GAS DETECTOR

INSTALLATION GUIDE

P/N: 6309-9002

Revision 1

October 2016

IP66

Housing

Standard

Sensor

Housing

2: SAFETY INSTRUCTIONS

USER MANUAL: Before using this equipment,

carefully read and strictly follow the User Manual

(part number 6309-9000). The user must fully

understand and strictly observe the instrucons.

Use the equipment only for the purposes listed and

under the condions specified in those documents.

CODE COMPLIANCE: Comply with all local and

naonal laws, rules and regulaons associated with

this equipment.

GENUINE PARTS: Use only genuine Bacharach spare

parts and accessories, otherwise proper funconing

of the equipment may be impaired.

TECHNICIAN USE ONLY: This unit must be installed

by a suitably qualified technician who will install this

unit in accordance with these instrucons and the

standards in their parcular industry/country. Operators of the unit should be aware of the regulaons

and standards in their industry/country for the

operaon of this unit. These notes are only intended

as a guide and the manufacturer bears no responsibility for the installaon or operaon of this unit.

Failure to install and operate the unit in accordance

with these instrucons and with industry guidelines

may cause serious injury including death and the

manufacturer will not be held responsible in this

regard.

SAFE MOUNTING: This monitor must be connected

by a marked, suitably located and easily reached

switch or circuit-breaker as means of disconnecon.

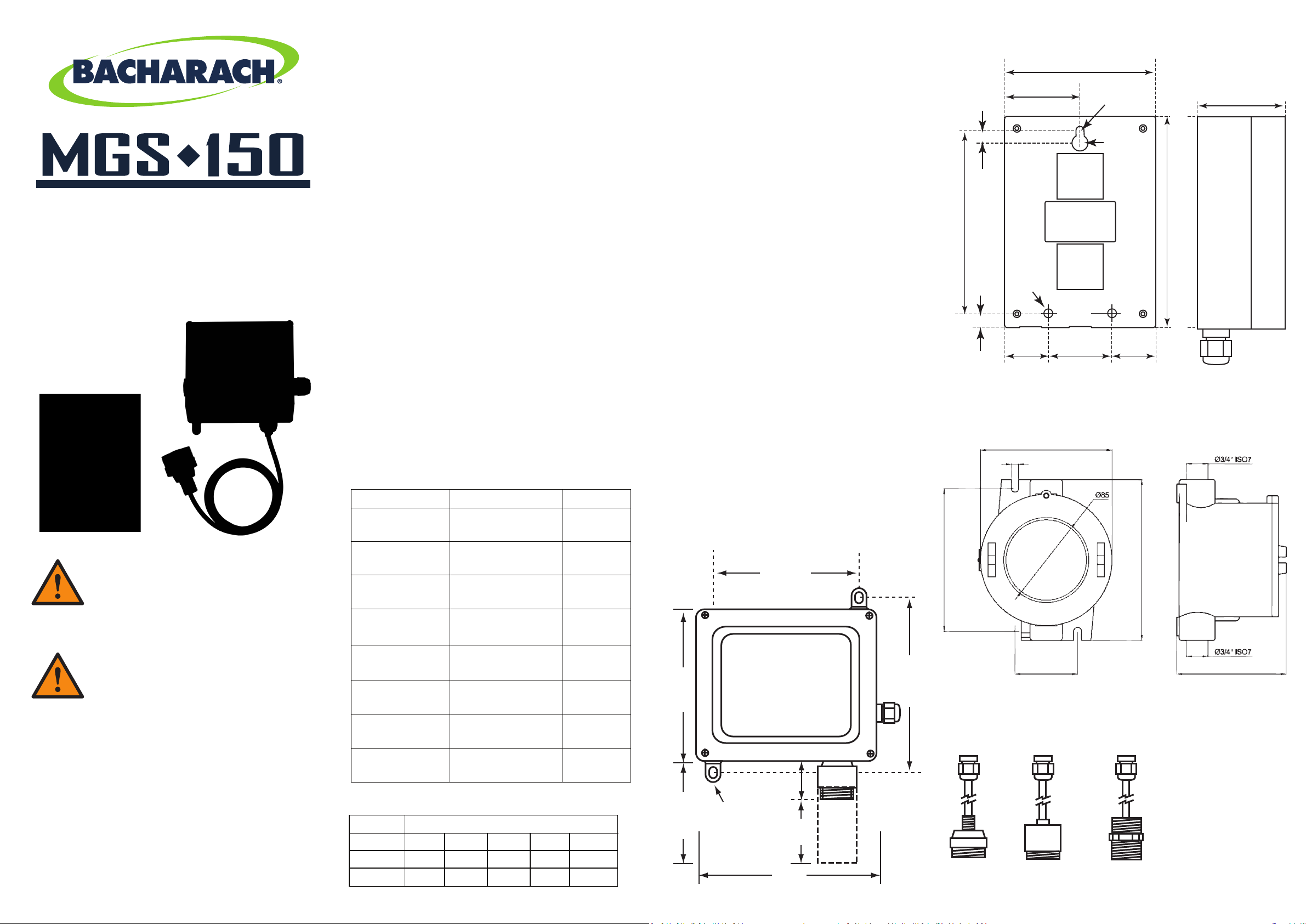

3: WEIGHTS AND DIMENSIONS

4: MOUNTING

ENVIRONMENTAL CONSIDERATIONS: Careful-

ly consider the full range of environmental

condions to which the instruments will be

exposed.

TARGET GAS CONSIDERATIONS: The physical

data of the gas or vapor to be detected must

be observed.

APPLICATION CONSIDERATIONS: The specifics

of the applicaon (for example, possible leaks,

air movement/dra, etc.) must be observed.

ACCESSIBILITY CONSIDERATIONS: The degree

of accessibility required for maintenance

purposes must be granted.

ACCESSORY CONSIDERATIONS: The types of

oponal and accessory equipment that will be

used with the system must be kept in mind.

ELECTRONIC CONSIDERATIONS: The system

contains sensive electronic components that

can be easily damaged. Do not touch nor

disturb any of these components.

Mount the MGS-150 according to the above

consideraons, product dimensions (see

Secon 3), maximum wiring lengths (see

Secon 5), and the corresponding mounng

dimensions shown in the illustraons that

follow.

0.28 in

(7.0 mm)

4.07 in (103.50 mm)

0.31 in

(8.0 mm)

1.69 in (43.0 mm)

�

018 in

(4.50 mm)

1.0 in

(25.00 mm)

5.8 in (147 mm)

0.3 in (8 mm)

3.39 in (86.0 mm)

1.4 in

(36.00 mm)

Ex d Housing

�

0.18 in

(4.50 mm)

�

0.35 in

(9.0 mm)

1.0 in

(25.00 mm)

Standard

Housing

2.09 in (53 mm)

4.72 in (120 mm)

CAUTION: DO NOT MOUNT the

MGS-150 in an area that may contain

flammable liquids or vapors. Operaon of electrical equipment in such

an area constutes a safety hazard.

WARNING: Strictly follow the instrucons in the Gas Detector Manual (part

number 6309-9000) available at

www.MyBacharach.com.

1: OPERATING AREA AND CONDITIONS

The Bacharach MGS-150 is an instrument for the

connuous monitoring of refrigerant, combusble,

and toxic gases.

The instrument is powered by 12-24V AC or DC (selectable by an on-board jumper). The output signal can be

selected as either voltage or current. The on-board

relay can be used to switch alarm devices.

Type/Enclosure Dimensions Weights

IP41

IP66

IP66 w/ Splash

Guard

IP66 w/ Remote

Sensor

IP66 w/ Ex d

Remote Head

IP66 w/ PRV

Sensor Head

IP66 Airflow/

Duct (See Table)

Ex d (Enclosure)

3.35” x 5.59” x 2.09”

86 x 142 x 53 mm

6.89” x 6.5” x 3.29”

175 x 165 x 82 mm

6.89” x 8.9” x 3.29”

175 x 225 x 82 mm

6.89” x 6.1” x 3.29”

175 x 155 x 82 mm

6.89” x 6.1” x 3.29”

175 x 155 x 82 mm

6.89” x 6.1” x 3.29”

175 x 155 x 82 mm

6.89” x 4.9” x 3.29”

175 x 125 x 82 mm

5.8” x 7.1” x 5.0”

147 x 180 x 128 mm

6.3 oz

180 g

1 lb 6 oz

629 g

1 lb 9 oz

700 g

1 lb 11 oz

790 g

2 lb 10 oz

1185 g

2 lb 0.3 oz

916 g

1 lb 4 oz

578 g

4 lb 10 oz

2100 g

Supported CFM & Duct Sizes for Duct Mount Housing

Units

Inches

Feet

Area (ft2)

12 x 12 12 x 24 18 x 18 24 x 24 24 round

1 x 1

1 2 2.25 4 3.14

Duct Size

1 x 2 1.5 x 1.5 2 x 2 Pi x 1 x 1

IP66 Housing

4.8 in

(122 mm)

4.8 in

(123 mm)

1.7 in

(42 mm)

mounng slots =

0.35 in (9mm) long x

4.0 in

0.24 in (6mm) wide

(101 mm)

Use 3/16-inch screws

(5mm - 6mm )

2.3 in

(59 mm)

5.7 in

(146 mm)

5.7 in

(144 mm)

6.3 in (160 mm)

M42 thread

2.8 in (70 mm)

Exd Remote

Head

Thread varies

with model

7.1 in (180 mm)

5.0 in (128 mm)

PRV/IP66

Vent Pipe

Monitoring 1

in BSP Head

1”BSP thread

Semiconductor

Sensors Only

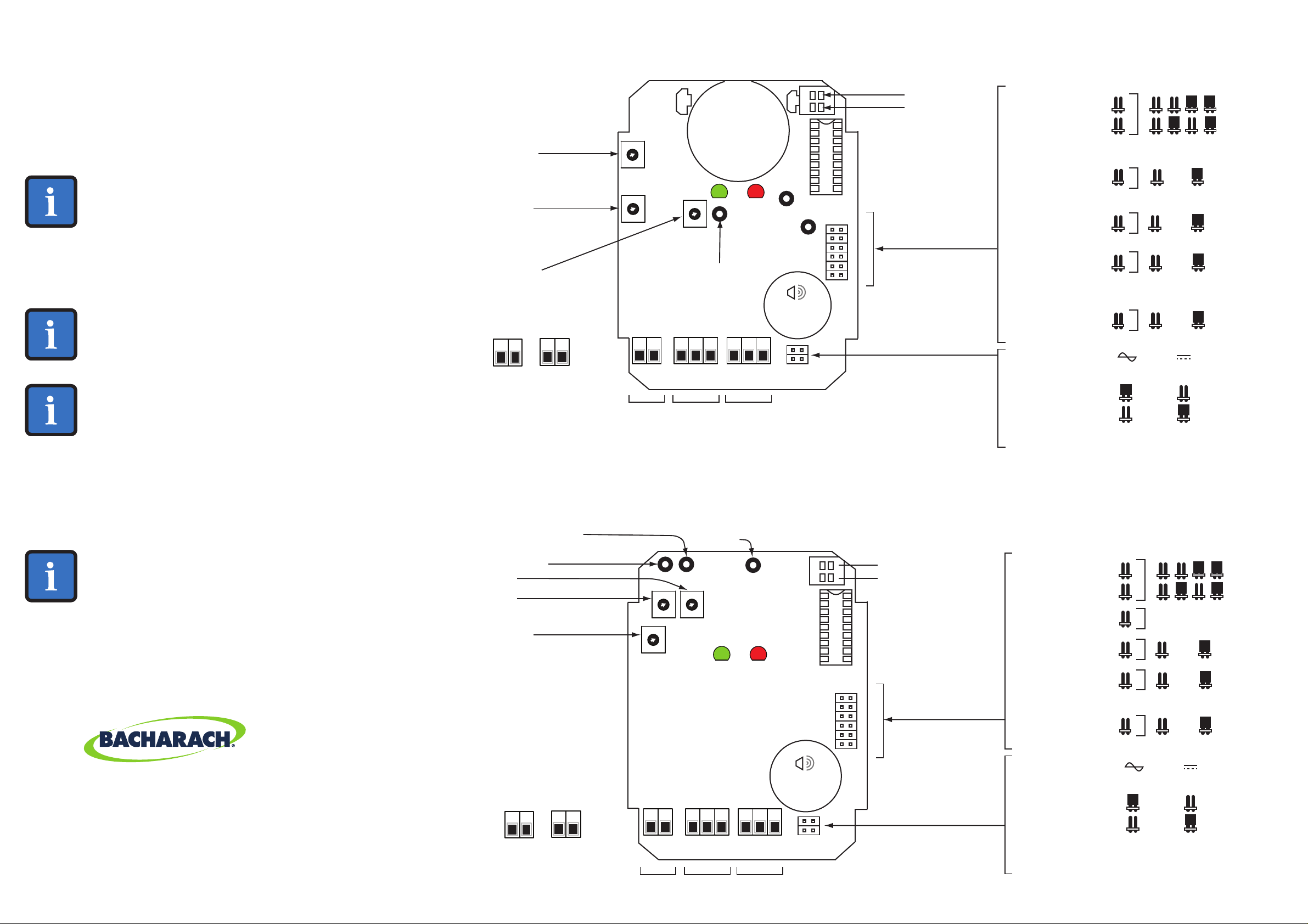

5: WIRING AND CONFIGURATION

Electrochemical (EC) or Infrared (IR) Sensor

CABLE OPENINGS: Each MGS-150 IP41 transmier

will have a single opening for a PG7 cable gland, as

well as an oponal knockout opening. Each

MGS-150 IP66 tranmier has 3 openings These

openings can be used for field wiring, direct aachment of a sensor or wiring of a remote sensor.

Unused openings must be closed with a suitable

plug and gasket, maintaining the IP or Ex d rang.

NOTE: To make wiring connecons,

you must first open the MGS-150

housing. The enclosure lid of the IP66

housing has four capve screws.

Refer to the User Manual (part number

6309-9000) at www.MyBacharach.com for detailed

instrucons on accessing the internal components

for wiring.

NOTE: For AC-powered configuraons, ensure that the AC neutral

supply line is not used as the ground

reference for the analog outputs.

NOTE: Aer wiring is completed,

carefully re-assemble the enclosure

and its components, nong the

keyed ribbon cable and sensor

connectors. Aer installaon is

complete, be sure to refer to the

User Manual (part number

6309-9000) at www.MyBacharach.com for detailed instrucons on

registering the sensors and configuring the MGS-150 for proper

operaon.

IMPORTANT CONFIGURATION

NOTE: For detecon of R449A or

R450A, the maximum linear range

of 500 ppm equals 50% of the

range of the analog output (e.g.,

500 ppm = 12 mA, when using

4-20mA output). Data above this

range should be discarded as

invalid. The alarm set point must

not be adjusted higher than 500

ppm for these gases.

Adjust Span

(Adjust Zero in

IR Model)

Adjust Zero

(Adjust Span in

IR Model)

Adjust Audible

Alarm and Relay

Set Point (P1)

CN1

12-24

VAC

0V V+

12-24 VDC

Audible Alarm and Relay

Set Point Voltage

0 V

Adjust Span

Adjust Zero

Adjust Audible

Alarm and Relay

Set Point (P1)

CN1

SW1

S

GREEN

LED

Audible Alarm & Relay Set

Point Voltage (Ref 1)

CN1 CN2 CN3

0V V+

Power

Supply

0V V I

Output

Signal

E

N

S

N/O

Relay

Out

R

O

RED

LED

Voltage (VS)

U

N/C

COM

A

D

0V

Sensor

I

B

L

A

D

6

5

4

3

2

1

M

R

A

L

A

E

Semiconductor (SC) Sensor

Sensor

Voltage

GREEN

LED

RED

LED

SW2

6

5

4

3

2

1

Short to Cancel

Warm Up Delay

Short to Cancel

Warm Up Delay

Relay and

Audible

Alarm Delay

(Minutes)

Sensor Output

(Factory Set)

Output

Range

Audible

Alarm

Divide

Voltage

Output

by 2

Jumpers

for

AC or DC

Relay and

Audible

Alarm Delay

(Minutes)

Sensor Output

(Factory Set)

Output

Range

Audible

Alarm

Divide

Voltage

Output

by 2

0 1 5 10

6

5

Inverted

Only)

Normal

(O

2

4

0-10V

4-20 mA

or 2-10V

3

Disabled

Enabled

2

Disabled

(0-10V,

2-10V)

Enabled

(0-5V or

1-5V)

1

AC POWER

SELECTED

A

D

Change AC/DC Power Jumper

ONLY under No Power

DC POWER

SELECTED

A

D

1 5 10

0

6

5

4

Do Not Change

4-20 mA

0-10V

or 2-10V

3

Disabled

Enabled

2

Disabled

(0-10V,

2-10V)

Enabled

(0-5V or

1-5V)

1

World Headquarters

621 Hunt Valley Circle

New Kensington, PA 15068 USA

Phone: 724-334-5000 • Fax: 724-334-5001

Toll Free: 1-800-736-4666

Website: www.MyBacharach.com

E-mail: help@MyBacharach.com

114A Georges Street Lower

Dun Laoghaire • Co Dublin • Ireland

Phone: +353 1 284 6388 • Fax: +353 1 284 6389

CN1

12-24

VAC

CN1

0V V+

12-24 VDC

CN1 CN2 CN3

0V V I0V V+

Power

Supply

Output

Signal

N/O

Relay

Out

A

U

D

I

B

L

A

D

N/C

COM

M

R

A

L

A

E

Jumpers

for

AC or DC

AC POWER

SELECTED

A

D

Change AC/DC Power Jumper

ONLY under No Power

DC POWER

SELECTED

A

D

Loading...

Loading...