D

ecrement character

–

–

Select the displayed character and advance t o the next

character position

Save the text line and return to the initial User Name Screen

–

–

Abort any changes to the text line and return to the initial

User Name Screen

4.23 Saving Test Data

O2 4.0 CO

C2 9.5 NX 15 NG

TA 68.0 TS 374 P

EF 82.6 EA 21 «S

To save the data displayed in either the Combustion Test or Draft

Screen, first use the

function and then press the

memory, and can be recalled at a later time for viewing from the

Directory Screen (Section 4.10).

NOTE:

memory location. After all memory locations are filled, any

additional data that is saved will start overwriting data

starting at the first memory location.

Instruction 0024-9219

12 HLD

st keys to move the cursor (z) in front of the save (S)

Data will be automatically stored in the next free

DRAFT

HOT SPOT 374 °F

ENTER

key. The displayed data will be saved

–

0.25 WC

Operation

to save the

DRAFT

P

«S

Memory

4-29

in

Page 46

Operation

4.24 Printing Test Data

O2 4.0 CO

C2 9.5 NX 15 NG

TA 68.0 TS 374 «P

EF 82.6 EA 21 S

Before printing, ensure that the correct

connection and printer has been select ed per

Section 4.19.

The Print function is available in either the

Combustion Test Screen or the Draft Screen.

NOTE:

memory can also be printed. First go to

the Memory Directory Screen (Section

4.10) and display the data to be

printed; then print the data as described below.

When using an infrared printer:

1.

Place analyzer in-line with the printer’s

IR input (see Figure 4-5).

2.

Use the

st keys to move the cursor (z) in

front of the print (

3.

Press the

4-30

12 HLD

DRAFT

HOT SPOT 374 °F

The data which is stored in

P

) function.

ENTER

key to start printing.

Figure 4-5. Aligning the Printer’s

–

0.25 WC

)

)

/)0

.

IR input to the Analyzer

Instruction 0024-9219

DRAFT

«P

S

PCA

Page 47

PCA

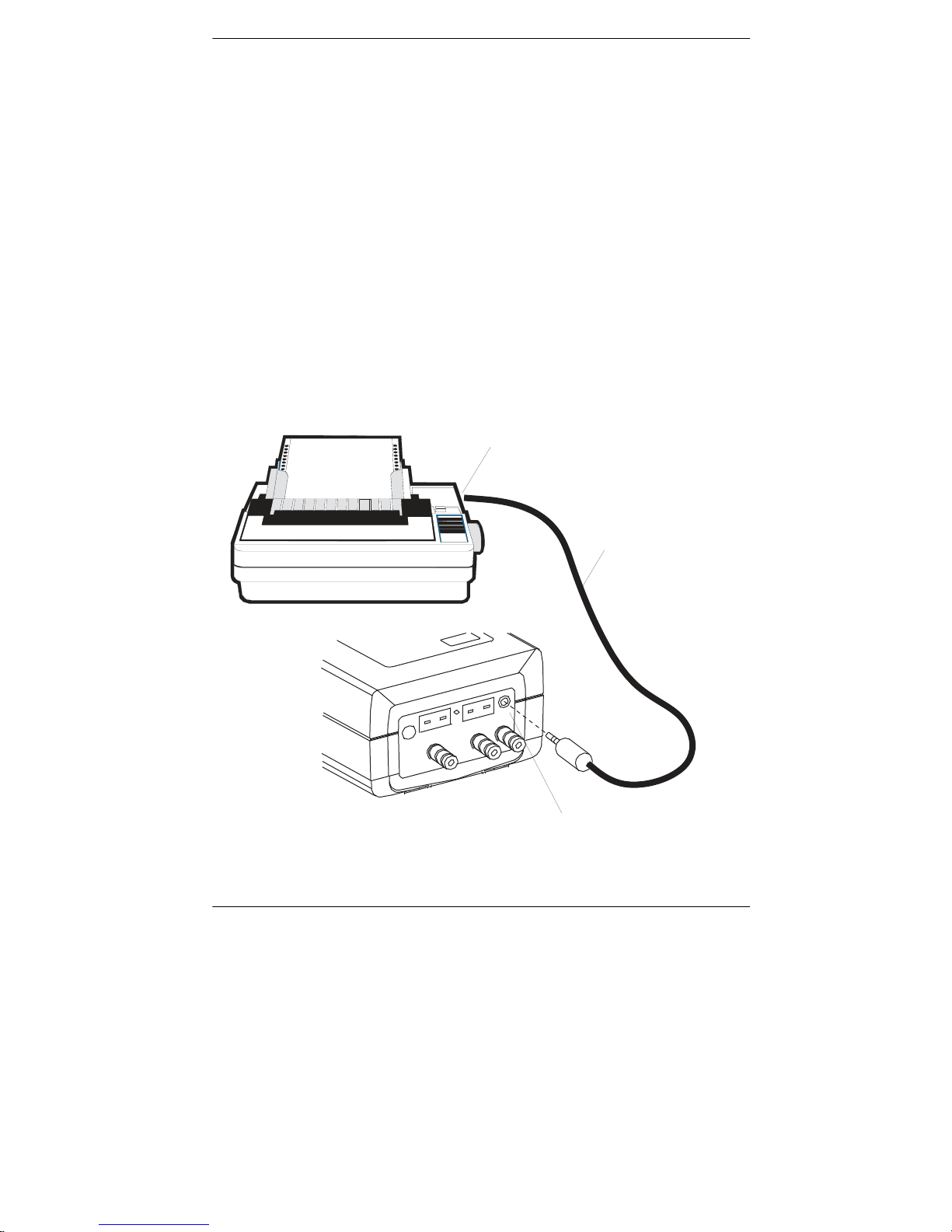

When using a serial printer:

1.

First connect the analyzer to the printer using the optional RS-232

cable (see Figure 4-6).

2.

Set the printer’s communication parameters to 9600 baud, 8 data bits,

stop bit, no parity, and no handshaking.

1

3.

Use the

function.

st keys to move the cursor (z) in front of the print (P)

4.

Press the

Instruction 0024-9219

ENTER

key to start printing.

Figure 4-6. Connecting a Serial Printer to the Analyzer

"$ "

! "

" #

& '

"$

"

( )*

Operation

%$

4-31

Page 48

Operation

4.25 Clear Memory Screen

CLEAR MEMORY

C

«E

The Clear Memory Screen is accessed from either the Memory Director y

Screen (Section 4.10) or the Memory to PC Screen (Section 4.11).

To clear all memory locations, use the

front of the clear (C) function, and then press the

st keys to move the cursor (z) in

ENTER

key.

To return to the previous screen without clearing memory, place the cursor

(

z

) in front of the exit (E) function and press

ENTER.

4.26 Resetting the Microprocessor

If the analyzer “locks-up” and cannot be turned OFF, reset the microprocessor by pressing the RESET button (Figure 4-7). The button can be

activated using the end of a paper clip.

Figure 4-7. Reset Button

4-32

RESET

BUTTON

Instruction 0024-9219

PCA

Page 49

PCA

5.0 CALIBRATION

Calibration

NOTE:

by your nearest Bacharach Servi ce Ce nter. Calibr at ion,

however, can be performed in the field if your facility has the

necessary equipment and qualified personnel to perform the

procedures described in the sections that follow.

Important! To prevent the loss of data during calibration,

perform the following procedures usin g fresh batteries, or

using an optional Power Supply (see Section 3.2).

Do not make calibration adjustments to the instrument without applying calibration span gas. Making

adjustments without applying span gas could render

the instrument inaccurate or unusable until re-calibration is performed correctly with span gas.

Bacharach recommends that the PCA be calibrated

5.1 Sensor Check

Important! Before turning on the analyzer or performing

any of the calibration procedures, ensure that the analyzer

will be sampling fresh air, and that the probe is at room

temperature.

When the analyzer is first turned on and allowed to cycle through its

second warmup period, and while sampling fresh air, the sensors are

60

checked (read) and calibrated (set) to the following ambient conditions:

•

Oxygen sensor is spanned to 20.9%

• Carbon Monoxide sensor (if install ed) is zeroed

• Nitric Oxide sensor (if installed) is zeroed

• Pressure sensor (if inst alled) is zer oed

If a sensor problem is detected by the analyzer’s microproce ssor during

the warm-up cycle, an error message will be displayed at the b ottom of

the LCD display. Refer to Section 7.2 for a listing of the error codes.

Instruction 0024-9219

5-1

Page 50

Calibration

5.2 Calibration Fixtures

A gas and a draft fixture will be required to perform the various calibration procedures described in this manual.

Material Required:

• Calibration Kit (Refer to Section 8.2)

• Calibration Gas Cylinder (Refer to Section 8.2)

• Bellows

• Micromanometer

Procedure:

Assemble the appropriate fixture shown in Figure 5-1 as required by the

calibration procedure being performed.

GAS

FIXTURE

Leave Top

Port Open

2

3

1

3

DRAFT

FIXTURE

Parts Shown:

1. Gas Cylinder

2. Regulator*

3. Tubing*

4. Tee*

5. Flowmeter*

6. Fitting, Gas*

7. Fitting, Draft*

* Contained in Calibration Kit

3

4

7

5-2

Micromanometer

Figure 5-1. Calibration Fixtures

4

3 5

3

6

Bellows

Instruction 0024-9219

PCA

Page 51

PCA

5.3 Calibrate Menu Screen

«TS-ZERO CALIBRATE

TS-SPAN NX

TA-ZERO CO

TA-SPAN DRAFT

Calibration

The Calibrate Menu Screen is displayed after entering either the correct

password in the Calibration Password Screen for ‘standard’ PCAs, or the

Maintenance Password Screen and selecting CALIBRATION from the

Maintenance Screen for ‘advanced’ PCAs (refer to Sections 4.19 and 4.20).

Use this screen to select the sensor to be calibrated.

Press the

and then press the

st keys

until the cursor (z) is in front of the desired function,

ENTER

key.

NOTE: TS is the stack temperature sensor, while TA is the

optional Room Air/Primary Air temperature sensor.

NOTE: If an optional sensor is not installed, the user will

not be able to enter the corresponding calibration screen.

Front Panel Key Functions:

–

Move cursor

(z) up

–

Move cursor

(z) down

–

Select sensor to be calibrated next t o cursor

–

Go to Combustion Test Screen

–

Return to previous screen

Instruction 0024-9219

5-3

Page 52

Calibration

5.4 Calibrate TS-Zero

Material Required:

• Thermocouple Simulator (K-type) Range: 0 to 600 °F

Accuracy: ±0.5 °F

Procedure:

1.

With the analyzer turned off, first plug the simulator’s K-type connec-

tor

into the T-STACK jack (Figure 3-2); then turn on the analyzer and

wait for its warm-up cycle to complete.

2.

Enter the Calibration Menu Screen per Section 5.3; then choose

TS-ZERO to zero the analyzer’s stack temperature channel.

3.

Adjust the simulator to 32 °F (0 °C).*

4.

Wait until the MEASURED reading on the screen stabilizes. Then use

the

st and

(0 °C).

ENTER

keys to enter an APPLIED value that equals 32 °F

Typical Calibrate TS-Zero Screen During Calibration Procedure:

CALIBRATE TS-ZERO

MEASURED 37.0°F

APPLIED 0032.0°F

4.

Press the

of the APPLIED value. At this time the Calibrate Menu Screen is

redisplayed.

* The TS-Zero calibration range is 32 – 41 °F (0 – 5 °C). Any attempt to

calibrate outside this range will cause the analyzer to display the

message BAD CALIBRATION ENTRY.

5-4

RUN

key to calibrate the analyzer’s MEASURED value to

Instruction 0024-9219

PCA

that

Page 53

PCA

5.5 Calibrate TS-Span

Material Required:

• Thermocouple Simulator (K-type) Range: 0 to 600 °F

Accuracy: ±0.5 °F

Procedure:

1.