Page 1

Getting to Know:

Diana

A-LINE SERIES

Model BL480A

Baby Lock Consumer Helpline: 800-313-4110

www.babylock.com

Page 2

Diana

Model BL480A

Introducing Diana, the easy-to-use serger from the Baby Lock A-Line Series

designed for creative techniques. If you’re bursting at the seams with ambition,

Diana’s the perfect friend to help keep those stitches secure with cover stitching,

chain stitching, rolled hems and more. Diana loves a challenge, and she’s the

perfect friend to call when you need an extra hand.

This Getting to Know You Guide will take you through a simple, step-by-step

process on how to thread your serger and set tension dials for balanced stitches.

Once you’re familiar with your machine, refer to the instruction and reference guide

(packaged with your machine) for additional directions.

Like all machines in the A-Line Series, Diana has the features and the durability to

handle all of your projects – you can always count on her to be there for you. Be

sure to ask your Baby Lock Retailer about Diana’s friends in the A-Line Series, like

Audrey, Anna and Grace. From classic tailored looks to modern-day fashions, the

machines in the A-Line Series will help you sew and serge with success – all with

the quality you’ve come to expect from Baby Lock.

Page 3

Setting Up Your Serger

When threading, it’s important to consider the type of thread you use for serging. Remember, a serger

creates a finished look with reinforced stitches, so strong thread is an important ingredient. A top quality, long

staple, polyester or poly/cotton blend is the best choice. Skipped stitches and broken threads are often the

direct result of using old or inferior thread.

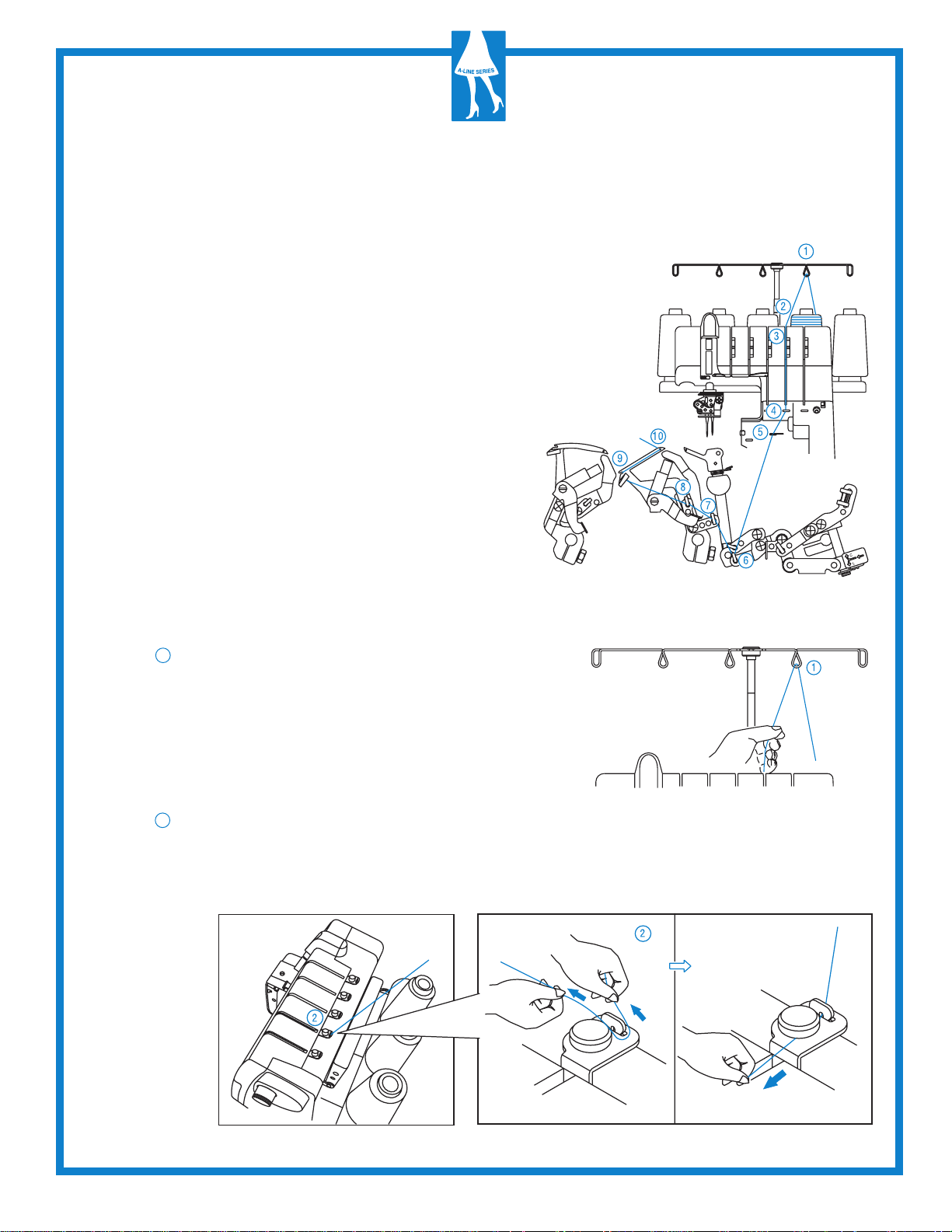

Preparation For Threading

Setting Up the Thread Antenna

• Take out the thread antenna from the top of

styrofoam, and insert it as shown in first illustration.

• Fully extend the thread antenna.

• The two joints on the telescope will click into place

when they are correctly positioned as shown in

second illustration

• Center the thread guides above the spool pins.

• Place thread over the cone adapters on the spool

pins.

Thread Net

When using synthetic threads that easily spill off the

cone, slip the thread net furnished with the machine,

over the thread from bottom of the cone leaving the

thread end hanging free at the top as shown on the

right.

1

Thread

Page 4

Setting Up Your Serger

Thread

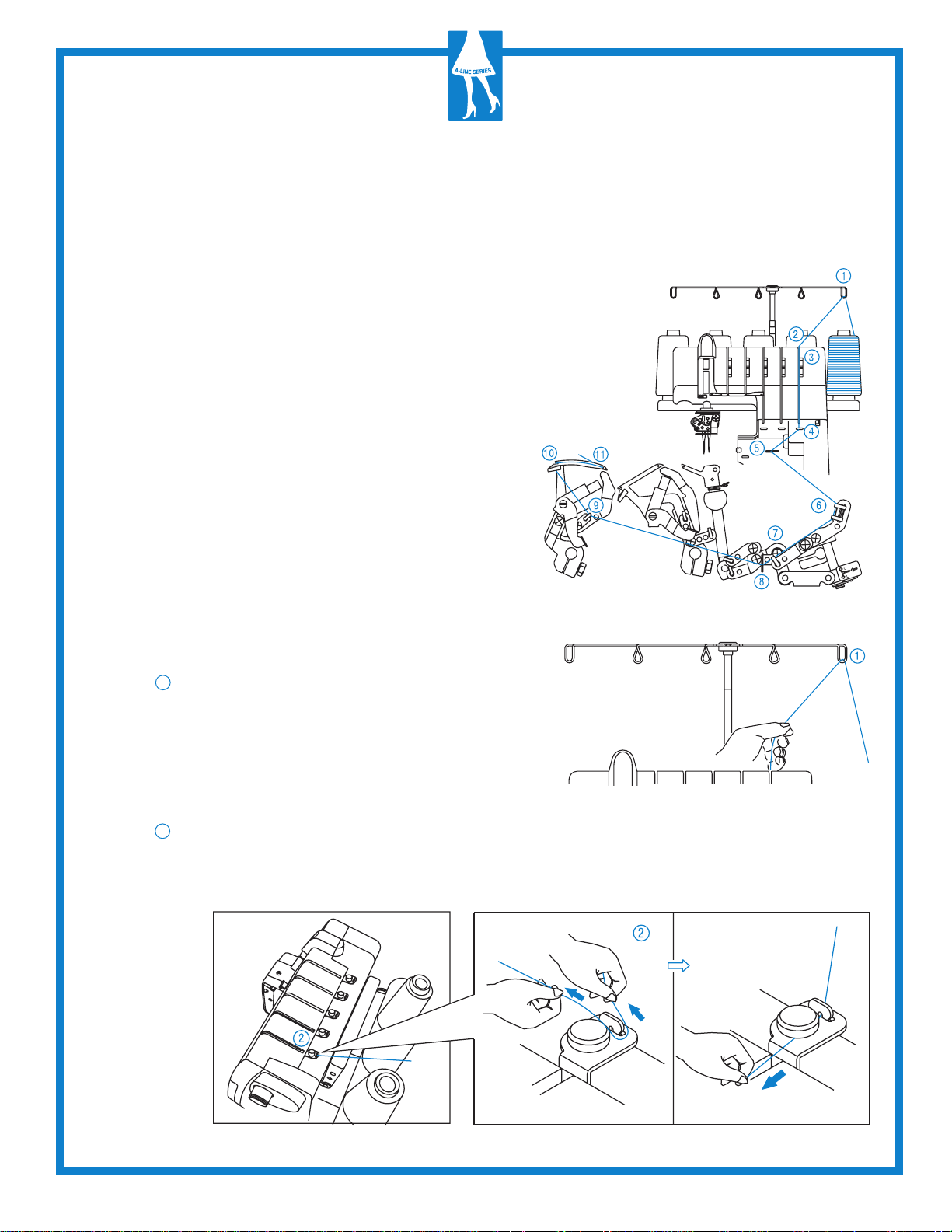

Spool Cap

• When using a regular thread spool, fit the spool cap

supplied with the machine onto the thread spool as

shown at right.

Threading the Machine

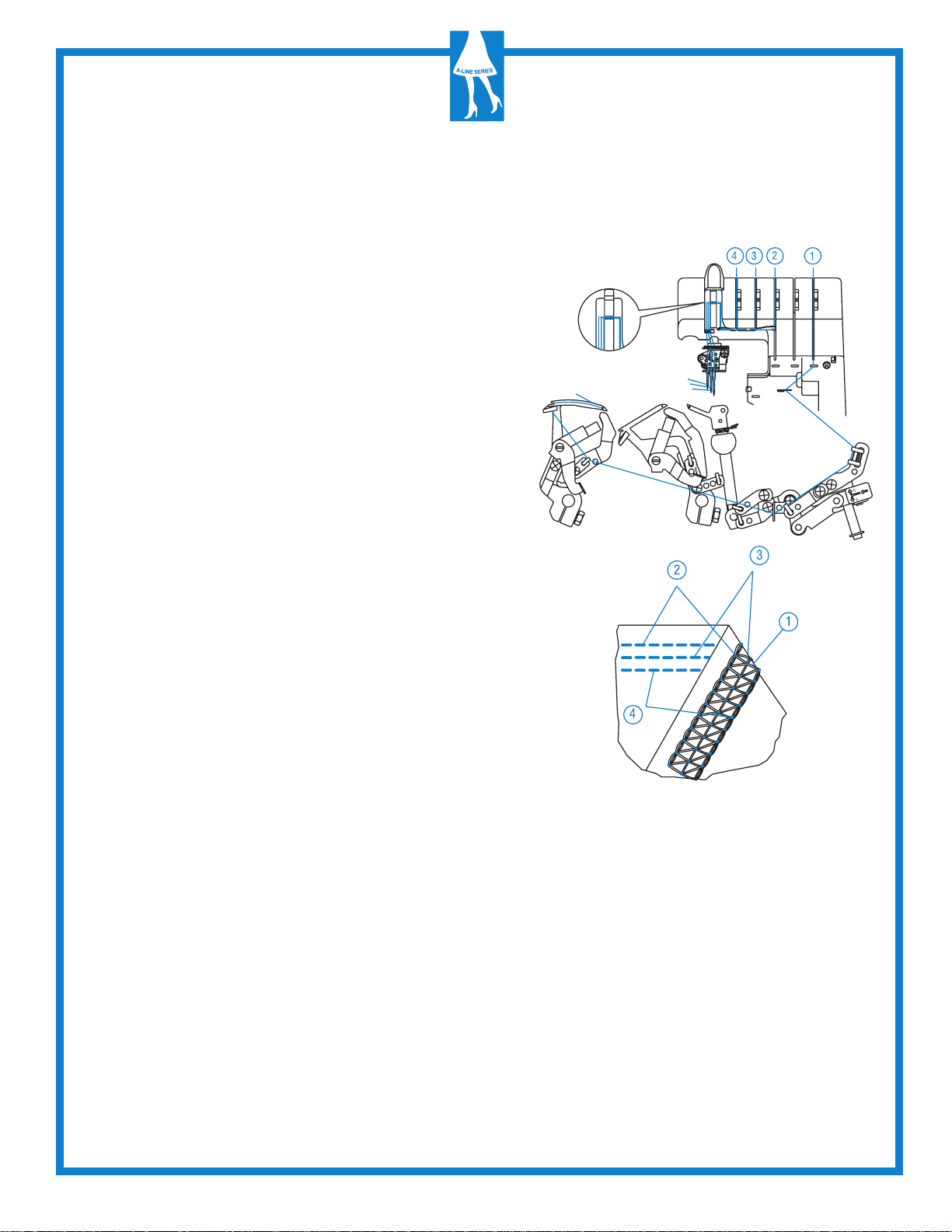

Threading Diagram Sequence: 5-Thread

Chain Stitch-3-Thread overlock

• A color coded threading diagram is located inside

the front cover for quick reference.

• Thread the machine in the order 1 to 5 as shown

at right.

Note: Threads go through the take-up lever cover

for Overlock and Chain stitching as shown.

Spool cap

Press in

Thread spool

Tension Color Code: 5-Thread Chain

Stitch-3-Thread overlock

1. Upper looper thread ............................ Green

2. Lower looper thread ............................ Blue

3. Chain stitch looper thread ................... Purple

4. Right needle thread ............................. Yellow

5. Chain stitch needle thread ................... Red

2

Page 5

Threading Triple Cover Stitch

Threading Diagram Sequence: Triple

Cover Stitch

• A color threading diagram is located inside the front

cover for quick reference.

• Thread the machine in the order 1 to 4 as shown at

right.

Note: Threads go through the take-up lever cover for

cover stitch as shown.

Tension Color Code: Triple Cover Stitch

1. Cover stitch looper thread .................. Purple

2. Right needle thread ............................ Green

3. Middle needle thread .......................... Yellow

4. Left needle thread ............................... Red

3

Page 6

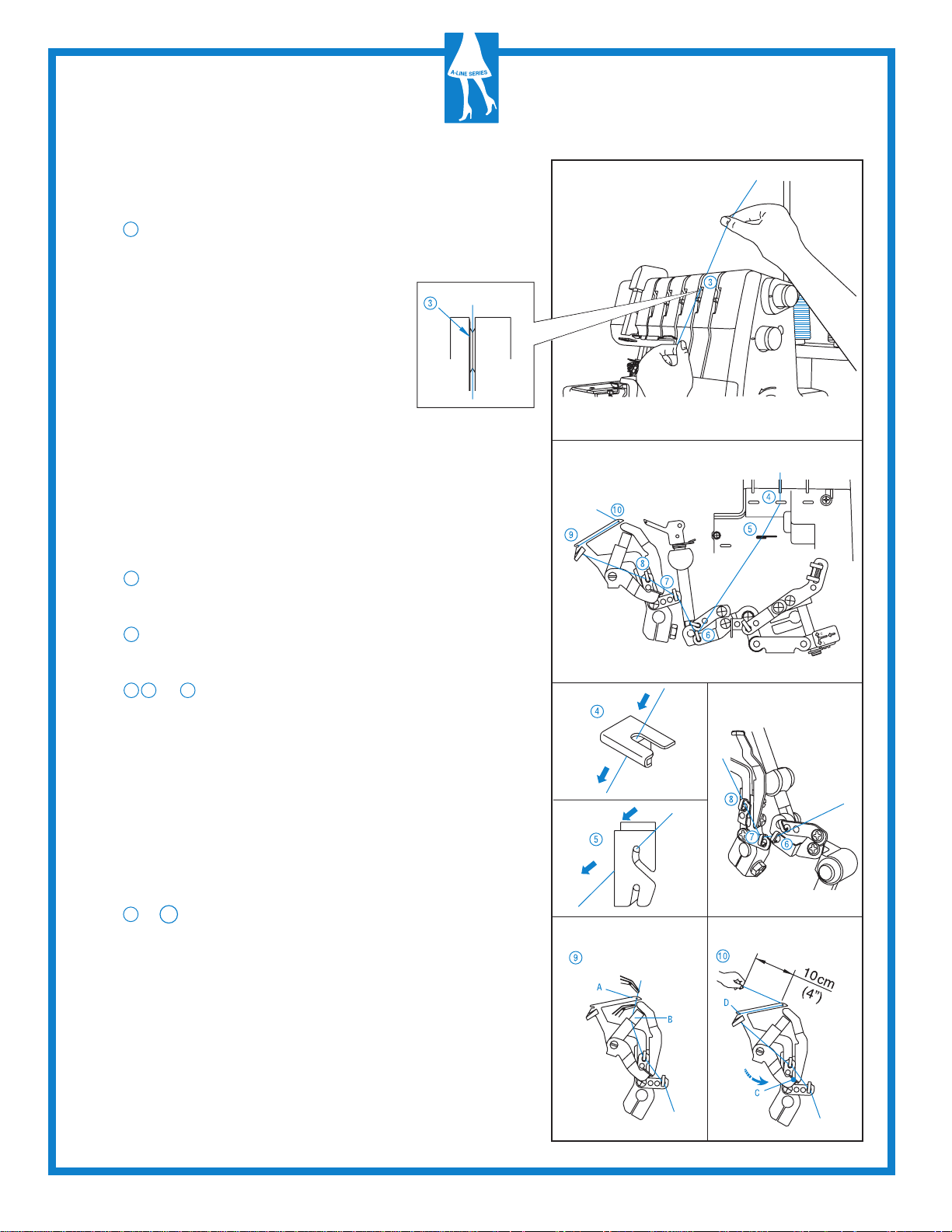

Manual Threading

Threading the Upper Looper (Green)

Open the front cover and thread the upper

looper as indicated in steps 1 through 9.

CAUTION: Be sure to turn off power switch

• Raise Presser foot to release tension discs.

• Thread the upper area of the machine following

the green color-coded thread guides.

1 Pass thread from back to the front through the

thread guide.

1

2

3

4

9

8

7

1

5

6

2 Thread the top cover thread guide by pulling

the thread towards the left until it slips under

guide. Then pull thread along the right side of

pretension disc as illustrated.

3 While holding thread with fingers, pass it

between the tension discs and pull thread

down to make certain it is properly located in

between the tension discs.

4 Place the thread from right to left into

thread guide.

5 Place the thread from left to right and

position thread behind finger on thread

guide.

4

Page 7

6 7 & 8 Thread the balance of the upper

looper area of the machine following the

green color-coded thread guides.

9 Thread the hole in the upper looper from

front to back. Make sure thread passes

behind lower looper. Pull about 10cm

(4 inches) of thread through the looper

and place to the back of the needle plate.

Note: Use tweezers provided in the

accessory case to aid in threading

the looper.

5

Page 8

Manual Threading

Threading the Lower Looper (Blue)

Open the front cover and thread the lower looper

as indicated in steps 1 through 10.

• Raise Presser foot to release tension discs.

• Turn the handwheel toward you until the

lower looper eye extends out 5 - 10mm from the

needle plate edge.

• Thread the lower looper area of the machine following

the blue color-coded thread guides.

1 Pass thread from back to the front through the

thread guide.

2 Thread the top cover thread guide by pulling

the thread towards the left until it slips under

guide. Then pull thread along the right side of

pretension disc as illustrated.

6

Page 9

3 While holding thread with fingers,

pass it between the tension discs

and pull thread down to make

certain it is properly located in

between the tension discs.

4 Place the thread from right to left, into

the thread guide.

5 Place the thread from right to left, into

the thread guide.

6 7 & 8 Thread the balance of the lower

looper area of the machine following the

blue color-coded thread guides, placing

thread in guides.

9 & 10 Thread the lower looper eye (A) from

front to back. Pull about 10cm (4 inches)

of thread and position into V cutout (B) on

looper threader. Firmly hold thread tail

with left hand and pull threader lever (C)

up into place (D).

Note: Use tweezers provided in the

accessory case to aid in threading

the looper.

7

Page 10

Manual Threading

Threading the Chain and Cover Chain

Stitch Looper (Purple)

Open the front cover and thread the chain

stitch/cover stitch looper as indicated in

steps 1 through 11.

• Raise Presser foot to release tension discs.

• Turn the handwheel toward you until the chain

stitch looper eye extends out 5 - 10mm from the

needle plate edge.

• Thread the chain looper area of the machine

following the purple color-coded thread guides.

1 Pass thread from back to the front through the

thread guide.

2 Thread the top cover thread guide by pulling

the thread towards the left until it slips under

guide. Then pull thread along the right side of

pretension disc as illustrated.

8

Page 11

3 While holding thread with fingers, pass it

between the tension discs and pull thread

down to make certain it is properly located in

between the tension discs.

4 Place the thread from right and to left

into threading guide..

5 Place the thread from right to left

into threading guide.

6 7 8 & 9 Thread the balance of the

lower looper area of the machine following

the purple color-coded thread guides,

placing thread in guides.

10 & 11 Thread the looper eye (A) from front

to back. Pull about 10cm (4 inches) of

thread and position into V cutout (B) on

threader. Firmly hold thread tail with left

hand and pull threader lever (C) up to

place thread into correct position (D) for

sewing.

Note: Use tweezers provided in the

accessory case to aid in threading

the looper.

9

Page 12

Manual Threading

Threading the Overlock Right Needle

(Yellow) (B on needle clamp)

Thread the center needle as indicated in

steps 1 through 9.

• Raise Presser foot to release tension discs.

1 Pass thread from back to the front through the

thread guide.

2 Thread the top cover thread guide by pulling

the thread towards the left until it slips under

guide. Then pull thread along the right side of

pretension disc as illustrated.

10

Page 13

3 While holding thread with fingers, pass it

between the tension discs and pull thread

down to make certain it is properly located in

between the tension discs.

4 & 5 Slip thread behind metal guide and

into rear slot on thread guide.

6 Pass thread into the slot of take-up lever

cover.

7 Position thread into the right guide

located at base of take-up lever cover.

8 Slip thread from left to right into the thread

guide located on bottom of the needle

clamp. Position the thread into the right

section of the guide.

Note: Before threading eye of needle, slip

thread behind thread guide located on the

bottom of the needle clamp.

9 Thread the eye of the right needle from

front to back. Draw about 10cm (4 inches)

of thread through needle eye toward the

rear of machine and place thread to the

back, under the presser foot.

Note: Use tweezers provided in the

accessory case to aid in threading

the needle.

11

Page 14

Manual Threading

Threading the Chain Stitch Needle

(Red) (D on needle clamp) Center Needle

Thread the center needle as indicated in

steps 1 through 9.

• Raise Presser foot to release tension discs.

1 Pass thread from back to the front through the

thread guide.

2 Thread the top cover thread guide by pulling

the thread towards the left until it slips under

guide. Then pull thread along the right side of

pretension disc as illustrated.

12

Page 15

3 While holding thread with fingers, pass it

between the tension discs and pull thread

down to make certain it is properly located in

between the tension discs.

4 & 5 Slip thread behind metal guide and

into center slot on thread guide.

6 Pass thread into the slot of take-up lever

cover.

7 Position thread into the center slot on guide

located at base of take-up lever cover.

8 Slip thread from left to right into the thread

guide located on bottom of the needle

clamp. Position the thread into the center

section of the guide.

Note: For 4-Thread overlock left needle: Use

Needle A.

Note: Before threading eye of needle, slip

thread behind thread guide located on the

bottom of the needle clamp.

Note: For Chain stitch: Use needle D before

threading eye of needle, make sure thread is

in front of thread guide located at bottom of

the needle clamp.

9 Thread the eye of the center needle from

front to back. Position of the thread must

be behind the thread guide for overlock

stitching. Draw about 10cm (4 inches) of

thread through needle eye toward the rear

of machine and place thread to the back,

under the presser foot.

Note: Use tweezers provided in the

accessory case to aid in threading

the needle.

13

Page 16

Manual Threading

Threading the Left Cover Stitch Needle

(Red) (C on needle clamp)

Thread the cover stitch/left chain stitch needle

as indicated in steps 1 through 9.

• Raise Presser foot to release tension discs.

1 Pass thread from back to the front through the

thread guide.

2 Thread the top cover thread guide by pulling

the thread towards the left until it slips under

guide. Then pull thread along the right side of

pretension disc as illustrated.

14

Page 17

3 While holding thread with fingers, pass it

between the tension discs and pull thread

down to make certain it is properly located in

between the tension discs.

4 & 5 Slip thread behind metal guide and

into rear slot on thread guide.

6 Pass thread into the slot of take-up lever

cover.

7 Position thread into the left guide

located at base of take-up lever cover.

8 Slip thread from left to right into the thread

guide located on bottom of the needle

clamp. Position the thread into the left

section of the guide.

Note: Before threading eye of needle, make

sure thread is in front of thread guide located

on the bottom of the needle clamp, for cover

stitch and for chain stitch.

9 Thread the eye of the left needle. Draw

about 10cm (4 inches) of thread through

needle eye to hang free. Place the thread

to the back, and slightly to left under the

presser foot.

Note: Use tweezers provided in the

accessory case to aid in threading

the needle.

15

Page 18

Manual Threading

Threading the Cover Stitch

Middle/Chain Needle (Yellow)

(D on needle clamp) Center Needle

Thread the center needle as indicated in

steps 1 through 9.

• Raise Presser foot to release tension discs.

1 Pass thread from back to the front through the

thread guide.

2 Thread the top cover thread guide by pulling

the thread towards the left until it slips under

guide. Then pull thread along the right side of

pretension disc as illustrated.

16

Page 19

3 While holding thread with fingers, pass it

between the tension discs and pull thread

down to make certain it is properly located in

between the tension discs.

4 & 5 Slip thread behind metal guide and

into center slot on thread guide.

6 Pass thread into the slot of take-up lever

cover.

7 Position thread into the center guide

located at base of take-up lever cover.

8 Slip thread from left to right into the thread

guide located on bottom of the needle

clamp. Position the thread into the center

section of the guide.

Note: Before threading eye of needle, make

sure thread is in front of thread guide located

on the bottom of the needle clamp, for cover

stitch and for chain stitch.

9 Thread the eye of the middle needle. Draw

about 10cm (4 inches) of thread through

needle eye to hang free. Place the thread

to the back, and slightly to left under the

presser foot.

Note: Use tweezers provided in the

accessory case to aid in threading

the needle.

17

Page 20

Manual Threading

Threading the Cover Stitch Right Needle

(Green) (E on needle clamp)

Thread the cover stitch right needle as indicated

in steps 1 through 9.

• Raise Presser foot to release tension discs.

1 Pass thread from back to the front through the

thread guide.

2 Thread the top cover thread guide by pulling

the thread towards the left until it slips under

guide. Then pull thread along the right side of

pretension disc as illustrated.

18

Page 21

3 While holding thread with finger, pass it

between the tension discs and pull thread

down to make certain it is properly located in

between the tension discs.

4 & 5 Slip thread behind metal guide and

into front slot on thread guide.

6 Pass thread into the slot of take-up lever

cover.

7 Position thread into right guide located at

base of take-up lever cover.

8 Slip thread from left to right into the thread

guide located on bottom of the needle

clamp. Position the thread into the right

section of the guide.

Note: Before threading eye of needle, make

sure thread is in front of thread guide located

on the bottom of the needle clamp, for cover

stitch.

9 Thread the eye of the right needle. Draw

about 10cm (4 inches) of thread through

needle eye to hang free. Place the thread

to the back, and slightly to left under the

presser foot.

Note: Use tweezers provided in the

accessory case to aid in threading

the needle.

19

Page 22

Manual Threading

Tie-on Method

How to Change Threads Tie On Method

• To change thread type or color, clip thread near the

spool.

• Place new thread on stand.

• Tie new thread and old thread ends together with a

square knot. Clip thread tails to 2-3cm (1 inch) length.

If clipped too short, threads may come untied.

• Firmly pull both thread to test knot security.

• Raise Presser foot to release Tension discs.

• Pull the threads through the machine one at a time.

• If threads do not pull easily, check for tangles on

thread guides or looping under thread stand.

• When pulling thread through the needles, STOP

when the knot is in front of the needle.

• Cut the thread, and insert it through the needle.

20

Page 23

Stitch Settings

Stitch Length

How to Adjust the Stitch Length

• The stitch length dial should be set on the N setting for

most sewing conditions.

• Adjust the stitch length to N-4 when sewing heavy

weight fabrics.

• Adjust the stitch length to 2-N when sewing lightweight

fabrics to obtain excellent seams without puckering.

Stitch Width

Width adjustment dial

As shown on the illustration, turn the dial counter

clockwise to increase width of cutting, and clockwise to

decrease width of cutting.

21

Page 24

Starting to Serge

Chaining Off and Test Sewing

Note: The following instructions do not apply to cover

stitch.

For instructions on cover stitch, see page 48 “How to

Sew a Cover Stitch”, in the instruction manual.

• When the machine is completely threaded, bring all of

the threads across the throat plate and slightly to the

left under the pressor foot.

• Hold the threads and apply a slight tension.

• Turn the hand wheel toward you 2 or 3 complete turns

to start the thread chain.

• Lower presser foot.

• Continue holding the chain and press on the foot

controller until chain is 5-7.5cm (2-3 inches) in length.

• Place fabric under the front of the presser foot and

sew a test sample.

Note: Do not pull on the fabric while sewing as this may

deflect the needle, causing it to break.

• At the end of the sample, continue to run the machine

with the presser foot down until the chain reaches

15-20cm (6-8 inches) in length.

Note: In case it is difficult to chain off when chain

stitching, pull the fabric lightly backward.

Presser Foot Markings

• A mark to indicate the needle location is provided on the

presser foot fitted on this machine. Use this mark as a

guide when sewing.

Presser Foot Lifter

• Put the presser foot lifter in the raised position to lower

the presser foot for sewing.

• Swing the presser foot lifter down to lift the presser foot.

• For bulky fabrics, pull forward on the presser foot lifter

to allow additional clearance under the foot.

22

Page 25

Starting to Coverstitch

At start of sewing

1 Raise presser foot.

2 Place fabric under presser foot behind the needle.

3 Lower presser foot.

4 Note: When you start to sew from the middle of the fabric,

place the fabric at the desired starting point of sewing.

At end of sewing

Stop sewing when the fabric is not under the

needles

5 Raise presser foot.

6 Turn the handwheel toward you one circle

(Counter-clockwise), then turn handwheel one circle

back. (Clockwise)

7 Pull out the fabric lightly to rear of machine and

cut the threads to take out the fabric.

8 Note: Follow the instructions given, when sewing

cover stitches, because chaining-off at the end of

sewing is not possible.

23

Page 26

This machine is capable of producing various types of stitches according to the combination of Auto Tension

Selected, needle positions, threading methods, and the use of convertible right looper/converter.

22. SELECTION OF STITCHES & AUTO TENSION

Selection of Stitches & Auto Tension

This machine is capable of producing various types of stitches according to the combination of Auto

Tension Selected, needle positions, threading methods, and the use of convertible right looper/

converter.

Stitch Type Reference

ATD: Auto Tension Dial Selected

1. Chain Stitch

ATD:D

2. 2-Thread

Wrapped Edge

Overlock

ATD:D

ATD:G

3. 2-Thread

Overlock

ATD:E

4. 3-Thread

Overlock

ATD:A

ATD:B

Narrow

Wide

Narrow

Wide

A 1-needle 2-thread straight stitch is used

for construction or decorative stitching.

Seams also can be sewn at desired

distance from edge of fabric by

disengaging the right looper and movable

knife.

1-needle 2-thread stitch is used for

seaming lightweight or stretch fabrics.

It is also ideal for rolled and blind hemming.

A 4 mm and 6 mm overlock seam width

can be obtained by changing the needle

position.

1-needle 2-thread stitch is used for

overedging common fabrics. It is also

ideal for flatlock (butted or lapped) seams

and blind hemming. A 4 mm and

6 mm overedge seam width can be

obtained by changing the needle position.

1-needle 3-thread stitch is used for

overedging and seaming on common

fabrics. A mm and 6 mm overlock seam

width can be obtained by changing the

needle position.

Instruction

Manual

Page

Reference Page

39

40

41

42

5. 3-Thread

Flatlock

ATD:F

6. 3-Thread Mock

Safety Stitch

Overlock

ATD:G

7. 4-Thread Mock

Safety Stitch

Overlock

ATD:A

1-needle 3-thread stitch is used for

butted or lapped seams and ornamental

stitching with decorative thread. Also,

a 4 mm and 6 mm flatlock width can

be obtained by changing the needle

position.

2-needle 3-thread stitch that is ideal for

lightweight, extremely stretchy fabrics

such as tricot and spandex.

2-needle 4-thread stitch that is ideal

for medium to heavyweight stretchy

fabrics such as double knits and swim

wear.

24

43

44

45

Page 27

Selection of Stitches & Auto Tension

This machine is capable of producing various types of stitches according to the combination of Auto

Tension Selected, needle positions, threading methods, and the use of convertible right looper/

converter.

Stitch Type Reference

8. 4-Thread

Chain Stitch2-Thread

Overlock

ATD:I

ATD: Auto Tension Dial Selected

The 4-thread stitch is a safety stitch

made up of combined 2-thread

overedge and double chain stitch.

Instruction

Manual

Page

Reference Page

46

9. 5-Thread

Chain Stitch3-Thread

Overlock

ATD:A

Narrow

ATD:B

Wide

10. Cover Stitch

ATD:K

Narrow

(2.8mm)

ATD:H

Wide

(5.6mm)

The 5-thread stitch is a safety stitch

made up of combined 3-thread overlock

and double chain stitch.

A wide seam is formed by using left needle.

Overedge and seaming can be done in one

operation on non-stretch fabrics.

The 5-thread stitch is a safety stitch

made up of combined 3-thread

overlock and double chain stitch.

A narrow seam is formed by using right

needle Overedge and seaming can be dane

in one operation on non-stretch fabrics.

2-needle, 3-thread cover stitch is

suitable for stretchy fabrics such as

knits, etc.

A narrow seam is formed by using left

and middle needles.

2-needle 3-thread cover stitch is

suitable for stretchy fabrics such as

knits, etc.

A wide seam is formed by using left

and right needles.

one

47

47

50

50

11.Triple Cover

Stitch (5.6mm)

ATD:J

12. 3-Thread

Rolled Hem

(4.0mm)

ATD:C

3-needle 4-thread cover stitch is

suitable for stretchy fabrics such as

knits, etc.

A triple seam is formed by using left,

middle, and right needles

1-needle 3-thread stitch is used for sewing

narrow rolled hems.

.

25

51

54

Page 28

2 . HANDY REFERENCE CHART3

Handy Reference Chart

Stitch Type

Chain Stitch

1

2-Thread Wrapped

2

Edge Overlock

2-Thread Overlock

3

4

3-Thread Overlock

3-Thread Flatlock

5

A

T

D

D

D

G

E

E

A

B

F

F

SLDFL

N

N

2

N

2

N

2

N

2

N

N

N

N

N

2

N

2

N

/

C

C

L

L

L

L

L

L

L

L

Needle

Position

4.0mm

narrow

6.0mm

wide

4.0mm

narrow

6.0mm

wide

4.0mm

narrow

6.0mm

wide

4.0mm

narrow

6.0mm

wide

Tension Dial Selected :As select ATD option,

the tension dial are set automatically.

Yellow

GreenRed Purple

converter

converter

converter

converter

Blue

Instruction

Manual

Page

Reference

Page

39

40

40

41

41

42

42

43

43

3-Thread Mock Safety

6

Stitch Overlock

4-Thread Mock Safety

7

Stitch Overlock

4-Thread Chain Stitch-

8

2-Thread Overlock

5-Thread Chain Stitch-

9

3-Thread Overlock

Cover Stitch

10

Narrow/ Wide

Triple Cover Stitch

11

Three - Thread

12

Rolled Hem

G

2

A

N

I

N

A

N

B

N

K

N

H

N

J

N

C

1

ATD: Auto Tension Dial Selection

DF: Differential Feed

N

L

N

L

N

L

N

N

N

N

N

N

narrow

L

wide

L

2.8mm

C

narrow

5.6mm

C

wide

5.6mm

C

4.0mm

L

SL: Stitch Length

L/C: Upper Looper driving clutch position

converter

converter

44

45

46

47

47

50

50

51

54

* When option 2, 3, 6, 8 selected, use converter.

* When option 1, 10, and 11 selected, turn upper knife down, move seam width finger knob to setting R, and change front cover

attached cover (A) into (B).

* Auto tension settings are based on medium weight fabric and standard #60 polyester spun thread. It can satisfy most requirements

for sewing. If using different thread number or fabric and the result is not what you expected, please adjust in small increments.

26

Page 29

Create a classic silhouette by making a

Wrap Skirt

Skill Level: Beginner

Supplies:

• Baby Lock Diana serger

• Wrap skirt pattern or template below

• Paper to trace pattern

• 4 Cones of Maxi-Lock serger thread

• 1 Spool decorative or contrasting color thread

• Measuring tape

• 2 ½ yards linen

• Interfacing

• Hand sewing needle

• Skirt hook and eye

• Pencil

• Ruler

• Iron and ironing board

simple A-line skirt all on the serger.

Instructions:

1. Measure and trace off pattern on to the pattern paper.

Template front

27

Template back

Page 30

2. Measure your back waist (from hipbone to hipbone). Then, measure your front waist.

3. Adjust the pattern width according to your measurements. Add or subtract as needed.

Remember the front pieces overlap.

4. On the front and back pattern, measure from the waist edge 4” down and draw a line.

Trace this section off to form the front and back facings.

5. Cut the back on the fold. Cut two front pieces.

6. Cut four tie pieces 3-½” x 22”. Cut one short end of the ties off at an angle.

7. Set up the serger for a 4-thread stitch.

8. Place two ties right sides together. Serge both long ends and the angled end. Turn the

tie right side out through the open short end. Press.

9. Repeat for the remaining tie strand.

10. Serge the front to the back at the side seam. Place one of the ties in the left side seam.

11. Serge the facing front to the facing back at the side seams.

12. With right sides together serge facing to the skirt at the waist band edge.

13. Place the remaining tie on the right front.

14. Serge the front sides catching the facings. Continue along the front edge to the hem

edge. Serge across the hem edge.

15. Turn the waistband edge to the right side and press.

16. Set the serger up for a chain stitch using a decorative or contrasting thread in the chain

looper.

17. Chain stitch along the edges of the skirt waistband, skirt ties and skirt front, and hem

turning under the serged edge when needed.

18. Hand stitch a skirt hook in place to secure the front without a tie to the waist band edge.

27

Page 31

For other exciting projects like this one, visit our Web site at www.babylock.com

28

Page 32

Visit our Web site at www.babylock.com

LBIN-BL480A

Loading...

Loading...