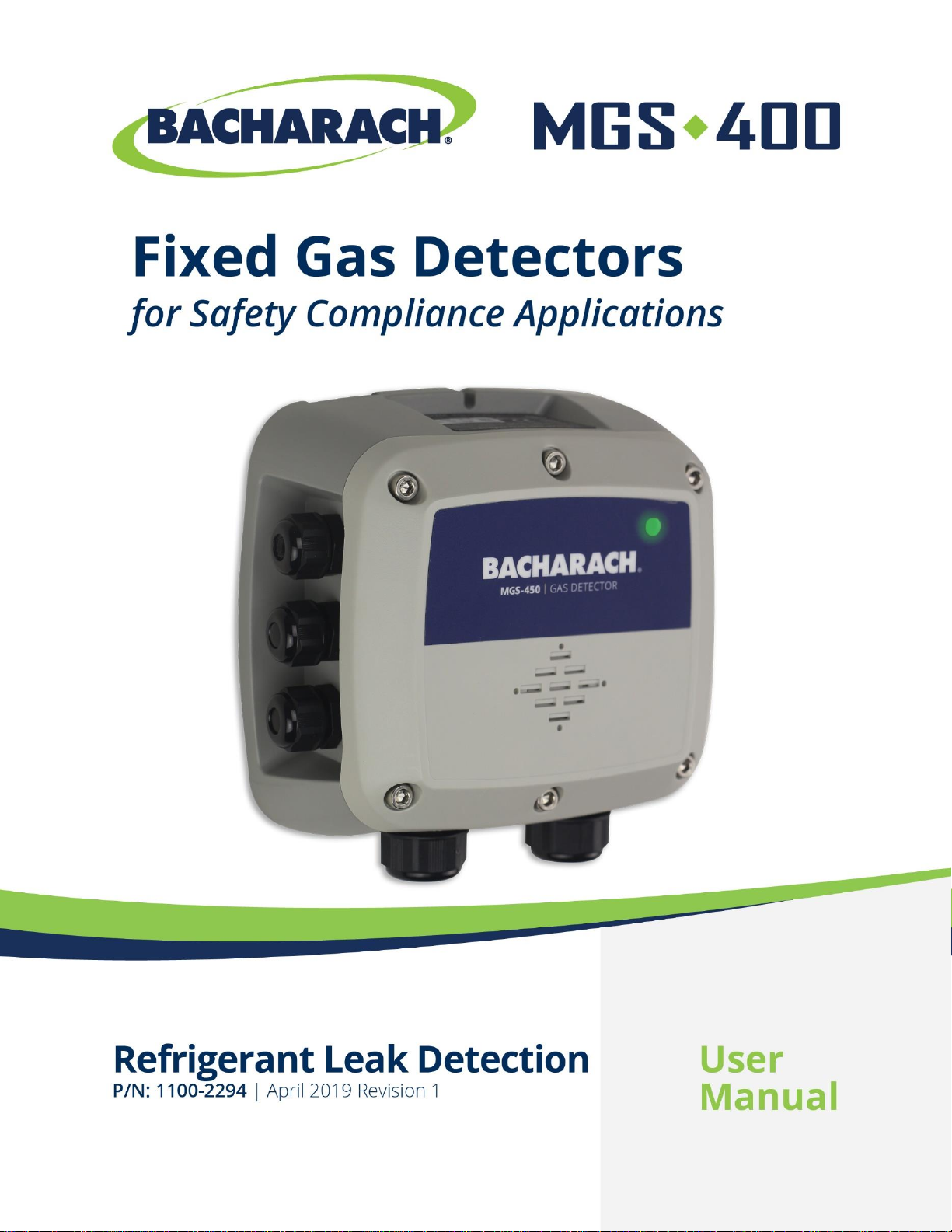

Page 1

1100-2294 Rev 1 1

Page 2

1100-2294 Rev 1 1

WARRANTY POLICY

Bacharach, Inc. warrants to buyer that at the time of delivery this product will be free from defects in material and manufacture and

will conform substantially to Bacharach, Inc.’s applicable specifications. Bacharach’s liability and buyer’s remedy under this warranty

are limited to the repair or replacement, at Bacharach’s option, of this product or parts thereof returned to seller at the factory of

manufacture and shown to Bacharach, Inc.’s reasonable satisfaction to have been defective; provided that written notice of the

defect shall have been given by buyer to Bacharach, Inc. within one (1) year after the date of delivery of this product by Bacharach,

Inc.

Bacharach, Inc. warrants to buyer that it will convey good title to this product. Bacharach’s liability and buyer’s remedy under this

warranty of title are limited to the removal of any title defects or, at the election of Bacharach, to the replacement of this product or

parts thereof that are defective in title.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND ARE GIVEN AND ACCEPTED IN LIEU OF (I) ANY AND ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE: AND (II) ANY OBLIGATION, LIABILITY, RIGHT, CLAIM OR

REMEDY IN CONTRACT OR TORT, WHETHER OR NOT ARISING FROM BACHARACH’S NEGLIGENCE, ACTUAL OR

IMPLIED. The remedies of the buyer shall be limited to those provided herein to the exclusion of any and all other remedies

including, without limitation incidental or consequential damages. No agreement varying or extending the foregoing warranties,

remedies or this limitation will be binding upon Bacharach, Inc. unless in writing,

signed by a duly authorized officer of Bacharach.

Register Your Warranty by Visiting: www.mybacharach.com/warranty-registration/

SERVICE POLICY

Bacharach, Inc. maintains a service facility at the factory. Some Bacharach distributors / agents may also have repair facilities;

however, Bacharach assumes no liability for service performed by anyone other than Bacharach personnel. Repairs are warranted

for 90-days after date of shipment (sensors, pumps, filters and batteries have individual warranties). Should your analyzer require

non-warranty repair, you may contact the distributor from whom it was purchased or you may contact Bacharach directly.

If Bacharach is to do the repair work, send the monitor, prepaid, to the closest service center. Prior to shipping equipment to

Bacharach, visit www.mybacharach.com for a Returned Merchandise Authorization Number (RMA #). All returned goods must be

accompanied by a RMA #. Pack the equipment securely (in its original packing, if possible), as Bacharach cannot be held

responsible for any damage incurred during shipping to our facility. Always include your RMA #, shipping address, telephone

number, contact name, billing information and a description of the defect as you perceive it. You will be contacted with a cost

estimate for expected repairs prior to the performance of any service work. For liability reasons, Bacharach has a policy of

performing all needed repairs to restore the monitor to full operating condition.

NOTICES

Product improvements and enhancements are on-going, therefore the specifications and information contained in this document

may change without notice.

Bacharach, Inc. shall not be liable for errors contained herein or for incidental or consequential damages in connection with the

furnishing, performance, or use of this material.

No part of this document may be photocopied, reproduced, or translated to another language without the prior written consent of

Bacharach, Inc.

Copyright © 2019, Bacharach, Inc., All Rights Reserved.

BACHARACH is a registered trademark of Bacharach, Inc. All other trademarks, trade names, service marks and logos referenced

herein belong to their respective companies.

Page 3

1100-2294 Rev 1 2

Table of Contents

Table of Contents 2

1. Introduction 6

1.1 About this Manual 6

1.2 Conventions 6

1.2.1 Short Form Instructions 6

1.2.2 Iconography 6

1.3 General Safety Statements 7

1.4 Safe Connection of Electrical Devices 8

2. Product Descriptions 9

2.1 Intended Uses / Applications 9

2.2 Transmitter Construction 9

2.3 Power Options 9

2.4 Diagnostic / Status LED 10

2.5 Configurable Output Signals 10

2.6 User Interface 10

2.7 Technical Specifications 10

2.8 Components 13

2.8.1 MGS-410 Components 13

2.8.2 MGS-450 Components 14

2.8.3 MGS-460 Components 15

3. Installation 16

3.1 General Information 16

3.2 Restrictions 17

3.3 Mechanical Installation 17

3.4 Electrical Installation 17

3.4.1 Preparations 17

3.4.2 Power & Signal Wiring 18

3.4.3 Relay Wiring 19

3.4.4 Installation of Remote Sensing Head 19

3.4.5 Connecting to MGS-408 Gas Detection Controller 20

3.4.6 Modbus RTU RS-485 Interface 20

Page 4

1100-2294 Rev 1 3

3.4.7 Confirming Instrument Functionality 21

4. Operation 22

4.1 Overview of Normal Operation 22

4.1.1 Applying Power & the Start-up Sequence 22

4.1.2 Verifying Analog Signals 22

4.1.3 Verifying the Modbus Signal 23

4.1.4 Status Indication 24

4.1.5 Switch Functions 24

4.1.6 Reset System to Factory Default Settings 25

4.2 MGS-400 Smartphone Application 26

4.2.1 Enable Bluetooth® Connection 26

4.2.2 Checking Status 26

4.2.3 Instrument Configuration 28

4.2.3.1 Change Alias 28

4.2.3.2 Change Unlock Code 28

4.2.3.3 Change Bluetooth Passcode 28

4.2.3.4 Reset to factory defaults 29

4.2.3.5 Alarm Configuration 29

Low Alarm Setpoint 29

High alarm Setpoint 30

Alarm Latching 30

4.2.3.6 Modbus Configuration 30

Address 30

Baud Rate 31

Stop Bits 31

Parity 31

Enable 120Ω Termination 31

4.2.3.7 Output Configuration 31

Analog Output Range 31

Buzzer 32

Relay Failsafe 32

Alarm Delay 32

Analog Zero Adjust 32

Page 5

1100-2294 Rev 1 4

Analog Span Range 33

5. Care & Maintenance 34

5.1 Maintenance Intervals 34

5.2 Adjustments 35

5.2.1 Introduction 35

5.2.2 General Calibration Procedure 36

5.2.3 Zero Adjustment 36

5.2.4 Span Adjustment 37

5.2.5 System Bump Test 38

5.3 Troubleshooting 39

5.3.1 Hexadecimal Format 39

5.3.3 Fault Codes 39

5.4 Sensor Maintenance 41

5.4.1 Replacing the Sensor Module 41

5.5 Cleaning the Instrument 42

6. Additional Information 43

6.1 Sensor Principle 43

6.1.1 Electrochemical Sensors 43

6.1.2 Catalytic Bead Sensors 43

6.1.3 Semiconductor Sensors 44

6.1.4 Infrared Sensors 44

6.2 Disposing of the Instrument 45

6.2.1 Disposing of the Electrical & Electronic Equipment 45

6.2.2 Disposing of Sensors 45

6.3 Sensor Specifications 45

6.4 Modbus Registers 46

6.4.1 Integration - Dynamic Sensor Data 46

6.4.2 Integration - Static Sensor Data 47

6.4.3 Integration - General System Setup 48

6.4.4 Integration – Calibration 49

6.4.5 Integration - User Debug Tools 50

6.4.6 MGS Compatibility - Status Flags 50

6.4.7 Integration - Status Flags 50

Page 6

1100-2294 Rev 1 5

6.4.8 MGS Compatibility - Clear Special States 51

6.4.9 Integration - User Tasks 51

7. Ordering Information 52

7.1 Part Numbers 52

7.1.1 MGS-400 Gas Detector Configurations 52

7.1.2 MGS-400 Series Accessories 54

7.2 Service Center Locations 55

Page 7

1100-2294 Rev 1 6

1. Introduction

1.1 About this Manual

Thank you for investing in a Bacharach MGS-400 gas detector. To ensure operator safety and

the proper use of the gas detector, please read the contents of this manual for important

information on the operation and maintenance of the instrument.

1.2 Conventions

1.2.1 Short Form Instructions

This document uses a short form for describing steps (e.g. executing a command).

Example:

Accessing sensor calibration.

Short Form Instructions:

To select access sensor calibration: Home Tab Calibrate enter Unlock Code

Steps Required:

1. Open the Home Tab.

2. Select Calibrate.

3. When prompted, enter the Unlock Code to access calibration screen.

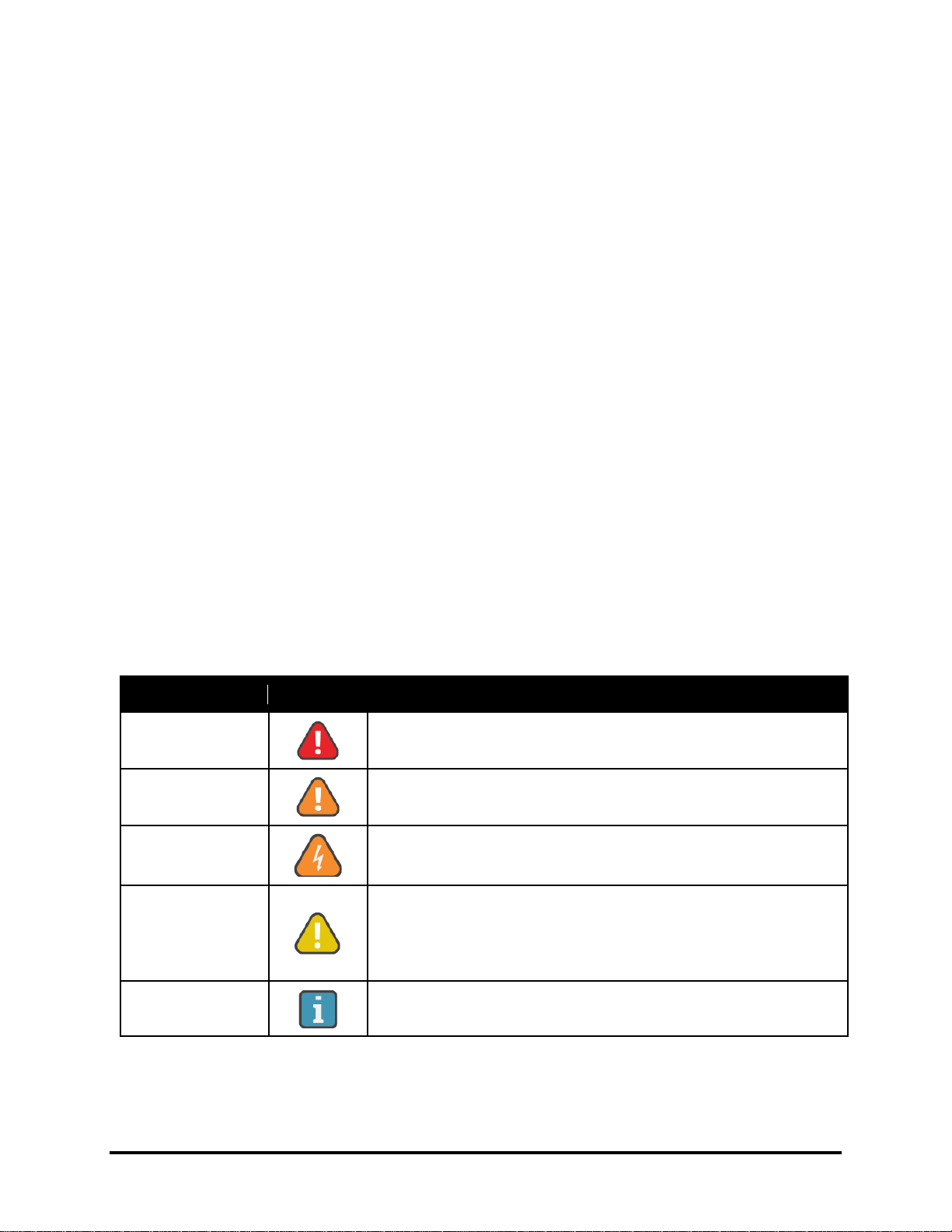

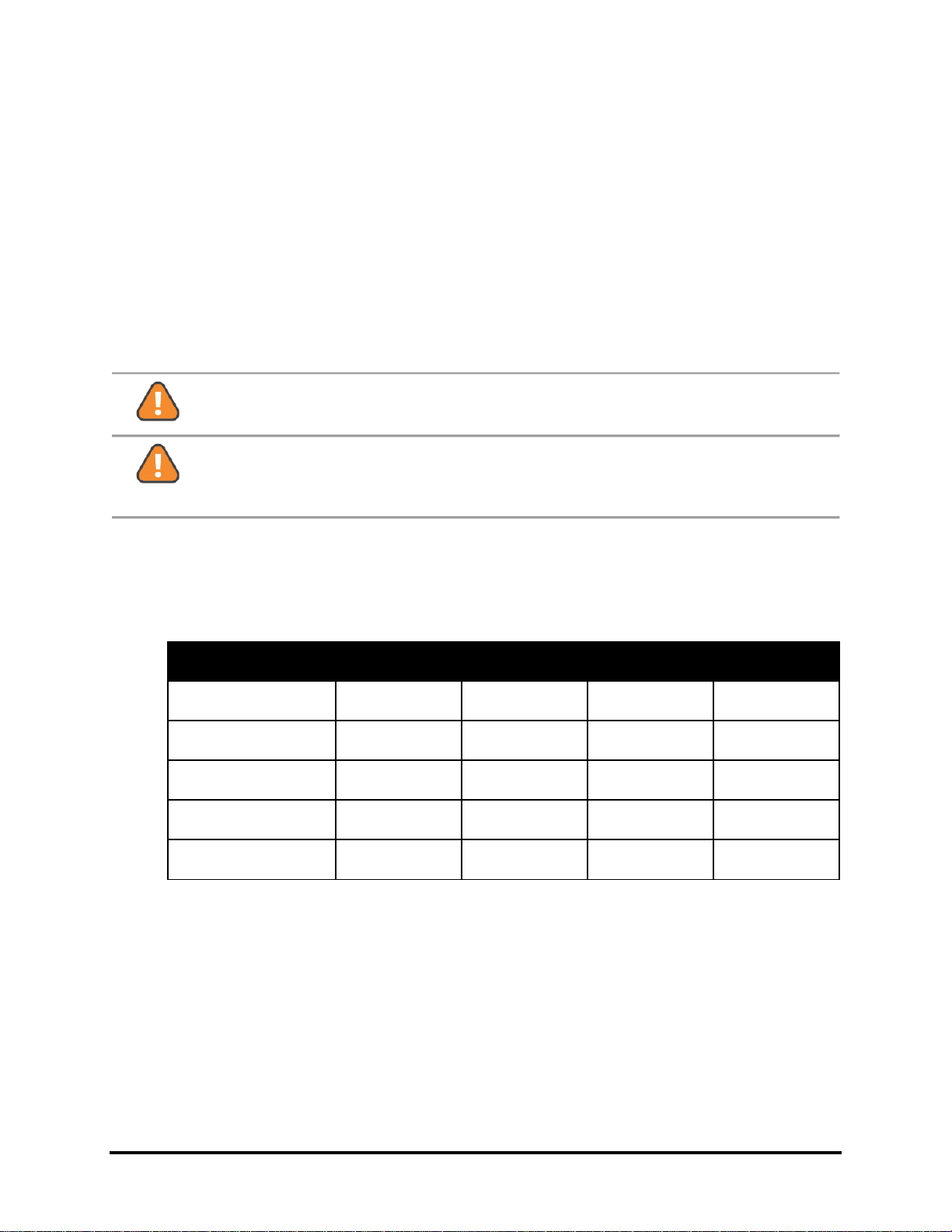

1.2.2 Iconography

Alert

Icon

Description

Danger

Imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Warning

Potentially hazardous situation which, if not avoided, could

result in death or serious injury.

Warning

Potential electrical shock hazard which, if not avoided, could

result in death or serious injury.

Caution

Potentially hazardous situation which, if not avoided, could

result in physical injury or damage to the product or

environment. It may also be used to alert against unsafe

practices.

Important

Additional information on how to use the product.

Page 8

1100-2294 Rev 1 7

1.3 General Safety Statements

IMPORTANT: Before using this product, carefully read and strictly follow the

instructions in the manual. Ensure that all product documentation is retained and

available to anyone operating the instrument.

DANGER: This instrument is neither certified nor approved for operation in

oxygen-enriched atmospheres. Failure to comply may result in personal injury or

death.

WARNING: Use this product only for the purposes specified in this document and

under the conditions listed.

WARNING: This instrument has not been designed to be intrinsically safe for use

in areas classified as being hazardous locations. For your safety, DO NOT use it in

hazardous (classified) locations.

WARNING: In the event of an alarm or over-range condition, the sensor must be

recalibrated to ensure continued accuracy.

WARNING: This product must be recalibrated if installed in a non-room condition

environment (i.e. temperature or humidity extremes).

WARNING: The gas diffusion path can become occluded (moisture, dust, debris,

frozen condensation) over time resulting in reduced or complete lack of gas

detection and alarming function. Routine visual inspection of the gas detector and

bump testing are suggested to ensure proper gas detection and alarm function.

CAUTION: Except for maintenance detailed in this manual, these products should

only be opened and / or serviced by authorized Bacharach personnel. Failure to

comply may void the warrant.

CAUTION: Operator assumes responsibility for complying with all laws, rules and

regulations governing the use of this product.

CAUTION: Use only genuine Bacharach parts and accessories. Failure to comply

may impair the operation of the product and / or void the warranty.

CAUTION: Only operate the product within the framework of a risk-based alarm

signaling concept.

Page 9

1100-2294 Rev 1 8

1.4 Safe Connection of Electrical Devices

WARNING: Before connecting this instrument to electrical devices not mentioned

in this manual, consult the manufacturer or a qualified professional. Failure to

comply may result in injury and / or damage to the product.

Page 10

1100-2294 Rev 1 9

2. Product Descriptions

2.1 Intended Uses / Applications

MGS-400 gas detectors are to be installed in non-classified, non-hazardous, permanent

locations for the purpose of continuously monitoring ambient air (indoor or outdoor) for the

following gas types:

• Refrigerants

• Oxygen

• Toxic and combustible gases

WARNING: This instrument is neither certified nor approved for operation in

oxygen-enriched atmospheres. Failure to comply may result in EXPLOSION.

WARNING: This instrument has not been designed to be intrinsically safe for use

in areas classified as being hazardous locations. For your safety, DO NOT use it

in hazardous (classified) locations.

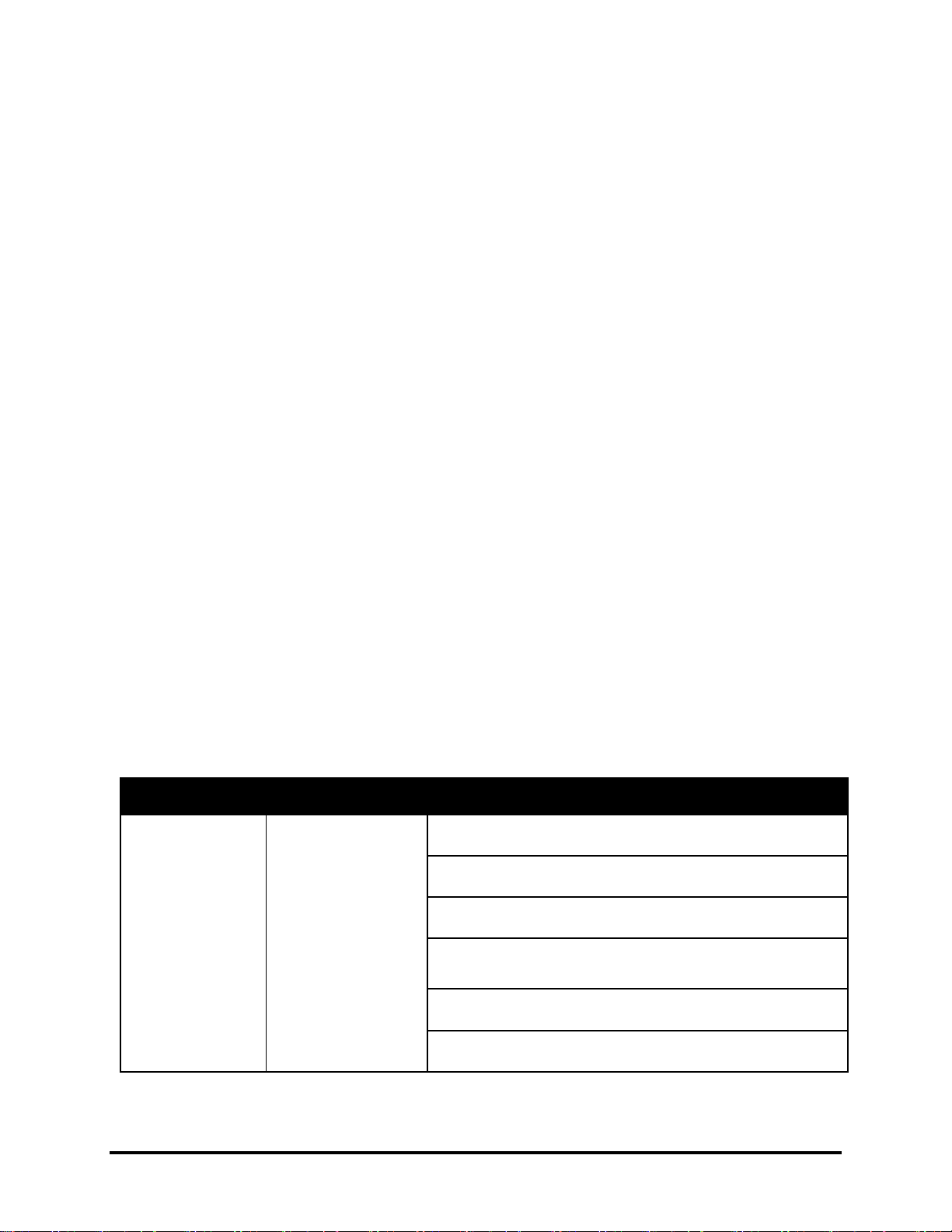

2.2 Transmitter Construction

MGS-400 gas detectors may be purchased in the following configurations:

MGS-410

MGS-450

MGS-450

MGS-460

Enclosure

IP66

IP41

IP66

IP66

Relays

- 3 3

3

Communication

Modbus

Modbus

Modbus

Modbus

Output

-

Analog

Analog

Analog

Sensor

Integrated

Integrated

Integrated

Remote

2.3 Power Options

MGS-400 gas detectors may use the following power options:

• 24 VAC

• 19.5 to 28.5 VDC

Page 11

1100-2294 Rev 1 10

2.4 Diagnostic / Status LED

MGS-400 gas detectors feature a three-color LED (green, orange and red) which are used, in

combination with an audible alarm, to communicate the status of the instrument.

2.5 Configurable Output Signals

MGS-400 gas detectors may be connected to a Bacharach’s MGS-408 Gas Detection Controller

or a third-party device capable of accepting digital and/or analog outputs from the gas detectors,

such as a Building Management System (BMS) or Programmable Logic Controller (PLC). With

the integrated audio-visual alarm indication, an instrument can be operated as a stand-alone

unit (with additional local alarm signaling as required). Configurable output signal options

include the following:

MGS-410, MGS-450, MGS-460 – Digital Output (Modbus RTU signal)

MGS-450, MGS-460 – 3× Relays (high alarm / low alarm / fault)

MGS-450, MGS-460 – 1× Analog Output (4 to 20 mA, 0 to 5 V, 0 to 10 V, 1 to 5 V,

2 to 10 V)

2.6 User Interface

MGS-400 gas detectors allow users to interface directly with the instrument via the following:

Bluetooth® Communication (MGS-400 App allows users to configure the gas

detector, initiate calibration, bump test / functional test modes and view status

information.)

Tactile / Magnetic Switches (A non-intrusive magnetic wand allows users to

initiate calibration of the device.)

2.7 Technical Specifications

Category

Specifications

Signals to

Central

Controller

Analog Current

Normal operation:............................................. 4 to 20 mA

Drift below zero:..................................................... 3.8 mA

Measuring range exceeded:................................. 20.5 mA

Instrument fault:.................................................. ≤ 1.2 mA

Fault on analog interface:.................................... > 21 mA

Offline mode/Maintenance signal:....... 3 mA steady signal

Page 12

1100-2294 Rev 1 11

Signals to

Central

Controller

Analog Voltage

0 to 5V; 1 to 5V; 0 to 10V; 2 to 10V (selectable). During

fault condition, 1 to 5V and 2 to 10V outputs are 0V.

Modbus RTU over

RS-485

Baud rate:............................. 9,600 or 19,200 (selectable)

Start bits:......................................................................... 1

Data bits:......................................................................... 8

Parity:.................................. None, odd, even (selectable)

Stop bits:............................................... 1 or 2 (selectable)

Retry time:.................... 500 ms, min time between retries

End of message:............................... Silent 3.5 characters

Power Supply

and Relays

Operating Voltage

19.5 to 28.5 VDC; 24 VAC ± 20%, 50/60 Hz

Inrush Current

1.5 A

Operating Current,

Max.

MGS-410: 2W, 85mA @ 24VDC

MGS-450/60: 4W, 170mA @ 24VDC

Relay Rating

3 SPDT

1A at 30 VAC/VDC, resistive load

Audible Alarm

Internal Buzzer ≥72 dB at 4”

(10 cm)

Alarm Delay

0 to 15 minutes (selectable)

Wiring

Power and Analog

Signal

2-core shielded cable, 16 to 20 AWG (0.5 to 1.5 mm2)

Modbus Network

3-core, 2 twisted pair + ground, shielded cable with 120 Ω

characteristic impedance, 16 to 24 AWG (0.2 to 1.5

mm2).

Cable Gland

M20, 10-14mm cable outer diameter

M16, 4-8mm cable outer diameter

Page 13

1100-2294 Rev 1 12

Physical

Specifications

Enclosure

Protection

IP41 / IP66

Enclosure Size

(W×H×D) (Approx.)

MGS-410: 5.1×5.1×2.7” (130×130×68 mm)

MGS-450 IP41: 6.5× 6.5×3.0” (165×165×77 mm)

MGS-450 IP66: 6.5×6.5×3.4” (165×165×87 mm)

MGS-460: 6.5×6.5×3.4” (165×165×87 mm)

MGS-460 Remote: 4.5× 5.4×2.7” (115×136×68 mm)

Weight (Approx.)

MGS-410: 9.2oz

(260 g)

MGS-450: 1lb, 1oz

(480 g)

MGS-460: 1lb, 11.7oz

(758 g)

Environmental

Temperature

- 40 to 120 ºF (-40 to 50 ºC)

Storage

Temperature

- 5 to 100 ºF (-20 to 40 ºC)

Humidity

5 to 90 %RH, non-condensing

(15 to 90 %RH, non-condensing, EC sensors excl. O2)

Pressure

23.6 to 32.5 inch Hg / 800 to 1,100 mbar

Elevation

0 to 10,000 ft. (3,050 m) altitude

Sensors

See Section 6.3 for sensor specifications.

Influences

For influences on the measurement performance and

restrictions of a particular sensor see sensor data sheet.

Agency

Approvals

CE, EN 50270:2015, UL/CSA/IEC/EN 61010-1

Page 14

1100-2294 Rev 1 13

2.8 Components

CAUTION: This product uses semiconductors which can be damaged by

electrostatic discharge (ESD). When handling the printed circuit boards (PCBs),

observe proper ESD precautions so that the electronics are not damaged.

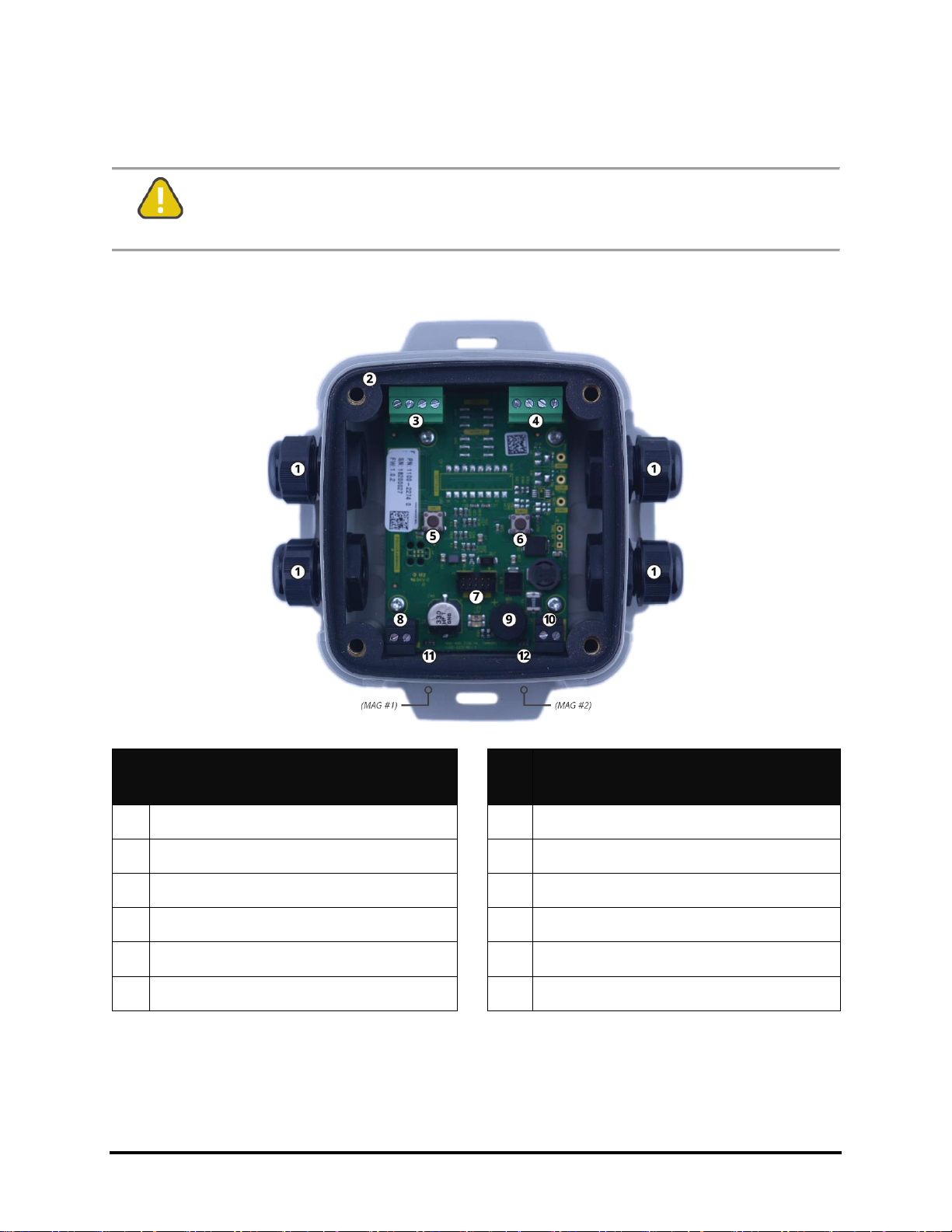

2.8.1 MGS-410 Components

#

Component Description

#

Component Description

1

M16 Cable Glands (×4)

7

Ribbon Cable Connection (To Sensor)

2

Rubber Gasket

8

Power Connection (In)

3

Digital Connection / Modbus (In)

9

Internal Alarm Buzzer

4

Digital Connection / Modbus (Out)

10

Power Connection (Out)

5

Tactile Switch #1

11

Magnetic Switch #1

6

Tactile Switch #2

12

Magnetic Switch #2

Page 15

1100-2294 Rev 1 14

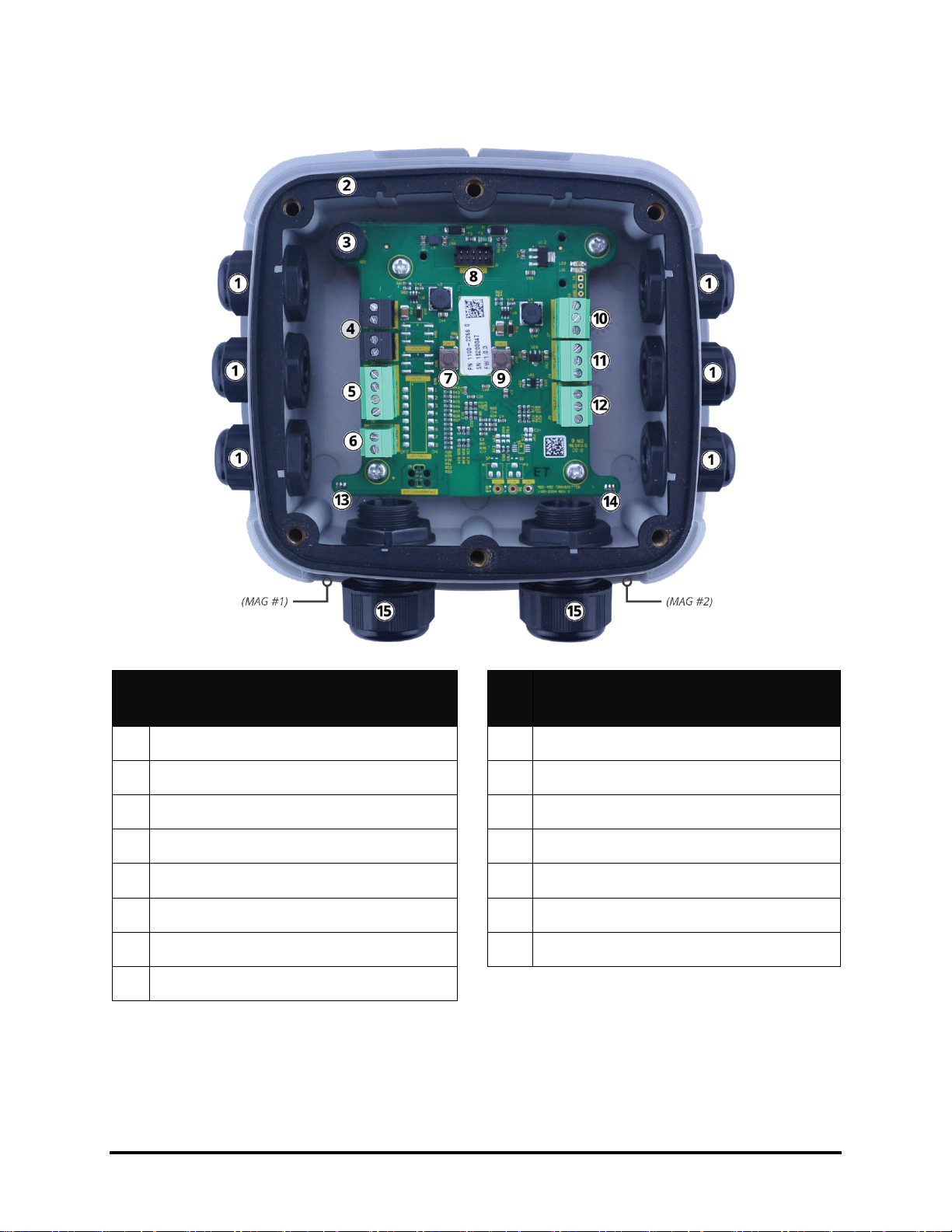

2.8.2 MGS-450 Components

#

Component Description

#

Component Description

1

M16 Cable Glands (×6)

9

Tactile Switch #2

2

Rubber Gasket (IP66 Version Only)

10

Relay 3 Connection (FAULT)

3

Internal Alarm Buzzer

11

Relay 2 Connection (HIGH)

4

Power Connections (×2)

12

Relay 1 Connection (LOW)

5

Digital Connection (Modbus)

13

Magnetic Switch #1

6

Analog Connection

14

Magnetic Switch #2

7

Tactile Switch #1

15

M20 Cable Glands (×2)

8

Ribbon Cable Connection (To Sensor)

Page 16

1100-2294 Rev 1 15

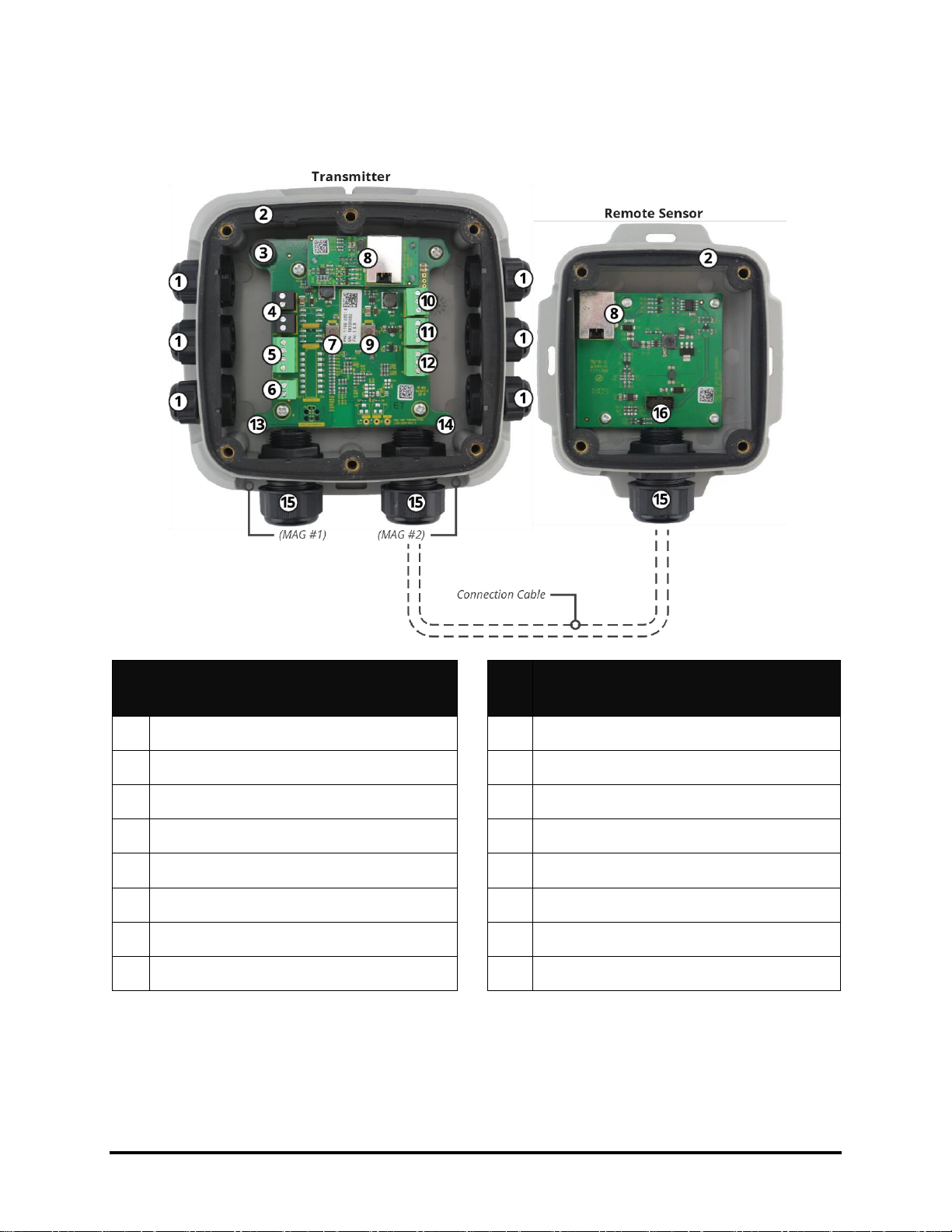

2.8.3 MGS-460 Components

#

Component Description

#

Component Description

1

M16 Cable Glands (×6)

9

Tactile Switch #2

2

Rubber Gasket (×2)

10

Relay 3 Connection (FAULT)

3

Internal Alarm Buzzer

11

Relay 2 Connection (HIGH)

4

Power Connections (×2)

12

Relay 1 Connection (LOW)

5

Digital Connection (Modbus)

13

Magnetic Switch #1

6

Analog Connection

14

Magnetic Switch #2

7

Tactile Switch #1

15

M20 Cable Glands (×3)

8

RJ45 Connects (×2)

16

Ribbon Cable Connection (To Sensor)

Page 17

1100-2294 Rev 1 16

3. Installation

IMPORTANT: The manufacturer of this product requires that a bump test or

calibration be performed following installation to verify instrument functionality.

3.1 General Information

Installation site selection is critical to ensuring system performance and effectiveness. Strict

compliance and considerable thought must be given to every detail of the installation process,

including, but not limited to the following:

● Regulations as well as local, state, and national codes that govern the installation of gas

monitoring equipment

● Electrical codes that govern the routing and connection of electrical power and signal

cables to gas monitoring equipment

● The full range of environmental conditions to which the instruments will be exposed

● The physical characteristics of the gas or vapor to be detected

● The specifics of the application (e.g., possible leaks, air movement/draft, etc.)

● The degree of accessibility required for maintenance purposes

● The types of optional equipment and accessories that will be used with the system

● Any limiting factors or regulations that would affect system performance or installations

● Wiring details, including:

MGS-410

MGS-450

MGS-460

M16 Cable Glands

(4-8mm cable diameter)

4

6

6

M20 Cable Glands

(10-14mm cable diameter)

-

2

1

● Secondary circuit must be supplied from an isolating source

● The wiring for the relays must be selected and fused according to the rated voltages,

currents, and environmental conditions

● If stranded conductors are used, a ferrule should be used

● To comply with RFI immunity regulations, it is necessary to ground the shield of the

communications cable at the PLC, GDA controller, front-end controller, or Building

Management System (e.g., the chassis, the ground bus-bar, etc.).

Page 18

1100-2294 Rev 1 17

3.2 Restrictions

The installation location must have appropriate supply power available for the instrument

(i.e., 19.5 to 28.5 VDC or 24 VAC). This ultimately determines the distance the instrument can

be mounted from the controller or power supply.

3.3 Mechanical Installation

WARNING: DO NOT allow the lid / sensor to hang from the ribbon cable. Failure

to comply may result in damage to the product.

1. Using the provided hardware, securely mount the MGS-400 gas detector according to

the product dimensions, maximum wiring lengths and following considerations:

a. Environment: the full range of environmental conditions when selecting a

location.

b. Application: the specifics of the application (possible leaks, air movement / draft,

etc.) when selecting a location.

c. Accessibility: the degree of accessibility required for maintenance purposes when

selecting a location.

d. Target Gas: the specific gravity of the target gas when selecting the height of the

instrument.

2. Using a 5/32″ (4 mm) hex key / allen wrench (not included) remove the lid and

disconnect the ribbon cable from the base.

3. Set the lid and rubber gasket (IP66-rated enclosures only) aside to be reinstalled later.

3.4 Electrical Installation

3.4.1 Preparations

IMPORTANT: If analog output is configured for 4 to 20 mA output, ensure that

the current loop is connected to a sinking current loop monitor before powering

on the instrument. Otherwise, a fault may be displayed indicating an open loop

condition. If analog output is unused, ensure it is configured as a voltage output

(default: 1-5V) to prevent an open loop fault condition. The analog output is

designed as sourcing.

CAUTION: Ensure wiring for relays and connections for sensor(s) are made

before applying power.

CAUTION: This product uses semiconductors which can be damaged by

electrostatic discharge (ESD). When handling the printed circuit boards (PCBs),

observe proper ESD precautions so that the electronics are not damaged.

Page 19

1100-2294 Rev 1 18

3.4.2 Power & Signal Wiring

1. Locate the relevant connections (Power, Analog, Modbus) and remove the terminal

block from the PCBA. (The PCB terminal blocks are pluggable type and may be

removed to aid termination.)

Connection

Description

Label

Wiring Termination

Power

24 VDC/VAC IN

24V IN: -

24 VDC/VAC neutral /

ground

24V IN: +

24 VDC positive / VAC live

24 VDC/VAC OUT

(power daisy chain

terminal)

24V OUT: -

24 VDC/VAC neutral /

ground

24V OUT: +

24 VDC positive / VAC live

Digital Output

Modbus Network

Communications

MODBUS: B

RS-485 “B” (inverted)

MODBUS: A

RS-485 “A” (non-inverted)

MODBUS: GND

RS-485 GND

MODBUS: SH

RS-485 Shield

Analog Output

Voltage or Current

Output

ANALOG: -

Analog output ground

ANALOG: +

Analog output signal (+)

2. Remove plugs from the corresponding M16 cable glands.

The product comes with cable glands and plugs pre-installed. (The power entry

cable gland is shipped from the factory without a plug.)

3. Using the appropriate cable glands, insert wires into the enclosure.

4. Secure the wires in each terminal block and, pressing firmly, reinstall the terminal block

into the PCBA.

Polarity must not be reversed.

For 24 VAC installations in a daisy-chain configuration, the neutral polarity must

be maintained for all instruments.

5. Remove all excess cable from the housing before securing the cable glands.

Page 20

1100-2294 Rev 1 19

3.4.3 Relay Wiring

WARNING: Relays are rated for 0 to 30V AC/DC. DO NOT apply mains power

onto these relays.

1. Locate the relevant connections (Relay 1, Relay 2, Relay 3) and remove the terminal

block from the PCBA.

Relay

Function

1

Low Alarm

2

High Alarm

3

Fault Alarm

2. Remove plugs from the corresponding M16 cable glands.

3. Using the appropriate cable glands, insert wires into the enclosure.

4. Secure the wires in each terminal block and, pressing firmly, reinstall the terminal block

into the PCBA.

5. Remove all excess cable from the housing before securing the cable glands.

When configured according to the factory default settings, the relays are de-energized during

normal operation (not fail-safe). Fail-safe mode can be configured. When configured for fail-safe

operation, relays are energized during normal operation. Fail-safe operation ensures relays are

triggered in cases of power failure at the instrument. In failsafe operation normally open and

normally closed terminals are reversed as indicated by the following table:

Terminal

Normal operation

Failsafe Operation

NC

Normally Closed

Normally Open

COM

Common

Common

NO

Normally Open

Normally Closed

3.4.4 Installation of Remote Sensing Head

IMPORTANT: Non standard cable lengths less than 5 meters may be used.

Where non standard remote cables are used these must be shielded to comply

with EMI regulations.

IMPORTANT: Remote sensor is automatically recognized and registered by the

instrument after a power cycle.

Page 21

1100-2294 Rev 1 20

The MGS-460 features a remote sensor, which allows users to detect the presence of gases in

inaccessible locations. Standard RJ45 “Cat 5E STP” Ethernet cable up to 5 meters long

(included) may be used with the remote sensor.

1. Remove the bottom right M20 cable gland plug and gland cap, and carefully remove the

gland rubber insert. (The rubber insert is split to allow it to be installed around the

provided RJ45 cable.)

2. Slip the cable gland nut over one end of the terminated RJ45 cable.

3. Apply the split rubber insert onto the cable so that it is between the gland nut and the

end of the cable.

4. Feed the RJ45 connector through a cable gland and into the enclosure, taking care to

not damage the PCB.

5. Remove all excess cable from the housing before securing the cable gland. (Confirm

that the RJ45 cable is not binding or stressing the PCB terminal block.)

6. Plug the RJ45 connector into the provided RJ45 socket.

3.4.5 Connecting to MGS-408 Gas Detection Controller

For wiring and configuration information, please refer to the manual which is included with the

MGS-408 (P/N: 1100-2295).

At the central control system, connect the shield of the wires to the earth ground of the

controller (e.g., the chassis, the ground bus-bar, etc.).

For 24 VDC installations, the input is protected. If the polarity is reversed, the instrument

will not power-up.

For 24 VAC installations in daisy-chain, the neutral polarity must be maintained for all

instruments.

3.4.6 Modbus RTU RS-485 Interface

For the Modbus RS-485 network use a 16 to 24 AWG (0.2 to 1.5 mm2) 3-core, 2 twisted pair +

ground, shielded cable with 120 Ω characteristic impedance. (Recommended: Belden 3106A or

equivalent.)

The Modbus address, baud rate, stop bit, parity and slave termination is configured through the

setup menu. No jumpers or hardware switch settings are required.

Ensure that the communication parameters within the network, including the Building

Management System, are configured identically.

To ensure optimal performance of the Modbus network, ensure the following guidelines are

implemented:

● Instruments are configured in a single bus topology, connecting multiple buses in parallel

or branching multiple units from the main bus, may introduce impedance mismatches,

reflections and/or signal distortions.

● Avoid long stubs when connecting instruments to the bus (stubs should be less than 1

meter in length).

Page 22

1100-2294 Rev 1 21

● Instruments at end of bus have 120Ω terminating resistor enabled. Terminating resistors

may be enabled via the MGS-400 App (refer to Section 4.2.3.6 for more information).

● A/B signal polarity is maintained throughout RS-485 network.

● Connect cable shield drain to physical earth or ground at the controller only.

● Connect cable shield drain to (SH) terminal at instrument.

● Cable shield integrity is maintained throughout RS-485 network.

● Do not use shield connection for signal ground. Use cable that provides dedicated

ground conductor for signal ground. Connect signal ground to (GND) terminal of

instrument.

3.4.7 Confirming Instrument Functionality

After all wiring has been completed, power the transmitter and perform a calibration / bump test

to verify instrument functionality:

1. Switch power on.

2. Allowing the instrument to complete its start-up sequence and the sensor to stabilize.

3. Perform a calibration or bump test to confirm instrument functionality. (For instructions

on performing a calibration or bump test, see Section 5.2.)

4. After verifying instrument functionality, reinstall the enclosure lid.

Reinstall the rubber gasket in the transmitter and / or remote sensor. Ensure that

it is seated correctly before replacing lid. (Note that the IP41-rated configurations

do not include a rubber gasket.)

Using a 5/32″ (4 mm) hex key / allen wrench (not included) tighten the lid screws

in an “X” tightening pattern. (Tightening torque should be limited to hand tight,

and should be uniform.)

Page 23

1100-2294 Rev 1 22

4. Operation

4.1 Overview of Normal Operation

WARNING: Before leaving the instrument for normal operation, check the

configuration for proper settings and check calibration.

4.1.1 Applying Power & the Start-up Sequence

After applying power, the instrument will go through a start-up sequence (initialization,

audible/visual test and self-test sequence). After start-up sequence completes, the instrument

will enter a warm-up period to allow the sensor element to stabilize before reporting a valid

output.

1. Switch power on.

2. Observe the start-up sequence and warm-up phase:

Green LED will blink at 0.5 HZ for about 5 minutes.

Modbus flag for warm-up is set.

Buzzer is off.

Relay state is “no alarm.”

Gas reading is invalid.

3. Observe normal operation:

Green LED is steady on.

Modbus flag for warm-up is cleared.

Buzzer is off.

Relay state is “no alarm.”

Gas reading is valid.

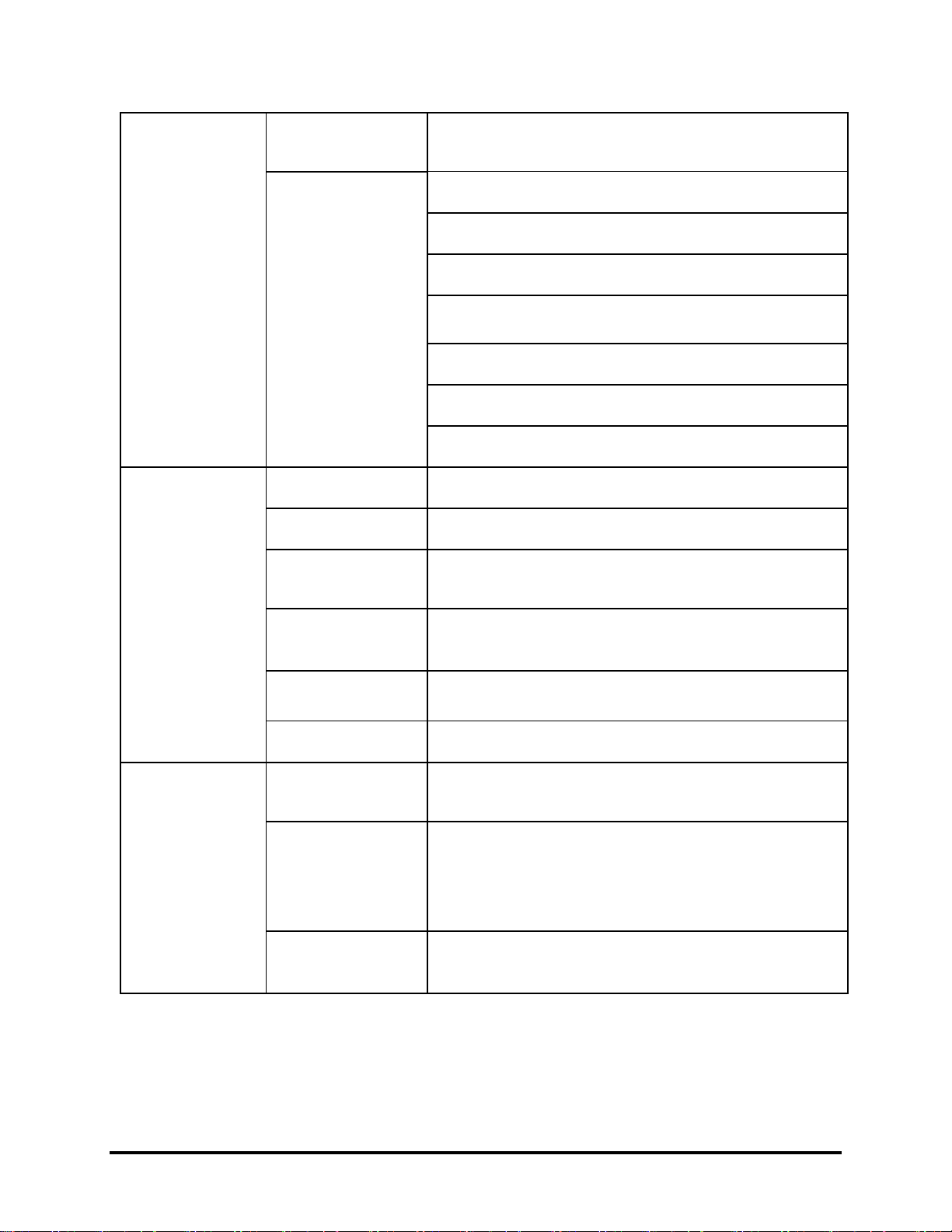

4.1.2 Verifying Analog Signals

MGS-450 / 460 gas detectors feature a single configurable analog output. During normal

operation, the analog output of the instrument is proportional to the detected gas concentration.

Output level is proportional to the gas level as shown below:

Gas Concentration

1-5V

0-5V

2-10V

0-10V

4-20mA

0%

1V

0V

2V

0V

4 mA

50%

3V

2.5V

6V

5V

12 mA

100%

5V

5V

10V

10V

20 mA

Page 24

1100-2294 Rev 1 23

The instrument may also enter several special states, these are indicated by the specific analog

output levels indicated below:

Mode of Operation

1-5V

0-5V

2-10V

0-10V

4-20mA

Instrument Fault

≤ 0.3V

N/A

≤ 0.6V

N/A

≤ 1.2 mA

Offline Mode / Maintenance

0.75V

N/A

1.5V

N/A

3 mA

Drift Below Zero

0.95V

N/A

1.9V

N/A

3.8 mA

Normal Operation

1-5V

0-5V

2-10V

0-10V

4-20 mA

Measuring Range Exceeded

5.12V

5.12V

10.25V

10.25V

20.5 mA

Fault on Analog Interface

> 5.25V

> 5.25V

> 10.5V

> 10.5V

> 21mA

4.1.3 Verifying the Modbus Signal

The MGS-400 gas detectors provide a Modbus RTU digital interface. All status messages and

most parameters can be accessed and / or configured via the MGS-400 App (Bluetooth®

communications) or via a Building Management (Modbus network).

Page 25

1100-2294 Rev 1 24

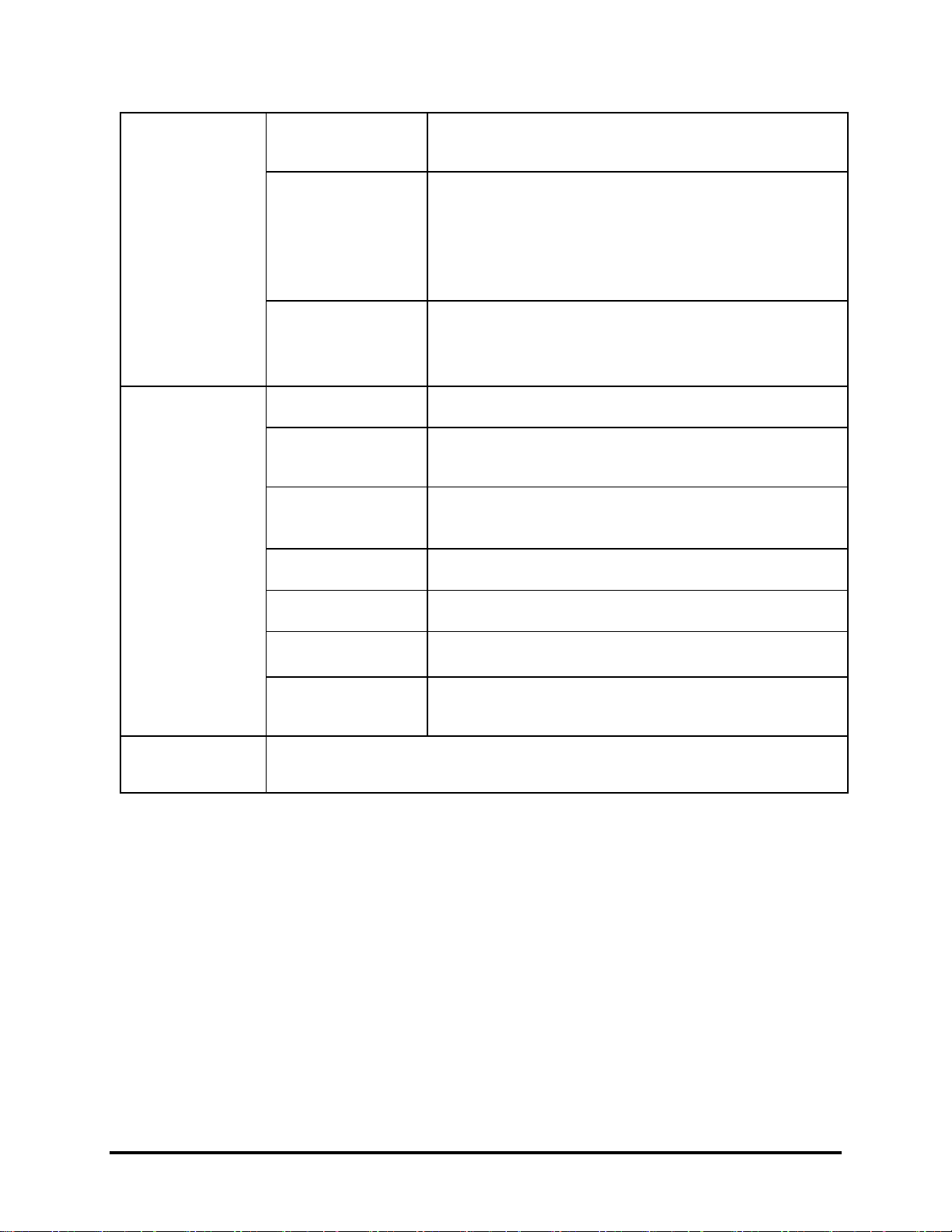

4.1.4 Status Indication

The MGS-400 gas detectors provide external indication of their current operational state via

audible and visual feedback. (MGS-450 / 460 gas detectors also provide relays outputs.) Visual

indication of the instrument status is provided by a single tri-color LED (Green / Red / Orange)

as indicated below:

State

LED

Buzzer

Relay 1

(LOW)

Relay 2

(HIGH)

Relay 3

(Fault)

Warm-up

OFF

OFF

OFF

Normal

OFF

OFF

OFF

Low Alarm

ON

OFF

OFF

High Alarm

ON

ON

OFF

Offline

OFF

OFF

OFF

Fault

OFF

OFF

ON

Negative Gas Fault

OFF

OFF

ON

Zero Cal. Fault

OFF

OFF

OFF

Span Cal. Fault

OFF

OFF

OFF

4.1.5 Switch Functions

User interaction with the MGS-400 gas detector is accomplished through the use of two

magnetic switches located on the bottom of each unit. To actuate a magnetic switch (referred to

as MAG#1 or MAG#2), apply the supplied magnetic wand (P/N: 1100-1004) to the relevant

switch location as indicated below:

Page 26

1100-2294 Rev 1 25

Depending on the duration the switch is held, a short “TAP” or long “HOLD” will be detected:

To carry out a tap function, tap the relevant switch location for 1 second, until a single

“chirp” is heard, remove wand to confirm a “TAP.”

To carry out a hold function, do not remove the magnetic wand after the first chirp but

continue to hold for >5 seconds, until a double “chirp” is heard, remove wand to confirm

a “HOLD.”

If either switch is held for >30s, a stuck switch fault will be indicated.

To interact with the instrument without use of the magnetic wand, two internal push button

tactile switches may be used. Remove lid without removing ribbon cable to access. Internal

switches TACT#1 and TACT#2 mirror the functions of MAG#1 and MAG#2.

The function of each switch depends on the current state of the instrument as indicated in the

following table:

State

Switch 1

(Tap)

Switch 1

(Hold)

Switch 2

(Tap)

Switch 2

(Hold)

Warm-up

Enable

Bluetooth®

Connectivity

-

Disable

Bluetooth®

Connectivity

-

Normal

Start Zero Calibration

Start Span

Calibration

Low Alarm

Mute Buzzer

Ack. Latched Alarm

High Alarm

Mute Buzzer

Ack. Latched Alarm

Offline - -

Fault

Mute Buzzer

Ack. Latched Fault

Negative Gas

Fault

Mute Buzzer

Start Zero

Calibration

Zero Cal. Fault

Acknowledge Fault

-

Span Cal. Fault

-

Acknowledge Fault

4.1.6 Reset System to Factory Default Settings

To reset system to factory defaults, remove lid and hold TACT#1 and TACT#2 simultaneously

for 30 seconds. Instrument will restart to confirm factory reset. Alternatively, see Section 4.2.3.4

“Reset to Factory Defaults”, for instructions on resetting instrument configuration via the MGS400 App.

Page 27

1100-2294 Rev 1 26

4.2 MGS-400 Smartphone Application

To download the MGS-400 App, visit www.mybacharach.com/apps. The companion

smartphone application allows users to perform a variety of functions to configure and interact

with the MGS-400 gas detector, including:

● View real-time measurements

● Configure instrument

● Test outputs

● Calibrate / bump test instrument

● Generate customizable calibration certificates

4.2.1 Enable Bluetooth® Connection

1. Enable Bluetooth® discovery by tapping MAG#1 for 1-second. (After 10-seconds, device

will indicate that it is discoverable with audible heartbeat until it has been paired,

discovery has timed-out or has been cancelled.)

2. Launch the MGS-400 App and click the Bluetooth® icon at the bottom of the screen to

initiate a scan.

3. Select the instrument from the list of available Bacharach gas detectors.

MGS-410 default alias is “18TMA-DT”

MGS-450 / 460 default alias is “18TMA”

4. When prompted, enter the passkey (default is “123456”).

WARNING: Default alias, passkey and unlock code can be changed via the

MGS-400 App’s configuration menu. Default values should be changed after

instrument installation for security purposes.

4.2.2 Checking Status

Current instrument status can be viewed from the Home tab, including the following:

Page 28

1100-2294 Rev 1 27

#

Description

1

Alias - user configured instrument

name

2

Serial Number - instrument 8 digit

serial number

3

Gas - gas type currently detected

by instrument

4

Status Ring - provides visual

indication of various instrument

states (expanded on below)

5

Live Measurement - current

measurement in given

measurement units

6

Measurement Unit - displayed

measurement unit (PPM / PPB /

%LEL / %VOL)

State

Status Ring

Description

Warm-up

Green

Gas detector stabilizing after power on or restart

Normal

Green

Normal operation

Low Alarm

Yellow

Gas measurement has exceeded low alarm setpoint

High Alarm

Red

Gas measurement has exceeded high alarm setpoint

Offline

Orange

Gas Detector in maintenance mode and is not actively

monitoring gas

Fault

Orange

A fault has been detected

Negative Gas

Fault

Orange

Gas detector calibration has drifted below zero, requires

zero calibration

Zero Cal. Fault

Orange

Error occurred during zero calibration. Zero calibration

has not be updated. Zero calibration required.

Span Cal. Fault

Orange

Error occurred during span calibration. Span calibration

has not be updated. Span calibration required.

Page 29

1100-2294 Rev 1 28

4.2.3 Instrument Configuration

For security, access to configuration and calibration options are restricted to authorized users

only. Access to these functions require use of an unlock code. To unlock instrument

configuration:

Configure Tab When prompted, enter unlock code to access device configuration.

(The instrument’s default code is “1234”). Instrument will remain unlocked until

Bluetooth® connection has ended.

WARNING: Default alias, passkey and unlock code can be changed via the

MGS-400 App’s configuration menu. Default values should be changed after

instrument installation for security purposes.

4.2.3.1 Change Alias

To allow easy identification of a given instrument, an alias can be assigned to each instrument.

This alias is displayed when searching for an instrument via Bluetooth®, on calibration cert and

in home tab. To set alias:

Configure Tab Alias, Enter required alias for instrument, select OK.

Instrument must be restarted for change to take effect. Home Tab Restart, will reboot

device.

Reconnect to instrument to confirm alias has been updated.

4.2.3.2 Change Unlock Code

To prevent unauthorized access to instrument configuration and calibration, default instrument

unlock code should be changed during commissioning. To change unlock code:

Configure Tab Modbus Unlock Code, enter new 4-digit unlock code for instrument,

select OK.

Instrument must be restarted for change to take effect. Home Tab Restart, will reboot

device.

Reconnect to instrument to confirm unlock code has been updated.

IMPORTANT: If custom unlock code is forgotten, unlock code may be reset to

default value (1234) by resetting system to factory defaults. Refer to section

4.1.6 for system reset procedure. Note system reset will return all custom system

configurations to defaults

4.2.3.3 Change Bluetooth Passcode

To prevent unauthorized access to instrument status, default instrument Bluetooth® passcode

code should be changed during commissioning. To change Bluetooth® passcode:

Configure Tab Bluetooth Passcode, enter new 6-digit passcode for instrument, select

OK.

Page 30

1100-2294 Rev 1 29

Instrument must be restarted for change to take effect. Home Tab Restart, will reboot

device.

Reconnect to instrument to confirm unlock code has been updated.

IMPORTANT: If custom passcode is forgotten, unlock code may be reset to

default value (123456) by resetting system to factory defaults. Refer to section

4.1.6 for system reset procedure. Note system reset will return all custom system

configurations to defaults.

4.2.3.4 Reset to factory defaults

Instrument configuration may be reset to factory defaults via the smartphone application:

Configure Tab Reset to factory default, select OK to confirm.

Instrument will automatically restart and disconnect from smartphone application.

WARNING: Resetting system to factory defaults will remove all custom system

configuration including unlock code and Bluetooth passcode. After system reset

custom unlock and Bluetooth passcodes should be configured to prevent

unauthorized access and reconfiguration of instrument.

4.2.3.5 Alarm Configuration

Low Alarm Setpoint

Value above which a low alarm condition occurs. Low alarm setpoint must be less than the high

alarm setpoint and greater than the low alarm limit. The low alarm limit is the fixed minimum limit

that is sensor–specific and not editable.

Range of acceptable setpoints is displayed when updating parameter. To update setpoint:

Configure Tab Alarm Low Alarm Setpoint, enter new setpoint, select OK to confirm.

IMPORTANT: In instruments with an oxygen sensor installed, low alarm

behavior operates in a depletion mode where gas measurements BELOW the

low alarm setpoint initiate a low alarm. This allows monitoring of oxygen

displacement and enrichment scenarios.

IMPORTANT: To prevent intermittent alarm operation at the setpoint due to

measurement noise this instrument implements hysteresis at the setpoint. Once

the alarm level is exceeded, the gas measurement must return a fixed

percentage below the alarm threshold before the alarm is disabled. Typical

hysteresis value is set at 5% of full scale however this is sensor specific and

non-editable.

Page 31

1100-2294 Rev 1 30

High alarm Setpoint

Value above which a high alarm condition occurs. High alarm setpoint must be less than the

sensor full scale range and greater than the low alarm setpoint.

Range of acceptable setpoints is displayed when updating parameter. To update setpoint:

Configure Tab Alarm High Alarm Setpoint, enter new setpoint, select OK to confirm.

IMPORTANT: To prevent intermittent alarm operation at the setpoint due to

measurement noise this instrument implements hysteresis at the setpoint. Once

the alarm level is exceeded, the gas measurement must return a fixed

percentage below the alarm threshold before the alarm is disabled. Typical

hysteresis value is set at 5% of full scale however this is sensor specific and

non-editable.

Alarm Latching

Enabling alarm latching will maintain alarm or fault condition even after the alarm or fault

condition is no longer active. When latched, the alarm or fault condition must be manually

acknowledged before the condition will be cleared. This allows transient alarm or fault

conditions to be identified.

If an alarm is latched, i.e. the condition has occurred but is no longer active, an

acknowledgement button will appear on the home screen. Select this button to acknowledge the

latched condition and clear the alarm or fault.

When disabled the alarm or fault status clears automatically as soon as the condition is no

longer active. To configure:

Configure Tab Alarm Alarm Latching, select enable/disable, select OK to confirm

4.2.3.6 Modbus Configuration

Address

Sets instrument address for connection to RS-485 Modbus interface. (Default: 1).

To set address:

Configure Tab Modbus Address, select 1-247, select OK to confirm

IMPORTANT: Ensure all instruments on RS-485 bus have been configured with

unique node addresses. If two instruments have been configured with same

address, bus contention will occur preventing communications with these

instruments via the RS-485 interface.

Page 32

1100-2294 Rev 1 31

Baud Rate

Sets instrument baud rate for connection to RS-485 Modbus interface. (Default: 9600 baud) To

set baud rate:

Configure Tab Modbus Baud Rate, select 9600/19200, select OK to confirm

Stop Bits

Sets instrument stop bits for connection to RS-485 Modbus interface. (Default: 1 stop bits) To

set number of stop bits:

Configure Tab Modbus Stop Bits, select 1 or 2, select OK to confirm

Parity

Sets instrument parity for connection to RS-485 Modbus interface. (Default: None) To set parity:

Configure Tab Modbus Parity, select None/Odd/Even, select OK to confirm

IMPORTANT: Stop bits must be set to 1 where parity is odd or even.

Enable 120Ω Termination

For optimal communication reliability, in RS-485 Modbus networks the last instrument physically

connected to the RS-485 bus must include a 120Ω termination resistor. This is to reduce the

potential for electrical signal reflection on long buses due to impedance mismatches.

Typically, this requires a physical resistor with the same characteristic impedance of the bus

cable to be installed on the bus.

MGS-400 instruments include this termination resistor on all instruments and allow this

termination to be enabled via this configuration setting without the need for an external physical

resistors. To enable this termination resistor:

Configure Tab Modbus Enable 120Ω Termination, select enable/disable, select OK

to confirm

IMPORTANT: Termination resistor should only be enabled on last instrument

physically connected to RS-485 bus. An external resistor should not be

connected where this is enabled on the instrument.

4.2.3.7 Output Configuration

Analog Output Range

Sets instrument analog output range. Available ranges: 1-5V (Default), 0-5V, 0-10V, 2-10V, 420mA. To set range:

Configure Tab Outputs Analog Output Range, select desired range, select OK to

confirm

Page 33

1100-2294 Rev 1 32

Buzzer

Enable or disable buzzer. Buzzer provides local audible alarm/fault indication. Buzzer is enabled

by default. To enable/disable buzzer:

Configure Tab Outputs Buzzer, select enable/disable, select OK to confirm

Relay Failsafe

Enable or disable Relay Failsafe operation. When configured for fail-safe operation, relays are

energized during normal operation. Fail-safe operation ensures relays are triggered in cases of

power failure at the instrument. In failsafe operation normally open and normally closed

terminals are reversed as indicated in Section 3.4.3.

Relays are configured as non-failsafe by default. To enable/disable relay failsafe:

Configure Tab Outputs Relay Failsafe, select enable/disable, select OK to confirm

Alarm Delay

Sets delay in minutes before instrument will indicate an alarm condition after low or high alarm

threshold has been exceeded. May be used to prevent short transient alarm conditions from

activating alarms. Alarm delays may be set for 0-15 minutes. Alarm delay is configured as 0

minutes by default. To set alarm delay:

Configure Tab Outputs Alarm Delay, enter desired delay in minutes (0-15), select

OK to confirm.

Analog Zero Adjust

Analog zero adjust applies a fixed offset to the analog output. This allows removal of small

errors in the output between the gas detection instrument and the measurement at the controller

due to cable resistance when using voltage outputs.

NOTE: MGS-408 controller uses digital interface, this analog adjustment is only

required where using third party controller using analog interface for gas

concentration and status monitoring.

To apply adjustment ensure instrument is outputting fixed voltage (default 1V at zero ppm or

use output test function to set specific voltage value), monitor remote measurement and adjust

zero offset until remote measurement matches expected voltage output.

Adjustment is limited to ±10% full scale To set analog zero adjustment:

Configure Tab Outputs Analog Zero Adjust, use slider to set desired offset

adjustment.

Alternatively, tap “Analog Zero Adjust (X.X%)” text and enter specific offset required (-10

to 10)

Page 34

1100-2294 Rev 1 33

Analog Span Range

Analog span range scales the FSD (full-scale deflection) of the analog output. The selected

range determines the equivalent gas measurement at the analog output maximum range.

Example: R134A 1000 ppm, 0-5V analog output. If Analog Span Range is set to 20%, the full

analog output range only covers the first 20% of the gas measurement range, i.e 0-200 ppm will

output 0-5V, above 200 ppm the output will be truncated to 5V.

Note, sensor resolution stays at the value for the max range.

Adjustment is limited to between 20%-100% FSD, Default is set to 100%. To set analog span

range:

Configure Tab Outputs Analog Span Range, use slider to set desired range

Alternatively, tap “Analog Span Range (X.X%)” text and enter specific range required.

Page 35

1100-2294 Rev 1 34

5. Care & Maintenance

5.1 Maintenance Intervals

Interval

Function

During

Commissioning

Check calibration.

Check LEDs for proper operation.*

Check for proper buzzer and relay operation.*

Check signal transmission to the BMS/BAS (central controller) if

connected.*

Every 6-12

Months**

Inspection by trained service personnel.

Check LEDs for proper operation.*

Check for proper buzzer and relay operation.*

Check signal transmission to the BMS/BAS (central controller) if

connected.*

Calibrate the sensor or contact Bacharach for sensor exchange with

factory‑ calibrated sensor.

As Required

Replace sensor module(s)

* Feature may be activated via Modbus commands or MGS-400 App.

** Typical maintenance frequency may vary by sensor type.

Page 36

1100-2294 Rev 1 35

Sensor Type

Maintenance Interval

Typical Sensor Lifetime

Electrochemical* 12 months

2-3 years

Catalytic Bead

Zero calibration -1-3 months

Span calibration - 6 months

5-7 years

Semiconductor*

6 months after commissioning

12 months thereafter

4-6 years

Infrared

12 months

5-7 years

* Sensors should be checked after exposure to significant concentrations of gas,

which can shorten the sensor lifetime and/or reduce its sensitivity.

5.2 Adjustments

5.2.1 Introduction

Adjustment of the detector must be performed at regular intervals as required by national

standards or regulations (e.g., EN 378, ASHRAE 15, BREEAM, etc.).

Breathing Hazard: Calibration gas MUST NOT be inhaled! See appropriate Safety Data

Sheets. Calibration gas should be vented into a fume hood or to the outside of the building.

Zero First, Then Span: For proper operation, never adjust the span before completing a zero

adjustment. Performing these operations out of order will cause faulty calibration.

IMPORTANT: Bacharach recommends calibrating detectors within the

application-specific condition and with target gas. This method of zeroing the

detector in the application environment and performing a target gas calibration is

more accurate. A surrogate gas calibration may only be performed as an

alternative if a target gas calibration is not possible.

IMPORTANT: The sensor should be fully stabilized (at least 2 hours, preferably

24 hours).

IMPORTANT: When entering the functions for zero or span adjustment, the

detector will automatically enter OFFLINE mode, and will remain OFFLINE until

either the OFFLINE mode is canceled by tapping the respective magnetic switch,

or the OFFLINE mode times out within 6 minutes (typical) after the adjustment

has ended.

Page 37

1100-2294 Rev 1 36

5.2.2 General Calibration Procedure

WARNING: The MGS-400 Gas Detector MAY NOT be in an alarm or fault

condition during calibration. Acknowledge any alarms or faults BEFORE

attempting to begin the calibration process.

WARNING: Except for CO2 or O2 sensors, calibration gas must be in a balance

of air, not nitrogen (N2).

IMPORTANT: Calibration and / or bump testing requires the MGS-400

calibration adapter kit (P/N: 6302-9990).

IMPORTANT: At elevations higher than 6,560’ (2,000 m), calibration will result in

a lower reading. Above 6,560’, the instrument should be calibrated in the

environment of operation.

1. Fit calibration adapter to the gas detector lid.

2. If using a variable flow regulator, adjust the gas flow to approximately 0.3 L/min.

5.2.3 Zero Adjustment

Ambient air can be used to zero the sensor instead of synthetic air only if the area is known to

be free of the target gas or any gas to which the sensor may be cross-sensitive. In this case, no

cylinder or calibration adapter is needed for the zero adjustment.

WARNING: The MGS-450 MAY NOT be in an alarm or fault condition during

calibration. Acknowledge any alarms or faults BEFORE attempting to begin the

calibration process.

WARNING: Except for CO2 or O2 sensors, ambient air may be used instead of

zero gas if the area is know to be free of the target gas or any gases to which

the sensor may be cross-sensitive.

IMPORTANT: Calibration and / or bump testing requires the MGS-400

calibration adapter kit (P/N: 6302-9990).

1. Begin zero adjustment:

a. MGS-400 App: Home Tab

Calibrate scan barcode on gas cylinder or manually

enter values for zero gas.

b. Manual: hold MAG#1 for >5-seconds. The LED will blink green-green-red when

the instrument is ready.

2. Apply zero gas (or ambient air per warning above).

3. Confirm the start of calibration:

a. MGS-400 App: press the Start Zero button.

Page 38

1100-2294 Rev 1 37

b. Manual: tap MAG#1 within 30-seconds or the instrument will time-out and return

to normal operation.

4. Complete zero adjustment:

a. MGS-400 App: app will countdown to completion. If calibration is successful,

proceed to Step 5. If calibration is unsuccessful, return to the Home screen and

press the Acknowledge button to clear the zero calibration fault.

b. Manual: the LED will blink green-red, green-red-red, green-red-red-red, etc. until

calibration is complete. To abort, hold MAG#1 for >5-seconds, turn off gas flow

and remove the calibration adapter. If calibration is successful (green LED),

proceed to Step 5. If calibration is unsuccessful (LED blinks orange @ 2 Hz), tap

MAG#1 to discard the calibration attempt.

5. Turn off gas flow from zero gas.

6. Replace zero gas with calibration gas in preparation for span adjustment.

5.2.4 Span Adjustment

WARNING: Except for CO2 or O2 sensors, calibration gas must be in a balance

of air, not nitrogen (N2).

IMPORTANT: At elevations higher than 6,560’ (2,000 m), calibration will result in

a lower reading. Above 6,560’, the instrument should be calibrated in the

environment of operation.

1. Begin span adjustment:

a. MGS-400 App: scan barcode on gas cylinder or manually enter values for

calibration gas.

b. Manual: hold MAG#2 for >5-seconds. The LED will blink green-green-orange

when the instrument is ready.

2. Apply calibration gas at the concentration listed on the calibration gas concentration

label (located on top of the instrument).

Part Number

Serial Number

Sensor Type

Maximum Range

3. Confirm the start of calibration:

a. MGS-400 App: press the Start Span button.

b. Manual: tap MAG#2 within 30-seconds or the instrument will time-out and return

to normal operation.

4. Complete span adjustment:

a. MGS-400 App: app will countdown to completion. If calibration is successful,

proceed to Step 5. If calibration is unsuccessful, return to the Home screen and

press the Acknowledge button to clear the span calibration fault.

Page 39

1100-2294 Rev 1 38

b. Manual: the LED will blink green-orange, green-orange-orange, green-orange-

orange-orange, etc. until calibration is complete. To abort, hold MAG#2 for >5seconds, turn off gas flow and remove the calibration adapter. If calibration is

successful (LED blinks green-orange-red), proceed to Step 5. If calibration is

unsuccessful (LED blinks orange @ 2 Hz), tap MAG#2 to discard the calibration

attempt.

5. Turn off gas flow from calibration gas and remove the calibration adapter.

6. Allow sensor to recover / stabilize before the instrument returns to normal operation

(green LED).

5.2.5 System Bump Test

IMPORTANT: The manufacturer of this product requires that a bump test or

calibration be performed following installation to verify instrument functionality.

A bump test is a live test of the system to verify that the detector responds to gas and all

connected alarm devices, BMS, etc. are operating accordingly. It is recommended that all

involved persons are informed about the test and certain alarms might have to be inhibited

(e.g., shutdown valves, notification of authorities, etc.).

1. Connect adapter and gas cylinder according to the instructions in the General

Calibration Procedure.

2. If desired, disable / silence external annunciators (e.g., shutdown valves, notification of

authorities, etc.):

a. MGS-400 App: Home Tab Calibrate Bump toggle TAKE OFFLINE to

disable communications to external devices.

b. Manual: Inform building personnel of test so that external devices can be

disabled / silenced.

3. Apply a sufficiently high concentration of the target gas to trigger alarms, but NOT pure

refrigerant or hydrocarbons (e.g., do not use a butane lighter).

4. Once thresholds have been exceeded, relays should activate, digital outputs should

transmit the gas concentration and:

a. MGS-400 App: gas concentration should be displayed, the instrument status

should be “LOW ALARM” or “HIGH ALARM” and alarms states should be “ON.”

b. Manual: LED status should display “LOW ALARM” or “HIGH ALARM.”

5. Turn off gas flow and remove the calibration adapter.

6. Allow sensor to recover / stabilize before the instrument returns to normal operation

(green LED).

Page 40

1100-2294 Rev 1 39

5.3 Troubleshooting

5.3.1 Hexadecimal Format

All fault codes can be retrieved through the Modbus interface and are shown in hexadecimal (hex)

format. A hex digit can represent multiple codes as shown below:

Hex

Code

Equivalent

Error Code(s)

0 0 1 1 2

2

3

1+2 4 4 5 1+4

Hex

Code

Equivalent

Error Code(s)

6

1+2+3

7

1+2+4

8

8

9

1+8

A

2+8

B

1+2+8

Hex

Code

Equivalent

Error Code(s)

D

1+4+8

E

2+4+8

F

1+2+4+8

5.3.3 Fault Codes

NOTICE: If a sensor fault occurs during a gas alarm condition, then the fault

overrides the alarm condition.

Sensor faults may be decoded using the following table. Note that several faults may be reported

at the same time For example, fault code “00000003” is a combination of fault codes 00000001

(No sensor signal) and 00000002 (Voltage out of specification 1V).

NOTICE: If a “last fault” attribute indicates that a fault has occurred at some

point in time, but the corresponding “current fault” attribute shows no fault, then

the problem has self-healed and no service action is required.

Page 41

1100-2294 Rev 1 40

Fault Bit

System Fault

Possible Causes

Required Action(s)

0x00000001

Software fault

Firmware error (e.g.

unexpected state)

Power-cycle.

If it re-occurs, call product

support

0x00000002

Voltage out of

specification 1V

Voltage rail out of range

Call product support

0x00000004

Voltage out of

specification 3.3V

Voltage rail out of range

0x00000008

Voltage out of

specification 5V

Voltage rail out of range

0x00000010

Voltage out of

specification 5.4V

Voltage rail out of range

0x00000020

Voltage out of

specification 12V

Voltage rail out of range

0x00000040

Voltage out of

specification VIN

Voltage rail out of range

0x00000080

System Flash Memory

Read Fault

Error reading from

internal Flash

Power-cycle.

If it re-occurs, call product

support

0x00000100

System Flash Memory

Write Fault

Error writing to internal

Flash

0x00000200

System Flash Memory

CRC fault

Error in internal Flash

CRC

0x00000400

System Invalid

Configuration

Error in system

configuration

0x00000800

GPIO fault

Error detected on GPIO

pin

Call product support

0x00001000

Modbus Fault

Error detected in Modbus

Communications

Power-cycle.

If it re-occurs, call product

support

0x00002000

Analog Output Fault

(MGS-450 Only)

Error updating DAC value

0x00004000

Bluetooth Fault

Error detected in

Bluetooth module

0x00008000

Stuck switch

Magnetic and/or Tactile

switch activated for > 1

minute

Call product support

0x00010000

Sensor Element Out

Cannot detect sensor

element

Check sensor connection

0x00020000

Sensor Element Fault

Fault detected in sensor

element

Replace sensor nodule

0x00040000

Sensor ADC Sensor

Read Fault

Cannot read from sensor

ADC

Check sensor

connection/Replace Sensor

Module

0x00080000

Sensor ADC Current

Read Fault

Cannot read from current

ADC

0x00100000

Sensor AFE Read Fault

(EC only)

Cannot read from EC

sensor AFE

0x00200000

Sensor AFE Write Fault

(EC only)

Cannot write to EC

sensor AFE

0x00400000

Sensor AFE Status Fault

(EC only)

Error in EC sensor AFE

Page 42

1100-2294 Rev 1 41

0x00800000

Sensor EEPROM Read

Fault

Error in reading from

sensor EEPROM

Power-cycle / check sensor

connection / replace sensor

module

0x01000000

Sensor EEPROM Write

Fault

Error in writing to sensor

EEPROM

Call product support

0x02000000

Sensor EEPROM CRC

Fault

Error in CRC from sensor

EEPROM

Power-cycle / replace sensor

module

0x04000000

Sensor EEPROM

Configuration Fault

Error in sensor EEPROM

data

Replace sensor module

0x08000000

Sensor UART Read

Fault

Cannot read from sensor

UART

Check sensor connection /

replace sensor module

0x10000000

Sensor Temperature

Fault

Temperature cannot be

read or is out of

specification

Ensure sensor is operating

within specified temperature

range / check sensor

connections

0x20000000

Negative Gas

Concentration Fault

Sensor output has drifted

too negative

Initiate zero calibration

(Via App / Hold MAG#2)

0x40000000

Zero Calibration failure

Zero calibration failed

Acknowledge failed

calibration

(Via App / Hold MAG#1)

0x80000000

Span Calibration failure

Span calibration failed

Acknowledge failed

calibration

(Via App / Hold MAG#2)

5.4 Sensor Maintenance

CAUTION: This product uses semiconductors which can be damaged by

electrostatic discharge (ESD). When handling the PCB, care must be taken so

that the electronics is not damaged.

5.4.1 Replacing the Sensor Module

MGS-400 gas detectors are compatible with pre-calibrated sensor modules which maintain the

sensor’s gas type and calibration information. To replace the gas detector’s sensor module:

1. Power-down the gas detector.

2. Using a 5/32” (4mm) hex key / allen wrench (not included), remove the lid and

disconnect the ribbon cable from the sensor module.

3. Remove installed sensor module from lid by holding onto the housing and turning

counter-clockwise 90°. Take care not to apply excessive force to the sensor module’s

circuit board. When the square tab of the sensor housing is aligned with the lock icon,

firmly pull the module to remove it from the housing.

4. Install the new sensor module by aligning the square tab with the lock icon before firmly

pressing it into the enclosure. Taking care not to apply excessive force to the sensor

module’s circuit board, rotate the sensor module clockwise 90° (or until the triangle icon

aligns with the lock icon on the lid).

5. Connect the ribbon cable (to the sensor module and transmitter) and close the lid.

Page 43

1100-2294 Rev 1 42

6. Ensure gasket is aligned correctly (IP66 versions only) and tighten the lid using the

supplied hardware in an “X” pattern. Tightening torque should be limited to hand tight

and should be uniform.

7. Power-up the gas detector.

8. After start-up sequence has finished, check sensor response (bump test).

5.5 Cleaning the Instrument

Clean the detector with a soft cloth using water and a mild detergent. Rinse with water. Do not

use any alcohols, cleaning agents, sprays, polishes, detergents, etc.

Page 44

1100-2294 Rev 1 43

6. Additional Information

6.1 Sensor Principle

6.1.1 Electrochemical Sensors

Electrochemical sensors measure the partial pressure of gases under atmospheric conditions.

The monitored ambient air diffuses through a membrane into the liquid electrolyte in the sensor.

The electrolyte contains a measuring electrode, a counter-electrode and a reference electrode.

An electronic “potentiostat” circuit ensures a constant electrical voltage between measuring

electrode and reference electrode. Voltage, electrolyte, and electrode material are selected to suit

the gas being monitored so that it is transformed electrochemically on the measuring electrode

and a current flows through the sensor. This current is proportional to the gas concentration. At

the same time, oxygen from the ambient air reacts at the counter electrode electrochemically. The

current flowing through the sensor is amplified electronically, digitized and corrected for several

parameters (e.g., the ambient temperature).

6.1.2 Catalytic Bead Sensors

A catalytic bead sensor measures the partial pressure of combustible gases and vapors in

ambient air. It uses the heat-of-combustion principle.

The monitored air diffuses through the sintered metal disc into the sensor. The mixture of

combustible gases, vapors, and air are catalytically combusted at a heated detector element

(called a pellistor). The oxygen content in the air must be greater than 12 Vol%. Due to the

resulting heat-of-combustion, the temperature of the detector element rises. This increase in

temperature causes a change of resistance in the detector element, which is proportional to the

concentration of the mixture of combustible gases and vapors in the monitored air. In addition to

the catalytically active detector element, there is a compensator element. Both elements are parts

of a Wheatstone bridge. Thus environmental effects like changes in ambient temperature or

humidity are almost entirely compensated.

IMPORTANT: Certain substances in the atmosphere to be monitored may impair

the sensitivity of the sensors. Such substances include, but are not limited to:

Polymerizing substances such as acrylonitrile, butadiene and styrene.

Corrosive compounds such as halogenated hydrocarbons (releasing

halogens such as bromine, chlorine or fluorine when oxidized) and

halogen hydride acids as well as acidic gaseous compounds such as

sulfur dioxide and nitrogen oxides.

Catalyst poisons such as sulfurous and phosphorous compounds,

silicon compounds (especially silicones), and metal-organic vapors.

Page 45

1100-2294 Rev 1 44

It may be necessary to check the calibration if the sensor has been exposed for a long time to a

high concentration of flammable gases, vapors, or the above-mentioned contaminating

substances.

The nature of catalytic bead sensor technology means that sensor drift may typically be up to

±5% LEL per month. Instruments using these sensors should be zeroed regularly following the

instructions in section 5 of this manual.

6.1.3 Semiconductor Sensors

Semiconductor or metallic oxide sensors (MOSs) are among the most versatile of all broad-range

sensors. They can be used to detect a variety of gases and vapors in low ppm or even combustible

ranges. The sensor is made up of a mixture of metallic oxides. They are heated to a temperature

between 150º and 300º C depending on the gas(es) to be detected. The temperature of operation

as well as the “recipe” of mixed oxides determines the sensor selectivity to various toxic gases,

vapors, and refrigerants. Electrical conductivity greatly increases as soon as a diffusion process

allows the gas or vapor molecules to come in contact with the sensor surface. Water vapor, high

ambient humidity, temperature fluctuations, and low oxygen levels can result in higher readings.

IMPORTANT: Certain substances in the environment to be monitored may

impair the sensitivity of the sensors:

Materials containing silicone or silicone rubber/putty

Corrosive gases such as hydrogen sulfide, sulfur oxide, chlorine, hydrogen

chloride, etc.

Alkaline metals, salt water spray.

6.1.4 Infrared Sensors

The infrared (IR) gas sensor is designed to measure the concentration of combustible gases and

vapors in the ambient air. The sensor principle is based on the concentration-dependent

absorption of infrared radiation in measured gases.

The monitored ambient air diffuses through a sintered metal material into the enclosure of an

optical “bench”. The broadband light emitted by an IR source passes through the gas in the optical

bench and is reflected by the walls from where it is directed towards a dual-element detector. One

channel of the detector measures the gas-dependent light transmission, while the other channel

is used as a reference. The ratio between measurement and reference signal is used to determine

the gas concentration. Internal electronics and software calculate the concentration and produce

an output signal.

Page 46

1100-2294 Rev 1 45

6.2 Disposing of the Instrument

6.2.1 Disposing of the Electrical & Electronic Equipment

EU-wide regulations governing the disposal of electrical and electronic appliances which have

been defined in the EU Directive 2012/19/EU and in national laws have been effective since

August 2012 and apply to this device.

Common household appliances can be disposed of using special collecting and recycling

facilities. However, this device has not been registered for household usage. Therefore it must

not be disposed of through these channels. The device can be returned to your national

Bacharach Sales Organization for disposal. Please do not hesitate to contact Bacharach if you

have any further questions on this issue.

6.2.2 Disposing of Sensors

Dispose of sensors in accordance with local laws.

DANGER: Do not dispose of sensors in fire due to the risk of explosion and

resulting chemical burns.

WARNING: Do not force open electrochemical sensors.

WARNING: Observe the applicable local waste disposal regulations. For

information, consult your local environmental agency, local government offices or

appropriate waste disposal companies.

6.3 Sensor Specifications

Sensor

Information

Electro-Chemical (EC)

Semi-

Conductor

(SC)

Catalytic

Bead (CAT)

Infrared (IR)

Sensor Life

(Typical)

2 to 3 years

5 to 8 years

5 years

5 years

Temperature

Range

NH3 100 / 1,000 ppm: -40 to 40° C

NH3 5,000 ppm: -20 to 40° C

CO 500 ppm: -40 to 50° C

NO2 20 ppm: -20 to 40° C

O2 30% Volume: -20 to 50° C

-40º to 50º C

-40º to 50º C

-40º to 50º C

NH3 100 / 1,000 ppm: -40 to 104° F

NH3 5,000 ppm: -4 to 104° F

CO 500 ppm: -40 to 122° F

NO2 20 ppm: -4 to 104° F

O2 30% Volume: -4 to 50° F

-40º to 122º

F

-40º to 122º

F

-40º to 122º

F

Page 47

1100-2294 Rev 1 46

6.4 Modbus Registers

IMPORTANT: If items span two registers (e.g., 1005 and 1006), then the

registers are “long” or “float” data types. Otherwise, the registers are integer data

types or ASCII.

To unlock the Modbus registers:

Write the correct unlock code to Modbus register 2100 to allow changes to be made to

the system configuration. The unlock code is a 4 digit decimal value from 0000-9999

(default “1234”). System parameters which require the system be unlocked are indicated

in the below table with a lock symbol (🔒).

6.4.1 Integration - Dynamic Sensor Data

Input Register (Function 04 Read)

1094

Signed Raw Gas

Concentration

(PPM/PPB/VOL/LEL)

Signed Raw Gas Concentration PPM or % VOL or %