Gas Detector

Instal l a tion and Oper ation Manual

Instruction 6309-9000

Revision 4 – O ctober 2016

Product Leadership • Training • Servi ce • Reliability

MGS-150 Manual

www.mybacharach.com/rmaform/

Fax: 724-334-5001

Bacha rach, Inc.

ATTN: Service Department

Mur c o L t d – A Bacha rach Compa ny

ATTN: Service Department

ATTN: Service Department

BA CHA RA CH, I NC. WA RRANTS THIS INST RUMENT, EX CL UDI NG S ENSO RS, TO BE

FREE FRO M DEFECTS IN MATERIALS AND WORKMANSH I P F O R A P ER I OD OF ONE

YEAR FROM THE DATE OF PURCHASE BY THE ORIGINAL OW N E R. TH E S E NS O RS

HAVE A WARRANTY PERIOD OF ONE YEAR FROM T HE DA T E O F PURCHA SE. IF

TH E PR ODU CT S HOUL D B E CO ME D EFEC T IV E W IT H IN T HIS WA RRA NTY PE RIOD,

WE WILL REPAIR O R REPLACE IT AT OUR DISCRETION.

THE WAR RA NTY S TA TUS MA Y BE A FFE CTE D IF THE INSTRUMENT HAS NOT BEEN

US E D AND MAI NTA IN E D PER THE INSTRUCTIONS IN TH I S MA N UA L O R HAS BEEN

ABUSED, DA MAGED, OR MODIFIED I N ANY WAY. THIS INS TR U M ENT IS O N LY TO BE

USED FOR PURPOS ES STAT ED HEREIN. THE MANUFA CTU R E R IS NOT L IABLE FOR

AUXILI ARY INTERFACED EQ U I P M ENT OR CO NS EQ U ENTIAL DAMAGE.

DUE TO ONGOING RESEARCH, DEVELOPMENT, AND PRODUCT TESTING, THE

MA NUFA CT UR ER R ES ERV ES T HE R IG HT TO CHA NG E S PECI FICAT IONS WIT HOUT

NOTICE. THE INFORMATION CONTAINED HEREIN IS BASED ON DATA CONSIDERED

A CCURA T E. HOW EV ER, NO WARRANTY IS EXPRESS ED O R IM PL IE D REGA RDING

THE ACCURACY OF THIS DATA.

A LL GOODS MUST B E SHIPPE D TO THE MAN UFA CTURER BY PREPA ID FR EIGHT.

ALL RETURNED GOODS MUST BE PRE-AUTHORIZ ED BY OBTAINING A RETURN

ME RC HAN D ISE AUT HOR IZ A TIO N (R MA ) NU MBE R. CO NTA CT THE MA NUFA CT URER

FOR A NUMBER AND PROCEDURES REQUIRED FOR PRO D U CT T RA NS PO R T.

BACHARA CH, INC. MAINTAINS AN INSTRUMENT SERVICE FACILITY AT THE

FA CT O RY. S OM E BA CHA RACH DISTRIBUTORS / AGENTS MAY ALSO HAVE REPA IR

FACILITIES, HOWEVER, BACHARACH ASSUMES NO LIABILITY FOR SERVICE

PE RF O R ME D B Y A NY O NE O T H ER T HAN B A CHARACH PERSONN EL. R EPAIRS ARE

WARRANTED FOR 90 DAYS AFTER DATE OF SHIPMENT (SENSORS, PUMPS,

FILTERS AND BATTERIES HAVE INDIVIDUAL WARRANTIES). SHOULD Y OUR

INSTRUMENT REQUIRE NON-WARRANTY REPAIR, YOU MAY CONTACT THE

DISTRIBUTOR FROM WHOM IT WAS PURCHASED OR YOU MAY CONTACT

BACHARA CH D IR EC TL Y .

IF BA CHA RA CH IS TO DO THE REPA IR WORK, SEND THE INS TRU MENT , PREPAID,

TO BACHARACH, INC. AT THE FOLLOWING ADDRESS.

WARRANTY POLICY

SERVICE POLICY

Location Contact Information Shipping Address

United States

Irela nd

Canada

2 6309-9000 Rev 4

Phone: 724-334-5000

Toll Free: 1-800-736-4666

Phone: +353 1 284 6388

Fax: +353 1 284 6389

Phone: 905-470-8985

Fax: 905-470-8963

Email: support@BachCan.ca

621 Hunt Valley Circle

New Kensington, P A 15068, USA

114A Georges Street Lower

Dun Laoghai re, Dubli n, Irela nd

Bacharach of Canada

20 Amber Street Unit #7

Markham, Ontario L3R 5P4, Canada

ALWAY S INCLUDE Y O UR RMA #, A DDRESS , T ELEPHONE NUMBER, CONTA CT

NAME, SHIPPING/BILLING INFORMATION AND A DESCRIPTION OF THE

DEFECT AS YOU PERCEIVE IT. YOU WILL BE CONTACTED WITH A COST

ESTIMA TE FO R EX PECT ED R EPA IRS PRIO R TO THE PERFO RMA NCE OF A NY

SERV ICE WORK. FOR L IABILITY REASONS, BACHA RACH HA S A POLICY OF

PERFORMING ALL NEEDED REPAIRS TO RESTORE THE INSTRUMENT TO

FULL OPERA TING CONDITION.

PRIOR TO SHIPPING EQUIPMENT TO BACHARACH, CONTACT OUR OFFICE

FOR AN RMA # ( RETURN ED MERCHANDISE AUTHORIZATION ). ALL RETURNE D

GOODS M UST BE ACCOMPANIED WITH AN RMA NUMBER.

PA CK THE EQUIPMENT WELL (IN ITS ORIGINAL PA CKING IF POSSIBLE), AS

BACHA RA CH CA NNOT BE HELD RESPON S I BL E FO R A NY DA MA G E INCURR ED

DURING SHIPPING TO OU R FA CILITY.

NOTICES

COPYRIGHTS: THIS MANUAL IS SUBJECT TO COPYRIGHT PROTECTION; ALL

RIGHTS ARE RESERVED UNDER INTERNATIONAL AND DOMESTIC

COPY RIGHT LAWS. THIS MA NUAL MAY NOT B E C OP IED O R T RA NS LA TED, IN

WHOLE O R IN PA RT, IN ANY MANNER OR FORMA T, WITHOUT THE WRITTEN

PER MI S S IO N OF BAC HARA CH, INC.

ALL SOFTWARE UTILIZ ED AND/ OR DISTRIBUT ED BY BACHARACH IS SUBJECT

TO COPY RIGHT PROTECTION. ALL RIGHT S ARE RESERV ED. NO PARTY MAY

USE OR COPY SUCH SOFTWARE IN ANY MANNER OR FORMAT, EXCEPT TO

TH E EX TEN T T HAT BA CHARACH GRANTS THEM A LICENSE TO DO SO. IF THIS

SOFTWA RE IS BEING LOADED ONTO MORE THAN ONE COMPUTER, EXTRA

SOF T WAR E L IC ENS ES MU ST BE PURCHASED.

MGS-150 Manual

TECHNI CIAN USE ONL Y

THIS UNIT MUST BE INS TALLED BY A SUITA BL Y Q UALIFIED TECH NICIA N W H O

WILL INSTALL THIS UNIT IN A CCO RDA NCE WITH THESE INSTRUCTIONS AND

THE STANDARDS IN THEIR PARTICULAR INDUSTRY/COUNTRY. OPERATORS

OF THE UNIT SHOULD B E A WAR E O F THE R EGU LATIONS AND STANDARDS IN

THEIR INDUSTRY/COUNTRY FOR THE OPERATION OF THIS UNIT. THESE

NO TES A RE O NLY INTEN DED A S A G UID E AN D THE MA NUFA CTURE R B EA RS

NO RESPONSIBILITY FOR THE INSTALLA TIO N OR OP E RA TI ON O F T H I S UNIT.

FAILURE TO INS TALL AND OPERA TE THE UNIT IN A CCO RDANCE WITH THESE

INSTRUCTIONS AND WITH INDUSTRY GUIDELINES MAY CAUSE SERIOUS

INJURY INCLUDING DEATH A ND THE MANUFACTURER WILL NOT BE HELD

RES PO NS I BL E IN TH IS REGARD.

6309-9000 Rev 4 3

MGS-150 Manual

Ta ble of Co nt ent s

Section 1.

Overview ................................................................................................... 5

1.1. Genera l Infor mati on ............................................................................................... 5

1.2. Technical Specifications ......................................................................................... 6

Sect ion 2. Installatio n and Wiring........................................................................... 8

2.1. Genera l Pla cement Gui del i nes ............................................................................. 9

2.2. Compon ents a nd Acces s Overview ...................................................................... 9

2.3. Machi nery Rooms ................................................................................................. 12

2.4. Refrigera ted Spa ces .............................................................................................. 14

2.5. Chi ll ers..................................................................................................................... 14

2.6. Air Conditioning (Direct Systems VRF/VRV) ..................................................... 15

2.7. Remote S ensor Hea d I nstalla ti on....................................................................... 16

Section 3. Housing D imension s ............................................................................. 17

Section 4. Operation and Stabilization ................................................................ 21

Section 5. Configurations........................................................................................ 22

5.1. O ver vi ew ................................................................................................................. 22

5.2. Adjus ting the Alarm Set Point............................................................................. 22

Section 6. Function al Tests an d Calibration ....................................................... 23

6.1. Introduction ........................................................................................................... 23

6.2. Bump Testing ......................................................................................................... 25

6.3. Calibration Overview ............................................................................................ 28

6.4. Calculating Calibration Voltage........................................................................... 29

6.5. Calibrating Semiconductor (SC) Sensors ........................................................... 29

6.6. Calibrating Electrochemical (EC) Sensors ......................................................... 30

6.7. Calibrating Infrared (IR) Sensors......................................................................... 30

Section 7. Troubleshooting .................................................................................... 31

EU Declaration of Conf ormity..................................................................................... 32

4 6309-9000 Rev 4

Section 1. Overview

1.1. General Information

The MGS -150 is a st ate-of-the-art fixe d gas detec to r which c an d etec t a

wide rang e of different gas es. The gas sensors can be used on a standalone basis or int egrated into Control s or Bui l di ng Mana gement Sy stem s

(BMS).

The MGS-150 c an be us ed:

• in new buildings/areas that requi re contin uous monitori ng with

high t ech gas sensor transm i tters .

• to add gas detect i on solut ions to an exi s ting s ystem.

Typical detec tion applic ations i nc l ude the det ecti on of:

• refriger ant gases

• com bus tible gas es

• tox i c gases and/or volatile organic com pou nds.

The MGS Controll er is an opti onal de vice used t o remotely monitor up t o

six MGS-150 devic es. Fo r more inform ati on, refer to t he MGS Control ler

manual (P/N 6709-9000).

Electrochemical a nd Infrared Board Semiconductor Board

MGS-150 Manual

Figure 1. MGS-150 Sensor Board (EC, I R, and SC)

6309-9000 Rev 4 5

MGS-150 Manual

Monitoring LEDs

Po we r: Green LED Ala rm: Red LED

Audible Alarm

Bu zze r, ena ble/dis able

Ana lo g O u tputs

4-20 mA; 0-5 V; 0-10 V; 1-5 V ; 2-10 V

T empe ra tu re

3.35” x 5.59” x 2.09”

6.3 oz

6.89” x 8.9” x 3.29”

1 lb 9 oz

6.89” x 6.1” x 3.29”

2 lb 10 oz

6.89” x 4.9” x 3.29”

1 lb 4 oz

140 x 180 x 90 mm

2234 g

Approvals

CE; UL/CSA/IEC/EN 61010-1; EN 55011

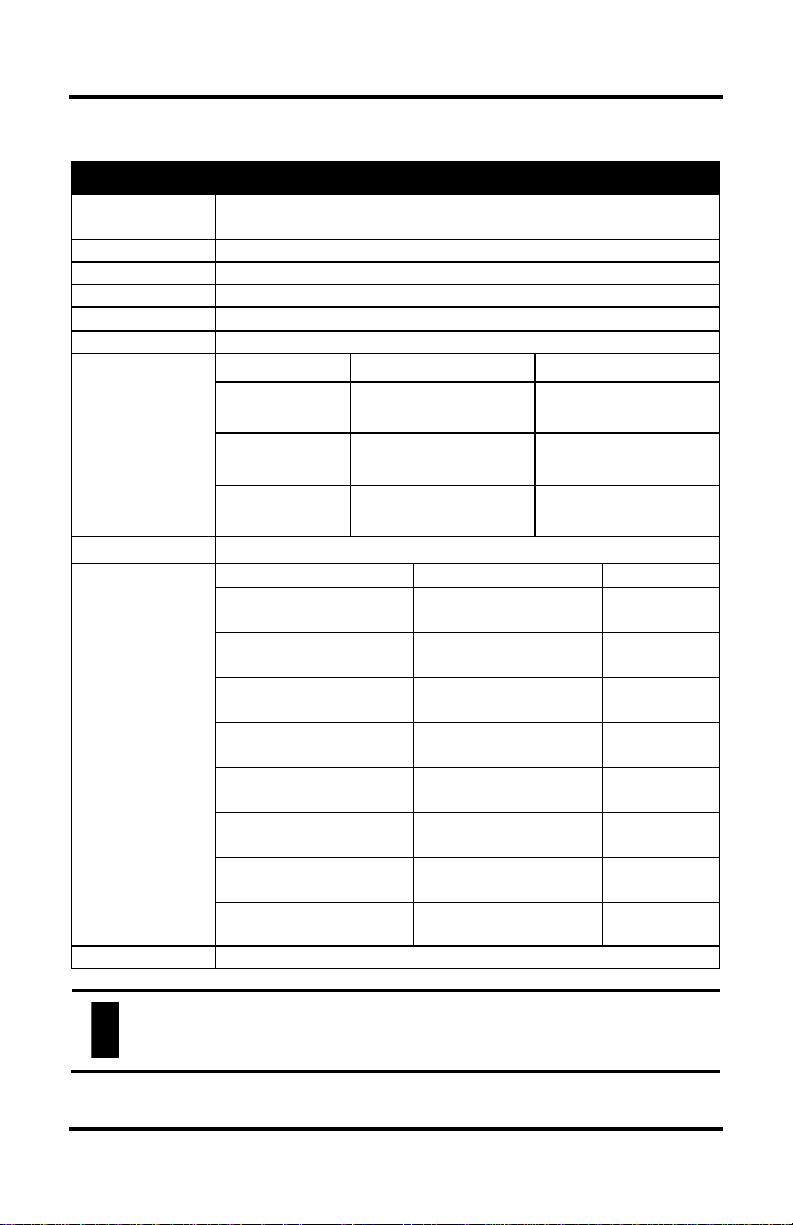

1.2. Technical Specif i cations

Specification Description

Power Suppl y 12-24 VDC, 12-24 VAC 50/60 Hz, 2 W max.

Po we r co nsump tion (12V): 60mA (EC), 153mA (SC), 136mA (IR)

Rela y Outputs 1 rela y ra ted 1 A @ 24 VAC/VDC; Dela y: 0, 1, 5, o r 10 minutes

I P R a tin g I P41 (sta ndard); I P66 (op ti onal)

Ra tin g

Humidity Rating

Di mensions/

W ei gh ts pe r

Enclosure Type

(see Note

belo w)

Sensor IP41 Hous ing IP66 Hous ing

I R and S C (all)

EC (all but NH3)

EC (NH3)

-4° to 122° F

(-20° to 50 ° C)

-4° to 104° F

(-20° to 40 ° C)

-4° to 104° F

(-20° to 40 ° C)

-40° to 122° F

(-40° to 50 ° C)

-4° to 104° F

(-20° to 40 ° C)

-40° to 104° F

(-40° to 40 ° C)

0-95% non-condensing

Hous ing Di mensions Weight

IP41 (sta nda rd)

IP66 (optional)

86 x 142 x 53 mm

6.89” x 6.5” x 3.29”

175 x 165 x 82 mm

1 lb 6 oz

180 g

629 g

w/ Spla sh Gua rd

w/ Re mote Se nso r

w/ Exd Sensor Head

w/PRV Sensor Head

w/ Airflow/Duct

Exd (ATE X onl y)

NOTE: Enc l osures listed abo ve are for all m odels/

configurations except IR H al oge n, which use the standa rd IP41

6 6309-9000 Rev 4

encl osure wi t h a different t em perature rating.

175 x 225 x 82 mm

6.89” x 6.1” x 3.29”

175 x 155 x 82 mm

175 x 155 x 82 mm

6.89” x 6.1” x 3.29”

175 x 155 x 82 mm

175 x 125 x 82 mm

5.51” x 7.09” x 3.54”

700 g

1 lb 11 oz

790 g

1185 g

2 lb 0.3 oz

916 g

578 g

4 lb 15 oz

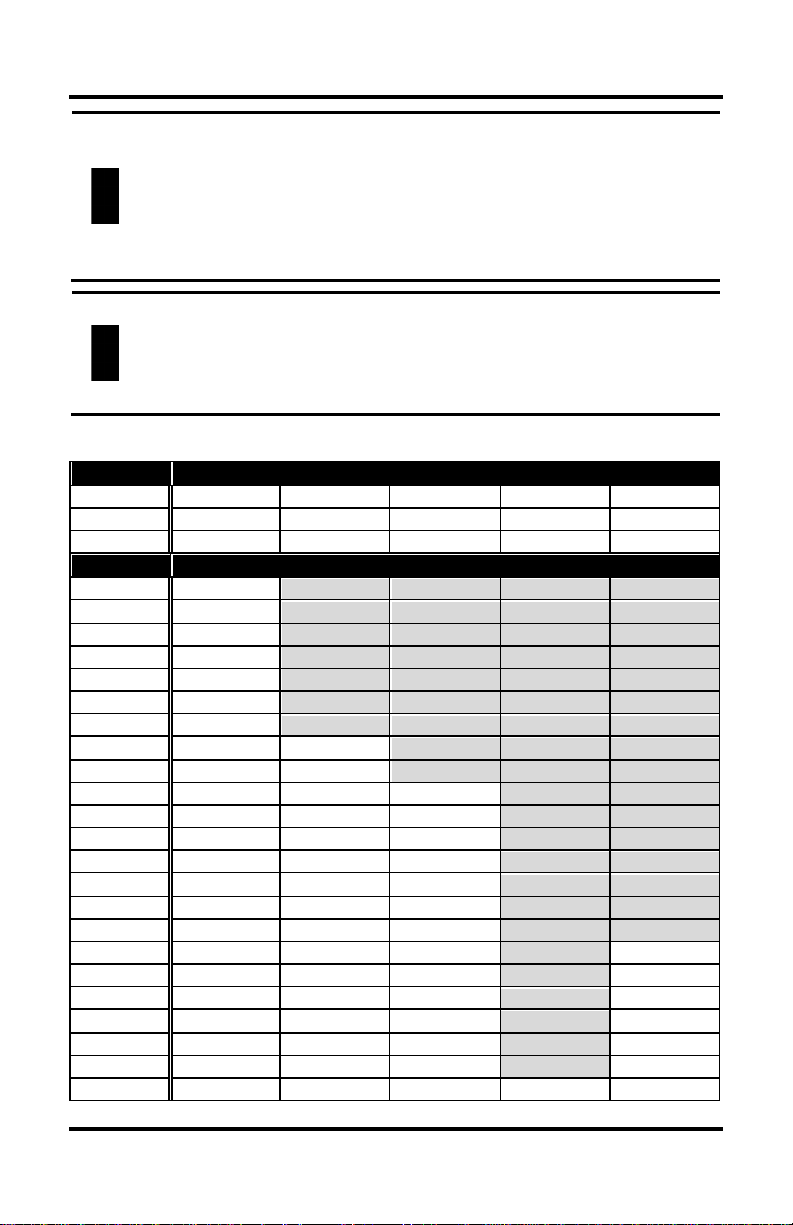

Units

Duct Si ze

Inches

12 x 12

12 x 24

18 x 18

24 x 24

24 round

Feet

1 x 1

1 x 2

1.5 x 1.5

2 x 2

Pi x 1 x 1

Ar ea ( ft2)

CFM

Ft/min (Based on CFM and Duct Size)

3400

3400

n/a

n/a

n/a

n/a

3800

3800

n/a

n/a

n/a

n/a

5000

5000

2500

n/a

n/a

n/a

5400

5400

2700

n/a

n/a

n/a

6400

6400

3200

2844

n/a

n/a

6800

6800

3400

3022

n/a

n/a

7000

7000

3500

3111

n/a

n/a

8400

8400

4200

3733

n/a

2675

8800

8800

4400

3911

n/a

2803

9800

9800

4900

4356

n/a

3121

10000

10000

5000

4444

2500

3185

NOTE: Th e hazardous ar ea EX d Ga s Monitor product s are

desi gned with individuall y cert i fied EXd main housing

encl osures and certi fied EXD rem ote or attac hed s ensor

encl osures. Th e m ai n housi ng enc l osure and it s PCB

assembly are also EXd certifie d, but t he final EXd Ga s Monitor

assembli es (main encl osu re and/or senso r as sembly) a re not

currentl y EXD ce rtifie d, but are pe ndi ng ad di t i onal t esti ng.

MGS-150 Manual

NOTE: Fo r detecti on of R449A or R4 50A , the maximum l i near

ran ge of 500 ppm equal s 50% of the rang e of the analo g output

(e.g., 500 ppm = 12 mA , when using 4-20m A out put ). Data

abo ve t hi s range should be di scarde d as invalid. The al arm set

point m ust not be adjus ted hi gher than 50 0 ppm.

Supported CFM/Duct Sizes for the Du ct Moun t Hou sing

1 2 2.25 4 3.14

2800 2800 n/a n/a n/a n/a

3000 3000 n/a n/a n/a n/a

4000 4000 n/a n/a n/a n/a

4400 4400 n/a n/a n/a n/a

4800 4800 n/a n/a n/a n/a

5800 5800 2900 2578 n/a n/a

6000 6000 3000 2667 n/a n/a

7400 7400 3700 3289 n/a n/a

7800 7800 3900 3467 n/a n/a

8000 8000 4000 3556 n/a 2548

9000 9000 4500 4000 n/a 2866

9400 9400 4700 4178 n/a 2994

6309-9000 Rev 4 7

MGS-150 Manual

Section 2. Install ation and Wiring

WARNING: Explos i on hazard! Do not m ount the MGS i n an

are a t hat may contain flammable li qui ds, vapo rs , or aerosols .

Ope rat i on of any electric al equipment i n s uch an envir onm ent

consti t utes a safety hazard.

CAUTION: The M GS cont ains sensi ti ve electroni c

components that can be eas i l y damage d. Do not touch nor

dis turb any of thes e c omponent s .

CAUTION: For AC-powere d con figurati ons, ensure that the

AC neutral sup pl y line is not used as the ground r eference fo r

the analog output s.

NOTE: Th e m ounti ng location of t he m onit or sh ould all ow it t o

be easi l y accessible fo r vis ual m oni t oring an d servi c i ng.

NOTE: The mo ni t or m ust be connected by a m ark ed, suitabl y

loc ated and eas i l y reached switch or circui t-breaker as means

of discon nec tion.

NOTE: Connect monitor powe r and si gnal ing term i nal s usi ng

wiring that compli es with local electrical c odes or regulati ons

for t he i ntended application.

NOTE: This i nstrument can be equipped wi t h a sem i c onduc tor

sensor for t he detecti on of refrig erant, com bus tible and VOC

gases. Semi conduct or s ens ors a re not gas specific and

respond to a vari ety of ot her g ases i nc l udi ng pr opane exhaust,

cl eaners, and solvent s . Chan ges in t em per ature and humidity

may al so affec t the sensor’ s performance.

8 6309-9000 Rev 4

2.1. General Placement Guidelines

NOTE: The MG S-150 should be install ed plumb and level

and secu rely fast ene d to a rigid mount ing s urface.

Sensors m ust be located within the appr opriate wir e lengt hs from the

central c ontr ol uni t (i f us ed).

In al l c ases th e sensor suppli ed is des i gned f or maximum se nsitivity to a

partic ula r g as. How e ver, i n cert ai n circ ums tanc es fal se al arms m ay be

caus ed by t he occ asi onal pres ence o f su ffici ent ly hi gh conc ent rati ons of

other gaseous impurities. Examples of situations where such

abn ormali ties m ay arise i nclude the following:

• Plant room m ai ntenanc e activity i nvolvin g solvent or p ai nt fumes

or re f ri gera nt leak s .

• Accident al gas migration in frui t ripe ni ng/storage facilities

(bananas - ethylene, apples - carb on diox i de).

• Heavy localized exhaust fumes (carbo n m onox i de, dioxide,

propane) from engine-driven forkli ft s in c onfine d spaces or close

to sensors .

Bacharach recommends setting the alarm delay to minimize false

alarms.

MGS-150 Manual

2.2. Component s and A ccess Overview

NOTE: The wiring is the same for the electro-chemical,

semi-conduct or, a nd inf rared m odels . The c ontrol ler wi ring is

the same for al l controllers.

There is a 5-minute power-up delay to allow the sensor to stabilize.

Refe r to Fi gure 2 and Fi gur e 3 for int ernal c omponents an d wiring.

6309-9000 Rev 4 9

MGS-150 Manual

Figure 2. EC or IR Sensor Com ponent s and W i r ing

10 6309-9000 Rev 4

MGS-150 Manual

1.

Figure 3. SC Sensor Components and W i r ing

6309-9000 Rev 4 11

Loading...

Loading...