Page 1

Gas Detector and Controllers

Installation and Operation Manual

Instruction 6109-9000

Revision 4 – June 2014

Product Leadership • Training • Service • Reliability

Page 2

MGD-100 Manual

WARRANTY POLICY

BACHARACH, INC. WARRANTS THIS INSTRUMENT, EXCLUDING SENSORS, TO BE

FREE FROM DEFECTS IN MATERIALS AND WORKMANSHIP FOR A PERIOD OF ONE

YEAR FROM THE DATE OF PURCHASE BY THE ORIGINAL OWNER. THE SENSORS

HAVE A WARRANTY PERIOD OF ONE YEAR FROM THE DATE OF PURCHASE. IF

THE PRODUCT SHOULD BECOME DEFECTIVE WITHIN THIS WARRANTY PERIOD,

WE WILL REPAIR OR REPLACE IT AT OUR DISCRETION.

THE WARRANTY STATUS MAY BE AFFECTED IF THE INSTRUMENT HAS NOT BEEN

USED AND MAINTAINED PER THE INSTRUCTIONS IN THIS MANUAL OR HAS BEEN

ABUSED, DAMAGED, OR MODIFIED IN ANY WAY. THIS INSTRUMENT IS ONLY TO BE

USED FOR PURPOSES STATED HEREIN. THE MANUFACTURER IS NOT LIABLE FOR

AUXILIARY INTERFACED EQUIPMENT OR CONSEQUENTIAL DAMAGE.

DUE TO ONGOING RESEARCH, DEVELOPMENT, AND PRODUCT TESTING, THE

MANUFACTURER RESERVES THE RIGHT TO CHANGE SPECIFICATIONS WITHOUT

NOTICE. THE INFORMATION CONTAINED HEREIN IS BASED ON DATA CONSIDERED

ACCURATE. HOWEVER, NO WARRANTY IS EXPRESSED OR IMPLIED REGARDING

THE ACCURACY OF THIS DATA.

ALL GOODS MUST BE SHIPPED TO THE MANUFACTURER BY PREPAID FREIGHT.

ALL RETURNED GOODS MUST BE PRE-AUTHORIZED BY OBTAINING A RETURN

MERCHANDISE AUTHORIZATION (RMA) NUMBER. CONTACT THE MANUFACTURER

FOR A NUMBER AND PROCEDURES REQUIRED FOR PRODUCT TRANSPORT.

SERVICE POLICY

BACHARACH, INC. MAINTAINS AN INSTRUMENT SERVICE FACILITY AT THE

FACTORY. SOME BACHARACH DISTRIBUTORS / AGENTS MAY ALSO HAVE

REPAIR FACILITIES, HOWEVER, BACHARACH ASSUMES NO LIABILITY FOR

SERVICE PERFORMED BY ANYONE OTHER THAN BACHARACH PERSONNEL.

REPAIRS ARE WARRANTED FOR 90 DAYS AFTER DATE OF SHIPMENT

(SENSORS, PUMPS, FILTERS AND BATTERIES HAVE INDIVIDUAL

WARRANTIES). SHOULD YOUR INSTRUMENT REQUIRE NON-WARRANTY

REPAIR, YOU MAY CONTACT THE DISTRIBUTOR FROM W HOM IT W AS

PURCHASED OR YOU MAY CONTACT BACHARACH DIRECTLY.

IF BACHARACH IS TO DO THE REPAIR WORK, SEND THE INSTRUMENT,

PREPAID, TO BACHARACH, INC. AT THE FOLLOWING ADDRESS.

BACHARACH, INC.

621 HUNT VALLEY CIRCLE

NEW KENSINGTON, PA 15068

ATTENTION: SERVICE DEPARTMENT

ALWAYS INCLUDE YOUR RMA #, ADDRESS, TELEPHONE NUMBER, CONTACT

NAME, SHIPPING/BILLING INFORMATION AND A DESCRIPTION OF THE

DEFECT AS YOU PERCEIVE IT. YOU WILL BE CONTACTED WITH A COST

ESTIMATE FOR EXPECTED REPAIRS PRIOR TO THE PERFORMANCE OF ANY

SERVICE WORK. FOR LIABILITY REASONS, BACHARACH HAS A POLICY OF

2 6109-9000 Rev 4

Page 3

PERFORMING ALL NEEDED REPAIRS TO RESTORE THE INSTRUMENT TO

FULL OPERATING CONDITION.

PRIOR TO SHIPPING EQUIPMENT TO BACHARACH, CONTACT OUR OFFICE

FOR AN RMA # (RETURNED MERCHANDISE AUTHORIZATION). ALL RETURNED

GOODS MUST BE ACCOMPANIED WITH AN RMA NUMBER.

PACK THE EQUIPMENT WELL (IN ITS ORIGINAL PACKING IF POSSIBLE), AS

BACHARACH CANNOT BE HELD RESPONSIBLE FOR ANY DAMAGE INCURRED

DURING SHIPPING TO OUR FACILITY.

NOTICES

MGD-100 Manual

COPYRIGHTS: THIS MANUAL IS SUBJECT TO COPYRIGHT PROTECTION; ALL

RIGHTS ARE RESERVED UNDER INTERNATIONAL AND DOMESTIC

COPYRIGHT LAWS. THIS MANUAL MAY NOT BE COPIED OR TRANSLATED, IN

WHOLE OR IN PART, IN ANY MANNER OR FORMAT, W ITHOUT THE WRITTEN

PERMISSION OF BACHARACH, INC.

ALL SOFTWARE USED AND/OR DISTRIBUTED BY BACHARACH IS SUBJECT TO

COPYRIGHT PROTECTION. ALL RIGHTS ARE RESERVED. NO PARTY MAY USE

OR COPY SUCH SOFTWARE IN ANY MANNER OR FORMAT, EXCEPT TO THE

EXTENT THAT BACHARACH GRANTS THEM A LICENSE TO DO SO. IF THIS

SOFTWARE IS BEING LOADED ONTO MORE THAN ONE COMPUTER, EXTRA

SOFTWARE LICENSES MUST BE PURCHASED.

TECHNICIAN USE ONLY

THIS UNIT MUST BE INSTALLED BY A SUITABLY QUALIFIED TECHNICIAN WHO

WILL INSTALL THIS UNIT IN ACCORDANCE WITH THESE INSTRUCTIONS AND

THE STANDARDS IN THEIR PARTICULAR INDUSTRY/COUNTRY. OPERATORS

OF THE UNIT SHOULD BE AWARE OF THE REGULATIONS AND STANDARDS IN

THEIR INDUSTRY/COUNTRY FOR THE OPERATION OF THIS UNIT. THESE

NOTES ARE ONLY INTENDED AS A GUIDE AND THE MANUFACTURER BEARS

NO RESPONSIBILITY FOR THE INSTALLATION OR OPERATION OF THIS UNIT.

FAILURE TO INSTALL AND OPERATE THE UNIT IN ACCORDANCE WITH THESE

INSTRUCTIONS AND WITH INDUSTRY GUIDELINES MAY CAUSE SERIOUS

INJURY INCLUDING DEATH AND THE MANUFACTURER WILL NOT BE HELD

RESPONSIBLE IN THIS REGARD.

6109-9000 Rev 4 3

Page 4

MGD-100 Manual

Table of Contents

SECTION 1.

OVERVIEW ................................................................................ 5

1.1. General Information ................................................................................ 5

1.2. Technical Specifications ........................................................................ 10

SECTION 2. PLACING SENSORS .................................................................. 13

2.1. Installation Warnings ............................................................................ 13

2.2. General Guidelines ................................................................................ 13

2.3. Machinery Rooms ................................................................................. 15

2.4. Refrigerated Spaces ............................................................................... 16

2.5. Chillers ................................................................................................... 16

2.6. Air Conditioning (Direct Systems VRF/VRV) .......................................... 17

SECTION 3. HOUSING DIMENSIONS .......................................................... 18

SECTION 4. WIRING INSTRUCTIONS .......................................................... 23

4.1. Wiring MGD-100s .................................................................................. 23

4.2. External Audible Alarm .......................................................................... 24

4.3. DC Output .............................................................................................. 24

4.4. Relays .................................................................................................... 25

4.5. Power Connection ................................................................................. 25

SECTION 5. OPERATION AND STABILIZATION ............................................ 30

SECTION 6. FUNCTIONAL TESTS AND CALIBRATION .................................. 32

6.1. Introduction .......................................................................................... 32

6.2. Electrical Reset ...................................................................................... 34

6.3. Bump Testing ......................................................................................... 35

6.4. Calibration Overview ............................................................................. 38

6.5. Calibration Options ............................................................................... 38

6.6. Sensor Board Exchange ......................................................................... 38

6.7. On-Site Gas Calibration ......................................................................... 39

SECTION 7. TROUBLESHOOTING ............................................................... 41

DECLARATION OF CONFORMITY .................................................................... 43

4 6109-9000 Rev 4

Page 5

Section 1. Overview

1.1. General Information

The MGD-100 is the ideal gas detection solution for installations

requiring a quality and affordable stand-alone gas detector. It consists of

1 to 6 remote gas sensors connected to and powered by a controller.

The controller provides visual, audible, and relay alarms on the detection

of gases. The system is available with one or two levels of alarm.

The MGD-100 can be used for:

MGD-100 Manual

• detecting refrigerant gases (including NH

and CO2)

3

• speedy detection of combustible gases

• detection of toxic and VOC gases.

A range of gas detector and sensor enclosures are available for special

applications.

The MGD-100 Controller is required. With the MGD-100, it creates a

stand-alone gas detection system and is used to remotely monitor up to

six MGD-100 devices. Models are available with 1, 2, 4, and 6 channels.

Wiring diagrams are provided later in this manual.

6109-9000 Rev 4 5

Page 6

MGD-100 Manual

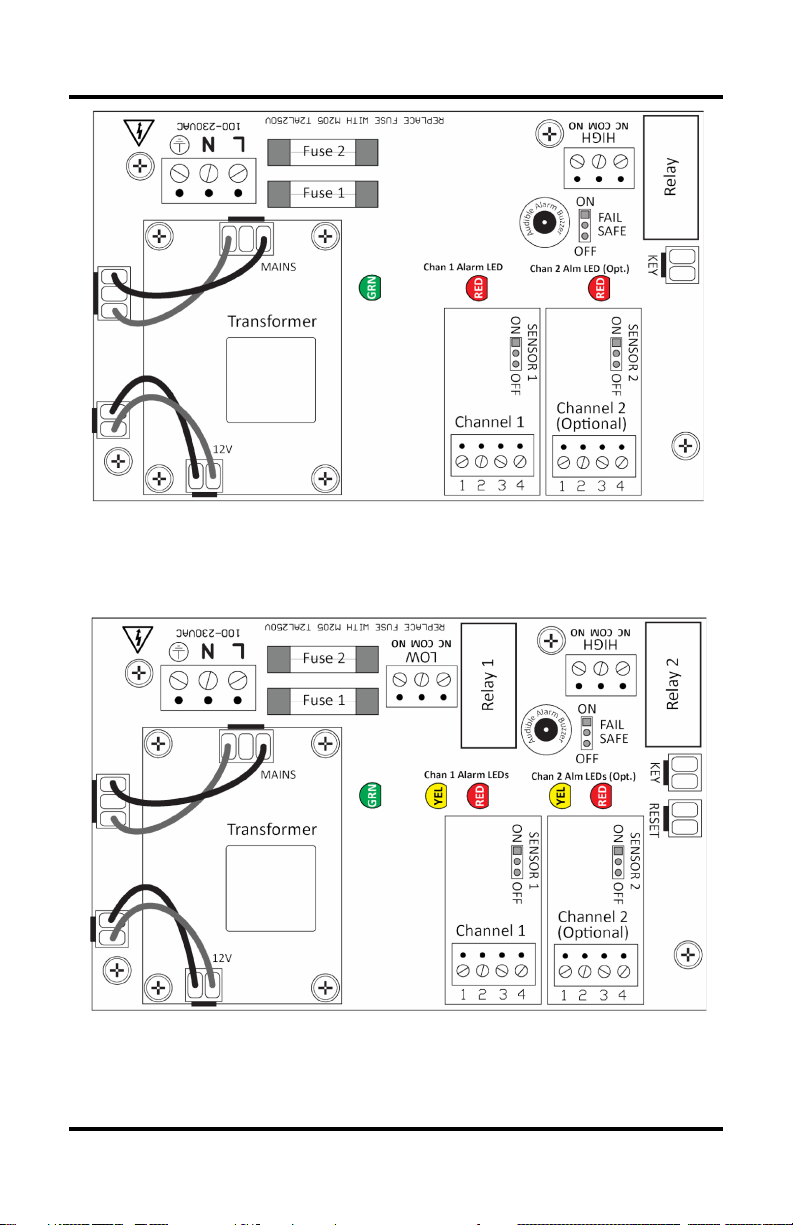

Figure 1. MGD-100 1- and 2-Channel Controller PCB

(Single Level Alarm)

Figure 2. MGD-100 1- and 2-Channel Controller PCB

(Dual Level Alarm)

6 6109-9000 Rev 4

Page 7

MGD-100 Manual

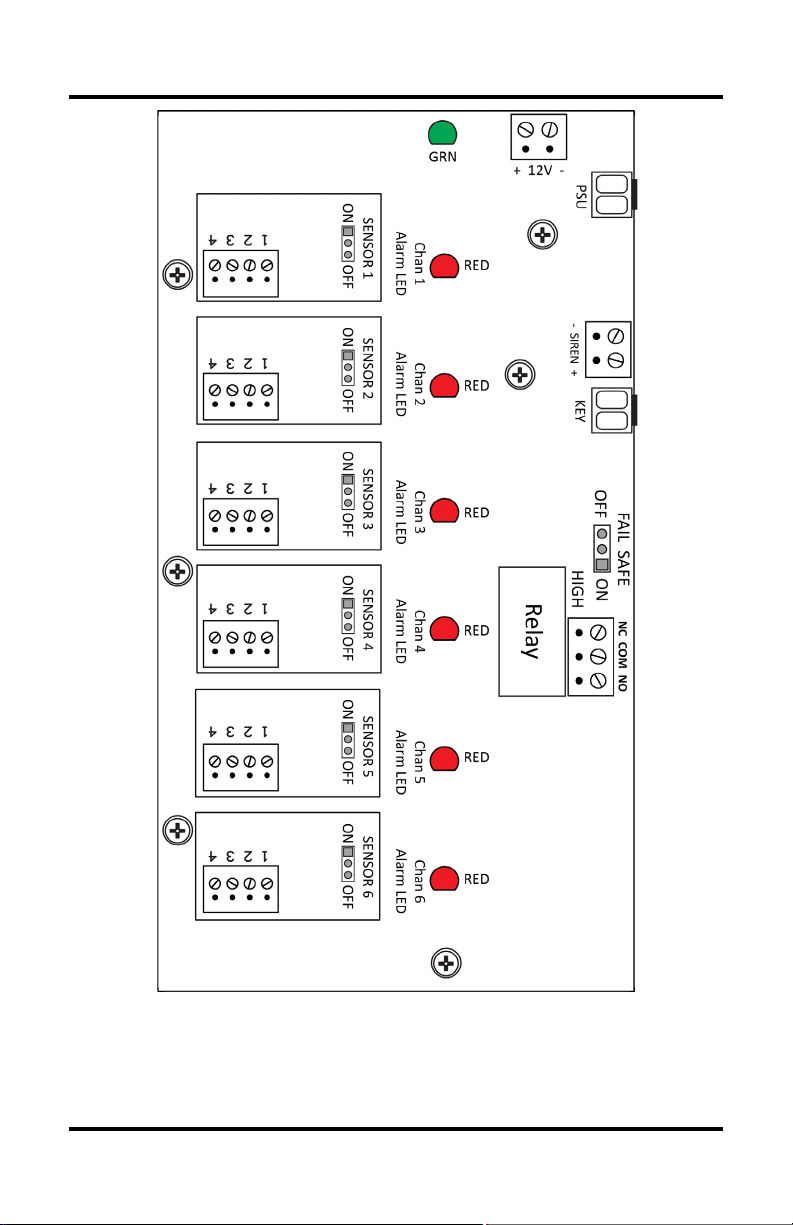

Figure 3. MGD-100 4- and 6-Channel Controller PCB

(Single Level Alarm)

6109-9000 Rev 4 7

Page 8

MGD-100 Manual

Figure 4. MGD-100 4- and 6-Channel Controller PCB

(Dual Level Alarm)

8 6109-9000 Rev 4

Page 9

MGD-100 Manual

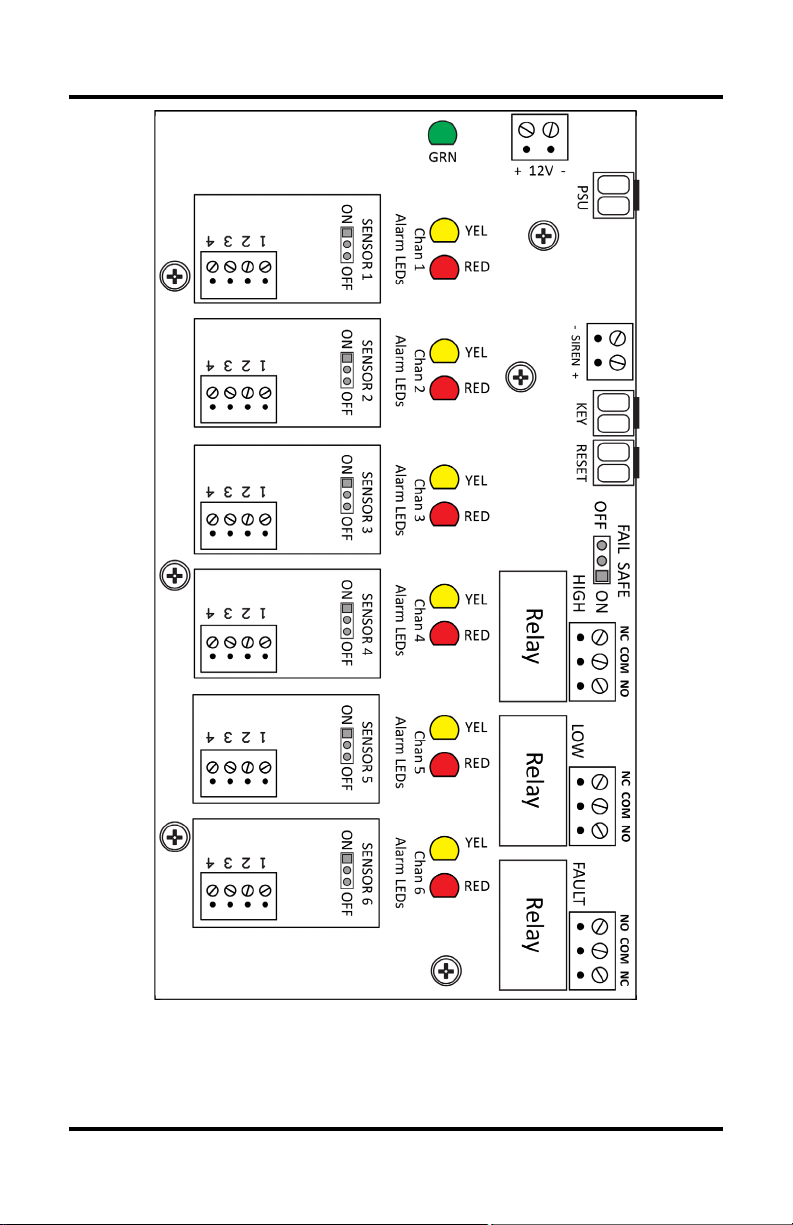

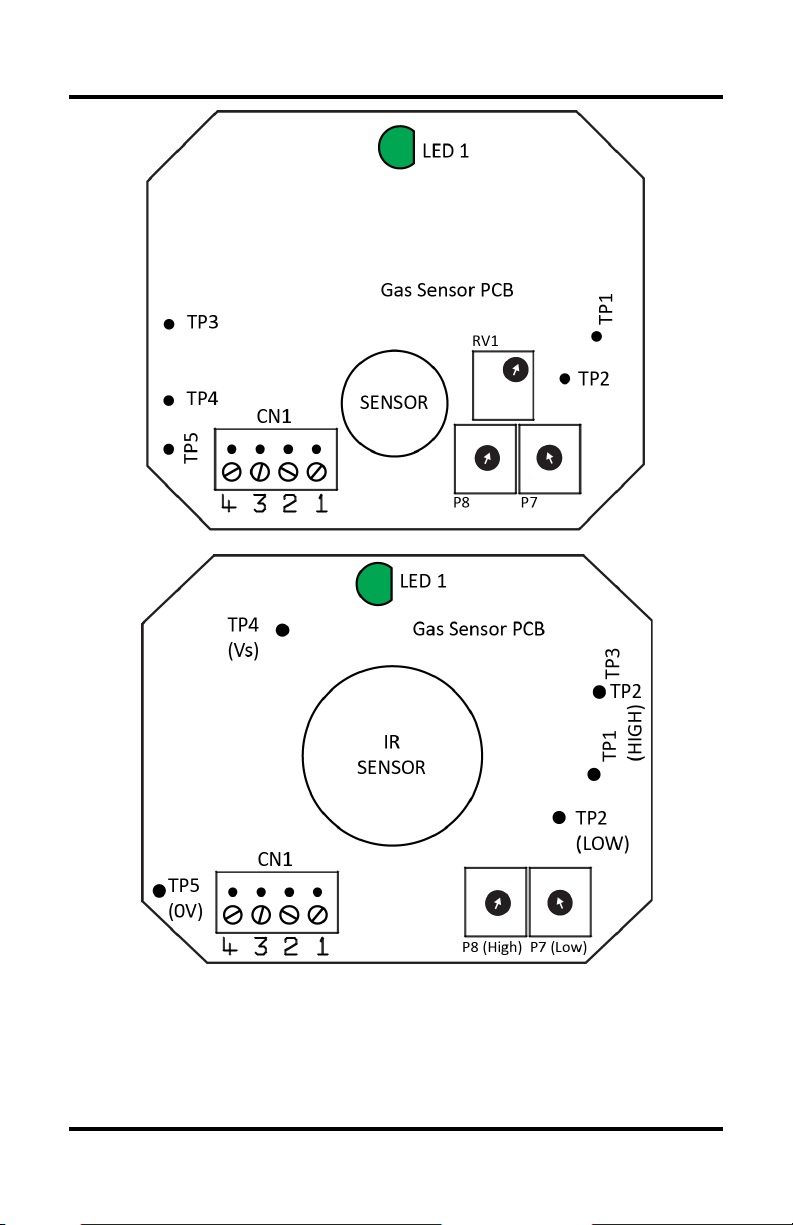

Figure 5. Examples MGD-100 PCBs

6109-9000 Rev 4 9

Page 10

MGD-100 Manual

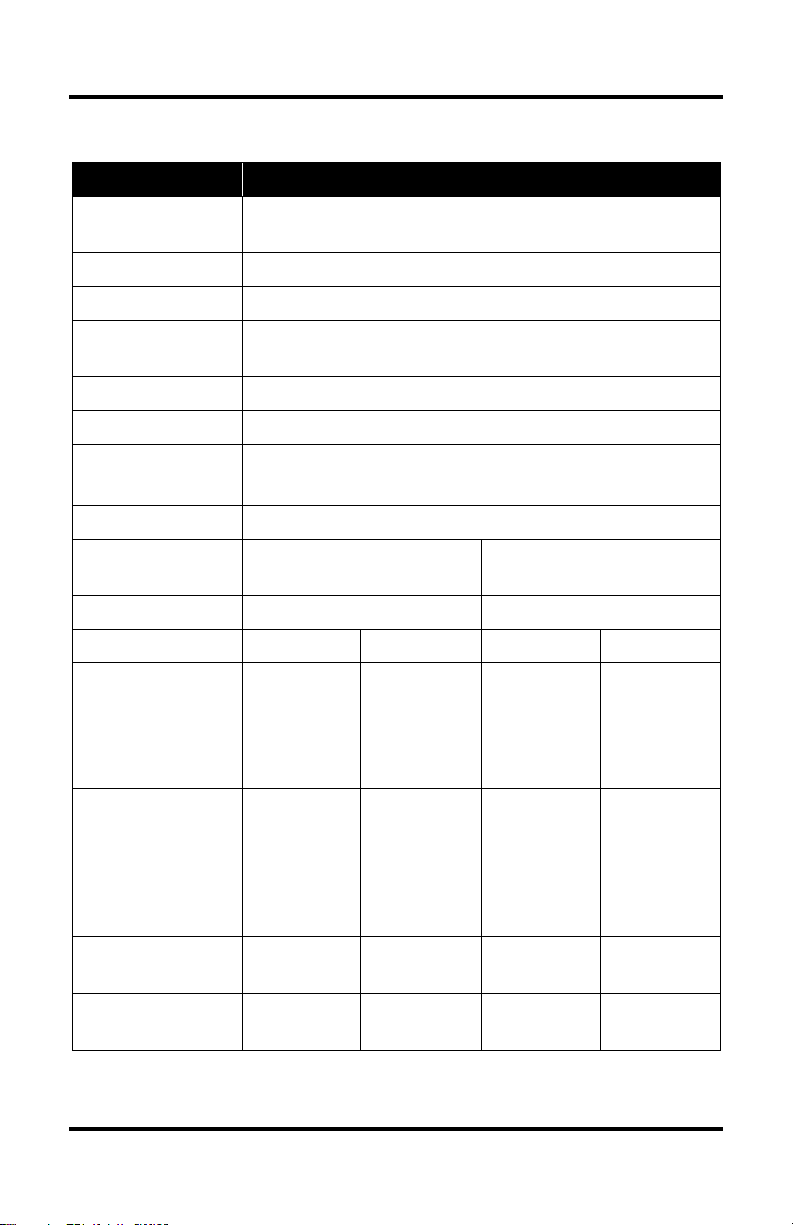

1.2. Technical Specifications

Specification Description

Power Supply 100 - 230 VAC 50 - 60 Hz, or 12 VDC (specified at

time of order)

Alarm Silence Key Switch

Alarm Delay Preset: 25 sec (low), 30 sec (high)

Power

Green

Monitoring LED

Alarm Relay(s) 10 A, 120V/230V

Warm-up Delay Minimum of 3 minutes

Communications

Wiring

4-conductor cable (stranded); 500 ft (152 m) max;

22 AWG; Max 8.8Ω/wire

Approvals UL/CSA/IEC/EN 61010-1; CE

Sensor

Channels

1- and 2-channel

systems

4- and 6-channel

systems

Max Power 15 W 25 W

Alarm Levels 1 Level 2 Levels 1 Level 2 Levels

Audible Alarm

(Buzzer)

Alarm Reset Automatic Automatic

Visual Alarm

LED(s)

Fault

Indication(s)

Internal,

continuous

Internal,

intermittent

(low),

continuous

(high)

Internal,

continuous

Internal,

intermittent

(low),

continuous

(high)

Automatic Automatic

(low

alarm),

manual

(high

alarm)

Red Yellow,

Red

Red Yellow,

(low

alarm),

manual

(high

alarm)

Red

Red LED Red LED Red LED Red LED,

relay

10 6109-9000 Rev 4

Page 11

main housing

remote or attached sensor

enclosures. The main housing enclosure and its PCB

Specification Description

Std. Enclosure

Ratings

Dimensions

and Weight:

Controller

Sensor

Dimensions

and Weights

1- and 2-chan systems 4- and 6-chan systems

MGD: IP41

Controller: IP51

8.4” x 4.1” x 3.15”

214 x 105 x 80 mm

2.2 lbs / 1.0 kg

Type/Enclosure Dimensions

IP41

IP66

IP66 w/ Splash

Guard

IP66 w/ Remote

Sensor

IP66 w/ Exd

Remote Head

IP66 w/ PRV

Sensor Head

IP66 Airflow/

Duct (See Table)

Exd (ATEX only)

3.35” x 5.59” x 2.09”

86 x 142 x 53 mm

6.89” x 6.5” x 3.29”

175 x 165 x 82 mm

6.89” x 8.9” x 3.29”

175 x 225 x 82 mm

6.89” x 6.1” x 3.29”

175 x 155 x 82 mm

6.89” x 6.1” x 3.29”

175 x 155 x 82 mm

6.89” x 6.1” x 3.29”

175 x 155 x 82 mm

6.89” x 4.9” x 3.29”

175 x 125 x 82 mm

5.12” x 6.3” x 3.54”

130 x 160 x 90 mm

NOTE: The hazardous area Exd Gas Monitor products are

designed with individually certified Exd

enclosures and certified Exd

MGD-100 Manual

MGD: IP41

Controller: IP51

10.3” x 10.4” x 303”

262 x 265 x 84 mm

5.1 lbs / 2.3 kg

Weights

6.3 oz

180 g

1 lb 6 oz

629 g

1 lb 9 oz

700 g

1 lb 11

oz

790 g

2 lb 10

oz

1185 g

2 lb 0.3

oz

916 g

1 lb 4 oz

578 g

9 lb 4 oz

4200 g

assembly are also Exd certified, but the final Exd Gas Monitor

assemblies (main enclosure and/or sensor assembly) are not

currently Exd certified, but are pending additional testing.

6109-9000 Rev 4 11

Page 12

MGD-100 Manual

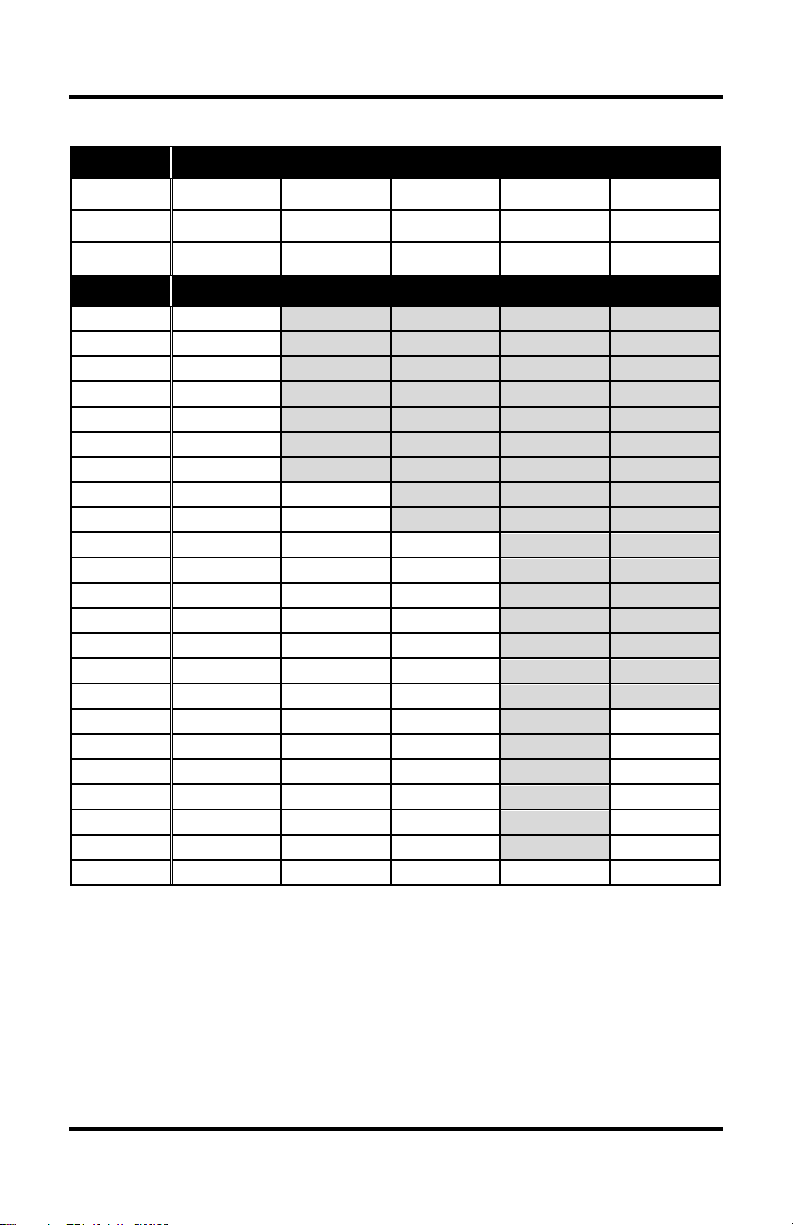

Supported CFM and Duct Sizes for the Duct Mount Housing

Units Duct Size

Inches

Feet

Area (ft2)

CFM Ft/min (Based on CFM and Duct Size)

2800 2800 n/a n/a n/a n/a

3000 3000 n/a n/a n/a n/a

3400 3400 n/a n/a n/a n/a

3800 3800 n/a n/a n/a n/a

4000 4000 n/a n/a n/a n/a

4400 4400 n/a n/a n/a n/a

4800 4800 n/a n/a n/a n/a

5000 5000 2500 n/a n/a n/a

5400 5400 2700 n/a n/a n/a

5800 5800 2900 2578 n/a n/a

6000 6000 3000 2667 n/a n/a

6400 6400 3200 2844 n/a n/a

6800 6800 3400 3022 n/a n/a

7000 7000 3500 3111 n/a n/a

7400 7400 3700 3289 n/a n/a

7800 7800 3900 3467 n/a n/a

8000 8000 4000 3556 n/a 2548

8400 8400 4200 3733 n/a 2675

8800 8800 4400 3911 n/a 2803

9000 9000 4500 4000 n/a 2866

9400 9400 4700 4178 n/a 2994

9800 9800 4900 4356 n/a 3121

10000 10000 5000 4444 2500 3185

12 x 12 12 x 24 18 x 18 24 x 24 24 round

1 x 1 1 x 2 1.5 x 1.5 2 x 2 Pi x 1 x 1

1 2 2.25 4 3.14

12 6109-9000 Rev 4

Page 13

Section 2. Placing Sensors

2.1. Installation Warnings

NOTE: This instrument can be equipped with a semiconductor

sensor for the detection of refrigerant, combustible and VOC

gases. Semiconductor sensors are not gas specific and respond

to a variety of other gases including propane exhaust, cleaners,

and solvents. Changes in temperature and humidity may also

affect the sensor’s performance.

WARNING: Explosion hazard! Do not mount the MGD-100 in

an area that may contain flammable liquids, vapors, or

aerosols. Operation of any electrical equipment in such an

environment constitutes a safety hazard.

CAUTION: The MGD-100 contains sensitive electronic

components that can be easily damaged. Do not touch nor

disturb any of these components.

NOTE: The mounting location of the monitor should allow it to

be easily accessible for visual monitoring and servicing.

NOTE: The monitor must be connected by a marked, suitably

located and easily reached switch or circuit-breaker as means

of disconnection.

NOTE: Connect monitor power and signaling terminals using

wiring that complies with local electrical codes or regulations

for the intended application.

MGD-100 Manual

2.2. General Guidelines

NOTE: The MGD-100 should be installed plumb and level

and securely fastened to a rigid mounting surface.

The MGD-100 controller and its sensor(s) should be positioned carefully

to avoid mechanical damage (from moving machinery, doors, etc.) and

thermal extremes (close to heaters). Units should not be placed

unprotected in direct strong drafts/airflows and areas where water or

moisture is present unless an appropriate enclosure is used.

6109-9000 Rev 4 13

Page 14

MGD-100 Manual

Avoid routing sensor cabling outside of premises, or between buildings

via overhead cables. Also, sensor wiring should be kept to a minimum of

20 in (500mm) from the main power supply and telephone cables.

When connecting the main power supply and/or sensor cables ensure a

second mechanical fixing is used. Use a cable tie inside the enclosure

within 1 in (25mm) of the cable termination.

When power to the unit is switched on, there is a 3-minute delay before

the system activates. This allows the sensors to warm up to the correct

temperature for gas detection. On a two-alarm unit, the green light on the

alarm panel comes on after the delay, indicating that the system is ready.

On a one-alarm system the green light comes on immediately. When a

unit has been off or stored for a long time the stabilizing period may be

longer than 3 minutes. After the 3 minutes has expired, alarms may

activate. You may deactivate the siren until stabilization is complete.

(Use the key switch on two-alarm units. Remove jumper JP1 in the case

of a one-alarm unit).

Mount the controller using the mounting holes in the base such that the

sensor cable terminal blocks are at the bottom of the unit in a convenient

position.

Sensors must be located within the appropriate wire lengths from the

controller.

In all cases the sensor supplied is designed for maximum sensitivity to a

particular gas. However, in certain circumstances false alarms may be

caused by the occasional presence of sufficiently high concentrations of

other gaseous impurities. Examples of situations where such

abnormalities may arise include the following:

• Plant room maintenance activity involving solvent or paint fumes

or refrigerant leaks.

• Accidental gas migration in fruit ripening/storage facilities

(bananas - ethylene, apples - carbon dioxide).

• Heavy localized exhaust fumes (carbon monoxide, dioxide,

propane) from engine-driven forklifts in confined spaces or close

to sensors.

A sensor response delay is built in to the system to minimize the

possibilities of false alarms.

14 6109-9000 Rev 4

Page 15

2.3. Machinery Rooms

There is no absolute rule in determining the number of sensors and their

locations. However, a number of simple guidelines will help to make a

decision. Sensors monitor a point as opposed to an area. If the gas leak

does not reach the sensor then no alarm will be triggered. Therefore, it

is extremely important to carefully select the sensor location. Also

consider ease of access for maintenance.

The size and nature of the site will help to decide which method is the

most appropriate to use. Locations requiring the most protection in a

machinery or plant room would be around compressors, pressurized

storage vessels, refrigerant cylinders or storage rooms or pipelines. The

most common leak sources are valves, gauges, flanges, joints (brazed or

mechanical), filling or draining connections, etc.

• When mechanical or natural ventilation is present, mount a

sensor in the airflow.

• In machinery rooms where there is no discernible or strong

airflow then options are:

Point Detection, where sensors are located as near as

possible to the most likely sources of leakage, such as

the compressor, expansion valves, mechanical joints or

cable duct trenches.

MGD-100 Manual

Perimeter Detection

the area or equipment.

• For heavier-than-air gases such as halocarbon and

hydrocarbon refrigerants such as R404A, propane, and butane

sensors should be located near ground level.

• For lighter-than-air gas (e.g., ammonia), the sensor needs to

be located above the equipment to be monitored on a bracket or

high on a wall within 12 in (300 mm) of (or on) the ceiling –

provided there is no possibility of a thermal layer trapped under

the ceiling preventing gas from reaching the sensor.

, where sensors completely surround

NOTE: At very low temperatures (e.g., refrigerated

cold store), ammonia gas becomes heavier than air.

• With similar density or miscible gases, such as CO or CO2,

sensors should be mounted about head high (about 5 feet

[1.5 m]).

• Sensors should be positioned just far enough back from any

6109-9000 Rev 4 15

high-pressure parts to allow gas clouds to form and be detected.

Page 16

MGD-100 Manual

Otherwise, a gas leak might pass by in a high-speed jet and not

be detected by the sensor.

• Make sure that pits, stairwells and trenches are monitored since

they may fill with stagnant pockets of gas.

• If a pressure relief vent (PRV) pipe is fitted to the system, it may

be a requirement to mount a sensor to monitor this vent pipe. It

could be positioned about 6.5 ft (2 m) above the PRV to allow

gas clouds to form.

• For racks or chillers pre-fitted with refrigerant sensors, these

should be mounted so as to monitor the compressors. If extract

ducts are fitted the airflow in the duct may be monitored.

2.4. Refrigerated Spaces

In refrigerated spaces, sensors should be located in the return airflow to

the evaporators on a sidewall (below head-high is preferred), or on the

ceiling, not directly in front of an evaporator. In large rooms with multiple

evaporators, sensors should be mounted on the central line between 2

adjacent evaporators, as turbulence will result in airflows mixing.

2.5. Chillers

In the case of small water- or air-cooled enclosed chiller units mount the

sensor so as to monitor airflow to the extract fans. With larger models

also place a sensor inside the enclosure under or adjacent to the

compressors.

In the case of outdoor units:

• For enclosed air-cooled chillers or the outdoor unit for

variable refrigerant volume and variable refrigerant flow

(VRV/VRF) systems, mount the sensor so as to monitor airflow

to the extractor/exhaust fan. With large units also place a sensor

inside the enclosure under or adjacent to the compressors.

In the case of non-enclosed outdoor units:

• If there is an enclosed machinery section, locate a sensor there.

• In the case of units with enclosed compressors, mount sensors

in the enclosures.

• Where you have protective or acoustic panels mount the sensor

low and under the compressors where it is protected by the

panels.

16 6109-9000 Rev 4

Page 17

• With air-cooled chillers or air-cooled condensers with non-

enclosed condenser sections it is difficult to effectively monitor

leaks in the coil sections. With some designs it will be possible

using an airflow sensor to monitor airflow to the start–up fans in

the front or rear sections.

• If there is a possibility of refrigerant leaks into a duct or air-

handling unit install a sensor to monitor the airflow.

Weatherproof sensors should be used for unprotected outdoor

applications.

2.6. Air Conditioning (Direct Systems VRF/VRV)

For compliance with EN378, at least one detector shall be installed in

each occupied space being considered and the location of detectors

shall be chosen in relation to the refrigerant and they shall be located

where the refrigerant from the leak will collect. In this case refrigerants

are heavier than air and detectors should have their sensors mounted

low, e.g., at less than bed height in the case of an hotel or other similar

Category Class A spaces. Ceilings or other voids if not sealed are part of

the occupied space.

CAUTION: Monitoring ceiling voids in a hotel room would

not strictly comply with EN378.

Do Mount In-Room Sensors… Don’t Mount Sensors…

MGD-100 Manual

…at less than the normal heights of the

occupants. E.g., in a hotel room this is

less than bed height ( between 8 and

20 in [200 and 500 mm] off the floor).

…away from drafts and heat sources like

radiators, etc.

… to avoid sources of steam. …in or near bathrooms.

…under mirrors.

…at vanity units.

IMPORTANT: Carefully consider ramifications of using too few

sensors. A few extra sensors could make a significant

difference if a gas leak occurs.

6109-9000 Rev 4 17

Page 18

MGD-100 Manual

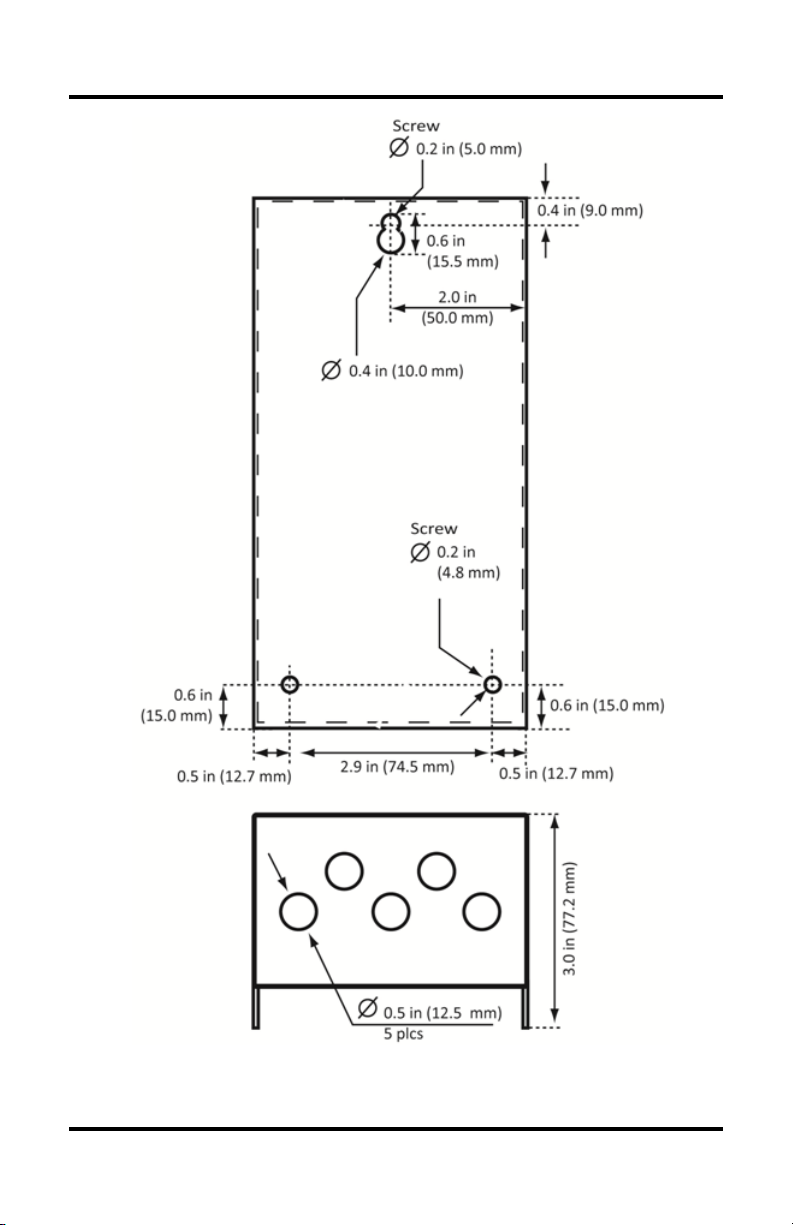

Section 3. Housing Dimensions

Figure 6. MGD-100 Standard Housing

18 6109-9000 Rev 4

Page 19

Figure 7. MGD-100 Exd Housing

MGD-100 Manual

Figure 8. MGD-100 IP66 Housing (with Splash Guard)

6109-9000 Rev 4 19

Page 20

MGD-100 Manual

Figure 9. MGD-100 IP66 Housing with Remote Sensor

See Figure 8 for

mounting locations.

Cut out in

duct for

pitot 22mm

Figure 10. MGS-100 IP66 Housing with Airflow Duct

Mount

20 6109-9000 Rev 4

Page 21

MGD-100 Manual

Figure 11. 4- & 6-Sensor Controller Housing

6109-9000 Rev 4 21

Page 22

MGD-100 Manual

Figure 12. 1- to 2-Sensor Controller Housing

22 6109-9000 Rev 4

Page 23

Section 4. Wiring Instructions

4.1. Wiring MGD-100s

Step Wiring MGD-100s

Connect a 4-conductor cable (18 AWG recommended) to a

1

terminal block on the MGD-100 controller (CN1, CN2, etc).

2 Route the cable to an MGD-100.

For standard (IP41) MGD-100 housings, remove the lid by:

MGD-100 Manual

3

4 Mount the MGD-100. See Section 3 for dimensions.

5

6 Close the housing.

7 Repeat above sequence for any/all remaining MGD-100s.

• turning the cable clamp ½ turn counter clockwise to

loosen the internal nut

• depressing the clip on top of the enclosure to open.

Connect the other end of the cable to the MGD-100 using

terminal block CN1 positions 1,2,3 & 4. (Installation should

be such that pin 1 of the MGD-100 controller is connected to

pin 1 of the MGD-100).

NOTE: Install a 2200 Ohm resistor between input pins 2 and 3

on any unused channels. If unused channels do NOT have a

resistor installed a fault will occur.

IMPORTANT: Ensure that connections 1 to 4 on the sensor

connect to their corresponding numbers on the terminal block

in the main control unit, otherwise it could cause damage to the

MGD-100.

Maximum Wiring Lengths between MGD-100 and Controller

Requirement Description

Length:

AWG:

Type:

Resistance:

6109-9000 Rev 4 23

500 feet maximum

22 AWG cable (minimum)

Stranded 4-wire cable

Max 8.8Ω/wire

Page 24

MGD-100 Manual

is not

NOTE: You may use different cables and longer distances

provided the corresponding resistance shown above

exceeded.

4.2. External Audible Alarm

NOTE: This section applies to the external audible alarm (4-6

channel systems only).

Step Wiring the External Audible Alarm

To install the audible alarm, connect positive (red) lead to the

1

“+” connection of the SIREN terminal.

Connect the negative (black) lead to the “-” connection of the

2

SIREN terminal.

4.3. DC Output

NOTE: This section applies to the 12 VDC output (4-6 channel

systems only).

Step Wiring the DC Output

The 12 VDC/500 mA output is obtained via the 12V terminal.

This output may be wired via the relays to obtain a switching

1

12 VDC output to drive an external relay or solenoid.

NOTE: The 12VDC output should not exceed 500 mA.

If a switching 12VDC signal is required, connect the "+" of the

12V terminal to the ‘COM’ terminal of the relay and the

2

device to be switched to either the N/O or N/C terminal

(depending on whether a 12V output is required during an

alarm condition or while the system is on standby).

The return from the device is connected to "-" on the 12V

3

terminal.

24 6109-9000 Rev 4

Page 25

cable should be of an

4.4. Relays

MGD-100 Manual

All relay outputs are labeled HIGH, LOW and FAULT on the silkscreen.

Connect leads to terminal block for Common (COM) and N/O and/or N/C

connections as required. Note that relays are rated as 10A @

120/230 VAC.

NOTE: N/O (normally open) and N/C (normally closed) refer to

contact status in standby mode. On a two-alarm system, a

high-level alarm condition on any sensor will override a lowlevel alarm condition on another sensor.

NOTE: The high-level relay may be set for normal or Fail-Safe

operation by setting the fail safe jumper on the control unit’s

printed circuit board.

4.5. Power Connection

Use 3-wire, 20 AWG wire for 230V systems or 3-wire, 18 AWG wire for

120V systems. Connect the main power supply to the MAINS input

terminal block.

NOTE: Connection to the main power supply must be made

via an approved, readily-accessible, switched and fused plug

and socket (or as per local wiring regulations) which should be

within 10 feet (3 meters) of the control unit.

NOTE: The main power supply

approved type based on local regulations.

NOTE: The blanking plugs for cable entries should only be

removed if being replaced by conduit fittings.

NOTE: If replacement of either main power fuse is required,

use only a 2A 250V slow fuse (0.79 in/20mm) T2AL250V.

6109-9000 Rev 4 25

Page 26

MGD-100 Manual

Figure 13. 1- & 2-Sensor, One-Alarm Installation

Diagram

26 6109-9000 Rev 4

Page 27

MGD-100 Manual

Figure 14. 1- & 2-Sensor, Two-Alarm Installation

Diagram

6109-9000 Rev 4 27

Page 28

MGD-100 Manual

Figure 15. 4- & 6-Sensor, One-Alarm Installation

28 6109-9000 Rev 4

Page 29

MGD-100 Manual

Figure 16. 4- & 6-Sensor, Two-Alarm Installation

6109-9000 Rev 4 29

Page 30

MGD-100 Manual

Section 5. Operation and Stabilization

When power to the unit is switched on, the green LED is illuminated, and

then there is a 3-minute delay before the system activates. This allows

the sensors to warm up to the correct temperature for gas detection.

When a unit has been off or stored for a long time the stabilizing period

may be longer than 3 minutes. After the 3 minutes has expired, alarms

may activate. You may deactivate the siren using the key switch until

stabilization is complete.

After the MGD has been installed in accordance with the installation

instructions, the MGD system is ready to monitor the chosen air space

and detect gas leaks.

Each of the remote sensors has a green light to indicate that power is

present.

To minimize false alarms, the system has a built in delay enforced

between the arrival time of gas at the sensor unit, and the time when the

alarm occurs. This delay is 20-25 seconds before a low-level alarm, and

25-30 seconds before a high-level alarm.

30 6109-9000 Rev 4

Page 31

On one-alarm units all of which have automatic reset no

Operation

State

Idle

Power

Interrupted

Alarm

Conditions

Resetting

Alarms

MGD-100 Manual

Description

Only the green light on the panel is on. No gas is

present.

If the green light is off, power to the unit has been

interrupted. Refer to Section 7.

One-alarm Units:

One or more red lights on the panel turn on. The siren

and the relays operate. This indicates that gas at one or

more sensors is at a level higher than the alarm point.

Two-alarm Units:

Low Alarm: One of more yellow lights on the panel turn

on. The audible alarm operates intermittently, and the

low alarm relay operates: this indicates presence of a

low level of gas on one or more sensors.

High Alarm:

One or more red lights on the panel turn on.

The audible alarm operates continuously, and the high

alarm relay operates: this indicates presence of a high

level of gas on one or more of the sensors.

user intervention is required. The unit will reset shortly

after the gas dissipates (all one-alarm systems reset

automatically).

On two-alarm units, low-level alarm conditions will reset

automatically when the gas dissipates. High-level alarm

conditions require a manual reset (by pressing the reset

button). Please note that a high alarm condition can

only be reset 30-60 seconds after the gas clears from

around the sensors.

Audible

Alarm

For the purpose of system maintenance, the audible

alarm may be disabled temporarily by using the key

switch.

Fault

This indicates a wiring or sensor problem.

6109-9000 Rev 4 31

Page 32

MGD-100 Manual

contains sensitive electronic

be required due to

Section 6. Functional Tests and Calibration

6.1. Introduction

To comply with the requirements of EN378 and the European F-GAS

regulation, sensors must be tested annually. However, local regulations

may specify the nature and frequency of this test.

CAUTION: Check local regulations on calibration or testing

requirements.

CAUTION: The MGD-100

components that can be easily damaged. Do not touch nor

disturb any of these components.

NOTE: The MGD-100 is calibrated at the factory. After

installation, a zero adjustment may

differences in environmental conditions.

IMPORTANT: If the MGD-100 is exposed to a large leak it

should be tested to ensure correct functionality by electrically

resetting the zero setting and carrying out a bump test. See

procedures below.

IMPORTANT: The testing and/or calibration of the unit must

be carried out by a qualified technician, and must be done in

accordance with this manual and in compliance with locally

applicable guidelines and regulations.

Suitably qualified operators of the unit should be aware of the

regulations and standards set down by the industry/country

for the testing or calibration of this unit. This manual is only

intended as a guide and, insofar as permitted by law, the

manufacturer accepts no responsibility for the calibration,

testing, or operation of this unit.

The frequency and nature of testing or calibration may be

determined by local regulation or standards.

EN378 and the F-GAS Regulation require an annual check in

accordance with the manufacturer’s recommendation.

32 6109-9000 Rev 4

Page 33

Failure to test or calibrate the unit in

guidelines may result in serious injury or death. The

from improper testing, incorrect calibration, or

. Bacharach also recommends sensor

IMPORTANT: Before testing the sensors on-site, the MGD100 must have been powered up and allowed to stabilize for

at least 24 hours. See Section 5.

IMPORTANT:

accordance with applicable instructions and with industry

manufacturer is not liable for any loss, injury, or damage

arising

inappropriate use of the unit.

IMPORTANT: Bacharach recommends annual checks and

gas calibration

replacement every 3 years or as required. Calibration

frequency may be extended based on application, but should

never exceed 2 years.

IMPORTANT: In applications where life safety is critical,

calibration should be done quarterly (every 3 months) or on a

more frequent basis. Bacharach is not responsible for setting

safety practices and policies. Safe work procedures including

calibration policies are best determined by company policy,

industry standards, and local codes.

NOTE: For improved accuracy and response, the instrument

should be zeroed and calibrated in the environment in which

it is being installed.

There are two concepts that need to be differentiated:

MGD-100 Manual

Bump Test Exposing the sensor to a gas and observing its response

to the gas. The objective is to establish if the sensor is

reacting to the gas and all the sensor outputs are working

correctly. There are two types of bump test.

• Quantified: A known concentration of gas is used.

• Non-Quantified: A gas of unknown concentration is

used.

Calibration Exposing the sensor to a calibration gas, setting the “zero”

or “Standby voltage”, the span/range, and checking/

adjusting all the outputs, to ensure that they are activated

at the specified gas concentration.

6109-9000 Rev 4 33

Page 34

MGD-100 Manual

See Section 5 for more

CAUTION: Before you carry out the bump test or calibration:

• Advise occupants, plant operators, and supervisors.

• Check if the MGD-100 is connected to external systems

such as sprinkler systems, plant shut down, external

sirens and beacons, ventilation, etc. and disconnect as

instructed by the customer.

• Ideally, for bump test or calibration the MGD-100 should

be powered up overnight.

information.

6.2. Electrical Reset

If necessary, reset the Standby and low/high Alarm Threshold Voltages

to the factory settings as shown on the calibration label. This is

performed on the MGD-100 Sensor PCB.

Electrical reset information is listed on the label on the side of the

enclosure and is unique to that sensor.

Tools required:

• A voltmeter (crocodile clips recommended)

• Factory set point electric values (as shown on the rating label)

• Screwdriver (depending on enclosure).

Step Electrical Reset

For semiconductor sensors only, connect a DC voltmeter

1

between TP5 (0V) and TP4 (+V) as shown in Figure 14 and

Figure 16. Adjust pot RV1.

For two-level sensors only, connect your DC voltmeter

2

between TP5 (0V) and TP2 (+V) as shown in Figure 14 and

Figure 16. Adjust pot P8.

For high-level alarm voltage, connect your DC voltmeter

3

between TP5 (0V) and TP1 (+V) as shown in Figure 14 and

Figure 16. Adjust pot P7.

34 6109-9000 Rev 4

Page 35

Procedures for bump test and calibration vary

For semiconductor sensors, you MUST use

6.3. Bump Testing

After installation the units should be bump tested. Expose the sensors to

MGD-100 Manual

test gas ampoules (NH

installation). The gas is heavier than air and should fall into the sensor,

putting the system into alarm and lighting the red LED. The delay will

prevent the audible alarm from sounding or the relay from switching (if a

delay is set).

With a bump test you can see the functions of the sensor - the yellow/red

LED will light, and the relay and audible alarm will function.

Ideally bump tests are conducted on site in a clean air atmosphere.

NOTE: Prior to carrying out a bump test, check and adjust

the zero setting as described in the Calibration section.

NOTE:

depending on the sensor technology used and the gas in

question. The MGD-100 is available in two sensor versions:

Semiconductor (SC) and Infrared (IR).

, CO2, etc.) or test cylinder (appropriate to the

3

NOTE: Do not pressurize the sensor.

NOTE:

calibration gas in a balance of air (not N2).

Step Bump Testing Using Calibration Gas Cylinders

1 Remove the enclosure lid of the gas sensor and controller.

Connect the voltmeter to the sensor under test between TP5

2

and TP4 to monitor sensor response.

Expose the sensor to gas from the cylinder by using a plastic

3

hose/hood to direct gas to the sensor head.

6109-9000 Rev 4 35

Page 36

MGD-100 Manual

If the bump test is unsuccessful, perform a

Figure 17. Gas Cylinder and Test Hardware

NOTE:

calibration as described later in this manual.

IMPORTANT: After a semiconductor sensor is exposed to a

substantial gas leak, the sensor should be checked and

replaced if necessary.

Gas ampoules are convenient and inexpensive alternatives to using gas

cylinders for bump testing.

36 6109-9000 Rev 4

Page 37

Figure 18. Gas Ampoules for Bump Testing

Step Bump Testing Using Gas Ampoules

Make sure that both the ampoules and the calibration beaker

1

are clean and dry.

Unscrew the beaker wing nut and place the ampoule so that

2

it sits in the base of the beaker (see Figure 18).

Tighten the wing-nut screw onto the ampoule without

3

breaking it.

4 Remove the enclosure lid of the gas detector.

Connect the voltmeter to the sensor under test between TP5

5

and TP4, to monitor sensor response.

Place the beaker over the sensor head using the multi sensor

adaptor to fit the sensor, or, if an Exd, IP66 or remote sensor

6

head version, screw the beaker on the remote sensor head

M42 thread or M35 thread adaptor. It should be as tight

fitting as possible to allow maximum gas exposure.

Tighten the wing-nut screw onto the ampoule until it shatters

7

allowing the gas to diffuse in the beaker. It should be left in

place for approximately 5 min.

The voltage output will increase. This confirms that the

8

sensor is responding. A response equivalent to at least 50%

(typical) of the test gas confirms that the system is in order.

Remove the beaker from the sensor. Carefully remove any

9

ampoule remains from the gas detector and beaker.

6109-9000 Rev 4 37

MGD-100 Manual

Page 38

MGD-100 Manual

6.4. Calibration Overview

To comply with the requirements of EN378 and the European F-GAS

regulation, sensors must be tested annually. However, local regulations

may specify the nature and frequency of this test.

CAUTION: Check local regulations on calibration or testing

requirements.

6.5. Calibration Options

There are two available calibration options:

• Exchanging the sensor board for a new, pre-calibrated one and

send old one to Bacharach for recalibration (available for twoalarm units and 1- and two-alarm IR units)

• On-site gas calibration.

These are explained in the next two sections.

6.6. Sensor Board Exchange

There are a number of advantages to sensor board exchange. It is

simpler and quicker than gas calibration.

NOTE: Bacharach recommends exchanging your sensor

PCB for a new pre-calibrated one every 3 years.

Tools required:

• A pre-calibrated sensor board

• A voltmeter (crocodile clips recommended)

Step Sensor Board Exchange

1 Power off the unit and remove lid of sensor enclosure.

Note the color code of the cable in positions 1,2,3 and 4 of

2

the connector block.

Undo the cable and 2 screws securing the sensor board and

3

remove the board.

38 6109-9000 Rev 4

Page 39

Step Sensor Board Exchange

MGD-100 Manual

Fit the new pre-calibrated sensor and reconnect the cable in

4

the correct color sequence at positions 1,2,3 and 4.

Power on the unit and allow to stabilize for 15 minutes

5

(minimum).

Check voltage readings on positions 1,2,3 and 4 (see Table 1

6

on page 42) to ensure that wiring is correct. Note also in the

table how to monitor the sensor as it stabilizes.

7 Carry out a bump test to confirm the sensor is responding.

Keep records of the test date, sensor serial number, and any

8

observations.

6.7. On-Site Gas Calibration

This section and the next cover calibration using calibration gas

cylinders. Bacharach offers a calibration kit that consists of a calibration

gas cylinder and a flow regulation valve with flexible non-absorbent

tubing and vented calibration hood.

In some cases this option may be expensive relative to sensor exchange

because of the cost of visiting a site, calibration gas, etc.

The procedure involves electrical set-up followed by adjustment using

calibration gases. Equipment required is as follows:

• Gas cylinder with the appropriate target gas and concentration

• Fixed flow regulator – rate 0.3L/min

NOTE: The sensor delay is approximately 25 seconds and

cannot be deactivated

All adjustments are performed on the MGD-100 sensor PCB. The

Sensor Standby Voltage and two Alarm Threshold Voltages must be

adjusted.

Step Adjusting the Sensor Standby Voltage (SSV)

Connect the voltmeter between TP5 (0V) & TP4 (+Ve) and

1

6109-9000 Rev 4 39

adjust pot RV1 for 0.3V (on IR units SSV is fixed).

Page 40

MGD-100 Manual

threshold or the unit will not

Step Adjusting the Low Alarm Threshold Voltage (ATV)

Monitor the voltage between TP5 (0V) & TP4 (+Ve)/0V and

2

VS on IR units.

Apply the low concentration calibration gas to the sensor and

3

wait until the sensor output signal stabilizes. Record this

voltage.

Adjust P8 to the new value. Record and use the new value

4

for subsequent electrical set-ups.

Step Adjusting the High Alarm Threshold Voltage (ATV)

Monitor voltage between TP5 (0V) & TP4 (+Ve)/0V and VS

5

on IR units.

Apply the high concentration calibration gas to the sensor

6

and wait until the sensor output signal stabilizes. Record this

voltage.

Adjust P7 to the new value. Record and use the new value

7

for subsequent electrical set-ups.

CAUTION: The high alarm threshold voltage must be set

higher than the low alarm

function correctly.

40 6109-9000 Rev 4

Page 41

controller PCB board

connectors on the controller.

Section 7. Troubleshooting

Symptom Possible Cause(s)

No lights displayed

on panel

• Power failure (check supply)

• Tripped circuit breaker or blown fuse on

electrical supply

• Blown fuse at the electrical supply on the

MGD-100 Manual

Red light is on, but

no alarm condition is

active (i.e., no siren

and no relay

• Make sure the siren has not been

deactivated by key switch.

• This indicates a wiring or sensor fault (call

service provider).

operation after 3

minutes)

Controller is on, but

the MGD-100 is not

• This may indicate a wiring fault between

the controller and sensor or a sensor fault.

Check power supply to the controller.

Check connections between the controller

and the sensor to ensure that the wires

from positions 1 to 4 on the sensor are

connected to the corresponding 1 to 4

NOTE: If false alarms are being triggered by background

gases, paint fumes, etc., or extreme humidity or temperature

conditions, you may adjust the settings to compensate.

You should adjust the relevant sensor alarm threshold

voltage upwards in 0.2 V increments until the condition

clears.

To make sure the gas detectors are wired up correctly you can check the

voltages at the sensor cable terminal blocks on the controller PCB or

sensor PCB using a voltmeter as outlined below in Table 1.

Place the negative probe on terminal position 4 and with the positive on

1, 3, 2, check the values. The readings are lower at the sensor due to

power drop in the line.

The terminals should have the values shown in the table below.

You can monitor this as follows:

6109-9000 Rev 4 41

Page 42

MGD-100 Manual

• Connect voltmeter and monitor voltage between TP5 (0V) and

TP4 (+Ve). For IR, monitor between 0V and VS.

Table 1. Connections Correct Values

Position

Number

At the Sensor Controller

1 12V Power Supply +10V

2 Sensor output, These are approximate,

typical internal reference values.

(0=Fault)

+0.4V

+1.6V

+2.8V

3 Approximately 4-5V +4.8-5V

4 Is the negative side of the power supply Negative

* The voltage signal from the sensor will start high and gradually fall (in clean

air) to the SSV value shown on the calibration label. IR unit will display 0 Volts

until the 2 minute warm-up has finished.

42 6109-9000 Rev 4

Page 43

MGD-100 Manual

ECLARATION OF CONFORMITY

D

The manufacturer of the

products covered by this

declaration:

Year(s) conformity is

declared:

Product(s): MGD

Model(s): MGD-100

The undersigned hereby declares that the above referenced products are in conformity

with the provisions of the following standard(s) and is in accordance with the following

directive(s).

Directive(s):

2004/108/EC EU EMC Directive

2006/95/EC Low Voltage Directive (LVD)

Standard(s):

Bacharach, Inc.

621 Hunt Valley Circle

New Kensington, PA 15068

2014 (IEC/EN61010), 2011 (EN61326/EN55011)

IEC 61010-1: 2010

EN 61010-1: 2010

EN 61326-1: 2006

Safety Standards

Electromagnetic

Compatibility

(EMC) Standards

Electrical Equipment for Measurement,

Control, and Laboratory Use; Part 1:

General Requirements

Electrical Apparatus for the Detection

and Measurement of Combustible

Gases, Toxic Gases, or Oxygen

Signature:

Name: Aaron Kennison

Title: Engineering Manager

Date: June 11, 2014

The technical documentation file required by this directive is maintained at the corporate

6109-9000 Rev 4 43

headquarters of Bacharach, Inc.

Page 44

MGD-100 Manual

World Headquarters

621 Hunt Valley Circle, New Kensington, Pennsylvania 15068

Phone: 724-334-5000 • Toll Free: 1-800-736-4666 • Fax: 724-334-5001

Website: www.MyBacharach.com • E-mail: help@MyBacharach.com

44 6109-9000 Rev 4

Loading...

Loading...