Avdel T40, T51 Instruction Manual

Hydro-Electric Power Tool

T40 Installation Tool

Instruction Manual

Original Instruction

3

Contents

Safety 4

Specifications

Intent of Use 5

Tool Specification 5

Tool Dimensions 5

Putting into Service

Principle of Operation 6

Preparation for Use 6

Hydraulic Hose Kits 6

Operating Instructions 7

Maintenance

Dismantling Instructions 8

Assembling the Tool 8

To Bleed the Tool 9

General Assembly for T40 Installation Tool

73414-02000 10

Parts List for T40 Installation Tool

73414-02000 11

Avdel UK Limited policy is one of continuous product development and improvement and we reserve the right to change the specification of any product without prior notice.

Warranty

The ninety day warranty herein expressed shall be the exclusive warranty on items

manufactured by seller and shall be in the place and stead of any other warranty, expressed or

implied, including but not limited to the implied warranties of merchantability and fitness for a

particular purpose.

Seller shall not be liable for any loss or damage resulting from delays or non-fulfilment or

orders owing to strikes, fires, accidents, transportation companies or for any reason or

reasons beyond the control of seller or its suppliers.

All warranty claims must be submitted to the seller in writing, within 90 days from date of

shipment, and no returns will be accepted without written permission.

Other provisions hereof notwithstanding, seller shall not be liable for any loss of business

profits or any incidental or consequential damages incurred by Buyer or any third person in

connection with the items or use thereof, however caused.

Tool Warranty

Seller expressly disclaims any warranty express or implied, as to the condition, design,

operation, merchantability or fitness for use of any tool, or part(s) thereof not manufactured by

seller. The only warranties made with respect to such tool or part(s) thereof are those made

by the manufacturer thereof and seller agrees to cooperate with buyer in enforcing such

warranties when such action is necessary. Seller agrees to repair or replace F.O.B. seller's

plant, any tool or part(s) thereof manufactured by it and proved to seller to be defective due to

faulty workmanship or material.

Servicing the Tool

Daily 12

Weekly 12

Every 1200 Working Hours (at least once a year) 12

Service Tools 12

Hydraulic Oil General Safety Data 12

Fault Diagnosis

Symptom, Possible Cause and Remedy 13-14

4

Safety

1 Do not use outside the design intent.

2 Do not use equipment with this tool/machine other than that recommended by Avdel UK Limited.

3 Any modification undertaken by the customer to the tool/machine shall be the customer’s entire responsibility.

4 Always disconnect the tool from the HydraPac before attempting to adjust, remove or fit the nose assembly.

5 Do not operate a tool/machine that is directed towards any person(s).

6 Always adopt a firm footing or a stable position before operating the tool/machine.

7 If cycling the tool without the nose assembly, care must be taken to avoid contact with the moving piston.

8 Ear protection must be worn by the operator and others in the vicinity as noise levels exceed the permitted maximum. For values

see Tool Specification on page 5.

9 Do not fit flexible hoses rated at less than 10,000 psi (69 mPa) working pressure.

10 The operating pressure shall not exceed 8,000 psi (55.2 mPa).

11 Care shall be taken to ensure that spent pintails are not allowed to create a hazard.

12 When using the tool, the operator and others in the vicinity are recommended to wear safety glasses.

13 Take care to avoid entanglement of loose clothes, ties, long hair, cleaning rags etc. in the moving parts of the tool.

14 The tool should be kept clean and dry for the best possible grip.

15 When carrying the tool from place to place keep hands away from the trigger to avoid inadvertent start up.

16 The machine must be maintained in a safe working condition at all times and examined at regular intervals for damage and function

by trained competent personnel. Any dismantling procedure shall be undertaken only by personnel trained in Avdel

®

procedures.

Do not dismantle the machine without prior reference to the maintenance instructions. Contact Avdel®with your training

requirements.

17 The machine shall at all times be operated in accordance with relevant Health and Safety legislation. In the UK the "Health & Safety

at Work Act 1974" applies. Any question regarding the correct operation of the machine must be directed to Avdel

®

.

This instruction manual must be read with particular attention to the following safety rules, by any person

installing, operating, or servicing this tool.

CAUTIONS

AVDEL RECOMMENDS THAT ONLY HYDRAPAC UNITS BE USED TO DRIVE INSTALLATION TOOLS, AS OTHER MAKES OF

HYDRAULIC POWER UNITS MAY NOT OPERATE AT THE SAFE DESIGNED WORKING PRESSURES.

ENSURE THAT THERE IS ADEQUATE CLEARANCE FOR THE TOOL OPERATOR'S HANDS BEFORE PROCEEDING.

DO NOT ABUSE THE TOOL BY DROPPING OR USING IT AS A HAMMER.

KEEP DIRT AND FOREIGN MATTER OUT OF THE HYDRAULIC SYSTEMS OF THE TOOLS AS THIS WILL CAUSE THE TOOL AND

HYDRAPAC TO MALFUNCTION

5

Intent of Use

Tool Specification

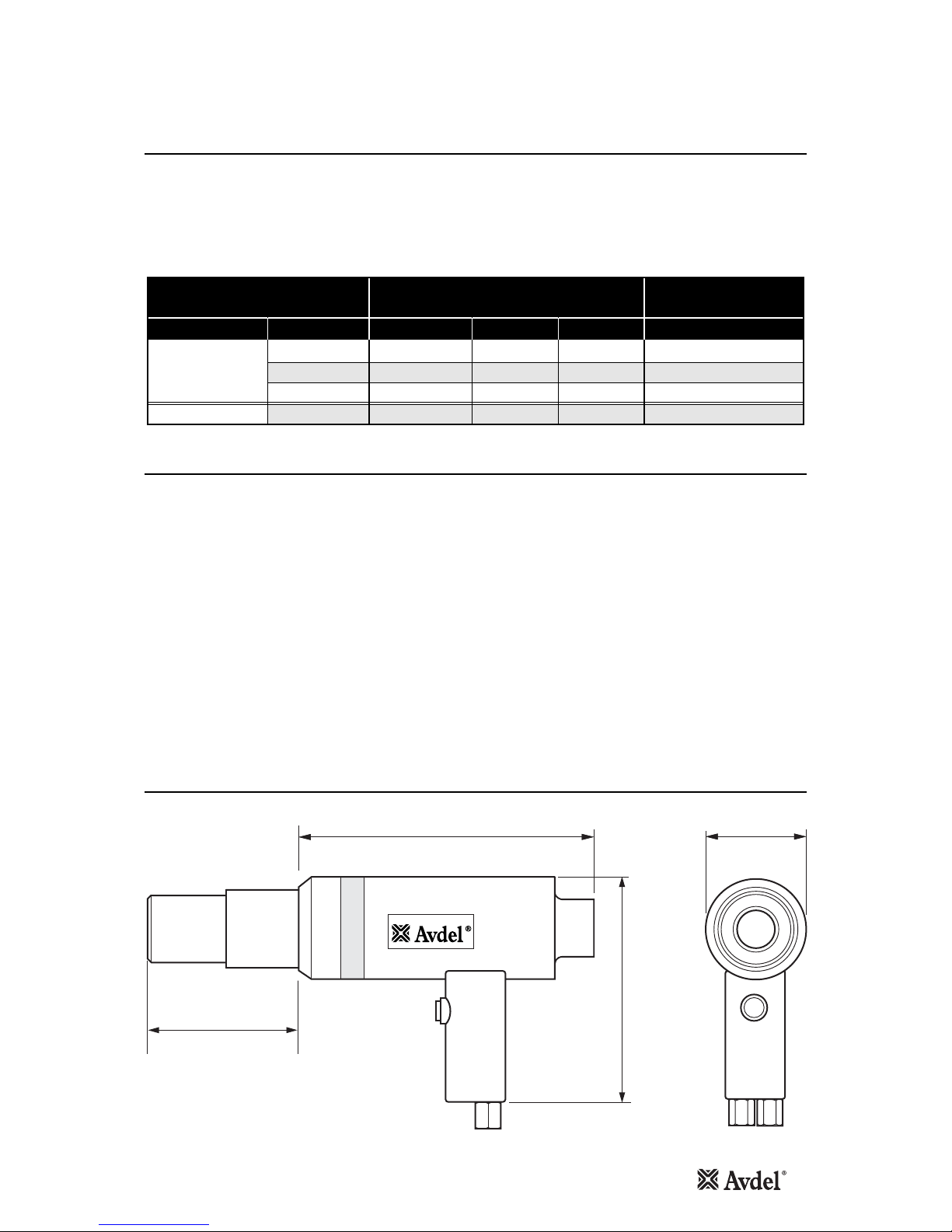

Tool Dimensions

Specifications

The T40 Installation Tool is basically a Piston and Cylinder Assembly. When coupled Hydraulically and Electrically to a compatible

Hydraulic Power Source and the relevant Nose Assembly is attached, it is then used to install

1

/2’’ to 3/4” Avdelok®and 5/8” Avbolt

®

in industrial environments.

Refer to the table below for the list of applicable fasteners and associated nose equipment.

Refer to the datasheets listed in the table for the relevant nose assembly instructions.

FASTENER

TYPE SIZE

NOSE ASSEMBLY

PART Nº HAT REF. DIM. ‘A’

NOSE ASSEMBLY

DATASHEET

PART Nº

®

07900-00919

07900-00919

07900-00919

07900-00905

73412-03100

73412-03200

73412-03300

73412-03400

N31

N37

N30

Avbolt

LD Avdelok

1

/

2

”

3

/

4

”

5

/

8

”

5

/

8

”

110mm

113mm

131mm

113mm

N32

®

Length 250 mm 9.8 in

Body Diameter 76 mm 2.9 in

Height 190 mm 7.50 in

Weight 7 kg 15.5 lbs

Stroke 41 mm 1.6 in

Pull Force 175kN 39340lbf

Pull pressure 55.2 mPa 8000 PSI

Return Pressure 20.7 mPa 3000 PSI

Hydraulic Oil ISO VG 46 OR EQUIVALENT

Fastener Range

1

/2’’ to 3/4” Avdelok®and 5/8” Avbolt

®

Noise Level 126.2 dB(A)

Sound Power 100.9 dB(A)

Vibration 8.6 m/sec

3

A

250 mm

76 mm

190 mm

Loading...

Loading...