Avdel nG2S 71401 Instruction Manual

Hydro-Pneumatic Power Tool

Genesis

®

Instruction Manual

3

Contents

Safety Rules 4

Specifications

Tool Specifications 5

Tool Dimensions 5

Intent of Use

Range of Fasteners 6

Part Numbering 6

Putting into Service

Air Supply 7

Operating Procedure 7

Nose Assemblies

Fitting Instructions 8

Servicing Instructions 8

Nose Tips 9

Type 1 9

Avseal®II 10

Fitting Types 2/3 or Nose Extension 11

Type 2 and Type 3 12

Accessories

Stem Deflector 13

Preparing the Base Tool for use with Stem Deflector 13

Extension 13

Swivel Heads 14

Straight Swivel Head Capability 14

Preparing the Base Tool for Right-Angle and Straight

Swivel Head Attachment 15

Straight and Right-Angle Heads 16

Fitting Instructions 16

Servicing Instructions 17

Constant Components 17

Servicing the Tool

Daily 18

Weekly 18

MolyLithium Grease EP 3753 Safety Data 18

MolyKote®55m Grease Safety Data 19

MolyKote®111 Grease Safety Data 19

Service Kit 07900-00716 20

Maintenance 20

Annually 20

Nose Equipment 20

Head Assembly 21

Rotary Valve 22

Trigger 22

Stop Plate Assembly (71213-03900) 23

Intensifier 24

General Assembly and Parts List

General Assembly of Pistol 71401-02000 (s) 26

Parts List for 71401-02000 (s) 27

General Assembly of Intensifier 71421-02000 (s) 28

Parts List for 71421-02000 (s) 29

Priming

Oil Details 30

Hyspin®VG 32 Oil Safety Data 30

Priming Procedure 31

Fault Diagnosis

Symptom, Possible Cause and Remedy 32

LIMITED WARRANTY

Avdel makes the limited warranty that it’s products will be free of defects in workmanship and materials

which occur under normal operating conditions. This Limited Warranty is contingent upon: (1) the product

being installed, maintained and operated in accordance with product literature and instructions, and (2)

confirmation by Avdel of such defect, upon inspection and testing. Avdel makes the foregoing limited

warranty for a period of twelve (12) months following Avdel’s delivery of the product to the direct purchaser

from Avdel. In the event of any breach of the foregoing warranty, the sole remedy shall be to return the

defective Goods for replacement or refund for the purchase price at Avdel’s option. THE FOREGOING

EXPRESS LIMITED WARRANTY AND REMEDY ARE EXCLUSIVE AND ARE IN LIEU OF ALL OTHER WARRANTIES

AND REMEDIES. ANY IMPLIED WARRANTY AS TO QUALITY, FITNESS FOR PURPOSE, OR MERCHANTABILITY

ARE HEREBY SPECIFICALLY DISCLAIMED AND EXCLUDED BY AVDEL.

Avdel UK Limited policy is one of continuous product development and improvement and we reserve the right to change the specification of any product without prior notice.

4

Safety Rules

This instruction manual must be read with particular attention to the following safety rules, by any person

installing, operating, or servicing this tool.

1 Do not use outside the design intent.

2 Do not use equipment with this tool/machine other than that recommended and supplied by Avdel UK Limited.

3 Any modification undertaken by the customer to the tool/machine, nose assemblies, accessories or any equipment supplied by

Avdel UK Limited or their representatives, shall be the customer’s entire responsibility. Avdel UK Limited will be pleased to advise

upon any proposed modification.

4 The tool/machine must be maintained in a safe working condition at all times and examined at regular intervals for damage and

function by trained competent personnel. Any dismantling procedure shall be undertaken only by personnel trained in Avdel UK

Limited procedures. Do not dismantle this tool/machine without prior reference to the maintenance instructions. Please contact

Avdel UK Limited with your training requirements.

5 The tool/machine shall at all times be operated in accordance with relevant Health and Safety legislation. In the U.K. the “Health

and Safety at Work etc. Act 1974” applies. Any question regarding the correct operation of the tool/machine and operator safety

should be directed to Avdel UK Limited.

6 The precautions to be observed when using this tool/machine must be explained by the customer to all operators.

7 Always disconnect the air line from the tool/machine inlet before attempting to adjust, fit or remove a nose assembly.

8 Do not operate a tool/machine that is directed towards any person(s) or the operator.

9 Always adopt a firm footing or a stable position before operating the tool/machine.

10 Ensure that vent holes do not become blocked or covered.

11 The operating pressure shall not exceed 7 bar.

12 Do not operate the tool if it is not fitted with a complete nose assembly or swivel head unless specifically instructed otherwise.

13 Care shall be taken to ensure that spent stems are not allowed to create a hazard.

14 Vacuum Air MUST be turned off using the Trigger before removing the Stem Collector Bottle which Must be emptied when half full.

15 The Tool MUST NOT be operated with the Stem Collector Bottle removed.

16 If the tool is fitted with a stem deflector, it should be rotated until the aperture is facing away from the operator and other person(s)

working in the vicinity.

17 When using the tool, the wearing of safety glasses is required both by the operator and others in the vicinity to protect against

fastener ejection, should a fastener be placed ‘in air’. We recommend wearing gloves if there are sharp edges or corners on the

application.

18 Take care to avoid entanglement of loose clothes, ties, long hair, cleaning rags etc. in the moving parts of the tool which should be

kept dry and clean for best possible grip.

19 When carrying the tool from place to place keep hands away from the trigger/lever to avoid inadvertent start up.

20 Excessive contact with hydraulic fluid oil should be avoided. To minimize the possibility of rashes, care should be taken to wash

thoroughly.

21 C.O.S.H.H. data for all hydraulic oils and lubricants is available on request from your tool supplier.

Specifications

5

Air Pressure Minimum - Maximum 5-7 bar

Free Air Volume Required @ 5.5 bar 3.6 litres

Stroke Minimum 17 mm

Pull Force @ 5.5 bar 10.88 kN

Cycle time Approximately 1 second

Noise Level 75 dB(A)

Weight Without nose equipment or intensifier 0.88 kg

Vibration Less than 2.5 m/s

2

Intensifier Ratio 44:1

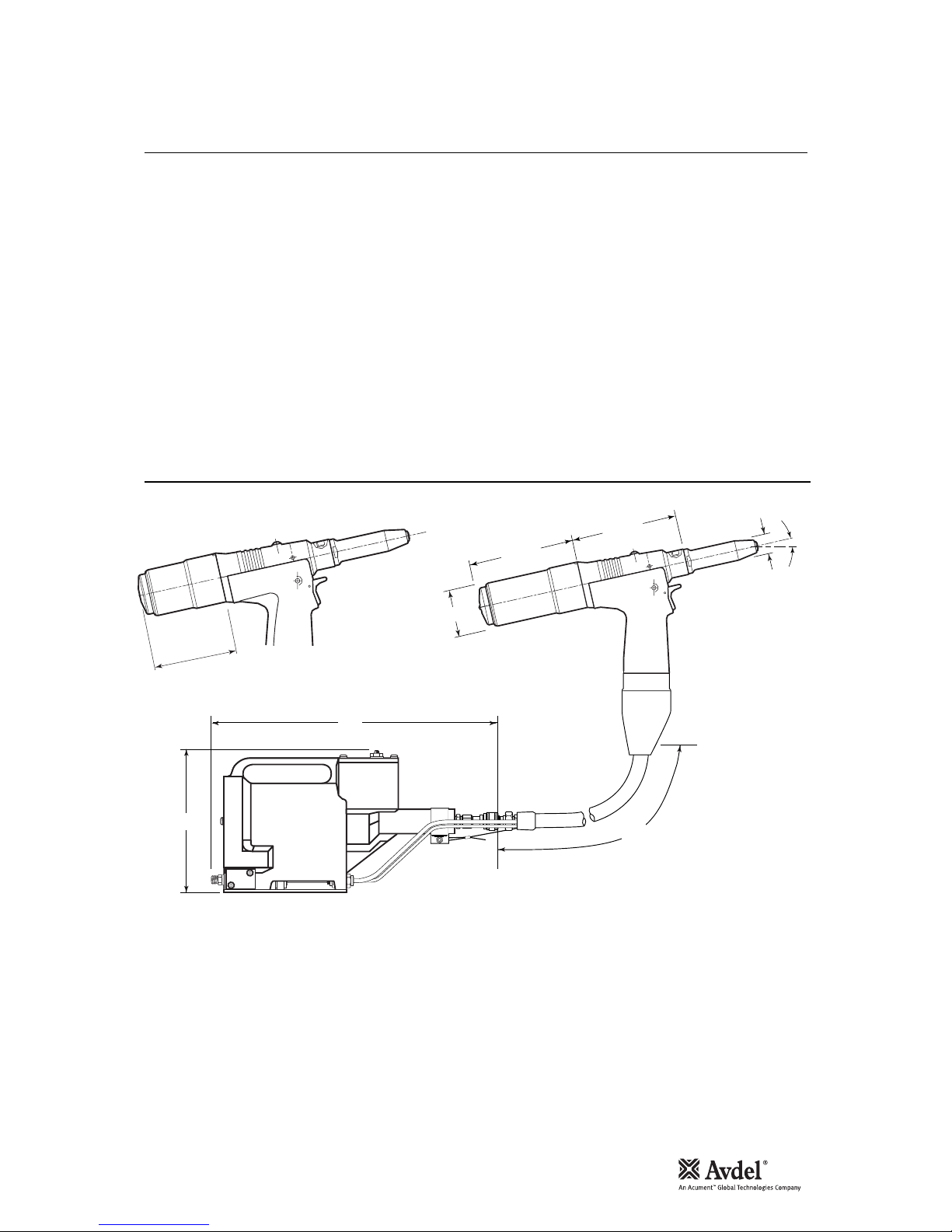

Dimensions in millimetres

Tool Dimensions

200

417

12°30'

123.30

128.61

54.88

22.80

2150

SCRAP VIEW SHOWING BOTTLE

STEM COLLECTOR SHORT VERSION

91.00

6

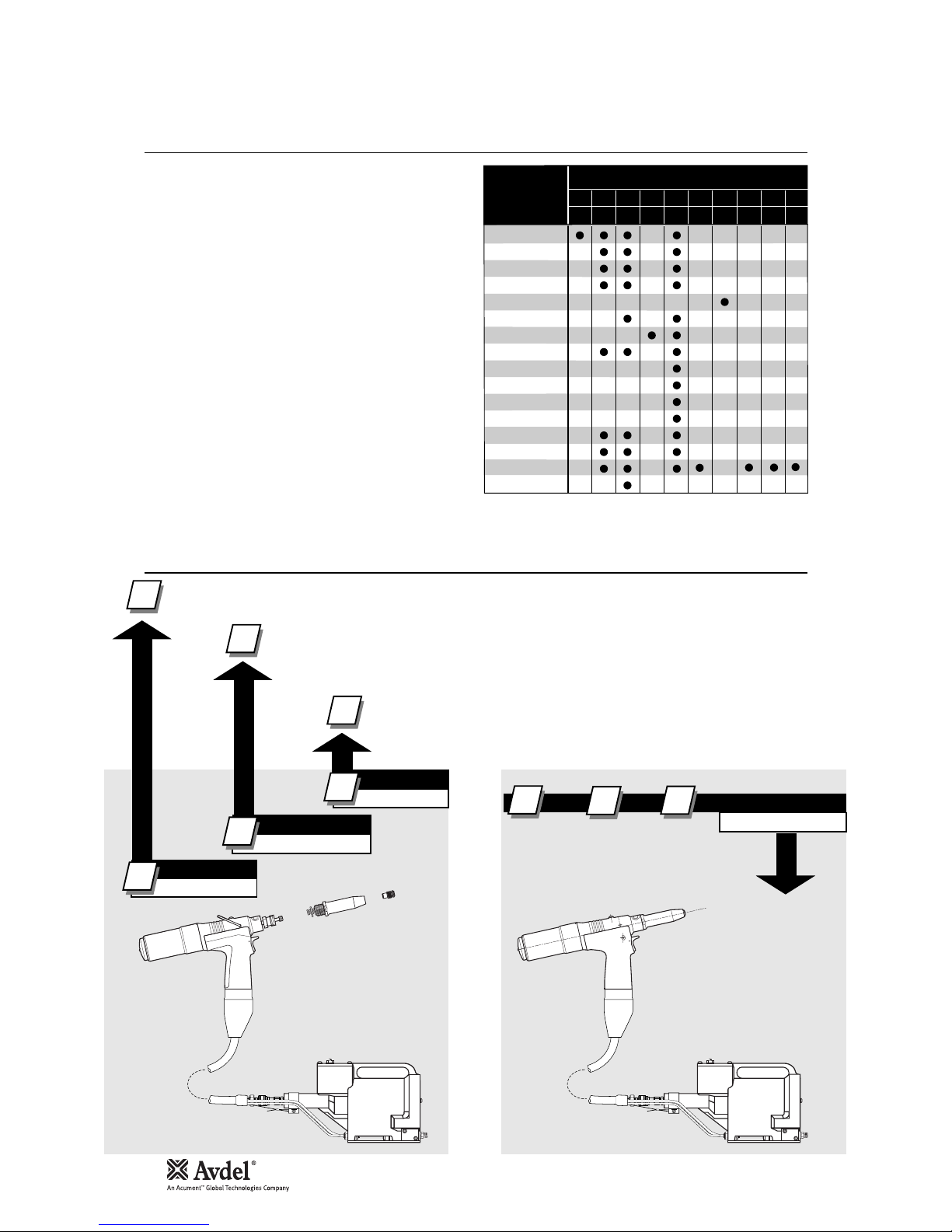

Intent of Use

COMPLETE TOOL

71401-00 . . .

*

BASE TOOL

1

1

2

3

1

NOSE ASSEMBLY

NOSE TIP

2

71401-01000

71213-15000

see note 3

2

3

++=

3

n

G2s is a hydro-pneumatic tool designed to place Avdel

®

breakstem fasteners at high speed making it ideal for batch or

flow-line assembly in a wide variety of applications throughout

all industries. It can place all fasteners listed opposite.

The tool features a vacuum system for fastener retention and

trouble free collection of the spent stems regardless of tool

orientation.

See the ‘Operating Procedure’, page 7, for adjustment

instructions.

A complete tool, except the 71401-00039, is made up of three

separate elements which must be ordered individually.

See diagram below.

If you wish to place most of the fasteners in the table

opposite, you can order the 71401-00039 complete tool

comprising:

• 71401-01000 base tool.

• 71213-15000 nose assembly.

• Nose tips 71210-05002, 71210-16070 and 07381-

04701.

Fit nose tips as indicated on pages 8 to 12.

The part number of the base tool remains the same whichever nose assembly, or nose tip is fitted. For details of the pistol, see

page 26. If a swivel head is fitted, the same base tool must be adapted. See details page 15.

This single nose assembly will allow placing of non-aerospace fasteners by simply selecting the appropriate

nose tip from the range of type 1 nose tips. Other nose assemblies are available for applications with

restricted access, for aerospace and special fasteners. See tables pages 9, 10 and 12. A nose

assemblycan be substituted by a swivel head (see pages 14 to16). In this case the nose tip is part of the

swivel head.

The nose tip part number relates to a specific fastener. If access to the application is

restricted, some extended nose tips are available. See page 12 for selection table.

* ADD 3 DIGITS FROM THE

LAST COLUMN OF A NOSE

TIP TABLE ON PAGE 9, 10

and 12.

FOR TOOLS WITH SWIVEL

HEADS USE TABLE PAGES 14

to 15.

You can order the above three nose tips and nose assembly as a nose assembly kit part number 71213-15100. For some

fasteners, the base tool, nose assembly and nose tip must be ordered separately.

NOSE EQUIPMENT MUST BE FITTED AS DESCRIBED ON PAGE 8.

Part Numbering

FASTENER

NAME

MM

IN

FASTENER SIZE ( )

AVEX

®

STAVEX

®

AVINOX®II

AVIBULB

®

ETR

BULBEX

®

T-LOK

®

AVDEL® SR

MONOBOLT

®

INTERLOCK

®

KLAMPTITETM KTR

KLAMPTITE

TM

AVDEL

®

MBC

®

MBC®/LC

AVSEAL®II

3 3.2 4.0 4.3 4.8 5 5.2 6 6.5 7

–

1/85

/32 –3/16 –––––

Range of Fasteners

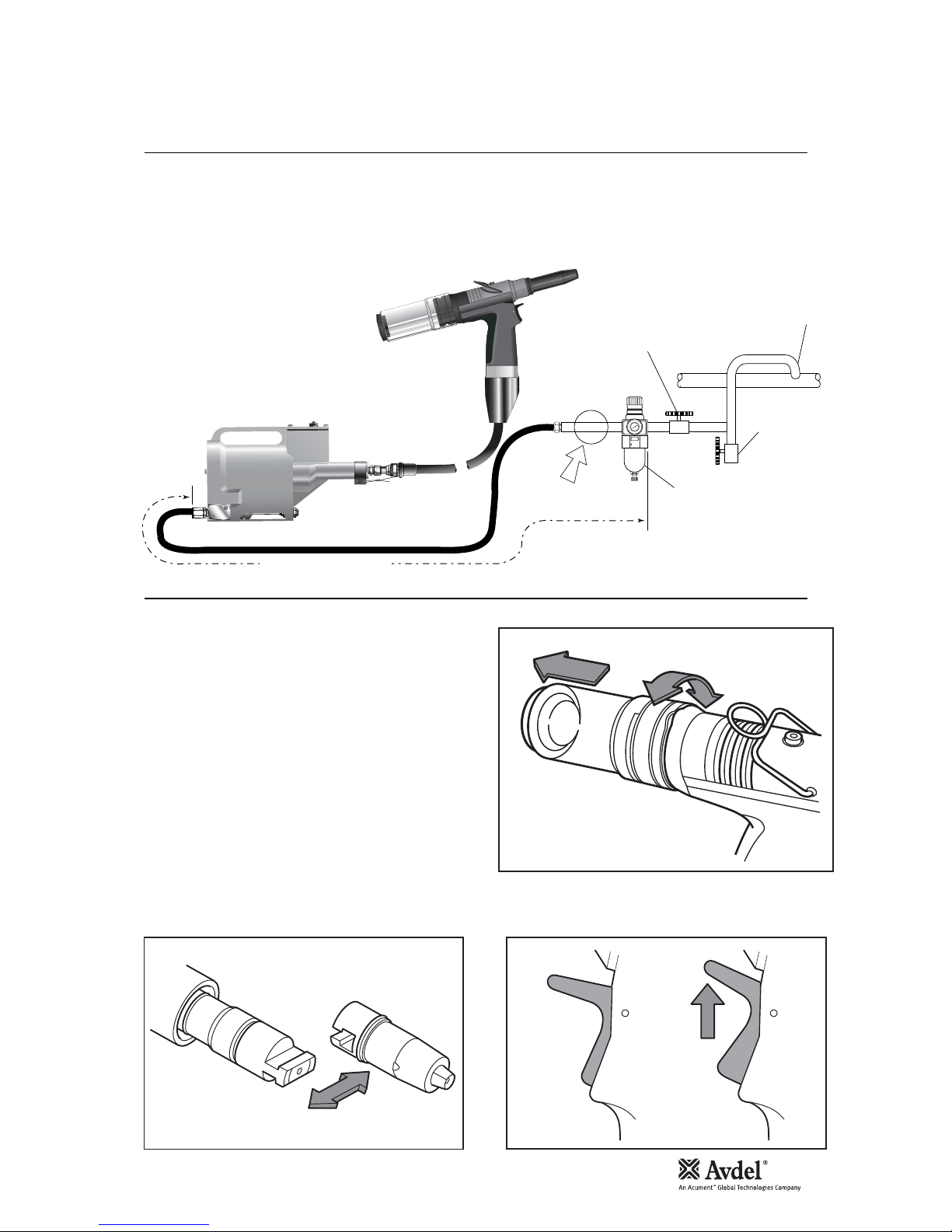

Air Supply

Putting into Service

7

All tools are operated with compressed air at an optimum pressure of 5.5 bar. We recommend the use of pressure regulators and filtering

systems on the main air supply. These should be fitted within 3 metres of the tool (see diagram below) to ensure maximum tool life and

minimum tool maintenance.

Air supply hoses should have a minimum effective working pressure rating of 150% of the maximum pressure produced in the system or

10 bar, whichever is the highest. Air hoses should be oil resistant, have an abrasion resistant exterior and should be armoured where

operating conditions may result in hoses being damaged. All air hoses MUST have a minimum bore diameter of 6.4 millimetres or

1

/4 inch

• Ensure that the correct nose assembly suitable for the fastener

is fitted.

• Connect the tool to the air supply.

• Insert the fastener stem into the nose of the tool. If using a

standard nose assembly, the fastener should remain held in by

the vacuum system.

• Bring the tool with the fastener to the application so that the

protruding fastener enters squarely into the hole of the

application.

• Fully actuate the Trigger. The tool cycle will broach the fastener

and with standard nose assemblies the broken stem will be

projected to the rear of the tool into the collector bottle.

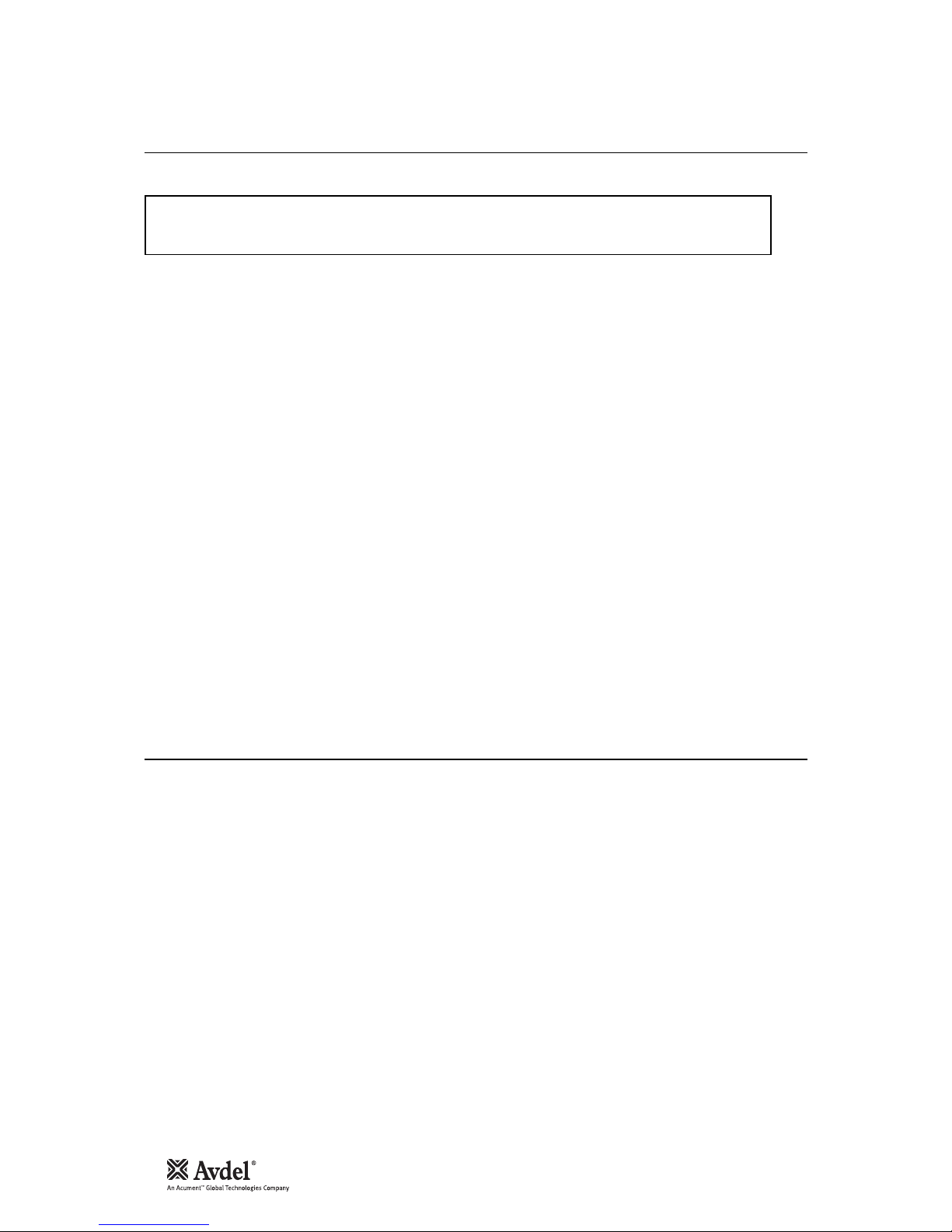

• A partial rotation and pull movement removes the collector

bottle. The Trigger should be lifted to cut-off the vacuum supply

air prior to removing the collector bottle.

• To minimise air consumption, the Trigger should be ‘lifted” to cut-off the vacuum air supply if the tool is not to be used for a period of

time.

Operating Procedure

8

6

4

2

0

1

0

1

2

14

1

6

TAKE OFF POINT

FROM MAIN SUPPLY

STOP COCK

(USED DURING MAINTENANCE

OF FILTER/REGULATOR

OR LUBRICATION UNITS)

MAIN SUPPLY

DRAIN POINT

PRESSURE REGULATOR

AND FILTER

(DRAIN DAILY)

3 METRES MAXIMUM

AIR LUBRICATION

PERMISSABLE

Lift Trigger to

cut-off the

vacuum air

supply.

Do not use tool when Stem

Collector Bottle is removed

8

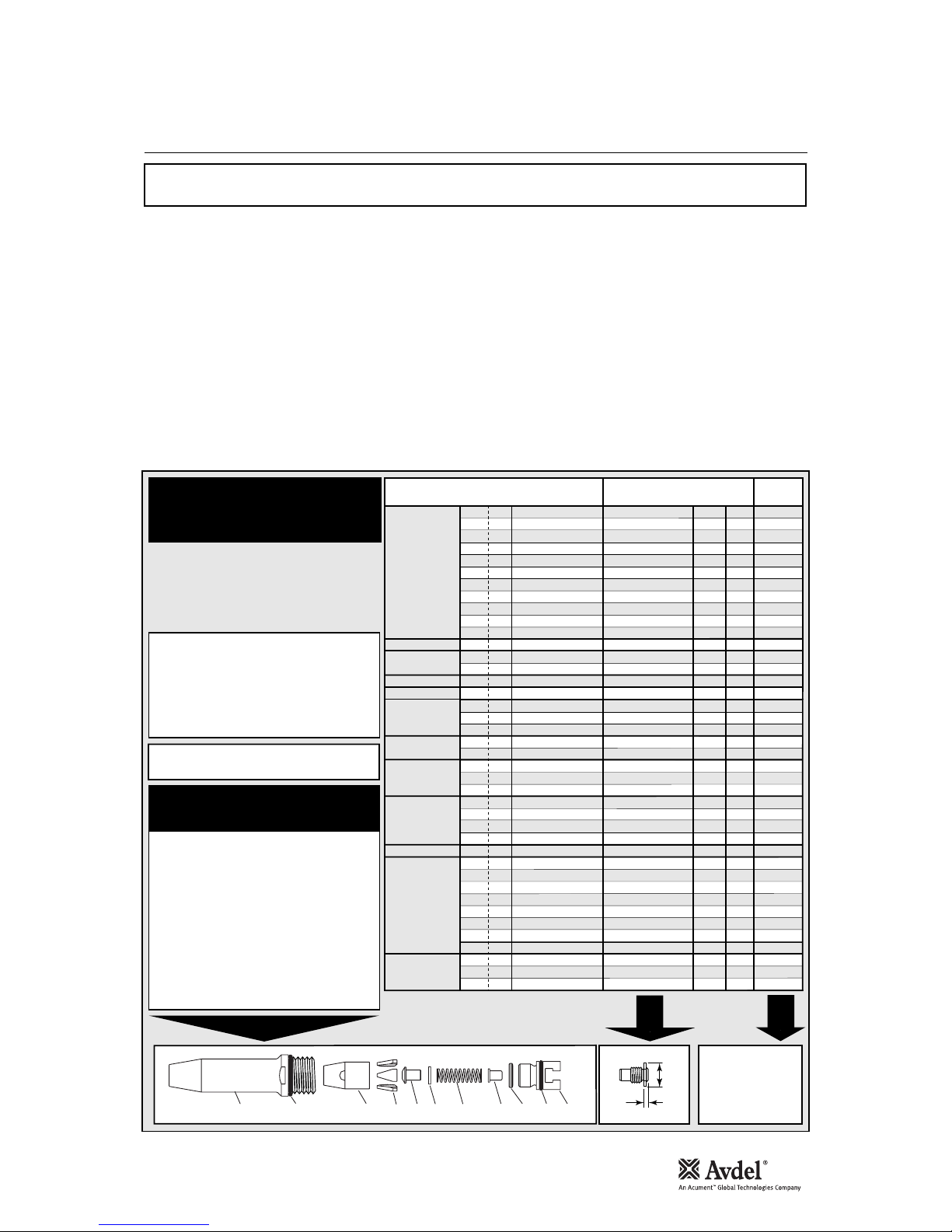

Fitting Instructions

IMPORTANT

The air supply must be disconnected when fitting or removing nose assemblies.

Item numbers in bold refer to nose assembly components in all 4 Nose Tip tables (pages 9, 10 and 12).

• Lightly coat Jaws 4 with MolyLithium grease*.

• Drop jaws 4 into Jaw Housing 3.

• Insert Jaw Spreader 5 into Jaw Housing 3.

• Locate Buffer 6 on Jaw Spreader 5.

• Locate Spring 7 onto Jaw Spreader 5.

• Insert Detent Sleeve 10 into Jaw Spreader Housing ‘T’ 9. Not applicable to Type 2 and 3 Nose Assemblies.

• Fit Locking Ring 8 onto the Jaw Spreader Housing ‘T’ 9.

• For tools converted to nose assemblies Type 2 and 3, fit Locking Ring 8 onto the Jaw Spreader Housing ‘T’ 9 attached to the

tool.

• Tighten Jaw Housing 3 and assembled components onto Jaw Spreader Housing ‘T’ 9.

• Utilising the ‘T’ section profiles assemble Nose Assembly onto the tool piston via the Male ‘T’ Adaptor (item 1 pages 26-27).

Not applicable to Type 2 and 3 Nose Assemblies.

• Screw the nose tip into Nose Casing 1 and tighten with spanner*.

• Place Nose Casing 1 over Jaw Housing 3 and screw onto the tool, tightening with spanner*.

Nose assemblies should be serviced at weekly intervals. You should hold some stock of all internal components of the nose assembly

and nose tips as they will need regular replacement.

Use Spanner 07900-00849 (supplied with tool) to assist when servicing the nose assembly.

• Remove the nose equipment using the reverse procedure to the ‘Fitting Instructions’.

• Any worn or damaged part should be replaced.

• Clean and check wear on jaws.

• Ensure that the jaw spreader is not distorted.

• Check Spring 7 is not distorted.

* Item included in the nG2s service kit. For complete list see page 20.

Item numbers in bold refer to the nose assembly components in all four Nose Tip tables on pages 9, 10 and 12.

Servicing Instructions

9

A tool (except part number 71401-00039) must always be fitted with the correct nose assembly and nose tip for your fastener and

must be ordered separately, refer to the ‘NOSE TIPS’ tables below and pages 10 and 12.

If your application presents no access restriction use a Type ‘1’ Nose Tip unless you are placing aerospace fasteners which requires a

Type ‘3’ Nose Tip.

Dimensions ‘A’ and ‘B’ below will help you assess the suitability of a particular nose tip.

You should also check that the dimensions of the nose casing will not restrict access to your application. If access is restricted Type

‘2’ Nose Tips are available for some fasteners. Refer to the table on page 12.

It is essential that nose assembly and nose tip are compatible with the fastener prior to operating the tool. If you have ordered a

71401-00039 complete tool, it is important that you check that the nose tip already fitted to the nose assembly is the correct one to

place your fastener by sliding the fastener stem into the nose tip. No force should be required and play should be minimal.

Swivel heads are available as an alternative to nose assemblies when further reach is required. See pages 14 to 16 in the

‘Accessories’ section.

IMPORTANT

Nose assemblies do NOT include nose tips. Nose tips must be ordered separately.

Nose Tips

1

In inches then in millimetres.

2

Head forming nose tips for use with countersunk heads

ONLY.

3

Long nose tip for deep placing.

4

Dome head.

5

Countersunk.

TYPE 1

NOSE TIPS

NOSE ASSEMBLY

part nº 71213-15000

(+ 3 nose tips above = 71213-15100)

FASTENER

MATERIAL

Ø

1

NOSE TIP (mm)

see

below

PART Nº 'A' 'B'NAME

Al Alloy

Steel

Al Alloy

Al Alloy

Al Alloy

Steel

Al Alloy

Al Alloy

Al Alloy

Steel

Al Alloy

Any

Al Alloy

Al Alloy

Al Alloy

Al Alloy

Stainless Steel

Stainless Steel

Stainless Steel

Steel

Steel

Steel

Steel

Steel

Any

Any

Any

Any

Any

Steel

Steel

Steel

Steel

Steel

Stainless Steel

Stainless Steel

Stainless Steel

Any

Any

Any

1

/

8

1

/

8

1

/

8

–

5

/

32

5

/

32

5

/

32

3

/

16

3

/

16

3

/

16

3

/

16

3

/

16

5

/

32

3

/

16

3

/

16

3

/

16

1

/

8

5

/

32

3

/

16

–

3

/

16

1

/

8

5

/

32

3

/

16

1

/

8

5

/

32

3

/

16

3

/

16

3

/

16

1

/

8

5

/

32

3

/

16

3

/

16

3

/

16

1

/

8

5

/

32

3

/

16

1

/

8

5

/

32

3

/

16

4.8

3.3

2.9

4.8

3.3

2.8

3.3

2.8

3.3

3.3

4.1

4.1

3.3

2.8

4.5

2.8

3.3

2.8

4.8

3.3

3.3

3.3

2.8

4.8

4.8

3.3

5.7

5.7

2.8

3.3

2.8

2.8

3.3

2.8

3.3

2.8

2.8

4.8

3.3

3.3

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

19.0

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

19.0

12.7

12.7

12.7

12.7

12.7

12.7

12.7

71210-05002

71210-16070

07340-06401

2

71210-05002

71210-16070

07381-04701

07340-06501

2

07381-04701

07340-04800

07490-04401

07340-06601

2

71210-16020

71210-16070

07381-04701

71220-16060

07381-04701

71210-16070

07381-04701

07498-01401

07340-06201

07340-06201

71210-16070

07381-04701

07498-01401

71210-05002

71210-16070

07348-07001

4

71210-16050

5

07381-04701

71210-16070

07381-04701

07381-04701

07340-04800

07381-04701

71210-16070

07381-04701

07381-04701

71210-05002

07340-06201

07340-06201

3.2

3.2

3.2

3.0

4.0

4.0

4.0

4.8

4.8

4.8

4.8

4.8

4.0

4.8

4.8

4.8

3.2

4.0

4.8

4.3

4.8

3.2

4.0

4.8

3.2

4.0

4.8

1.8

4.8

3.2

4.0

4.8

4.8

4.8

3.2

4.0

4.8

3.2

4.0

4.8

AVEX

®

Large flange

MONOBOLT

®

BULBEX

®

KLAMPTITE™KTR

KLAMPTITE

™

AVINOX® II

T-LOK

®

AVIBULB

®

AVDEL® SR

INTERLOCK

®

STAVEX

®

Large flange

Countersunk

Q-RIVET

™

…039*

…039*

…003

…039*

…039*

…039*

…009

…039*

…016

…017

…015

…200

…039*

…039*

…141

…039*

…039*

…039*

…082

…120

…120

…039*

…039*

…082

…039*

…039*

…062

…064

…039*

…039*

…039*

…039*

…016

…039*

…039*

…039*

…039*

…039*

…120

…120

A

B

ITEM DESCRIPTION PART Nº

1 TAPERED NOSE CASING 71213-00350

2 'O' RING 07003-00067

3 JAW HOUSING - TAPERED 71210-15902 *

4 JAW 71210-15001 *

5 JAW SPREADER 07498-04502 *

6 BUFFER 71210-05001 *

7 SPRING 07500-00418 *

8 LOCKING RING 07340-00327 *

9 JAW SPREADER HOUSING 'T' 71210-20321 *

10 DETENT SLEEVE 71210-20322 *

11 'O' RING 07003-00277 *

*

Complete tool part number 71401-00039 does

not only include the 71213-15000 nose assembly

below but also the following three nose tips:

71210-05002, 71210-16070 and 07381-04701

making up a nose assembly kit part number 71401-

15100.

Use the nose tip listed in the table.

COMPLETE TOOL

PART NUMBER :

precede with 71401-00.

1

2

3

4

5

6

7

10

11

98

*

Items 3-11 available as cartridge assembly

71213-20320

Nose Tips

10

AVSEAL®II

NOSE TIPS

FASTENER

MATERIAL

Ø

1

NOSE TIP (mm)

see

below

PART Nº 'A' 'B'

NAME

Standard Al. Alloy - Flush Nose Tip

Standard Al. Alloy - 2mm Extended Nose Tip

Standard Al. Alloy - 8mm Extended Nose Tip

Standard Al. Alloy - Flush Nose Tip

Standard Al. Alloy - 2mm Extended Nose Tip

Standard Al. Alloy - 8mm Extended Nose Tip

Standard Al. Alloy - Flush Nose Tip

Standard Al. Alloy - 2mm Extended Nose Tip

Standard Al. Alloy - 8mm Extended Nose Tip

Standard Al. Alloy - Flush Nose Tip

Standard Al. Alloy - 2mm Extended Nose Tip

Standard Al. Alloy - 8mm Extended Nose Tip

Standard Al. Alloy - Flush Nose Tip

Standard Al. Alloy - 2mm Extended Nose Tip

Standard Al. Alloy - 8mm Extended Nose Tip

5

/

32

5

/

32

5

/

32

–

–

–

–

–

–

–

–

–

–

–

–

2.5

5.4

11.4

2.5

5.4

11.4

2.5

5.4

11.4

2.5

5.4

11.4

2.5

5.4

11.4

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

71210-16102

71210-16106

71210-16110

71210-16103

71210-16107

71210-16111

71210-16104

71210-16108

71210-16112

71210-16114

71210-16115

71210-16116

71210-16105

71210-16109

71210-16113

71213-16100

71213-16100

71213-16100

71213-16100

71213-16100

71213-16100

71213-16100

71213-16100

71213-16100

71213-16100

71213-16100

71213-16100

71213-16100

71213-16100

71213-16100

4.0

4.0

4.0

5.0

5.0

5.0

6.0

6.0

6.0

6.5

6.5

6.5

7.0

7.0

7.0

AVSEAL®II

… 401

… 402

… 403

… 404

… 405

… 406

… 407

… 408

… 409

… 413

… 414

… 415

… 410

… 411

… 412

A

B

COMPLETE TOOL

PART NUMBER :

precede with 71401-00.

NOSE ASSEMBLY

part nº 71213-16100

ITEM DESCRIPTION PART Nº

1 TAPERED NOSE CASING 71213-00350

2 'O' RING 07003-00067

3 JAW HOUSING - TAPERED 71210-15902 *

4 JAW 71210-16101 *

5 JAW SPREADER 07498-04502 *

6 BUFFER 71210-05001 *

7 SPRING 07500-00418 *

8 LOCKING RING 07340-00327 *

9 JAW SPREADER HOUSING 'T' 71210-20321 *

10 DETENT SLEEVE 71210-20322 *

11 'O' RING 07003-00277 *

*

Items 3-11 available as cartridge

assembly 71213-16320

1

2

3

4

5

6

7

10

11

98

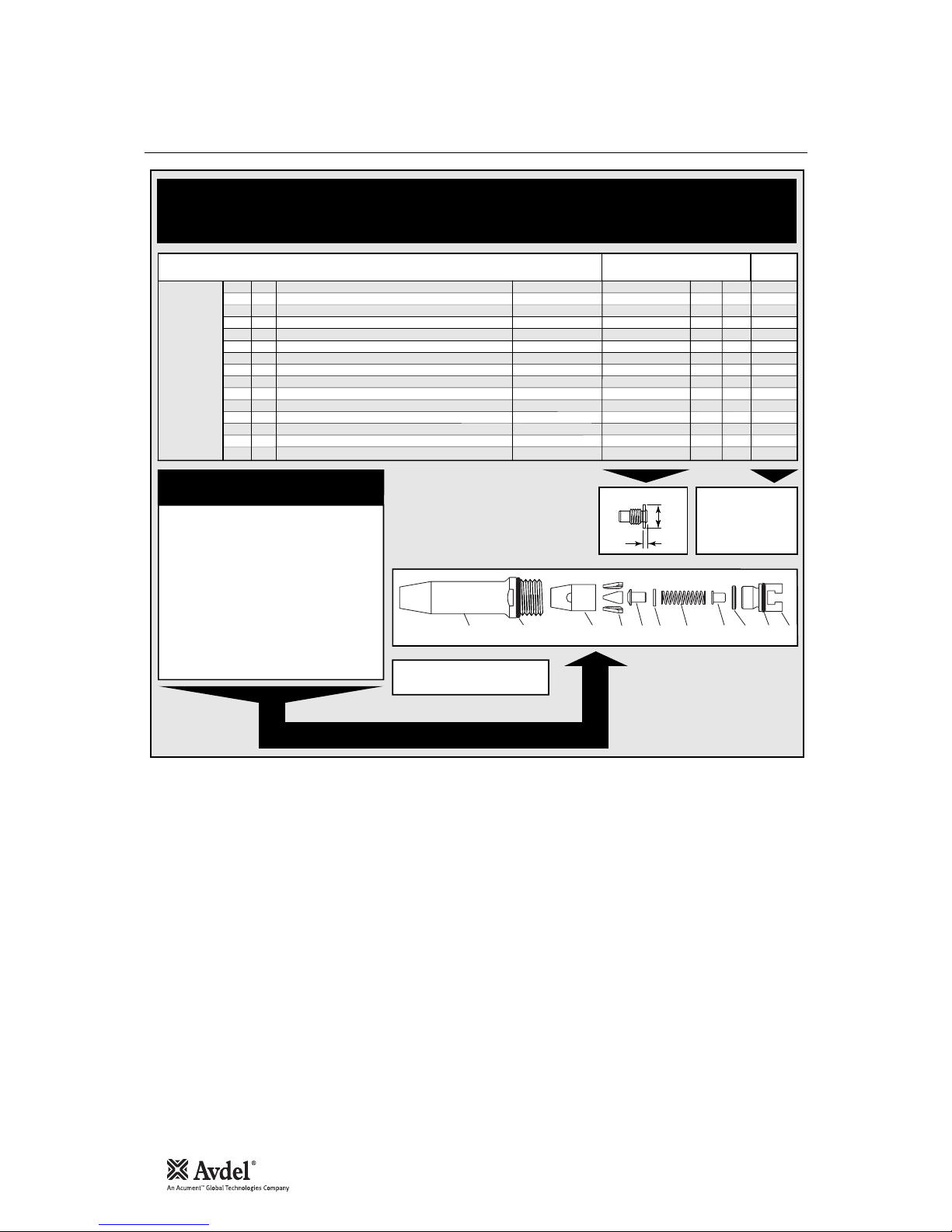

Fitting Types 2/3 or Nose Extension

11

To fit Nose Tips Type 2/3 or Nose Extension, the ‘T’ Adaptor 1 must be replaced with Jaw Spreader Housing 9*.

• Loosen Locknut 3 using 16mm AF Spanner.

• Unscrew and remove ‘T’ Adaptor 1 together with ‘O’ Ring 2.

1

2

27

43

3

• Fit Jaw Spreader Housing 9* together with ‘O’ Ring 10* (supplied with Type 2 and 3 Nose Assemblies)

• The Jaw Spreader Housing 9* must be tightened onto Head Piston 27 trapping Vacuum Sleeve 43 finally tighten

Locknut 3 against Jaw Spreader Housing 9*.

9*

10*

27

43

Items 9* and 10* refer to nose assembly components in Nose tip tables on page 12.

For other items in bold refer to the general assembly drawing and parts list on pages 26 and 27.

Loading...

Loading...