Page 1

Monoxor ® III

Carbon Monoxide Analyzer

Instruction 19-9326

Operation & Maintenance

Rev. 3 – July 2009

Product Leadership • Training • Service • Reliability

Page 2

WARRANTY

Bacharach, Inc. warrants to Buyer that at the time of delivery this Product will be free from defects in material

and manufature and will onform substantially to Baharah In.’s aliable seiations. Baharah’s

liability and Buyer’s remedy under this warranty are limited to the repair or replacement, at Bacharach’s option,

of this Product or parts thereof returned to Seller at the factory of manufacture and shown to Bacharach Inc.’s

reasonable satisfaction to have been defective; provided that written notice of the defect shall have been given

by Buyer to Bacharach Inc. within two (2) years after the date of delivery of this Product by Bacharach, Inc.

Bacharach, Inc. warrants to Buyer that it will convey good title to this Product. Bacharach’s liability and Buyer’s

remedy under this warranty of title are limited to the removal of any title defects or, at the election of Bacharach,

to the replacement of this Product or parts thereof that are defective in title.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND ARE GIVEN AND ACCEPTED IN LIEU OF (I) ANY

AND ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE: AND (II) ANY

OBLIGATION, LIABILITY, RIGHT, CLAIM OR REMEDY IN CONTRACT OR TORT, WHETHER OR NOT ARISING FROM BACHARACH’S NEGLIGENCE, ACTUAL OR IMPLIED. The remedies of the Buyer shall be limited

to those provided herein to the exclusion of any and all other remedies including, without limitation incidental or

consequential damages. No agreement varying or extending the foregoing warranties, remedies or this limita-

tion will be binding uon Baharah, In. unless in writing, signed by a duly authorized ofer of Baharah.

Register Your Warranty by Visiting

www.mybacharach.com

Declaration of Conformity

Manufacturer’s name: Bacharach, Inc.

Manufacturer’ address: 621 Hunt Valley Circle

New Kensington, PA 15068

Product name: Monoxor III

onforms to the following seiations:

European Directive 89/336/EEC

EN50082-1: 1997 (Electrostatic Discharge)

EN50082-1: 1997 (Immunity)

EN55022; Group 1, Class B (Emission)

Notice:

Produt imrovements and enhanements are ontinuous, therefore the seiations and information ontained in this document may change without notice.

Bacharach, Inc. shall not be liable for errors contained herein or for incidental or consequential damages in connection with the furnishing, performance, or use of this material.

No part of this document may be photocopied, reproduced, or translated to another language without the prior

written consent of Bacharach, Inc.

Copyright © 2002–2009, Bacharach, Inc., all rights reserved.

BACHARACH and Monoxor are registered trademarks of Bacharach, Inc. All other trademarks,

trade names, service marks and logos referenced herein belong to their respective companies.

A

Instruction 19-9326

Page 3

Monoxor III

Contents

1.0 INTRODUCTION .................................................................................. 1

2.0 TECHNICAL CHARACTERISTICS...................................................3

3.0 PREPARING THE ANALYZER FOR OPERATION .......................5

3.1 Battery Installation .........................................................................5

3.2 Probe Installation ............................................................................6

3.3 Front Panel Pushbuttons .................................................................7

3.4 Setup Mode .......................................................................................8

3.4.1 Entering Setup ......................................................................8

3.4.2 Temperature Units Setup .....................................................8

3.4.3 CO Channel Zero Setup ........................................................9

3.4.4 Time Setup ...........................................................................10

3.4.5 Date Setup ........................................................................... 10

3.4.6 Year Setup ...........................................................................11

3.4.7 Selecting Printer Protocol ...................................................11

3.4.8 Exiting the Setup Screen .................................................... 11

4.0 OPERATION ........................................................................................13

4.1 Taking a Gas Sample ..................................................................... 13

4.2 Ending a Test ................................................................................. 14

4.3 Turning OFF the Analyzer ............................................................ 14

4.4 CO Purge During Turn OFF .........................................................14

4.5 CO Sensor Error Screen ................................................................15

4.6 Using the Backlight ....................................................................... 15

4.7 Using the Probe ..............................................................................15

4.8 Operating Tips ...............................................................................16

4.9 Resetting the Microprocessor ........................................................ 16

4.10 Printing Test Results ................................................................... 17

5.0 CALIBRATION & MAINTENANCE ................................................19

5.1 Entering the Calibration Mode and Testing the Display Segments ...19

5.2 Ambient Temperature Calibration ...............................................20

5.3 CO Sensor Zero & Calibration .......................................................20

5.4 Water Trap / Filter Maintenance ..................................................22

5.5 CO Sensor Replacement ................................................................23

5.6 Pump Assembly Replacement ....................................................... 24

6.0 PARTS & SERVICE ............................................................................27

6.1 Replacement Parts ......................................................................... 27

6.2 Accessories ......................................................................................27

6.3 Service Centers ..............................................................................28

7.0 HAZARDS OF CARBON MONOXIDE .............................................29

Instruction 19-9326

i

Page 4

Monoxor III

Notes

ii

Instruction 19-9326

Page 5

Monoxor III

1.0 INTRODUCTION

The Monoxor III is a portable analyzer designed to detect and display

concentrations of Carbon Monoxide (CO) gas between 0 and 2000 ppm. The

analyzer is capable of testing for CO in both ambient room air, and in the

ue-gas stream of fossil-fuel red furnaces and boilers.

Ordering Information:

Part No. Description

19-8104 Monoxor III, includes 4 ‘AA’ batteries, probe & hose assembly

with integral water-trap / lter, and a hard carrying case

19-8105 Monoxor III, includes 4 ‘AA’ batteries, probe & hose assembly

with integral water-trap / lter, hard carrying case, plus

an IrDA printer with an assortment of printer accessories

including an AC adapter, roll of paper, in-car charger, belt

clip, and magnet

The analyzer detects and displays the presence of CO by rst drawing in a

gas sample from the area being tested by the analyzer’s built-in motorized

pump. The gas sample is next directed into a sensor chamber where the

sample is analyzed for the presence of CO. If CO is detected, the CO ppm

level is displayed on the analyzer’s LCD.

A permanent record of the detected CO level, along with the current time

and date, can be made by using the optional wireless IrDA printer.

A backlight enables the operator to read the display in dimly-lit areas. A

power-saver feature causes the backlight to automatically turn OFF after

10 minutes, and causes the analyzer to shut OFF after 20 minutes of inactivity. The power saver feature, however, is disabled while the detected CO

level is above 50 ppm.

When the analyzer is used to measure the CO content in ue-gas, a rigid

stainless steel probe with handle is provided that allows gas samples to

be taken from within the ue stack. An integral water-trap / lter pre-

vents water and soot from being drawn into the analyzer. The probe can

also be used in ambient testing to draw in gas samples from cramped and

conned areas.

If the analyzer is turned OFF while a high level of CO is still present

within the unit, the analyzer’s pump remains running and the unit will

not turn OFF until the detected CO level drops below 50 ppm.

Instruction 19-9326

1

Page 6

Monoxor III

Notes

2

Instruction 19-9326

Page 7

Monoxor III

2.0 TECHNICAL CHARACTERISTICS

CO Display Range ...................... 0–2000 ppm

Accuracy ..................................... ±5% of reading or ±10 ppm,

whichever is greater*

Resolution ...................................1 ppm

Response Time ........................... 90% of nal value within 40 sec.

Battery Requirement ................. Four disposable ‘A A’ Alkaline batteries

Operating Time .......................... Up to 18 hours continuous (pump running

and backlight off)

Warm Up Time ........................... 10 or 60 seconds (depending on CO

channel zero setup, refer to Page 9)

Display ........................................ 4 digit by 2 line, 7-segment Liquid Crystal

Display

Front Panel Controls .................. Six push button switches

(refer to Section 3.3)

Operating Temperature:

Analyzer ................................. 32–104 °F (0–40 °C)

Probe ....................................... 1000 °F (538 °C) max. at 5" insertion

Humidity ..................................... 15 to 90% RH (non-condensing)

Printer Port ................................ IrDA or HP protocol

Weight ......................................... 16 oz with batteries

Size .............................................. 7.5"H x 3.1"W x 2.1"D (190x79x53 mm)

* Tighter accuracy in the lower ranges, up to ±2 ppm, may be attained if a

lower range calibration gas (e.g. 100 ppm CO) is used.

Instruction 19-9326

3

Page 8

Monoxor III

Notes

4

Instruction 19-9326

Page 9

Monoxor III

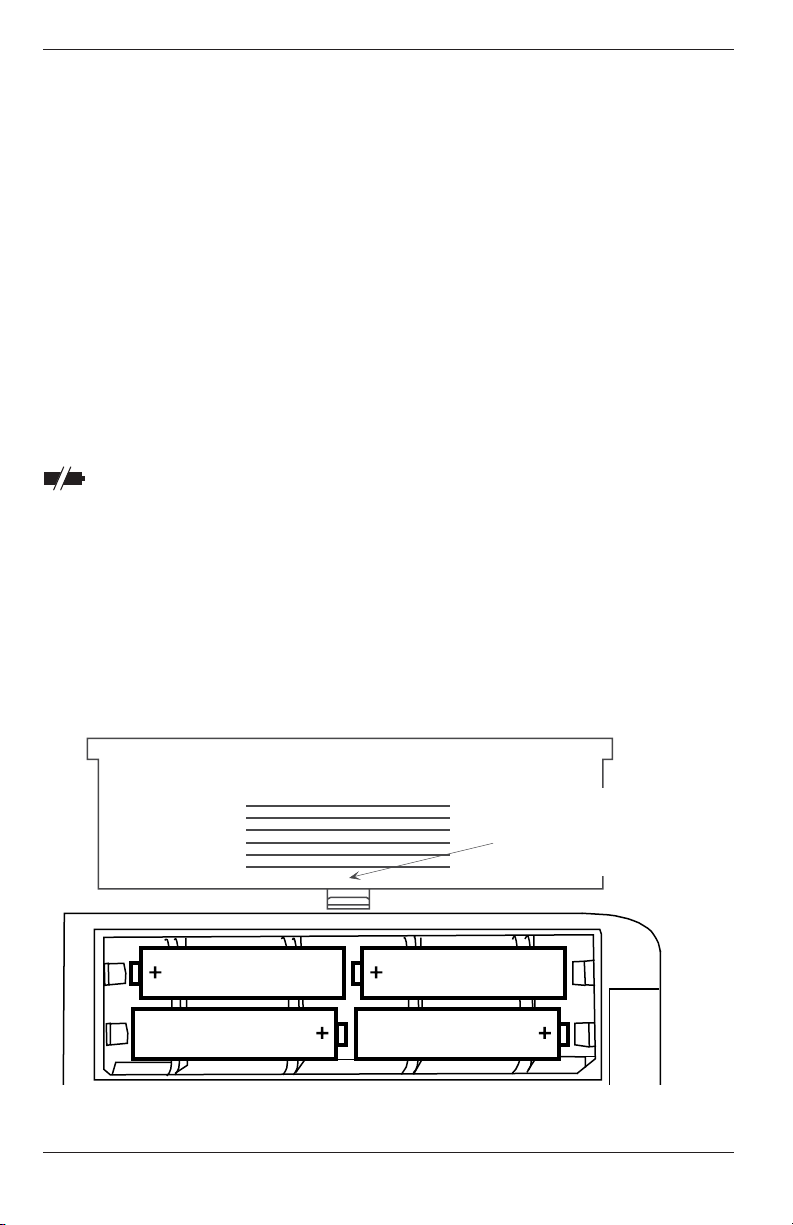

Remove battery cover

by pressing here and

sliding cover outward

3.0 PREPARING THE ANALYZER

FOR OPERATION

To prepare a new analyzer for operation, you must install four ‘AA’

Alkaline batteries, install the probe (if needed), and set the correct time

and date as described in the following paragraphs.

For your convenience, and to ensure that the analyzer will provide reliable

CO readings, the CO sensor was installed and the analyzer calibrated on

500 ppm CO at the factory.

3.1 Battery Installation

Install fresh batteries as described below. Check the analyzer for sufcient

charge prior to each use. Replace the batteries if the low-battery symbol

appears in the lower right corner of the LCD. To install batteries:

1. Remove battery cover from back of unit (see Figure 3-1).

2. If old batteries are installed, remove and properly dispose of the

batteries.

3. Observing the polarity markings inside the battery compartment,

install four ‘AA’ Alkaline batteries.

4. Replace battery cover.

Figure 3-1. Battery Installation

Instruction 19-9326

5

Page 10

Monoxor III

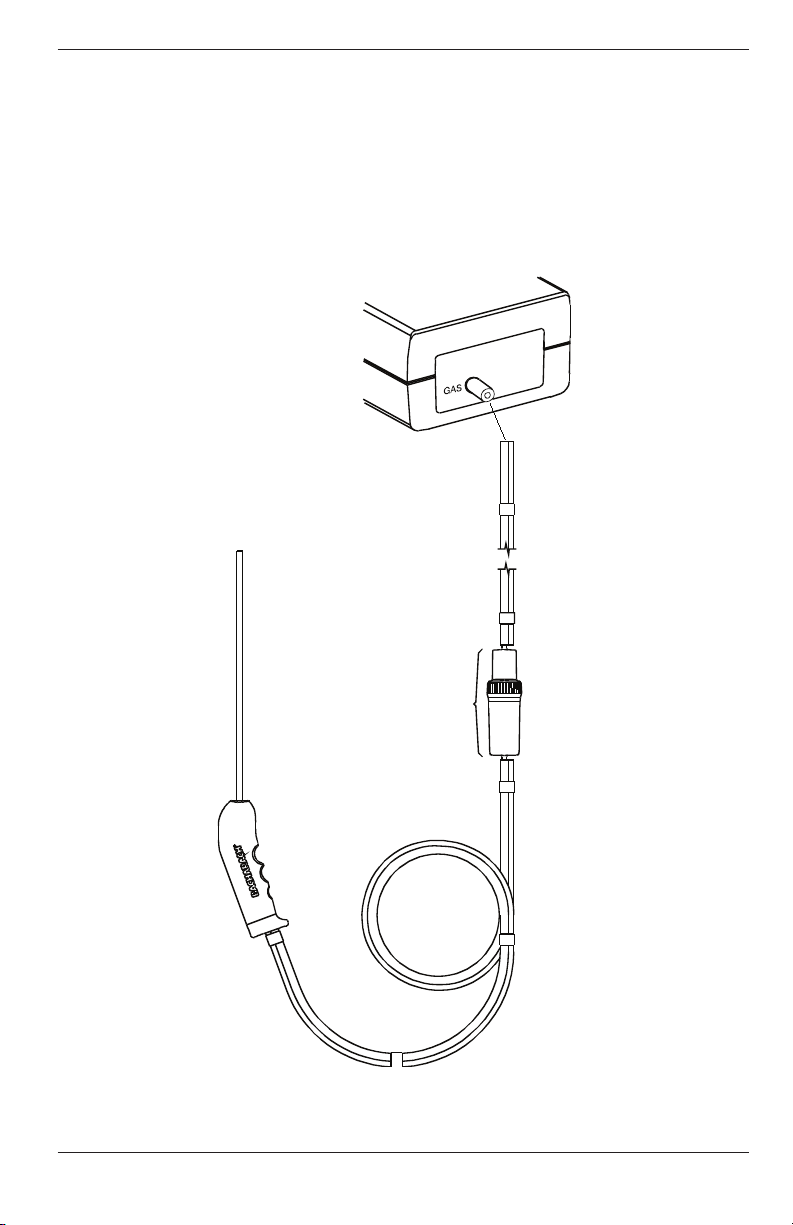

FLUE-GAS

HOSE

WATER TRAP /

FILTER ASSEMBLY

3.2 Probe Installation

Install the probe if the analyzer is going to be used for ue-gas CO mea-

surements, or if gas measurements need to be taken from a cramped or

conned area.

To install the probe, simply slide its hose over the GAS inlet of the analyzer (see Figure 3-2).

Figure 3-2. Probe Connection

6

Instruction 19-9326

Page 11

Monoxor III

3.3 Front Panel Pushbuttons

Note that a push button may perform several functions, depending on what

screen is being displayed at the time.

I/O • Turns analyzer ON/OFF. There is a 10 or 60 second warm-

up and a 5 second turn-off-delay period.

• Places the analyzer into either its Setup or Calibration Mode

when used in conjunction with the ENTER or HOLD button.

• Bypasses the CO purge function during turn-off.

• Causes the displayed value to increase or change while in

the Calibration or Setup Mode.

• Causes the displayed value to decrease or change while in

the Calibration or Setup Mode.

ENTER • Starts a test – pump ON.

• Sets up the analyzer to be placed into its Calibration Mode

when held down with the analyzer OFF. (Used in conjunction with the I/O button.)

• Stores the displayed value and automatically steps to the

next screen when pressed during calibration or setup.

• Displays the CO screen when held down for 2 seconds while

in the Calibration Mode.

• Aborts turn-off and keeps the analyzer turned ON when

pressed during either the 5 second turn-off-delay period, or

the CO purge cycle.

HOLD • Freezes the display and stops the pump during a test.

• Starts a printout when pressed twice with the pump running, or when pressed once with the pump OFF.

• Sets up the analyzer to be placed into its Setup Mode when

held down with the analyzer OFF. (Used in conjunction with

the I/O button.)

LIGHT Toggles the backlight ON and OFF.

Instruction 19-9326

7

Page 12

Monoxor III

3.4 Setup Mode

The analyzer is preset at the factory for the parameters shown below, but

can be changed as described in their associated sections.

Function Parameter To Change

Temperature Unit °F Section 3.4.2

CO Channel Auto Zero Section 3.4.3

Time Not Set Section 3.4.4

Date Not Set Section 3.4.5

Year Not Set Section 3.4.6

Printer IrDA Section 3.4.7

3.4.1 Entering Setup

1. With the analyzer turned OFF, press and hold down the HOLD

button.

2. Press and release the I/O button.

3. Release the HOLD button.

4. The analyzer is now in its Setup Mode. Refer to Sections 3.4.2 thru

3.4.7 for information on how to set the analyzer’s various parameters.

3.4.2 Temperature Units Setup

The Temperature Units Setup Screen is labeled “Unit”.

Note: The analyzer uses an internal temperature sensor

to maintain CO sensor accuracy under varying ambient

temperature conditions. This sensor’s temperature reading is

displayed only during calibration as described in Sec-

tion 5.2.

8

Instruction 19-9326

Page 13

Monoxor III

1. Enter the Setup Mode per Section 3.4.1. If necessary, repeatedly

press ENTER until the Temperature Units Setup Screen is displayed.

2. Press the or button until the desired temperature unit

(°F or °C) is displayed.

3. Press ENTER to move to the next Setup Screen, or I/O to exit setup.

3.4.3 CO Channel Zero Setup

The CO Channel Setup Screen is labeled “CO”.

1. Enter the Setup Mode per Section 3.4.1. If necessary, repeatedly

press ENTER until the CO Channel Setup Screen is displayed.

2. Press the or button until the desired parameter is displayed.

- no Sensor disabled. Note that when the CO sensor is dis-

abled the CO measurement screen will display “Err” instead of the current CO level.

- 2Ero Manual Zero – Warm-up time is 10 seconds, and the

analyzer does not zero the CO sensor to ambient conditions

during this period. For example, if the atmosphere contains 25 ppm CO at start up, the analyzer will immediately

display 25 ppm. The zero point, however, can be manually

adjusted by performing Steps 1–4 of Section 5.3.

- A2 Auto Zero – Warm-up time is 60 seconds, and the CO sen-

sor is zeroed to the ambient CO level during this period. For

example, if the atmosphere contains 25 ppm CO at start up,

the analyzer will display 0 ppm. It’s very important that

when in this mode the analyzer be turned ON in fresh

air; otherwise, incorrect CO readings will occur.

3. Press ENTER to move to the next Setup Screen, or I/O to exit setup.

Instruction 19-9326

9

Page 14

Monoxor III

�

3.4.4 Time Setup

There are two Time Setup Screens, one for hours and the other for minutes. Two bars appear above the segments being changed. The clock is in

a 24 hour format, but will appear as AM/PM on the printout.

1. Enter the Setup Mode per Section 3.4.1. If necessary, repeatedly

press ENTER until the rst Time Setup Screen is displayed—the

one with two bars over the hour digits.

2. Press the or button until the correct hour value is displayed.

3. Press ENTER to move the selection bars over the minute digits.

4. Press the or button until the correct minute value is displayed.

5. Press ENTER to move to the next Setup Screen, or I/O to exit setup.

3.4.5 Date Setup

There are two Date Setup Screens, each labeled “DAtE”. The rst screen

sets the month while the second screen sets the day.

1. Enter the Setup Mode per Section 3.4.1. If necessary, repeatedly

press ENTER until the rst Date Setup Screen is displayed.

2. Press the or button until the correct month is displayed.

3. Press ENTER to switch to the second Date Setup Screen.

4. Press the or key until the correct day is displayed.

5. Press ENTER to move to the next Setup Screen, or I/O to exit setup.

10

Instruction 19-9326

Page 15

Monoxor III

3.4.6 Year Setup

The Year Setup Screen is labeled “yEAr”.

1. Enter the Setup Mode per Section 3.4.1. If necessary, repeatedly

press ENTER until the Year Setup Screen is displayed.

2. Press the or button until the correct year is displayed.

3. Press ENTER to move to the next Setup Screen, or I/O to exit setup.

3.4.7 Selecting Printer Protocol

The Printer Setup Screen is labeled “Prnt”. The analyzer can be set up to

send data to a wireless printer using either HP or IrDA protocol.

1. Enter the Setup Mode per Section 3.4.1. If necessary, repeatedly

press ENTER until the Printer Setup Screen is displayed.

2. Press the or button to select the desired protocol.

3. Press ENTER to move to the next Setup Screen, or I/O to exit setup.

3.4.8 Exiting the Setup Screen

Press the I/O button at any time to exit the Setup Mode and turn the analyzer OFF. Note that the last displayed parameter is automatically saved

in memory.

Instruction 19-9326

11

Page 16

Monoxor III

Notes

12

Instruction 19-9326

Page 17

Monoxor III

�

4.0 OPERATION

To operate the Monoxor III, you simply . . .

• Turn the analyzer ON

• Wait for the unit to warm up

• Take a gas sample

4.1 Taking a Gas Sample

Important! If the CO channel is set up for Auto Zero (refer

to Section 3.4.3), ensure that the analyzer will be sampling

fresh air (containing no CO) when turned ON.

Turn ON the analyzer by pressing the I/O button. Observe that when

power is rst applied, the software revision level is rst displayed followed

by a screen that counts down the warm-up period. The warm-up period is

either 60 seconds (Auto Zero Mode) or 10 seconds (Manual Zero Mode).

Following warm-up, the CO screen appears. This screen shows the current

detected CO level in ppm. If the probe is being used, insert the probe tip

into the area to be sampled.

Note: If a sensor error was detected during warm-up, the CO

Sensor Error Screen will be displayed. Refer to Section 4.5.

Front Panel Button Functions:

– No effect

– No effect

HOLD – Freezes display and stops pump; pressing a second time

activates printing

ENTER – Restarts testing after the HOLD button was pressed

LIGHT – Toggles backlight ON/OFF

I/O – Turns analyzer OFF (with a 5 second delay)

Instruction 19-9326

13

Page 18

Monoxor III

4.2 Ending a Test

WARNING! Burn Hazard. Do not touch the probe after

removing it from a ue. Allow the probe to cool before handling (about 5 minutes).

After taking a gas sample, remove the probe and take the analyzer to an

area containing fresh air. Allow the pump to run until the CO reading

drops to near zero.

4.3 Turning OFF the Analyzer

Turn OFF the analyzer by pressing the I/O button. The analyzer will count

down from 5 before turning OFF. Pressing ENTER, however, will abort the

count down and keep the analyzer ON.

Note: The analyzer will automatically turn itself OFF after

20 minutes of keyboard inactivity, unless the detected CO

level is above 50 ppm.

4.4 CO Purge During Turn OFF

If the detected CO level is above 50 ppm when the analyzer is turned OFF,

the unit will remain ON with its pump running and display “PUrG CO”.

The countdown from 5 will not begin until the CO level drops below

50 ppm.

Pressing ENTER during CO purge will return the analyzer to the CO

measurement screen. Although not recommended for routine use, the CO

purging process can be bypassed by pressing the I/O button a second time,

which will immediately turn OFF the analyzer.

14

Instruction 19-9326

Page 19

Monoxor III

4.5 CO Sensor Error Screen

When the CO channel is set up for Auto Zero (refer to Section 3.4.3), a

CO sensor error will occur if the detected Carbon Monoxide level is above

50 ppm during the warm-up period.

Note, however, that if the CO channel is set up for manual calibration,

the analyzer does not auto-zero the CO sensor during warm-up, and thus

does not generate a CO sensor error when the analyzer is turned ON in an

atmosphere containing a high background level of CO.

Make the following checks before replacing a suspected spent or defective

sensor:

1. Turn OFF the analyzer and turn it back ON in an area of fresh air.

2. If Step 1 doesn’t eliminate the error condition, replace the sensor

per Section 5.5.

4.6 Using the Backlight

The LCD can be read in dimly-lit areas by pressing the LIGHT button.

The backlight automatically turns OFF after 10 minutes of keyboard

inactivity, but can be turned OFF at any time by again pressing the

LIGHT button.

4.7 Using the Probe

A rigid stainless steel probe with handle, connected to a exible hose with

integral water-trap / lter can be used to draw a gas sample into the analyzer from the room, grilles, diffusers, and furnace ues.

The hose and probe assembly can be detached from the analyzer when the

operator desires to sample without the probe.

Instruction 19-9326

15

Page 20

Monoxor III

4.8 Operating Tips

• When an analyzer is brought in from a cold vehicle, let it warm up

slowly to minimize condensation. Temperatures below freezing will not

damage the analyzer; however, bringing a cold analyzer into a warm,

humid environment may cause condensate to form inside the case.

• If the CO channel is set up for Auto Zero (refer to Section 3.4.3), ensure

that the analyzer is sampling fresh air when turned ON. Pulling a

ue-gas sample through the analyzer during its warm-up period will

not damage the analyzer, but it will result in incorrect CO readings.

Also note that a CO sensor error will occur if the detected CO level is

above 50 ppm during warm-up.

• Flue-gas condensate is acidic and very corrosive. It is important not to

allow the analyzer’s internal components to become soaked in condensate for long periods of time.

• Before each use, inspect the lter element of the water-trap / lter assembly. Replace the lter if it looks dirty.

• During a test, keep the analyzer above the water-trap, and keep the trap

in a vertical position. This will maximize the effectiveness of the trap

and keep liquid condensate from being drawn directly into the analyzer.

• When liquid condensate is seen inside the water trap, empty the trap

before it becomes full. Refer to Section 5.4.

• It is recommended that the analyzer be purged after taking a ue-gas

measurement before turning it OFF. Once the probe is removed from the

stack, disconnect the hose assembly from the bottom of the analyzer and

let the pump run for 10 minutes or so to completely remove any remain-

ing ue gases, and dry any condensate from inside the sensor chamber.

• When storing the analyzer, it’s a good idea to empty the water trap and

leave it open to further dry it out.

• Calibrate the analyzer about every 6 months to ensure its accuracy.

4.9 Resetting the Microprocessor

If the analyzer ‘locks up’ and cannot be turned OFF, reset the microprocessor by removing one of the batteries for 5 seconds.

16

Instruction 19-9326

Page 21

Monoxor III

60°

max.

45 cm

(18 in.)

max.

ENTER

HOLD

I/O

LIGHT

4.10 Printing Test Results

Turn ON the printer. Refer to the printer’s

instruction manual for detailed operation and

maintenance information.

If not already done, set the printer parameters as follows:

• Data – 8 bits

• Baud – 9600

• Parity – None

• Handshaking – X-on/X-off

Align the printer with the top of the analyzer

as shown in Figure 4-1.

Begin printing by doing one of the following:

- If the pump is running, press the HOLD

button twice.

- If the display has been previously frozen,

press the HOLD button only once.

Tip: If the printer does not operate correctly,

ensure that the correct printer protocol has

been selected per Section 3.4.7.

Figure 4-1. Printer Alignment & Sample Printout

Instruction 19-9326

17

Page 22

Monoxor III

Notes

18

Instruction 19-9326

Page 23

Monoxor III

�

5.0 CALIBRATION & MAINTENANCE

Important: Fresh batteries should be installed, and the unit

allowed to stabilize at room temperature for at least two

hours before proceeding with calibration. To maintain accuracy as listed in the Technical Characteristics Section of

this manual, the standards used must be at least 4 times as

accurate as the stated accuracy of the Monoxor III.

5.1 Entering the Calibration Mode and

Testing the Display Segments

1. With the analyzer turned OFF, place the unit in fresh, ambient air;

then press and hold down the ENTER button.

2. Press the I/O button and release it. Observe that all LCD segments

are turned ON.

3. Release the ENTER button. Observe the unit’s model number and

software version are displayed. The word “CAL” is then displayed

while the unit counts down from either 10 or 60 seconds. Note that

the count-down time is dependent on whether the CO channel is set

up for manual or automatic zero – refer to Page 9.

At the end of the count-down period, the rst calibration screen is

automatically displayed.

Note: During calibration, the and buttons are used to

increase or decrease a displayed calibration value. ENTER is

used to store the new value and move to the next screen. Exit

the Calibration Mode by holding down the ENTER button

for 2 seconds.

Instruction 19-9326

19

Page 24

Monoxor III

5.2 Ambient Temperature Calibration

Material Required: Calibrated Thermometer

Procedure:

1. Enter the Calibrate Mode as described in Section 5.1. Observe that

“AMBIENT” is displayed at the top of the display; if not, repeatedly

press ENTER until it appears.

2. Use the and buttons to adjust the displayed value to match the

reading of a calibrated thermometer.

3. Press ENTER to store the displayed value and move to the next

calibration screen, or hold down ENTER for 2 seconds to store the

displayed value and display the CO screen, or press the I/O button

to exit the Calibration Mode and turn OFF the analyzer without

saving the changes.

5.3 CO Sensor Zero & Calibration

Material Required: • Cylinder of 100 ppm (P/N 51-1994) or

500 ppm (P/N 24-0492) CO calibration gas

• Calibration Kit, P/N 24-7059

If you are primarily performing ue-gas testing, calibrate the Monoxor III

with 500 ppm CO calibration gas. If the analyzer will be primarily used for

ambient testing, then you may wish to consider 100 ppm CO calibration gas.

Procedure:

1. With the analyzer sampling fresh air, enter the Calibration Mode as

described in Section 5.1. Then repeatedly press the ENTER button

until “CO” appears in the upper left side of the display.

20

Instruction 19-9326

Page 25

Monoxor III

1

2 3 4 5

LEAVE TOP

PORT OPEN

Parts Shown:

1. Gas Cylinder

2. Regulator*

3. Tubing*

4. Tee*

5. Flowmeter*

6. Fitting, Gas

* Contained in Calibration Kit

3

6

ENTER

HOLD

I/O

LIGHT

2. Allow the pump to run and sample fresh air for at least 1 minute.

3. Use the and buttons to set the displayed value to 0 ppm.

4. Do one of the following:

a. End this procedure and save the new zero value by holding down

the ENTER button for 2 seconds; after which, the CO screen is

displayed.

b. Continue with Step 5 to span the CO sensor to a known concen-

tration of carbon monoxide.

5. Set up the Calibration Kit with 100 or 500 ppm CO as described in

the instructions supplied with the kit.

6. Connect the tubing of the Calibration Kit to the inlet of the analyzer; then adjust the regulator for approximately 2 SCFH of excess

ow (see Figure 5.1).

7. After the analyzer has stabilized (2 to 3 minutes), use the and

buttons to set the displayed value to match the CO concentration

stamped on the gas cylinder.

8. Press ENTER to store the new calibration values and move to the

next calibration screen, or hold down ENTER for 2 seconds to store

the new calibration values and display the CO screen, or press the

I/O button to exit the Calibration Mode and turn OFF the analyzer

without saving the changes.

9. Disconnect tubing from analyzer and turn off gas ow.

Instruction 19-9326

Figure 5-1. Calibration Kit Hookup

21

Page 26

Monoxor III

Pull apart using a slight

twisting motion

WATER TRAP

CHAMBER

FILTER

CHAMBER

FILTER ELEMENT

Pry apart filter chamber using

a small flat-blade screwdriver

inserted into notch

When reassembling

the trap, make sure

that surfaces "A" and

"B" are in contact

"A"

"B"

5.4 Water Trap / Filter Maintenance

The Water Trap / Filter Assembly removes water condensate from the gas

sample, and also prevents soot from contaminating the internal components of the analyzer.

Drain the water condensate after every test.

Procedure:

1. Pull apart the Water Trap / Filter assembly (see Figure 5-2).

2. Pour out all water condensate; then reassemble the trap.

Replace the Filter Element when dirty.

Material Required: Filter Element, P/N 07-1644

Procedure:

1. Pull apart the Water Trap / Filter assembly (see Figure 5-2).

22

2. Pry apart the Filter Chamber; then remove and discard old lter.

3. Install new lter and reassemble trap, making sure that surfaces

“A” and “B” are in contact.

Figure 5-2. Water Trap / Filter Assembly

Instruction 19-9326

Page 27

Monoxor III

5.5 CO Sensor Replacement

Material Required: • CO Sensor, P/N 24-7265

• CO Sensor Gasket, P/N 24-1112

• #1 Phillips Screwdriver

Procedure:

1. Disassemble the analyzer as follows:

a. Remove the battery cover and the batteries, uncovering one of

the cover hold-down screws.

b. Remove and set aside all four cover hold-down screws.

c. With the analyzer on its back, remove the front cover, laying it

face down to the left of the body.

d. Carefully remove the circuit board, slipping off the battery con-

nector on top, and then laying the circuit board face down in the

top cover.

2. Gently pull CO sensor out of its socket (see Figure 5-3).

3. Properly dispose of the old CO sensor (see the instruction sheet that

comes with the new sensor).

4. It is recommended that the CO sensor gasket (see Figure 5-4) be

replaced at the same time as the sensor. Remove the old gasket and

discard. Remove the paper backing from the new gasket and adhere

it to the case in the same position as the old one.

5. Insert the new CO sensor into its socket.

6. Reassemble the analyzer.

Instruction 19-9326

23

Page 28

Monoxor III

5.6 Pump Assembly Replacement

Material Required: • Pump, P/N 24-3048

• #1 Phillips Screwdriver

Procedure:

1. Disassemble the analyzer as follows:

a. Remove the battery cover and the batteries, uncovering one of

the cover hold-down screws.

b. Remove and set aside all four cover hold-down screws.

c. With the analyzer on its back, remove the front cover, laying it

face down to the left of the body.

d. Carefully remove the circuit board, slipping off the battery con-

nector on top, and then laying the circuit board face down in the

top cover.

2. Slip off the pump motor’s electrical connector from the circuit

board.

3. Unscrew the pump’s hold down clamp and remove it from the pump

(see Figure 5-4). Make note of how the pump wiring is routed.

4. Make note of how the tubing connects to the pump; then carefully

remove tubing from pump.

5. Remove the old pump and discard.

6. Install the new pump and reinstall the tubing, taking care not to

pinch or crimp the tubing. Also be sure that the pump wiring is

routed as was noted in Step 3.

7. Reassemble the analyzer.

24

Instruction 19-9326

Page 29

CO

SENSOR

Not Used

To

PUMP

(RED

WIRE)

(RED

WIRE)

Monoxor III

Figure 5-3. CO Sensor Located on Backside

Instruction 19-9326

of Printed Circuit Board

25

Page 30

CO SENSOR

GASKET

PUMP

HOLD

DOWN

CLAMP

Monoxor III

26

Figure 5-4. Back Case Component Locations

Instruction 19-9326

Page 31

Monoxor III

6.0 PARTS & SERVICE

6.1 Replacement Parts

Description Part No.

Carbon Monoxide Sensor .....................................................................24-7265

Carbon Monoxide Sensor Gasket ......................................................... 24-1112

Pump Assembly ................................................................................... 24-3048

Water Trap / Filter Assembly, Complete .............................................19-3265

Water Trap / Filter Assembly, Filter Element (pack of 3) .................. 07-1644

6.2 Accessories

STANDARD ACCESSORIES:

Battery, ‘AA’ Alkaline (Qty 4) ........................................................... 204-0004

Instruction Manual ..............................................................................19-9326

Probe, Hose, and Water Trap / Filter Assembly ................................. 19-7110

Quick Start Guide ................................................................................19-9327

Hard Carrying Case ........................................................................... 24-0865

OPTIONAL ACCESSORIES:

AC Adapter (Battery Eliminator) ........................................................24-1254

Calibration Kit .....................................................................................24-7059

Gas Cylinder, 100 ppm CO .................................................................. 51-1994

Gas Cylinder, 500 ppm CO ................................................................. 24-0492

Soft Carrying Case ..............................................................................24-1267

Printer, Wireless IrDA w/120 VAC Charger (part of kit 19-8105) .....24-1229

Printer Paper:

1 Roll ............................................................................................. 06-8733

5 Roll Pack ..................................................................................... 24-1310

Protective Rubber Boot w/Magnet ......................................................24-1127

True Spot Smoke Test Set ................................................................... 21-7006

Filter Paper, True Spot (40 strips) .................................................21-0019

Instruction 19-9326

27

Page 32

Monoxor III

6.3 Service Centers

Replacement parts and service can be obtained by contacting one of the following Bacharach Service Centers:

United States

Bacharach, Inc.

621 Hunt Valley Circle

New Kensington, PA 15068

Phone: 724-334-5051

Fax: 724-334-5723

Email: help@mybacharach.com

Canada

Bacharach of Canada, Inc.

250 Shields Court Unit #3

Markham, Ontario L3R 9W7

Canada

Phone: 905-470-8985

Fax: 905-470-8963

Email: bachcan@idirect.com

México

Bacharach de México

Playa Regatas No. 473 Tercer Piso

Col. Militar Marte

Delegación Iztacalco, 08830

México D.F.

México

Phones: +52-555-634-7740

+52-555-634-7741

Fax: +52-555-634-7738

Email: bacharachservicio@

bacharach.com.mx

Website: www.bacharach-mexico.com

28

Instruction 19-9326

Page 33

Monoxor III

7.0 HAZARDS OF CARBON MONOXIDE

Carbon Monoxide (CO) poisoning results in headache, nausea, chronic

tiredness, confusion, dizziness, and sometimes coma or death. CO effects

people by cutting off the supply or Oxygen to their muscles and brain. The

harmful effects of CO exposure depend on both the concentration of CO in

the air and the length of exposure.

Concentration of

CO in Air

50 ppm* (0.005%) Maximum allowable concentration for continuous

200 ppm* (0.02%) Slight headache, tiredness, dizziness, nausea after

400 ppm (0.04%) Frontal headaches within 1–2 hours, life

800 ppm (0.08%) Dizziness, nausea and convulsions within

1,600 ppm (0.16%) Headache, dizziness and nausea within

3,200 ppm (0.32%) Headache, dizziness and nausea within

6,400 ppm (0.64%) Headache, dizziness and nausea within

Inhalation Time and Toxic Symptoms Developed

exposure in any 8-hour period.

2–3 hours.

threatening after 3 hours.

45 minutes. Unconsciousness within 2 hours.

Death within 2–3 hours.

20 minutes. Death within 1 hour.

5–10 minutes. Death within 30 minutes.

1–2 minutes. Death within 10–15 minutes.

12,800 ppm (1.28%) Death within 1–3 minutes.

For additional information on CO and its dangers, ask your sales representative about Bacharach’s Institute of Technical Training CO Seminars.

* Maximum CO concentration for exposure at any time as prescribed by

OSHA. Effects can vary signicantly based on age, sex, weight, and overall state of health.

Instruction 19-9326

29

Page 34

Monoxor III

Notes

30

Instruction 19-9326

Page 35

Monoxor III

Notes

Instruction 19-9326

31

Page 36

Printed in U.S.A.

621 Hunt Valley Circle, New Kensington, PA 15068

World Headquarters

Ph: 724-334-5000 • Fax: 724-334-5001 • Toll Free: 800-736-4666

Website: www.mybacharach.com • E-mail: help@mybacharach.com

Loading...

Loading...