Page 1

Page 2

Page 3

CONTENTS

INTRODUCTION......................................................................................................................2

USING THE CIRCULAR ATTACHMENT TO SEW PATTERNS IN A CIRCLE...............................2

About the Circular Attachment.............................................................................................. 2

Included Accessories............................................................................................................. 2

Attaching the Circular Attachment......................................................................................... 3

Sewing a Circle ..................................................................................................................... 3

Using the Quarter Circle Template........................................................................................ 5

Using the Included Presser Feet............................................................................................. 5

CREATING BOBBIN WORK......................................................................................................7

About Bobbin Work .............................................................................................................. 7

Required Materials ................................................................................................................ 8

Upper Threading................................................................................................................... 9

Preparing the Bobbin Thread................................................................................................. 9

Positioning the Fabric and Sewing....................................................................................... 12

Adjusting the Thread Tension.............................................................................................. 15

Troubleshooting .................................................................................................................. 16

LIST OF STITCHES THAT CANNOT BE USED WITH THE CIRCULAR ATTACHMENT............ 17

ENGLISH

1

Page 4

INTRODUCTION

Note

CAUTION

This Addendum provides additional information not described in the Instruction and Reference Guide.

Refer to these instructions after first reading the Instruction and Reference Guide provided with your sewing

machine.

USING THE CIRCULAR ATTACHMENT TO SEW

PATTERNS IN A CIRCLE

About the Circular Attachment

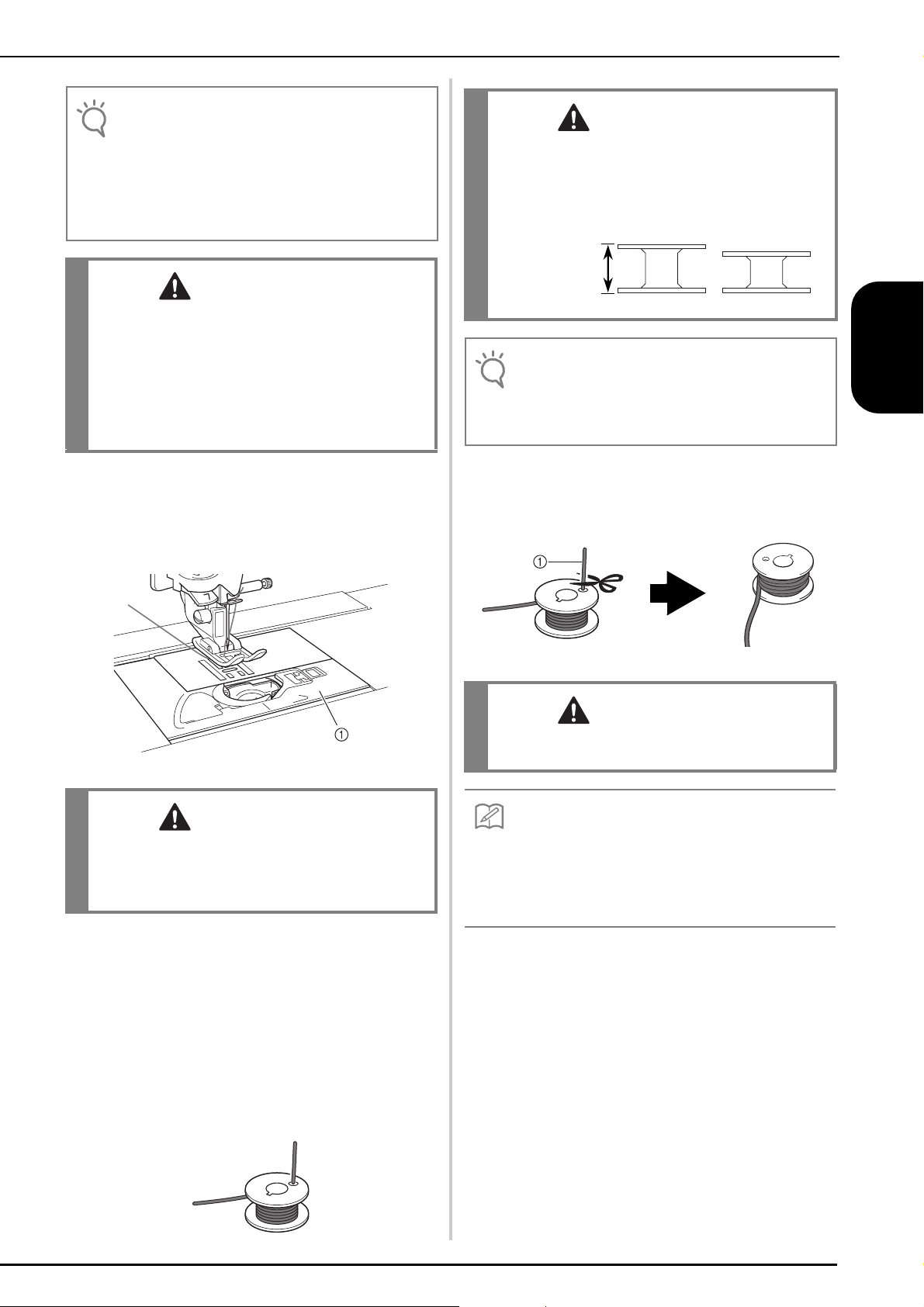

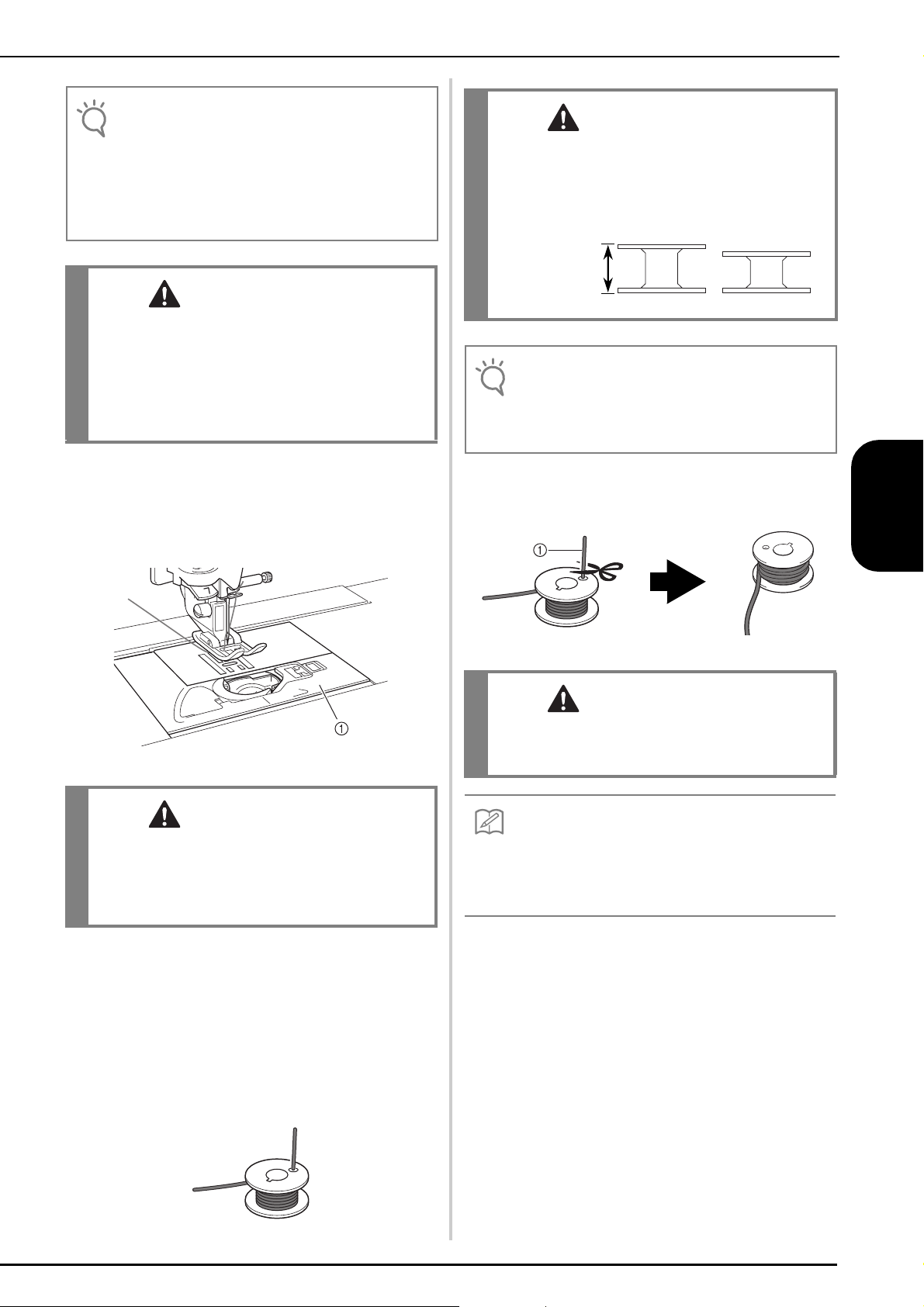

This device can sew circular patterns that graduate out at 5mm intervals, ranging from 30mm to 130mm in

radius* when the center needle position is selected. The device is set to the left of the needle on your sewing

machine. Utility and decorative stitches can both be sewn using this device.

*

Radius= Distance from center of circle to any point on the circle.

• You cannot use any decorative stitch with side feeding or stitches with a width over 7.0 mm. Before sewing on your

project, be sure to sew trial stitches and check the sewing results. If stitches that cannot be used are sewn, the pattern

may become misaligned. For a list of stitches that cannot be used, refer to the table “LIST OF STITCHES THAT CANNOT

BE USED WITH THE CIRCULAR ATTACHMENT” located on page 17.

• Special care is required for the pivot pin; neglectful treatment may cause injury. Young children should be

supervised to ensure that they do not play with the attachment. When attachment is not in use, always

keep the pivot pin in the indicator to avoid its loss.

Included Accessories

1 4 Conversion Chart 5

mm (f)inch

130 5 3/16

120 4 3/4

110 4 3/8

100 4

2 3 90 3 1/2 6

80 3 3/16

70 2 3/4

60 2 3/8

50 2

40 3/2

30 13/16

No. Part Name Part Code

1 Circular Attachment

a Indicator

b Handle/Flips Up

c Release button

d Setting position for pivot pin

e Scale

2 Pivot Pin XE6016-001

3 Attachment Screw

(2pcs. one is extra)

-

XE6022-001

No. Part Name Part Code

4 Template

f Radius of circle in mm

g Angular lines listed in degrees

starting at 0 with 5 degree

intervals

h Center

5 Braiding Foot XE5680-001

6 Cording Foot XA6871-001

XE6024-001

2

Page 5

Note

• We recommend that you use the extension table on

3040

Note

Note

your sewing machine for smooth fabric control.

• Do not raise the extension table when the circular

devise is attached.

• The pivot pin may be released if you hold up the

fabric while attached to the circular attachment.

When holding up the fabric gently press down on the

top of the pivot pin.

• When sewing smaller circles or using fabric with a

grain or uneven textures, a perfect circle may not be

achieved.

• Some of presser feet such as the side cutter cannot

be used with this attachment, always test your

accessory feet with the attachment.

• When using this attachment test the sewing speed

of your machine for the best results.

• When sewing larger pieces of fabric or garments,

make sure that your fabric or garment does not get

caught on the machine creating drag or distortion of

your design.

Securely tighten the screw with the disc-

c

shaped screwdriver included in your

machine.

a Disc-shaped screwdriver

Sewing a Circle

• Thread the machine needle before setting the pivot

pin into the circular attachment. Threading lever

may hit the pivot pin and damage the pin or the

machines threading mechanism.

ENGLISH

Attaching the Circular Attachment

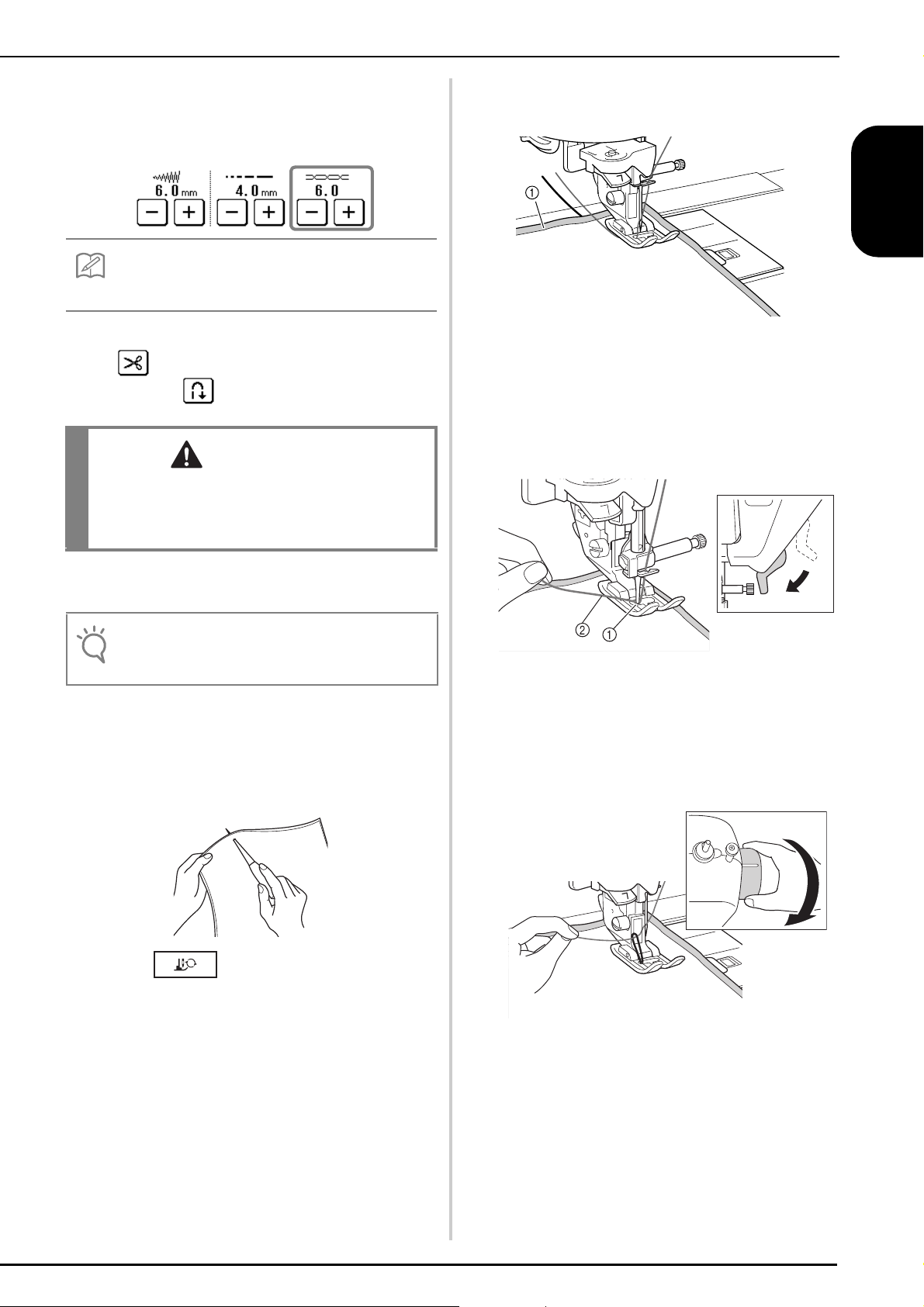

Place the circular attachment at left as shown

a

in the figure.

→ The two tabs on the underside of the attachment will

drop down into corresponding holes in the needle

plate, so that the attachment lays flat on the bed of

your machine.

Insert the screw on the circular attachment in

b

the screw hole at the right of the needle plate

(a).

Raise the handle.

a

Slide the indicator to match the desired size

b

of your circle.

• Do not slide the indicator by holding onto the pivot

pin, doing so may cause the pivot pin to bend or

break.

a Attachment Screw

3

Page 6

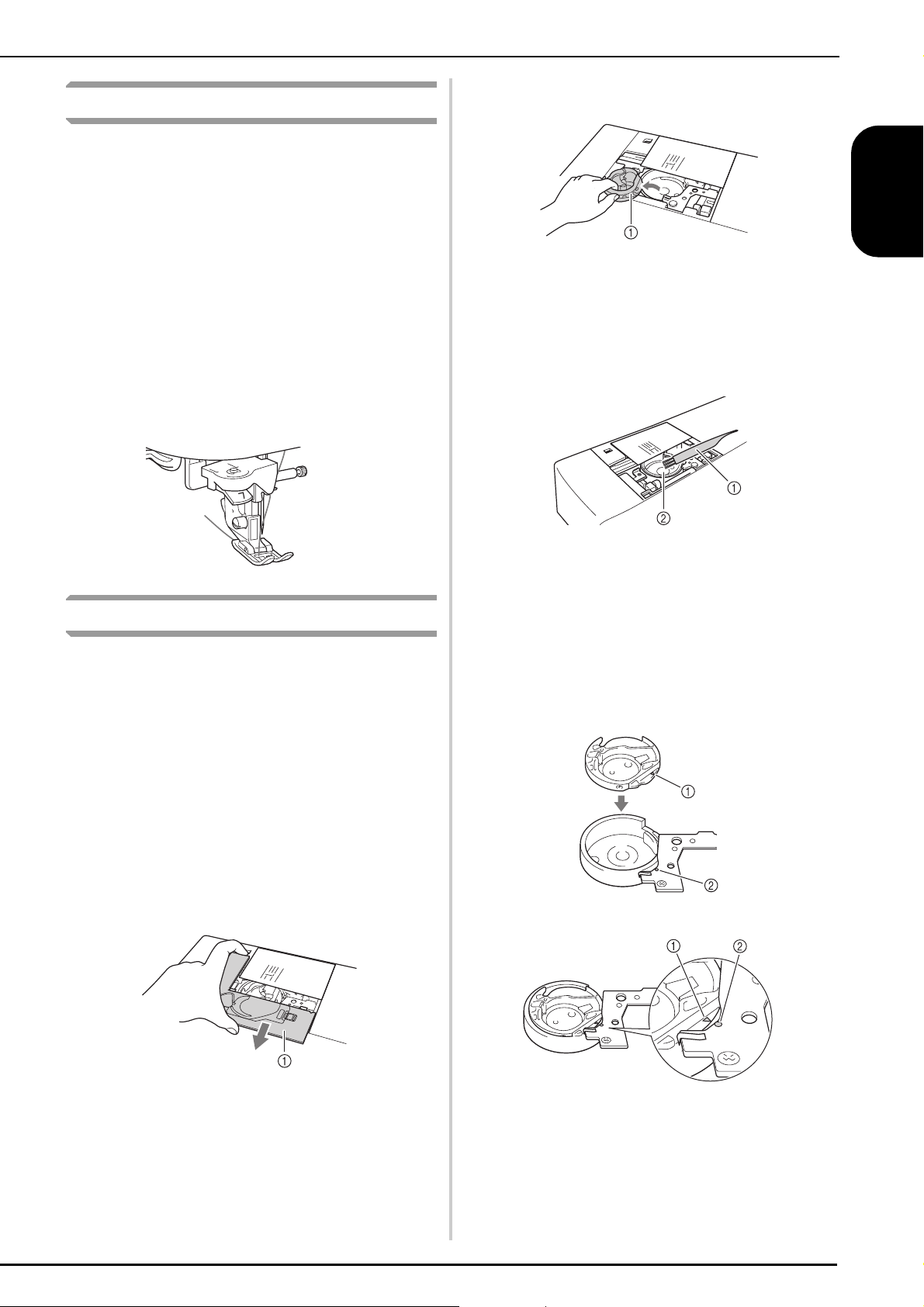

Use a piece of stabilizer that is larger than

Note

Note

CAUTION

c

your design area, reinforcing with a smaller

piece of the stabilizer at the center of the

circle when using fine fabric or the same

pivot pin area repeatedly.

a Wrong side of Fabric

b Stabilizer

c Reinforcement Stabilizer

d Pivot Pin area

• A stabilizer is always required when sewing on any

fabric or garment to prevent stretching or puckering.

Depending on the type of fabric being sewn, will

determine wether you use permanent, iron on,

temporary or a sticky stabilizer.

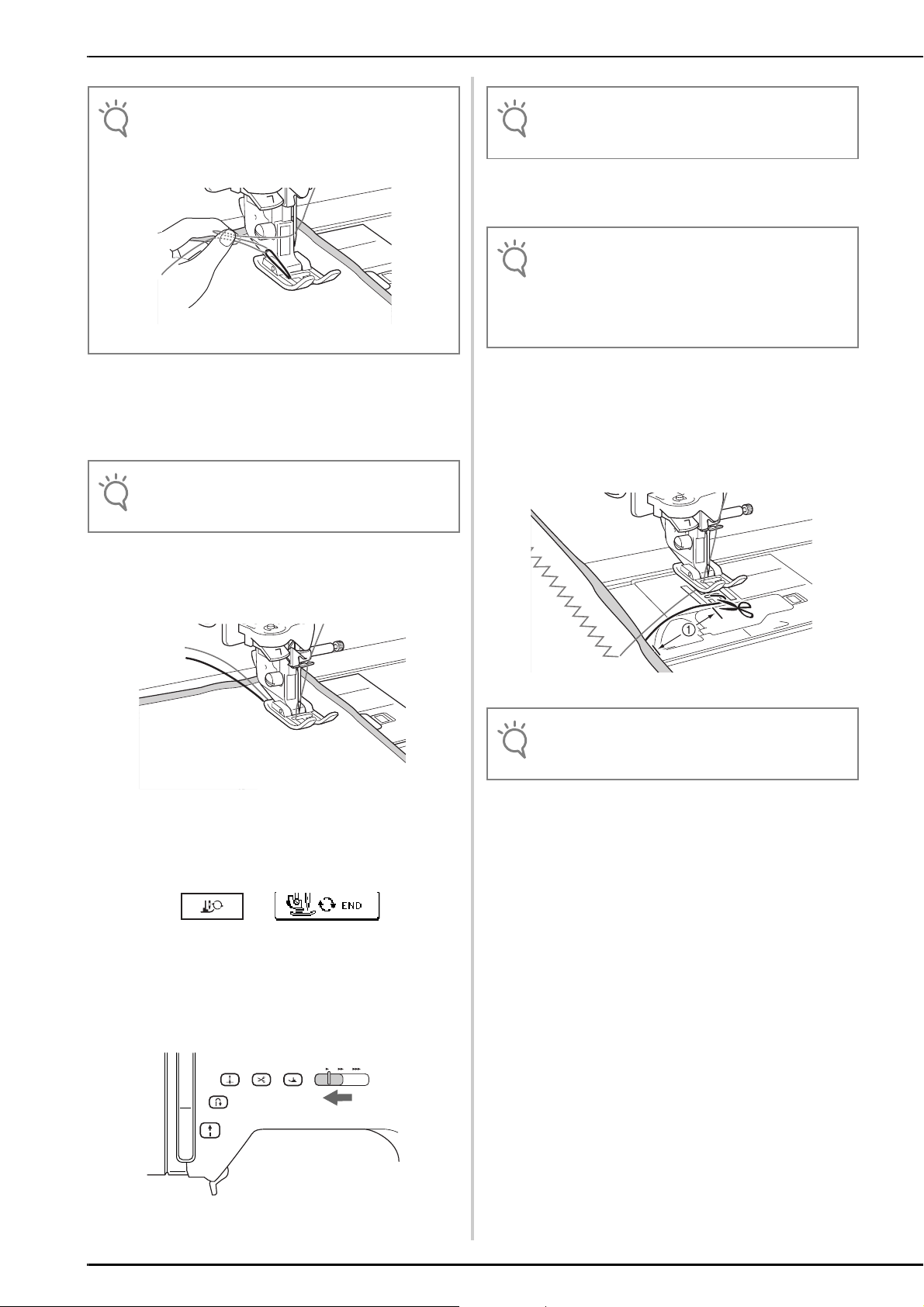

Insert the pivot pin at the center of circle

d

from the right side of fabric.

Pressing the top of the pivot pin, insert the

e

point of the pivot pin into the “Y” mark on

the attachment.

a Right side of Fabric

b Wrong side of Fabric

Select the desired stitch and sew allowing the

f

fabric to feed smoothly, making sure that you

do not push or pull your fabric causing an

uneven circle.

a Pivot Pin

b Center of circle

c Right side of Fabric

• When sewing a small diameter circle, we

recommend that you first pin the fabric to the

attachment and then set the indicator to your

desired size.

After sewing, always press the release button

g

to remove the pin and fabric from the circular

attachment.

a Release button

• Do not leave the pivot pin inserted in your fabric

and not attached to the circular attachment. To do

so may result in accidental injury or machine

damage.

4

Page 7

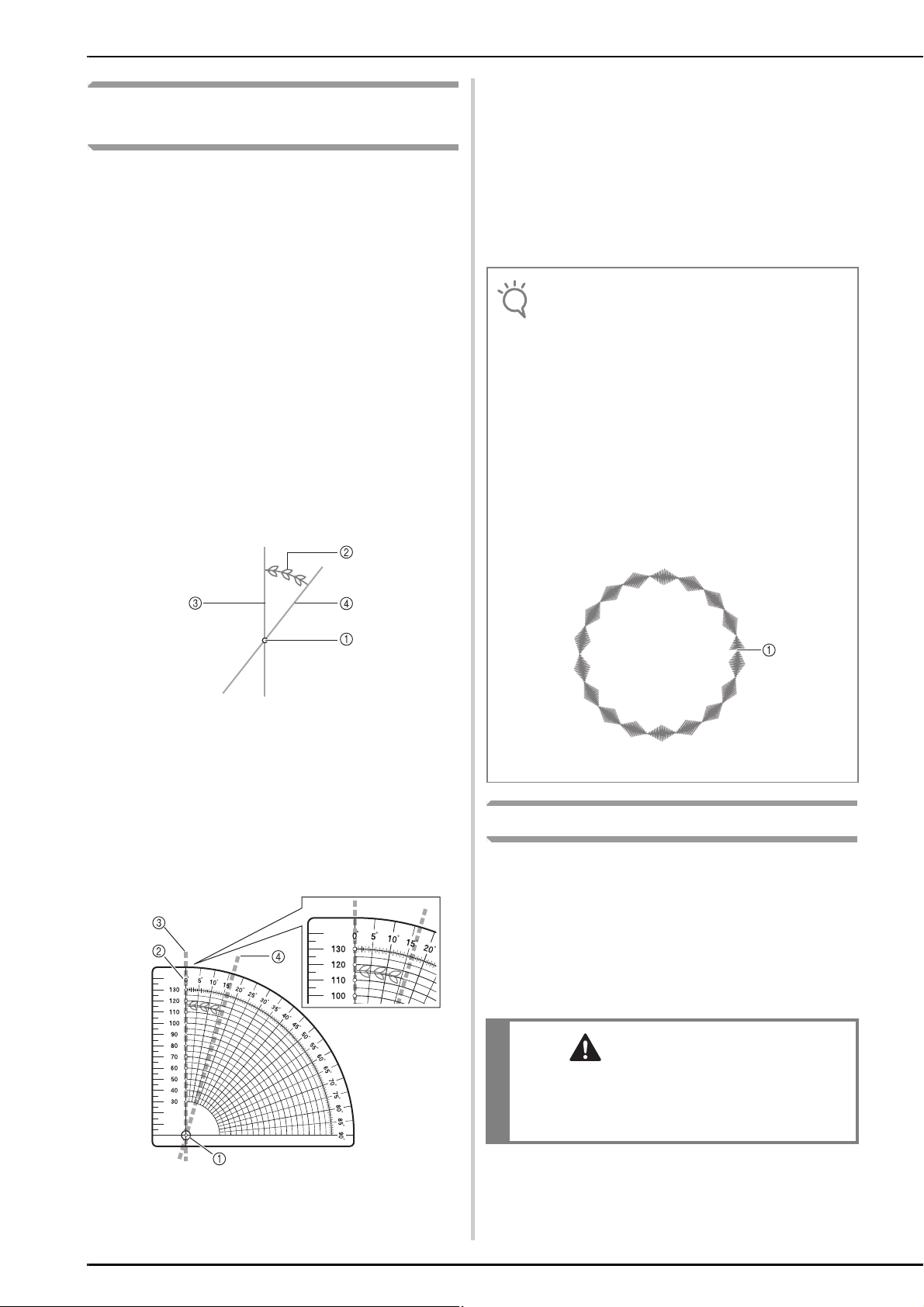

Using the Quarter Circle Template

Note

CAUTION

When combining utility or decorative stitches, or

repeating an individual stitch, use the included

template as a guide.

Mark the pivot point (center of your circle)

a

prior to sewing on the fabric (a).

Select your desired stitch and the size of a

b

circle using the markings on the attachment,

then place the fabric on the attachment.

Sew a single stitch or one pattern

c

combination (b).

Remove fabric or garment from attachment.

d

With temporary pencil draw two lines from

e

the pivot point, one at the start of your stitch

pattern (c) and one at the end of the stitch

pattern (d).

Check the line at the end of the stitch (d) and

g

note the approximate degrees. With a circle

measuring 360 degrees divide the stitch

length (your degree/stitch measurement) into

360 and that will give you an approximate

count on the stitch repetitions. SAMPLE: Your

stitch is 16 degrees long so: 360 divided by 16

equals 22.5 repetitions.

• This is not an exact count due to the number of

variables i.e. stitch length, fabric used, thread and

the stabilizer. You may be able to adjust the length

of the stitch, depending on the stitch used,

increasing or decreasing to get a closer match so

that your circle closes without overlapping or

shortage (a).

• Always stitch a trial version of the design checking

the stitch length, width and the direction of sewing,

making sure that it is suitable for your project.

• Additional calculations may be necessary if your

pattern overlaps.

Example: Shortage of the Pattern

ENGLISH

a Pivot Point

b Single stitch/Pattern combination

c Start of the stitch

d End of the stitch

Place the template on top of your design,

f

lining up the center pivot point and the center

marking on the template (a). Then place the

0 degree line on the right side of template (b)

at the start of the stitch (c).

a End of the stitch

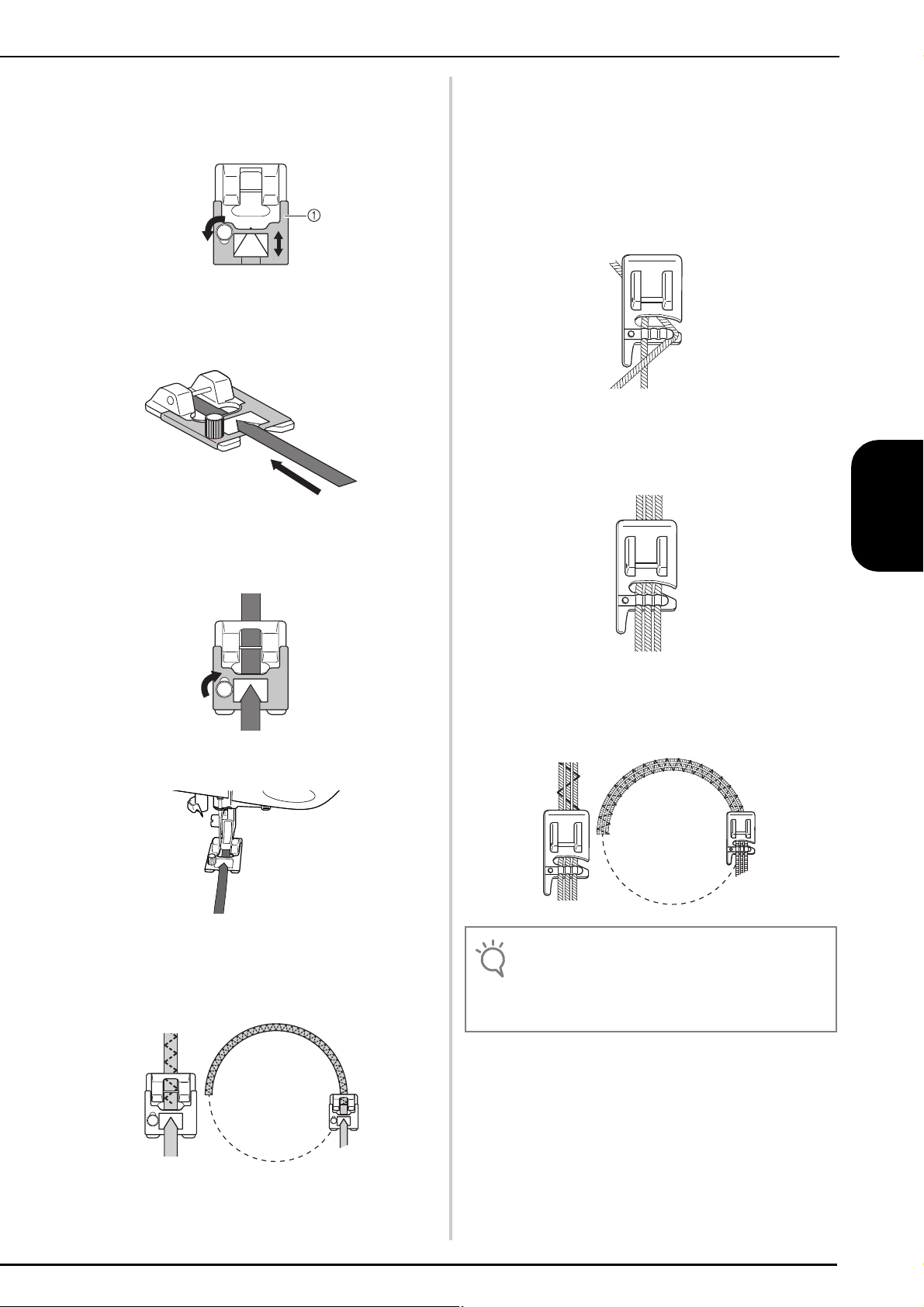

Using the Included Presser Feet

Using the included presser feet, you can embellish

your sewing projects, giving them a professional look

with your personal flair.

■ BRAIDING FOOT

You can use a wide variety of braiding up to 5mm in

width, using straight, zigzag and select decorative

stitches.

• Do not use this foot when sewing with densely

woven braiding that is difficult for the needle to

penetrate easily. Doing so could result in needle

breakage, damage and/or injury.

a Center on template

b 0 degree line

c Start of the stitch

d End of the stitch

5

Page 8

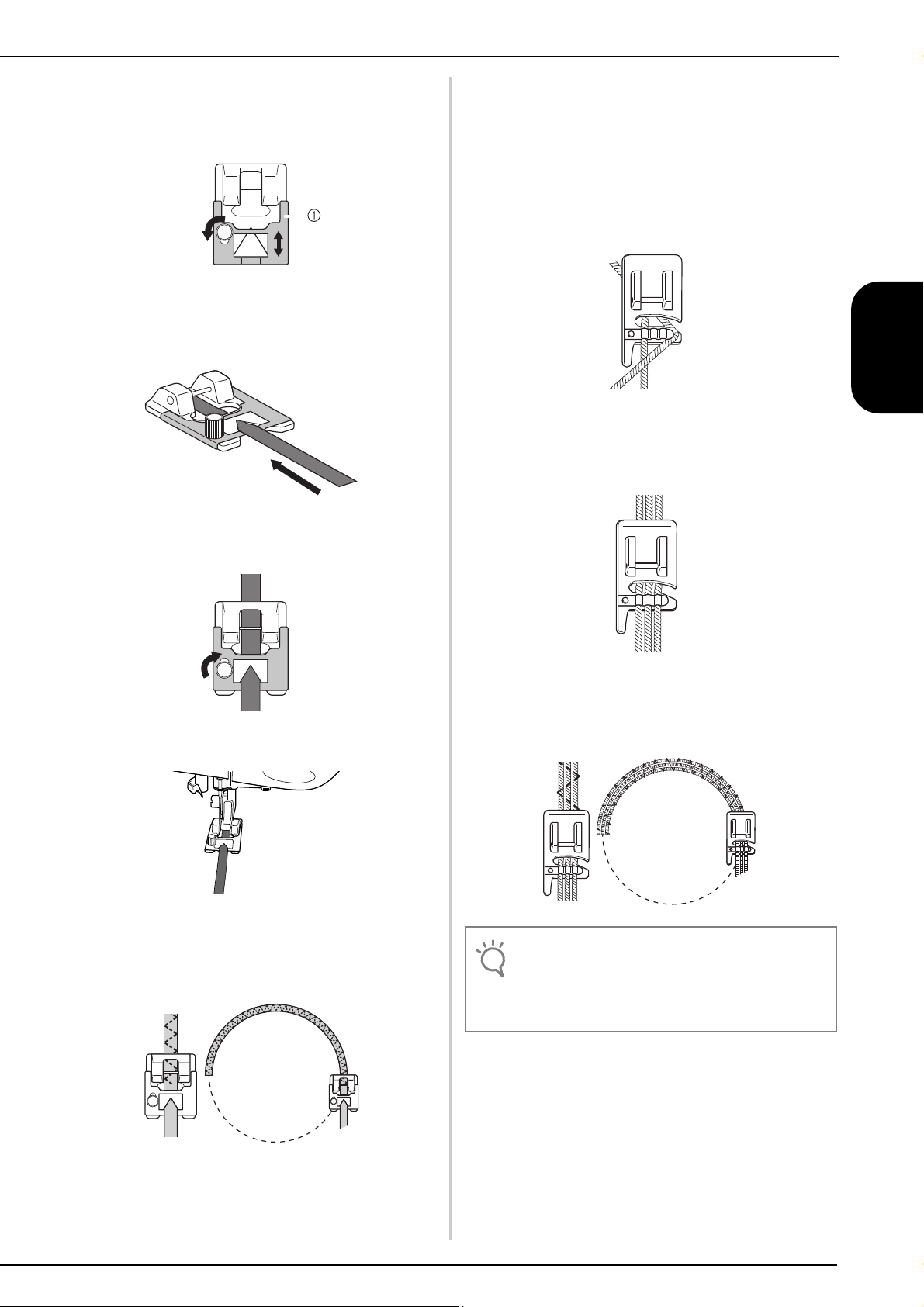

Loosen the screw on the guide plate sliding

Note

a

the plate to fit the width of the braid.

a Plate

Insert the braid through the guide before

b

attaching the foot onto the machine.

Tighten the screw and pull the braid to the

c

back of the braiding foot.

■ CORDING FOOT

You can embellish using 1 to 3 cords of decorative

threads or yarn.

Slip a cord from the right of the presser foot,

a

into each guide (to use single cord, use the

center guide).

Place the cords under and to the back of the

b

cording foot.

Attach the foot onto the machine.

d

Select the desired stitch and sew in a circular

e

manner gently guiding the braid.

Select a zigzag or decorative stitch and sew in

c

a circular manner gently guiding the cords.

• When sewing with zigzag or decorative stitches,

adjust the stitch width, so that it is slightly wider than

the width of the braid or cording.

6

Page 9

CREATING BOBBIN WORK

About Bobbin Work

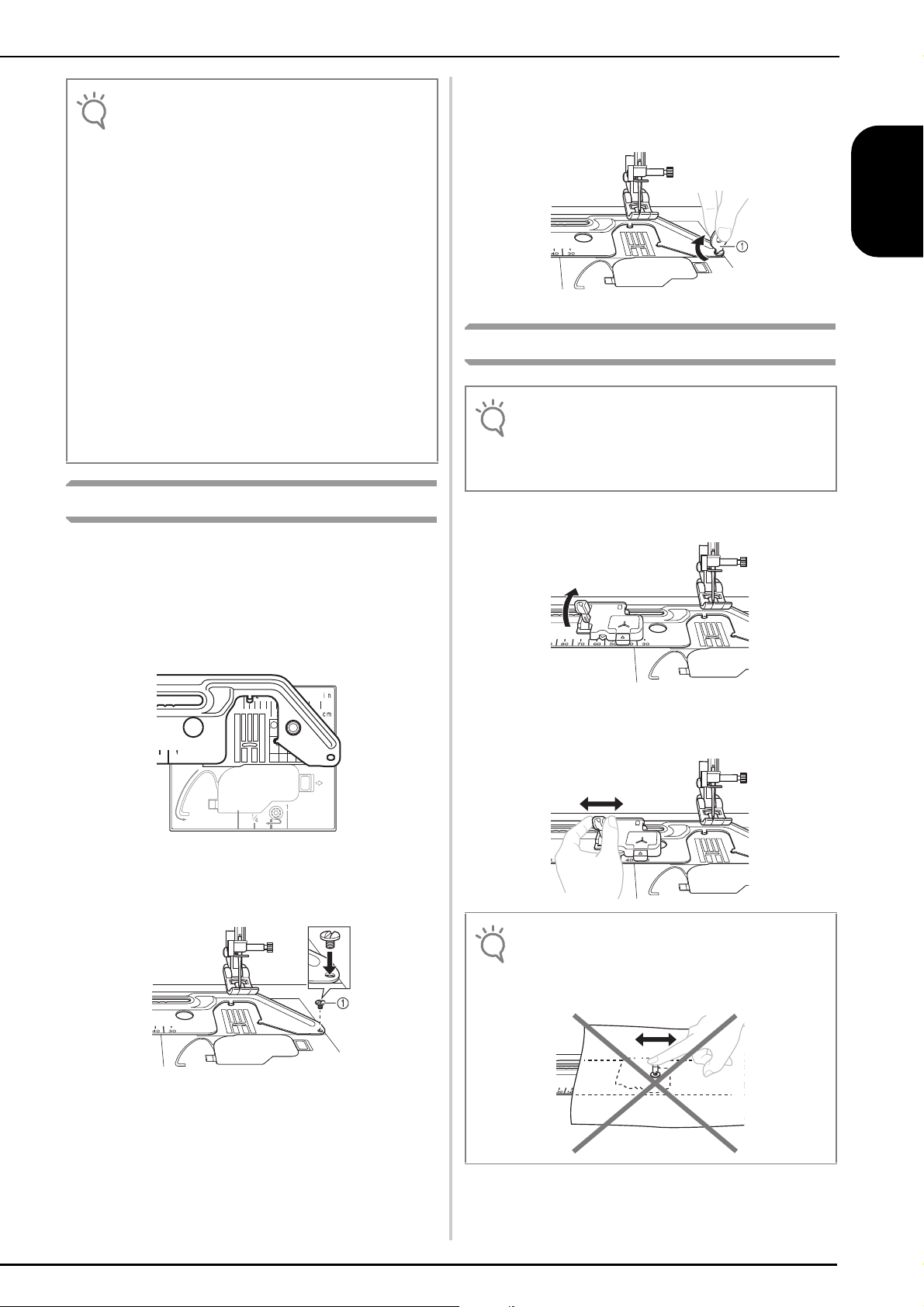

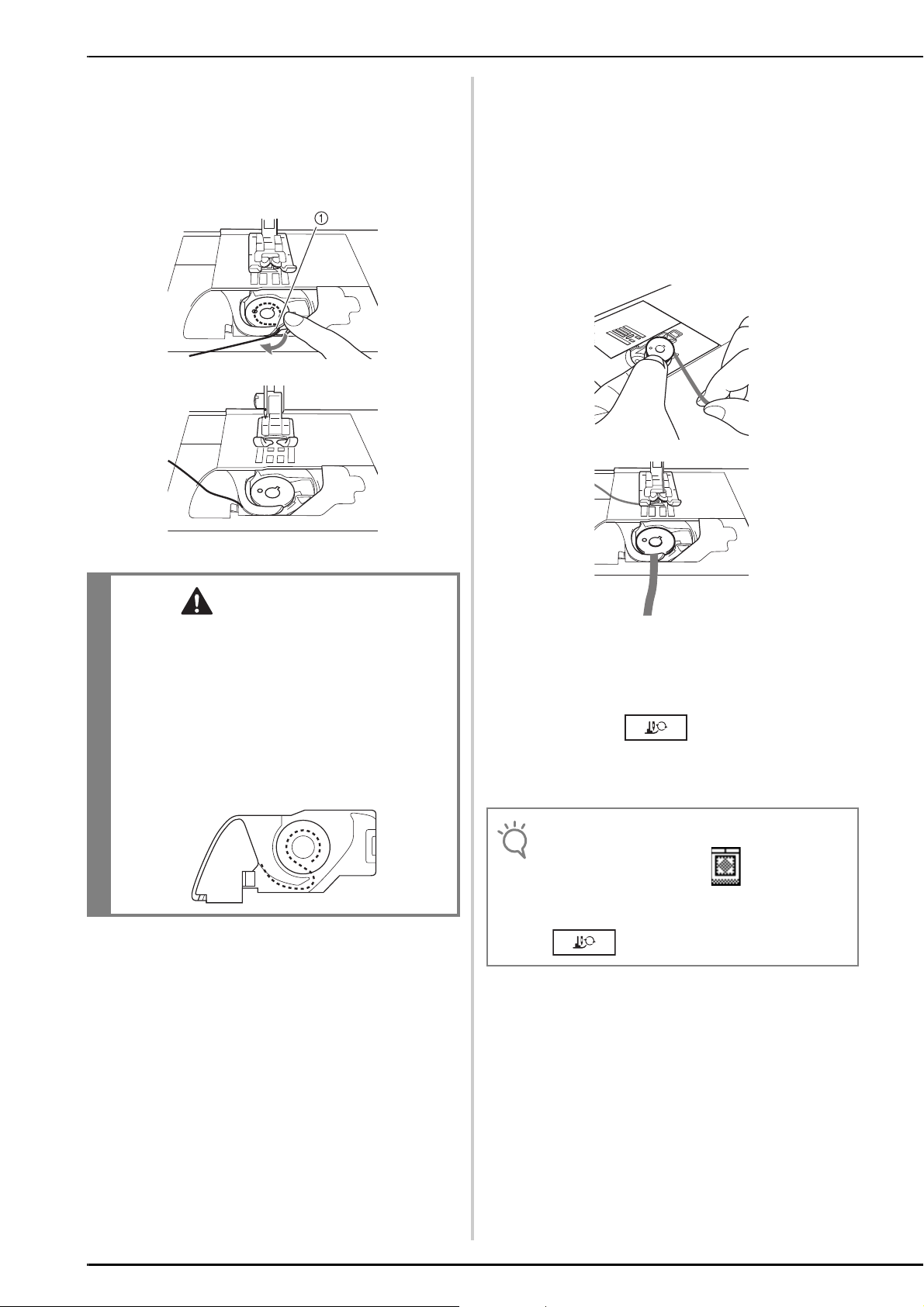

Beautiful embroidery work, with a three-dimensional appearance, can be created by winding the bobbin with heavy

weight thread or ribbon, which is too thick to be threaded through the machine’s needle. The decorative thread or

ribbon will stitch out on the underneath side of fabric while sewing with the fabric wrong side facing up.

ENGLISH

1. Utility stitches 2. Decorative stitches 3. Free motion sewing

7

Page 10

Required Materials

Note

Note

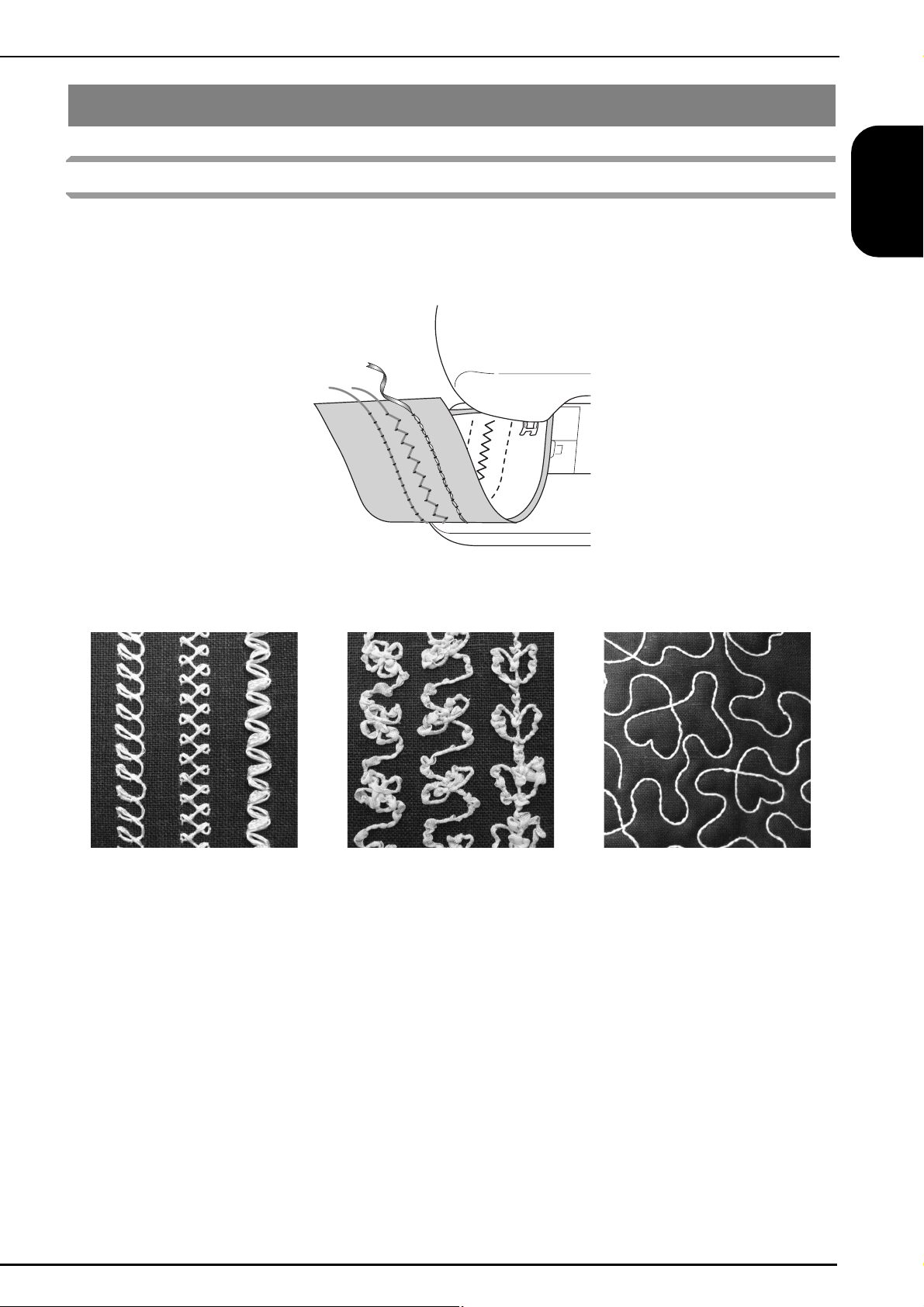

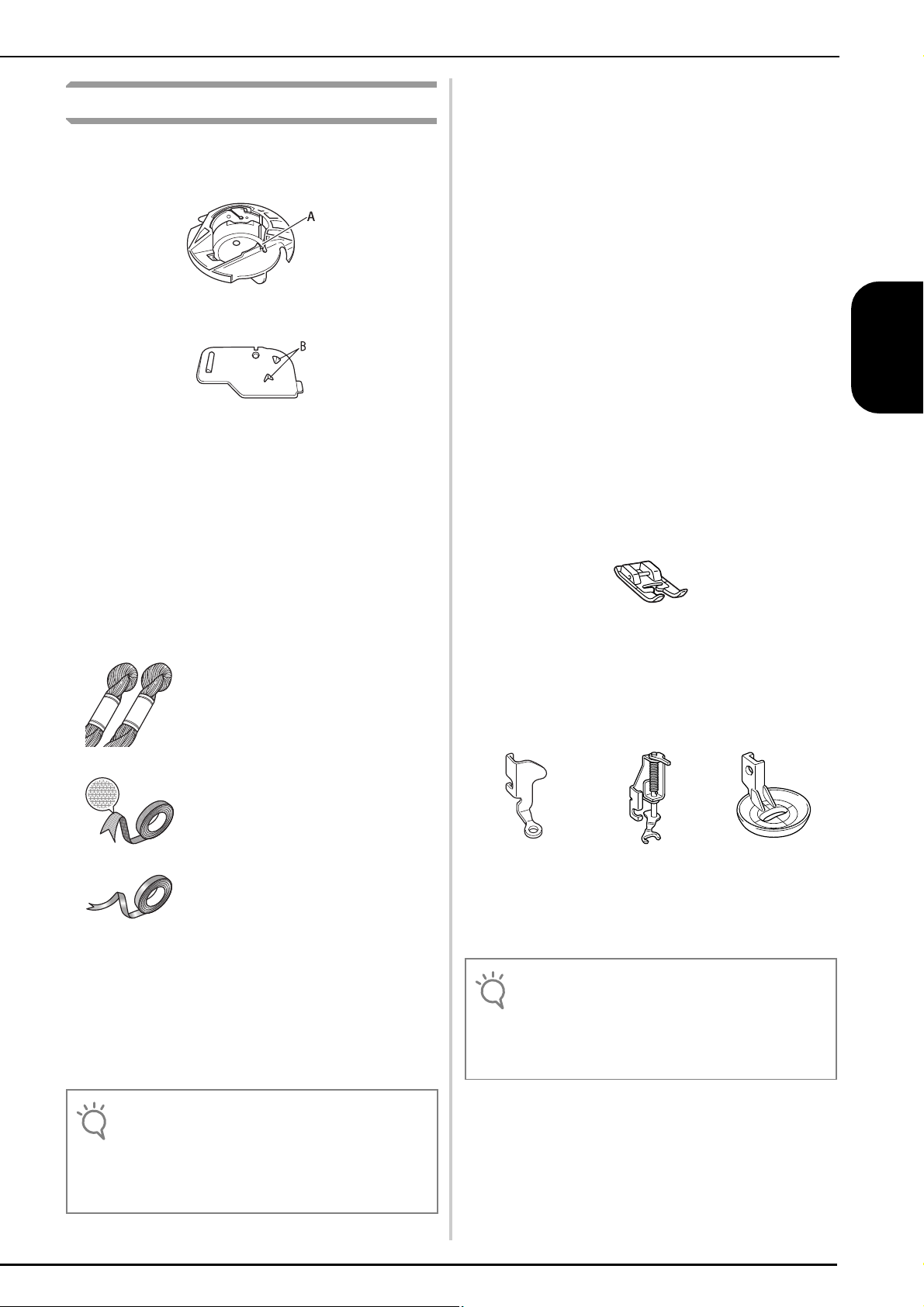

■ Bobbin case and cord guide bobbin cover

a Bobbin case (gray)

There is a notch at the location indicated by the letter

“A”.

b Cord guide bobbin cover (for bobbin work or attaching

cording using single hole).

There are two small v-shaped tabs on the back of the

bobbin cover as indicated by the letter “B”.

The tabs help hold the bobbin in place so it does not lift

up while thick thread is being pulled through.

■ Lower thread

We recommend the following types of threads for

bobbin work.

■ Upper thread

Upper thread choices can vary depending on the

finished look you would like to achieve. By using

sewing machine embroidery thread (polyester),

multipurpose polyester thread, or monofilament

(transparent nylon) thread the appearance of a single

design can be changed many times just by choosing a

different upper thread weight and/or color.

If you do not wish for the upper thread to be visible, we

recommend using monofilament thread or polyester

light weight thread (50wt. or above) that is the same

color as the lower thread.

■ Needle

Use a needle appropriate for the upper thread and

fabric being used. Refer to “Fabric/Thread/Needle

Combinations” (in the chapter “CHANGING THE

NEEDLE”) in the Instruction and Reference Guide.

■ Presser foot

Utility stitches or decorative stitches: Monogramming

foot “N”

No.5 or finer hand embroidery

thread or decorative thread

Flexible woven ribbon

Fine embroidery ribbon (silk or

silk-like material) (3.5 mm (approx.

1/8 inch) or less, recommended)

* When wide ribbon or heavy weight threads are being used, we

recommend test sewing with and without bobbin case tension

being applied to see which gives the best stitching results.

If wide ribbon such as 3.5mm (approx. 1/8 inch) is to be used,

we recommend that bobbin case tension not be applied. Refer

to page 11 for more detailed instructions.

• Do not use thread heavier than No.5 hand

embroidery thread.

• Some threads may not be appropriate for bobbin

work. Be sure to sew trial stitches before sewing on

your project.

Free motion sewing: Free motion quilting foot “C”, Free

motion open toe quilting foot “O” or Free motion echo

quilting foot “E”

■ Fabric

Be sure to sew trial stitches on a piece of scrap fabric,

which includes the same threads and fabric as what is

being used in your project.

• The sewing results may be affected by the type of

fabric used. Before sewing your project, be sure to

sew trial stitches on a piece of scrap fabric that is

the same as the fabric used in the project.

8

Page 11

Upper Threading

Install a needle appropriate for the upper

a

thread and fabric to be used.

For details on installing the needle, refer to

“CHANGING THE NEEDLE” in the Instruction

and Reference Guide.

Remove the bobbin case.

d

ENGLISH

Attach the presser foot.

b

For details on attaching the presser foot, refer to

“CHANGING THE PRESSER FOOT” in the

Instruction and Reference Guide.

Thread the machine with the upper thread.

c

For details on threading the machine, refer to

“Upper Threading” in the Instruction and

Reference Guide.

Preparing the Bobbin Thread

In order to create bobbin work, the bobbin case must

be replaced with the one for bobbin work.

Before creating bobbin work, clean the bobbin case

and the race.

a Bobbin case

Use the cleaning brush included with the

e

machine or a vacuum cleaner to remove any

lint and dust from the race and its

surrounding area.

a Cleaning brush

b Race

Wipe the bobbin case (gray) with a soft lint

f

free cloth to clean it.

Insert the bobbin case (gray) so that the S

g

mark on bobbin case aligns with the ● mark

on machine as shown below.

Raise the needle and presser foot, and then

a

turn off the machine.

Remove the flat bed attachment.

b

Grasp both sides of the needle plate cover,

c

and then slide it toward you to remove it.

a Needle plate cover

a S mark

b ● mark

9

Page 12

Note

• The bobbin case (gray) cannot be used for sewing in

CAUTION

CAUTION

CAUTION

Note

CAUTION

Memo

any way other than bobbin work. After sewing

bobbin work, refer back to the steps in "Preparing

the Bobbin Thread" for removing and cleaning the

bobbin case (gray), and then reinstall the standard

bobbin case (black).

• Be sure to use the bobbin case (gray) when creating

bobbin work. Using any other bobbin case may

result in the thread becoming tangled or damage to

the machine.

• Make sure that the bobbin case is correctly

installed. If the bobbin case is incorrectly installed,

the thread may become tangled or the machine may

be damaged.

• Be sure to use the included bobbin or one designed

specifically for this machine (Class 15). Using any

other bobbin may result in damage or injuries.

Actual size

11.5 mm

(approx.

7/16 inch)

This model Other models

• Slowly and evenly wind the thread around the

bobbin.

• For best results, wind the bobbin so the thread is not

twisted.

Install the needle plate cover.

h

For details on installing the needle plate cover,

refer to “Cleaning the Race” in the Instruction

and Reference Guide.

a Needle plate cover

• When creating bobbin work, use the cord guide

bobbin cover (for bobbin work and attaching

cords), otherwise the thread may become tangled

or the needle may break.

Install the flat bed attachment.

i

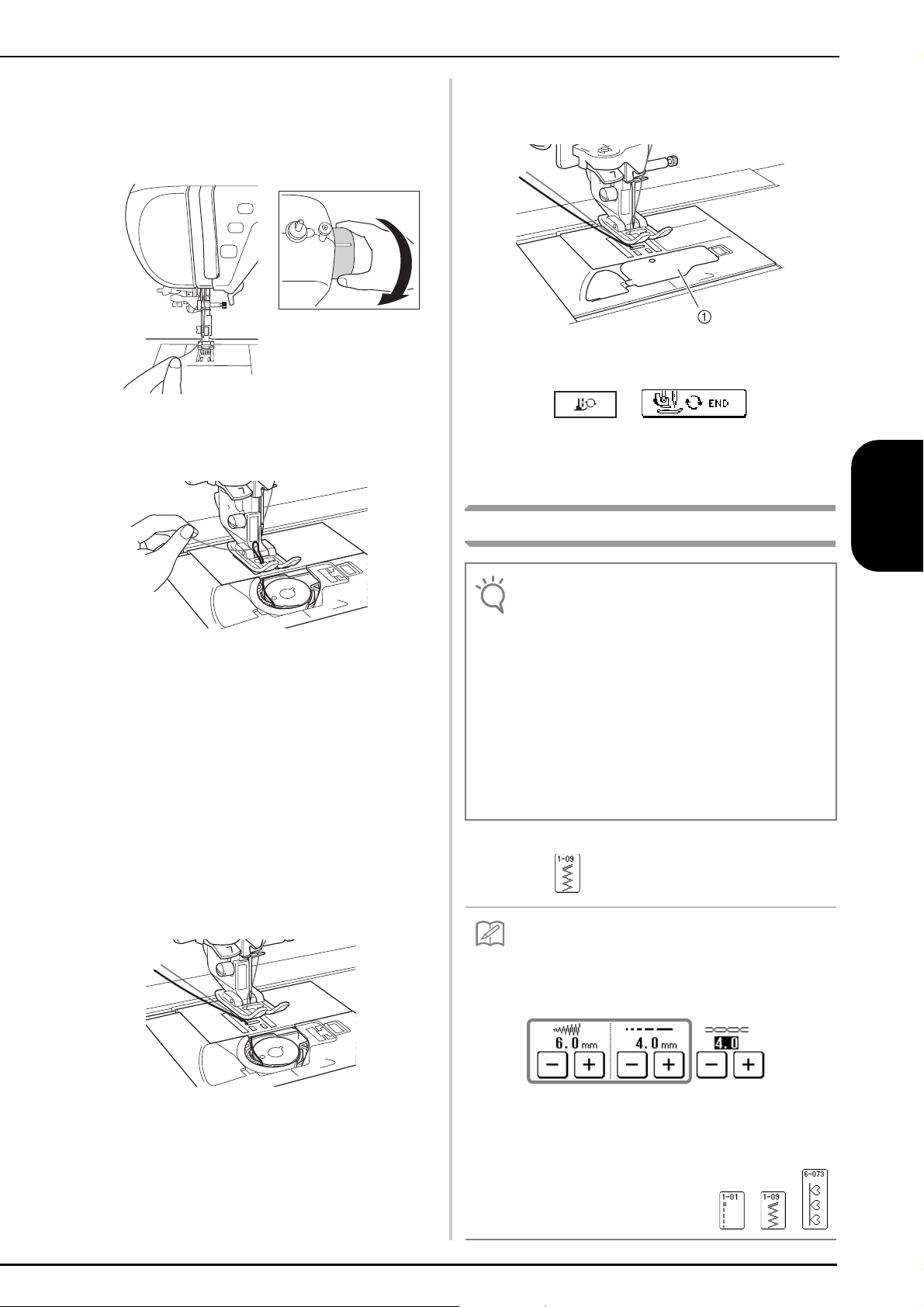

Insert the thread tail from the spool of thread

j

through the hole in the bobbin from the inside

to the outside. Hold the thread tail while

winding the thread around the bobbin by

hand. After winding the bobbin so it is filled

as shown below (about 80%), cut the thread.

Using scissors carefully trim the thread tail as

k

close to the bobbin as possible.

a Beginning of wound thread

• If thread extends beyond the top of the bobbin too

much, the thread may become tangled or the

needle may break.

If inserting thread tail through bobbin hole is difficult

bobbin can be wound by holding tail and wrapping

thread around inside base. Then carefully trim thread

tail so it does not extend from the side of the bobbin.

Install the bobbin wound with thread.

l

Whether or not tension should be applied to the

bobbin thread depends on the type of thread

used.

10

Page 13

■ When tension is applied to the bobbin

CAUTION

Note

thread

Insert bobbin into bobbin case so the thread unwinds

from the left side. Pass the thread carefully through

groove of needle plate cover as shown below.

a Groove of needle plate cover

■ When tension is not applied to the bobbin

thread

If the bobbin thread in the trial stitching is too tight and

adjusting the bobbin case tension does not help, do not

pass the thread through the tension spring.

Hold the bobbin with your left hand so the thread

unwinds from the right side and hold the end of the

thread with your right hand.

ENGLISH

• When winding the bobbin, make sure the thread is

not frayed. Sewing with frayed thread may result in

the thread catching on the tension spring of the

bobbin case, the thread completely becoming

tangled or damage to the machine.

• Do not guide the bobbin thread completely through

the groove in the needle plate cover, otherwise the

lower threading will not be done correctly. Thread

only as far as shown below.

Pull out about 8 cm (approx. 3 inches) of

m

bobbin thread.

Turn on the sewing machine, and then press

n

.

→ The screen changes, and all keys and operation

buttons are locked.

• If “OPENING DISPLAY” in the Settings Screen is

turned “ON” press anywhere on the LCD screen

before pressing the icon.

11

Page 14

Lightly hold the end of the upper thread while

Note

Memo

o

turning the handwheel toward you

(counterclockwise) until the mark on the

handwheel aligns with the line on the

machine.

Gently pull the upper thread to pull up the

p

bobbin thread through the needle plate.

Install the the cord guide bobbin cover (for

t

bobbin work and attaching cords).

a Cord guide bobbin cover (for bobbin work and

attaching cords)

Press or on the

u

screen.

→ All keys and operation buttons are unlocked, and

the previous screen is displayed.

Positioning the Fabric and Sewing

→ A loop of the bobbin thread comes out through the

hole in the needle plate.

Use the presser foot lever to raise the presser

q

foot.

Insert tweezers through bobbin thread loop

r

and pull bobbin thread above the needle

plate.

Align the upper thread and bobbin thread,

s

and then pull out about 10 cm (approx.

4 inches) of the threads and pass them under

the presser foot toward the rear of the

machine.

• Recommended stitches for bobbin work are open

“airy” type stitches.

• Be sure to sew trial stitches using same fabric and

threads as project in order to check the sewing results.

• The bobbin thread may become tangled due to the

type of pattern and thread that are being used. Since

this may cause the needle to break, immediately

stop sewing if this occurs. Turn off the machine, and

then cut out the tangled thread with scissors. Then,

clean the race and bobbin case as described in

“Preparing the Bobbin Thread” on page 9.

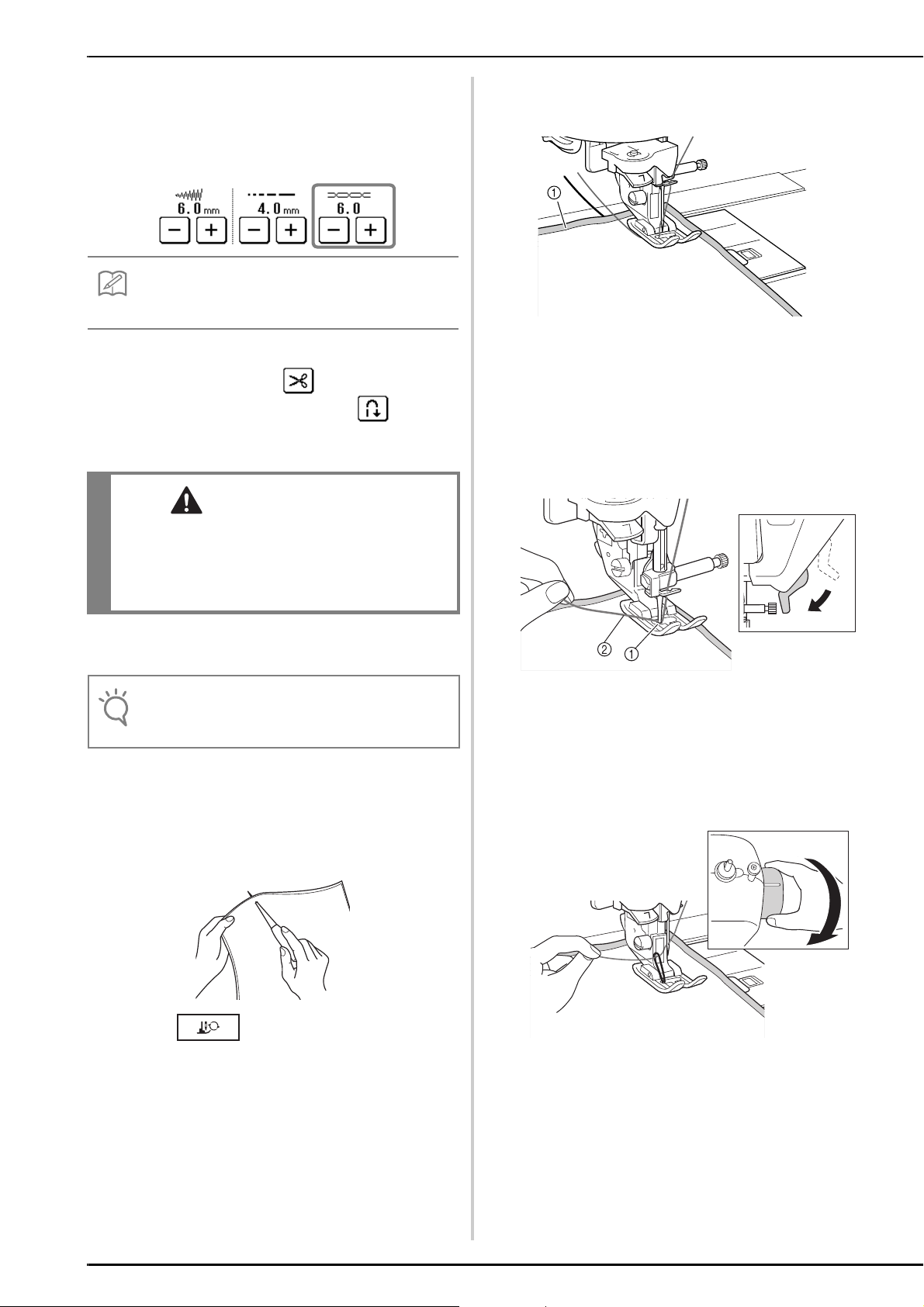

Select a stitch. For this example, press .

a

• For best results, select a longer stitch length and a

wider stitch width. Depending on the selected stitch,

it may not be possible to change the stitch length

and stitch width.

12

• Depending on the fabric, bunched stitches may

result. We recommend selecting a simple stitch and

sewing trial stitches to check the sewing results.

Examples of simple stitches: , ,

Page 15

Adjust the upper thread tension.

Memo

CAUTION

Note

b

For details on adjusting the upper thread tension,

refer to “Adjusting the Thread Tension” in the

Instruction and Reference Guide.

We recommend a setting between 6 and 8 for the

upper thread tension.

With the wrong side facing up, place the

h

fabric under the presser foot.

ENGLISH

Make sure that automatic thread cutting

c

( ) and automatic reinforcement/reverse

stitching ( ) have been turned off.

• Before sewing, make sure that automatic thread

cutting has been turned off. If sewing is started with

automatic thread cutting turned on, the thread may

become tangled or the machine may be damaged.

Place stabilizer on top (wrong side) of the

d

fabric.

• Type and weight of stabilizer will depend on fabric

and thread being used.

If thread is too thick to pull through fabric to

e

machine surface use an awl to punch a hole in

the fabric at the beginning of stitching so the

bobbin thread can be fed through the

opening.

a Wrong side of fabric

Turn the handwheel toward you

i

(counterclockwise) to feed the needle into the

fabric or punched hole. Position the upper

thread over the presser foot and lightly hold

then, lower the presser foot lever.

a Punched hole

b Upper thread over the presser foot

Pulling the upper thread gently, turn the

j

handwheel toward you (counterclockwise)

until the mark on the handwheel aligns with

the line on the machine.

f

g

Press .

→ The screen changes, and all keys and operation

buttons are locked.

Use the presser foot lever to raise the presser

foot.

→ A loop of the bobbin thread comes out through the

hole in the fabric.

13

Page 16

Note

• If the bobbin thread does not come up, hold the

Note

Note

Note

Note

upper thread as shown below to pull up the bobbin

thread.

a Upper thread

• Before sewing, check that there is enough thread in

the bobbin.

When you have reached the end of the

p

stitching area, stop the machine.

• Do not sew reinforcement/reverse stitches at the

end of the stitching, otherwise the threads may

become tangled or the needle may break. In

addition, it may be difficult to pull the bobbin thread

up to the wrong side of the fabric.

Raise the presser foot lever, and then use

k

tweezers to pull up the bobbin thread and

bring the end of the thread to the top of the

fabric.

• Pull the thread while holding down the fabric so it

does not move out of place.

Align the upper thread and bobbin thread,

l

and then pass them under the presser foot

toward the rear of the machine.

While gently holding threads at the rear of the

m

machine, turn the handwheel to feed the

needle into the fabric or punched hole again,

and then lower the presser foot lever.

Raise the needle and presser foot.

q

Leaving about 10 cm (approx. 4 inches) of

r

thread at the ends, use scissors to cut the

threads.

a 10 cm (approx. 4 inches)

• Do not press the “Thread Cutter” button to cut the

threads, otherwise the machine may be damaged.

14

Press or in the

n

screen.

→ All keys and operation buttons are unlocked, and

the previous screen is displayed.

Select a low speed , gently hold the threads

o

behind the presser foot and start sewing.

Page 17

■ Finishing the thread ends

Note

Note

Note

At the end of the stitching, use a hand sewing

a

needle to bring the bobbin thread up to the

wrong side of the fabric.

a Wrong side of fabric

b Bobbin thread

• If it is difficult to place bobbin thread through the eye

of a hand sewing needle, use a ribbon embroidery

needle to pull the thread up to the wrong side of the

fabric. Otherwise, use an awl to pull up the bobbin

thread.

■ Adjusting the upper thread tension

Refer to “Adjusting the Thread Tension” in the

Instruction and Reference Guide. We recommend a

setting between 6 and 8 for the upper thread tension.

■ Adjusting the tension of the bobbin thread

If the desired stitching cannot be achieved after

adjusting the upper thread tension, adjust the tension of

the bobbin thread. The tension of the bobbin thread can

be adjusted by turning the slotted-head (–) screw on the

bobbin case (gray) for bobbin work.

a Do not turn the phillips screw (+).

b Adjust with a screwdriver (small).

To increase the tension of the bobbin thread, turn the

slotted-head (–) screw 30° to 45° clockwise.

ENGLISH

Working from the wrong side of the fabric, tie

b

the bobbin and upper threads together by

hand. Cut away excess threads with scissors.

a Wrong side of fabric

b Right side of fabric

• To ensure threads do not come undone after being

tied place a drop of fabric glue on knots.

If the desired results could not be achieved,

c

adjust the tension of the bobbin thread and of

the upper thread, and then try sewing the

stitching again.

For more details, refer to “Adjusting the Thread

Tension”.

To decrease the tension of the bobbin thread, turn the

slotted-head (–) screw 30° to 45° counterclockwise.

• Turning the screw on the bobbin case (gray) may

push up the spring plate, as shown below.

If this occurs, gently press down the spring plate

with a screwdriver so it is lower than the top surface

of the bobbin case (gray), and then insert the bobbin

case into the machine.

Adjusting the Thread Tension

After sewing trial stitches and checking the sewing

results, adjust the thread tensions if necessary. After

adjusting the tensions, be sure to sew trial stitches in

order to check the sewing results.

a Spring plate

15

Page 18

CAUTION

• DO NOT adjust the position of the phillips (+)

Note

CAUTION

screw on the bobbin case (gray) as this may result in

damage to the bobbin case, rendering it useless.

• If the slotted screw (-) is difficult to turn, do not use

force. Turning the screw too much or providing

force in either (rotational) direction may cause

damage to the bobbin case. Should damage occur,

the bobbin case may not maintain proper tension.

• If the bobbin thread tension is tight, the thread

cannot be passed through the tension spring when

the bobbin is installed in the bobbin case. (Refer to

“When tension is not applied to the bobbin thread”

on page 11.)

Troubleshooting

Several solutions for minor problems are described

below. If the problem persists, contact your nearest

authorized retailer.

Apply slight tension on bobbin thread by

d

holding thread out to the left side of presser

foot. Press the “Thread Cutter” button again.

■ The thread was accidentally cut

automatically and the bobbin thread is

caught inside the machine

Cut the thread near the fabric above the

a

needle plate, and then remove the fabric.

a Thread

Remove the bobbin, and then hold it out

b

toward the left side of the machine.

• Do not pull on the thread with excessive force,

otherwise the machine may be damaged.

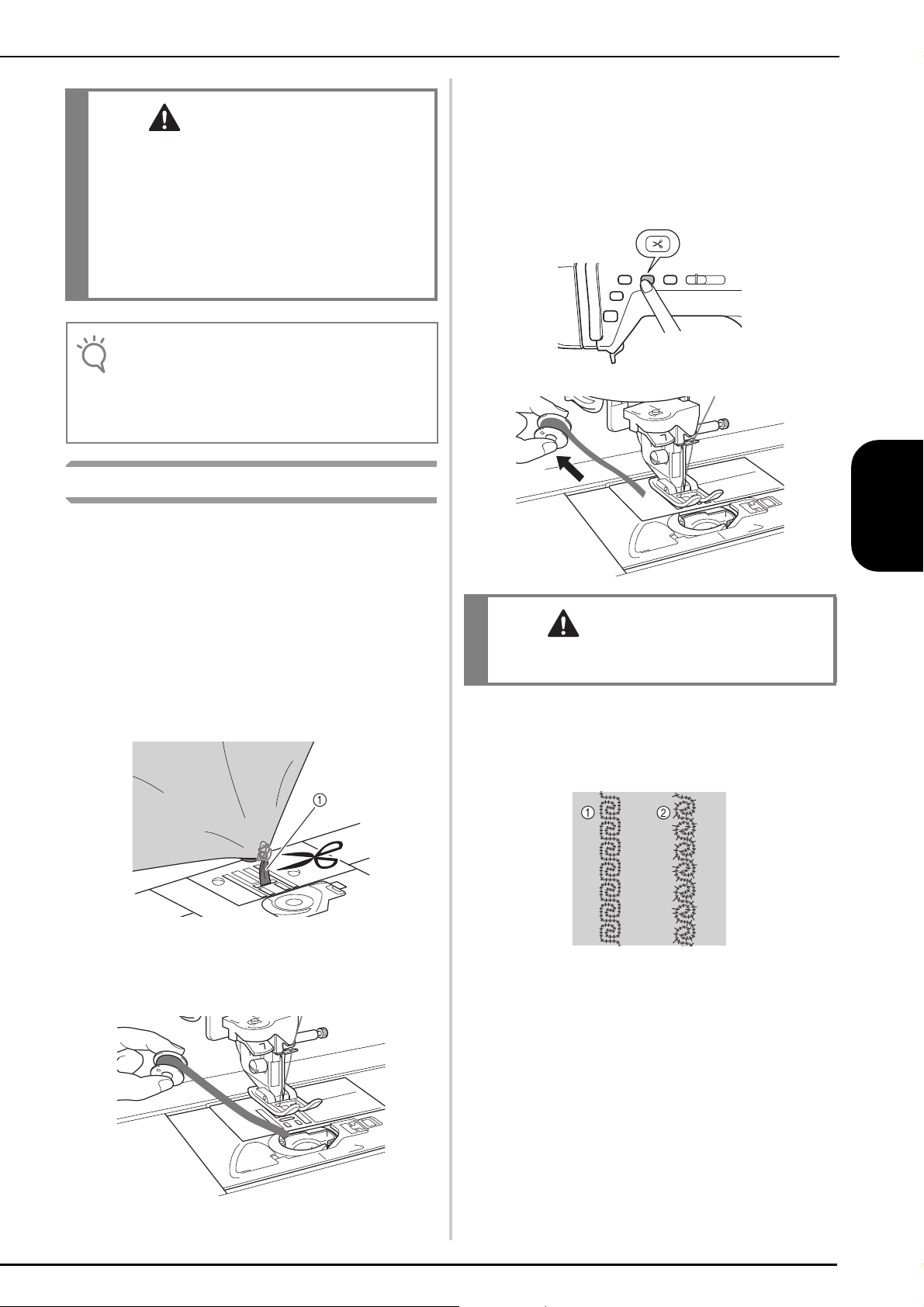

■ The pattern is misaligned

Refer to“Adjusting the thread tension”and increase the

upper thread tension. If the pattern is still misaligned,

reduce the tension of the bobbin thread.

a Correct tension

b The upper thread tension is too loose, or the bobbin

thread tension is too tight.

■ The bobbin thread catches on the tension

spring of the bobbin case

Sew with no tension applied to the bobbin thread.

(Refer to “When tension is not applied to the bobbin

thread” on page 11.)

16

Lower the presser foot.

c

Page 19

LIST OF STITCHES THAT CANNOT BE USED WITH

THE CIRCULAR ATTACHMENT

Category Stitches that cannot be used

1* - All usable

2*- All usable

3 - All usable

4 - All not usable

5 - 01, 03, 04, 05, 06, 08, 09, 10

Q All usable

015, 016, 017, 018, 019, 020, 022, 023, 024, 025, 026, 027, 028, 029, 030, 032, 033,

034, 035, 036, 037, 038, 039, 040, 041, 042, 043, 044, 045, 046, 051, 052, 053, 054,

055, 056, 057, 058, 059, 063, 064, 065, 066, 067, 068, 069, 071, 072, 075, 076, 077,

078, 079, 080, 081, 082, 083, 084, 085, 086, 087, 088, 089, 090, 091, 092, 093, 094,

6 -

095, 096, 097, 098, 099, 100, 101, 102, 103, 104, 105, 106, 107, 108, 109, 110, 111,

112, 113, 114, 117, 118, 119, 121, 124, 125, 126, 127, 128, 129, 130, 131, 132, 133,

134, 135, 136, 137, 138, 139

ENGLISH

064, 082, 084, 085, 086, 087, 088, 089, 090, 091, 092, 093, 094, 095, 096, 097, 098,

099, 100, 101, 103, 104, 105, 106, 107, 108, 109, 110, 111, 112, 113, 114, 126

7 - All usable

01, 02, 03, 04, 06, 07, 09, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 24, 25, 26,

28, 29, 30, 31, 32, 33, 34, 36, 37, 38, 39, 40, 41, 42, 43, 44, 47, 48, 50, 51, 52, 53, 54,

8 -

9 - All usable

10 - 04, 09

11 - All usable

Alphabet patterns

* Do not use overcasting foot “G”, side cutter “S” or blind stitch foot “R” even if they appear in the screen as the presser foot to be used with

the selected stitch.

56, 57, 58, 60

09, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 24, 25, 28, 29, 30, 53

All not usable

17

Page 20

TABLE DES MATIÈRES

INTRODUCTION....................................................................................................................19

UTILISATION DU GUIDE POUR COUTURE CIRCULAIRE POUR COUDRE DES MOTIFS

CIRCULAIRES.......................................................................................................................... 19

À propos du guide pour couture circulaire.......................................................................... 19

Accessoires inclus............................................................................................................... 19

Fixation du guide pour couture circulaire............................................................................ 20

Couture d’un cercle ............................................................................................................ 20

Utilisation du gabarit quart de cercle .................................................................................. 22

Utilisation du pied-de-biche fourni ..................................................................................... 22

CRÉATION D’UN TRAVAIL À LA CANETTE............................................................................ 24

À propos du travail à la canette........................................................................................... 24

Matériel nécessaire ............................................................................................................. 25

Enfilage supérieur................................................................................................................ 26

Préparation du fil de la canette............................................................................................ 26

Positionnement du tissu et couture...................................................................................... 29

Réglage de la tension du fil................................................................................................. 32

Dépannage ......................................................................................................................... 33

LISTE DES POINTS NE POUVANT PAS ÊTRE UTILISÉS AVEC LE GUIDE POUR COUTURE

CIRCULAIRE............................................................................................................................ 34

18

Page 21

INTRODUCTION

Remarque

ATTENTION

Cet addendum fournit des informations supplémentaires non décrites dans le Guide d’instructions et de référence.

Reportez-vous à ces instructions après avoir lu le Guide d’instructions et de référence accompagnant votre machine

à coudre.

UTILISATION DU GUIDE POUR COUTURE CIRCULAIRE

POUR COUDRE DES MOTIFS CIRCULAIRES

À propos du guide pour couture circulaire

Ce guide permet de coudre des motifs circulaires à des intervalles de 5 mm, en rayons* allant de 30 mm à 130

mm lorsque l’aiguille est au centre. Le guide est placé à gauche de l’aiguille sur votre machine à coudre. Il

permet également de coudre des points de couture courants et décoratifs.

*

Rayon : distance entre le centre et le bord du cercle.

• Vous ne pouvez pas utiliser de point décoratif lorsque le fil passe par le côté, ni de points de plus de 7,0 mm de largeur.

Avant de commencer votre travail de couture, nous vous conseillons de coudre quelques points d’essai et d’en vérifier le

résultat. Si vous cousez des points ne pouvant pas être utilisés, le motif risque d’être décalé. Pour consulter la liste des

points ne pouvant pas être utilisés, reportez-vous au tableau « LISTE DES POINTS NE POUVANT PAS ÊTRE UTILISÉS

AVEC LE GUIDE POUR COUTURE CIRCULAIRE » à la page 34.

• Accordez une attention particulière au pivot ; une utilisation négligente peut provoquer des blessures.

Veillez à ce que les jeunes enfants ne jouent pas avec le guide. Lorsque vous n’utilisez pas le guide, gardez

toujours le pivot dans l’indicateur pour éviter de le perdre.

FRANÇAIS

Accessoires inclus

1 4 Tableau de conversion 5

mm (f) pouces

130 5 3/16

120 4 3/4

110 4 3/8

100 4

2 3 90 3 1/2 6

80 3 3/16

70 2 3/4

60 2 3/8

50 2

40 3/2

30 13/16

N° Nom de la pièce Code de la pièce

1 Guide pour couture circulaire

a Indicateur

b Poignée/Inversion vers le haut

c Bouton de dégagement

d Position d’insertion pour le

pivot

e Échelle

2 Pivot XE6016-001

3 Vis de fixation

(2 pcs, une de réserve)

-

XE6022-001

N° Nom de la pièce Code de la pièce

4 Gabarit

f Rayon du cercle en mm

g Lignes angulaires indiquées en

degrés, commençant à 0 avec

des intervalles de 5 degrés

h Centre

5 Pied de tressage XE5680-001

6 Pied pour cordonnet XA6871-001

XE6024-001

19

Page 22

Remarque

• Nous vous recommandons d’utiliser la table

3040

Remarque

Remarque

d’extension avec votre machine à coudre pour un

meilleur contrôle du tissu.

• Ne relevez pas la table d’extension lorsque le guide

pour couture circulaire est fixé.

• Le pivot peut se retirer si vous soulevez le tissu fixé

au guide pour couture circulaire. Lorsque vous

soulevez le tissu, appuyez doucement sur la tête du

pivot.

• Lorsque vous cousez de plus petits cercles ou

utilisez du tissu à grain ou à texture irrégulière, il est

impossible de réaliser un cercle parfait.

• Certains pieds-de-biche, tels que le couteau raseur,

ne peuvent pas être utilisés avec ce guide. Testez

toujours vos pieds auxiliaires avec le guide.

• Lorsque vous utilisez ce guide, testez la vitesse de

couture de votre machine pour obtenir les meilleurs

résultats.

• Lorsque vous cousez de plus grandes pièces de

tissu ou vêtements, assurez-vous qu’ils ne

s’accrochent pas à votre machine, ce qui

provoquerait un glissement ou une distorsion de

votre motif.

Fixation du guide pour couture

Serrez fermement la vis à l’aide du tournevis

c

en forme de disque fourni avec votre

machine.

a Tournevis en forme de disque

Couture d’un cercle

• Enfilez l’aiguille de la machine avant de placer le

pivot dans le guide pour couture circulaire. Le levier

d’enfilage risque de toucher le pivot et

d’endommager ce dernier ou le dispositif d’enfilage

de la machine.

Soulevez la poignée.

a

circulaire

Placez le guide pour couture circulaire à

a

gauche comme illustré ci-dessous.

→ Les deux taquets en dessous du guide vont s’insérer

dans les emplacements correspondants dans la

plaque d’aiguille, de sorte que le guide repose à plat

sur le plateau de votre machine.

Insérez la vis sur le guide pour couture

b

circulaire dans l’emplacement prévu à cet

effet à droite de la plaque d’aiguille (a).

Faites glisser l’indicateur pour atteindre la

b

taille de cercle de votre choix.

• Ne faites pas glisser l’indicateur en appuyant sur le

pivot car cela pourrait le tordre ou le casser.

20

a Vis de fixation

Page 23

Utilisez un renfort plus large que le motif,

Remarque

Remarque

ATTENTION

c

avec un tissu fin. Renforcez le centre du

cercle avec une pièce de renfort si vous

utilisez le même centre de façon répétée.

a Envers du tissu

b Renfort

c Renfort

d Zone du pivot

• Utilisez toujours un renfort lorsque vous cousez sur

un tissu ou un vêtement pour éviter de l’étirer ou de

faire des plis. Selon le type de tissu à coudre,

choisissez un renfort permanent, thermocollant,

temporaire ou adhésif.

Insérez la pointe du pivot dans l’emplacement

e

désigné par « Y » sur le guide en appuyant

dessus.

a Endroit du tissu

b Envers du tissu

FRANÇAIS

Insérez le pivot au centre du cercle sur

d

l’endroit du tissu.

a Pivot

b Centre du cercle

c Endroit du tissu

• Lorsque vous cousez un cercle de petit diamètre,

nous vous recommandons de fixer d’abord le tissu

au guide et de placer ensuite l’indicateur à la taille

désirée.

Sélectionnez le point désiré et cousez en

f

permettant au tissu d’être librement entraîné.

Si vous poussez ou tirez sur le tissu, votre

cercle sera irrégulier.

Lorsque vous avez terminé de coudre,

g

appuyez toujours sur le bouton de

dégagement pour enlever le pivot et le tissu

du guide pour couture circulaire.

a Bouton de dégagement

• Ne laissez pas le pivot inséré dans le tissu et non

fixé au guide couture circulaire. Cela pourait causer

une blessure ou endommager la machine.

21

Page 24

Utilisation du gabarit quart de cercle

Remarque

ATTENTION

Lorsque vous combinez des points courants ou

décoratifs ou que vous répétez un point individuel,

utilisez le gabarit fourni comme guide.

Repérez d’abord le point pivot (centre de

a

votre cercle) avant de commencer à coudre

sur votre tissu (a).

Sélectionnez le point désiré et la taille du

b

cercle en utilisant les repères sur le guide ;

placez-y ensuite le tissu.

Cousez un point unique ou une combinaison

c

de motifs (b).

Retirez le tissu ou le vêtement du guide.

d

A l’aide d’un crayon effaçable, tracez deux

e

lignes à partir du point pivot, une au début du

motif de point, l’autre à la fin.

Vérifiez la ligne à la fin du point (d) et notez

g

les degrés approximatifs. À l’aide d’un cercle

de 360 degrés, divisez la longueur du point

(votre degré/mesure du point) par 360, ce qui

vous donnera un nombre de répétitions de

points approximatif. EXEMPLE : votre point

est long de 16 degrés, donc : 360 divisé par 16

est égal à 22,5 répétitions.

• TIl ne s’agit pas d’un compte exact en raison du

nombre de variables, p. ex. la longueur du point, le

tissu utilisé, le fil et le renfort. Selon le point utilisé,

vous pouvez ajuster la longueur du point,

l’agrandissant ou le réduisant pour réussir à fermer

votre cercle sans chevauchement ou insuffisance

(a).

• Cousez toujours une version d’essai du motif en

vérifiant la longueur et la largeur du point ainsi que

la direction de couture pour vous assurer qu’il

convienne à votre projet.

• Des calculs supplémentaires peuvent être

nécessaires si votre motif se chevauche.

Exemple: insuffisance du motif

a Point pivot

b Combinaison de motif de points/point unique

c Début du point

d Fin du point

Placez le gabarit au-dessus de votre motif,

f

alignant ainsi le point pivot central et le

repère central du gabarit (a). Placez ensuite

la ligne 0 degré (b) sur le côté droit du

gabarit au début du point (c).

a

Fin du point

Utilisation du pied-de-biche fourni

L’utilisation du pied-de-biche fourni vous permet de

décorer vos projets de couture en leur donnant un

aspect professionnel agrémenté de votre touche

personnelle.

■ PIED DE TRESSAGE

Vous pouvez utiliser une grande variété de tresses

mesurant jusqu’à 5 mm de largeur à l’aide des points

droits, des points zigzag et de certains points

décoratifs.

• N’utilisez pas ce pied lorsque vous cousez avec des

tresses tissées denses que l’aiguille pénètre

difficilement. Sinon, vous pourriez casser l’aiguille,

provoquer des dommages et/ou des blessures.

22

a Centre du gabarit

b Ligne 0 degré

c Début du point

d Fin du point

Page 25

Desserrez la vis de la plaque du guide sur le

Remarque

a

pied et faites glisser la plaque pour l’ajuster à

la largeur de la tresse.

■ PIED POUR CORDONNET

Vous pouvez décorer votre motif en utilisant 1 à 3

cordonnets de fils décoratifs.

Faites glisser les cordonnets à partir de la

a

droite du pied-de-biche et placez chacun

d’eux dans chaque guide (pour utiliser un seul

cordonnet, employez le guide central).

a Plaque

Insérez la tresse via le guide avant de fixer le

b

pied à la machine.

Serrez la vis et positionnez la tresse à l’arrière

c

du pied de tressage.

Fixez le pied à la machine.

d

Placez les cordonnets en dessous et à l’arrière

b

du pied pour cordonnet.

Sélectionnez un point zigzag ou décoratif et

c

cousez de manière circulaire en guidant

doucement les cordonnets.

FRANÇAIS

Sélectionnez le point désiré et cousez de

e

manière circulaire en guidant doucement la

tresse.

• Lorsque vous cousez des points zigzag ou

décoratifs, ajustez la largeur du point de sorte qu’il

soit légèrement plus large que la tresse ou le

cordonnet.

23

Page 26

CRÉATION D’UN TRAVAIL À LA CANETTE

À propos du travail à la canette

Il est possible de réaliser de magnifiques travaux de broderie en trois dimensions en bobinant sur la canette un fil ou

un ruban lourd trop épais pour être enfilé par l’aiguille de la machine. Le fil ou le ruban décoratif sera visible en

dessous du tissu alors que vous cousez avec le côté envers du tissu vers le haut.

1. Points de couture

courants

2. Points décoratifs 3. Couture en mouvement

libre

24

Page 27

Matériel nécessaire

Remarque

Remarque

■ Boîtier de la canette et capot du

compartiment à canette avec guide-cordon

a Boîtier de la canette (gris)

Il y a une encoche à l’emplacement marqué d’un « A ».

b Capot du compartiment à canette avec guide cordon (à

trou unique pour le travail à la canette ou la fixation de

cordon).

Deux petits taquets en forme de V (marqués d’un « B »)

se situent à l’arrière du capot du compartiment à

cannette.

Les taquets permettent de maintenir la canette en place

de sorte qu’elle ne se soulève pas pendant que le fil

épais est passé par cette dernière.

■ Fil supérieur

Le choix du fil supérieur peut varier selon la finition que

vous souhaitez atteindre. En utilisant un fil de broderie

(polyester), un fil en polyester à usages multiples ou un

fil monofilament (nylon transparent), l’aspect d’un seul

motif peut être modifié de nombreuses fois juste en

choisissant un poids et/ou une couleur de fil supérieur

différent.

Si vous souhaitez que le fil supérieur ne soit pas visible,

nous vous recommandons d’utiliser un fil monofilament

ou un fil léger en polyester (50 wt. ou plus) de la même

couleur que le fil inférieur.

■ Aiguille

Utilisez l’aiguille adéquate en fonction du fil supérieur

et du tissu utilisés. Reportez-vous à la section

« Combinaisons tissu/fil/aiguille » (du chapitre

« CHANGEMENT DE L’AIGUILLE ») du Guide

d’instructions et de référence.

■ Pied-de-biche

Points de couture courants ou points décoratifs : pied

pour monogrammes « N »

FRANÇAIS

■ Fil inférieur

Nous recommandons les types de fil suivants pour le

travail à la canette.

Fil de broderie à la main Nº 5 ou

plus fin ou fil décoratif

Ruban tissé flexible

Ruban fin de broderie (en soie ou

en tissu ressemblant à la soie) (3,5

mm (environ 1/8 pouce) ou moins

recommandé)

* Lorsqu’un ruban large ou des fils lourds sont utilisés, nous vous

recommandons de coudre quelques points d’essai avec et sans

tension sur le boîtier de la canette pour définir laquelle des

deux méthodes donne les meilleurs résultats de couture.

Si un ruban d’une taille de 3,5 mm (env. 1/8 de pouce) est

utilisé, nous vous recommandons de ne pas appliquer de

tension sur le boîtier de la canette. Reportez-vous à la page 28

pour des instructions plus détaillées.

Couture en mouvement libre : pied pour quilting en

mouvement libre « C », pied pour quilting ouvert en

mouvement libre « O » ou pied pour quilting en écho

en mouvement libre « E »

■ Tissu

Veillez à coudre quelques points d’essai sur un

morceau de tissu « brouillon » avec les mêmes fils et le

même tissu que ceux utilisés dans votre projet.

• Les résultats peuvent être affectés par le type de

tissu utilisé. Avant de commencer votre projet,

veillez à coudre quelques points d’essai sur un

morceau de tissu « brouillon » qui soit le même que

celui utilisé dans votre projet.

• N’utilisez pas de fil plus lourd que du fil de broderie

à la main Nº 5.

• Certains fils peuvent ne pas être adéquats pour le

travail à la canette. Veillez à coudre quelques points

d’essai avant de coudre sur votre projet.

25

Page 28

Enfilage supérieur

Installez une aiguille adéquate en fonction du

a

fil supérieur et du tissu utilisés.

Pour plus de détails sur l’installation de l’aiguille,

veuillez vous reporter à la section

« CHANGEMENT DE L’AIGUILLE » du Guide

d’instructions et de référence.

Fixez le pied-de-biche.

b

Pour plus de détails sur la façon de fixer le piedde-biche, veuillez vous reporter à la section

« CHANGEMENT DU PIED-DE-BICHE » du

Guide d’instructions et de référence.

Enfilez la machine avec le fil supérieur.

c

Pour plus de détails sur la façon d’enfiler la

machine, veuillez vous reporter à la section

« Enfilage supérieur » du Guide d’instructions et

de référence.

Retirez le boîtier de la canette.

d

a Boîtier de la canette

Utilisez la brosse de nettoyage fournie avec la

e

machine ou un aspirateur pour retirer les

peluches et la poussière de la coursière et de

la zone environnante.

Préparation du fil de la canette

Pour créer un travail à la canette, le boîtier de la canette

doit être remplacé par celui prévu pour le travail à la

canette.

Avant de créer votre travail à la canette, nettoyez le

boîtier de la canette et la coursière.

Soulevez l’aiguille et le pied-de-biche, puis

a

éteignez la machine.

Enlevez le plateau.

b

Saisissez les deux côtés du capot de la plaque

c

de l’aiguille, puis faites-le glisser vers vous

pour l’enlever.

a Brosse de nettoyage

b Coursière

Essuyez le boîtier de la canette (gris) avec un

f

chiffon doux non pelucheux pour le nettoyer.

Insérez le boîtier de la canette (gris) de telle

g

sorte que la marque S soit alignée avec la

marque ● comme illustré ci-dessous.

26

a Marque S

b Marque ●

a Capot de la plaque de l’aiguille

Page 29

Remarque

• Le boîtier de la canette (gris) ne peut pas être utilisé

ATTENTION

ATTENTION

ATTENTION

Remarque

ATTENTION

Mémo

pour coudre autrement que pour le travail à la

canette. Une fois le travail à la canette terminé,

reportez-vous à nouveau à la procédure décrite dans

la section « Préparation du fil de la canette » pour

enlever et nettoyer le boîtier de la canette (gris), puis

réinstallez le boîtier de la canette standard (noir).

• Veillez à bien utiliser le boîtier de la canette (gris)

quand vous créez un travail à la canette. Si vous

utilisez un autre boîtier de canette, le fil pourrait

s’emmêler ou la machine s’endommager.

• Veillez à ce que le boîtier de la canette soit

correctement installé. Si le boîtier de la canette est

mal installé, le fil pourrait s’emmêler ou la machine

s’endommager.

• Veillez à bien utiliser la canette fournie ou une

autre conçue spécifiquement pour cette machine

(Classe 15). L’utilisation d’une toute autre canette

peut entraîner des dommages ou des blessures.

Taille réelle

11,5 mm

(env.

7/16 de

pouce)

Ce modèle Autres modèles

• Enroulez le fil lentement et de façon homogène

autour de la canette.

• Pour obtenir les meilleurs résultats, enroulez le fil

autour de la canette de sorte qu’il ne s’emmêle pas.

FRANÇAIS

Installez le capot de la plaque de l’aiguille.

h

Pour plus de détails sur l’installation du capot de

la plaque de l’aiguille, veuillez vous reporter à la

section « Nettoyage du boîtier de la canette » du

Guide d’instructions et de référence.

a Capot de la plaque de l’aiguille

• Quand vous créez un travail à la canette, utilisez le

capot du compartiment à canette avec guide-cordon

(pour le travail à la canette et la fixation de cordons),

sinon le fil pourrait s’emmêler ou l’aiguille se casser.

Installez le plateau.

i

Insérez l’extrémité du fil de la bobine de fil à

j

travers le trou de la canette de l’intérieur vers

l’extérieur. Maintenez l’extrémité du fil tout

en bobinant le fil autour de la canette à la

main. Après avoir enroulé le fil autour de la

canette de sorte que cette dernière soit

remplie de la manière illustrée ci-dessous

(environ 80 %), coupez le fil.

À l’aide de ciseaux, coupez la queue du fil qui

k

dépasse avec soin aussi près de la canette que

possible.

a Début du fil enroulé

• Si le fil dépasse trop au delà du dessus de la canette,

il pourrait s’emmêler ou l’aiguille pourrait se casser.

Si l’insertion de l’extrémité du fil dans le trou de la

canette s’avère difficile, la canette peut être bobinée si

vous maintenez l’extrémité et enroulez le fil autour de

la base interne. Coupez ensuite doucement l’extrémité

du fil de sorte qu’il ne dépasse pas du côté de la

canette.

Installez la canette sur laquelle vous avez

l

enroulé le fil.

La tension ou non du fil autour de la canette

dépend du type de fil utilisé.

27

Page 30

■ Quand une tension est appliquée au fil de la

ATTENTION

Remarque

canette

Insérez la canette dans le boîtier de la canette de sorte

que le fil se déroule du côté gauche. Passez le fil

doucement par la rainure du capot de la plaque

d’aiguille comme illustré ci-dessous.

■ Quand une tension n’est pas appliquée au fil

de la canette

Si le fil de la canette est trop serré lors des essais de

couture et le réglage de la tension du boîtier de la

canette n’aide pas, ne passez pas le fil dans le ressort de

tension.

Maintenez la canette de la main gauche de sorte que le

fil se déroule du côté droit et tenez l’extrémité du fil de

la main droite.

a Rainure du capot de la plaque d’aguille

• En enroulant la canette, veillez à ce que le fil ne soit

pas effiloché. Si vous cousez avec un fil effiloché, ce

dernier peut s’accrocher au ressort de tension du

boîtier de la canette puis s’emmêler complètement

ou endommager la machine.

• Ne guidez pas le fil de la canette complètement

dans la rainure du capot de la plaque de l’aiguille,

sinon l’enfilage inférieur ne sera pas effectué

correctement. Enfilez-le uniquement jusqu’à la

limite illustrée ci-dessous.

Tirez environ 8 cm (env. 3 de pouces) de fil

m

de la canette.

Mettez la machine à coudre sous tension, puis

n

appuyez sur .

→ L’écran change et toutes les touches ainsi que toutes

les touches de fonctionnement sont bloquées.

• Si « Affichage d’ouverture ( ) » sur l’écran des

réglages est sur « ON », appuyez n’importe où sur

l’écran LCD avant d’appuyer sur l’icône

.

28

Page 31

Tenez légèrement l’extrémité du fil supérieur

Remarque

Mémo

o

tout en tournant le volant vers vous (sens

antihoraire) jusqu’à ce que la marque du

volant soit alignée avec la ligne de la

machine.

Tirez légèrement sur le fil supérieur pour tirer

p

le fil de la canette au travers de la plaque de

l’aiguille.

Installez le capot du compartiment à canette

t

avec guide-cordon (pour le travail à la canette

et la fixation de cordons).

a Capot du compartiment à canette avec guide-cordon

(pour le travail à la canette et la fixation de cordons)

Appuyez sur ou sur

u

à l’écran.

→ Toutes les touches et toutes les touches de

fonctionnement se débloquent et l’écran précédent

s’affiche.

FRANÇAIS

→ Une boucle formée par le fil de la canette sort par le

trou de la plaque de l’aiguille.

Utilisez le levier du pied-de-biche pour

q

soulever le pied-de-biche.

Insérez une petite pince dans la boucle du fil

r

de la canette et tirez le fil de la canette au

dessus de la plaque de l’aiguille.

Alignez le fil supérieur et le fil de la canette,

s

puis tirez les fils sur une longueur d’environ

10 cm (env. 4 de pouces) et passez-les sous le

pied-de-biche vers l’arrière de la machine.

Positionnement du tissu et couture

• Les points recommandés pour le travail à la canette

sont des points ouverts de type « aéré ».

• Veillez à effectuer vos essais de couture en utilisant

le même tissu et les mêmes fils pour pouvoir en

vérifier les résultats.

• Le fil de la canette pourrait s’emmêler à cause des

types de motifs et de fils utilisés. Comme ceci pourrait

casser l’aiguille, arrêtez immédiatement de coudre si

cela se produit. Éteignez la machine, puis coupez le fil

emmêlé avec des ciseaux. Ensuite, nettoyez la

coursière et le boîtier de la canette comme décrit dans

la section « Préparation du fil de la canette » page 26.

Sélectionnez un point. Pour cet exemple,

a

appuyez sur .

• Pour obtenir les meilleurs résultats, choisissez une

longueur de point plus longue et une largeur de point plus

large. Selon le point sélectionné, il se peut qu’il ne soit pas

possible de modifier la longueur et la largeur du point.

• Selon le tissu utilisé, les points peuvent se tasser. Nous

recommandons de sélectionner un point simple et de faire

des essais de couture pour vérifier les résultats.

Exemples de points simples : , ,

29

Page 32

Réglez la tension du fil supérieur.

Mémo

ATTENTION

Remarque

b

Pour plus de détails sur la façon de régler la

tension du fil supérieur, veuillez vous reporter à

la section « Réglage de la tension du fil » du

Guide d’instructions et de référence.

Nous recommandons un réglage entre 6 et 8 pour la

tension du fil supérieur.

Veillez à ce que les fonctions de coupure

c

automatique du fil ( ) et de point de

renfort/inverse automatique ( ) soient

désactivées.

• Avant de coudre, vérifiez que la fonction de

coupure automatique du fil a été désactivée. Si vous

commencez à coudre alors que la fonction de

coupure automatique du fil est activée, le fil

pourrait s’emmêler ou la machine s’endommager.

Orientez l’envers du tissu vers le haut et

h

placez le tissu sous le pied-de-biche.

a Envers du tissu

Tournez le volant vers vous (dans le sens

i

antihoraire) pour faire passer l’aiguille dans le

trou percé ou dans le tissu. Placez le fil

supérieur au dessus du pied-de-biche et

maintenez-le légèrement, puis abaissez le

levier du pied-de-biche.

Placez le renfort au-dessus (sur son côté

d

envers) du tissu.

• Le type et le poids du renfort dépendra du tissu et

du fil utilisés.

Si le fil est trop épais pour passer à travers le

e

tissu vers la surface de la machine, utilisez un

poinçon pour percer un trou dans le tissu au

début de la couture, de sorte que le fil de la

canette puisse passer par l’ouverture.

Appuyez sur .

f

→ L’écran change et toutes les touches ainsi que toutes

les touches de fonctionnement sont bloquées.

a Trou percé

b Fil supérieur au dessus du pied de biche

En tirant doucement sur le fil supérieur, faites

j

tourner le volant vers vous (sens antihoraire)

jusqu’à ce que la marque du volant soit

alignée avec la ligne de la machine.

→ Une boucle formée par le fil de la canette sort par le

trou fait dans le tissu.

g

30

Utilisez le levier du pied-de-biche pour

soulever le pied-de-biche.

Page 33

Remarque

• Si le fil de la canette n’apparaît pas, maintenez le fil

Remarque

Remarque

Remarque

Remarque

supérieur comme illustré ci-dessous pour soulever

le fil de la canette.

a Fil supérieur

Sélectionnez une vitesse lente, maintenez

o

doucement les fils derrière le pied-de-biche et

commencez à coudre.

FRANÇAIS

Soulevez le levier du pied-de-biche, puis

k

utilisez une petite pince pour tirer le fil de la

canette vers le haut et ramenez l’extrémité du

fil sur le dessus du tissu.

• Tirez sur le fil tout en maintenant le tissu vers le bas

pour qu’il ne bouge pas.

Alignez le fil supérieur et le fil de la canette,

l

puis passez-les sous le pied-de-biche vers

l’arrière de la machine.

Tout en maintenant légèrement les fils à

m

l’arrière de la machine, tournez le volant pour

refaire passer l’aiguille dans le trou percé ou

le tissu, puis abaissez le levier du pied-debiche.

• Avant de commencer à coudre, vérifiez qu’il y a

suffisamment de fil dans la canette.

Une fois arrivé au bout de la surface à coudre,

p

arrêtez la machine.

• Ne faites pas de point de renfort/inverse à la fin de

la couture, sinon les fils pourraient s’emmêler ou

l’aiguille se casser. De plus, il se peut qu’il soit

difficile de tirer le fil de la canette vers le haut sur

l’envers du tissu.

Relevez l’aiguille et le pied-de-biche.

q

Laissez environ 10 cm (env. 4 de pouces) de

r

fil aux extrémités et utilisez des ciseaux pour

couper les fils.

Appuyez sur ou sur

n

sur l’écran.

→ Toutes les touches et toutes les touches de

fonctionnement se débloquent et l’écran précédent

s’affiche.

a 10 cm (env. 4 de pouces)

• N’appuyez pas sur la touche « Coupe-fil » pour

couper les fils, au risque d’endommager la machine.

31

Page 34

■ Finition des extrémités de fil

Remarque

Remarque

Remarque

À la fin de la couture, utilisez une aiguille

a

pour couture à la main pour amener le fil de

la canette sur l’envers du tissu.

a Envers du tissu

b Fil de la canette

■ Réglage de la tension du fil supérieur

Reportez-vous à la section « Réglage de la tension du fil »

dans le Guide d’instructions et de référence. Nous

recommandons un réglage entre 6 et 8 pour la tension du

fil supérieur.

■ Réglage de la tension du fil de la canette

Si vous ne parvenez pas à obtenir le point souhaité

après avoir réglé la tension du fil supérieur, réglez la

tension du fil de la canette. La tension du fil de la

canette peut se régler en tournant la vis à tête fendue (–)

située sur le boîtier de la canette (gris) pour le travail à

la canette.

• En cas de difficulté pour passer le fil de la canette par

le chas de l’aiguille pour couture à la main, utilisez une

aiguille pour broderie de ruban pour tirer le fil vers le

haut jusqu’au côté envers du tissu. Ou alors, utilisez

un poinçon pour tirer le fil de la canette vers le haut.

En travaillant sur le côté envers du tissu,

b

nouez les fils de la canette et supérieur

ensemble à la main. Coupez l’excédent de fil

à l’aide d’une paire de ciseaux.

a Envers du tissu

b Endroit du tissu

a Ne faites pas tourner la vis cruciforme (+).

b Réglez avec un tournevis (petit).

Pour augmenter la tension du fil de la canette, tournez

la vis à tête fendue (–) de 30° à 45° dans le sens des

aiguilles d’une montre.

Pour diminuer la tension du fil de la canette, tournez la

vis à tête fendue (–) de 30° à 45° dans le sens inverse

des aiguilles d’une montre.

c

Réglage de la tension du fil

Après avoir fait des essais de couture et vérifié les

résultats, réglez la tension des fils si nécessaire. Après

avoir réglé les tensions, veillez à bien effectuer des

essais de couture afin de vérifier les résultats obtenus.

32

• Pour s’assurer que les fils ne se déferont pas après

les avoir noués, mettez une goutte de colle pour

tissus sur les nœuds.

Si vous n’êtes pas parvenu à obtenir les

résultats souhaités, réglez la tension du fil de

la canette et celle du fil supérieur, puis

essayez de coudre à nouveau.

Pour plus de détails, reportez-vous à la section

« Réglage de la tension du fil ».

• Si vous faites tourner la vis située sur le boîtier de la

canette (gris), la lame ressort pourrait se relever

comme illustré ci-dessous.

Si ceci se produit, enfoncez doucement la lame

ressort avec un tournevis pour qu’elle se retrouve

plus bas que la surface supérieure du boîtier de la

canette (gris), puis insérez le boîtier de la canette

dans la machine.

a Lame ressort

Page 35

Abaissez le pied-de-biche.

ATTENTION

Remarque

ATTENTION

c

• NE réglez PAS la position de la vis cruciforme (+)

sur le boîtier de la canette (gris) car ceci pourrait

endommager le boîtier de la canette et le rendre

inutilisable.

• Si la vis fendue (-) est difficile à tourner, ne forcez

pas. Trop tourner la vis ou forcer dessus dans

n’importe quel sens (de rotation) pourrait

endommager le boîtier de la canette. En cas de

dommage, le boîtier de la canette pourrait ne pas

pouvoir maintenir la tension adéquate.

• Si le fil de la canette est trop tendu, le fil ne parvient

pas à passer dans le ressort de tension quand la

canette est installée dans le boîtier de la canette.

(Veuillez vous reporter à la section « Quand une

tension n’est pas appliquée au fil de la canette »

page 28.)

Dépannage

Veuillez trouver ci-dessous plusieurs solutions à des

problèmes mineurs. Si le problème persiste, veuillez

contacter votre détaillant agréé le plus proche.

Appliquez une légère tension sur le fil de la

d

canette en tenant le fil hors du côté gauche

du pied-de-biche. Appuyez de nouveau sur la

touche « Coupe-fil ».

FRANÇAIS

■ Le fil a accidentellement été coupé

automatiquement et le fil de la canette est

coincé à l’intérieur de la machine

Coupez le fil près du tissu au dessus de la

a

plaque de l’aiguille, puis enlevez le tissu.

a Fil

Enlevez la canette, puis maintenez-la vers le

b

côté gauche de la machine.

• N’utilisez pas de force excessive en tirant sur le fil,

sinon vous pourriez endommager la machine.

■ Le motif est mal aligné

Reportez-vous à la section « Réglage de la tension du fil »

et augmentez la tension du fil supérieur. Si le motif est

toujours mal aligné, réduisez la tension du fil de la

canette.

a Tension correcte

b Le fil supérieur est trop lâche, ou le fil de la canette est

trop tendu.

■ Le fil de la canette s’accroche sur le ressort

de tension du boîtier de la canette

Cousez sans appliquer de tension sur le fil de la canette.

(Veuillez vous reporter à la section « Quand une

tension n’est pas appliquée au fil de la canette » page

28.)

33

Page 36

LISTE DES POINTS NE POUVANT PAS ÊTRE UTILISÉS

AVEC LE GUIDE POUR COUTURE CIRCULAIRE

Catégorie Points ne pouvant pas être utilisés

1* - Pris en charge

2*- Pris en charge

3 - Pris en charge

4 - Non pris en charge

5 - 01, 03, 04, 05, 06, 08, 09, 10

Q Pris en charge

015, 016, 017, 018, 019, 020, 022, 023, 024, 025, 026, 027, 028, 029, 030, 032, 033,

034, 035, 036, 037, 038, 039, 040, 041, 042, 043, 044, 045, 046, 051, 052, 053, 054,

055, 056, 057, 058, 059, 063, 064, 065, 066, 067, 068, 069, 071, 072, 075, 076, 077,

078, 079, 080, 081, 082, 083, 084, 085, 086, 087, 088, 089, 090, 091, 092, 093, 094,

6 -

095, 096, 097, 098, 099, 100, 101, 102, 103, 104, 105, 106, 107, 108, 109, 110, 111,

112, 113, 114, 117, 118, 119, 121, 124, 125, 126, 127, 128, 129, 130, 131, 132, 133,

134, 135, 136, 137, 138, 139

064, 082, 084, 085, 086, 087, 088, 089, 090, 091, 092, 093, 094, 095, 096, 097, 098,

099, 100, 101, 103, 104, 105, 106, 107, 108, 109, 110, 111, 112, 113, 114, 126

7 - Pris en charge

01, 02, 03, 04, 06, 07, 09, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 24, 25, 26,

28, 29, 30, 31, 32, 33, 34, 36, 37, 38, 39, 40, 41, 42, 43, 44, 47, 48, 50, 51, 52, 53, 54,

8 -

9 - Pris en charge

10 - 04, 09

11 - Pris en charge

Motifs alphabétiques

* N’utilisez pas le pied pour sujet « G », le couteau raseur « S » ni le pied pour ourlets invisibles « R » même s’ils apparaissent à l’écran

comme pied-de-biche à utiliser pour le point sélectionné.

56, 57, 58, 60

09, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 24, 25, 28, 29, 30, 53

Non pris en charge

34

Page 37

Page 38

CONTENIDO

INTRODUCCIÓN ................................................................................................................... 37

UTILIZACIÓN DE LA UNIDAD PARA COSTURA CIRCULAR PARA COSER PATRONES

CIRCULARES........................................................................................................................... 37

Información sobre la unidad para costura circular............................................................... 37

Accesorios incluidos........................................................................................................... 37

Colocación de la unidad para costura circular .................................................................... 38

Costura de un círculo.......................................................................................................... 38

Utilización de la plantilla de cuarto de círculo.................................................................... 40

Uso de los pies prensatela incluidos.................................................................................... 40

CREACIÓN DE EFECTOS DECORATIVOS CON BOBINAS..................................................... 42

Acerca de los efectos decorativos con bobinas.................................................................... 42

Materiales necesarios.......................................................................................................... 43

Hilo superior....................................................................................................................... 44

Preparación del hilo de la bobina ....................................................................................... 44

Colocación de la tela y costura........................................................................................... 47

Ajuste de la tensión del hilo................................................................................................ 50

Solución de problemas........................................................................................................ 51

LISTA DE PUNTADAS QUE NO SE PUEDEN UTILIZAR CON LA UNIDAD PARA

COSTURA CIRCULAR............................................................................................................. 52

36

Page 39

INTRODUCCIÓN

Nota

PRECAUCIÓN

Este apéndice proporciona información adicional no incluida en el Manual de instrucciones y referencia.

Consulte estas instrucciones después de leer el Manual de instrucciones y referencia que se suministra con la

máquina de coser.

UTILIZACIÓN DE LA UNIDAD PARA COSTURA

CIRCULAR PARA COSER PATRONES CIRCULARES

Información sobre la unidad para costura circular

Esta unidad puede coser en patrones circulares que se gradúan a intervalos de 5 mm, desde los 30 mm a los

130 mm de radio*, cuando se selecciona la posición de la aguja en el centro. La unidad se coloca a la

izquierda de la aguja en la máquina de coser. Con esta unidad pueden coserse puntadas de utilidad y

decorativas.

*

Radio = Distancia del centro del circulo a cualquier otro punto del circulo.

• No es posible utilizar puntadas decorativas con arrastre hacia los lados ni puntadas de más de 7,0 mm de ancho. Antes

de coser su labor, asegúrese de realizar algunas puntadas de prueba y compruebe los resultados de la costura. Si se

cosen puntadas que no se pueden utilizar, es posible que el patrón no quede alineado. Consulte la tabla “LISTA DE

PUNTADAS QUE NO SE PUEDEN UTILIZAR CON LA UNIDAD PARA COSTURA CIRCULAR” en la página 52 para ver

una lista de puntadas que no es posible utilizar.

ESPAÑOL

• Hay que tener especial cuidado con el perno giratorio; la negligencia en su manejo podría provocar

lesiones. Los niños deberán ser vigilados para asegurarse de que no juegan con la unidad. Cuando la

unidad no se utilice, guarde siempre el perno giratorio en el indicador para evitar que se pierda.

Accesorios incluidos

1 4 Tabla de conversión 5

mm (f) pulgada

130 5 3/16

120 4 3/4

110 4 3/8

100 4

2 3 90 3 1/2 6

80 3 3/16

70 2 3/4

60 2 3/8

50 2

40 3/2

30 13/16

Nº

1 Unidad para costura circular

2 Perno giratorio XE6016-001

3 Tornillo de montaje (2 tornillos, se

Nombre de la pieza Código de la pieza

a Indicador

b Asa/Abatible

c Botón de liberación

d Posición de ajuste del perno

giratorio

e Regla

incluye uno de más)

-

XE6022-001

Nº

4 Plantilla

5 Pie para cinturillas XE5680-001

6 Pie para cordones XA6871-001

Nombre de la pieza Código de la pieza

f Radio del círculo en mm

g Líneas angulares indicadas en

grados, comenzando en 0 con

intervalos de 5 grados

h Centro

XE6024-001

37

Page 40

Nota

• Se recomienda la utilización de la tabla extensible

3040

Nota

Nota

de la máquina de coser para controlar la tela con

más suavidad.

• No levante la tabla extensible cuando esté colocado

el dispositivo para costura circular.

• El perno giratorio puede soltarse si se levanta la tela

colocada en la unidad para costura circular. Para

levantar la tela, presione con suavidad sobre la

parte superior del perno giratorio.

• Al coser círculos más pequeños o utilizar tela con

texturas rugosas o irregulares, es posible que no se

consiga un círculo perfecto.

• Algunos de los pies prensatela, como el pie para

cuchilla lateral, no pueden utilizarse con esta

unidad; pruebe siempre los pies para accesorios

con la unidad.

• Cuando utilice esta unidad, pruebe la velocidad de

costura de la máquina para conseguir los mejores

resultados.