Page 1

Combustion Analyzer

for Commercial & Light Industrial Use

®

Combustion & Emissions

P/N: 0024-9551 | February 2019 Revision 2

User

Manual

Page 2

PCA® 400 User Manual

WARRANTY POLICY

Bacharach, Inc. warrants to buyer that at the time of delivery this product will be free from defects in material and

manufacture and will conform substantially to Bacharach, Inc.’s applicable specications. Bacharach’s liability and

buyer’s remedy under this warranty are limited to the repair or replacement, at Bacharach’s option, of this product or

parts thereof returned to seller at the factory of manufacture and shown to Bacharach, Inc.’s reasonable satisfaction to

have been defective; provided that written IMPORTANT of the defect shall have been given by buyer to Bacharach, Inc.

within one (1) year after the date of delivery of this product by Bacharach, Inc.

Bacharach, Inc. warrants to buyer that it will convey good title to this product. Bacharach’s liability and buyer’s remedy

under this warranty of title are limited to the removal of any title defects or, at the election of Bacharach, to the

replacement of this product or parts thereof that are defective in title.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND ARE GIVEN AND ACCEPTED IN LIEU OF (I) ANY AND ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE: AND (II) ANY OBLIGATION, LIABILITY, RIGHT,

CLAIM OR REMEDY IN CONTRACT OR TORT, WHETHER OR NOT ARISING FROM BACHARACH’S NEGLIGENCE,

ACTUAL OR IMPLIED. The remedies of the buyer shall be limited to those provided herein to the exclusion of any

and all other remedies including, without limitation incidental or consequential damages. No agreement varying or

extending the foregoing warranties, remedies or this limitation will be binding upon Bacharach, Inc. unless in writing,

signed by a duly authorized ocer of Bacharach.

Register Your Warranty by Visiting: www.mybacharach.com

SERVICE POLICY

Bacharach, Inc. maintains a service facility at the factory. Some Bacharach distributors / agents may also have repair

facilities; however, Bacharach assumes no liability for service performed by anyone other than Bacharach personnel.

Repairs are warranted for 90 days after date of shipment (sensors, pumps, lters and batteries have individual warranties).

Should your analyzer require non-warranty repair, you may contact the distributor from whom it was purchased or

you may contact Bacharach directly.

If Bacharach is to do the repair work, send the monitor, prepaid, to the closest service center.

Prior to shipping equipment to Bacharach, visit www.mybacharach.com for an Returned Merchandise Authorization

Number (RMA #). All returned goods must be accompanied with an RMA #. Pack the equipment securely (in its original

packing, if possible), as Bacharach cannot be held responsible for any damage incurred during shipping to our facility.

Always include your RMA #, shipping address, telephone number, contact name, billing information and a description

of the defect as you perceive it. You will be contacted with a cost estimate for expected repairs prior to the performance

of any service work. For liability reasons, Bacharach has a policy of performing all needed repairs to restore the

monitor to full operating condition.

IMPORTANT

Product improvements and enhancements are on-going, therefore the specications and information contained in

this document may change without IMPORTANT.

Bacharach, Inc. shall not be liable for errors contained herein or for incidental or consequential damages in connection

with the furnishing, performance, or use of this material.

No part of this document may be photocopied, reproduced, or translated to another language without the prior

written consent of Bacharach, Inc.

Copyright © 2019, Bacharach, Inc., All Rights Reserved.

BACHARACH, PCA, B-SMART, and FYRITE are registered trademarks of Bacharach, Inc. All other trademarks, trade names, service marks and logos

2

referenced herein belong to their respective companies.

0024-9551 Revision 2

Page 3

PCA® 400 User Manual

Table of Contents

Introduction ..................................................... 6

1.1 About this Manual ........................................................................................................... 6

1.2 Conventions ...................................................................................................................... 6

1.2.1 Short Form Instructions...............................................................................................................................6

1.2.2 Iconography .................................................................................................................................................. 7

1.3 General Safety Statements ............................................................................................. 7

1.4 Product Overview ............................................................................................................ 8

1.5 North America (NA) vs. Siegert (S) Combustion Equations .......................................... 9

Product Description ....................................... 10

2.1 Combustion & Emissions Analyzer .............................................................................. 11

2.1.1 Overview ......................................................................................................................................................11

2.1.2 Keypad .........................................................................................................................................................12

2.1.3 Display .........................................................................................................................................................12

2.1.4 Instrument Connections ............................................................................................................................14

2.1.5 Interfaces ....................................................................................................................................................15

2.1.6 Components ...............................................................................................................................................16

2.2 Sample Line & Probe Assembly .................................................................................... 17

2.3 PowerCongurations .................................................................................................... 18

Operation ........................................................ 19

3.1 Setup................................................................................................................................ 19

3.1.1 Operation Tips ............................................................................................................................................19

3.1.2 Inspection / Prerequisites ..........................................................................................................................21

3.1.3 Connecting Probe Assembly ......................................................................................................................22

3.2 Performing Combustion Test ....................................................................................... 23

3.2.1 Combustion User Preferences ..................................................................................................................23

3.2.2 Combustion Analysis .................................................................................................................................24

3.2.3 Additional Settings .....................................................................................................................................27

3.2.4 Combustion Average Test ..........................................................................................................................31

3.3 Performing Pressure Test ............................................................................................. 32

3.3.1 Pressure User Preferences ........................................................................................................................32

3.3.2 Pressure Analysis ........................................................................................................................................32

3.4 Performing Leak Tests (Siegert Only) ............................................................................ 34

3.4.1 Let-by Test ...................................................................................................................................................34

3.4.2 Tightness Test .............................................................................................................................................35

3.5 Performing Temperature Test ..................................................................................... 36

3.5.1 Temperature User Preferences .................................................................................................................36

3.5.2 Temperature Analysis ................................................................................................................................37

3

0024-9551 Revision 2

Page 4

PCA® 400 User Manual

Settings & Features ........................................ 39

4.1 Language Selection ........................................................................................................ 39

4.2 Date & Time .................................................................................................................... 39

4.3 Username ....................................................................................................................... 40

4.4 Button Sound ................................................................................................................. 41

4.5 Inactivity Timeout .......................................................................................................... 41

4.6 Post-Purge Period .......................................................................................................... 41

4.7 Carbon Monoxide (CO) Zero ......................................................................................... 41

4.8 Sensor Setup ................................................................................................................... 42

4.9 Bluetooth® Setup ........................................................................................................... 43

4.10 Printer Setup ..................................................................................................................44

4.11 Onboard Data Logging ..................................................................................................45

4.12 Memory File Management ............................................................................................46

4.13 Fresh Air Purge without Removing Probe ..................................................................47

4.14 Sensor Protection / Dilution Mode ..............................................................................48

4.15 Smoke Number Test ...................................................................................................... 49

4.16 Oil Derivative Test ..........................................................................................................50

4.17 Boiler Temperature Test ............................................................................................... 50

4.18 Combustion Equations .................................................................................................. 50

Care & Maintenance ...................................... 51

5.1 Emptying the Water Trap .............................................................................................. 51

5.2 Replacing the Filter Element ........................................................................................ 52

5.3 Cleaning the Probe Assembly ....................................................................................... 53

5.4 Sensor Replacement ...................................................................................................... 54

5.5 B-Smart® Sensor Calibration ........................................................................................ 57

5.5.1 B-Smart® Sensors .......................................................................................................................................57

5.5.2 Starting a Calibration ................................................................................................................................58

5.5.3 B-Smart® Sensor Calibration ....................................................................................................................58

4

0024-9551 Revision 2

Page 5

PCA® 400 User Manual

5.6 Manual Sensor Calibration ........................................................................................... 61

5.6.1 Starting a Calibration ................................................................................................................................61

5.6.2 CO

5.6.3 SO2 Sensor Calibration ..............................................................................................................................65

5.6.4 NO Sensor Calibration ...............................................................................................................................66

5.6.5 NO2 Sensor Calibration .............................................................................................................................67

5.6.6 CO

Sensor Calibration ..........................................................................................................................62

LOW

Sensor Calibration ..........................................................................................................................69

HIGH

5.7 Troubleshooting ............................................................................................................. 70

5.7.1 Error Codes .................................................................................................................................................70

5.7.2 Error Symbols .............................................................................................................................................71

5.7.3 Diagnostics & Status Screens ....................................................................................................................71

Additional Information ................................. 73

6.1 TechnicalSpecications ................................................................................................ 73

6.1.1 Instrument Details .....................................................................................................................................73

6.1.2 Approvals ....................................................................................................................................................74

6.1.3 Measurement Range & Accuracy ..............................................................................................................74

6.1.4 Calculated Readings ..................................................................................................................................75

6.2 PCA® Reporting Software .............................................................................................. 76

6.2.1 Downloading Stored Data to a Computer ...............................................................................................76

6.2.2 Importing Saved Data ................................................................................................................................76

6.3 Bacharach Combustion App ......................................................................................... 79

Parts & Accessories ........................................ 80

7.1 Part Numbers ................................................................................................................. 80

7.2 Service Center Locations ............................................................................................... 82

5

0024-9551 Revision 2

Page 6

PCA® 400 User Manual

1. Introduction

1.1 About this Manual ............................................................................................................ 6

1.2 Conventions ....................................................................................................................... 6

1.2.1 Short Form Instructions...............................................................................................................................6

1.2.2 Iconography .................................................................................................................................................. 7

1.3 General Safety Statements .............................................................................................. 7

1.4 Product Overview ............................................................................................................. 8

1.5 North American (NA) vs. Siegert (S) Combustion Equations ....................................... 9

1.1 About this Manual

Thank you for investing in a Bacharach PCA® 400 Combustion Analyzer. To ensure operator

safety and the proper use of the PCA® 400, please read the contents of this manual for

important information on the operation and maintenance of the analyzer.

IMPORTANT: Before using this product, carefully read and strictly follow the

instructions in the manual.

1.2 Conventions

1.2.1 Short Form Instructions

This document uses a short form for describing steps (e.g. executing a command).

Example:

Selecting fuel type of application being tested.

Short Form Instructions:

f To select Fuel Type: Main Menu Fuel Menu (

being tested.

Steps Required:

1. Open the Main Menu.

2. Select Fuel Menu (indicated by the

icon

) select the fuel used in the application

).

3. Select desired fuel type from the listed options.

6

0024-9551 Revision 2

Page 7

PCA® 400 User Manual

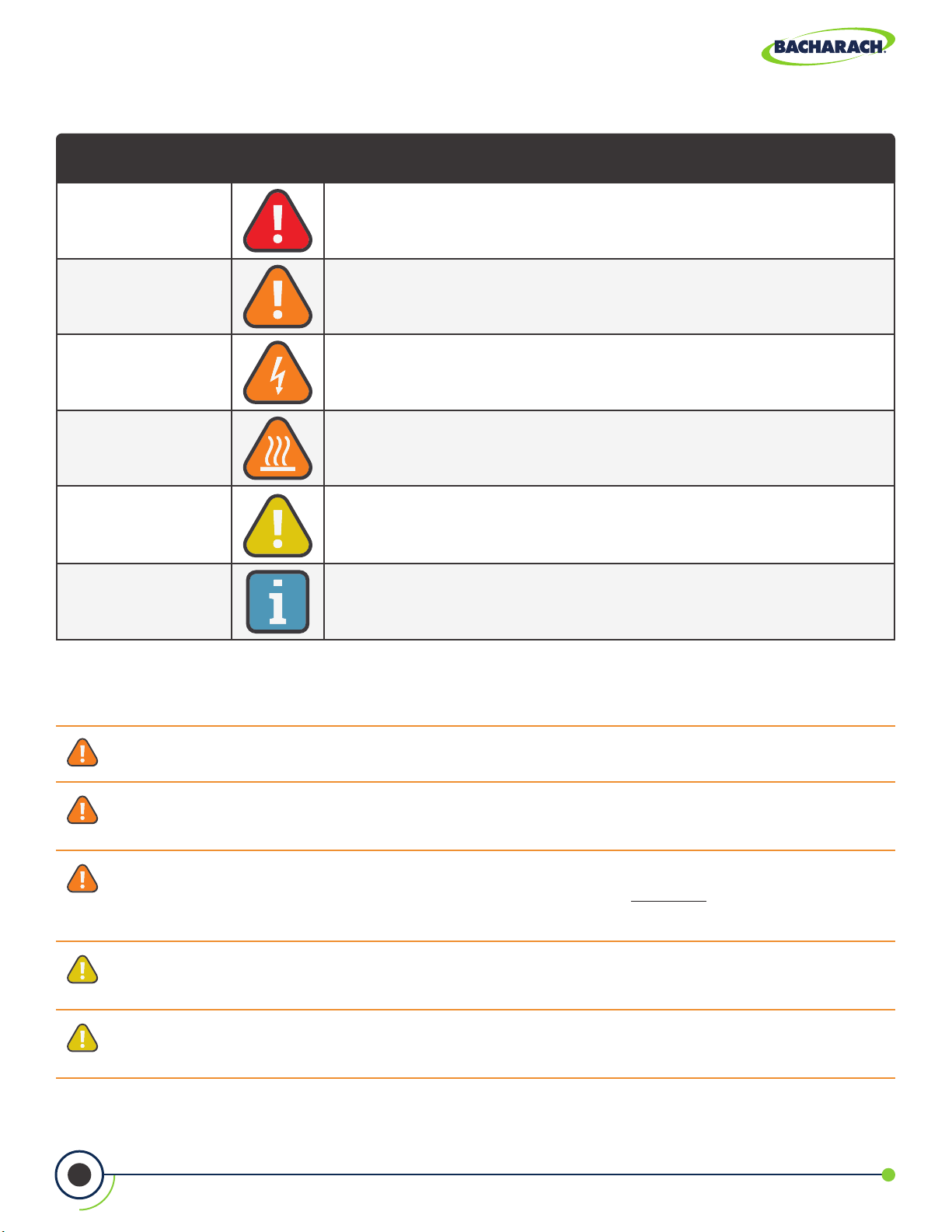

1.2.2 Iconography

Alert Icon Description

DANGER

WARNING

WARNING

WARNING

CAUTION

IMPORTANT

Imminently hazardous situation which, if not avoided, will result

in death or serious injury.

Potentially hazardous situation which, if not avoided, could

result in death or serious injury.

Potential electrical shock hazard which, if not avoided, could

result in death or serious injury.

Hot surface which, if not avoided, could result in physical injury

or damage to the product.

Potentially hazardous situation which, if not avoided, could result

in physical injury or damage to the product or environment. It

may also be used to alert against unsafe practices.

Additional information on how to use the product.

1.3 General Safety Statements

WARNING: This analyzer is not intended to be used as a safety device.

WARNING: When testing an appliance, a full visual inspection should be performed to

ensure its safe operation.

WARNING: This analyzer has not been designed to be intrinsically safe for use in areas

classied as being hazardous locations. For your safety, DO NOT use it in hazardous

(classied) locations.

CAUTION: This analyzer is designed for on-demand and / or semi-continuous sampling

and is not intended to be used on a continuous basis.

CAUTION: Do not store instrument or its sensors with solvents or products which

contain solvents.

7

0024-9551 Revision 2

Page 8

PCA® 400 User Manual

CAUTION: Except for sensor and battery replacement, this analyzer should only be

opened and / or serviced by authorized Bacharach personnel. Failure to comply may void

the warranty.

CAUTION: When the instrument is used in an inecient furnace or boiler application

where there is a high soot concentration, the probe’s sample lter may become

clogged. Before every use check the lter to conrm that it is clean or replace it with

a new lter.

CAUTION: Never disconnect the probe from the instrument until purging is complete.

Otherwise, leftover target gas (for example, CO) may remain in the probe and cause

inaccurate zeroing at power up that could lead to inaccurate gas measurements

afterwards.

1.4 Product Overview

The PCA® 400 is an industrial-grade, hand-held combustion and emissions analyzer

for on-demand and / or semi-continuous sampling of commercial and light industrial

appliances (furnaces, boilers and engines).

Standard Product Conguration

The base instrument is supplied with a probe and hose assembly, factory calibrated / installed

sensors, printer interface, hard carry case, lters, USB cable, PC Software (digital download),

AC adapter and a rechargeable lithium-ion battery pack. The reporting kit version (in addition

®

to the base) includes an IrDA + Bluetooth

printer and printer paper.

Intended Product Applications

The intended purpose of the measuring device is for:

• Engineerings servicing / monitoring industrial combustion plants process systems,

power stations

• Emissions inspectors, Engine manufacturers and operators, service engineers &

mechanics of burner /boiler manufacturers in the industrial sector.

®

Typical measuring tasks and particular characters of the PCA

400 include:

• Measurement on industrial engines (CO / NO dilution)

• Measurement on gas turbines (High precision CO and NO plus optional dilution).

• Emissions measurements (integrated ow speed and dierential pressure measurement)

The PCA® 400 has not been designed for and SHOULD NOT be used for the following:

• Continuous measurements over 5-hours

• As a safety (alarm) instrument.

8

0024-9551 Revision 2

Page 9

PCA® 400 User Manual

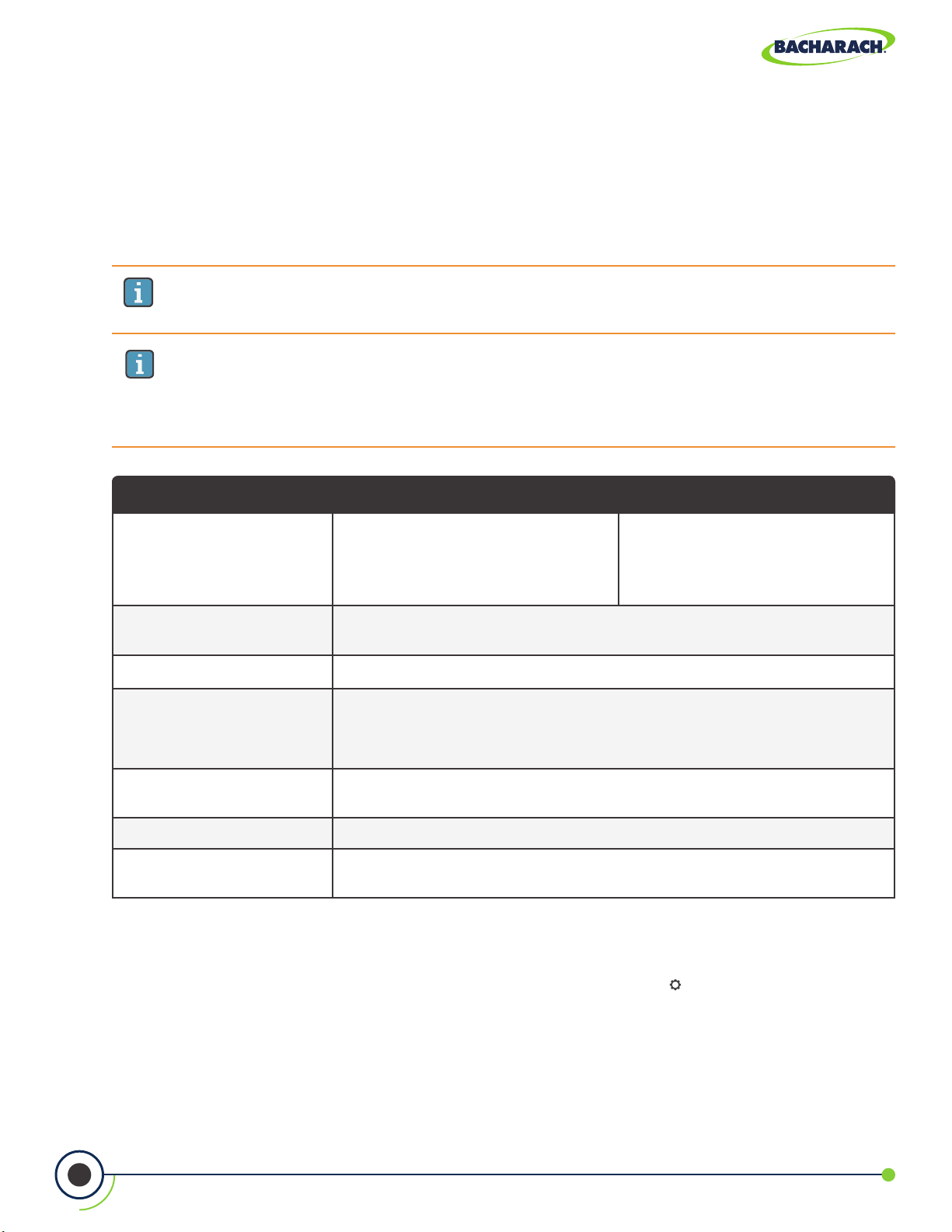

1.5 North American (NA) vs. Siegert (S)

Combustion Equations

Though the combustion process is fairly standardized across the globe, a combustion

analyzer intended for worldwide use demands a degree of exibility for a few regional

preferences.

IMPORTANT: Detailed dierences between North American and Siegert

congurations are noted where appropriate in this manual.

IMPORTANT: The Combustion Equations setting is used to congure the

instrument to use either North American combustion equations or Siegert

combustion equations. Changing this setting resets memory and the values of

other settings.

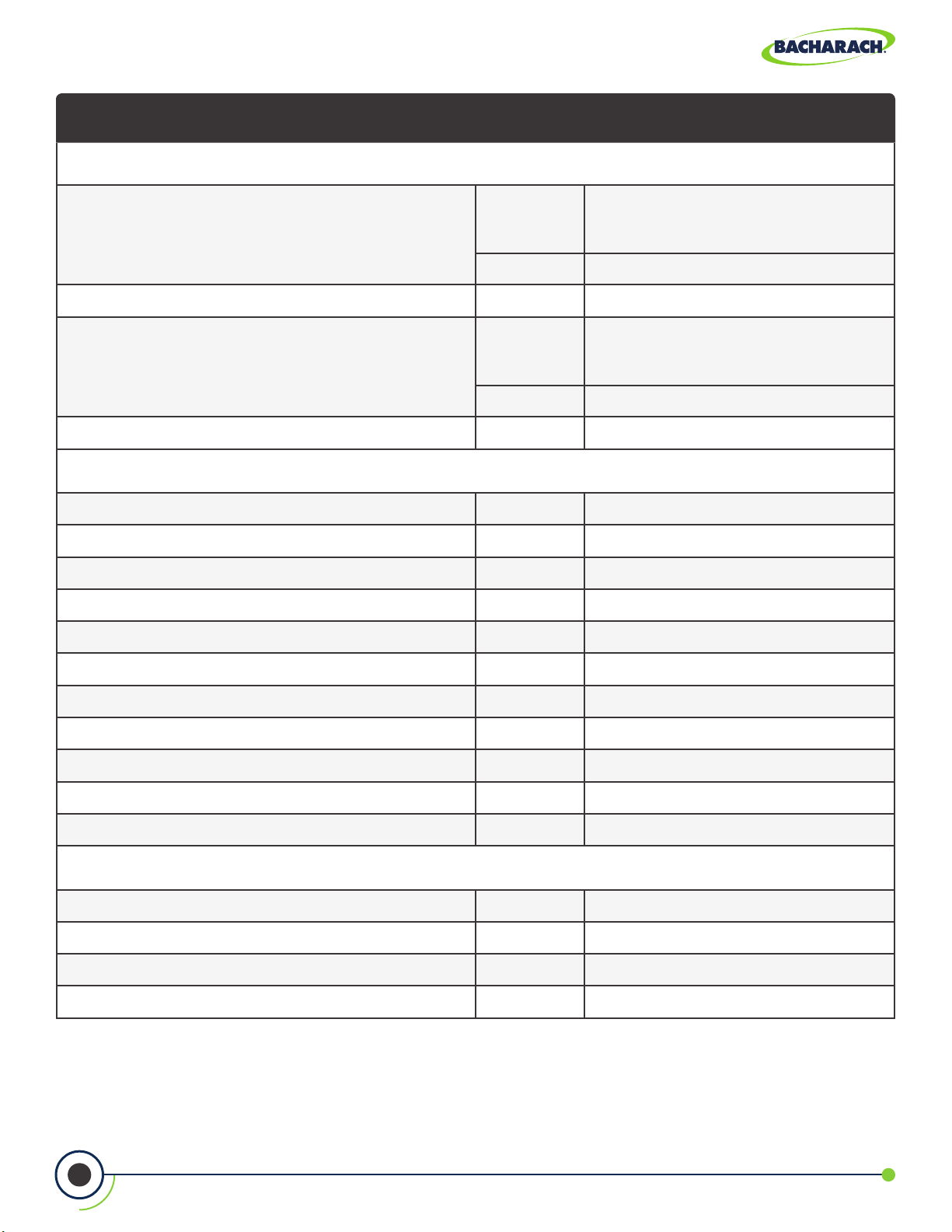

Feature North American (NA) vs. Siegert (S) Conguration

Countries

Heating Values

Fuels Dierent fuel sets and composition.

Dierent RUN

Parameters

Extra Siegert Parameters

CO

Max In the Siegert conguration, the user can set a CO2 Max number for the fuel.

2

Languages

®

The PCA

400 provides a North American (NA) conguration and a Siegert (S) conguration

Typical North American (NA) Users

Asia, Australia, Latin America,

North America, South America

For combustion calculations, Siegert uses the fuel’s lower heating value; NA

uses the higher value.

EFF (NA) vs. Stack loss and ETA (S)

Excess Air (NA) vs. Lambda (S)

(Lambda is similar to excess air)

CO/CO

displayed for Siegert only.

3 for the North American (NA) conguration and 8 for the Siegert (S)

conguration.

ratio, boiler temperature, smoke number, and oil derivative are

2

Typical Siegert (S) Users

Belgium, Denmark, France,

Germany, Italy, Netherlands,

Poland, Spain, United Kingdom

to address these and other needs, which are detailed in the table above.

f To change Combustion Equations: Main Menu Settings ( ) Combustion Eqns.

select Standard or Siegart (European).

9

0024-9551 Revision 2

Page 10

PCA® 400 User Manual

2. Product Description

2.1 Combustion & Emissions Analyzer ............................................................................... 11

2.1.1 Overview ......................................................................................................................................................11

2.1.2 Keypad .........................................................................................................................................................12

2.1.3 Display .........................................................................................................................................................12

2.1.4 Instrument Connections ............................................................................................................................14

2.1.5 Interfaces ....................................................................................................................................................15

2.1.6 Components ...............................................................................................................................................16

2.2 Sample Line & Probe Assembly ..................................................................................... 17

2.3 PowerCongurations ..................................................................................................... 18

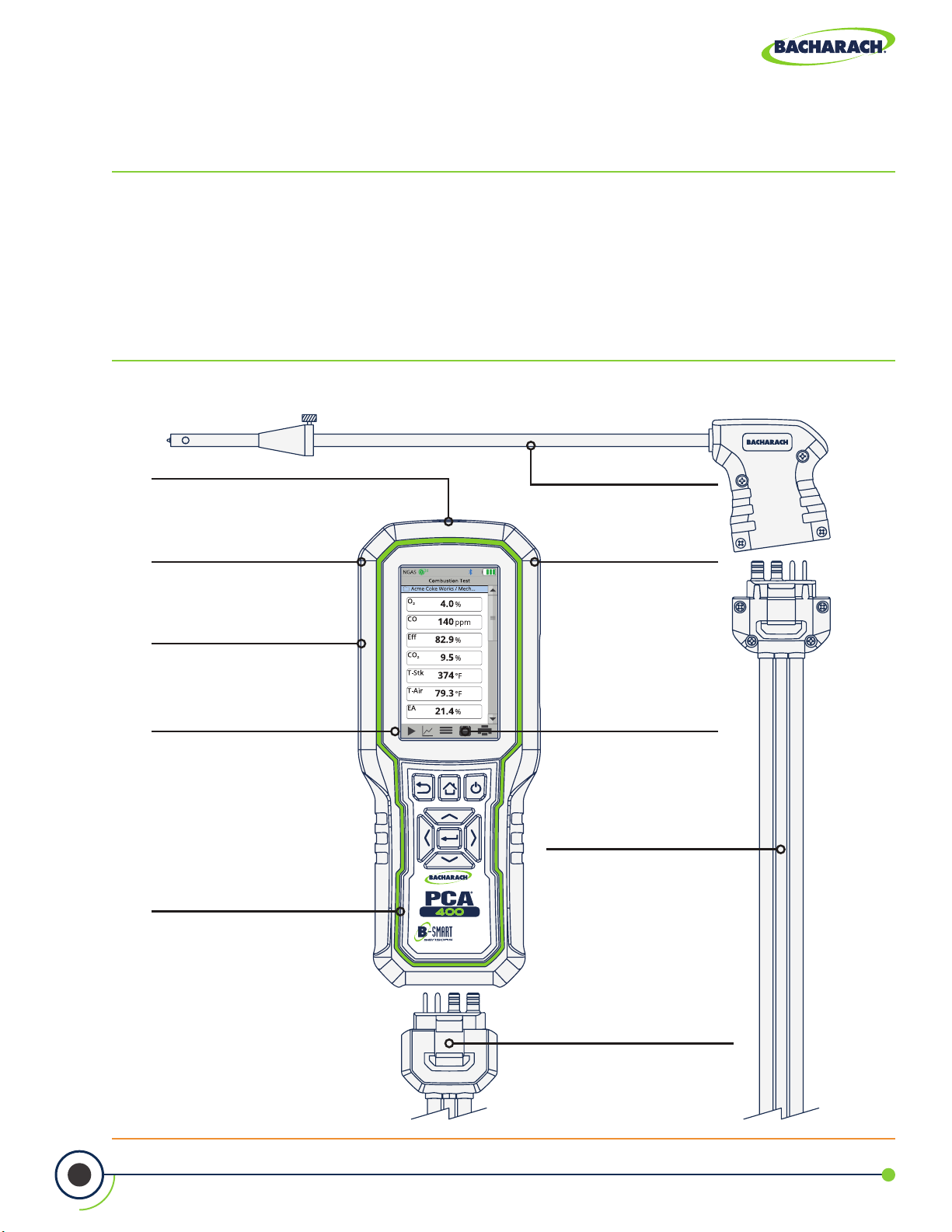

Fig. 2-1: Product Features

IrDA + Bluetooth® Communications

Wireless communications allow users to

conveniently stream data to printers and

compatible devices.

10 Standard Fuel Calculations

Combustion calculations for 10 common

fuel types and optional custom fuels.

4.3" Color Touch Display

Backlit display and resistive touch

make operation simple and intuitive

in the eld.

Enhanced Data Viewing

View data in list, tile or trending formats

making it easier to interpret results.

®

B-Smart

Pre-calibrated sensors eliminate

the need for costly down-time or

calibration gases.

Sensor Technology

Extended Probe Options

Probe assembly is available in 12",

The analyzer can be powered by a

rechargeable lithium-ion battery

pack, 4 × AA batteries or an AC

Stored analysis data can be

downloaded to a PC as a

Comma or Semicolon Separated

Sample Line Options

Sample line assembly is available with

Buna-N or Viton

in lengths of 7.5' and 15'.

24"and 36" lengths.

+

Hour Run Time

12

power adapter.

500 Memory Locations

Value (CSV) text le.

®

tubing construction

10

One-Step Connection

Keyed connectors ensure a quick, reliable

connection between the sample line

assembly and other components.

0024-9551 Revision 2

Page 11

PCA® 400 User Manual

2.1 Combustion & Emissions Analyzer

The PCA® 400 is designed for use in commercial and light industrial applications.

The analyzer is capable of measuring O2, CO, NO, NO2 or SO2, stack / ambient

temperatures, and pressure. The PCA® 400 also calculates CO2, NOx, combustion

eciency and excess air.

2.1.1 Overview

CAUTION: The analyzer contains strong magnets which may damage other

instruments. KEEP AWAY from products which could be damaged by magnetic

elds (e.g. monitors, computers, heart pacemakers, credit cards).

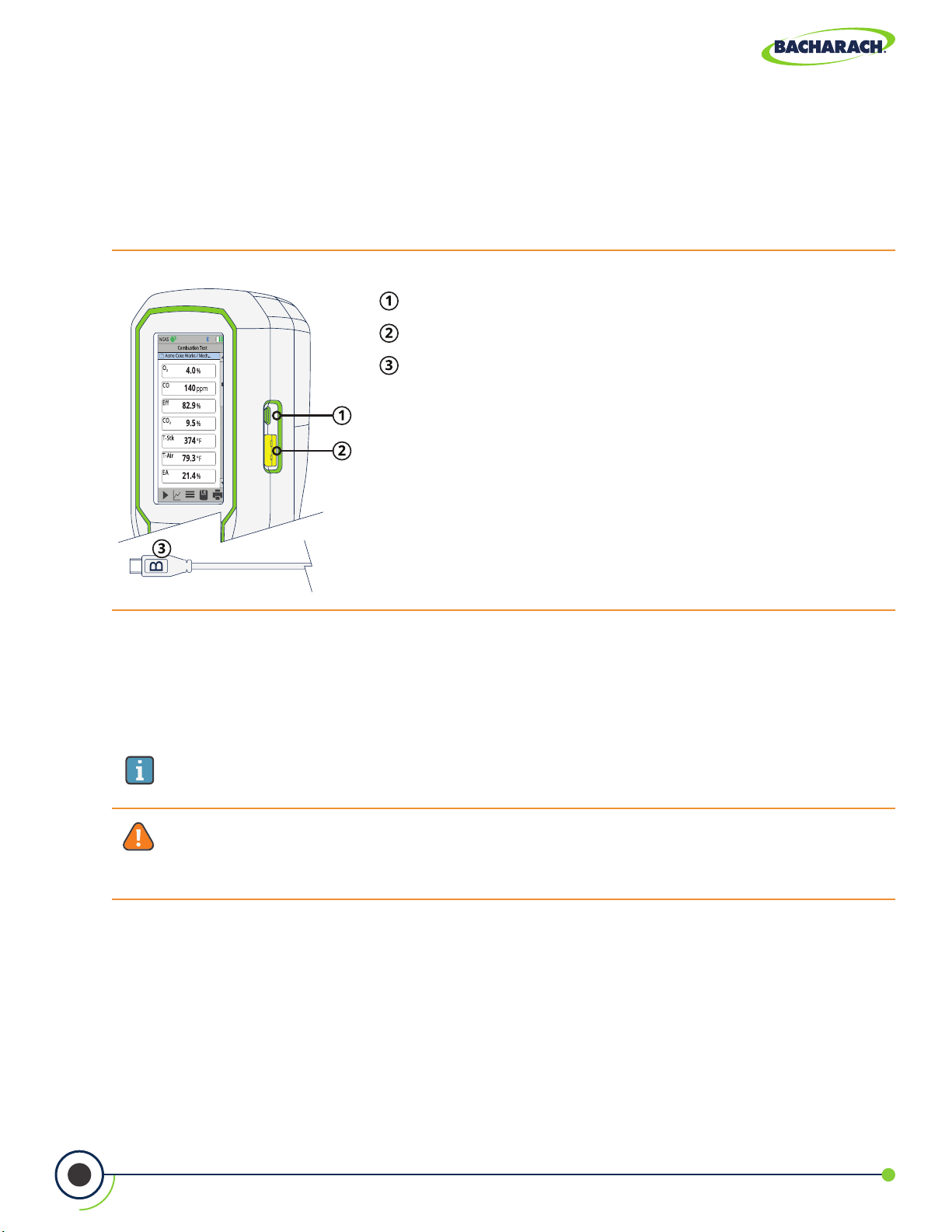

Fig. 2-2: Combustion & Emissions Analyzer

Infrared Printer Interface (top)

Integrated Magnetic Boot (rear) - High impact ABS

plastic with molded-in magnets protects the analyzer

and allows for hands-free use .

LCD Touch Display - 4.3" full color, backlit liquid-crystal

display with resistive touch panel.

Interfaces: USB, T-Air (side)

Tactile Keypad

Instrument Connections (bottom)

11

0024-9551 Revision 2

Page 12

PCA® 400 User Manual

2.1.2 Keypad

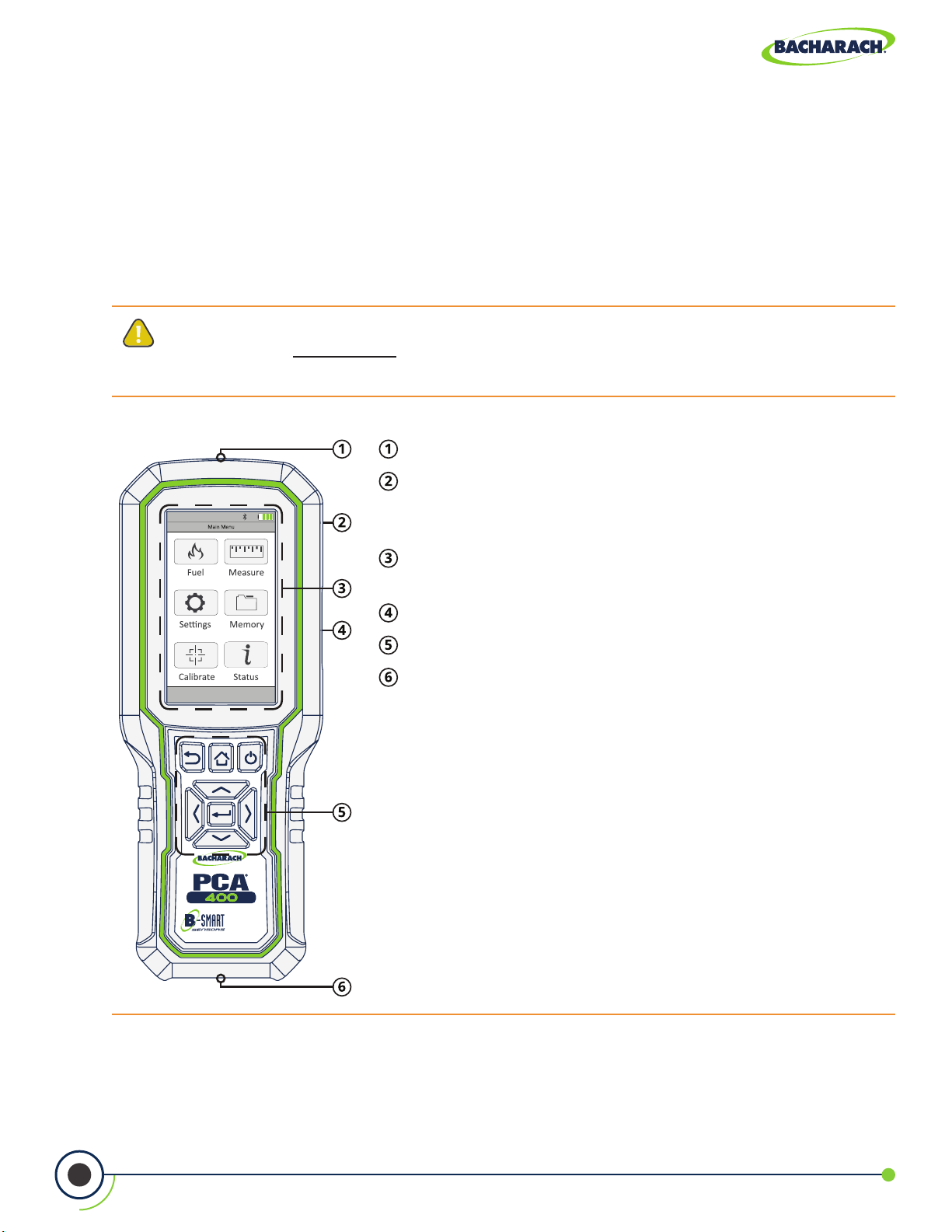

Fig. 2-3: Navigation Keypad

Back Key - Displays the previously viewed screen. In

addition, if changes have been made to one of the

analyzer’s operating parameters (e.g., date, time, O2

reference, etc.), pressing this button aborts any changes,

restores the old values and displays the previously

viewed screen.

Home Key - Displays the Main Menu. In addition, if

changes have been made to one of the analyzer’s

operating parameters (e.g., date, time, O2 reference, etc.),

pressing this button aborts any changes, restores the

old values and displays the Main Menu.

Power Key - Turns the analyzer ON and OFF.

Navigation Keys - Move the cursor on the display. When

viewing a directory, use the buttons to open and

close sub-directories.

2.1.3 Display

DANGER: Display contains liquid crystal which is poisonous. If liquid crystal comes

in contact with skin, wash immediately with soap and water. If ingested, immediately

contact the local poison control center.

CAUTION: DO NOT subject display to excessive shock.

CAUTION: Periodic cleaning with a lightly moistened soft cloth is recommended.

DO NOT wipe display with a dry cloth, as it may scratch the surface.

CAUTION: DO NOT use organic solvents or detergents to clean the display, as they

may cause damage to the screen.

Enter Key - Selects a highlighted item. In addition,

if changes have been made to one of the analyzer’s

operating parameter (e.g., date, time, O2 reference, etc.),

pressing this button conrms those changes and saves

them in memory.

12

0024-9551 Revision 2

Page 13

PCA® 400 User Manual

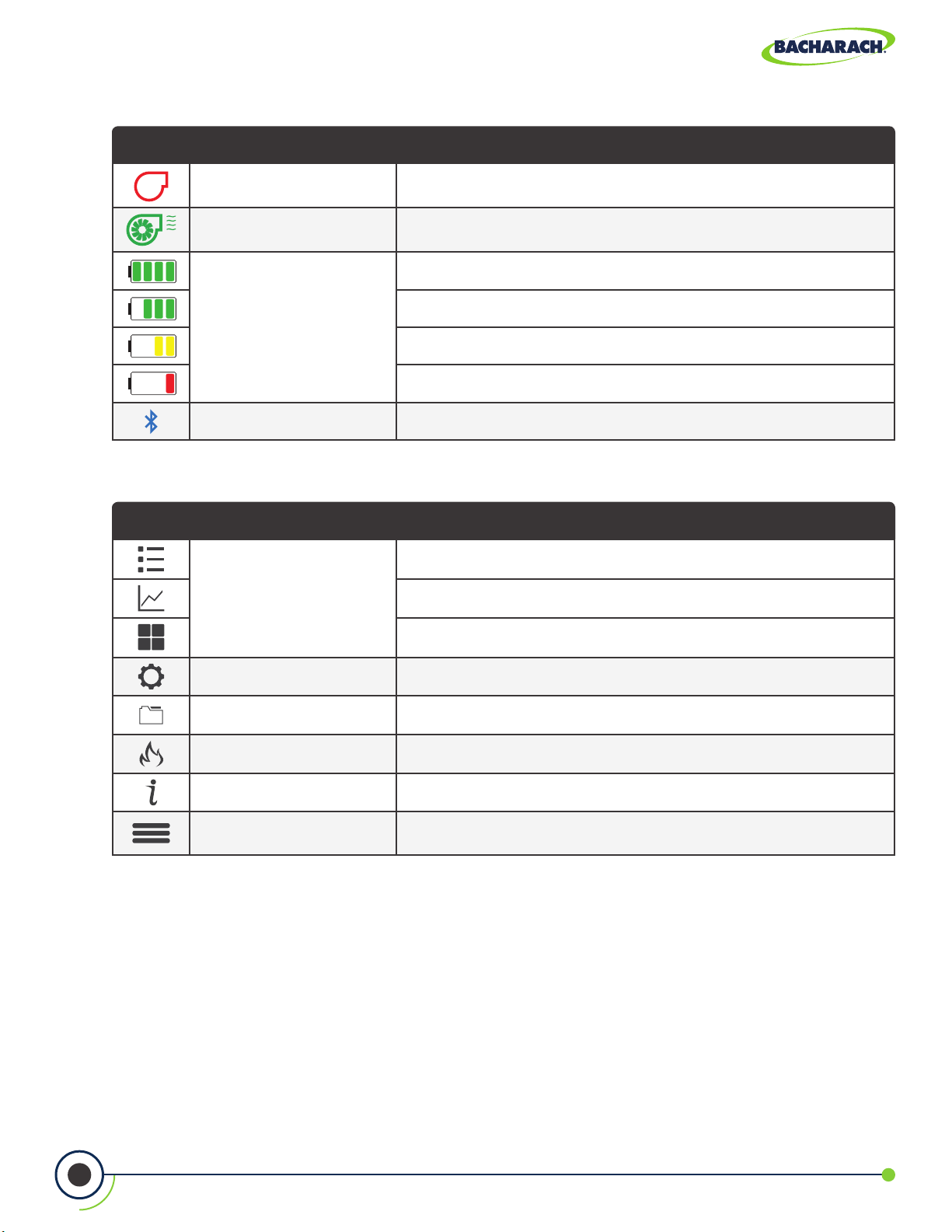

Status Icons

Icon Name Description

x

Battery / Power Status

Pump OFF Sample pump is idle

Pump ON Sample pump is operating

100% Charge

75% Charge

50% Charge

25% Charge

Bluetooth® Active Bluetooth® is enabled and compatible devices may be connected

Preference Icons

Icon Name Description

Display table / list format

Display Options

Display trending / line graph format

Display tile format

Settings Display conguration parameters

Memory Set le structure and naming conventions for data storage

Fuel Types Display list from which to select current test’s combustion fuel

Status Display device status, device information and main diagnostics

Options

Context-sensitive parameters; touch to adjust run/hold format,

low / high limits, features, options, etc.

13

0024-9551 Revision 2

Page 14

PCA® 400 User Manual

Function Icons

Icon Name Description

Measure Touch to select test to perform (combustion, pressure, temperature)

Turn On Pump Touch to turn on pump; used with to toggle RUN / HOLD mode

Stop Pump Touch to stop pump; used with to toggle RUN / HOLD mode

Print Touch to print data to IrDA + Bluetooth® printer

Save Touch to save data to default selected folder

Calibrate Touch to perform calibration functions

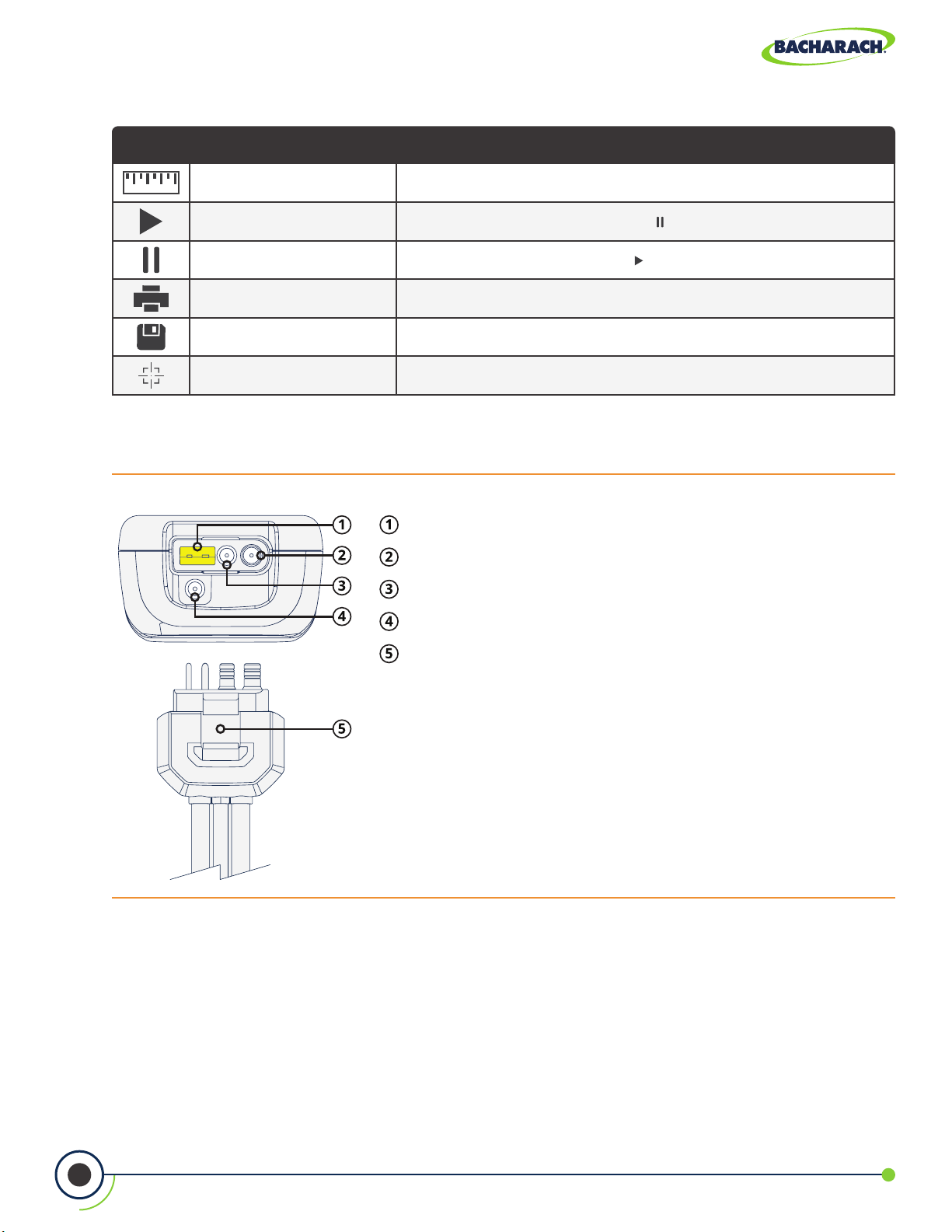

2.1.4 Instrument Connections

Fig. 2-4: Sample Line Connection Port

Stack Gas Type-K Thermocouple / T-STACK Port

Gas Sample Port

Pressure High Side (+∆P) Port

Pressure Low Side (-∆P) Port

Quick-Connector - keyed to t specic components:

gray analyzer, blue probe handle.

14

0024-9551 Revision 2

Page 15

PCA® 400 User Manual

2.1.5 Interfaces

Computer Interface

Data that has been stored in the analyzer’s onboard memory can be uploaded to a personal

computer by connecting the included Micro-B USB Cable between the USB ports of the

computer and the analyzer.

Fig. 2-5: Micro-B USB Port

Micro-B USB Port

Type-K Ambient Air Thermocouple / T-AIR Port

Micro-B USB Cable

Printer Interfaces

The PCA® 400 is capable of wirelessly transmitting data to compatible IrDA (Infrared Data

Associated) or IrDA + Bluetooth® Printers. The IrDA Interface is located at the top of the

device (Figure 2-2).

IMPORTANT: Interference can be caused by devices that are transmitting on the

same frequency band.

WARNING: Use of radio connection may not be permitted in some locations

(e.g. airplanes, hospitals). User assumes responsibility for complying with rules

governing the use of radio connections.

15

0024-9551 Revision 2

Page 16

PCA® 400 User Manual

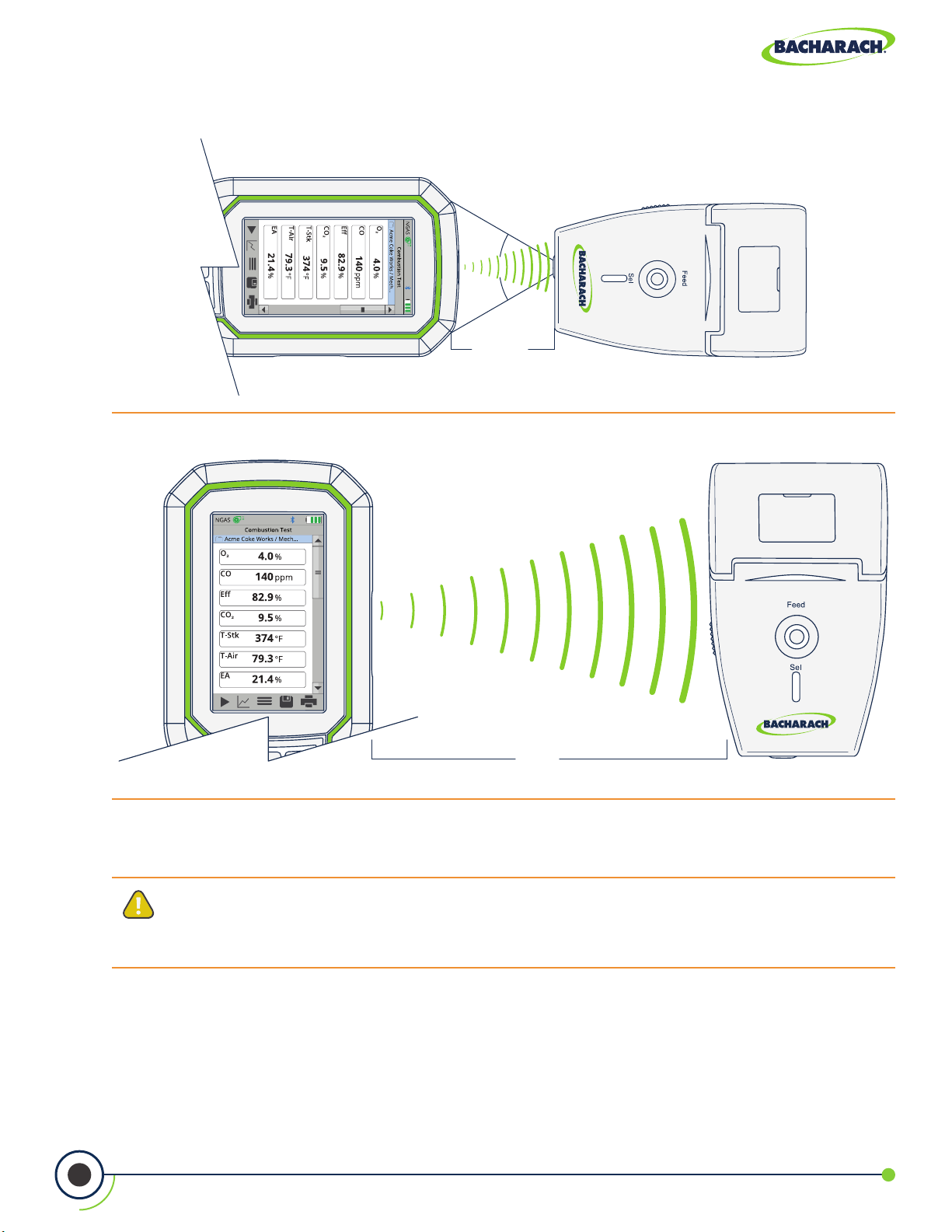

Fig. 2-6: IrDA Communication Range

Fig. 2-7: Bluetooth® Communication Range

60°

max.

4" to 16"

(10 to 30 cm)

2.1.6 Components

CAUTION: Except for sensor and battery replacement, this analyzer should only

be opened and / or serviced by authorized Bacharach personnel. Failure to comply

may void the warranty.

16

0024-9551 Revision 2

30'

(9.1 m)

Page 17

PCA® 400 User Manual

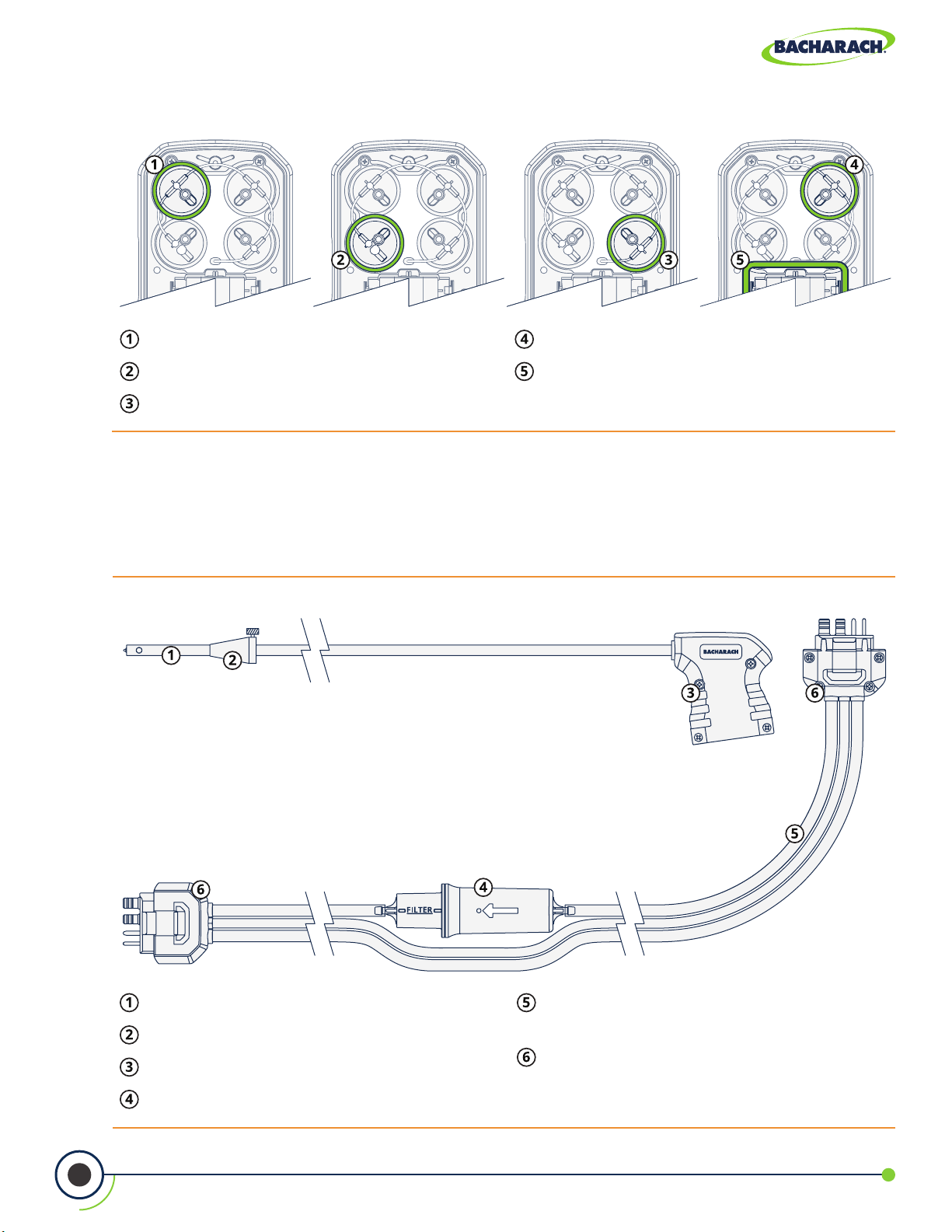

Fig. 2-8: Sensor & Battery Positions

Sensor Position 1 - O

Sensor Position 2 - CO

2

LOW

or CO

Sensor Position 3 - NO2 or SO

HIGH

2

Sensor Position 4 - NO

Battery Compartment

2.2 Sample Line & Probe Assembly

The PCA® 400’s sample line and probe are modular, allowing users to quickly swap

out dierent sized probe lengths, sample lines and the optional sample conditioner.

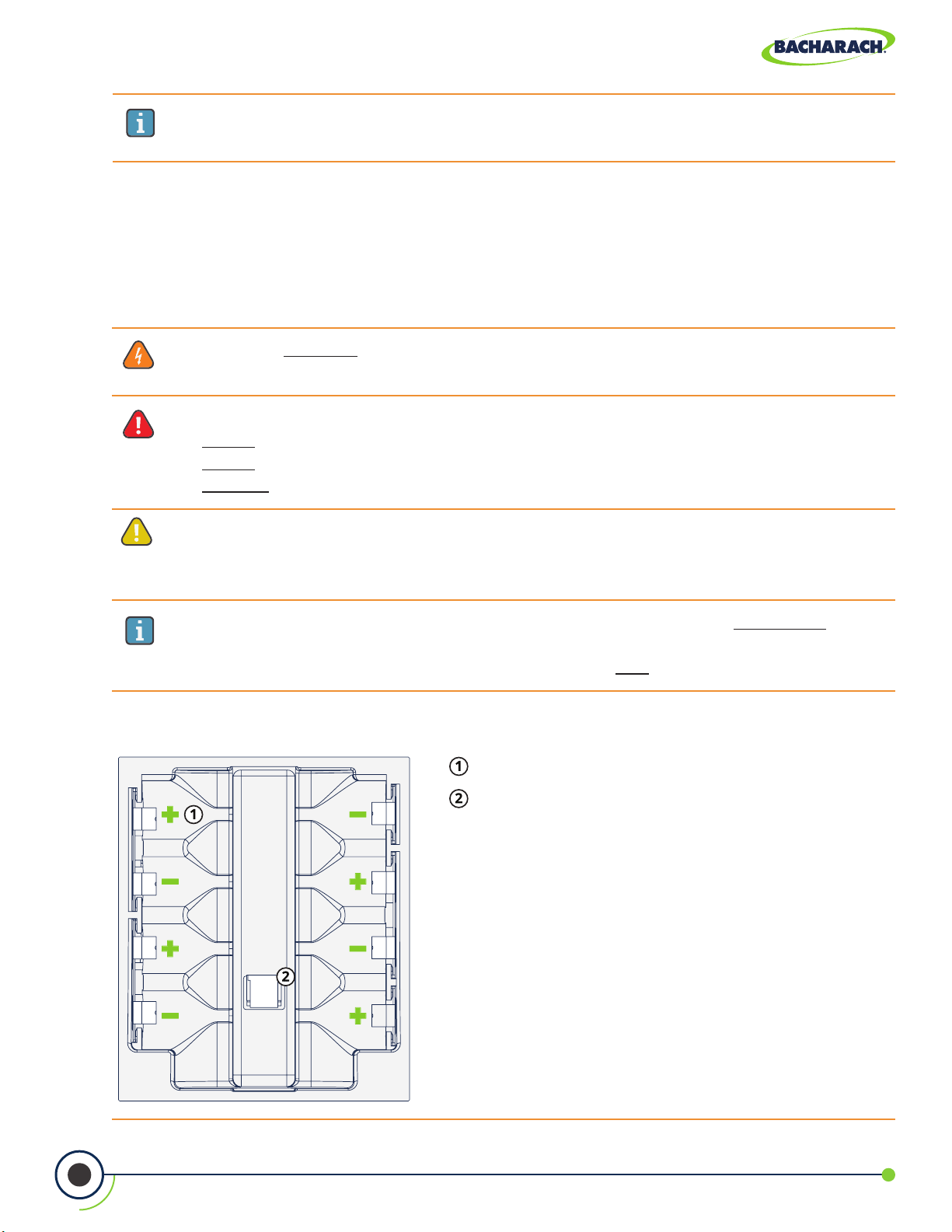

Fig. 2-9: Sample Line & Probe Assembly

17

Probe Tube - available in multiple lengths.

Probe Stop

Probe Handle

Water Trap / Filter Assembly

0024-9551 Revision 2

Sample Line - available in multiple

lengths and construction types.

Quick-Connector - keyed to t specic

components: gray analyzer, blue probe

handle.

Page 18

PCA® 400 User Manual

IMPORTANT: Replacement parts and accessories are sold separately. See Part

Numbers (Section 7.1) for more information.

2.3 Power Congurations

The PCA® 400 comes standard with a rechargeable lithium-ion battery pack which is

capable of powering the analyzer for up to 12-hours. Users may also run the analyzer

on 4 × AA batteries or via the supplied Micro-B USB cable and AC power adapter.

WARNING: DO NOT disassemble battery pack or short battery contacts, as this

may result in electrical shock.

DANGER: Batteries may pose risk of explosion, re or chemical burns if mistreated:

• NEVER dispose of batteries in a re or incinerator.

• NEVER expose batteries to corrosive liquids.

• DO NOT attempt to charge batteries which are swollen or bulging.

CAUTION: Lithium-Ion batteries contain elements that may pose health risks to

individuals if they are allowed to leach into the ground water supply. Always dispose

of batteries in accordance with local regulations.

IMPORTANT: Operating the analyzer with the AC power adapter DOES NOT charge

its rechargeable batteries. To recharge the analyzer’s batteries, supply power via

the AC power adapter when the analyzer is turned OFF.

Fig. 2-10: Congurations for Li-ion Battery Pack and 4 × AA Batteries

AA Battery Tray

Li-ion Battery Pack Connection

18

0024-9551 Revision 2

Page 19

PCA® 400 User Manual

3. Operation

3.1 Setup ................................................................................................................................ 19

3.1.1 Operation Tips ............................................................................................................................................19

3.1.2 Inspection / Prerequisites ..........................................................................................................................21

3.1.3 Connecting Probe Assembly ......................................................................................................................22

3.2 Performing Combustion Test ....................................................................................... 23

3.2.1 Combustion User Preferences ..................................................................................................................23

3.2.2 Combustion Analysis .................................................................................................................................24

3.2.3 Additional Settings .....................................................................................................................................27

3.2.4 Combustion Average Test ..........................................................................................................................31

3.3 Performing Pressure Test ............................................................................................. 32

3.3.1 Pressure User Preferences ........................................................................................................................32

3.3.2 Pressure Analysis ........................................................................................................................................32

3.4 Performing Leak Tests (Siegert Only) ............................................................................ 34

3.4.1 Let-by Test ..................................................................................................................................................34

3.4.2 Tightness Test .............................................................................................................................................35

3.5 Performing Temperature Test ..................................................................................... 36

3.4.1 Temperature User Preferences .................................................................................................................36

3.4.2 Temperature Analysis ................................................................................................................................37

3.1 Setup

Properly preparing the analyzer is critical to accurate analysis and safe operation. Be

sure to read the following instructions prior to use of this instrument.

3.1.1 Operation Tips

Allow Analyzer to Warm-up Slowly

When an analyzer is brought in from a cold vehicle, allow it to warm-up slowly to minimize

condensation. Temperatures below freezing will not damage the analyzer.

CAUTION: Although the analyzer itself is not damaged by extremely cold

temperatures, the electrochemical sensors may sustain damage. The O2 sensor’s

electrolyte will freeze at approximately -13ºF (-25ºC), and the other sensors at

approximately -94ºF (-70ºC). If the analyzer is exposed to extremely cold conditions,

it is strongly suggested that the sensor housings be examined for hairline cracks.

Be aware that a leaking sensor can cause chemical burns to the skin and possibly

damage the surrounding PCB assemblies.

19

0024-9551 Revision 2

Page 20

PCA® 400 User Manual

Start Analyzer in Fresh Air

Ensure that the analyzer is sampling fresh air during initial 60-second warm-up period.

Pulling a stack gas sample through the analyzer during its warm-up period will not damage

the analyzer, but it will result in incorrect sensor readings, and may result in sensor error

messages appearing after the warm-up cycle completes.

Inspect Water Trap / Filter Assembly

Before each use, inspect the lter element of the water trap / lter assembly. Replace the

lter if it looks dirty. See Replacing the Filter Element (Section 5.2) for more information.

Keep Analyzer Above Water Trap Assembly

When sampling ue gas, keep the analyzer above the water trap, and keep the trap in a

vertical position. This will maximize the eectiveness of the trap and keep liquid condensate

from being drawn directly into the analyzer. (Flue gas condensate can be acidic and very corrosive.

Do not to allow the analyzer’s internal components to come in contact with condensate.)

Don’t Allow Water Trap to Become Full

When liquid condensate is seen inside the water trap, empty the trap before it becomes full.

See Emptying the Water Trap (Section 5.1) for more information.

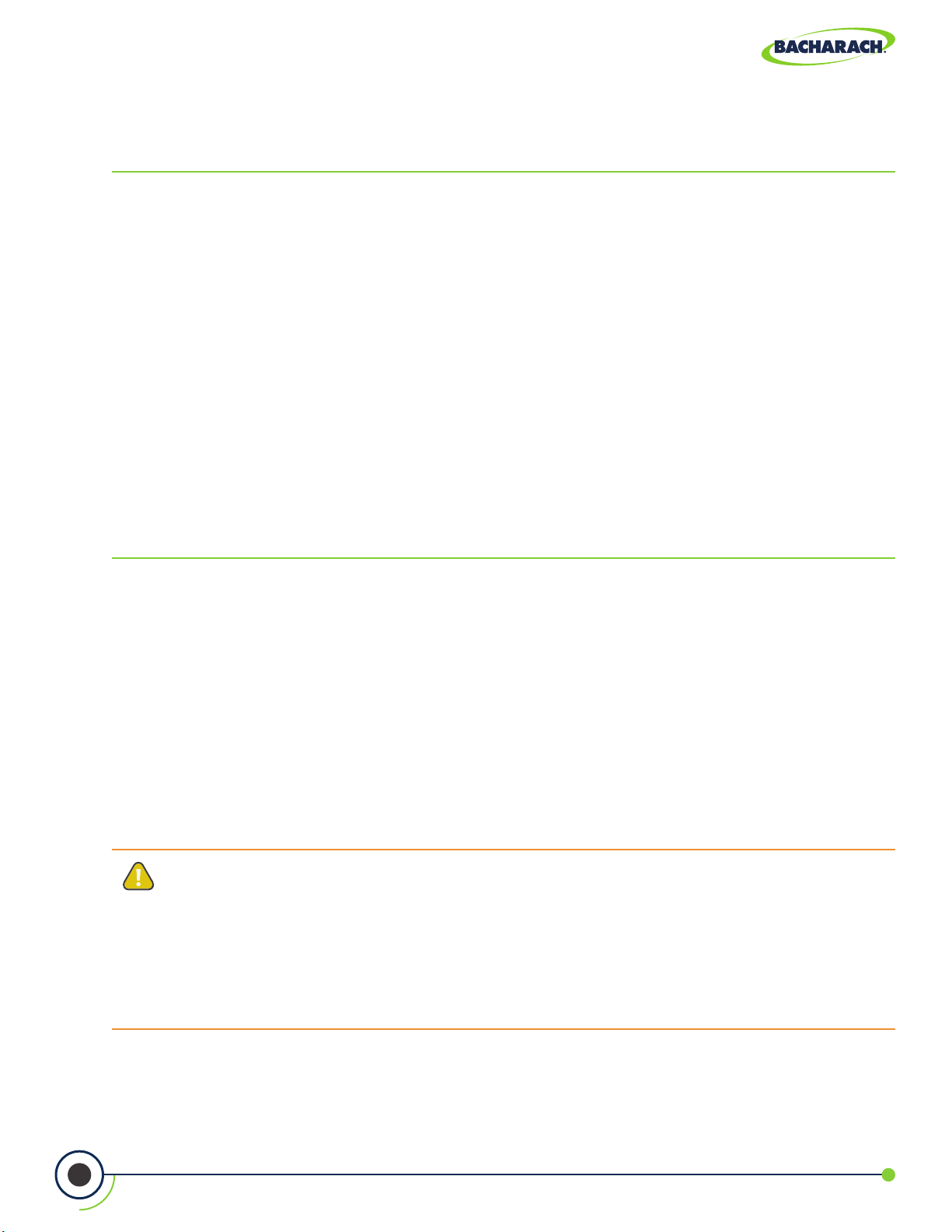

Fig. 3-1: Water Trap / Filter Assembly

To Gas Port on Analyzer

Ensure that lter is clean.

Never allow the water level

to rise above tip of riser tube

during operation.

Stack Gas from Probe

20

CAUTION: Use the Water Trap / Filter Assembly in a vertical position with the gas

ow arrow pointing up as shown in the illustration above.

0024-9551 Revision 2

Page 21

PCA® 400 User Manual

Purge Analyzer After Each Use

The analyzer should be purged after performing a combustion test. After removing probe

from the stack, let the pump run for at least 10-minutes to remove any stack gases and dry

any condensate from inside the sensor chamber and probe assembly.

Remove Moisture from Water Trap Before Storing

When storing the analyzer, it is recommended that users empty the water trap and leave it

open to prevent damage associated with prolonged exposure to moisture. See Emptying

the Water Trap (Section 5.1) for more information.

Maintain Sensor Calibration

Calibrate the analyzer every 6-months to 1-year to ensure its accuracy. See Calibration

(Sections 5.5 and 5.6) for more information.

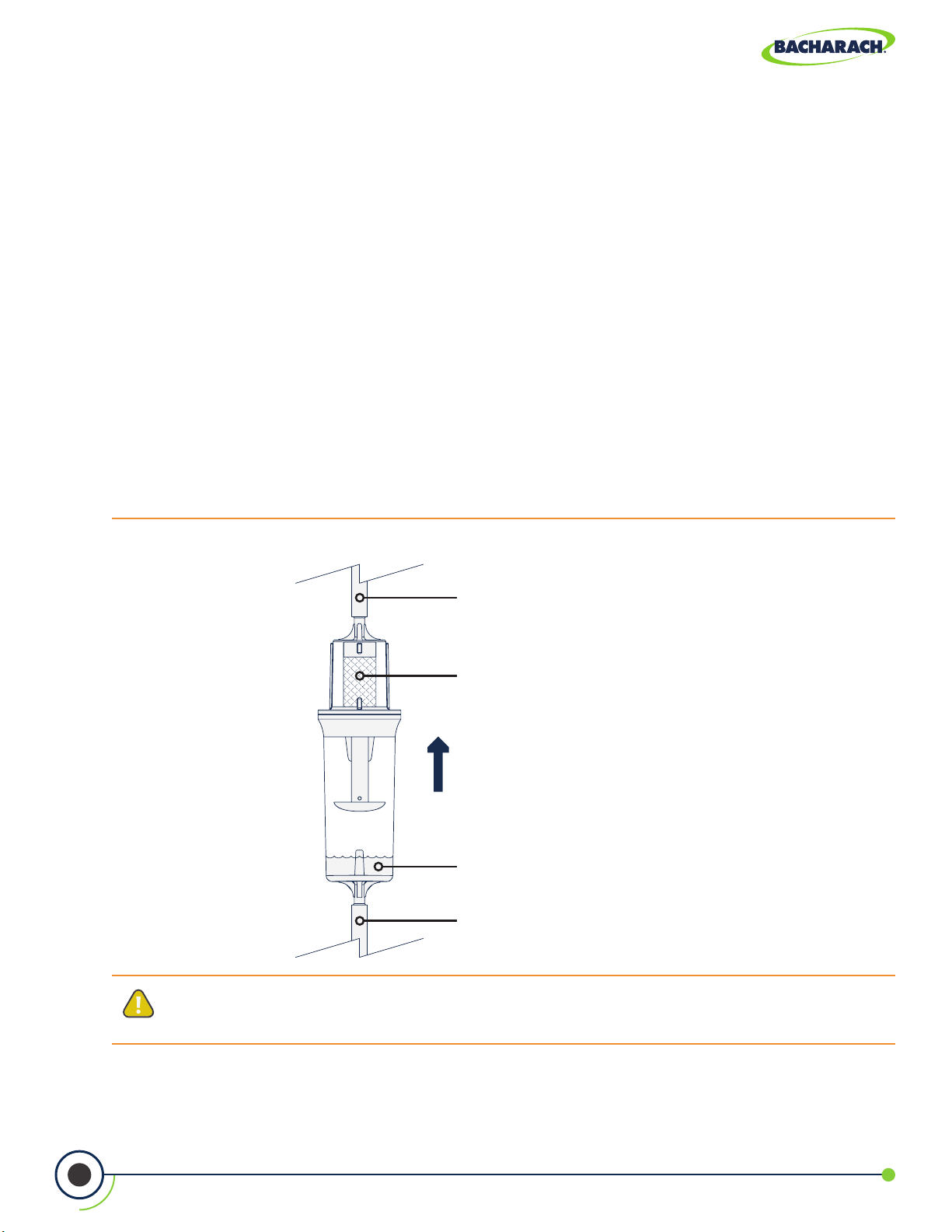

3.1.2 Inspection / Prerequisites

Before performing any tests with the analyzer, verify the following:

Thewatertrap/lterassemblyisempty,clean,andthearrowispointingUP.

Check for obvious signs of splits and or cracks in the sample line and other tubing.

Perform routine maintenance (replacing sensors, calibrating, etc.) as outlined in Care &

Maintenance.

Ensurethattheanalyzerhassucientchargebeforeoperation.Ifindoubt,recharge

Li-ion battery pack, replace disposable batteries or provide power via the AC adapter

and USB cable.

Fig. 3-2: Acceptable Battery Levels

21

0024-9551 Revision 2

Page 22

PCA® 400 User Manual

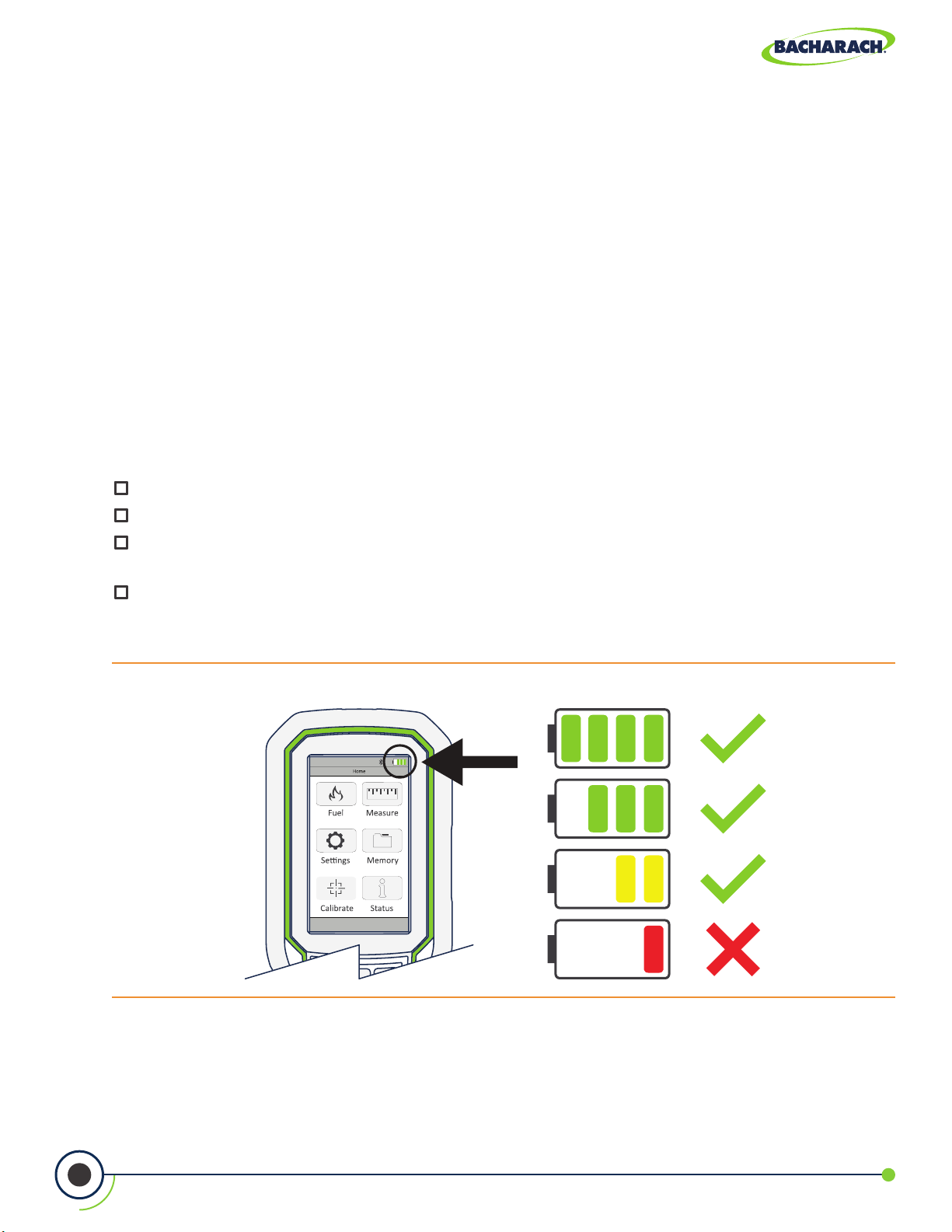

3.1.3 Connecting Probe Assembly

1. Connect Analyzer to Sample Line

Firmly insert the gray quick-connector into the base of the analyzer. Users will hear a click

once a secure connection has been made.

Fig. 3-3: Insert Gray Quick-Connector into Analyzer

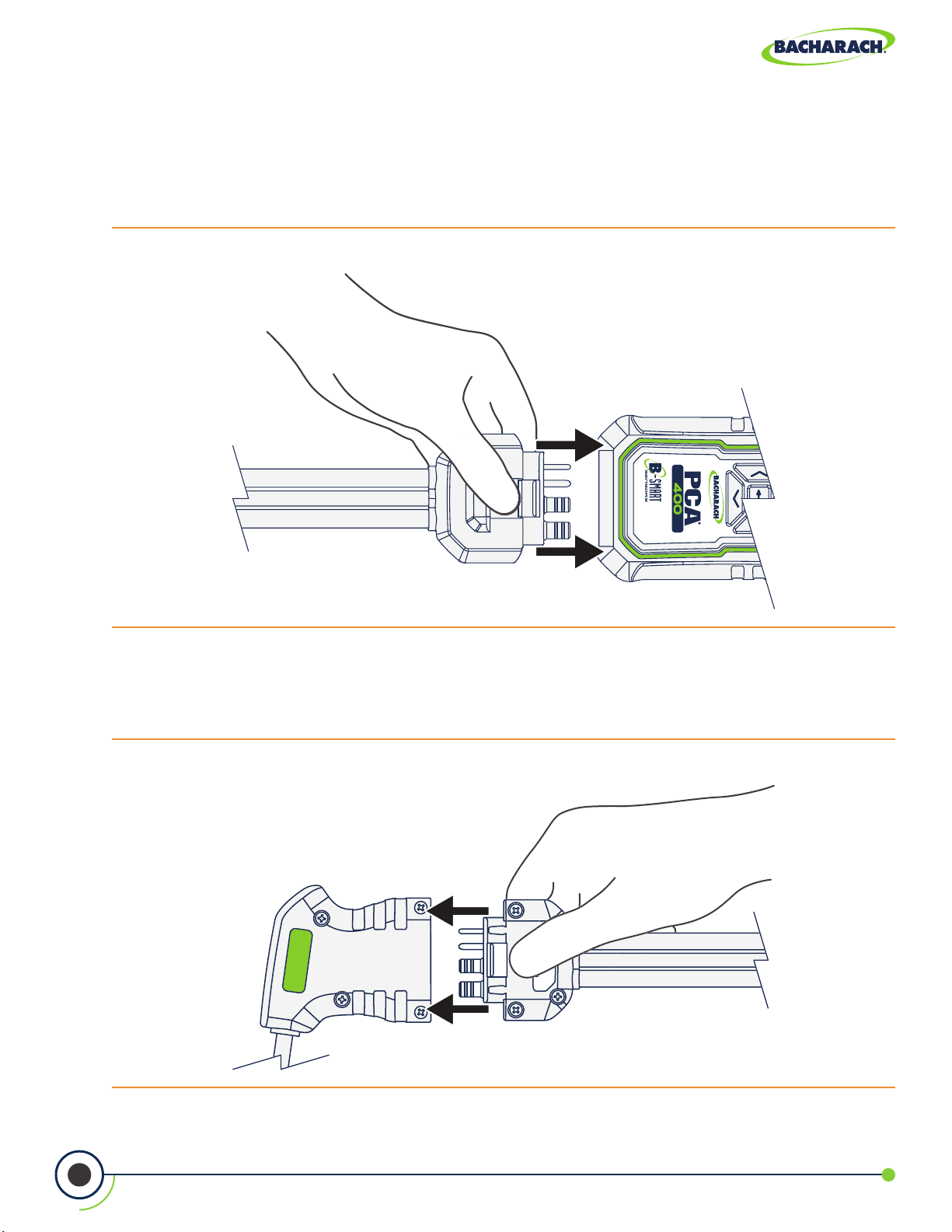

2. Connect Probe to Sample Line

Firmly insert the blue quick-connector into the base of the probe handle. Users will hear a

click once a secure connection has been made.

Fig. 3-4: Insert Blue Quick-Connector into Probe Handle

22

0024-9551 Revision 2

Page 23

PCA® 400 User Manual

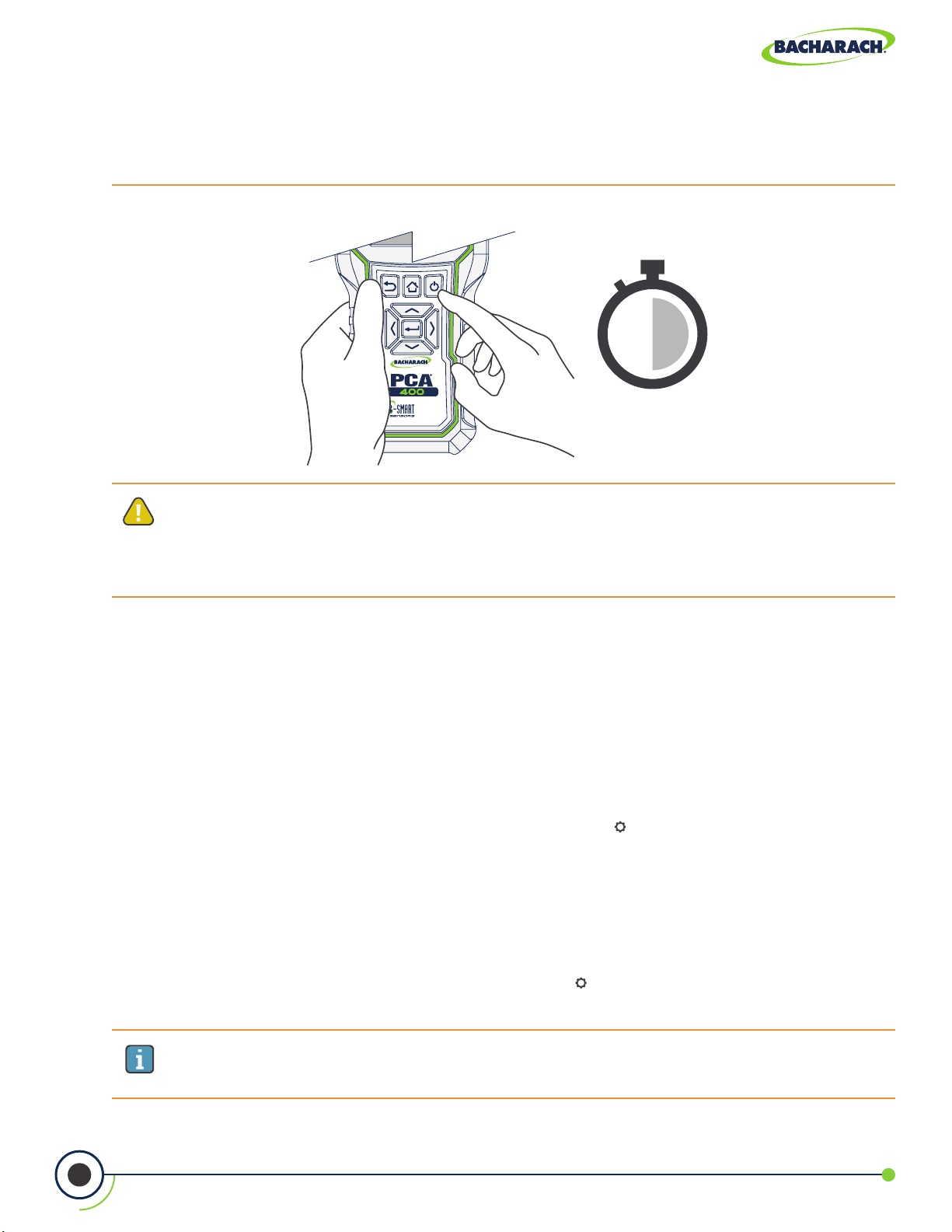

3. Turn On Analyzer

Press the POWER button to begin a 60-second warm-up period. Users will hear the pump

begin operation and splash screen should appear on the analyzer’s display.

Fig. 3-5: Press Power Button

60-SECOND

WARM-UP

CAUTION: Ensure that the analyzer is sampling fresh air during the warm-up.

Pulling a stack gas sample through the analyzer during its warm-up period will not

damage the analyzer, but it will result in incorrect sensor readings, and may result

in sensor error messages appearing after the warm-up cycle completes.

3.2 Performing Combustion Test

3.2.1 Combustion User Preferences

Temperature Units

Select to display temperature in Fahrenheit (ºF) or Celsius (ºC).

f To change Temperature Units: Main Menu Settings ( ) Temperature Units select

Fahrenheit or Celsius.

Pollution Units

®

The PCA

to various pollution units using CFR40 Part 60 emission factors. (Note that the pollution unit

conversions for NO, NO2 and NOx are based on the molecular weight of NO2.)

400 is capable of converting the measured ppm levels of CO, NO, NO2, and SO2

23

f To change Pollution Units: Main Menu Settings ( ) Pollution Units select ppm, lb/

MBtu, mg/m3 or g/GJ.

IMPORTANT: After saving changes to Temperature and Pollution Units, they will

become the analyzer’s default values for all future testing.

0024-9551 Revision 2

Page 24

PCA® 400 User Manual

3.2.2 Combustion Analysis

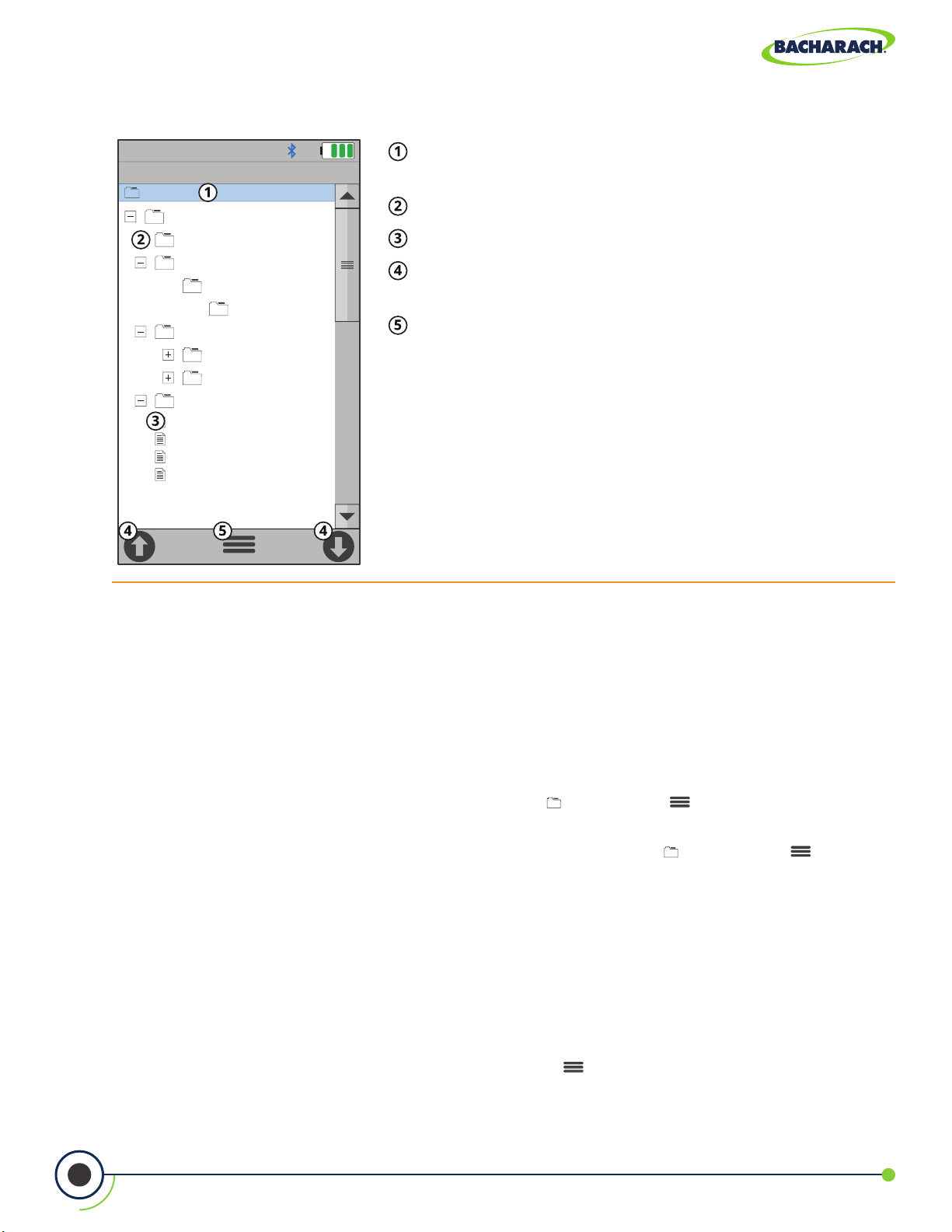

1. Select Folder / Memory Location (User Discretion)

®

The PCA

viewing and downloads.

f To change Folder / Memory Location: Main Menu Memory ( ) use navigation keys

to highlight the desired folder Options (

2. Select Fuel Type

400 gives users the ability to organize their records in a folder structure for later

) select Target.

f To select Fuel Type: Main Menu Fuel Menu (

) select the fuel used in the application

being tested.

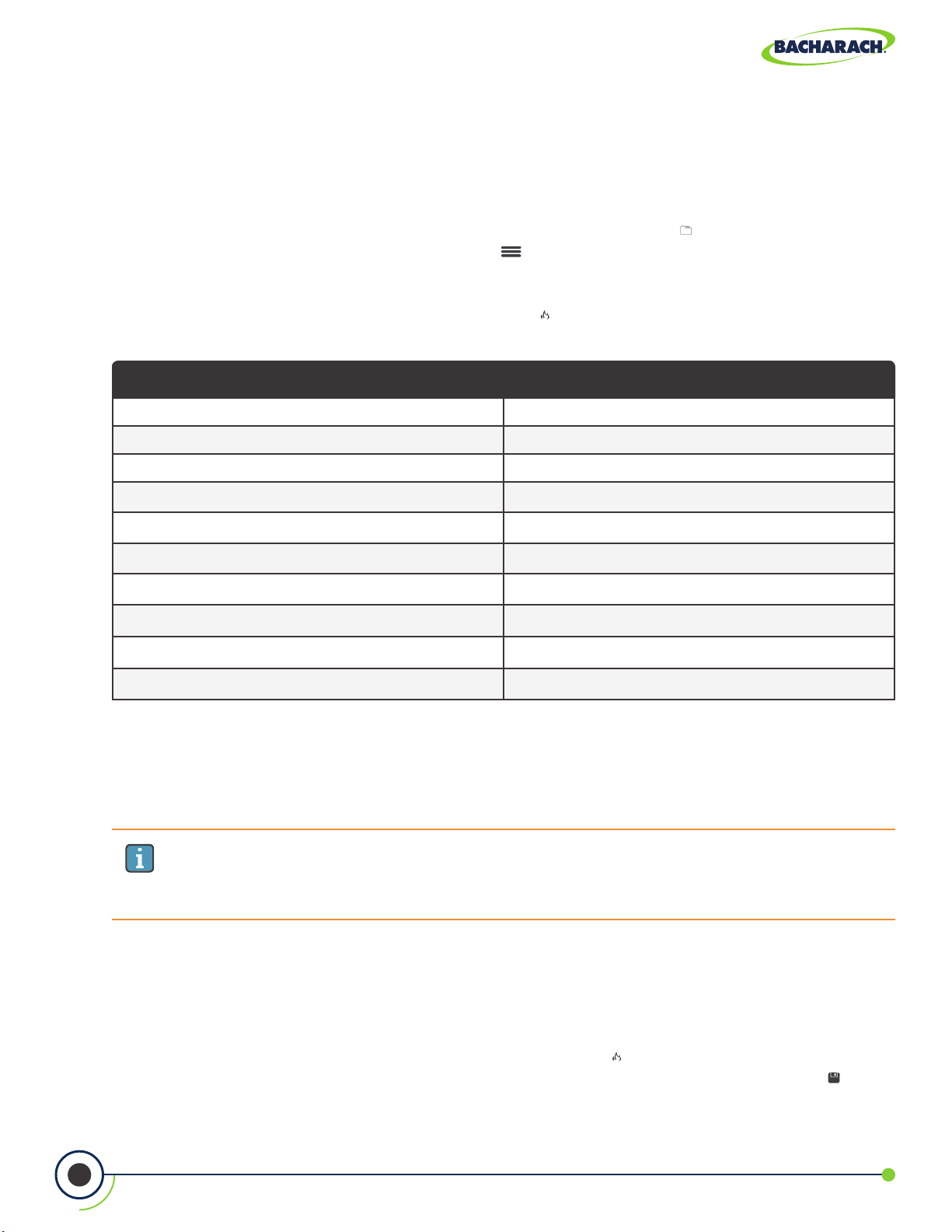

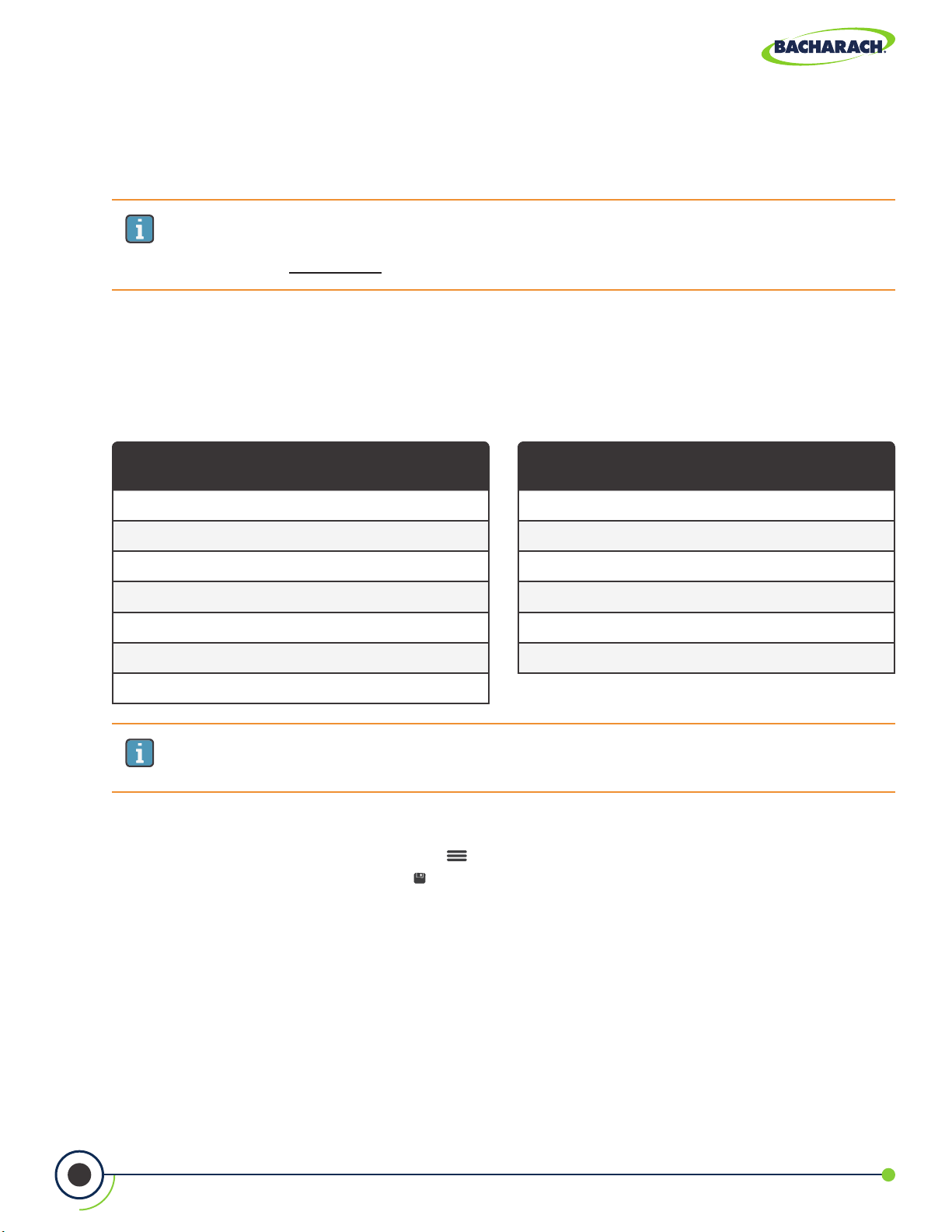

NA (Standard) Siegert

Natural Gas Natural Gas

Oil #2 KOKS

Oil #4 LEG

Oil #6 Propane

Propane Oil #2

Coal Oil #6

Wood Coal

Kerosene BioFuel

Bagasse LPG

Digester Gas Butane

If your combustion application requires a fuel type not listed in the Fuel menu, contact

Bacharach for information on additional fuel codes. Custom fuel codes may developed by

Bacharach at a customer’s request and can be loaded into the instrument using the PCA

Reporting Software.

IMPORTANT: Custom fuel codes are specific to the combustion equations that

are being used, so be sure to include your combustion equation type (North

American or Siegert) with any custom fuel code requests.

3. CO2 Max Value (Siegert Only)

When using the PCA® 400’s Siegert conguration, additional settings allow one to adjust the

CO2 max value to account for fuel variations. Adjusted CO2 Max values are stored with the

saved combustion records and

f To change the CO2 Max: Main Menu Fuel Menu ( ) select the fuel used in the

application being tested Adjust insert the desired CO2 Max press Save ( ).

24

0024-9551 Revision 2

Page 25

PCA® 400 User Manual

4. Select Measurement Type

f To select Measurement Type: Main Menu Measure (

) select Combustion.

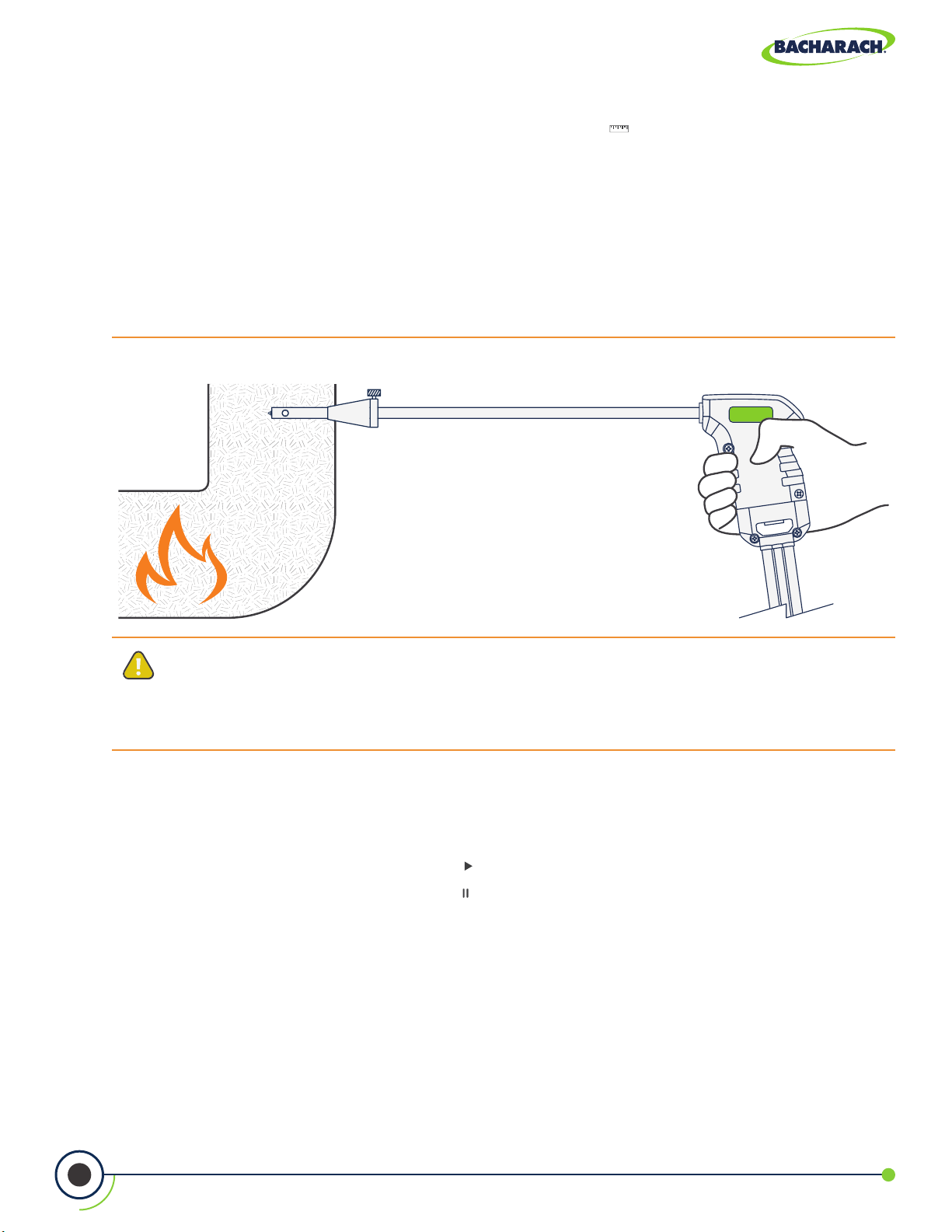

5. Insert Probe Tube into Measurement Area

After identifying the ue / exhaust stack, select a safe and convenient location from which

to draw the sample.

f Select length-appropriate probe.

f Set probe stop to ensure that the probe is inserted into the center of the ue / exhaust

stack / measurement area. (The probe stop also acts to secure the probe in the measurement

area during analysis.)

Fig. 3-6: Probe Placed in Center of Measurement Area

CAUTION: When the instrument is used in an inecient furnace or boiler application

where there is a high soot concentration, the probe’s sample lter may become

clogged. Before every use check the lter to conrm that it is clean or replace it with

a new lter (Section 5.2).

6. Run Sample Pump

After starting the pump, allow readings to stabilize for a minimum of 3-minutes or as long

as required by manufacturer specications / compliance testing procedures.

f To start the pump: press Run / Hold (

).

f To stop the pump: press Run / Hold ( ).

25

0024-9551 Revision 2

Page 26

PCA® 400 User Manual

Fig. 3-7: Combustion Test Screen

NGAS

Combustion Test

Acme Powerplant

Fuel Type - displays fuel calculation being used to

produce combustion data.

Pump Status - ( ) indicates that the pump is on,

( ) indicates that the pump is off.

Folder / Memory Location - location where

combustion data will be saved.

Combustion Data - results from combustion

analysis; display can be toggled by pressing (

).

Run / Hold - toggle sample pump operation; press ( )

to run and (

) to pause.

Toggle View - change data display between table /

list ( ), line graph ( ), tile ( ) formats.

Options - displays additional settings / conguration

(Fresh Air Purge, Logging, Pump Speed, Run / Hold Format,

Line Graph Settings, O2 Reference, Zoom, NOx Calculation).

Save - save combustion data to the selected folder /

memory location.

Print - print combustion data to IrDA / Bluetooth®

printer(s).

7. Save / Print Readings

®

The PCA

400 is capable of saving active data to the analyzer’s onboard storage and / or

printing to the optional IrDA / Bluetooth® printer.

f To save combustion readings / report: press Save ( ).

f To print combustion readings / report: press Print ( ).

IMPORTANT: Printing via Bluetooth® is diabled when the analyzer is connected to

the PCA® 400 App. If you wish to print, disconnect from the mobile app or enable

IrDA communications.

26

0024-9551 Revision 2

Page 27

PCA® 400 User Manual

)1

)1

CAUTION: The probe MAY BE HOT after analysis and can cause bodily harm and /

or damage to the analyzer. Allow the probe sucient time (about 5-minutes) to cool

before handling or storing in the supplied carrying case.

CAUTION: Never disconnect the probe from the instrument until purging is

complete. Otherwise, leftover target gas (for example, CO) may remain in the

probe and cause inaccurate zeroing at power up that could lead to inaccurate gas

measurements afterwards.

CAUTION: The probe and sample line may become dirty during normal use and

should be cleaned regularly to ensure proper function. See Cleaning the Probe

Assembly (Section 5.3) for more information.

3.2.3 Additional Settings

Data Display Options

Data can be viewed in list (text), tile and trending formats allowing users to easily analyze

their combustion analysis results. Users can further customize the PCA® 400 to show all the

parameters in the order they prefer.

f To toggle between Display Options: Display Options ( ) select Table / List Format ( ),

Line Graph Format ( ) or Tile Format ( ).

Fig. 3-8: Table / List, Line Graph and Tile Formats

NGAS

Combustion Test

Acme Powerplant

OIL2

Combustion Test

Acme Powerplant

500

CO (ppm)O

0

21

)

%

(

2

Time (min

NGAS

Combustion Test

Acme Powerplant

O

2

CO

Eff

CO

2

T-Stk

4.0

140

82.9

9.5

374

%

ppm

%

%

°F

27

0

0024-9551 Revision 2

Time (min

T-Air

EA

79.3

21.4

°F

%

Page 28

PCA® 400 User Manual

Zoom (List View)

Combustion test data can be shown with enlarged characters to make viewing easier.

The operator can set zoom levels to STANDARD or LARGE. The Standard zoom setting

will display fteen (15) lines of combustion test data at one time and the Large zoom

setting will display twelve (12) lines of combustion test data with enlarged characters. The

operator can scroll through the complete list of measured and calculated data no matter

what zoom level has been selected.

f To update Zoom: Options ( ) Zoom select Standard or Large.

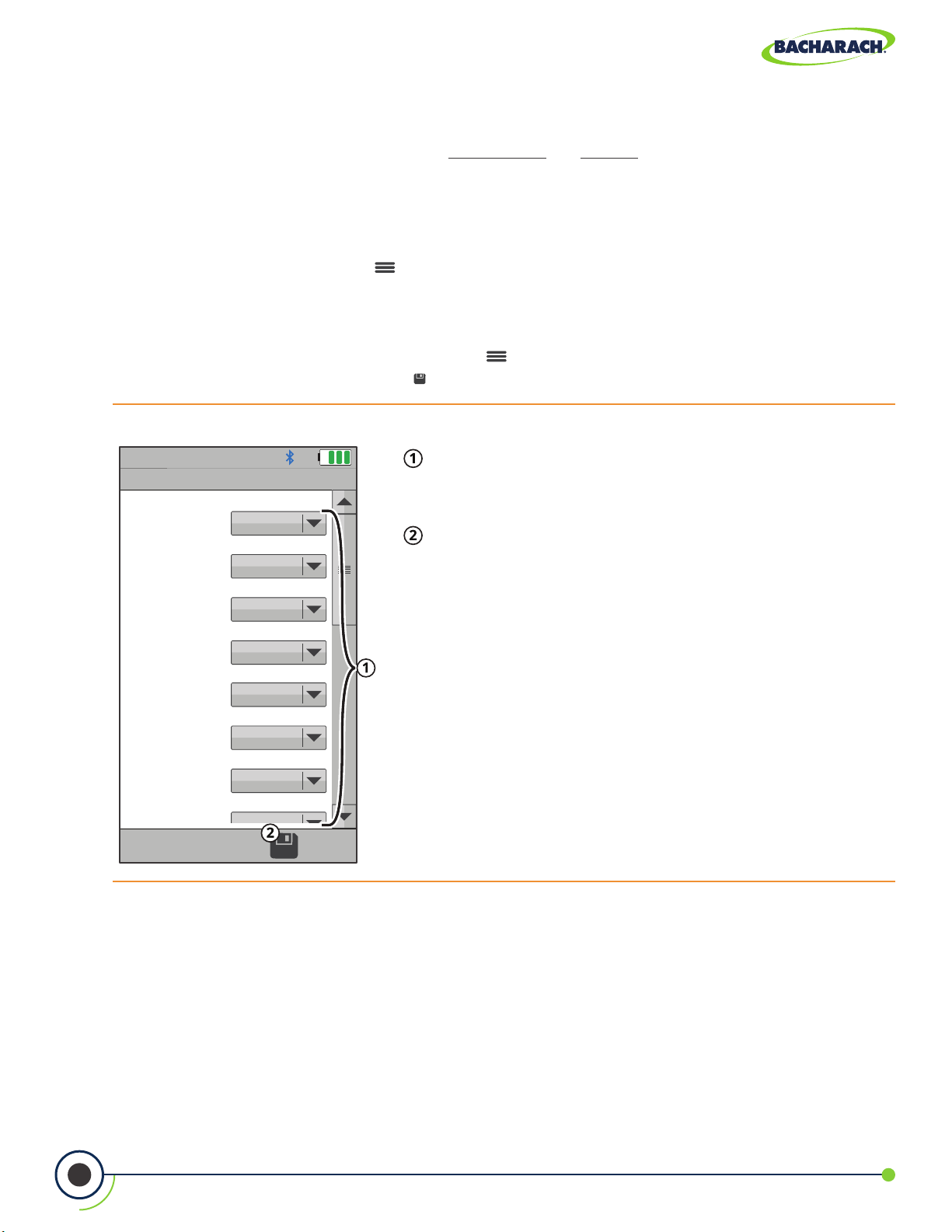

Run / Hold Format (List View)

The analyzer allows users to customize the order in which analysis results are displayed.

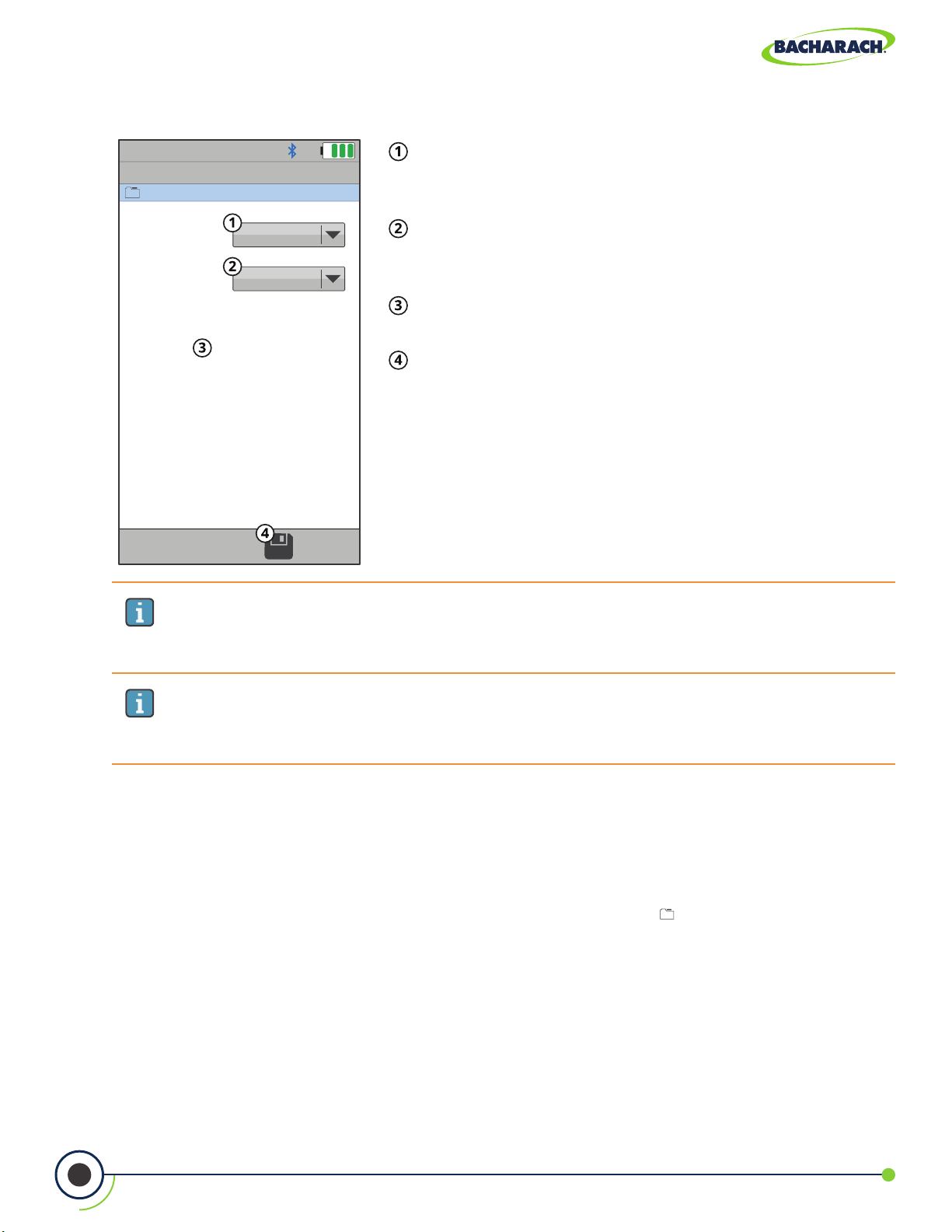

f To update Run / Hold Format: Options (

dropdown menu press Save (

).

Fig. 3-9: Run / Hold Format

Analysis Positions - use the dropdown menu to

Run/Hold Format

customize the order in which analysis results are

displayed in the List View.

Position 1O

Position 2CO

Position 3EA

Position 4CO

Position 5T-Stack

Position 6T-Air

Position 7Flow

Save - save Run / Hold Format and return to current

combustion analysis results.

) Run / Hold Format set prioritization via

28

Position 8None

0024-9551 Revision 2

Page 29

PCA® 400 User Manual

Combustion Test Parameters NA (Standard) Siegert

Oxygen O

2

O

2

Carbon Monoxide CO CO

Excess Air EA Lambda

Eciency Using Higher Heating Value E E

Carbon Dioxide CO

2

CO

2

Setting for Maximum Carbon Dioxide in Flue Gas ― CO2 Max

Stack Temperature T-Stk T-Stk

Ambient Air Temperature T-Air T-Air

Stack Loss ― qA

Eciency Using Lower Heating Value ― Eta

Carbon Monoxide/Carbon Dioxide Ratio ― CO/CO

CO Referenced to O2 Percentage n CO (n) CO (n)

Pump Flow Rate Flow Flow

Nitric Oxide NO NO

Nitrogen Dioxide NO

2

NO

2

2

Oxides of Nitrogen NO

Sulfur Dioxide SO

x

2

NO

SO

x

2

NO Referenced to O2 Percentage n NO (n) NO (n)

NO

Referenced to O2 Percentage n NO2 (n) NO2 (n)

2

NO

Referenced to O2 Percentage n NOx (n) NOx (n)

x

SO

Referenced to O2 Percentage n SO2 (n) SO2 (n)

2

Average of 3 Smoke Numbers (Manually Entered) ― Avg Smoke

Presence of Oil Derivatives (Manually Entered) ― Oil Derive

Boiler Temperature (Manually Entered) ― Boiler Temp

29

0024-9551 Revision 2

Page 30

PCA® 400 User Manual

Line Graph Settings (Trending View)

The analyzer allows users to customize the order in which analysis results are displayed.

f To update Line Graph Settings: Options (

time via dropdown menu press Save (

Fig. 3-10: Line Graph Settings

Parameter 1 - value of the top graph’s y-axis; choose

Line Graph Settings

from None, O2, CO, NO, NO2, SO2,T-AIR, T-STK, E,

EA, CO2, NOx, CO(0), NO (0), NO2(0), NOx(0) or SO2(0).

Parameter 1O

Parameter 2CO High

Parameter 2 - value of the bottom graph’s y-axis;

choose from None, O2, CO, NO, NO2, SO2,T-AIR, T-STK,

E, EA, CO2, NOx, CO(0), NO (0), NO2(0), NOx(0) or SO2(0).

Time 30 seconds

Time - value of each of the graph’s x-axis; choose

from 30-seconds, 1-minute, 3-minutes, 5-minutes

and 15-minutes.

Save - save Line Graph Settings and return to

current combustion analysis results.

) Line Graph Settings set parameters &

).

Pump Speed

The sample pump is capable of operating at two dierent rates; allowing users to

compensate for longer lengths of sample line or to overcome higher draft in the

measurement area.

f To change Pump Speed: Options (

) Pump Speed select Standard or High.

IMPORTANT: Operating the analyzer at a higher pump rate consumes more power

and will reduce the expected battery life.

IMPORTANT: Changes to this setting will not become the analyzer’s default

value for future testing. When restarting, the analyzer will revert to STANDARD

pump rate.

30

0024-9551 Revision 2

Page 31

PCA® 400 User Manual

3.2.4 Combustion Average Test

1. Select Folder / Memory Location (User Discretion)

®

The PCA

viewing and downloads.

f To change Folder / Memory Location: Main Menu Memory ( ) use navigation keys

to highlight the desired folder Options (

2. Select Measurement Type

400 gives users the ability to organize their records in a folder structure for later

) select Target.

f To select Measurement Type: Main Menu Measure (

) select Combustion Average.

3. Set Duration / Interval of Testing

f Select duration and interval of test: Select desired Duration and Interval from dropdown

menus press Save (

Combustion Average Durations

1-minute

2-minutes

5-minutes

10-minutes

15-minutes

20-minutes

30-minutes

1-hour

).

Combustion Average Intervals

1-second

10-seconds

30-seconds

1-minute

4. Insert Probe Tube into Measurement Area

After identifying the ue / exhaust stack, select a safe and convenient location from which

to draw the sample.

f Select length-appropriate probe.

f Set probe stop to ensure that the probe is inserted into the center of the ue / exhaust

stack / measurement area. (For more information on the placement of the sample probe, see

Figures 3-6.)

5. Run Sample Pump

After starting the pump, the analyzer will stabilize for 180-seconds before beginning the

combustion average test.

f To start the pump: press Run / Hold (

).

f To stop the pump: press Run / Hold ( ).

31

0024-9551 Revision 2

Page 32

PCA® 400 User Manual

7. Save / Print Readings

The PCA

printing to the optional IrDA / Bluetooth

®

400 is capable of saving active data to the analyzer’s onboard storage and / or

®

printer.

f To save combustion readings / report: press Save (

f To print combustion readings / report: press Print (

3.3 Performing Pressure Test

3.3.1 Pressure User Preferences

Pressure Units

Select to display pressure in Inches of Water Column (inwc), Millibar (mB), Pascal (Pa), HectoPascal (hPa) or Millimeters of Water Column (mmwc).

f To change Pressure Units: Main Menu Settings (

InchesWater, milliBar, Pascals, HectoPascals or mmH20.

3.3.2 Pressure Analysis

1. Select Folder / Memory Location (User Discretion)

The PCA® 400 gives users the ability to organize their records in a folder structure for later

viewing and downloads.

).

).

) Pressure Units select

f To change Folder / Memory Location: Main Menu Memory (

to highlight the desired folder Options (

2. Select Measurement Type

f To select Measurement Type: Main Menu Measure (

3. Zero Pressure Sensor (User Discretion)

Before taking a measurement, the pressure sensor may need to be re-zeroed if it is not

already displaying zero with both pressure ports open to the atmosphere.

f If necessary, zero the pressure sensor: Press Zero (

f Disconnect hoses and press OK to zero the pressure sensor.

f Reconnect hoses. When measuring draft, leave the -∆P port open to the atmosphere

and connect the probe’s draft hose to the + ∆P port.

) select Target.

) select Pressure.

).

) use navigation keys

32

0024-9551 Revision 2

Page 33

PCA® 400 User Manual

Fig. 3-13: Pressure Connection Ports

4. Insert Probe Tube into Measurement Area

After identifying the ue / exhaust stack, select a safe and convenient location from which

to take measurements.

f To measure draft: insert the probe tube into the ue / exhaust stack / measurement

area and observe the reading on the Pressure screen.

f To measure dierential pressure: connect sampling hoses to the +∆P and -∆P ports

and place the ends of the hoses into the measurement areas being compared. The

dierential pressure between the two areas will be displayed on the Pressure screen.

The dierential pressure reading will be positive if the pressure at the +∆P is higher than

that read at the -∆P and negative if it is lower than that read at the -∆P.

Pressure High Side (+∆P) Port

Pressure Low Side (-∆P) Port

Fig. 3-14: Pressure Test Screen

Pressure

Acme Powerplant

Delta P

0.05 inwc

Selected Folder / Memory Location - location where

data will be saved.

DierentialPressure- measured dierence between

Pressure High Side (+∆P) and Pressure Low Side (-∆P).

Zero Button - press to zero (calibrate) pressure

reading to ambient pressure.

Save - save pressure data to the selected folder /

memory location.

Print - print pressure data to IrDA / Bluetooth

®

printer(s).

33

0024-9551 Revision 2

Page 34

PCA® 400 User Manual

5. Save / Print Readings

®

The PCA

printing to the optional IrDA / Bluetooth

400 is capable of saving active data to the analyzer’s onboard storage and / or

®

printer.

f To save pressure readings / report: press Save (

f To print pressure readings / report: press Print (

IMPORTANT: Printing via Bluetooth® is diabled when the analyzer is connected to

the Bacharach Combustion App. If you wish to print, disconnect from the mobile

app or enable IrDA communications.

).

).

3.4 Performing Leak Tests (Siegert Only)

Let-by and Tightness are regional requirements in European markets with very

specic procedures. While they may be useful in other local jurisdictions to provide

means to have safe readings for leak checks of gas and safe combustion processes,

they are simply one way to test for these problems. Other procedures may be

specied by local authorities. Please refer to your local and regional regulations to

be sure you are in compliance accordingly.

3.4.1 Let-By Test

1. Select Folder / Memory Location (User Discretion)

The PCA® 400 gives users the ability to organize their records in a folder structure for later

viewing and downloads.

f To change Folder / Memory Location: Main Menu Memory ( ) use navigation keys

to highlight the desired folder Options ( ) select Target.

2. Select Measurement Type

f To select Measurement Type: Main Menu Measure (

3. Begin Let-By Test

f Disconnect hoses and press Enter to zero the pressure sensor.

f Reconnect hoses in accordance with specied procedures and press Enter to start the

Let-By Test.

) select Let-By Test.

34

0024-9551 Revision 2

Page 35

PCA® 400 User Manual

Fig. 3-15: Let-By Test Summary Screen

Summary of Test Data

Save - save pressure data to the selected folder /

memory location.

Print - print pressure data to IrDA / Bluetooth®

printer(s).

5. Save / Print Readings

The PCA® 400 is capable of saving active data to the analyzer’s onboard storage and / or

printing to the optional IrDA / Bluetooth® printer.

f To save pressure readings / report: press Save ( ).

f To print pressure readings / report: press Print ( ).

3.4.2 Tightness Test

1. Select Folder / Memory Location (User Discretion)

The PCA® 400 gives users the ability to organize their records in a folder structure for later

viewing and downloads.

f To change Folder / Memory Location: Main Menu Memory ( ) use navigation keys

to highlight the desired folder Options ( ) select Target.

2. Select Measurement Type

f To select Measurement Type: Main Menu Measure (

3. Select Volume

f To select the desired volume: select 0-99 L, 100-199 L or 200 L+.

) select Tightness Test.

35

0024-9551 Revision 2

Page 36

PCA® 400 User Manual

4. Begin Tightness Test

f Disconnect hoses and press Enter to zero the pressure sensor.

f Reconnect hoses in accordance with specied procedures and press Enter to start the

Tightness Test.

Fig. 3-15: Tightness Test Summary Screen

Summary of Test Data

Save - save pressure data to the selected folder /

memory location.

Print - print pressure data to IrDA / Bluetooth®

printer(s).

5. Save / Print Readings

The PCA

printing to the optional IrDA / Bluetooth® printer.

f To save pressure readings / report: press Save ( ).

f To print pressure readings / report: press Print ( ).

®

400 is capable of saving active data to the analyzer’s onboard storage and / or

3.5 Performing Temperature Test

3.5.1 Temperature User Preferences

Temperature Units

Select to display temperature in Fahrenheit (ºF) or Celsius (ºC).

f To change Temperature Units: Main Menu Settings ( ) Temperature Units select

Fahrenheit or Celsius.

36

0024-9551 Revision 2

Page 37

PCA® 400 User Manual

3.5.2 Temperature Analysis

1. Select Folder / Memory Location (User Discretion)

®

The PCA

viewing and downloads.

f To change Folder / Memory Location: Main Menu Memory ( ) use navigation keys

to highlight the desired folder Options (

2. Install Thermocouple

Plug Type-K Thermocouple into the T-AIR Port on the side of the analyzer.

Fig. 3-23: Ambient Air Thermocouple Port

400 gives users the ability to organize their records in a folder structure for later

Type-K Ambient Air Thermocouple / T-AIR Port

) select Target.

3. Select Measurement Type

f To select Measurement Type: Main Menu Measure (

) select Temperature.

4. Zero Readings

If the analyzer is not displaying zero with both thermocouples exposed to the same

conditions, the temperature channels need to be zeroed

5. Insert Thermocouples into Measurement Areas

37

0024-9551 Revision 2

Page 38

PCA® 400 User Manual

Fig. 3-24: Temperature Test Screen

Temperature

Metro Hospital

Delta T

-5 °F

Selected Folder / Memory Location - location where

data will be saved.

CalculatedTemperatureDierential- calculated

dierence between the measured T1 and T2.

Zero Button - press to zero (calibrate) temperature

reading in ambient temperature.

Save - save temperature data to the selected folder /

memory location.

Print - print temperature data to IrDA / Bluetooth®

printer(s).

6. Save / Print Readings

®

The PCA

400 is capable of saving active data to the analyzer’s onboard storage and / or

printing to the optional IrDA / Bluetooth® printer.

f To save temperature readings / report: press Save ( ).

f To print temperature readings / report: press Print ( ).

IMPORTANT: Printing via Bluetooth® is diabled when the analyzer is connected to

the PCA® 400 App. If you wish to print, disconnect from the mobile app or enable

IrDA communications.

38

0024-9551 Revision 2

Page 39

PCA® 400 User Manual

4. Settings & Features

4.1 Language Selection ......................................................................................................... 39

4.2 Date & Time ..................................................................................................................... 39

4.3 Username ........................................................................................................................ 40

4.4 Button Sound .................................................................................................................. 41

4.5 Inactivity Timeout ........................................................................................................... 41

4.6 Post-Purge Period ........................................................................................................... 41

4.7 Carbon Monoxide (CO) Zero .......................................................................................... 41

4.8 Sensor Setup.................................................................................................................... 42

4.9 Bluetooth® Setup ............................................................................................................ 43

4.10 Printer Setup ................................................................................................................... 44

4.11 Onboard Data Logging ................................................................................................... 45

4.12 Memory File Management ............................................................................................. 46

4.13 Fresh Air Purge without Removing Probe ................................................................... 47

4.14 Sensor Protection / Dilution Mode ............................................................................... 48

4.15 Smoke Number Test ....................................................................................................... 49

4.16 Oil Derivative Test .......................................................................................................... 50

4.17 Boiler Temperature Test ................................................................................................ 50

4.18 Combustion Equations ................................................................................................... 50

4.1 Language Selection

North American versions of the PCA® 400 will display information in English, French, and

Spanish. Languages are chosen through software menu selections.

Changing Language Preference

f To change Language Selection: Main Menu Settings (

language.

4.2 Date & Time

The instrument has the ability to store, recall to display, and print 500 sets of time and date

coded test records. (By default, the date is stored in the format: MM/DD/YY. Time is stored in the

format: hh:mm:ss AM/PM.) Date & Time are set through software menu selections.

) Language select desired

Changing Date / Time

f To change Date & Time of analyzer’s internal clock: Main Menu Settings (

Date update date and time press Save ( ).

39

) Time and

0024-9551 Revision 2

Page 40

PCA® 400 User Manual

Fig. 4-1: Date and Time Menu

Date and Time Menu

Date - change date (must delete / clear current date before

you can add new date).

Date

9/17/17

MM/DD/YY DD/MM/YY

Time

3:24

12H 24H

AM PM

0 1 2 3 4

5 6 7

8 9

/

CLR

4.3 Username

Date Format - change between month / day / year

and day / month / year calendar formats.

Time - change time (must delete / clear current time

before you can add new time).

Time Format - change between 12 and 24-hour time

formats.

AM / PM - if 12-hour format is selected, select AM or

PM.

Save - save changes to Date and Time and return to

the Settings menu.

The Username is typically the analyzer’s primary user or owner (e.g., company name, address,

phone number) and can be stored in memory by manually entering up to three lines of text,

with each line containing up to 18 alphanumeric characters.

Entering / Editing Username

f To change the analyzer’s Username: Main Menu Settings (

keyboard to input username press Save ( ).

IMPORTANT: Username information will appear at the top of each printout (Figure

4-4) until new information is entered or cleared.

) Username use

40

0024-9551 Revision 2

Page 41

PCA® 400 User Manual

4.4 Button Sound

The analyzer includes a sound transducer which beeps to signal when a button has

been pressed. The audible notification can be turned OFF and ON by changing the

user preferences.

Enabling / Disabling Button Sound

f To enable / disable Button Sound: Main Menu Settings (

No or Yes.

4.5 Inactivity Timeout

When enabled, the Inactivity Timeout feature will cause the analyzer to POWER DOWN if no

touch screen or keypad activity occurs within the selected duration.

Enabling / Disabling Inactivity Timeout

f To change the inactivity timeout settings: Main Menu Settings (

select None, 20-minutes, 30-minutes or 60-minutes.

4.6 Post-Purge Period

Purge feature at shutdown; if enabled, species a duration time (None, 1, 5, or 10 minutes)

during which the analyzer’s pump will remain on in order to purge gases from the analyzer

and probe after a shutdown request has been initiated.

Enabling / Disabling Post-Purge Period

) Button Sound select

) Inactivity Timeout

f To change the Post-Purge Period settings: Main Menu Settings (

select None, 1-minute, 5-minutes or 10-minutes.

4.7 Carbon Monoxide (CO) Zero

Congures the analyzer’s CO zeroing process to be done either manually or automatically.

Manual Zero

When the CO channel is set to Manual Zero, the analyzer does not zero the CO sensor to

ambient conditions during start up. In this mode, the “fresh air zero” established during

manual mode setup is stored in memory and used for the measurement of CO.

) Post-Purge Period

41

0024-9551 Revision 2

Page 42

PCA® 400 User Manual

Auto-Zero

When the CO channel is set to Auto-Zero, the CO sensor is zeroed to the ambient CO level

during start up.

Changing CO Zero Method

Auto-Zero determines the zero reading of the CO channel in fresh air and provides an oset

for the CO measurements. Manual Zero is used to detect CO that may be present during

start-up. The Auto / Manual Zeroing option allows the operator to select the start-up mode.

f To change the CO Zero settings: Main Menu Settings (

or Manual Zero.

IMPORTANT: Both methods for zeroing CO require that the analyzer be turned ON

in fresh air; otherwise, incorrect CO readings will occur.

IMPORTANT: The PCA® 400 performs a zero function during warm-up. Among

other purposes, an auto-zero determines the “zero reading” of the CO channel in

fresh air and provides an oset for the CO measurement. A manual zero detects

background CO during startup.

IMPORTANT: Both methods take the user through a 60-second count down to

establish a new zero. The manual mode establishes a fresh air zero and stores it for

use during instrument warm-up.

4.8 Sensor Setup

The PCA® 400 is designed to allow sensors to be interchanged in the eld; allowing users to

perform combustion tests for multiple gases with the same analyzer.

) CO Zero select Auto-Zero

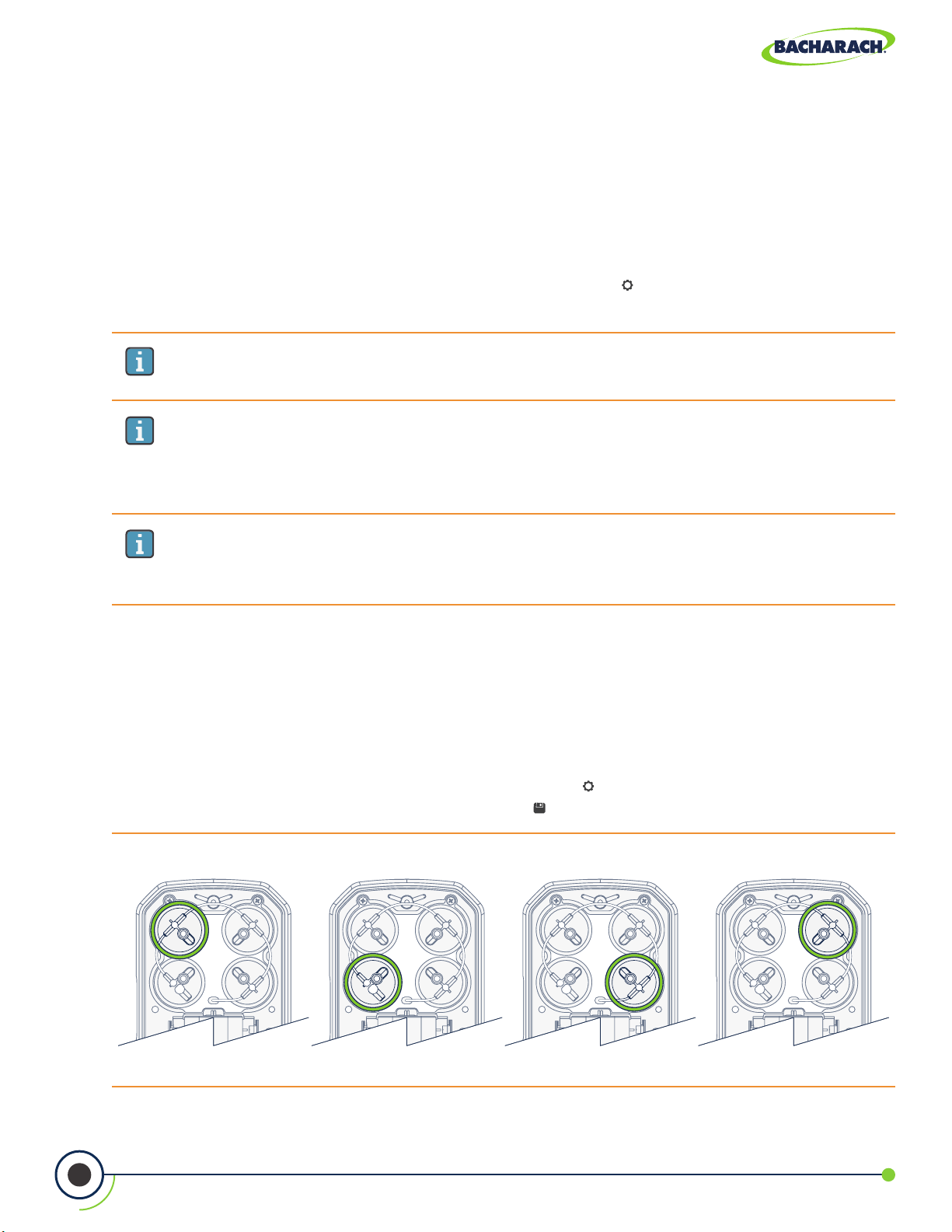

Changing Sensor Setup

f To change Sensor Setup: Main Menu Settings (

sensor from dropdown menus press Save ( ).

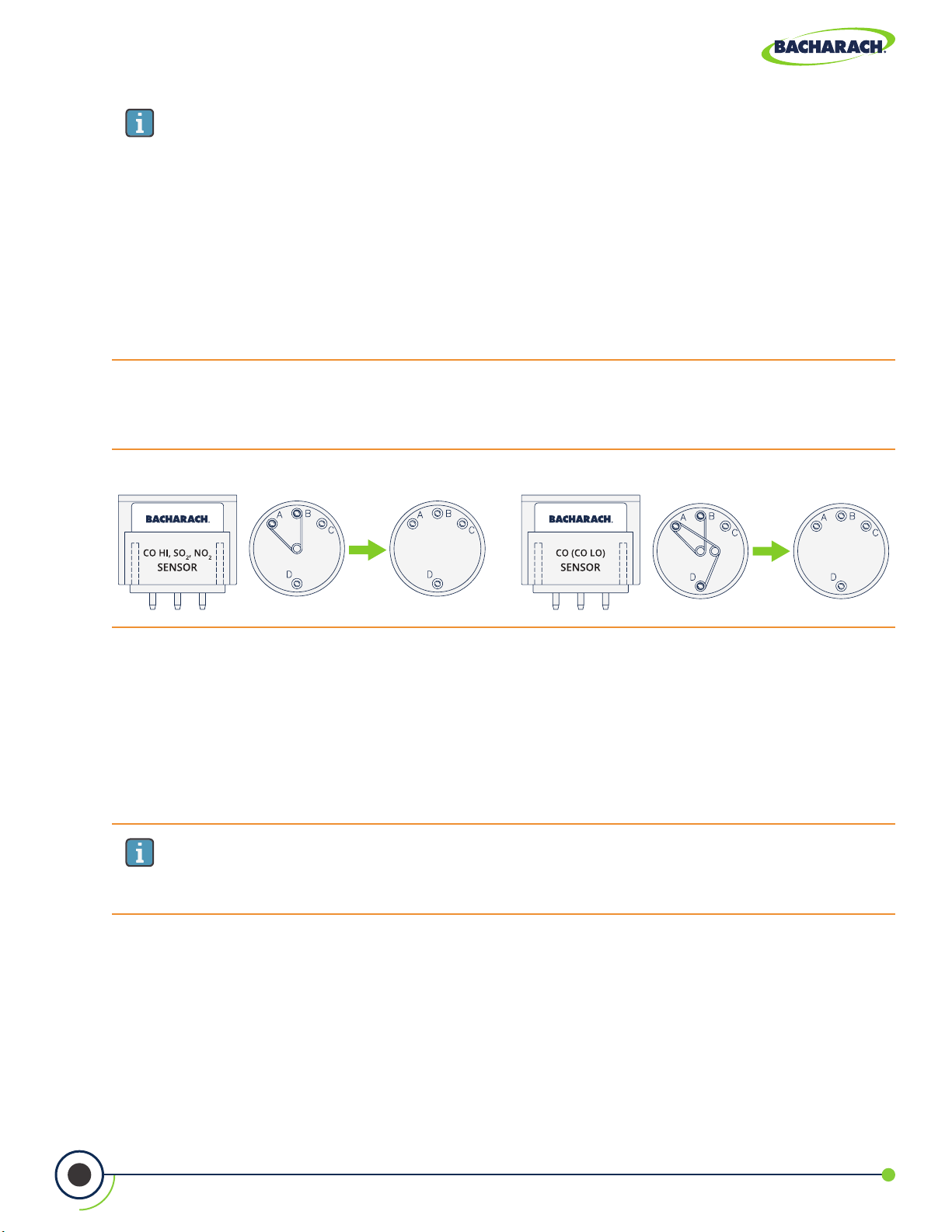

Fig. 4-2: Gas Sensor Positions

Position 1 Position 2 Position 3 Position 4

42

) Sensor Setup select desired

0024-9551 Revision 2

Page 43

PCA® 400 User Manual

Fig. 4-3: Sensor Setup

Sensor Setup

Position 1 - the analyzer is required have an O2 sensor

in this position.

Position 1O

Position 2CO-LO

Position 2 - the analyzer can optionally have either

CO

or a CO

LOW

sensor in this position.

HIGH

Position 3 - the analyzer can optionally have None,

NO2 or a SO2 sensor in this position.

Position 3NO

Position 4NO

2

Position 4 - the analyzer can optionally have either

None or a NO sensor in this position.

Save - save changes to Sensor Setup and return to the

Settings menu.

IMPORTANT: To ensure accurate analysis results, sensors must be properly

calibrated. See Calibration (Section 5.5 and 5.6) for more information.

Establish New Oset

Restart the analyzer in fresh air after changing the sensors to establish new oset.

4.9 Bluetooth® Setup

The PCA® 400 comes standard with Bluetooth® wireless communications; allowing users to

quickly connect the instrument to an IrDA + Bluetooth® Printer.

Enabling Bluetooth

f To enable Bluetooth® communications: Main Menu Settings ( ) Bluetooth select On.

IMPORTANT: Interference can be caused by devices that are transmitting on the

same frequency band.

WARNING: Use of radio connection may not be permitted in some locations

(e.g. airplanes, hospitals). User assumes responsibility for complying with rules

governing the use of radio connections.

®

43

0024-9551 Revision 2

Page 44

PCA® 400 User Manual

4.10 Printer Setup

The PCA® 400 is capable of wirelessly transmitting data to compatible IrDA (Infrared Data

Associated) or IrDA + Bluetooth® Printers. Users can quickly change between the two

communication protocols by selecting the appropriate printer type from the analyzer’s

settings. (For more information about wireless communication ranges, see Figures 2-6 and 2-7.)

IMPORTANT: Printing via Bluetooth® is diabled when the analyzer is connected to

the PCA® 400 App. If you wish to print, disconnect from the mobile app or enable

IrDA communications.

Enabling Printing via IrDA

The analyzer can communicate data via IrDA at a distance of up to 16” (41 cm). IrDA

communication requires that the analyzer has an unobstructed view of the printer at no

more than a 30° angle.

f To enable the use of IrDA for printing: Main Menu Settings (

Enabling Printing via Bluetooth

The analyzer can communicate data via Bluetooth at a distance of up to 30’ (unobstructed).

Use of Bluetooth® will require that the communication protocol has been enabled