Page 1

MVR-300™

Refrigerant Gas Detector

for Occupied Spaces

User Manual

Installation ● Operation ● Configuration ● Troubleshooting

P/N: 6203-9000

August 2018

Revision 3

Product Leadership Training Service Reliability

Page 2

MVR-300™ Refrigerant Gas Detector

2 P/N: 6203-9000 Revision 3

WARRANTY POLICY

Bacharach, Inc. warrants this detector, excluding sensors, to be free from defects in materials and workmanship for a period of 12

months from the date of purchase by the original owner. The sensor has a pro-rated warranty period of 12 months. If the product

should become defective within this warranty period, we will repair or replace it at our discretion.

The warranty status may be affected if the detector has not been used and maintained per the instructions in this manual or has been

abused, damaged, or modified in any way. This detector is only to be used for purposes stated herein. The manufacturer is not liable

for auxiliary interfaced equipment or consequential damage.

Due to ongoing research, development, and product testing, the manufacturer reserves the right to change specifications without

notice. The information contained herein is based on data considered accurate. However, no warranty is expressed or implied

regarding the accuracy of this data.

All goods must be shipped to the manufacturer by prepaid freight. All returned goods must be pre-authorized by obtaining a return

merchandise authorization (RMA) number. Visit www.mybacharach.com for an RMA number and procedures required for product

transport.

SERVICE POLICY

Bacharach, Inc. maintains a service facility at the factory. Some Bacharach distributors/agents may also have repair facilities; however,

Bacharach assumes no liability for service performed by anyone other than Bacharach personnel. Repairs are warranted for 90 days

after date of shipment (sensors, pumps, filters and batteries have individual warranties). Should your detector require non-warranty

repair, you may contact the distributor from whom it was purchased or you may contact Bacharach directly.

If Bacharach is to do the repair work, send the detector, prepaid, to the closest Service Center.

Location

Contact Information

Shipping Address

United States

Phone: 724-334 -5000

Toll Free: 800-736-4666

Fax: 724-334 -5001

Email: help@mybacharach.com

Bacharach, Inc.

621 Hunt Valley Circle

New Kensington, PA 15068, USA

ATTN: Service Department

Europe

Phone: +353 1 284 6388

Fax: +353 1 284 6389

Email: help@mybacharach.com

Bacharach, Inc.

114A Georges Street Lower

Dun Laoghaire, Dublin, Ireland

ATTN: Service Department

Canada

Phone: 905-882 -8985

Fax: 905-882 -8963

Email: support@bachcan.ca

Bacharach, Inc.

10 West Pearce Street, Unit 4

Richmond Hill, Ontario LB4 1B6, Canada

ATTN: Service Department

Always include your RMA #, address, telephone number, contact name, shipping/billing information and a description of the defect as

you perceive it. You will be contacted with a cost estimate for expected repairs prior to the performance of any service work. For

liability reasons, Bacharach has a policy of performing all needed repairs to restore the detector to full operating condition.

Prior to shipping equipment to Bacharach, visit www.mybacharach.com for an RMA # (returned merchandise authorization). All

returned goods must be accompanied with an RMA number.

Pack the equipment well (in its original packing, if possible), as Bacharach cannot be held responsible for any damage incurred during

shipping to our facility.

NOTICES

This manual is subject to copyright protection; all rights are reserved under international and domestic copyright laws. This manual

may not be copied or translated, in whole or in part, in any manner or format, without the written permission of Bacharach, Inc.

All software utilized and/or distributed by Bacharach is subject to copyright protection. All rights are reserved. No party may use or

copy such software in any manner or format, except to the extent that Bacharach grants them a license to do so. If this software is

being loaded onto more than one computer, extra software licenses must be purchased.

MVR-300™ is a trademark of Bacharach, Inc. All rights reserved.

Page 3

MVR-300™ Refrigerant Gas Detector

P/N: 6203-9000 Revision 3 3

TABLE OF CONTENTS

SECTION 1. SAFETY ............................................................................................................................ 5

1.1 Definition of Alert Icons .............................................................................................................. 5

1.2 General Safety Statements ....................................................................................................... 5

1.3 Safe Connection of Electrical Devices ...................................................................................... 6

SECTION 2. DESCRIPTION .................................................................................................................. 7

2.1 Product Overview ...................................................................................................................... 7

2.2 Intended Use ............................................................................................................................. 7

2.3 Design Features ........................................................................................................................ 7

2.4 Components Overview .............................................................................................................. 8

SECTION 3. INSTALLATION .............................................................................................................. 10

3.1 General Information for Installation ......................................................................................... 10

3.2 Mechanical Installation ............................................................................................................ 10

3.3 Configuration ........................................................................................................................... 12

3.4 Electrical Installation ................................................................................................................ 14

SECTION 4. OPERATION ................................................................................................................... 17

4.1 Start-up .................................................................................................................................... 17

4.2 Alarm Management Function and Configuration ..................................................................... 17

4.2.1 Default Alarm Function ............................................................................................... 17

4.2.2 Alarm Delay – Switches 2 and 3 ................................................................................ 18

4.2.3 Failsafe – Switch 4 ..................................................................................................... 20

4.2.4 Alarm 2 Relay – Switch 5 ........................................................................................... 20

4.2.5 Latching Alarm State – Switch 6 ................................................................................ 20

4.2.6 Buzzer Disable – Switch 7 .......................................................................................... 20

4.3 Other Switch Configurations .................................................................................................... 21

4.3.1 Reset (Cycle Power) - Switch 1 ................................................................................ 21

4.3.2 Reset to Factory Default Values - Switch 8 ............................................................... 21

4.4 Operation of Magnetic Switches, Buzzer, and LED ................................................................ 22

SECTION 5. MAINTENANCE .............................................................................................................. 23

5.1 Maintenance Intervals ............................................................................................................. 23

5.2 Adjustments ............................................................................................................................. 23

5.2.1 Introduction ................................................................................................................. 23

5.2.2 General Procedure ..................................................................................................... 24

5.2.3 Zero Adjustment ......................................................................................................... 25

5.2.4 Span Adjustment ........................................................................................................ 25

5.2.5 Bump Test .................................................................................................................. 26

5.3 Troubleshooting ....................................................................................................................... 26

5.3.1 Failed Span Adjustment ............................................................................................. 26

5.3.2 Hexadecimal Format .................................................................................................. 27

5.3.3 Fault Conditions .......................................................................................................... 28

5.3.4 Fatal Faults ................................................................................................................. 29

5.3.5 Critical Faults .............................................................................................................. 29

5.3.6 Negative Gas Fault ..................................................................................................... 29

5.3.7 Non-Critical Faults ...................................................................................................... 29

5.4 Replacing the Sensor Module ................................................................................................. 30

5.5 Cleaning the Detector .............................................................................................................. 31

SECTION 6. SENSOR PRINCIPLE ..................................................................................................... 32

SECTION 7. DISPOSING OF THE DETECTOR ................................................................................. 32

SECTION 8. TECHNICAL DATA......................................................................................................... 33

8.1 Approvals ................................................................................................................................. 33

8.2 Specifications for Modbus RTU Digital Communication over RS-485 .................................... 33

8.3 Power Supply and Relay Specifications .................................................................................. 33

8.4 Wiring Specifications ............................................................................................................... 33

8.5 Physical Specifications ............................................................................................................ 34

Page 4

MVR-300™ Refrigerant Gas Detector

4 P/N: 6203-9000 Revision 3

8.6 Environmental Specifications .................................................................................................. 34

8.7 Sensor Specifications .............................................................................................................. 34

8.8 Default Alarm Levels ............................................................................................................... 34

8.9 Modbus Registers .................................................................................................................... 35

8.9.1 Read Device Identification .......................................................................................... 35

8.9.2 Analog Input Registers ............................................................................................... 35

8.9.3 Analog Output Registers ............................................................................................ 37

8.9.4 Input Status Flags ....................................................................................................... 38

8.9.5 Output Status Flags .................................................................................................... 39

SECTION 9. ORDERING INFORMATION .......................................................................................... 41

9.1 MVR-300 Refrigerant Leak Detector Configurations ............................................................... 41

9.2 MVR-300 Refrigerant Leak Detector Configurations (UK Version) ......................................... 41

9.3 Accessories ............................................................................................................................. 42

SECTION 10. CUSTOM UK BACK BOXES AND FACEPLATES ....................................................... 43

10.1 Introduction to UK Version ....................................................................................................... 43

10.2 Hardware Overview – UK Version ........................................................................................... 43

10.3 Using Optional Metal Tabs ...................................................................................................... 44

10.4 Electrical Installation – UK Version ......................................................................................... 44

10.5 Customizing Face Plates ......................................................................................................... 45

10.6 Calibration ................................................................................................................................ 46

Page 5

MVR-300™ Refrigerant Gas Detector

P/N: 6203-9000 Revision 3 5

SECTION 1. SAFETY

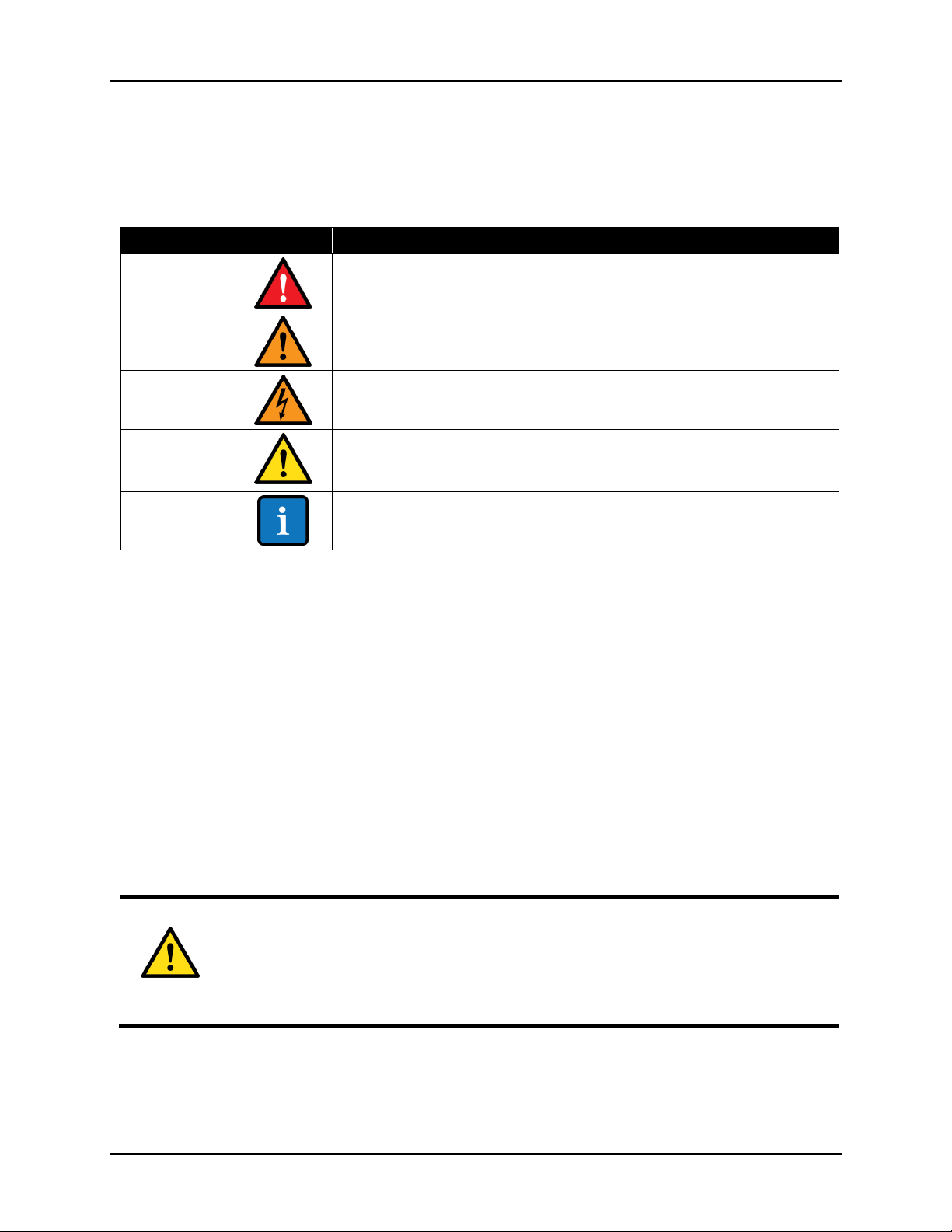

1.1 Definition of Alert Icons

The following alert icons are used in this document to highlight areas of the associated text that require a

greater awareness by the user.

Alert

Icon

Description

DANGER

Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

WARNING

Indicates a potential electrical shock hazard which, if not avoided,

could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, could

result in physical injury or damage to the product or environment. It

may also be used to alert against unsafe practices.

NOTICE

Indicates additional information on how to use the product.

1.2 General Safety Statements

Before using this product, carefully read and strictly follow the instructions in the manual.

Use the product only for the purposes specified in this document and under the conditions listed.

Ensure that product documentation is retained, made available, and appropriately used by anyone

operating the product.

Comply with all local and national laws, rules, and regulations associated with this product.

Only trained and competent personnel may use this product.

Only trained and competent personnel may inspect, repair and maintain the product as detailed in this

manual. Maintenance that is not detailed in this manual must be completed by Bacharach or

personnel qualified by Bacharach.

Use only genuine Bacharach spare parts and accessories. Otherwise, operation may be impaired.

Only operate the product within the framework of a risk-based alarm signaling concept.

CAUTION

REFRIGERANT SUFFOCATION RISK: Large refrigerant leaks into occupied spaces

can reach concentrations that pose a suffocation risk to the occupants. While the MVR300 can be used to detect refrigerant leaks well below those concentrations, it is not

designed as a stand-alone safety device. Safety of the occupants must take a system

design approach including ventilation, detection, early warning, mitigation, and design

redundancy among other considerations.

Page 6

MVR-300™ Refrigerant Gas Detector

6 P/N: 6203-9000 Revision 3

1.3 Safe Connection of Electrical Devices

Before connecting this detector to electrical devices not mentioned in this manual, consult the manufacturer

or a qualified professional.

NOTICE

The sensor must be connected by a marked, suitably located and easily reached switch

or circuit-breaker as means of disconnection.

NOTICE

If replacement of either main power fuse is required, use only a TR5 Radial 3.15A 250V

slow fuse (Littlefuse 372 1315 0001 or equivalent).

CAUTION

Wiring must be in compliance with national and local wiring codes.

CAUTION

RS-485 signal cable must be insulated to the highest voltage level in the system. Protect

the RS-485 signal cable by using the supplied installation kit.

Page 7

MVR-300™ Refrigerant Gas Detector

P/N: 6203-9000 Revision 3 7

SECTION 2. DESCRIPTION

2.1 Product Overview

The Bacharach MVR-300 continuously checks the ambient air of occupied spaces for refrigerant leaks. The

detector is for indoor applications. It is housed in an ABS enclosure that fits into many 2-gang and most 3gang electrical back boxes (not included).

NOTICE

The MVR-300 is designed for use in 2-gang and 3-gang back boxes with a minimum

depth of 47 mm (1.9”). Metal United Kingdom (UK) back boxes are also supported, but

require a special UK version of the MVR-300, slightly modified installation, and a

customized faceplate (not supplied by Bacharach). Otherwise, the UK version is

functionally the same. Refer to Chapter 10 for more information on the UK version and

its differences.

Figure 1. MVR-300 with Examples of Supported 2-gang Back Boxes

Gas alarms and status messages are indicated visually by a 3-colored LED and audibly by a buzzer. In

case of an alarm and / or fault, relays switch (for example, to shut-off valves or to activate alarm devices).

2.2 Intended Use

Checks ambient air of occupied spaces for refrigerant leaks

Intended for indoor applications

ABS enclosure fits into many 2-gang and most 3-gang electrical back boxes (not included)

Can be operated as a stand-alone detector or connected to a BMS/BAS (Building

Management/Building Automation) System

Designed to be installed in non-classified, non-hazardous, permanent locations.

2.3 Design Features

Powered by 100 to 240 VAC, 50/60 Hz

Gas alarms and status messages are indicated visually by a 3-colored LED and audibly by a buzzer

In case of an alarm and/or fault, relays can switch shut-off valves, alarm devices, or indicators at a

BMS/BAS

Measured gas concentration, status signals and configuration information are accessible via the

Modbus RTU interface (see Section 8.9 on page 34)

Can be calibrated and maintained non-intrusively using a magnetic wand

Page 8

MVR-300™ Refrigerant Gas Detector

8 P/N: 6203-9000 Revision 3

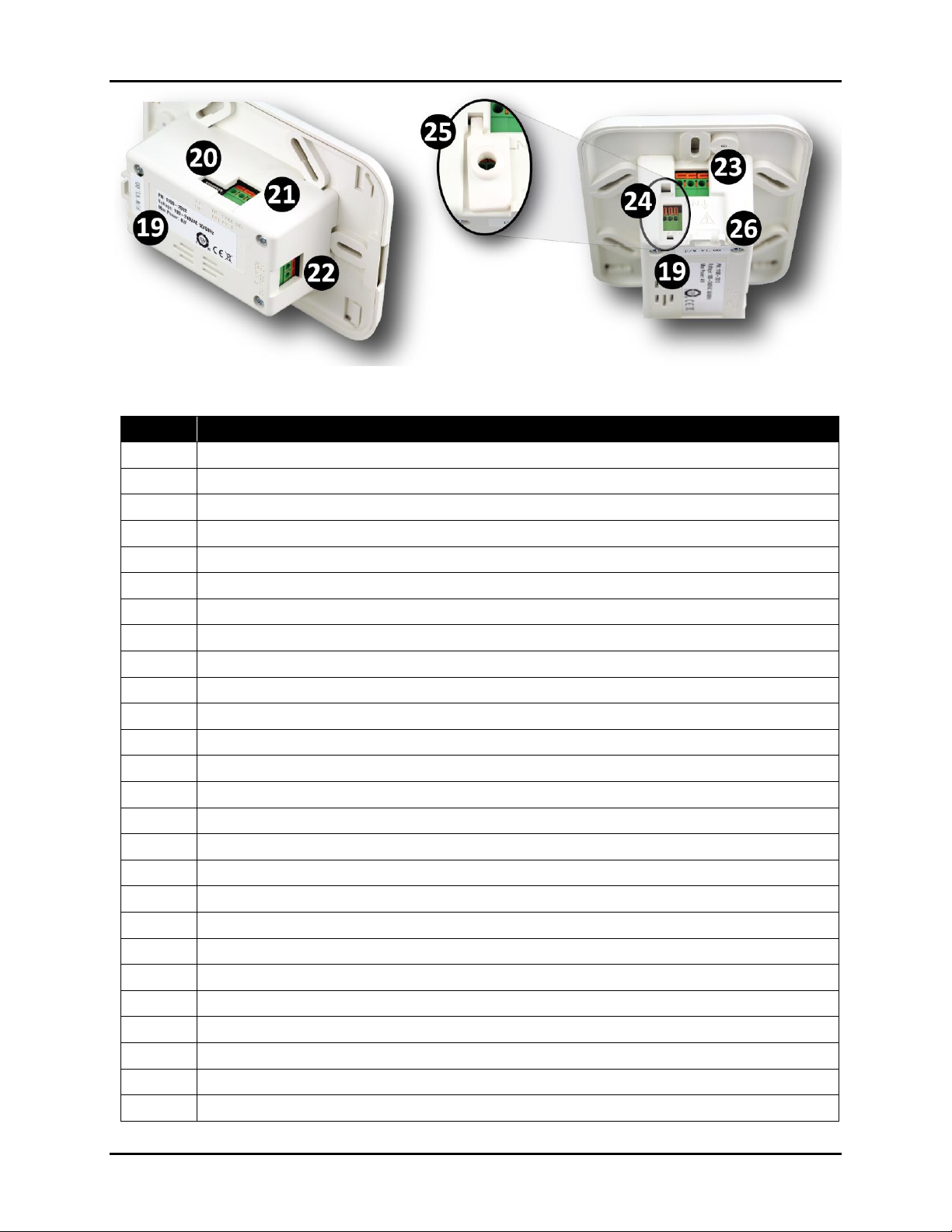

2.4 Components Overview

Figure 2. MVR-300 Components (Front)

Page 9

MVR-300™ Refrigerant Gas Detector

P/N: 6203-9000 Revision 3 9

Figure 3. MVR-300 Components (Back)

Item

Description of MVR-300 Components in Figure 2 and Figure 3

1

Coin slot to release bezel

2

Magnetic switch positions 1 (● on top) and 2 (●● on bottom)

3

Multi-color status LED

4

Grill

5

Decorative snap-on bezel

6

Cover plate (hinged)

7

Captive set screw

8

Detector base

9

Sensor type/calibration and ID/serial number labels

10

Mounting slots (×6)

11

Test point access holes (×2)

12

Sensor alignment ribs (×3)

13

Replaceable sensor module

14

Direction arrows (×2) for proper mounting

15

Hinges for cover plate

16

Hinges for bezel

17

Snap locks for bezel

18

Calibration adapter (fits cover plate and detector base)

19

Firmware version and part number/calibration labels

20

Configuration DIP switches (1-8)

21

Relay 1 output connectors (low gas alarm)

22

Relay 2 output connectors (high gas alarm or fault)

23

Power connectors

24

Modbus serial communications connectors

25

Rubber boot for Modbus port

26

Wiring harness

Page 10

MVR-300™ Refrigerant Gas Detector

10 P/N: 6203-9000 Revision 3

SECTION 3. INSTALLATION

3.1 General Information for Installation

Every detail of installation location is critical to ensure overall system performance and effectiveness. Strict

compliance and considerable thought must be given to every detail of the installation process, including,

but not limited to the following:

Regulations as well as local, state, and national codes that govern the installation of gas detection

equipment

Electrical codes that govern the routing and connection of electrical power and signal cables to gas

detection equipment

The full range of environmental conditions to which the detectors will be exposed (refer to section 6:

Sensor Principle on page 32 for more information on ambient conditions and cross-sensitivity)

The physical characteristics of the gas or vapor to be detected

The specifics of the application (e.g., possible leaks, air movement/draft, etc.)

The degree of accessibility required for maintenance purposes

The types of optional equipment and accessories that will be used with the system

Any limiting factors or regulations that would affect system performance or installations

Wiring details, including the following:

o Wiring must be connected as indicated in this manual.

o The wiring for power and relays must be selected and fused according to the rated voltages,

currents, and environmental conditions.

o If stranded conductors are used, a ferrule should be used.

o A switch or circuit breaker must be included in the installation.

o The switch or circuit breaker must be suitably located and easily reached.

o The switch or circuit breaker must be marked as the disconnect device for the equipment.

3.2 Mechanical Installation

The detector fits in most 2-gang and 3-gang electrical back boxes (not included) (See Section 10 for

details on the custom UK version of the MVR-300)

The detector must be accessible for maintenance (e.g., adjustment)

The access pathway of the refrigerant gas to the sensor must not be obstructed

The detector should be installed about 4 to 6 inches (100 to 150 mm) above the floor level

Figure 4. A Sampling of 2-Gang Electrical Boxes Supported by the MVR-300

Page 11

MVR-300™ Refrigerant Gas Detector

P/N: 6203-9000 Revision 3 11

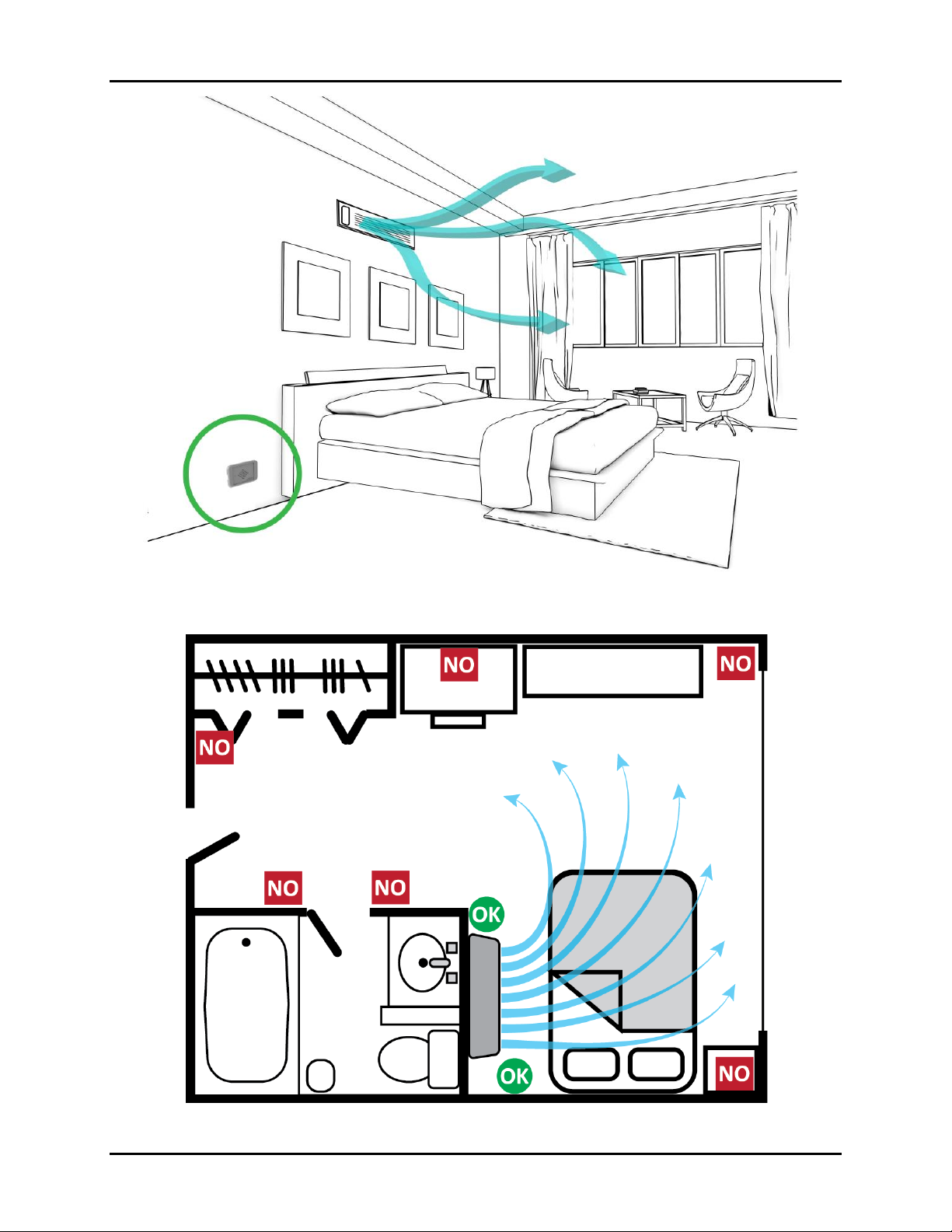

Figure 5. Typical MVR-300 Installation in an Occupied Space Application

Figure 6. Recommended Installation Locations

Page 12

MVR-300™ Refrigerant Gas Detector

12 P/N: 6203-9000 Revision 3

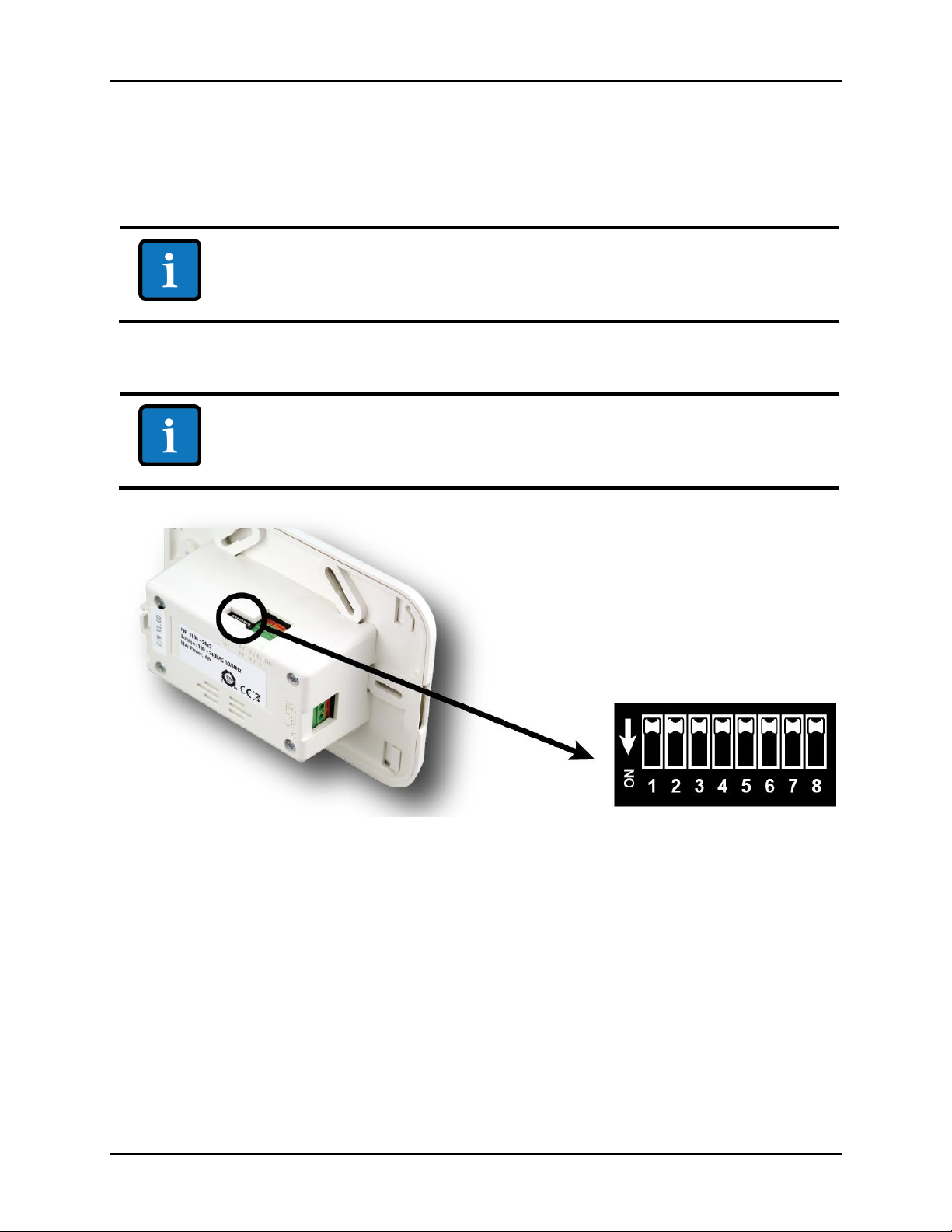

3.3 Configuration

Configuration is accomplished via switches or from a Remote Terminal Unit (RTU) on a Modbus serial

communications network. Review the default settings to determine if they are suitable for your particular

application. If default values are not suitable, change the configuration using the DIP switches, or via the

Modbus interface. A summary of switches is shown below. For details on Modbus communications

registers, refer to Section 8.9: Modbus Registers on page 35.

NOTICE

By default, switch configurations supersede Modbus configurations. Use Modbus register

2007 (Modbus Precedence over DIP Switch Settings) to change this precedence.

Changes of configurations will not take effect until the detector is restarted (i.e., toggling switch 1 or cycling

power).

NOTICE

For a proper reset, switch 1 must be toggled (ON then OFF). If it is left ON, the detector

is held in reset mode and will not function correctly until the switch is returned to the

OFF position.

Figure 7. Switches for Configuring the MVR-300

Page 13

MVR-300™ Refrigerant Gas Detector

P/N: 6203-9000 Revision 3 13

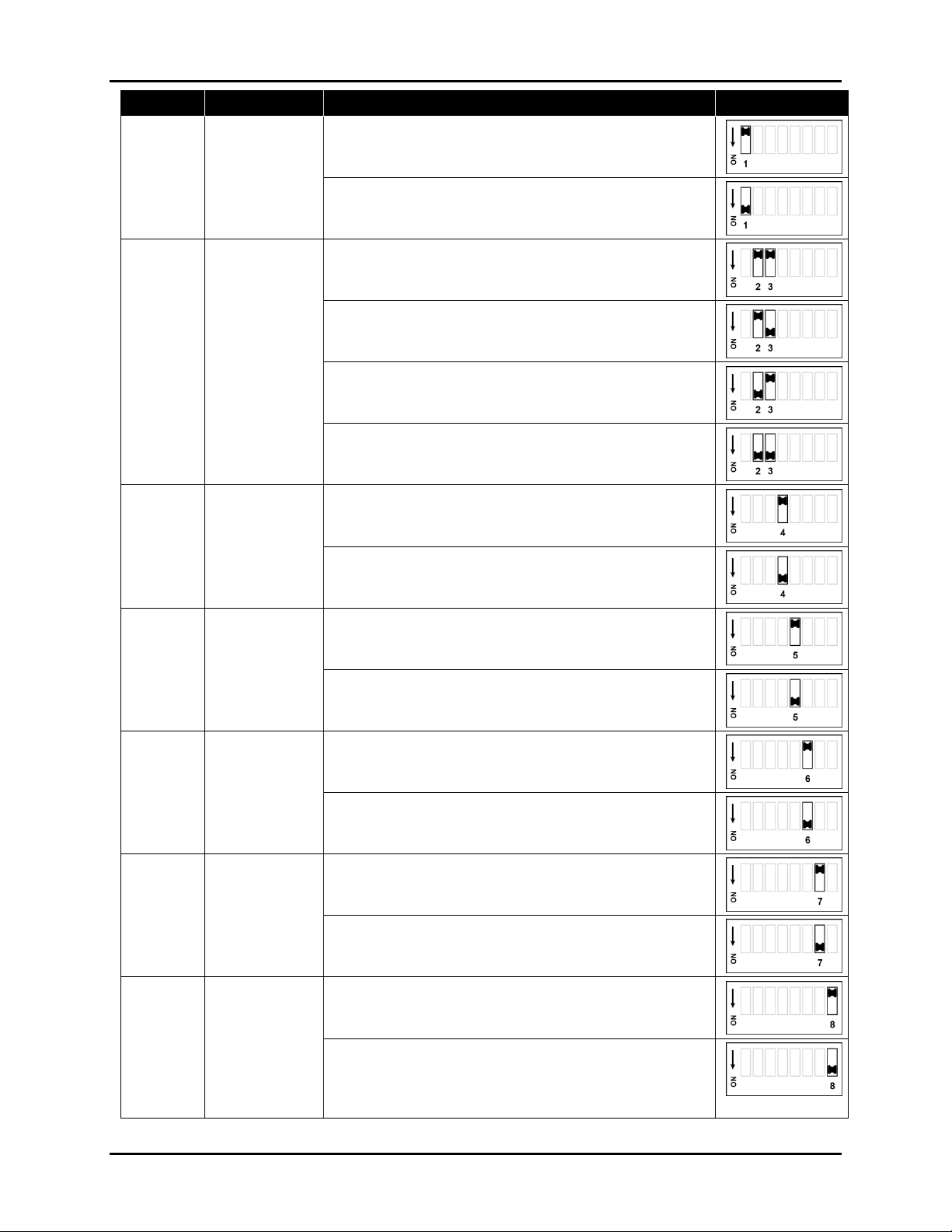

Switch

Function

Options and Descriptions

Positions

1

Restart

Off = Normal Operation (default)

On = Restart MVR-300 (must return switch to OFF

position)

2, 3

Alarm ON

Delay

Off, Off = No delay (default)

Off, On = 5 minute delay

On, Off = 10 minute delay

On, On = 15 minute delay

4

Failsafe Relay

Selection

Off = Normal Relay Operation (default)

On = Failsafe Relay Operation

5

Relay 2 Fault

Indication

Off = High Alarm or Fault (default)

On = High Alarm Only

6

Alarm

Latching

Off = Alarms automatically reset (default)

On = Alarms latch and require manual reset

7

Buzzer

Disable

Off = Buzzer enabled (default)

On = Buzzer disabled

8

Reset

Detector

Settings to

Factory

Default Values

Off = Normal operation

On = Used in reset procedure for resetting Modbus

registers to their factory default values (see section

4.3.2 on page 21 for reset information and section 8.9

on page 35 for Modbus registers and default values).

Page 14

MVR-300™ Refrigerant Gas Detector

14 P/N: 6203-9000 Revision 3

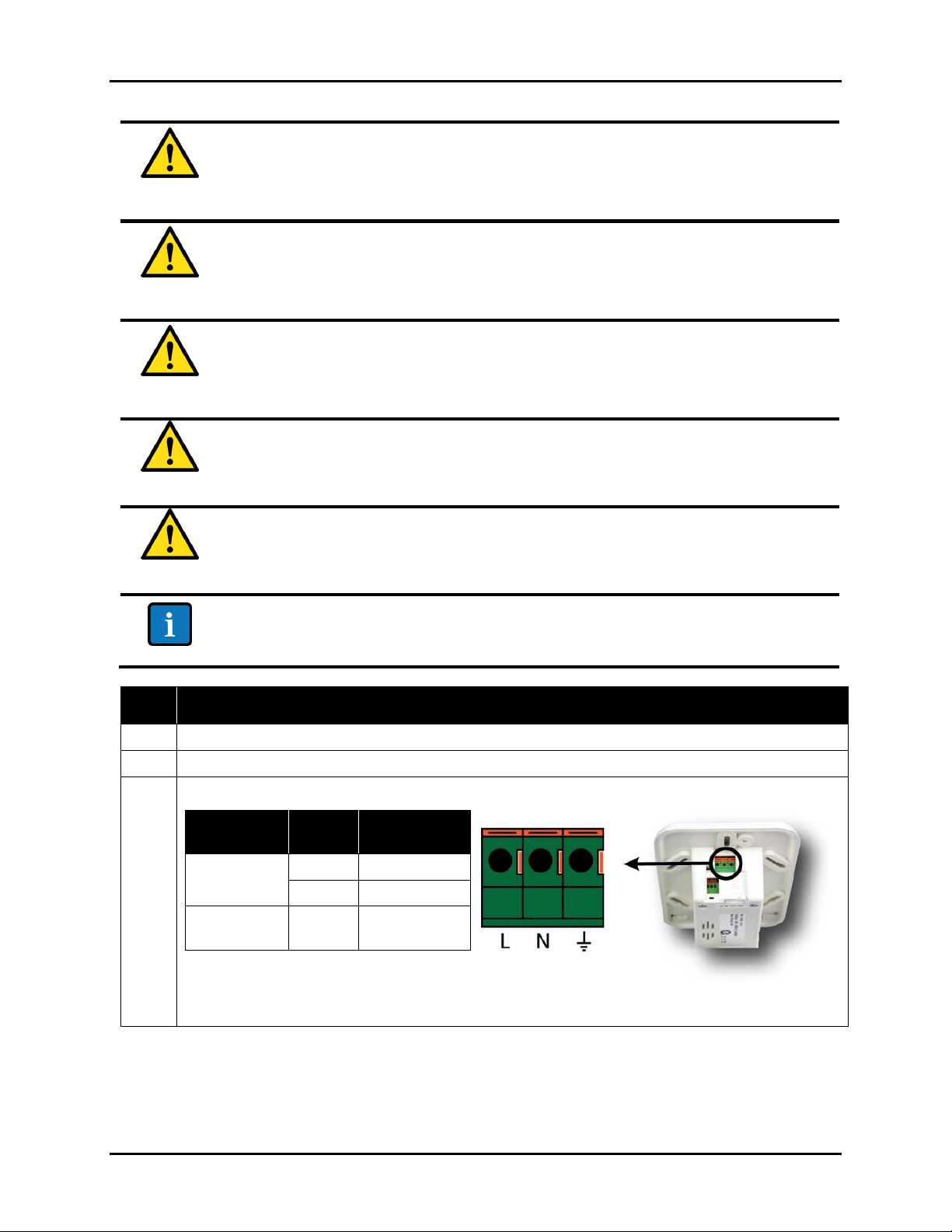

3.4 Electrical Installation

CAUTION

A switch or circuit breaker must be included in the installation. The switch or circuit

breaker must be suitably located and easily reached, and it must be marked as the

disconnect device for the equipment.

CAUTION

Ensure all wiring connections are made before applying power.

CAUTION

This product uses semiconductors which can be damaged by electrostatic discharge

(ESD). When handling the printed circuit boards (PCBs), observe proper ESD

precautions so that the electronics are not damaged.

CAUTION

RS-485 signal cable must be insulated to the highest voltage level in the system. Protect

the RS-485 signal cable by using the supplied installation kit.

CAUTION

Wiring must be in compliance with national and local wiring codes.

NOTICE

When inserting wire into the terminal, release the spring clamp by pushing the release

latch back.

Step

Description of Electrical Installation

1.

Remove bezel by releasing the two snap locks. When installed, insert coin into the slot to remove.

2.

Remove cover plate by loosening the set screw.

3.

Observing proper polarity, connect wires for power to the appropriate terminals.

Power

Label

Wiring

Termination

Figure 8. Wiring Power

100 to

240 VAC

L

VAC line

N

VAC neutral

Earth

Ground

G

VAC earth

ground

Page 15

MVR-300™ Refrigerant Gas Detector

P/N: 6203-9000 Revision 3 15

Step

Description of Electrical Installation

4.

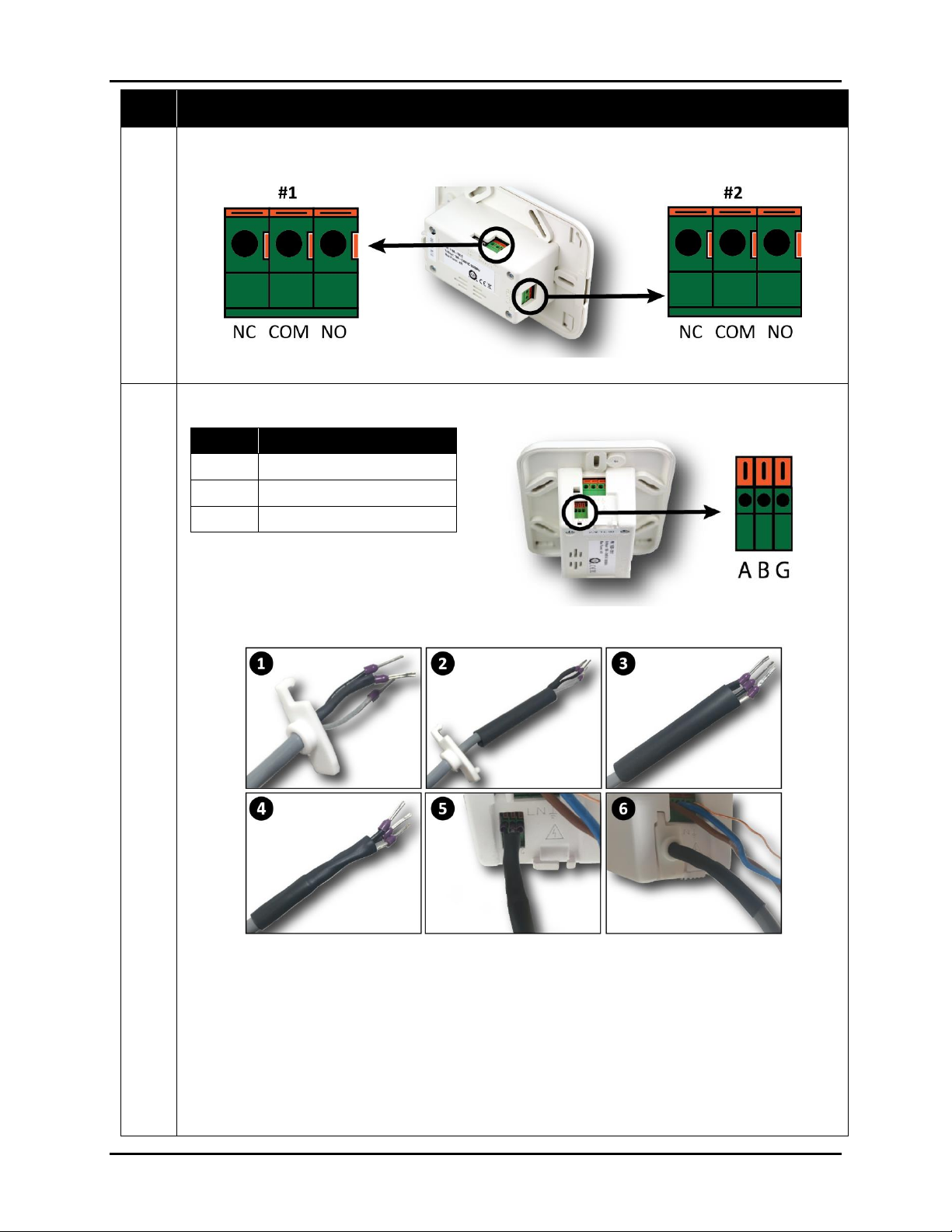

Observing proper polarity, connect normally closed (NC) common (COM), and normally open

(NO) wires for relays to the appropriate terminals.

Figure 9. Wiring Relay 1 (Low Gas Alarm) and Relay 2 (High Gas Alarm or Fault)

5.

Observing proper polarity, make the Modbus connections as follows, using the figures below for

reference.

Label

Description

Figure 10. Modbus Wiring Terminals

A

RS-485 “A” (non-inverted)

B

RS-485 “B” (inverted)

G

RS-485 shield

Prepare signal cable and put boot over the signal cable ().

Add ferules if required ().

Apply 10 cm piece of shrink wrap as close to the wire ends/ferules as possible while

leaving some free wire to allow connection to the detector ().

Heat the shrink wrap ().

Connect signal wires/ferules to the detector ().

Slide rubber boot along the wire and shrink wrap assembly and connect it to the

detector ().

Figure 11. Details for Connecting Modbus Communications Wiring

Page 16

MVR-300™ Refrigerant Gas Detector

16 P/N: 6203-9000 Revision 3

Step

Description of Electrical Installation

6.

Confirm configuration of switches. Refer to Section 3.3 on page 12.

7.

Place detector into electrical back box (not included) and secure through the appropriate

mounting slots.

Figure 12. Secure the MVR-300 and Wiring into the Back Box

8.

Put cover plate back into hinge and tighten the set screw.

Figure 13. Replace and Secure Cover Plate

9.

Put the bezel back into hinge and snap on.

Figure 14. Replace the Bezel

Page 17

MVR-300™ Refrigerant Gas Detector

P/N: 6203-9000 Revision 3 17

SECTION 4. OPERATION

4.1 Start-up

Step

Description

1.

Switch power on.

2.

Observe start-up sequence and warm-up phase.

Green LED will blink at 0.5 Hz for about 5 minutes

Modbus flag for warm-up is set

Buzzer is off

Relay state is “no alarm”

3.

Observe normal operation.

Green LED is steady on

Buzzer is off

Relay state is “no alarm”

4.

A bump test or calibration is required following installation to verify instrument functionality. (See

Section 5.2.5 for more information.)

4.2 Alarm Management Function and Configuration

The MVR-300 offers several different ways how the detector behaves in case of a refrigerant alarm. The

alarm manager can either be configured through the switches or the Modbus interface.

4.2.1 Default Alarm Function

If the refrigerant concentration raises above the alarm 1 set-point:

The LED flashes red with 0.5 Hz

The buzzer beeps at 0.5 Hz

The alarm 1 relay changes state

The Modbus alarm 1 flag is set.

Once the alarm 1 condition is no longer present and below the hysteresis value (imposed to avoid relay

chatter), the detector returns to normal operation.

If the refrigerant concentration raises above the alarm 2 set-point:

The LED flashes red with 2 Hz.

The buzzer beeps at 2 Hz

The alarm 2 relay changes state

The Modbus alarm 2 flag is set.

Once the alarm 2 condition is no longer present and below the hysteresis value (avoiding relay chatter), the

detector returns to alarm 1 state.

Page 18

MVR-300™ Refrigerant Gas Detector

18 P/N: 6203-9000 Revision 3

Figure 15. Default Alarm Generation

4.2.2 Alarm Delay – Switches 2 and 3

To avoid premature alarms, ensuring the presence of refrigerant for a certain amount of time, the triggering

of the alarm can be delayed for a short period of time. Unless the alarm condition is present for at least the

delay time, the alarm will not be triggered.

Figure 16. Alarm ON Delay (Alarm Condition Must Be Present for at Least the Programmed Time)

Page 19

MVR-300™ Refrigerant Gas Detector

P/N: 6203-9000 Revision 3 19

Figure 17. Alarm ON Delay (A Shorter Delay Time Is Disregarded)

Figure 18. Alarm ON Delay for Multiple Alarm Levels

Page 20

MVR-300™ Refrigerant Gas Detector

20 P/N: 6203-9000 Revision 3

4.2.3 Failsafe – Switch 4

If ON, the relays will change state whenever either of the following occurs.

Power loss

Alarm condition.

4.2.4 Alarm 2 Relay – Switch 5

If ON, the relay will only change state as a result of an alarm condition. In the default configuration, Relay

2 will also indicate critical faults.

4.2.5 Latching Alarm State – Switch 6

If ON, the relay and Modbus flag will not change state until the concentration is below the alarm level and

it is acknowledged. The acknowledgement can either happen by tapping and holding the magnetic wand

for 5 seconds to the switch indicated as (●●) or by changing the respective Modbus flag to 0.

In the default configuration the alarms will automatically reset when the gas level is below the alarm

thresholds.

Figure 19. Latched Alarm Requiring Acknowledgement and Gas Concentration below Alarm Level

4.2.6 Buzzer Disable – Switch 7

If ON, the buzzer is disabled and will not sound.

Page 21

MVR-300™ Refrigerant Gas Detector

P/N: 6203-9000 Revision 3 21

4.3 Other Switch Configurations

4.3.1 Reset (Cycle Power) - Switch 1

Use the following procedure to cycle power to the MVR-300.

Step

Description

1.

Move switch 1 to the ON position.

2.

Move switch 1 to the OFF position.

3.

Power is cycled to the MVR-300.

4.3.2 Reset to Factory Default Values - Switch 8

Use the following procedure to reset all configurable Modbus registers to their factory default values.

Step

Description

1.

Ensure that the detector is off. If the detector is on, turn off power.

2.

Set switch 8 to ON.

3.

Turn on the detector. The buzzer will be ON and the LED will be OFF.

4.

Set switch 8 to OFF. The buzzer will be OFF and the LED will be OFF.

5.

Using the magnetic wand, hold magnetic switch 1 (●) for 60 seconds. LED is GREEN during this

period.

6.

Wait for the LED to changes to ORANGE.

7.

Reset the detector by cycling power (by toggling switch 1).

8.

Detector will start-up as normal and re-read all switch settings.

Page 22

MVR-300™ Refrigerant Gas Detector

22 P/N: 6203-9000 Revision 3

4.4 Operation of Magnetic Switches, Buzzer, and LED

Figure 20. Operation of Magnetic Switches, Buzzer, and LED

NOTICE

If the drill pattern of the customized (metal) faceplate for the UK version of the MVR-300

does not accommodate the two magnetic switch locations, the faceplate must be

removed to use the magnetic wand functions (e.g., zero adjustment, span adjustment,

alarm latching, alarm silencing, etc.).

Page 23

MVR-300™ Refrigerant Gas Detector

P/N: 6203-9000 Revision 3 23

SECTION 5. MAINTENANCE

5.1 Maintenance Intervals

Interval

Function

During

Commissioning

Check calibration.

Check LEDs for proper operation.*

Check for proper buzzer and relay operation.*

Check signal transmission to the BMS/BAS (central controller) if connected.*

Every 6 Months

Inspection by trained service personnel.

Check LEDs for proper operation.*

Check for proper buzzer and relay operation.*

Check signal transmission to the BMS/BAS (central controller) if connected.*

Calibrate the sensor or contact Bacharach for sensor exchange with

factory-calibrated sensor.

As Required

Replace sensor module(s) (see page 30).

* These can be activated via Modbus commands.

5.2 Adjustments

5.2.1 Introduction

Adjustment of the detector must be performed at regular intervals as required by national standards or

regulations (e.g., EN 378, ASHRAE 15, BREEAM, etc.).

WARNING

Breathing Hazard: Calibration gas must not be inhaled! See appropriate Safety Data

Sheets. Calibration gas should be vented into a fume hood or to the outside of the

building.

WARNING

Zero First, Then Span: For proper operation, never adjust the span before completing

a zero adjustment. Performing these operations out of order will cause faulty calibration.

WARNING

Bacharach recommends calibrating detectors within the application-specific condition

and with target gas. This method of zeroing the detector in the application environment

and performing a target gas calibration is more accurate. A surrogate gas calibration may

only be performed as an alternative if a target gas calibration is not possible.

NOTICE

The sensor should be fully warmed-up (at least 2 hours, preferably 24 hours).

NOTICE

When entering the functions for zero or span adjustment, the detector will automatically

enter OFFLINE mode, and will remain OFFLINE until either the OFFLINE mode is

canceled by tapping the respective magnetic switch, or the OFFLINE mode times out

within 6 minutes (typical) after the adjustment has ended.

Page 24

MVR-300™ Refrigerant Gas Detector

24 P/N: 6203-9000 Revision 3

5.2.2 General Procedure

Step

Description

1.

Verify that the detector is NOT in alarm and does not have a fault condition (i.e., it must not have

a continuous orange LED).

2.

Verify that the calibration gas is in a balance of air, not Nitrogen (N2).

3.

Attach the pressure regulator to the calibration gas cylinder.

4.

Fit calibration adapter to the cover plate or base plate (see below).

5.

Connect the tubing to the barbed fittings of the pressure regulator and calibration adapter.

6.

Verify that gas flow is approximately 0.3 to 1.0 L/min.

7.

If operation is intended to be at higher altitudes, the factory calibration will result in a reading

lower than the reading at sea level (reduced partial pressure). A new span adjustment is

recommended if the altitude or the ambient pressure is changed. The factory calibration is set

to sea level.

8.

Always perform a zero adjustment before a span adjustment.

Item

Description of Calibration Components

1

Calibration adapter

2

Flow meter

3

Pressure regulator

4

Calibration gas

5

Tubing

6

Calibration from base plate (with test point access)

7

Calibration from cover plate

Figure 21. Calibration Assembly

Page 25

MVR-300™ Refrigerant Gas Detector

P/N: 6203-9000 Revision 3 25

5.2.3 Zero Adjustment

WARNING

Ambient air can be used to zero the sensor instead of synthetic air only if the area is

known to be free of the target gas or any gas to which the sensor may be cross-sensitive.

In this case, no cylinder or calibration adapter is needed for the zero adjustment.

Step

Description (Continued from General Procedure)

9.

Tap and hold (●) for more than 5 seconds. The LED will blink green-green-red to indicate the

detector is ready.

10.

Apply synthetic air (or use ambient air per the warning above).

11.

Tap (●) within 30 seconds to confirm start of calibration. Otherwise the detector will time-out and

return to normal operation.

12.

As the process progresses, the LED will blink green-red, green-red-red, green-red-red-red, etc.

To abort calibration, tap and hold (●) for >5 seconds, turn off gas flow and remove the

calibration adapter. The detector will return to normal operation.

If calibration is successful (green LED), skip to step 15.

If calibration is unsuccessful (orange LED blinks @ 2 Hz), then tap (●) to discard the

calibration attempt, and see Section 5.3 on page 26 for troubleshooting.

13.

Turn off gas flow from synthetic air.

14.

Replace synthetic air tank with calibration gas tank in preparation for span adjustment.

5.2.4 Span Adjustment

Step

Description (Continued from Zero Adjustment)

15.

Tap and hold (●●) for >5 seconds. The LED will blink green-green-orange when the detector is

ready.

16.

Apply span gas in the concentration listed on the cal gas concentration label (beneath the

detector’s cover plate). This may require the temporary removal of the bezel and cover plate to

see the label.

17.

Tap (●●) within 30 seconds to confirm initiation of the calibration. Otherwise the detector will

time-out and return to normal operation.

18.

As the calibration process progresses, the LED will blink green-orange, green-orange-orange,

green-orange-orange-orange, etc.

To abort calibration, tap and hold (●●) for >5 seconds, turn off gas flow and remove the

calibration adapter. The detector will return to normal operation.

If calibration is successful, the LED will blink green-orange-red indicating ‘offline’. Turn

off gas flow and remove the calibration adapter. After 6 minutes the detector will return

to normal operation.

If calibration is unsuccessful (orange LED blinks @ 2 Hz), then tap (●●) to discard the

calibration attempt, and see Section 5.3 on page 26 for troubleshooting. Turn off gas

flow and remove the calibration adapter. After 6 minutes the detector will return to

normal operation.

Page 26

MVR-300™ Refrigerant Gas Detector

26 P/N: 6203-9000 Revision 3

5.2.5 Bump Test

A bump test is a live test of a system to verify that the detector responds to gas and all connected alarm

devices, BMS, etc. are operating accordingly. In this case it is necessary that all involved persons are

informed about the test and certain alarms might have to be inhibited (e.g., shutdown valves, notification

of authorities, etc.).

Step

Description

1.

Inform building personnel of test so that certain alarms may be inhibited (e.g., shutdown

valves, notification of authorities, etc.).

2.

Connect adapter and target gas according to instructions in Section 5.2.2: General Calibration

Procedure on page 24.

3.

Apply a sufficiently high concentration of target gas to trigger alarms, but not pure refrigerant or

hydrocarbons (e.g., do not use a butane lighter), as this might damage the sensor.

4.

Once the alarm thresholds are exceeded, all designated gas alarm relays will be activated and

the digital outputs will transmit the corresponding gas concentrations.

5.

Turn off gas flow and remove calibration adapter.

5.3 Troubleshooting

5.3.1 Failed Span Adjustment

Step

Description

1.

Remove bezel and face plate.

2.

Attach calibration adapter.

3.

Configure voltmeter to measure 0 to 5 VDC.

4.

Insert voltmeter probes into the marked test points.

5.

Tap and hold (●●) for more than 5 seconds.

6.

The LED will blink green-green-orange to indicate the detector is ready.

7.

Apply span gas in the concentration listed on the cal gas concentration label on the detector

base.

8.

Tap (●●) within 30 seconds confirm to initiate calibration. Otherwise the detector will time-out

and return to normal operation.

9.

While gas is being applied the analog output will generate a voltage proportional to the measured

gas concentration. For example, for a 5,000 ppm span detector, applying 2,500 ppm cal gas

should, once stable, result in a 2.5 VDC reading.

𝑅𝑒𝑎𝑑𝑖𝑛𝑔 = 5 ×

2500

5000

= 2.5 𝑉𝐷𝐶

10.

As the process progresses, the LED will blink green-orange, green-orange-orange, greenorange-orange-orange, etc.

11.

To abort the calibration tap and hold (●●) for more than 5 seconds.

12.

The LED will blink green-orange-red indicating “offline”.

13.

Turn off gas flow and remove the calibration adapter from the detector.

14.

The detector will return after 6 minutes (typical) to normal operation.

15.

If the calibration was successful, skip the next step.

16.

If the calibration was not successful, the orange LED will blink at 2 Hz.

17.

Tap (●●) to discard the calibration attempt.

Page 27

MVR-300™ Refrigerant Gas Detector

P/N: 6203-9000 Revision 3 27

Step

Description

18.

The voltage reading is an indicator of the sensitivity of the sensor. If the voltage reading is

significantly lower than the expected value, the sensor module must be replaced.

19.

The LED will blink green-orange-red indicating “offline”.

20.

Turn off gas flow and remove the calibration adapter from the detector.

21.

Put cover plate back on and tighten set screw.

22.

Put bezel back on.

23.

The detector will return to normal operation after 6 minutes (typical).

Item

Description

1

Magnetic switch position 1 (●)

2

Magnetic switch position 2 (●●)

3

Multi-color status LED

4

0-5 V test point access hole (-)

5

0-5 V test point access hole (+)

6

Calibration adapter

Figure 22. Test Point Access with Calibration Adapter in Place

5.3.2 Hexadecimal Format

All fault codes can be retrieved through the Modbus interface and are shown in hexadecimal (hex) format.

A hex digit can represent multiple codes as shown below.

Hex

Code

Equivalent

Error Code(s)

Hex

Code

Equivalent

Error Code(s)

Hex

Code

Equivalent

Error Code(s)

Hex

Code

Equivalent

Error Code(s)

0 0 4 4 8 8 C

4 + 8

1 1 5

1 + 4

9

1 + 8

D

1 + 4 + 8

2 2 6

1 + 2 + 3

A

2 + 8

E

2 + 4 + 8

3

1 + 2

7

1 + 2 + 4

B

1 + 2 + 8

F

1 + 2 + 4 + 8

Page 28

MVR-300™ Refrigerant Gas Detector

28 P/N: 6203-9000 Revision 3

5.3.3 Fault Conditions

Bit

Mask

(HEX)

Fault

Description

Fault

State

Pri-

ority

Clearing Action

Required

Actions During

Fault

All bits

cleared

No fault

0x0001

Software fault

Firmware error (e.g.,

unexpected switch

state)

Fatal

fault

1

Acknowledge (reset

firmware)

Wait for switch 2

hold

0x0002

Sensor out

Cannot detect sensor

Critical

fault

2

Sensor Detected

Check sensor

0x0004

Input voltage

fault

Power supply voltage

out of range.

Critical

fault

2

Input voltage within

specification

Check Input

voltage

0x0008

Memory fault

Error in

reading/writing to

RAM, flash or internal

(PIC) EEPROM

Critical

fault

2

Memory test

passed

Test memory

0x0010

DAC fault

Error updating DAC

value

Non

critical

fault

4

DAC can be written

to

Write to DAC

0x0020

Stuck

magnetic

switch

Magnetic switch

activated for > 1

minute

Non

critical

fault

4

Switch released

Check switch

state

0x0040

Negative gas

concentration

fault

Sensor output has

drifted too negative

Nega-

tive gas

fault

3

Gas concentration

exceeds negative

gas limit

Check gas

concentration

0x0080

Invalid

calibration

Error in calibration

configuration

Critical

fault

2

Load valid

calibration

Read from

external EEPROM

0x0100

Zero

calibration

failure

Zero calibration failed

Calibra-

tion

failure

5

Acknowledgement

of failed calibration

Wait for switch 2

hold

0x0200

Sensor read

EEPROM fault

Error in reading from

external EEPROM

Critical

fault

2

External EEPROM

read success

Read from

external EEPROM

0x0400

Sensor write

EEPROM fault

Error in reading

writing to external

EEPROM

Critical

fault

2

External EEPROM

write success

Wait for write

0x0800

Sensor

configuration

fault

Error in external

EEPROM data

Critical

fault

2

External EEPROM

write valid data

Wait for write

0x1000

Span

calibration

failure

Span calibration

failed

Calibra-

tion

failure

5

Acknowledgement

of failed calibration

Wait for switch 2

hold

0x2000

System read

EEPROM fault

Error in reading from

internal EEPROM

Critical

fault

2

Internal EEPROM

read/write success

Read from internal

EEPROM

0x4000

System write

EEPROM fault

Error in reading

writing to internal

EEPROM

Critical

fault

2

Internal EEPROM

read/write success

Wait for write

0x1000

System

configuration

fault

Error in internal

EEPROM data

Critical

fault

2

Internal EEPROM

write valid data

Wait for write

Page 29

MVR-300™ Refrigerant Gas Detector

P/N: 6203-9000 Revision 3 29

5.3.4 Fatal Faults

Orange LED is on

Relay 2 indicates fault, if configured

Buzzer is on

Modbus flag is set to fault

Gas reading is invalid

Fatal faults can only be recovered by rebooting the system. To reboot the system do the following.

Step

Description

1.

Tap and hold (●●) for more than 5 seconds or set the Modbus flag.

2.

If the reboot was successful, the detector will return to normal operation. Otherwise exchange

detector.

5.3.5 Critical Faults

Orange LED is on

Relay 2 indicates fault, if configured

Buzzer is on

Modbus flag is set to fault

Gas reading is invalid

Step

Description

1.

If the remedy suggestions are successful or the detector can resolve the issue, the critical fault

is canceled and the detector returns to normal operation.

2.

If the detector is set to latching, tap and hold (●●) to acknowledge the latch mode or set the

Modbus flag.

5.3.6 Negative Gas Fault

Orange LED blinks at frequency of 2 Hz

Relay 2 indicates fault, if configured

Buzzer is on

Modbus flag is set to fault

Gas reading is invalid

The zero point of the sensor has drifted below the acceptable limit. This could be intermittent if the zero

reading is chattering around the limit.

Step

Description

1.

Hold (●●) for 5 seconds to acknowledge a negative gas fault.

2.

If the fault is still active the detector begins the Zero Calibration process; otherwise the fault may

clear.

3.

If a zero calibration is not possible exchange the sensor.

5.3.7 Non-Critical Faults

Orange LED is on

Modbus flag is set to fault

Gas reading and alarm management is valid

The detector is fully functional, however, this condition needs to be resolved.

Page 30

MVR-300™ Refrigerant Gas Detector

30 P/N: 6203-9000 Revision 3

5.4 Replacing the Sensor Module

CAUTION

This product uses semiconductors which can be damaged by electrostatic discharge

(ESD). When handling the PCB, care must be taken so that the electronics is not

damaged.

Step

Description

1.

Power-down detector.

2.

Remove bezel and cover plate.

3.

Pull out sensor module. It is recommended to use extractor tool part number 1100-2022.

4.

Plug new sensor module into sensor control PCB. Ensure that the three notches of the sensor

module align with the 3 ribs of the detector base. Use the small triangles printed on the sensor

module as a guide.

5.

Put cover plate back on and tighten set screw.

6.

Put bezel back on and power-up detector.

7.

Wait until the start-up sequence is finished.

8.

Check sensor response.

Page 31

MVR-300™ Refrigerant Gas Detector

P/N: 6203-9000 Revision 3 31

Item

Description

1

Replaceable sensor module

2

Sensor alignment ribs (×3)

3

Sensor extractor tool (color may vary)

4

Recesses (×2) for extracting sensor

5

Alignment notches (×3) on sensor module

Figure 23. Sensor Replacement Showing Sensor Extractor Tool

5.5 Cleaning the Detector

Clean the detector with a soft cloth using water and a mild detergent. Rinse with water. Do not use any

alcohols, cleaning agents, sprays, polishes, detergents, etc.

Page 32

MVR-300™ Refrigerant Gas Detector

32 P/N: 6203-9000 Revision 3

SECTION 6. SENSOR PRINCIPLE

Semiconductor or metallic oxide sensors (MOSs) are among the most versatile of all broad-range sensors.

They are heated to a temperature between 150º and 300º C depending on the gas(es) to be detected. The

temperature of operation as well as the “recipe” of mixed oxides determines the sensor selectivity to various

refrigerants. Electrical conductivity greatly increases as soon as a diffusion process allows the refrigerant

molecules to come in contact with the sensor surface. Water vapor, high ambient humidity, temperature

fluctuations, alcohols, cleaning agents, sprays, polishes, detergents, and low oxygen levels can result in

higher readings.

NOTICE

Certain substances in the environment may impair the sensitivity of the sensors:

1. Materials containing silicone or silicone rubber/putty

2. Corrosive gases such as hydrogen sulfide, sulfur oxide, chlorine, hydrogen

chloride, etc.

3. Alkaline metals, salt water spray.

SECTION 7. DISPOSING OF THE DETECTOR

EU-wide regulations governing the disposal of electrical and electronic appliances

which have been defined in the EU Directive 2012/19/EU and in national laws have

been effective since August 2012 and apply to this device.

Common household appliances can be disposed of using special collecting and

recycling facilities. However, this device has not been registered for household

usage. Therefore it must not be disposed of through these channels. The device can

be returned to your national Bacharach Sales Organization for disposal. Contact

Bacharach if you have any questions.

Page 33

MVR-300™ Refrigerant Gas Detector

P/N: 6203-9000 Revision 3 33

SECTION 8. TECHNICAL DATA

8.1 Approvals

Specification

Description

EN 50270:2015

Electromagnetic compatibility. Electrical apparatus for the detection and

measurement of combustible gases, toxic gases or oxygen

CE

Approval pending

UL/CSA/IEC/EN 61010-1

Approval Pending

8.2 Specifications for Modbus RTU Digital Communication over RS-485

Specification

Description

Baud Rate

9,6001 or 19,200 (selectable)

Start Bits

1

Data Bits

8

Parity

None1, odd, even (selectable)

Stop Bits

11 or 2 (selectable)

Retry Time

500 ms, min time between retries

End of Message

Silent 3.5 characters

1

- Default Values

8.3 Power Supply and Relay Specifications

Specification

Description

Operating Voltage

100 to 240 VAC, 50/60 Hz

Operating Power

4 W max

Power Monitoring

Green LED

Relay Rating

2 SPDT; 1 A at 30 VDC, 1 A at 125 and 250 VAC, resistive load

Audible Alarm

Internal Buzzer; open enclosure

85 dBA at 10 cm (4 in); 80 dBA @ 30 cm (12 in)

Alarm Delay

0 to 15 minutes (selectable 0, 5, 10, 15)

8.4 Wiring Specifications

Specification

Description

Power

3-core cable, 14 to 20 AWG

Relay

3-core cable, 18 to 20 AWG

Modbus Network

Belden 3106A (or equivalent); 3-core, 2 twisted pair shielded cable 20 to

26 AWG with 120 Ω characteristic impedance

Max diameter of cable plus heat shrink must be 5 mm (0.2 in) (to fit

boot)

Page 34

MVR-300™ Refrigerant Gas Detector

34 P/N: 6203-9000 Revision 3

8.5 Physical Specifications

Specification

Description

Enclosure Material

ABS

Enclosure Protection

IP40, NEMA 1

Size L x W x D

(Approximate)

5.98 × 4.68 × 1.96". (152 × 119 × 50 mm) including bezel

Depth of bezel 0.39" (10 mm)

Weight (Approximate)

8 oz (230 g)

8.6 Environmental Specifications

Specification

Description

Temperature

32º to 122º F (0º to 50º C)

Storage Temperature

-40º to 122º F (-40º to 50º C)

Humidity

5 to 90% RH, non-condensing

Pressure

23.6 to 32.5 in. of Hg (800 to 1100 hPa)

Elevation

0 to 6,560 ft. (2000 m) altitude

8.7 Sensor Specifications

Specification

Description

Detectable Gases

R-22, R-32, R-404a, R-407c, R-410a

Measuring Ranges

0 to 2,500 ppm; 0 to 5,000 ppm; 0 to 10,000 ppm

8.8 Default Alarm Levels

Alarm #

Alarm Ranges

0 to 2,500 ppm

0 to 5,000 ppm

0 to 10,000 ppm

Alarm 1

500 ppm

1,000 ppm

2,000 ppm

Alarm 2

2,000 ppm

4,000 ppm

8,000 ppm

Page 35

MVR-300™ Refrigerant Gas Detector

P/N: 6203-9000 Revision 3 35

8.9 Modbus Registers

NOTICE

If items span two registers (e.g., 1005 and 1006), then the registers are “long” or “float”

data types. Otherwise the registers are integer data types or ASCII.

8.9.1 Read Device Identification

The following Object IDs are used with function code 43/14 to read ASCII device identification objects.

Object

ID

Name

Description

Def Val

0x00

Read Device Identification

Vendor name

"Bacharach"

0x01

Read Device Identification

Product code

“MVR-300"

0x02

Read Device Identification

Revision (Major/minor/“bug fix”)

"NN.nn.bb"

8.9.2 Analog Input Registers

Analog input registers are read only and use function code 04.

Reg

Addr

Name

Description

Data Type

Def Val

1000

16 bit Current Fault Code

Active or latched faults

Hex

0

1001

16 bit Last Fault Code

All faults which have occurred

since startup or fault register reset

Hex

0

1002

Gas Concentration PPM

Current gas concentration in PPM

Unsigned

Integer

1003

Gas Concentration % FS

(0-100)

Current gas concentration as

percentage of full scale

Unsigned

Integer

1004

Hours since last calibration

Can be reset by a calibration

operation

Unsigned

Integer

1005

PPM Hours

Sensor gas exposure clock.

Cannot be reset

32-bit long

1006

1012

Software Version Sensor

Major

Software Version in the format

NN.nn.bb.

Unsigned

Integer

1013

Software Version Sensor

Minor

Unsigned

Integer

1014

Software Version Sensor Bug

Fix

Unsigned

Integer

1015

Sensor Type Code

Hex code indicating the sensor

type, gas and range

Hex

1016

Full Scale in PPM

Limit of measurement of the

sensor

Unsigned

Integer

1017

Gas Low Alarm PPM

Low alarm threshold in PPM

Unsigned

Integer

1018

Gas High Alarm PPM

High alarm threshold in PPM

Unsigned

Integer

Page 36

MVR-300™ Refrigerant Gas Detector

36 P/N: 6203-9000 Revision 3

Reg

Addr

Name

Description

Data Type

Def Val

1019

Gas Low Alarm % FS (0-100)

Low alarm threshold as

percentage of full scale

Unsigned

Integer

1020

Gas High Alarm % FS (0-100)

High alarm threshold as

percentage of full scale

Unsigned

Integer

1021

Minimum Alarm Setting PPM

Lowest allowable alarm setting

Unsigned

integer

1022

Sensor Gas Type Text Char

1,2

Text string indicating the target gas

e.g., "R410a"

ASCII

1023

Sensor Gas Type Text Char

3,4

ASCII

1024

Sensor Gas Type Text Char

5,NULL

ASCII

1025

Main Electronics UID Char

1,2

Text string indicating the detector

serial number e.g., "U1234567"

ASCII

1026

Main Electronics UID Char

3,4

ASCII

1027

Main Electronics UID Char

5,6

ASCII

1028

Main Electronics UID Char

7,8

ASCII

1029

Sensor Module SID Char 1,2

Text string indicating the sensor

serial number e.g., "S7654321"

ASCII

1030

Sensor Module SID Char 3,4

ASCII

1031

Sensor Module SID Char 5,6

ASCII

1032

Sensor Module SID Char 7,8

ASCII

1036

Signed Raw Gas

Concentration PPM - no

thresholding

Raw gas concentration used for

calibration procedure

Signed

integer

1037

Rate of change of sensor

resistance

Rate of change of semiconductor

sensor resistance. Used to

determine stability of gas response

in calibration

Float

1038

1039

Sensor cal gas lower limit

PPM

Lower limit of the gas for

calibration

Unsigned

Integer

1040

Sensor cal gas upper limit

PPM

Upper limit of the gas for

calibration

Unsigned

Integer

1041

Auto Cal Zero Time

Remaining

Seconds remaining in auto zero

calibration procedure

Unsigned

Integer

0

1042

Auto Cal Span Time

Remaining

Seconds remaining in auto span

calibration procedure

Unsigned

Integer

0

1043

Auto Cal Recovery Time

Remaining

Seconds remaining in span

recovery

Unsigned

Integer

0

Page 37

MVR-300™ Refrigerant Gas Detector

P/N: 6203-9000 Revision 3 37

8.9.3 Analog Output Registers

Analog output registers are readable (using function code 03) and writable (using function code 06).

NOTICE

Before writing to any “locked” registers, be sure to use the Parameter Unlock register

(2000) first to unlock the registers and (if desired) to re-lock those registers afterwards.

Reg

Addr

Name

Description

Data

Type

Def Val

R/W

2000

Parameter Unlock

Writing the correct unlock code

(0x6388) to this register allows

an external controller to change

system parameters. Writing any

other value (or cycling power

thereby restoring the default

value of zero) re-locks the

lockable system parameters.

Unsigned

integer

0

R/W

2001

RS-485 Node

Address

Modbus address 1-247

Unsigned

integer

1

R/W

2002

Baud Rate

0 = 9600 Baud; 1 = 19200 Baud

Unsigned

integer

0 (9600

baud)

R/W

2003

Stop Bits

Number of stop bits

Unsigned

integer

1

R/W

2004

Parity

Parity (0=none, 1=odd, 2=even)

Unsigned

integer

None

R/W

2005

Gas Low Alarm

PPM

Low gas alarm in PPM

Unsigned

integer

Unit

dependent

R. W if

un-

locked

2006

Gas High Alarm

PPM

High gas alarm in PPM

Unsigned

integer

Unit

dependent

R. W if

un-

locked

2007

Modbus

Precedence over

DIP Switch Settings

If set then the values

programmed over Modbus take

precedence over the values set

by DIP switch

0 = DIP settings used

1 = MODBUS settings used

Unsigned

integer

0

R. W if

un-

locked

2008

Alarm On Delay

Value

Alarm On delay in minutes.

Range 0-15.

Note: Setting only has an effect

if the Modbus priority flag is set

Unsigned

integer

0

R. W if

un-

locked

2009

Relay Contact

Behavior / Failsafe

0 = NO relay

1 = Failsafe relay

Note: Setting only has an effect

if the Modbus priority flag is set

Unsigned

integer

0

R. W if

un-

locked

Page 38

MVR-300™ Refrigerant Gas Detector

38 P/N: 6203-9000 Revision 3

Reg

Addr

Name

Description

Data

Type

Def Val

R/W

2010

Relay 2 Fault

Indication

0 = Relay 2 indicates high alarm

only

1 = Relay 2 indicates high alarm

and fault condition

Note: Setting only has an effect

if the Modbus priority flag is set

Unsigned

integer

0

R. W if

un-

locked

2011

Alarm Latching

Behavior

0 = Alarms automatically reset

1 = Alarms must be

acknowledged

Note: Setting only has an effect

if the Modbus priority flag is set

Unsigned

integer

0

R. W if

un-

locked

2012

Buzzer disable

0 = Buzzer normal operation

1 = Buzzer disabled

Note: Setting only has an effect

if the Modbus priority flag is set

Unsigned

integer

0

R. W if

un-

locked

2017

Calibration Gas

Level PPM

Level of gas being applied

during calibration

Unsigned

integer

Unit

dependent

R. W if

un-

locked

8.9.4 Input Status Flags

Input status flags are readable (using function code 02).

Reg Addr

Name

Description

Data

Type

Def

Val

3000

Gas Low Alarm

Flag

0 = No low alarm state

1 = Low alarm active or latched

Boolean

0

3001

Gas High Alarm

Flag

0 = No high alarm state

1 = Low alarm active or latched

Boolean

0

3002

Saturation Overflow

0 = Gas level less than or equal to full scale

range

1 = Gas level exceeds full scale range

Boolean

0

3003

Saturation

Underflow

0 = Gas level greater than or equal to 0 ppm

1 = Gas level underflow condition

Boolean

0

3004

Startup

Detector is in startup. No valid gas level or

outputs

Boolean

0

3005

Detector Offline

Detector not reporting gas level or generating

alarm conditions

Boolean

0

3006

Detector Fault

The detector is reporting a fault which prevents

valid gas level or output generation

Boolean

0

3007

Relay 1 State

0 = Relay de-energized

1 = Relay energized

Boolean

0

3008

Relay 2 State

0 = Relay de-energized

1 = Relay energized

Boolean

0

Page 39

MVR-300™ Refrigerant Gas Detector

P/N: 6203-9000 Revision 3 39

8.9.5 Output Status Flags

Output status flags are readable (using function code 01) and writable (using function code 05).

NOTICE

Before writing to any “locked” registers, be sure to use the Parameter Unlock register

(2000) first to unlock the registers and (if desired) to re-lock those registers afterwards.

Reg

Addr

Name

Description

Data

Type

Def

Val

R/W

4000

Offline mode

Setting this flag places the detector into

offline mode. When offline the detector will

not respond to gas events or generate alarm

conditions. The flag will remain asserted for

the duration of offline mode. Offline mode will

end after expiry of the offline mode timeout

or by clearing this flag.

Boolean

0

R. W if

un-

locked

4001

Calibration

expired

1 => The sensor requires calibration

Can be cleared by performing a calibration or

by resetting this flag.

Boolean

0

R. W if

un-

locked

4002

Start Zero

Calibration

Procedure

Setting this flag triggers the automatic zero

calibration procedure. The flag will remain

asserted during the procedure. Writing a zero

to the flag during the procedure will cancel

the procedure and the detector will return to

normal operation.

Boolean

0

R. W if

un-

locked

4003

Start Span

Calibration

Procedure

Setting this flag places the detector offline

and triggers the automatic span calibration

procedure. The flag will remain asserted

during the procedure. Writing a zero to the

flag during the procedure will cancel the

procedure and the detector will remain offline

for the duration of the span calibration

recovery time.

Boolean

0

R. W if

un-

locked

4004

Perform

Immediate Zero

Calibration

Procedure

Setting this flag performs an immediate zero

calibration. The detector will return to normal

operation on completion.

Boolean

0

R. W if

un-

locked

4005

Perform

Immediate

Span

Calibration

Procedure

Setting this flag performs an immediate span

calibration as long as the detector is already

in offline mode. The detector will remain

offline for the duration of the span calibration

recovery time after completion of the

procedure

Boolean

0

R. W if

un-

locked

4006

Alarm Flag

If asserted then a gas alarm state exists.

Clearing this flag will clear any latched alarm

states.

Boolean

0

R. W if

un-

locked

4007

Clear last fault

Clear non-active faults from LAST FAULT

register. If any current faults are still active

then these will be held in LAST FAULT

register.

Boolean

0

R. W if

un-

locked

Page 40

MVR-300™ Refrigerant Gas Detector

40 P/N: 6203-9000 Revision 3

Reg

Addr

Name

Description

Data

Type

Def

Val

R/W

4013

Manual

Override

Setting this flag places the detector into

manual override mode to allow for testing of

outputs. During manual override mode the

relays, analog output and LEDs will not

respond to gas events, alarm conditions or

faults.

Manual override mode may be terminated by

clearing this flag. Alternatively the mode will

timeout after a set period after which normal

operation will resume.

Boolean

0

R. W if

un-

locked

4014

Relay 1 Manual

Control

If the detector is in manual override mode,

setting this flag energizes relay 1; clearing

this flag de-energizes relay 1.

Relay failsafe configuration has no effect on

this test.

Boolean

0

R. W if

un-

locked

4015

Relay 2 Manual

Control

If the detector is in manual override mode,

setting this flag energizes relay 2; clearing

this flag de-energizes relay 2.

Relay failsafe configuration has no effect on

this test.

Boolean

0

R. W if

un-

locked

4016

Buzzer Test

Mode

If the detector is in manual override mode,

setting this flag activates the buzzer; clearing

this flag deactivates the buzzer.

Buzzer mute control has no effect on this

test.

Boolean

0

R. W if

un-

locked

4017

Red LED

Manual Control

If the detector is in manual override mode,

setting this flag turns on the red LED;

clearing this flag turns off the red LED.

Boolean

0

R. W if

un-

locked

4018

Green LED

Manual Control

If the detector is in manual override mode,

setting this flag turns on the green LED;

clearing this flag turns off the green LED.

Boolean

0

R. W if

un-

locked

4019

Analog Output

Manual Control

If the detector is in manual override mode,

setting this flag sets the analog output to full

scale; clearing this flag sets the analog

output to zero.

Boolean

0

R. W if

un-

locked

Page 41

MVR-300™ Refrigerant Gas Detector

P/N: 6203-9000 Revision 3 41

SECTION 9. ORDERING INFORMATION

9.1 MVR-300 Refrigerant Leak Detector Configurations

P/N

Detection Range

Refrigerant

6203-0001

0 to 2500 ppm

R-410a

6203-0002

0 to 5000 ppm

6203-0003

0 to 10000 ppm

6203-0011

0 to 2500 ppm

R-407c

6203-0012

0 to 5000 ppm

6203-0013

0 to 10000 ppm

6203-0021

0 to 2500 ppm

R-404a

6203-0022

0 to 5000 ppm

6203-0023

0 to 10000 ppm

6203-0041

0 to 2500 ppm

R-32

6203-0042

0 to 5000 ppm

6203-0043

0 to 10000 ppm

9.2 MVR-300 Refrigerant Leak Detector Configurations (UK Version)

P/N

Detection Range

Refrigerant

6203-1001

0 to 2500 ppm

R-410a

6203-1002

0 to 5000 ppm

6203-1003

0 to 10000 ppm

6203-1011

0 to 2500 ppm

R-407c

6203-1012

0 to 5000 ppm

6203-1013

0 to 10000 ppm

6203-1021

0 to 2500 ppm

R-404a

6203-1022

0 to 5000 ppm

6203-1023

0 to 10000 ppm

6203-1041

0 to 2500 ppm

R-32

6203-1042

0 to 5000 ppm

6203-1043

0 to 10000 ppm

Page 42

MVR-300™ Refrigerant Gas Detector

42 P/N: 6203-9000 Revision 3

9.3 Accessories

P/N

Description

Std

UK

0051-2320

Pressure Regulator (1.0 l/min, 5/8''-18 UNF)

0051-2358

Pressure Regulator (0.5 l/min, 5/8''-18 UNF)

0051-3299

Pressure Regulator (0.3 l/min, 5/8''-18 UNF)

1100-1004

Magnetic Wand

1100-2018

Calibration Kit (Standard Version), includes:

MVR-300 Calibration Adapter, Standard Version (1100-2017)

DIP Extractor Tool (1100-2022)

Magnetic Wand (1100-1004)

Tubing for Calibrating Kit, Reactive Gases (1000-3718)

1100-2045

Calibration Kit (UK Version), includes:

MVR-300 Calibration Adapter, UK Version (1100-2056)

DIP Extractor Tool (1100-2022)

Magnetic Wand (1100-1004)

Tubing for Calibrating Kit, Reactive Gases (1000-3718)

1100-2022

Extractor Tool (for removing sensor module during replacement process)

1100-2043

MVR-300 Standard Version, Replacement Plastics Kit, includes:

Top Cover, Plastic (1100-2008)

Bottom Cover, Plastic (1100-2009)

Bezel, Plastic (1100-2010)

Faceplate, Bacharach Logo, Plastic (1100-2011)

Assembly Screws (1100-2026)

Faceplate Screw (1100-2027)

Light Pipe (1100-2038)

Standard Installation Kit, Standard Version (1100-2036), includes:

o Rubber Boot (1100-2025)

o Heat Shrink Tubing (1100-2028)

1100-2044

MVR-300 UK Version, Replacement Plastics Kit, includes:

Top Cover, UK Flush-mount, Plastic (1100-2023)

Bottom Cover, Plastic (1100-2009)

Assembly Screws (1100-2026)

Light Pipe (1100-2038)

Installation Kit, UK Version (1100-2037), includes:

o Rubber Boot (1100-2025)

o Heat Shrink Tubing (1100-2028)

o Mounting Clips, Qty 2 (1100-2039)

o Mounting Clip Screws, Qty 2 (1100-2039)

6203-0101

Calibrated Sensor Assembly

0 to 2500 ppm

R-410a

6203-0102

Calibrated Sensor Assembly

0 to 5000 ppm

6203-0103

Calibrated Sensor Assembly

0 to 10000 ppm

6203-0111