Hydro-Pneumatic Power Tool

Druckluftgerät

Outil oléo-pneumatique

Attrezzo oleopneumatico

Genesis

®

Instruction Manual

Manuel d’instructions

Betriebsanleitung

Manuale d’istruzione

4

G4

3

Safety Instructions 4

Specifications

Tool Specification 5

Tool Dimensions 5

Intent of Use

Range of Fasteners 6

Part Numbering 6

Putting into Service

Air Supply 7

Operating Procedure - All fasteners except

Avtainer® and Maxlok

®

7

Operating Procedure - Avtainer® and Maxlok

®

8

Nose Assemblies

Nose Tip Selection 9

Fitting Instructions - All Nose Assemblies except

Avtainer® and Maxlok

®

9

Nose Tips 10 - 13

Type 1 Standard 10

Avseal® II Nose Tip 11

Type 2 Limited Access 12

Type 3 Aerospace 12

Type 6 Hemlok®/Interlock

®

12

Type 5 Avtainer

®

13

Maxlok

®

13

Fitting Instructions for Avtainer® and Maxlok

®

Nose Assemblies 14

Servicing Instructions for all Nose Assemblies 14

Accessories

Stem Deflector 15

Preparing the Base Tool for use with Stem Deflector 15

Extension 15

Servicing the Tool

Daily / Weekly 16

Moly Lithium Grease EP 3753 Safety Data 16

Molykote

®

55m Grease Safety Data 17

Molykote

®

111 Grease Safety Data 17

Service Kit 18

Maintenance 18

Nose Equipment 18

Dismantling the Tool 19

Head Assembly 19

Pneumatic Piston Assembly 20

Air Valve 20

Rotary Valve 21

Trigger 21

Stop Plate Assembly (71213-03900) 22

General Assembly of Base Tool

General Assembly 24

Parts List 25

Priming

Oil Details 26

Hyspin®VG 32 Oil Safety Data 26

Priming Kit 26

Priming Procedure 27

Fault Diagnosis

Symptom, Possible Cause and Remedy 28

Français 33

Deutsch 63

Italiano 93

Avdel UK Limited policy is one of continuous product development and improvement and we reserve the right to change the specification of any product without prior notice.

LIMITED WARRANTY

Avdel makes the limited warranty that its products will be free of defects in workmanship and

materials which occur under normal operating conditions. This Limited Warranty is contingent

upon: (1) the product being installed, maintained and operated in accordance with product

literature and instructions, and (2) confirmation by Avdel of such defect, upon inspection and

testing. Avdel makes the foregoing limited warranty for a period of twelve (12) months following

Avdel’s delivery of the product to the direct purchaser from Avdel. In the event of any breach of

the foregoing warranty, the sole remedy shall be to return the defective Goods for replacement

or refund for the purchase price at Avdel’s option. THE FOREGOING EXPRESS LIMITED

WARRANTY AND REMEDY ARE EXCLUSIVE AND ARE IN LIEU OF ALL OTHER WARRANTIES AND

REMEDIES. ANY IMPLIED WARRANTY AS TO QUALITY, FITNESS FOR PURPOSE, OR

MERCHANTABILITY ARE HEREBY SPECIFICALLY DISCLAIMED AND EXCLUDED BY AVDEL.

Contents

4

Safety Instructions

1 Do not use outside the design intent.

2 Do not use equipment with this tool/machine other than that recommended and supplied by Avdel UK Limited.

3 Any modification undertaken by the customer to the tool/machine, nose assemblies, accessories or any equipment supplied by Avdel UK

Limited or their representatives, shall be the customer’s entire responsibility. Avdel UK Limited will be pleased to advise upon any

proposed modification.

4 The tool/machine must be maintained in a safe working condition at all times and examined at regular intervals for damage and function

by trained competent personnel. Any dismantling procedure shall be undertaken only by personnel trained in Avdel UK Limited procedures.

Do not dismantle this tool/machine without prior reference to the maintenance instructions. Please contact Avdel UK Limited with your

training requirements.

5 The tool/machine shall at all times be operated in accordance with relevant Health and Safety legislation. In the U.K. the “Health and

Safety at Work etc. Act 1974” applies. Any question regarding the correct operation of the tool/machine and operator safety should be

directed to Avdel UK Limited.

6 The precautions to be observed when using this tool/machine must be explained by the customer to all operators.

7 Always disconnect the airline from the tool/machine inlet before attempting to adjust, fit or remove a nose assembly.

8 Do not operate a tool/machine that is directed towards any person(s) or the operator.

9 Always adopt a firm footing or a stable position before operating the tool/machine.

10 Ensure that vent holes do not become blocked or covered.

11 The operating pressure shall not exceed 7 bar.

12 Do not operate the tool if it is not fitted with a complete nose assembly or swivel head unless specifically instructed otherwise.

13 Care shall be taken to ensure that spent stems are not allowed to create a hazard.

14 Vacuum Air MUST be turned off using the Trigger before removing the Stem Collector Bottle which MUST be emptied when half full.

15 The Tool MUST NOT be operated with the Stem Collector Bottle removed.

16 If the nG4 tool is fitted with a stem deflector, it should be rotated until the aperture is facing away from the operator and other person(s)

working in the vicinity.

17 When using the tool, the wearing of safety glasses is required both by the operator and others in the vicinity to protect against fastener

ejection, should a fastener be placed ‘in air’. We recommend wearing gloves if there are sharp edges or corners on the application.

18 Take care to avoid entanglement of loose clothes, ties, long hair, cleaning rags etc. in the moving parts of the tool which should be kept

dry and clean for best possible grip.

19 When carrying the tool from place to place keep hands away from the trigger/lever to avoid inadvertent start up.

20 Excessive contact with hydraulic fluid oil should be avoided. To minimize the possibility of rashes, care should be taken to wash

thoroughly.

21 C.O.S.H.H. data for all hydraulic oils and lubricants is available on request from your tool supplier.

This instruction manual must be read with particular attention to the following safety rules, by any person

installing, operating, or servicing this tool.

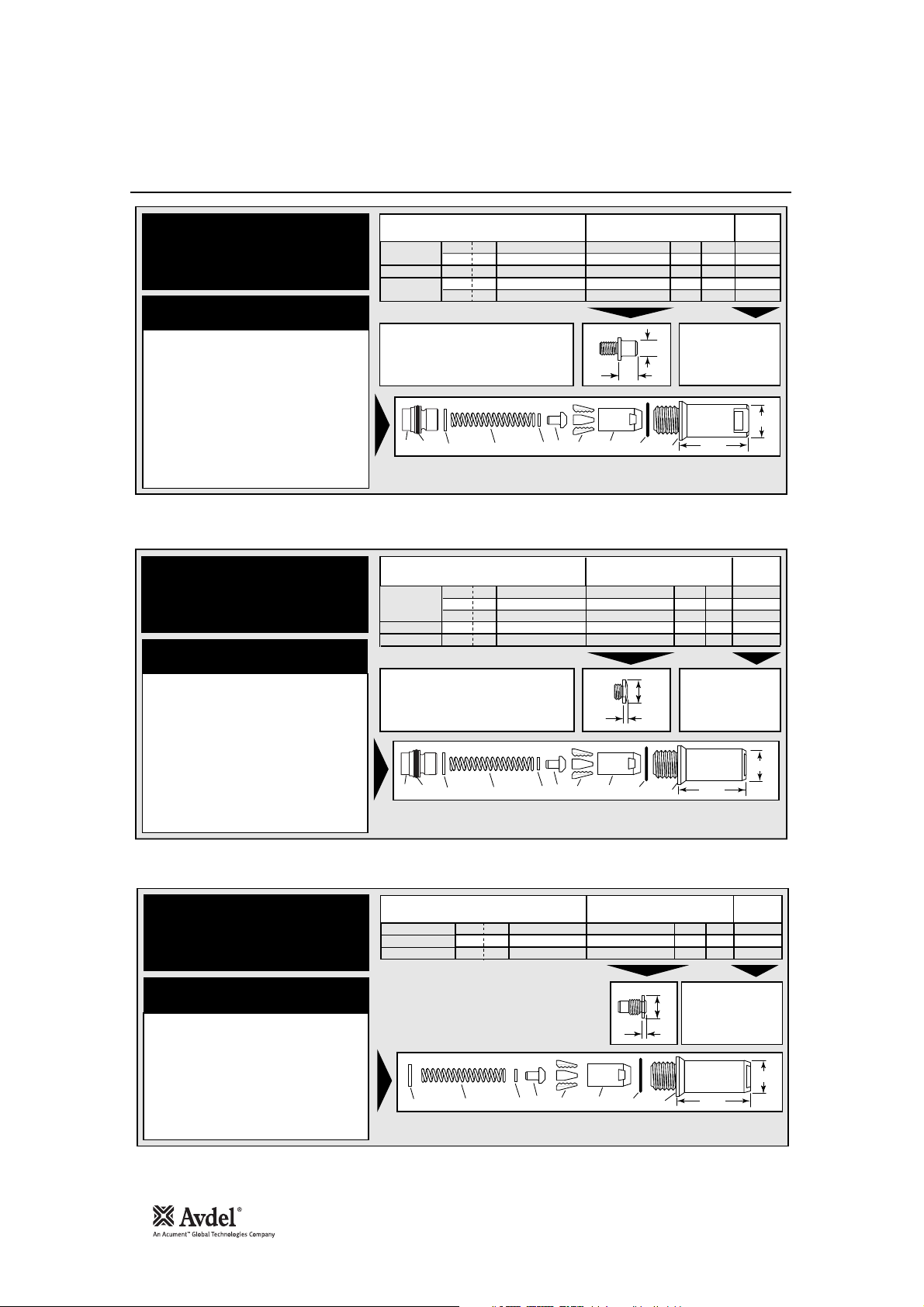

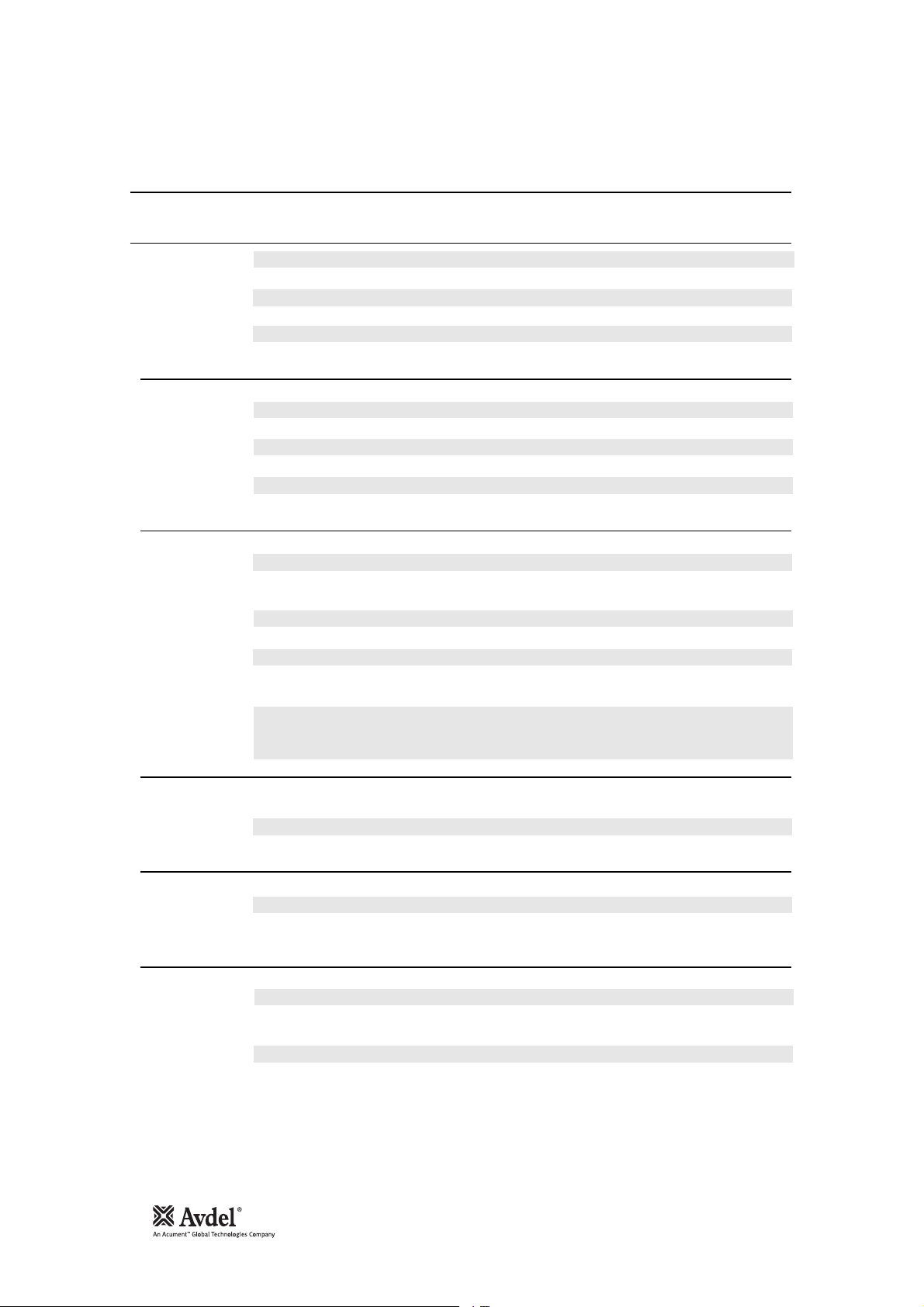

Tool Specification

Specifications

5

Air Pressure Minimum - Maximum 5-7 bar

Free Air Volume Required @ 5.5 bar 4.3 litres (0.15 cu ft)

Stroke Minimum 17 mm

Pull Force @ 5.5 bar 18.68 kN (4200 lbf)

Cycle Time Approximately 1.2 seconds

Noise Level 75 dB(A)

Weight Including nose equipment 2.3 kg

Vibration Less than 2.5 m/s

2

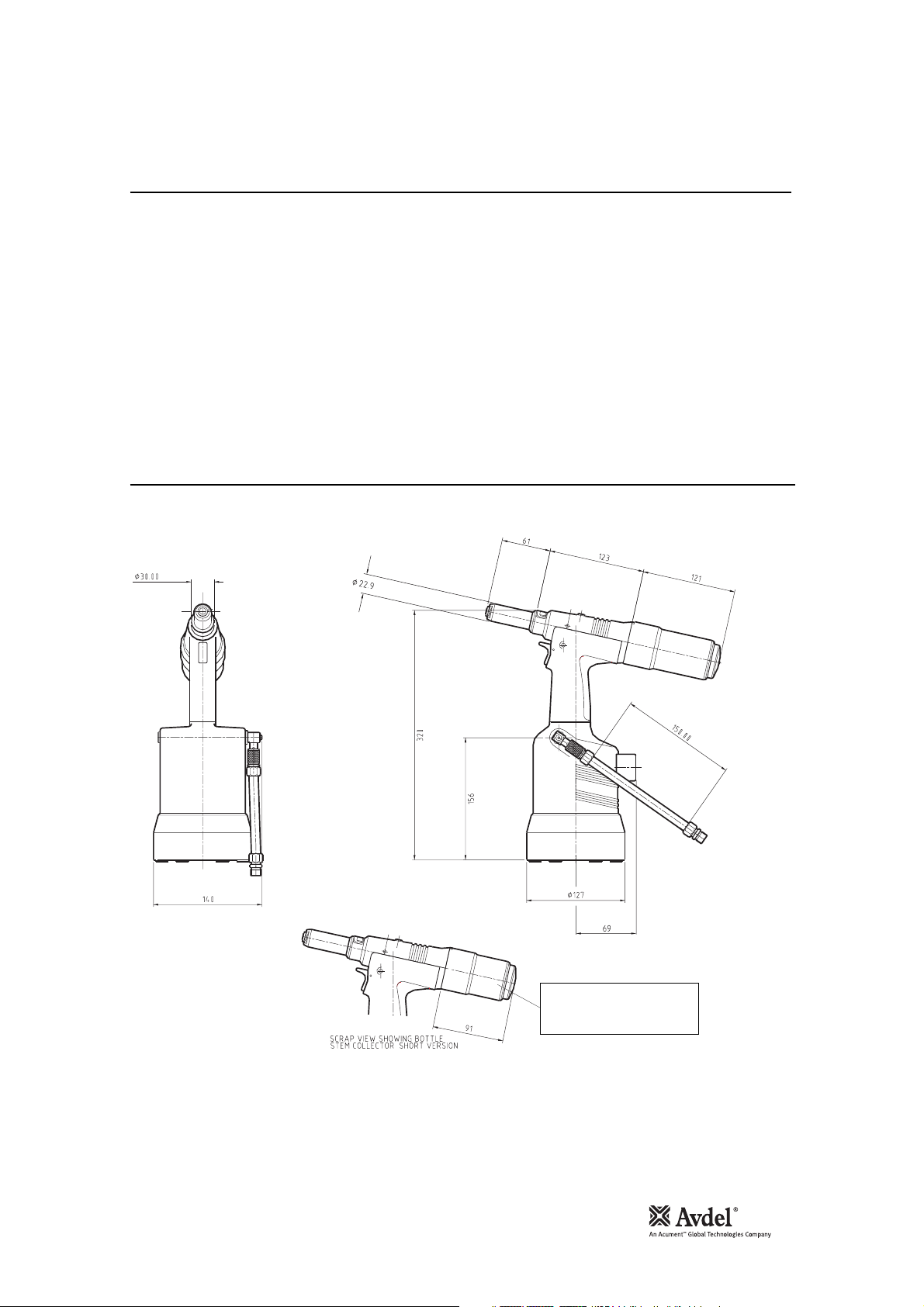

Dimensions in millimetres

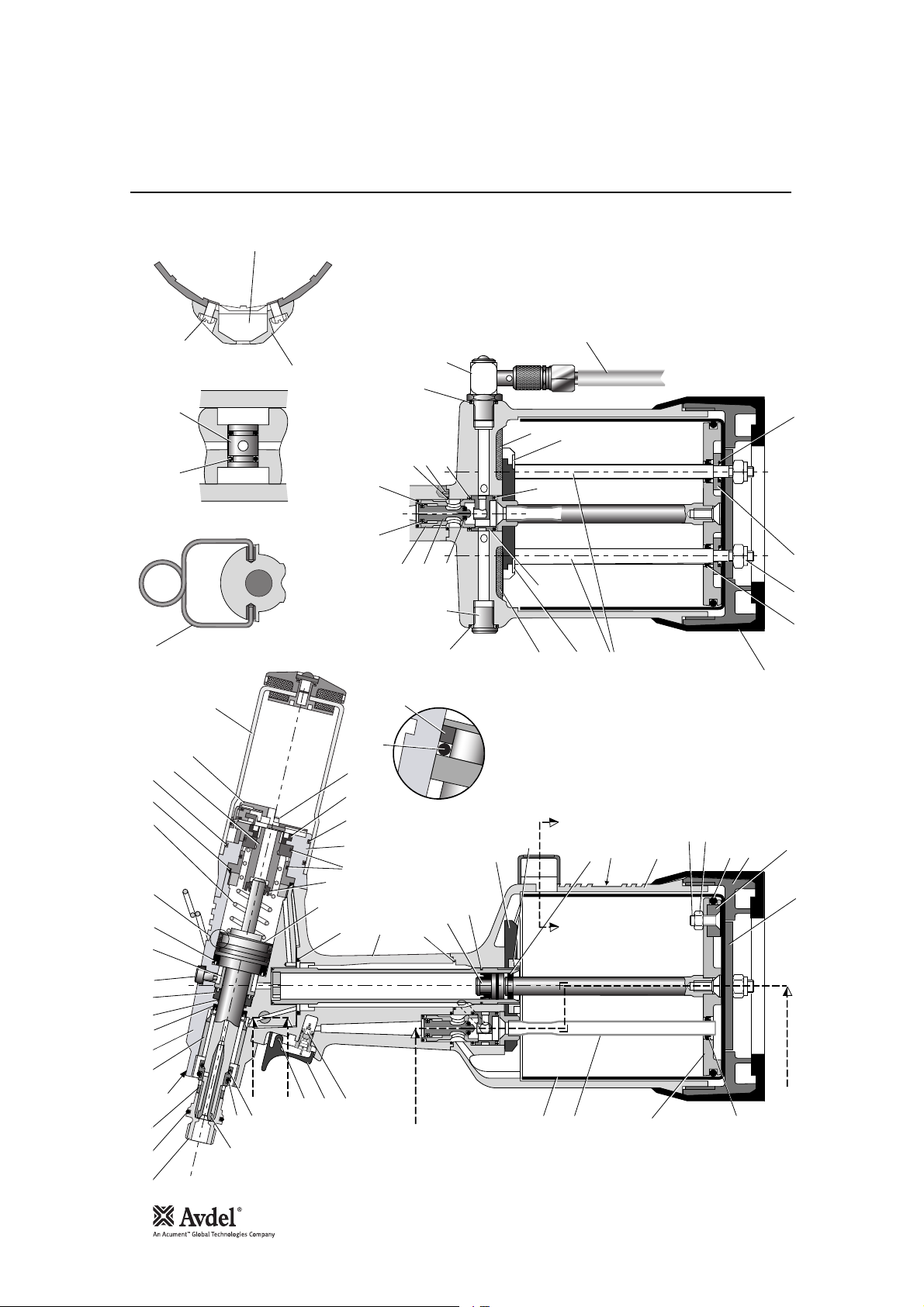

Tool Dimensions

Note: Stem Collector Short

Version Bottle is an accessory

part number 71213-03810.

English

6

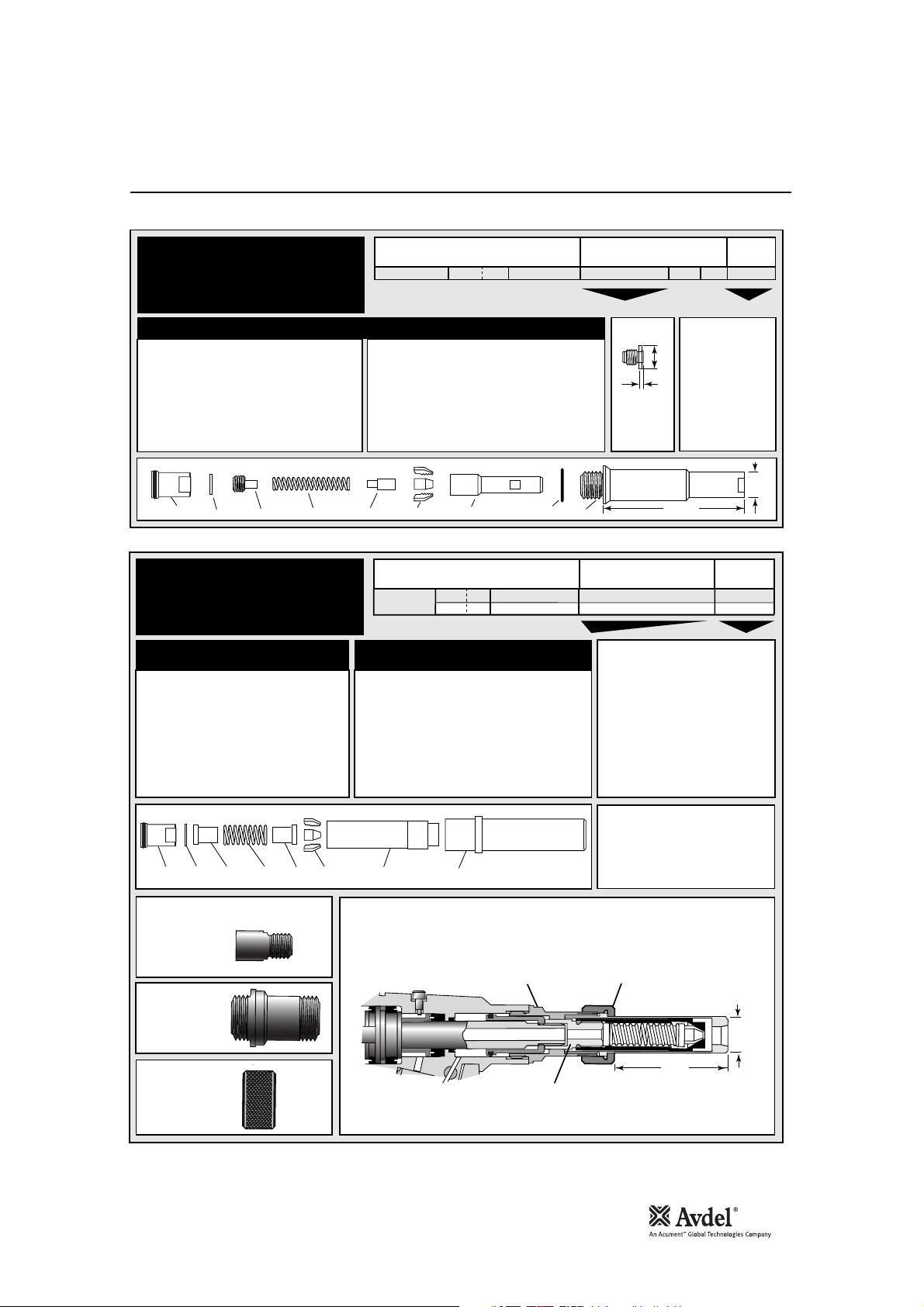

Intent of Use

nG4 is a hydro-pneumatic tool designed to place

Avdel

®

breakstem fasteners at high speed making it

ideal for batch or flow-line assembly in a wide

variety of applications throughout all industries. It

can place all fasteners listed opposite.

The tool features a vacuum system for fastener

retention and trouble free collection of the spent

stems regardless of tool orientation.

A complete tool is made up of three separate

elements which will be supplied individually.

See diagram below.

NOSE EQUIPMENT MUST BE FITTED AS

DESCRIBED ON PAGE 9.

.

The part number of the base tool remains the same whichever nose assembly, or nose tip is fitted. See the General Assembly

pages 24 and 25.

The nose tip part number relates to a specific fastener. If access to the application is

restricted, some extended nose tips are available. See table page 12.

This single nose assembly will allow placing of non-aerospace fasteners by simply selecting the appropriate

nose tip from the range of Type 1 Nose Tips. Other nose assemblies are available for applications with

restricted access, for aerospace and special fasteners see table page 12.

* ADD 3 DIGITS FROM THE

LAST COLUMN OF A NOSE

TIP TABLE ON PAGE 10, 11 or

12.

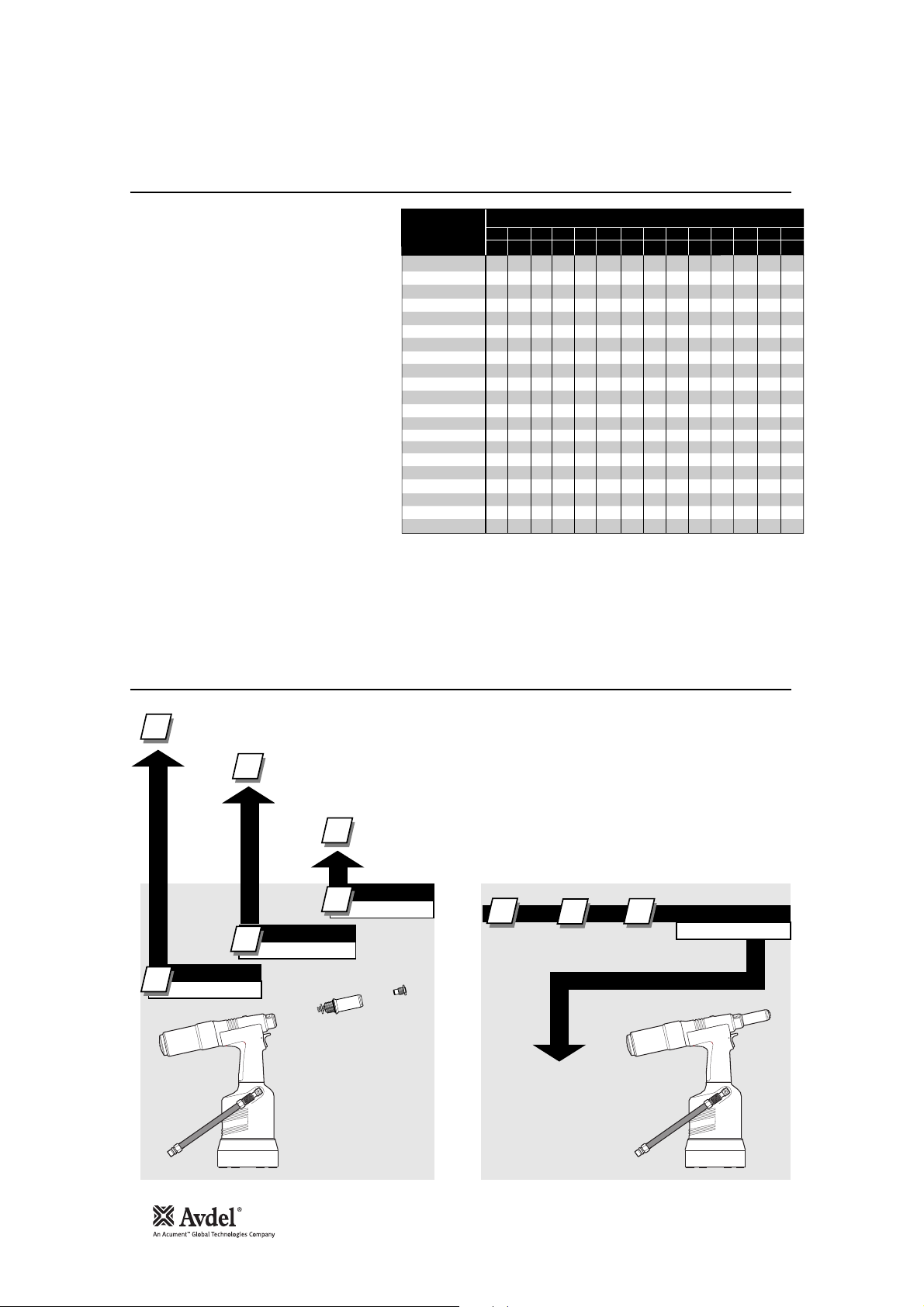

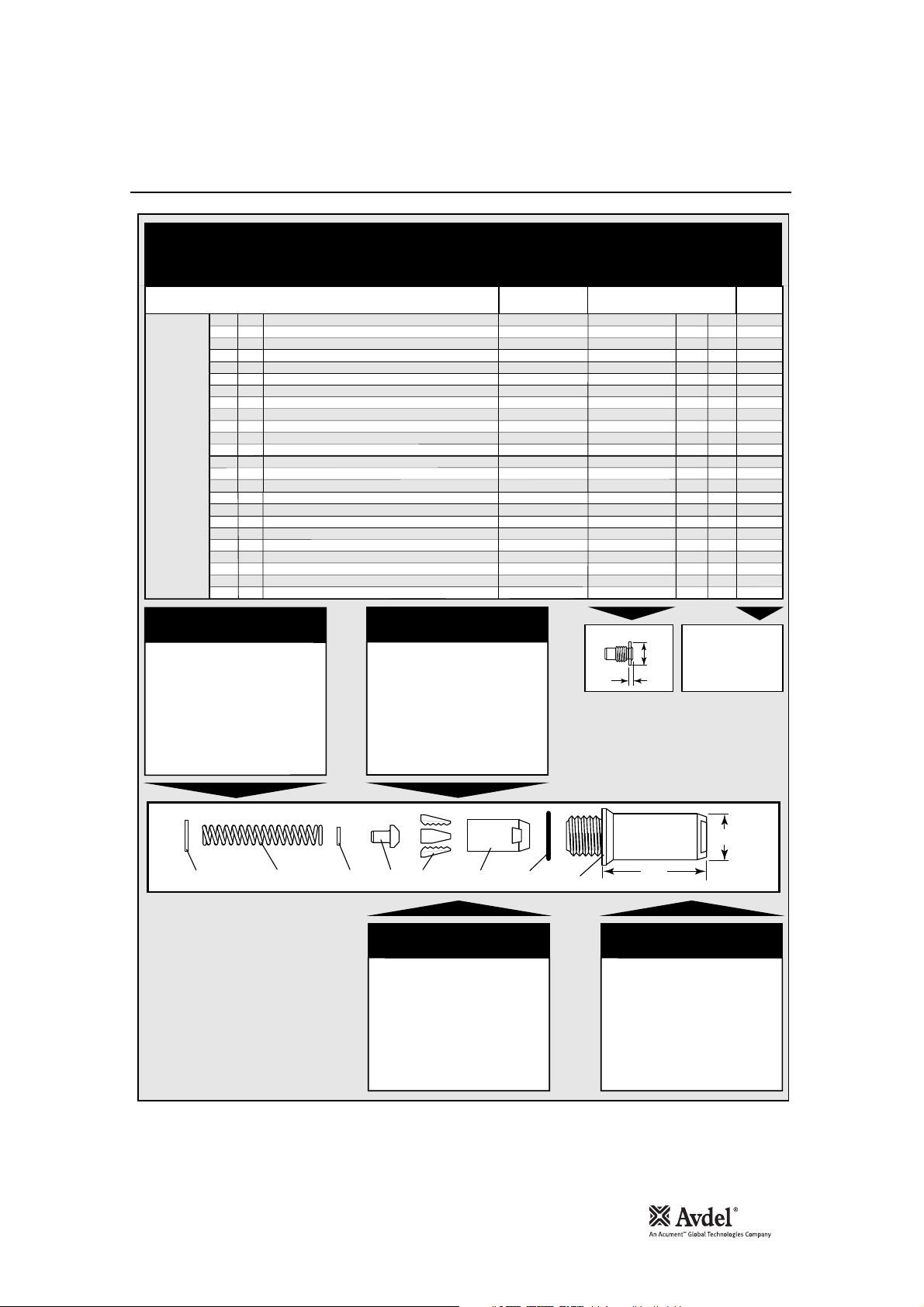

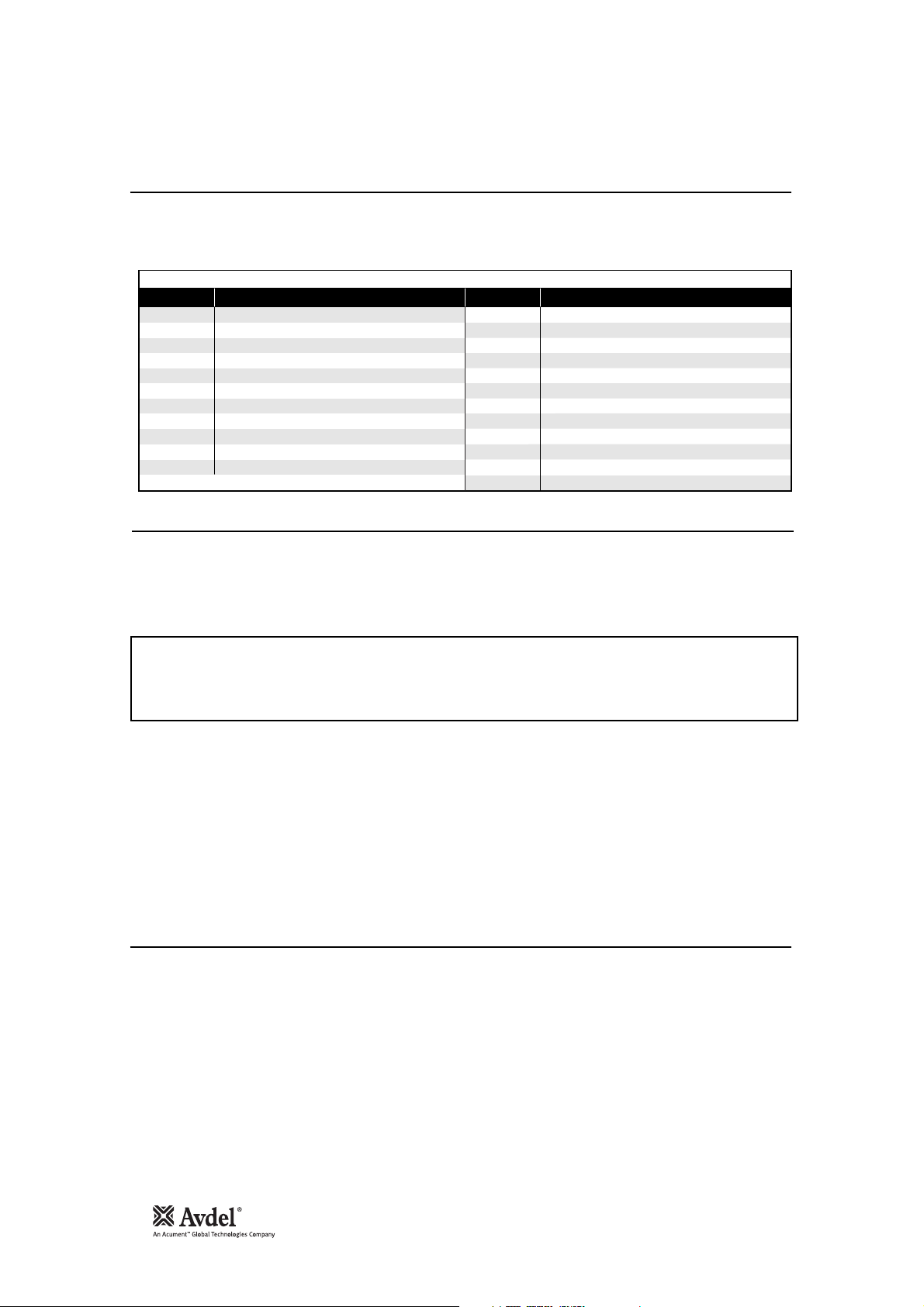

Range of Fasteners

Part Numbering

* For

3

/16and 1/4Lockbolt equipment refer to separate Data Sheet 07900-00795.

FASTENER

NAME

AVEX

STAVEX

AVINOX II

AVIBULB

BULBEX

T-LOK

AVDEL® SR

INTERLOCK

HEMLOK

MAXLOK

AVTAINER

AVDEL

MBC

MBC®/LC

AVSEAL

QTM RIVET

TTM RIVET

CHERRYMATE

KLAMPTITE

KLAMPTITETMKTR

LOCKBOLT

*

4.3 4.8 5 5.2 6 6.4 6.5 7 8 9 9.5 10 11 12

3

–

®

®

®

®

®

. .

®

®

®

®

®

®

®

®

II

TM

TM

FASTENER SIZE ( )

/16 – – – 1/4 – – – – 3/8 – – –

. .

. .

.

. .

.

. .

. .

.

. .

.

.

.

. .

. .

. .

. .

. .

. .

MM

IN

. . . . . .

.

1

2

2

BASE TOOL

1

71233-02000

3

3

NOSE ASSEMBLY

NOSE TIP

see note 3

1

2

++=

3

COMPLETE TOOL

71233-00 . . .

*

71210-15000

7

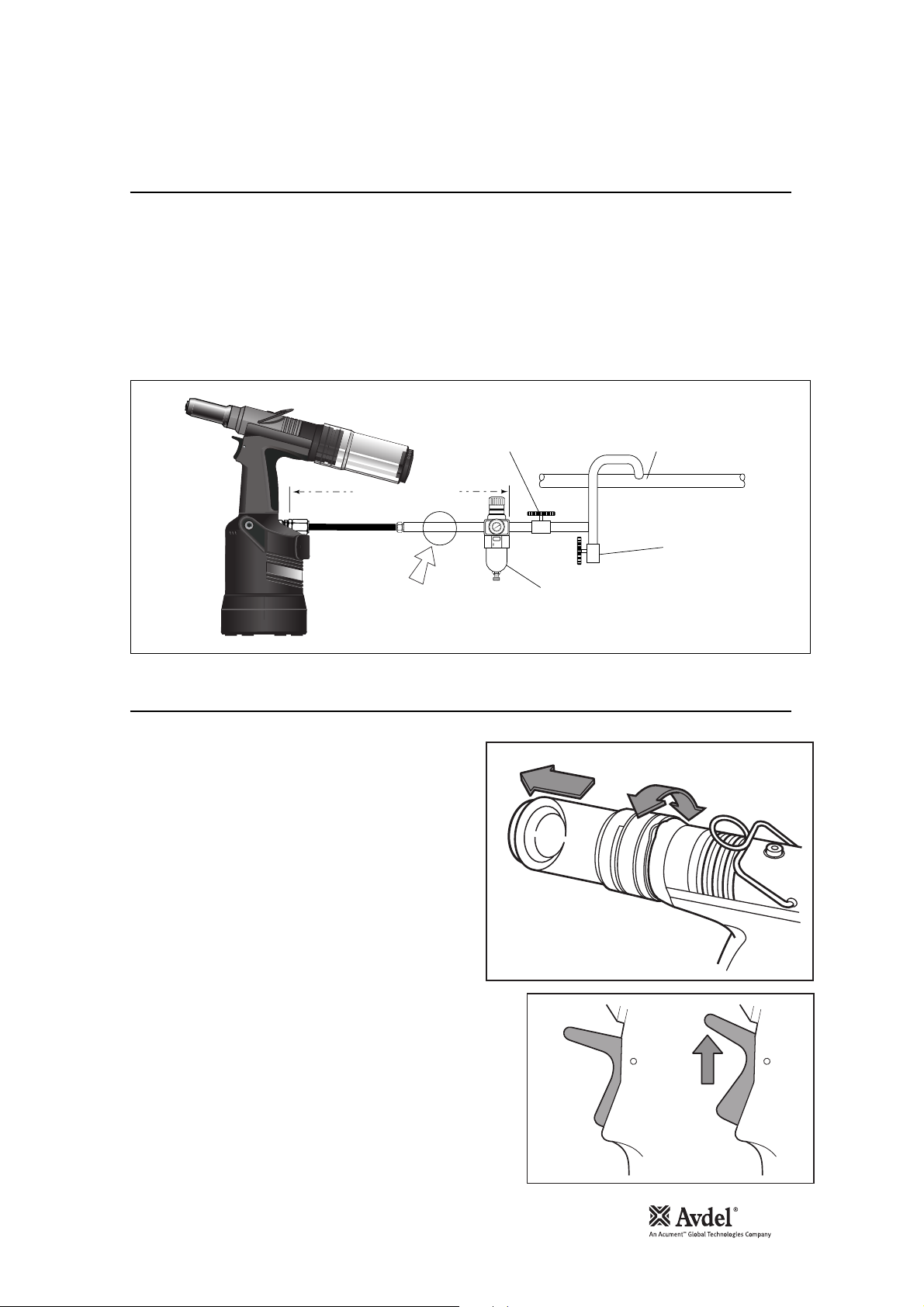

All tools are operated with compressed air at an optimum pressure of 5.5 bar. We recommend the use of pressure regulators and filtering

systems on the main air supply. These should be fitted within 3 metres of the tool (see diagram below) to ensure maximum tool life and

minimum tool maintenance.

Air supply hoses should have a minimum effective working pressure rating of 150% of the maximum pressure produced in the system or

10 bar, whichever is the highest. Air hoses should be oil resistant, have an abrasion resistant exterior and should be armoured where

operating conditions may result in hoses being damaged. All air hoses MUST have a minimum bore diameter of 6.4 millimetres or

1

/4 inch.

• Ensure that the correct nose assembly suitable for the fastener is

fitted.

• Connect the tool to the air supply.

• Insert the fastener stem into the nose of the tool. If using a

standard nose assembly, the fastener should remain held in by the

vacuum system.

• Bring the tool with the fastener to the application so that the

protruding fastener enters squarely into the hole of the

application.

• Fully actuate the trigger. The tool cycle will broach the fastener

and with standard nose assemblies the broken stem will be

projected to the rear of the tool into the collector bottle.

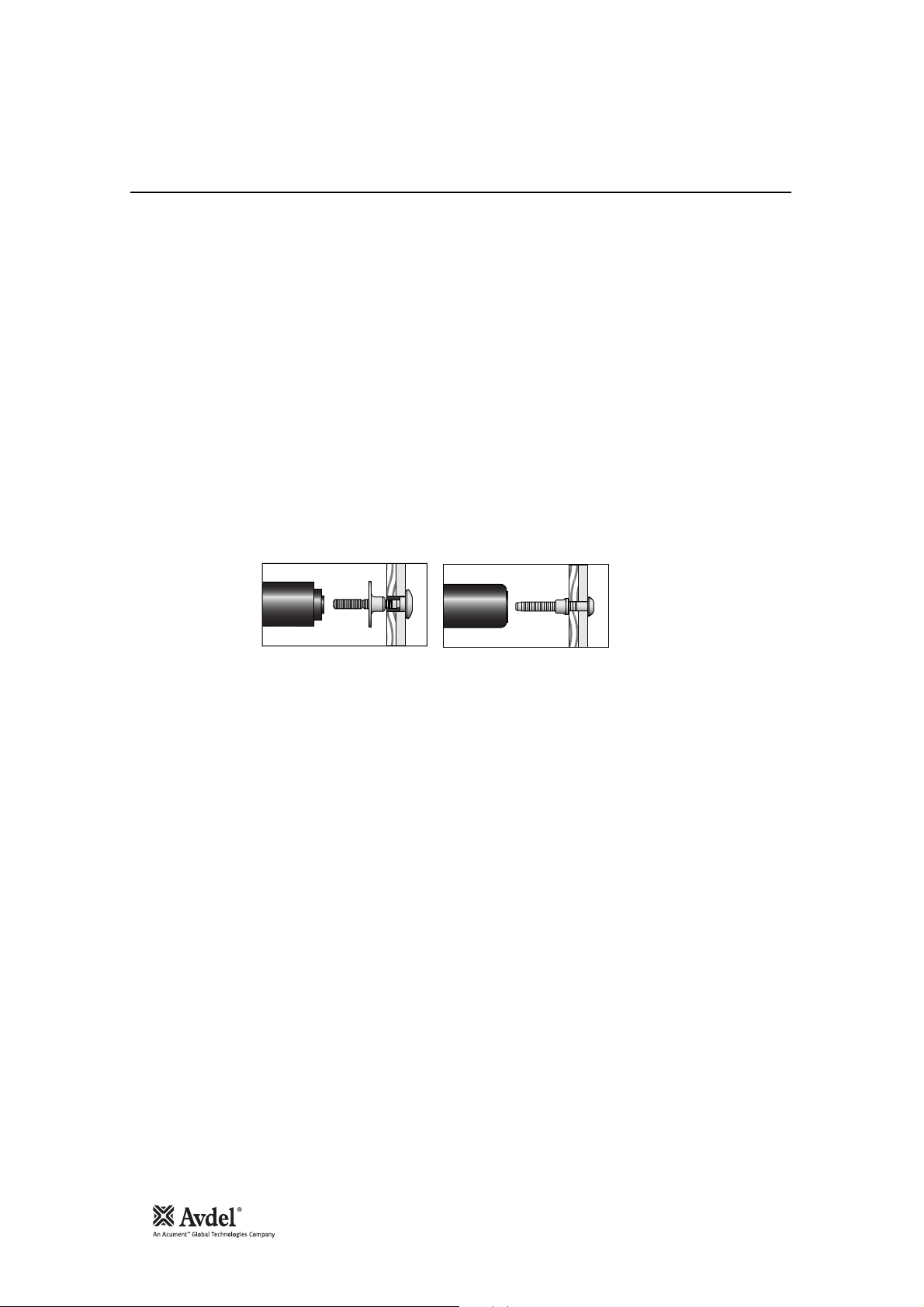

• A partial rotation and pull movement removes the collector bottle.

The Trigger should be lifted to cut-off the vacuum supply air prior

to removing the collector bottle.

Putting into Service

Air Supply

Operating Procedure -All fasteners except Avtainer®and Maxlok

®

• To minimise air consumption, the trigger should be ‘lifted’ to cut-off the

vacuum air supply if the tool is not to be used for a period of time.

English

Do not use tool when Stem

Collector Bottle is removed

STOP COCK

(USED DURING MAINTENANCE

OF FILTER/REGULATOR OR LUBRICATION UNITS)

TAKE OFF POINT

FROM

MAIN SUPPLY

3 METRES MAXIMUM

10

8

6

12

4

14

2

16

0

MAIN SUPPLY

DRAIN POINT

AIR LUBRICATION

PERMISSABLE

PRESSURE REGULATOR

AND FILTER (DRAIN DAILY)

Lift Trigger to

cut-off the

vacuum air

supply.

8

Putting into Service

Operating Procedure

AVTAINER®AND MAXLOK

®

• Ensure that the correct nose assembly is fitted see page 13.

• Connect the tool to the air supply.

• Push the Maxlok

®

or Avtainer®stem through the application hole.

• Place the collar on the stem (orientation as shown below).

• Keeping the head of the stem against the application, push the tool onto the protruding stem.

• Fully depress the trigger. One cycle will ensure that the collar is swaged into the lock grooves of the stem and that the

stem breaks at the breaker groove.

• Release the trigger. The tool completes its cycle by pushing itself off the collar and the spent stem will be pushed to

the rear of the tool on insertion of the next fastener.

Placing AVTAINER

®

Placing MAXLOK

®

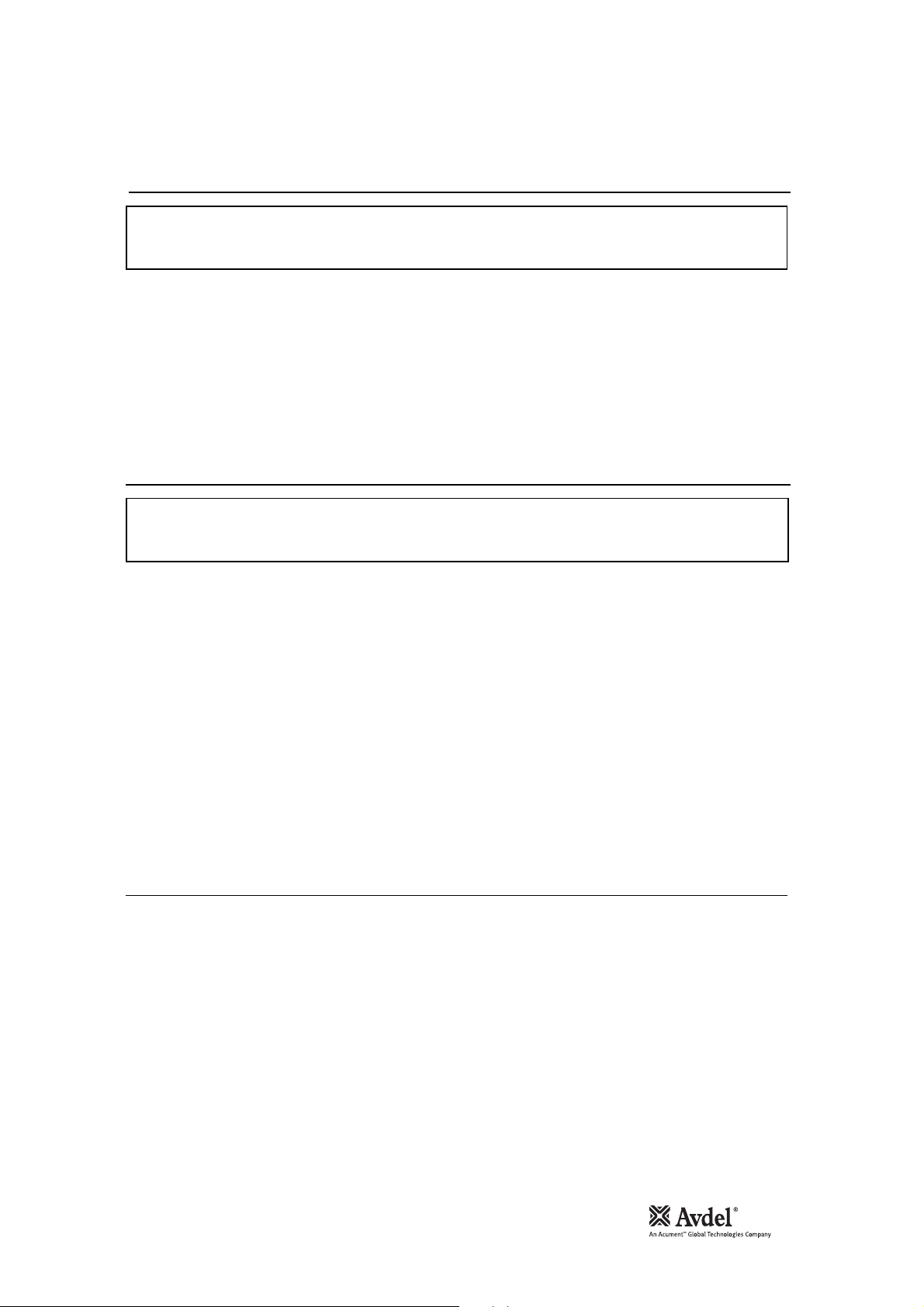

9

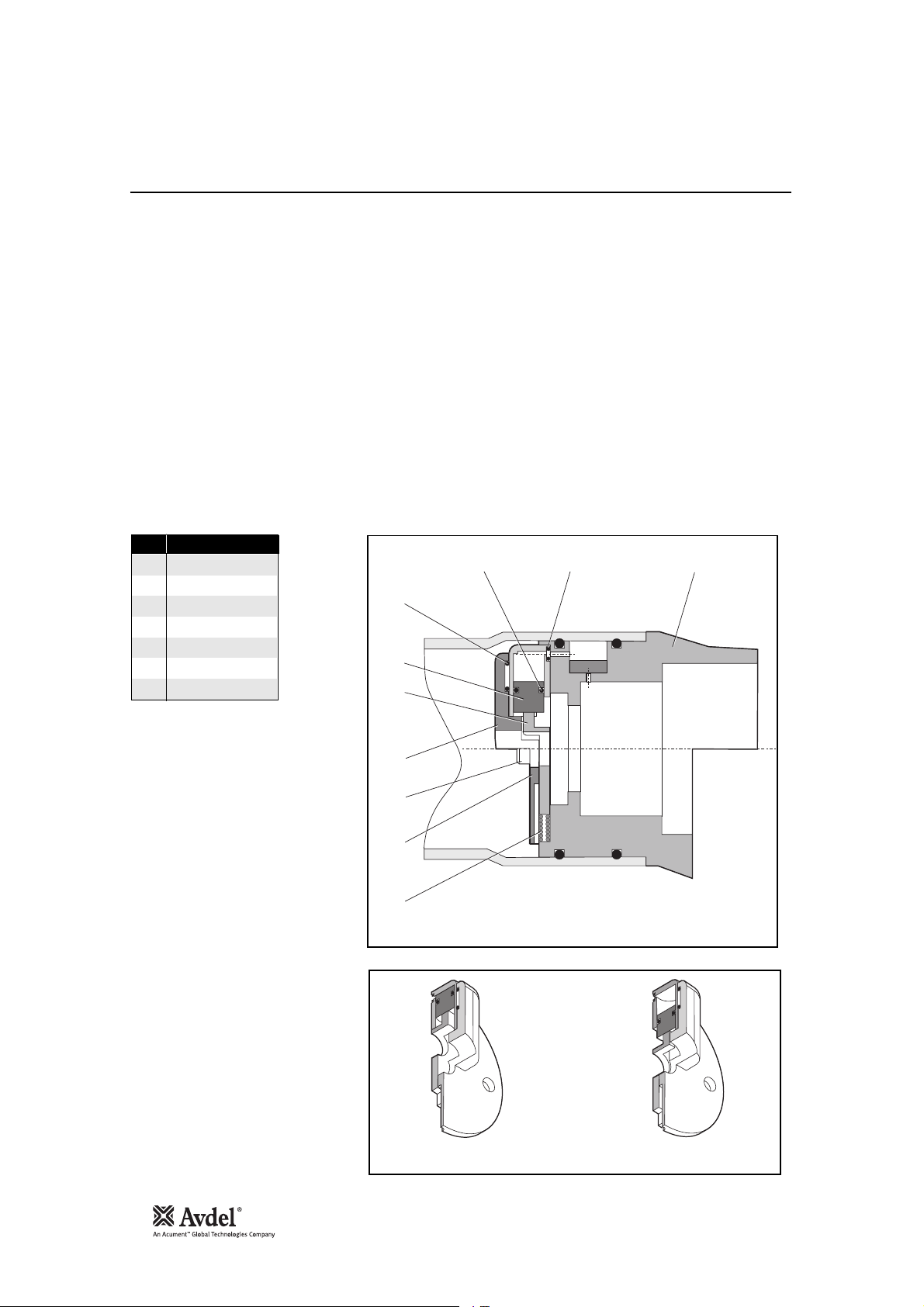

Nose Tip Selection

Nose Assemblies

IMPORTANT

Nose assemblies do NOT include nose tips. Nose tips must be ordered separately.

A tool must always be fitted with the correct nose assembly and nose tip for your fastener and must be ordered separately, refer to

the ‘NOSE TIPS’ tables on pages 10 to 13.

If your application presents no access restriction use a Type 1 nose tip unless you are placing aerospace fasteners which require a

Type 3 nose tip, Avtainer

®

a Type 5, Hemlok®and 1/4” Interlock®a Type 6. Maxlok®requires a special nose assembly which does

not make use of any nose tip, see pages 10 to 13.

Dimensions ‘A’ and ‘B’ will help you assess the suitability of a particular nose tip.

You should also check that the dimensions of the nose casing will not restrict access to your application. If access is restricted Type

2 nose tips with extra reach, are available for some fasteners. Refer to the table on page 12.

It is essential that a fastener-compatible nose assembly and nose tip are fitted prior to operating the tool (no nose tip with Maxlok

®

).

Fitting Instructions - All Nose Assemblies except Avtainer® and Maxlok

®

IMPORTANT

The air supply must be disconnected when fitting or removing nose assemblies.

Item numbers in bold refer to nose assembly components in all nose tip tables.

• Lightly coat Jaws 4 with Moly Lithium grease*.

• Drop Jaws 4 into Jaw Housing 3 or Chuck Collet 9 depending on which nose assembly you are using.

• Insert Jaw Spreader 5 into Jaw Housing 3 or insert Front Spring Guide 10 into Chuck Collet 9.

• Locate Buffer 6 on Jaw Spreader 5.

• Locate Spring 7 onto Jaw Spreader 5 or onto Front Spring Guide 10.

• Screw Rear Spring Guide 11 into Chuck Collet 9.

• Fit Locking Ring 8 onto the Jaw Spreader Housing of the tool.

• Holding tool pointing down, screw the assembled Jaw Housing or Chuck Collet onto the Jaw Spreader Housing and tighten with spanner*.

• Screw the nose tip into Nose Casing 1 and tighten with spanner*.

• Place Nose Casing 1 over Jaw Housing 3 or Chuck Collet 9 and screw onto the tool, tightening with spanner*.

* Item included in the nG4 Service Kit. For complete list see page 18.

English

Nose assemblies should be serviced at weekly intervals. You should hold some stock of all internal components of the nose assembly and

nose tips as they will need regular replacement.

Use Spanner 07900-00849 (supplied with the tool) to assist when servicing the nose assembly.

• Remove the nose equipment using the reverse procedure to the ‘Fitting instructions’.

• Any worn or damaged part should be replaced.

• Clean and check wear on Jaws.

• Ensure that neither the Jaw Spreader nor the Front Spring Guide is distorted.

• Check Spring 7 is not distorted.

• Assemble according to fitting instructions above.

Servicing Instructions

10

Nose Tips

Nose Assemblies

TYPE 1

NOSE TIPS

1

In inches then in millimetres.

2

Head forming nose tips for use with countersunk heads

ONLY.

3

Long nose tip for deep placing.

4

Material of the body then of the stem. 'Al' is the

abbreviation for Aluminium.

5

Domehead.

6

Countersunk.

NOSE ASSEMBLY

part nº 71210-15000

ITEM DESCRIPTION PART Nº

1 NOSE CASING 07340-00306

2 'O' RING 07003-00067

3 JAW HOUSING 07340-00304

4 JAWS 71210-15001

5 JAW SPREADER 07498-04502

6 BUFFER 71210-05001

7 SPRING 07500-00418

8 LOCKING RING 07340-00327

®

AVEX

Large flange

®

STAVEX

Countersunk

Large flange

®

BULBEX

®

AVINOX

II

®

T-LOK

®

AVIBULB

®

AVDEL

SR

Countersunk

INTERLOCK

Q™ RIVET

CHERRYMATE

T™ RIVET

Large flange

Large flange

Large flange

Large flange

KLAMPTITE

KLAMPTITE

FASTENER

®

®

™KTR

™

3

3

3

3

3

3

3

3

3

/

3

3

3

3

1

3

3

3

3

3/16

3/16

3/16

3/16

3/16

3/16

/

/

/

/

1

/

/

/

/

/

16

/

–

/

16

/

16

–

/

/

/

/

/

16

1

/

/

16

1

/

1/4

1/4

1/4

1/4

1/4

1/4

1

Ø

16

16

16

16

4

16

16

16

16

16

16

4

16

16

4

4

MATERIAL

4.8

Aluminium

4.8

Aluminium

4.8

Steel

4.8

Aluminium

6.4

Aluminium

4.8

Steel

4.8

Steel

4.8

Stainless Steel

4.8

Steel

4.8

Aluminium

4.8

Stainless Steel

4.3

Steel

4.8

Steel

4.8

Steel

6.0

Steel

4.8

Any

6.4

Any

4.8

Any

4.8

Any

4.8

Any

6.4

Any

4.8

Any

6.4

Any

4.8

Al/Al

4.8

Al/Al

4.8

Al/Steel

4.8

Al/Steel

6.4

Al/Al

6.4

Al/Al

6.4

Al/Steel

6.4

Al/Steel

4.8

Al Alloy

Al Alloy

6.4

Al Alloy

4.8

Al Alloy

6.4

2.8

3.3

3.3

4.1

3.3

3.3

2.8

2.8

2.8

2.8

4.8

3.3

3.3

4.8

3.3

5.7

3.3

5.7

2.8

3.3

3.3

3.3

3.3

9.5

8.0

9.5

9.0

11.2

8.0

10.2

8.3

4.8

4.8

2.8

2.8

see

below

…010

…016

…017

…015

…021

…016

…010

…010

…010

…010

…082

…120

…120

…082

…021

…062

…063

…064

…010

…120

…021

…120

…021

…380

…381

…383

…384

…385

…386

…387

…388

…500

…501

…010

…021

NOSE TIP (mm)

PART Nº 'A' 'B'NAME

07381-04701

07340-04800

07490-04401

07340-06601

07612-02001

07381-04701

07381-04701

07381-04701

07340-04800

71220-16080

07498-01401

07340-06201

07340-06201

07498-01401

07612-02001

07348-07001

71220-60001

71210-16050

07381-04701

07340-06201

07612-02001

07340-06201

4

4

4

4

4

4

4

4

07612-02001

703-A-25-6TA

703-B-21

703-A-25-6T

703-B-26

743-A-25-8TA

743-B-21

743-A-25-8T

743-B-26

71220-16060

71220-16061

07381-04701

07162-02001

2

5

6

12.7

19.0

12.7

12.7

12.7

19.0

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

15.9

12.7

15.9

12.7

17.5

12.7

16.7

12.7

12.7

12.7

12.7

12.7

8 7 6 5 4 23 1

61

22.9

COMPLETE TOOL

A

PART NUMBER :

B

precede with

71233-00

11

Nose Tips

Nose Assemblies English

AVSEAL®II

NOSE TIPS

NAME

AVSEAL®II

ITEM DESCRIPTION PART Nº

1 NOSE CASING 07340-00306

2 'O' RING 07003-00067

3 JAW HOUSING 07430-00304

4 JAWS 71210-16101

5 JAW SPREADER 07498-04502

6 BUFFER 71210-05001

7 SPRING 07500-00418

8 LOCKING RING 07340-00327

FASTENER

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

NOSE ASSEMBLY

part nº 71210-16100

MATERIAL

Ø

Standard Al. Alloy - Flush Nose Tip

7.0

Standard Al. Alloy - 2mm Extended Nose Tip

7.0

Standard Al. Alloy - 8mm Extended Nose Tip

7.0

Standard & Low Pressure - Flush Nose Tip

8.0

Standard & Low Pressure - 2mm Ext Nose Tip

8.0

Standard & Low Pressure - 8mm Ext Nose Tip

8.0

Standard Al. Alloy - Flush Nose Tip

9.0

Standard Al. Alloy - 2mm Extended Nose Tip

9.0

Standard Al. Alloy - 8mm Extended Nose Tip

9.0

Standard & Low Pressure - Flush Nose Tip

10.0

Standard & Low Pressure - 2mm Ext Nose Tip

10.0

Standard & Low Pressure - 8mm Ext Nose Tip

10.0

Low Pressure Al. Alloy - Flush Nose Tip

9.0

Low Pressure Al. Alloy - 2mm Ext Nose Tip

9.0

Low Pressure Al. Alloy - 8mm Ext Nose Tip

9.0

Low Pressure Al. Alloy - Flush Nose Tip

10.0

Low Pressure Al. Alloy - 2mm Ext Nose Tip

10.0

Low Pressure Al. Alloy - 8mm Ext Nose Tip

10.0

Low Pressure Al. Alloy - Flush Nose Tip

11.0

Low Pressure Al. Alloy - 2mm Ext Nose Tip

11.0

Low Pressure Al. Alloy - 8mm Ext Nose Tip

11.0

Low Pressure Al. Alloy - Flush Nose Tip

12.0

Low Pressure Al. Alloy - 2mm Ext Nose Tip

12.0

Low Pressure Al. Alloy - 8mm Ext Nose Tip

12.0

NOSE

ASSEMBLY

71210-16100

71210-16100

71210-16100

71220-16100

71220-16100

71220-16100

71230-15800

71230-15800

71230-15800

71230-16100

71230-16100

71230-16100

71220-16100

71220-16100

71220-16100

71230-15800

71230-15800

71230-15800

71230-16100

71230-16100

71230-16100

71230-16100

71230-16100

71230-16100

NOSE ASSEMBLY

part nº 71220-16100

ITEM DESCRIPTION PART Nº

1 NOSE CASING 07340-00306

2 'O' RING 07003-00067

3 JAW HOUSING 07612-02003

4 JAWS 71220-16120

5 JAW SPREADER 07498-04502

6 BUFFER 07498-03003

7 SPRING 07500-00418

8 LOCKING RING 07340-00327

NOSE TIP (mm)

PART Nº 'A' 'B'

71210-16105

71210-16109

71210-16113

71230-16102

71220-16103

71230-16104

71230-16102

71230-16104

71230-16106

71230-16103

71230-16105

71230-16107

71220-16105

71220-16106

71220-16107

71230-16109

71230-16112

71230-16115

71230-16110

71230-16113

71230-16116

71230-16111

71230-16114

71230-16117

12.7

12.7

12.7

14.3

14.3

14.3

14.3

14.3

14.3

14.3

14.3

14.3

13.9

13.9

13.9

13.9

13.9

13.9

17.3

17.3

17.3

17.3

17.3

17.3

A

B

see

below

… 410

2.5

… 411

5.4

… 412

11.4

… 413

2.5

… 414

5.4

… 415

11.4

… 416

2.5

… 417

5.4

… 418

11.4

… 419

2.5

… 420

5.4

… 421

11.4

… 430

3.3

… 431

5.4

… 432

11.4

… 433

3.3

… 434

5.4

… 435

11.4

… 436

3.3

… 437

5.4

… 438

11.4

… 439

3.3

… 440

5.4

… 441

11.4

COMPLETE TOOL

PART NUMBER :

precede with 71233-00.

8 7 6 5 4 23 1

NOSE ASSEMBLY

part nº 71230-15800

ITEM DESCRIPTION PART Nº

1 NOSE CASING 07340-00306

2 'O' RING 07003-00067

3 JAW HOUSING 07612-02003

4 JAWS 07612-02002

5 JAW SPREADER 07498-04502

6 BUFFER 07498-03003

7 SPRING 07500-00418

8 LOCKING RING 07340-00327

22.9

61

NOSE ASSEMBLY

part nº 71230-16100

ITEM DESCRIPTION PART Nº

1 NOSE CASING 07340-00306

2 'O' RING 07003-00067

3 JAW HOUSING 07612-02003

4 JAWS 71230-16101

5 JAW SPREADER 07498-04502

6 BUFFER 07948-03003

7 SPRING 07500-00418

8 LOCKING RING 07340-00327

12

Nose Assemblies

Nose Tips

NOTE: Items 9 & 10 are not required when assembling Type 2 or 3 Nose Tips to base tool nG4 (71233-02000).

NOTE: Items 9 & 10 are not required when assembling Type 2 or 3 Nose Tips to base tool nG4 (71233-02000).

FASTENER

1

MATERIAL

TYPE 2

NOSE TIPS

NOSE ASSEMBLY

part nº 71210-15200

ITEM DESCRIPTION PART Nº

1 NOSE CASING 07340-02804

2 'O' RING 07003-00067

3 JAW HOUSING 07340-00304

®

AVEX

BULBEX

®

T-LOK

1

In inches then in millimetres.

TYPE 2 NOSE TIPS ARE EXTENDED

TO ALLOW ACCESS INTO

APPLICATIONS WHERE TYPE 1

NOSE TIPS WILL NOT REACH.

Ø

3

/

3

/

16

3

®

/

16

–

3

/

Aluminium

4.8

16

4.8

Steel

Aluminium

4.8

4.3

Steel

4.8

Steel

16

4 JAWS 71210-15001

5 JAW SPREADER 07498-04502

6 BUFFER 71210-05001

7 SPRING 07500-00418

8 LOCKING RING 07340-00327

9 10

8 7 6 5 423

9 JAW SPREADER HOUSING 71210-02101

10 'O' RING 07003-00277

NOSE TIP (mm)

PART Nº 'A' 'B'NAME

07340-02807

07340-07301

07340-02807

07241-07101

07241-07101

A

B

10.0

12.7

11.8

12.7

10.0

12.7

10.0

12.7

10.0

12.7

COMPLETE TOOL

PART NUMBER :

precede with

71233-00

58.3

1

see

below

…014

…018

…014

…121

…121

22.9

TYPE 3

NOSE TIPS

NOSE ASSEMBLY

part nº 71210-15300

ITEM DESCRIPTION PART Nº

1 NOSE CASING 07344-02001

2 'O' RING 07003-00067

3 JAW HOUSING 07340-00304

FASTENER

1

MATERIAL

Ø

3

/

®

AVDEL

®

MBC

MBC L/C

1

In inches then in millimetres.

TYPE 3 NOSE TIPS ARE SPECIFICALLY

FOR THE AEROSPACE FASTENERS

LISTED ABOVE.

4.8

Aluminium

16

3

/

4.8

Aluminium

16

3

/

4.8

Stainless Steel

16

3

/

4.8

4.8

Any

Any

O

Oversize

16

3

/

®

16

O

NOSE TIP (mm) see

PART Nº 'A' 'B'NAME

71210-16036

71210-16037

71220-16038

07340-06901

07344-04701

A

B

4 JAWS 71210-15001

5 JAW SPREADER 07498-04502

6 BUFFER 71210-05001

7 SPRING 07500-00418

8 LOCKING RING 07340-00327

9 10

8 7 6 5 423

9 JAW SPREADER HOUSING 71210-02101

10 'O' RING 07003-00277

TYPE 6

NOSE TIPS

®

HEMLOK

INTERLOCK

®

STAVEX

FASTENER

1

Ø

1

/

6.4

4

1

®

/

6.4

4

1

/

6.4

4

MATERIAL

Any

Any

Any

NOSE TIP (mm)

PART Nº 'A' 'B'NAME

07612-02001

07612-02001

07612-02001

NOSE ASSEMBLY

part nº 71230-15800

ITEM DESCRIPTION PART Nº

1 NOSE CASING 07340-00306

2 'O' RING 07003-00067

3 JAW HOUSING 07612-02003

4 JAWS 07612-02002

5 JAW SPREADER 07498-04502

6 BUFFER 07498-03003

7 SPRING 07500-00418

8 LOCKING RING 07340-00327

1

In inches then in millimetres.

8 7 6 5 423

B

12.7

12.7

12.7

12.7

12.7

COMPLETE TOOL

PART NUMBER :

precede with

1

56.3

14.3

14.3

14.3

COMPLETE TOOL

A

PART NUMBER :

precede with

1

2.5

…293

2.5

…294

2.4

…295

5.1

…310

4.6

…320

71233-00

…261

3.6

…261

3.6

…261

3.6

71233-00

61

below

22.9

see

above

22.9

13

Nose Tips

Nose Assemblies

English

TYPE 5

AVTAINER®-

NOSE TIP

NOSE ASSEMBLY part nº 71230-15600

ITEM DESCRIPTION PART Nº

1 NOSE CASING 07498-00501

2 'O' RING 07003-00067

9 CHUCK COLLET 07498-00801

4 JAWS 07220-02302

13

11 7 10 4298

MAXLOK®-

NO NOSE TIP

NOSE ASSEMBLY NOSE ASSEMBLY

part nº 07610-02000 for

ITEM DESCRIPTION PART Nº

9

4 JAWS 07610-02003

10 SPRING GUIDE 07220-02104

7 SPRING 07610-02107

8 LOCKING RING 07610-02004

12 ANVIL

VAC SHUT-OFF STOP NUT ASSY

13

CHUCK COLLET 07610-02002

3

/

" ø part nº 07610-02100 for 1/4 " ø

16

07610-02001

71233-20200

FASTENER

AVTAINER

1

In inches then in millimetres

ITEM DESCRIPTION PART Nº

10 FRONT SPRING GUIDE 07498-00803

7 SPRING 07500-02005

11 REAR SPRING GUIDE 07498-00503

8 LOCKING RING 07340-00327

13 VAC SHUT-OFF STOP NUT ASSY 71233-20200

MAXLOK

1

In inches then in millimetres

ITEM DESCRIPTION PART Nº

9

4 JAWS 07610-02103

10 SPRING GUIDE 07220-02104

7 SPRING 07610-02107

8 LOCKING RING 07610-02004

12 ANVIL

13

VAC SHUT-OFF STOP NUT ASSY

®

FASTENER

®

1

MATERIAL

Ø

3

/

8

1

Ø

3

4.8

/

16

1

/

6.4

4

CHUCK COLLET 07610-02102

9.6

MATERIAL

All

All

Steel

07610-02101

71233-20200

NOSE TIP (mm) see

PART Nº 'A' 'B'NAME

B

1

NOSE ASSEMBLY see

PART NºNAME

07610-02000

07610-02100

COMPLETE TOOL PART NUMBER :

precede with 71233-00

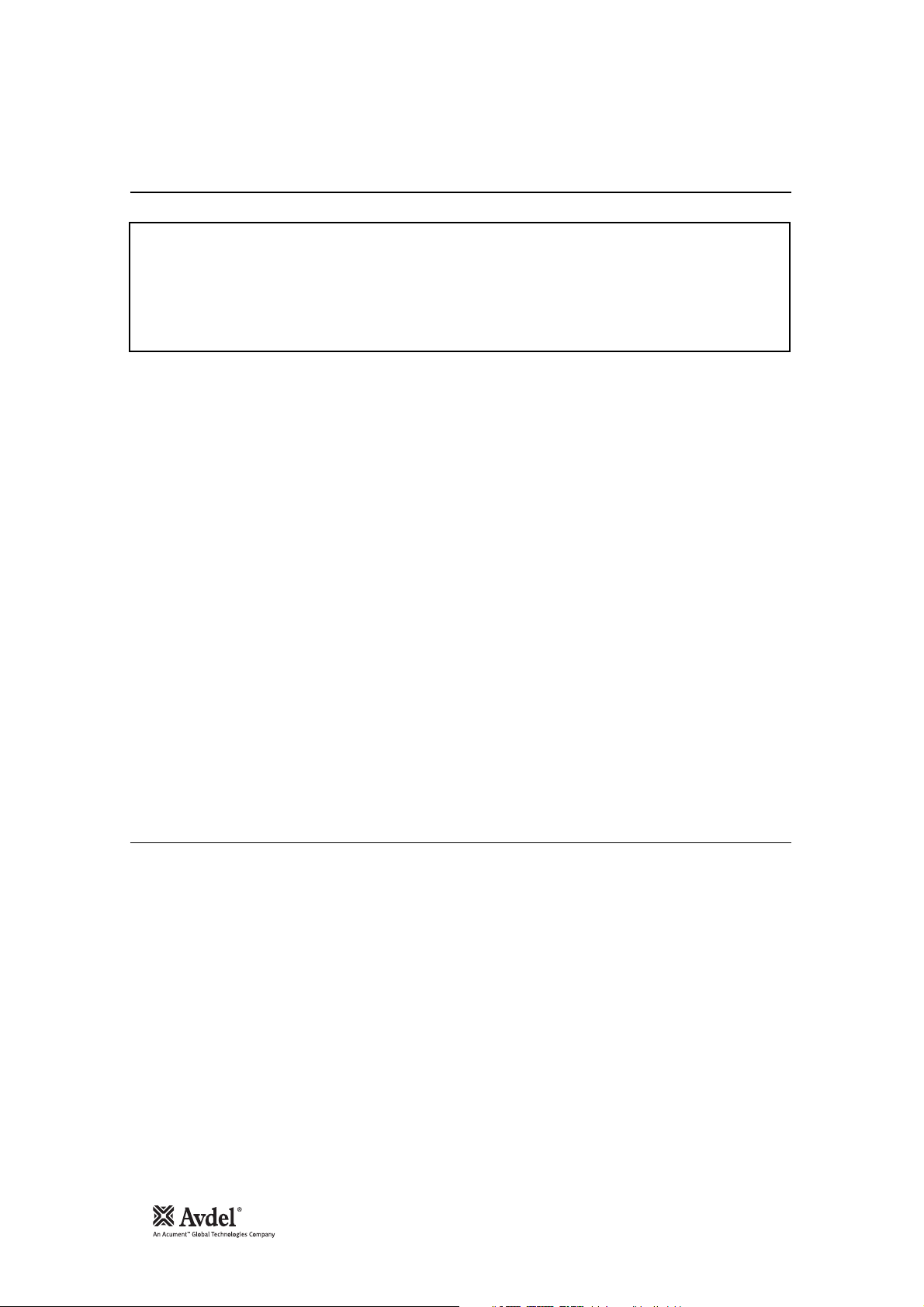

The three adapting components

illustrated below left are

not included in the nose

assembly part number.

Each item must be ordered

separately, using individual

part numbers.

4.119.107498-00802

COMPLETE TOOL

A

PART NUMBER :

precede with

71233-00

98.5

below

…243

below

…371

…372

20.6

8 7 10 9410

13

07610-00501

CHUCK COLLET ADAPTOR

71230-02063

ANVIL ADAPTOR

07610-00307

ANVIL NUT

®

MAXLOK

will place both the ordinary flange

12

THE THREE COMPONENTS ILLUSTRATED LEFT ARE ESSENTIAL WHEN FITTING

A MAXLOK® NOSE ASSEMBLY TO THE G4 TOOL.

READ MAXLOK® 'FITTING INSTRUCTIONS' PAGE 14.

ANVIL ADAPTOR

CHUCK COLLET ADAPTOR

collar and the large flange collars.

NOSE ASSEMBLIES

ANVIL NUT

64.5

19

* Item included in the nG4 service kit. For complete list see page 18

Item numbers in bold refer to the general assembly drawing and parts list on pages 24 and 25.

Nose Assemblies

IMPORTANT

The air supply must be disconnected when fitting or removing any nose assembly unless specifically instructed

otherwise.

The air vacuum extraction system MUST be disabled by fitting Vacuum ‘Shut-Off’ Stop Nut 71233-20200 before

operating a nG4 tool with a Maxlok®or Avtainer®nose assembly.

Refer to the ‘Operating Procedure’ for Avtainer®and Maxlok®, page 8.

AVTAINER

®

Item numbers in bold refer to the general assembly and parts

list pages 24 and 25. Other items numbers refer to the ‘Type 5

Nose Tip’ table page 13.

• Remove Jaw Spreader Housing 41, ‘O’ ring 12, Locknut

40, Vacuum Sleeve 42 and Seal Housing 52.

• Screw Vacuum ‘Shut-off’ Stop Nut Assy 13 onto Head Piston

36. (Items 40, 42 and 52 are not refitted).

• Replace Jaw Spreader Housing 41 and ‘O’ Ring 12.

• Lightly coat jaws 4 with Moly Lithium grease*.

• Drop jaws 4 into Chuck Collet 9.

• Insert Front Spring Guide 10 into Chuck Collet 9.

• Locate Spring 7 onto Front Spring Guide 10.

• Screw Rear Spring Guide 11 into Chuck Collet 9.

• Fit Locking Ring 8 onto the Jaw Spreader Housing of the

tool.

• Screw the assembled Chuck Collet onto the Jaw Spreader

Housing and tighten with spanner.

• Screw the Nose Tip into Nose Casing 1 and tighten with

spanner*.

• Place Nose Casing 1 with ‘O’ Ring 2 over Chuck Collet 9

and screw onto the tool, tightening with spanner*

MAXLOK

®

When fitting a Maxlok®nose assembly, the base tool must be

adapted using three auxiliary components illustrated page 13

and Vacuum ‘Shut-off’ Stop Nut Assembly 13, must be fitted.

Item numbers in bold refer to the general assembly and parts

list pages 26-27. Other items numbers refer to the ‘Maxlok

®

No

Nose Tip’ table page 12.

• Remove Jaw Spreader Housing 41, ‘O’ Ring 12, and

Vacuum Sleeve 42. Seal housing 52 and Locknut 40.

(None of the above parts are refitted).

• Screw Vacuum Shut-off ‘Stop Nut’ 13 onto Head Piston 36.

• Substitute Jaw Spreader Housing 1 with Chuck Collet

Adaptor 07610-00501. Tighten fully onto piston before

tightening the Stop Nut 13 against it.

• Fit Locking Ring 8 onto the Chuck Collet Adaptor.

• Lightly coat Jaws 4 with Moly Lithium grease.

• Drop Jaws 4 into Chuck Collet 9.

• Insert one Spring Guide 10 into Chuck Collet 9.

• Locate Spring 7 onto the Spring Guide already in place.

• Drop the other Spring Guide 10 into Spring 7.

• Holding tool pointing down, screw the assembled Chuck

Collet onto the Chuck Collet Adaptor and tighten with

spanner.

• Screw Anvil Adaptor 71230-02063 into the Head Assembly.

• Place Anvil 12 over Chuck Collet 9 and lock into place with

Anvil Nut 07610-00307.

Fitting instruction for Avtainer® and Maxlok® Nose Assemblies

Servicing Instructions for all Nose Assemblies

Nose assemblies should be serviced at weekly intervals. You should hold some stock of all internal components of the nose assembly

and nose tips as they will need regular replacement.

• Remove the nose assembly using the reverse procedure to the ‘Fitting instructions’.

• Any worn or damaged part should be replaced.

• Clean and check wear on jaws.

• Ensure that the jaw spreader is not distorted.

• Check that the spring is not distorted.

• On nose assemblies for Maxlok

®

and Avtainer®check that the spring guides are not distorted.

• On nose assemblies for Maxlok

®

check that the anvil is neither cracked nor has any scoring or corrosion marks on the inside face

of the concave shape at the front end.

• Assemble according to fitting instructions.

14

15

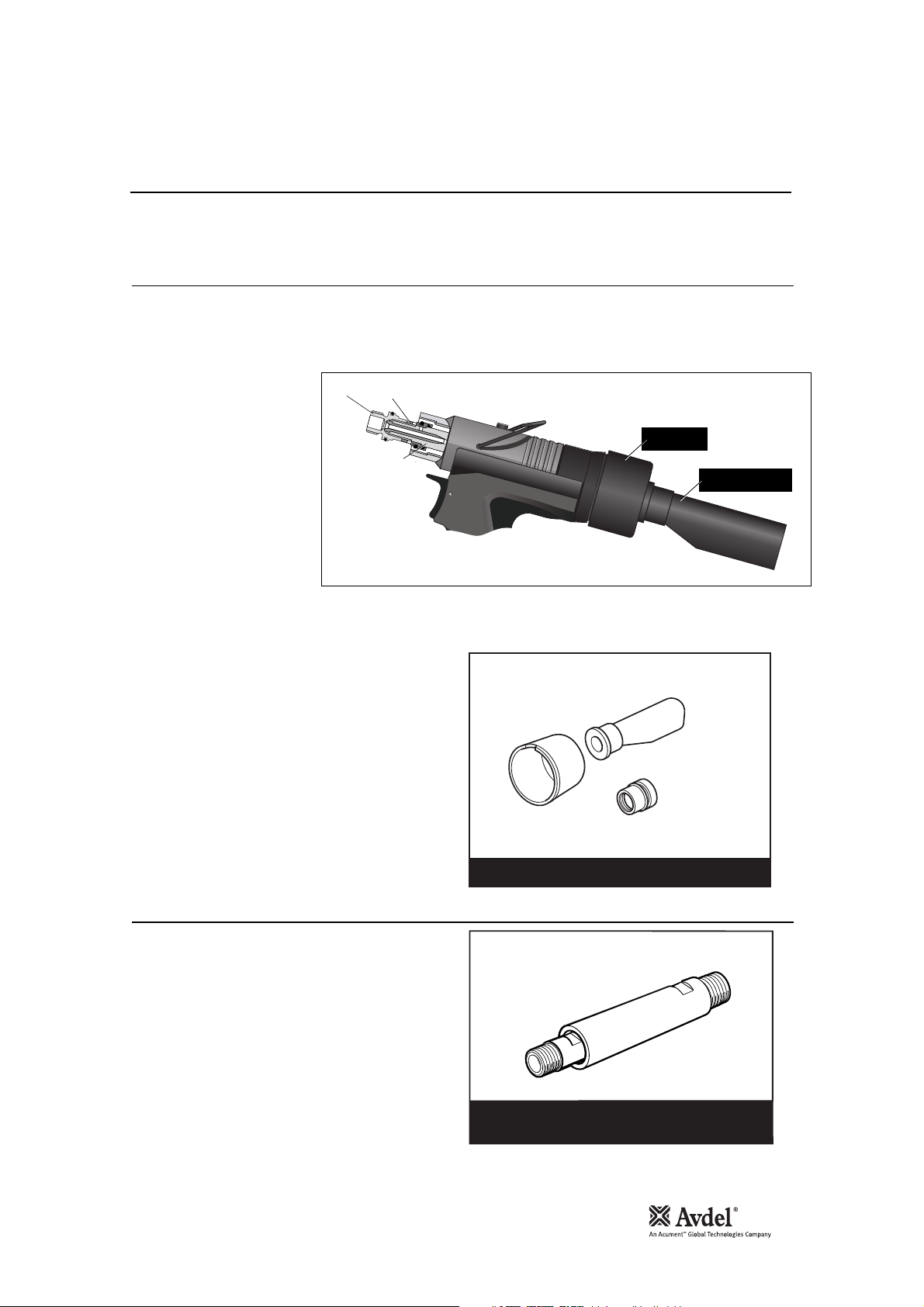

Stem Deflector

Accessories

The stem deflector is a very simple alternative to the standard stem collector and allows access in restricted areas. To replace the

stem collector with the stem deflector proceed as follows:

Item numbers in bold refer to the general assembly drawing and parts list on pages 24 and 25.

Fitted between the tool and the nose assembly the extension

allows access into deep channels.

• To fit the extension, remove any nose assembly

components.

• Screw the inner extension to Jaw Spreader Housing 41.

• Screw the outer onto Head Assembly 58.

• Fit the nose assembly onto the extension.

• Loosen Locknut 40 using

16mm A Spanner.

• Unscrew and remove both Jaw

Spreader Housing 41 and

Locknut 40.

• Replace Locknut 40 with

‘Sealed’ Nut 71213-02200,

screw ‘Sealed” Nut onto Piston

36.

• Jaw Spreader Housing 41

must be tightened onto Piston

36, finally tightening ‘Sealed’

Nut against it.

• Remove the Stop Plate

Assembly (page 22) by

unscrewing Screws 89 (2 off).

Extension

Preparing the Base Tool for use with Stem Deflector

The airline must be disconnected before any servicing or dismantling.

‘Sealed’ Nut 71213-02200 replaces Locknut 40 (to cut-off air supply to Vacuum System) as follows:

Note: If Pintail Deflector is used with Maxlok®equipment then Seal Housing 52 will need to be removed and Stop Nut 71233-20200

fitted instead of ‘Sealed’ Nut 71213-02200.

English

• Fit Stem Deflector (07340-00342) into Adaptor

(71213-20101).

• Push the assembled Stem Deflector and Adaptor over

Bottle Adaptor 32 and align with the cut-out feature.

41

40

36

71213-20101

ADAPTOR

07340-00342

STEM DEFLECTOR

STEM DEFLECTOR

07340-00342

SEALED NUT

71213-02200

ADAPTOR

71213-20101

STEM DEFLECTOR: 71213-20100

INNER

MAXLOK®/EXTENSION 71230-20300

EXTENSION PART NUMBER 71210-20300

OUTER

Servicing the Tool

• Daily, before use or when first putting the tool into service, pour a few drops of clean, light lubricating oil into the air inlet of the tool

if no lubricator is fitted on air supply. If the tool is in continuous use, the air hose should be disconnected from the main air supply

and the tool lubricated every two to three hours.

• Check for air leaks. If damaged, hoses and couplings should be replaced.

• If there is no filter on the pressure regulator, bleed the air line to clear it of accumulated dirt or water before connecting the air hose

to the tool. If there is a filter, drain it.

• Check that the nose assembly or swivel head is correct for the fastener to be placed.

• Check the stroke of the tool meets the minimum specification (page 5). The last step of the Priming Procedure on page 25 explains

how to measure the stroke.

• Either a stem collector or a stem deflector must be fitted to the tool unless using a swivel head.

• Check that Base Cover 31 is fully tightened onto Body 30.

• Stem Collector Bottle: ‘O’ Rings 20 and 28 to be checked for wear, cleaned and lubricated with Molykote

®

55m.

• Dismantle and clean the nose assembly with special attention to the jaws. Lubricate with Moly Lithium grease before assembling.

• Check for oil leaks and air leaks in the air supply hose and fittings.

Grease can be ordered as a single item, the part number is shown in the Service Kit page 18.

First Aid

SKIN:

As the grease is completely water resistant it is best removed with an approved emulsifying skin cleaner.

INGESTION:

Ensure the individual drinks 30ml Milk of Magnesia, preferably in a cup of milk.

EYES:

Irritant but not harmful. Irrigate with water and seek medical attention.

Fire

FLASH POINT: Above 220°C.

Not classified as flammable.

Suitable extinguishing media: CO

2

, Halon or water spray if applied by an experienced operator.

Environment

Scrape up for burning or disposal on approved site.

Handling

Use barrier cream or oil resistant gloves

Storage

Away from heat and oxidising agent.

Item numbers in bold refer to the general assembly drawing and parts list on pages 24 and 25.

IMPORTANT

Read Safety Instructions on page 4.

The employer is responsible for ensuring that tool maintenance instructions are given to the appropriate personnel.

The operator should not be involved in maintenance or repair of the tool unless properly trained.

The tool shall be examined regularly for damage and malfunction.

Daily

Weekly

Moly Lithium Grease EP 3753 Safety Data

16

17

Molykote®55m Grease Safety Data

First Aid

SKIN:

Flush with water. Wipe off.

INGESTION:

No first aid should be needed.

EYES:

Flush with water.

Fire

FLASH POINT: Above 101.1°C. (closed cup)

Explosive Properties: No

Suitable Extinguishing Media: Carbon Dioxide Foam, Dry Powder or fine water spray.

Water can be used to cool fire exposed containers.

Environment

Do not allow large quantities to enter drains or surface waters.

Methods for cleaning up: Scrape up and place in suitable container fitted with a lid. The spilled product produces an extremely

slippery surface.

Harmful to aquatic organisms and may cause long-term adverse effects in the aquatic environment. However, due to the physical

form and water - insolubility of the product the bioavailability is negligible.

Handling

General ventilation is recommended. Avoid skin and eye contact.

Storage

Do not store with oxidizing agents. Keep container closed and store away from water or moisture.

First Aid

SKIN:

No first aid should be needed.

INGESTION:

No first aid should be needed.

EYES:

No first aid should be needed.

INHALATION:

No first aid should be needed.

Fire

FLASH POINT: Above 101.1°C. (closed cup)

Explosive Properties: No

Suitable Extinguishing Media: Carbon Dioxide Foam, Dry Powder or fine water spray.

Water can be used to cool fire exposed containers.

Environment

No adverse effects are predicted.

Handling

General ventilation is recommended. Avoid eye contact.

Storage

Do not store with oxidizing agents. Keep container closed and store away from water or moisture.

Molykote®111 Grease Safety Data

Servicing the Tool

English

Service Kit

For an easy complete service, Avdel offers the complete service kit below.

Servicing the Tool

Maintenance

The airline must be disconnected before any servicing or dismantling is attempted unless specifically instructed otherwise.

It is recommended that any dismantling operation be carried out in clean conditions.

Before proceeding with dismantling, empty the oil from the tool following the first three steps of the ‘Priming Procedure’ on page 26.

Prior to dismantling the tool it is necessary to remove the nose equipment. For instructions see the nose assemblies section, pages 9 to

14.

For a complete service of the tool, we advise that you proceed with dismantling of sub-assemblies in the order shown.

After any dismantling REMEMBER to prime the tool see page 26 and to fit an appropriate nose assembly see pages 9 to 14.

(Annually or every 500,000 cycles whichever is the soonest)

Annually or every 500,000 cycles the tool should be completely dismantled and new components should be used where worn, damaged

or recommended. All ‘O’ rings and seals should be renewed and lubricated with Molykote

®

55m grease for pneumatic sealing or

Molykote

®

111 for hydraulic sealing.

IMPORTANT

Read Safety Instructions on page 4.

The employer is responsible for ensuring that tool maintenance instructions are given to the appropriate personnel.

The operator should not be involved in maintenance or repair of the tool unless properly trained.

The tool shall be examined regularly for damage and malfunction.

Nose Equipment

• Unscrew Nose Casing 1 and Nose Tip.

• Unscrew Jaw Housing 3 and remove Jaws 4, Jaw Spreader 5, Spring 7 and Buffer 6.

• Inspect all components. Renew all damaged or worn parts.

• Clean all parts and apply Moly Lithium Grease EP 3753 (07992-00020) to taper bore of Jaw Housing 3.

• Insert Jaws 4, Jaw Spreader 5, Spring 7 and Buffer 6 into Jaw Housing 3 and assemble onto Jaw Spreader Housing 41*.

• Screw Nose Tip into Nose Casing and tighten.

Item numbers in bold refer to Nose Tip Tables on pages 10 to 13.

41* refers to illustration on page 24.

18

SERVICE KIT : 71210-99990 Spanners are specified in inches and across flats unless otherwise stated

PART N DESCRIPTIONPART N DESCRIPTION

07900-00667 PISTON SLEEVE

07900-00692 TRIGGER VALVE EXTRACTOR

07900-00670 BULLET

07900-00672 'T' SPANNER

07900-00706 'T' SPANNER SPIGOT

07900-00684 GUIDE TUBE

07900-00685 INSERTION ROD

07900-00351 3 MM ALLEN KEY

07900-00469 2.5 MM ALLEN KEY

07900-00158

07900-00164

2 MM PIN PUNCH

CIRCLIP PLIERS

07900-00008

07900-00012

07900-00015

07900-00686 PEG SPANNER

07900-00677 SEAL EXTRACTOR

07900-00698 STOP NUT

07900-00700 PRIMING PUMP

07992-00020 GREASE - MOLYLITHIUM E.P.3753

07992-00075 GREASE - MOLYKOTE 55M

07900-00755

07900-00850

07900-00898

716 1/ x /2 SPANNER

916 5/ x /8 SPANNER

58 11/ x /16 SPANNER

®

GREASE - MOLYKOTE 111

PIN SPANNER

VALVE HOOK

®

19

Dismantling the Tool

Servicing the Tool

Before dismantling the tool the oil must be emptied from it.

• With the air supply switched OFF at ON/OFF Valve Assembly 62 remove Bleed Screw 1 and Bonded Seal 6.

• Insert tool over a suitable container, switch air supply ON and actuate tool.

• Oil will expel from bleed screw orifice into container.

• Switch air supply OFF after all oil is expelled.

This operation must have the Bleed Screw orifice facing away from the person performing this operation.

• Twist and pull off Stem Collector Bottle Assembly 25. See illustration on page 7.

• Remove Stop Plate Assembly 104 by unscrewing Screws 89 2 off.

• Unscrew Retaining Nut 50.

• Pull off Bottle Adaptor Assembly 32 together with ‘O’ Rings 20 and 28.

• Remove End Cap Assembly 35 together with ‘O’ Ring 97 and Lip Seal 9.

• Remove Spring 91.

• Loosen Locknut 40 with a spanner* and unscrew Jaw Spreader Housing 41 together with ‘O’ Ring 12.

• Remove Locknut 40 together with ‘O’ Rings 19 and 15, withdraw Vacuum Sleeve 42..

• Push Head Piston 36 to the rear and out of Head Assembly 58 taking care not to damage the cylinder bore

• Remove Seal Retainer 43. Push Lip Seal 8 and Bearing Tape 26 to the rear and out of Head Assembly 58 taking care not to damage

the cylinder bore.

• Remove Seal Housing 52 and Lip Seal 2.

Assemble in reverse order noting the following points:

• Place Lip Seal 8 onto the insertion rod* ensuring correct orientation. Locate the guide tube* into the head of the tool and push the

insertion rod* with the seal in place through the guide tube*. Pull the insertion rod* out and then the guide tube*.

• After fitting Lip Seals 11, ‘O’ Rings 18 and Bearing Tape 27 onto the Head Piston 36 ensuring correct orientation, lubricate the cylinder

bore and place the piston sleeve* into the back of Head Assembly 58. Slide the bullet* onto the threaded part of Head Piston 36 and

push the piston with the seals through the piston sleeve* as far as it will go. Slide the bullet* off the piston and remove piston sleeve*.

• Jaw Spreader Housing 41 must be fully tightened onto Head Piston 36 before tightening Locknut 40 against it.

• Reprime in accordance with the instructions on page 26.

* Item included in the nG4 Service Kit. For complete list see page 18.

Item numbers in bold refer to the general assembly drawing and parts list on pages 24 and 25.

Head Assembly

English

• Remove ‘ON/OFF’ valve assembly 62.

• Clamp the body of the inverted tool ACROSS THE AIR INLET BOSSES in a vice fitted with soft jaws.

• Pull off Rubber Boot 48.

• Using the peg spanner* unscrew Base Cover 31.

• Unscrew Nyloc Nuts 67 (2 off) and remove Base Plate Assembly 65.

• Remove Cylinder Liner 37 together with Sealing Washers 29 (2 off) and ‘O’ Rings 66 (2 off).

• Remove Pneumatic Piston Assembly 57 together with ‘O’ Ring 75, Lip Seal 90 (3 off) and Guide Ring 51.

• Engage the Seal Extractor* into Intensifier Seal Assembly 63 and withdraw Seal Assembly from intensifier tube of the Head Assembly 58.

Assemble in reverse order to dismantling.

* seals should be checked for damage and replaced as necessary. Lubricate Pneumatic seals with Molykote

®

55m Grease and Hydraulic

seals with Molykote

®

111 Grease.

Dismantling

•

Remove Pneumatic Piston Assembly 57 as described above in Pneumatic Piston Assembly.

• Using Spanner (07900-00672), and Location Spigot (07900-00671). Unscrew Clamp Nut 39 and remove together with Top Plate

Assembly 44 together with Tie Rods 56, Transfer Tube Assembly 61, ‘O’ Rings 14 and Silencer 53.

• Remove tool from vice and separate Body 30 from Handle Assembly 64. Remove ‘O’ ring 17.

• Push out the Valve Seat 34, from the Body 30, together with ‘O’ Rings 14.

• Pull out Valve Spool Assembly 59 from Handle Assembly 64. Remove ‘O’ Ring 7 from handle counterbore.

Assembly

Assemble in reverse order to Dismantling Instructions

• Seals should be checked for damage and replaced if necessary, lubricated with Molykote

®

55M Grease.

• Apply Loctite

®

243 to Clamp Nut 39 and tighten to torque 11ftlb (14.91 Nm)

IMPORTANT

Check the tool against daily and weekly servicing.

Priming is ALWAYS necessary after the tool has been dismantled and prior to operating.

* Item included in the nG4 Service Kit. For complete list see page 18.

Item numbers in bold refer to the general assembly drawing and parts list on pages 24 and 25.

Pneumatic Piston Assembly

Servicing the Tool

Air Valve

20

21

Servicing the Tool

Dismantling

• Using a 4mm pin punch (07900-00158) drive Trigger Pin 46 out and remove Trigger Assembly 33.

• Remove Pneumatic Piston Assembly 57 as described in Pneumatic Piston Assembly, see page 20.

• Using Spanner (07900-00672), and Location Spigot (07900-00671), unscrew Clamp Nut 39 and remove together with Top Plate

Assembly 44 together with Tie Rods 56, Transfer Tube Assembly 61, seperate Body 30 from Handle Assembly 64. Remove ‘O’

Rings 16 and 17 NOTE ORIENTATION OF ROTARY VALVE 38.

• Seperate Head Assembly 58 from Handle Assembly 64. NOTE ORIENTATION OF ROTARY VALVE 38

• Push out Rotary Valve 38 together with ‘O’ Rings 5.

Assemble in reverse order to Dismantling Instructions noting the following:

• Seals should be checked for damage and replaced if necessary, lubricated with Molykote

®

55m grease.

• Ensure Rotary Valve 38 is assembled in correct orientation, align pins with forks on the Trigger 33.

See illustration below.

Rotary Valve

Dismantling

• Using a 4mm pin punch (07900-00158) drive Trigger Pin 46 out and remove Trigger Assembly 33.

• Unscrew Trigger Valve 21 using trigger valve extractor (0900-00692).

Assemble in reverse order to Dismantling Instructions noting the following:

• When assembling Trigger 33 the trigger forks locate on the pins each side of the Rotary Valve 38.

• Ensure Rotary Valve 38 is orientated correctly. See illustration below.

Trigger

Item numbers in bold refer to the general assembly drawing and parts list on pages 24 and 25.

English

38

33

22

Stop Plate Assembly (71213-03900)

Servicing the Tool

Assembly (see illustration below)

• Place ‘O’ Ring 2 into the recess in Housing 5 retain in position using grease Molykote

®

55.

• Assemble ‘O’ Ring 4 onto Piston 1 and push assembly into Housing 5 making sure it is in as far as it will go.

• Position the slot in Piston 1 parallel to the step face in Housing 5.

• Slide Plate Shut Off 3 into the assembled parts 1, 2, 4, and 5. Retain parts in place using grease Molykote

®

55.

• Place ‘O’ Ring 4 into the recess of Cover Plate 6 retain in position using grease Molykote

®

55.

• Place Spring 7 into position locate using the recesses in both Plate Shut Off 3 and Bottle Adaptor Assembly 32*.

• Position the above assembled parts onto Bottle Adaptor Assembly 32*.

• Secure in position using two Screws 89*.

*see pages 24 and 25.

1 PISTON

2 ‘O’ RING

3 PLATE SHUT OFF

4 ‘O’ RING

5 HOUSING

6 COVER PLATE

7 SPRING

ITEM DESCRIPTION

89*

4

2

32*

4

1

3

5

6

7

OPEN

CLOSED

Notes

23

24

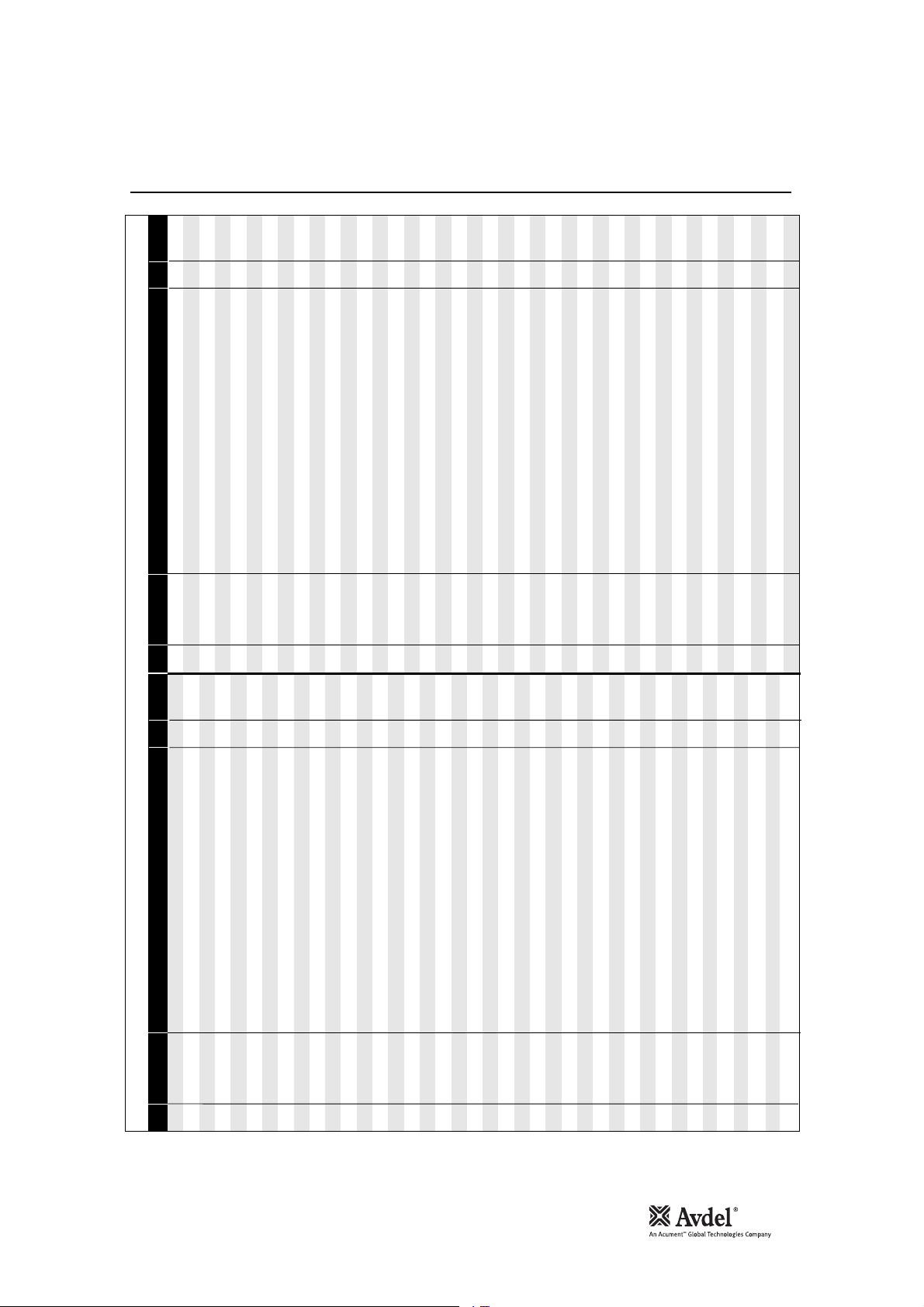

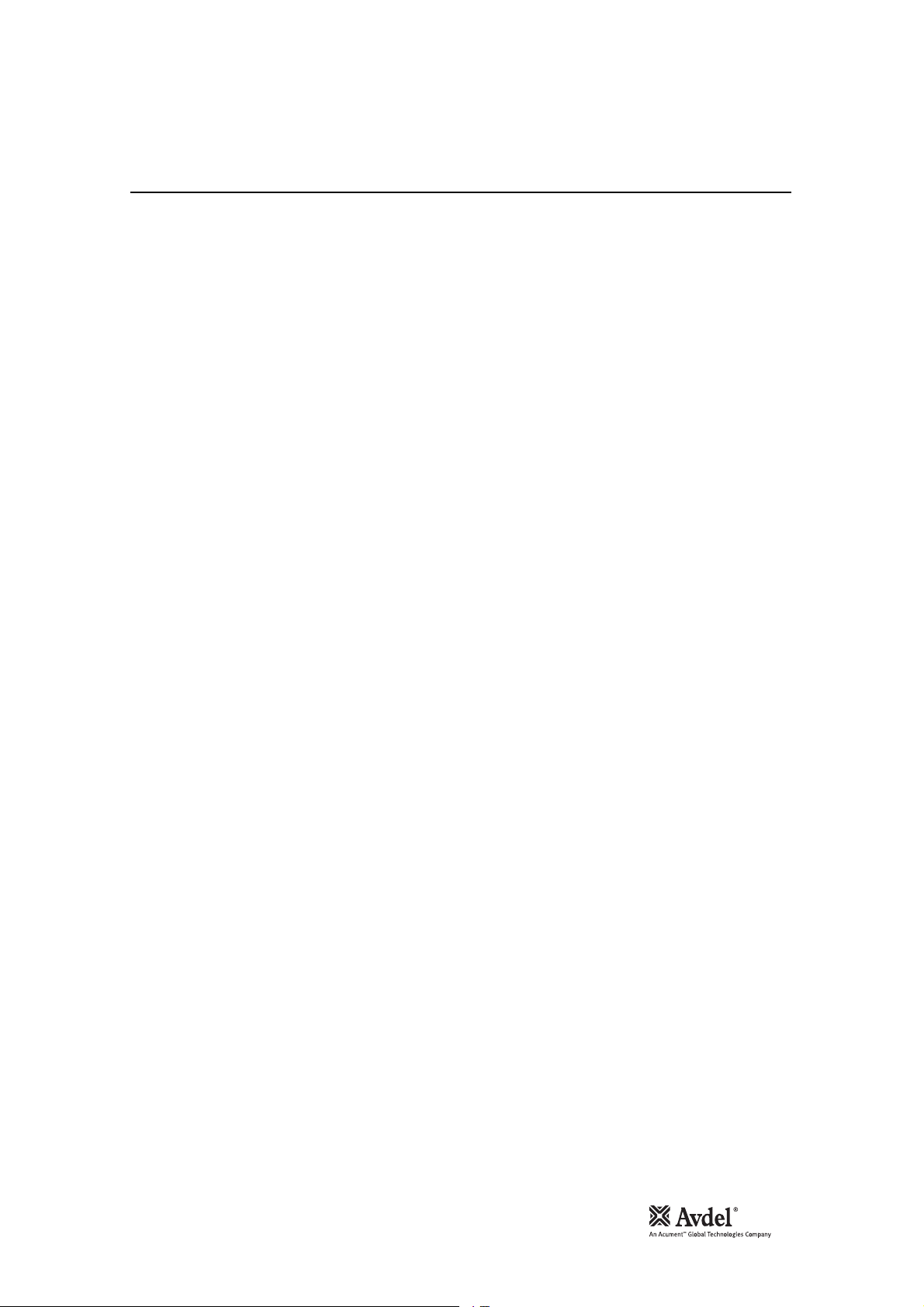

General Assembly of Base Tool 71233-02000

71

H - H

45

28 11

13

91

'X'

74

73

385

104 Assy

35 Assy

25 Assy

72

B - B

Ring

Suspension

8920

50

97 32

9

36

17

7

98

18

64 Assy

99

27

4

14

17

62 Assy

24

14

96

Assy 59

22

4

63 Assy

16

Detail 'X'

44

39

53

14

34

53

76

HH HH

76

23

51

56

49

30

79

80

75

31

A - A

90 67 29 66

48

77

65 Assy

Assy

26

2 8

58

41 12 40 1,6 4352

100

19

42

15

A

B

B

21

46

Assy 33

A

A

Assy 6137Assy 57

90

25

Parts List For 71233-02000

English

111111111221111111122112212111231121111

QTY SPARES

SEAL RETAINER

TOP PLATE ASSEMBLY

SUSPENSION RING

TRIGGER PIN

RUBBER BOOT

LABEL

RETAINING NUT

GUIDE RING

SEAL HOUSING

SILENCER

TIE ROD

PNEUMATIC PISTON ASSEMBLY

HEAD ASSEMBLY

VALVE SPOOL ASSEMBLY

TRANSFER TUBE ASSEMBLY

ON/OFF VALVE ASSEMBLY

INTENSIFIER SEAL ASSEMBLY

HANDLE ASSEMBLY

BASE PLATE ASSEMBLY

'O' RING

M6 NYLOC NUT

MODIFIED COUNTER

COUNTER MOULDING

MOULDING RETAINING NUT

SPECIAL M4 SCREW

'O' RING

WASHER

CENTRE POLE MAGNET

M5 X 19 COUNTERSUNK SCREW

M5 NYLOK NUT

SCREW

LIP SEAL

SPRING

'O' RING

'O' RING

'O' RING

71230-02019

71213-02010

71210-02022

71210-02024

71221-02007

71233-02027

71213-02028

71230-03205

71210-02104

71210-02031

71221-02004

71231-03210

71233-03300

71210-03400

71230-03600

71210-03700

71230-03800

71213-02013

71221-02014

07003-00027

07002-00108

71221-20105

71221-20101

71221-20103

71221-20102

07003-00182

07002-00163

07007-01993

71221-20104

07002-00098

07001-00677

07003-00274

07490-03002

07003-00268

07003-00398

07003-00042

43444546484950515253565758596162636465666771727374757677798089909196979899

1

VALVE BODY

LABEL BOOK SYMBOL

TOOL INSTRUCTION MANUAL

STOP PLATE ASSEMBLY

71210-03401

07007-01503

07900-00844

71213-03900

100

103

104

111211111113112211111211112111111111111

QTY SPARES

BLEED SCREW

LIP SEAL

'O' RING

'O' RING

M5 BONDED SEAL

'O' RING

LIP SEAL

LIP SEAL

LIP SEAL

'O' RING

'O' RING

'O' RING

'O' RING

'O' RING

'O' RING

'O' RING

'O' RING

'O' RING

TRIGGER VALVE

1/8" BSP PLUG

6" FLEXIBLE HOSE

3mm DIAx10mm SPIROL PIN

STEM COLLECTOR BOTTLE ASSEMBLY

BEARING TAPE - PISTON ROD

BEARING TAPE - PISTON

'O' RING

SEALING WASHER

BODY MACHINED

BASE COVER

BOTTLE ADAPTOR ASSEMBLY

TRIGGER ASSEMBLY

VALVE SEAT

END CAP ASSEMBLY

HEAD PISTON

71230-02041

07003-00333

07003-00127

07003-00189

07003-00194

07003-00271

07003-00273

07003-00274

07003-00341

07003-00277

07003-00278

07003-00281

07003-00204

07003-00287

07003-00288

07003-00342

07003-00310

07003-00415

07005-00088

07005-01274

07008-00010

07007-00224

71213-03800

71213-02021

71213-02022

07003-00416

71221-02006

71223-02001

71221-02002

71213-03000

71213-02008

71210-02009

71233-02025

71233-02121

71233-02000 PARTS LIST * These are minimum recommended levels of spares based on regular servicing

010204050607080911121314151617181920212223242526272829303132333435363738394041

ITEM PART Nº DESCRIPTION ITEM PART Nº DESCRIPTION

CYLINDER LINER

ROTARY VALVE

CLAMP NUT

LOCKNUT

71221-02008

71213-02012

71210-02014

71230-02015

1

JAW SPREADER HOUSING

VACUUM SLEEVE

71210-02101

71230-02102

42

Priming

Priming is ALWAYS necessary after the tool has been dismantled and prior to operating. It may also be necessary to restore the full stroke

after considerable use, when the stroke may be reduced and fasteners are not fully placed by one operation of the trigger.

The recommended oil for priming is Hyspin®VG32 available in 0.5 litre (part number 07992-00002) or one gallon containers (part number

07992-00006). Please see safety data below.

First Aid

SKIN:

Wash thoroughly with soap and water as soon as possible. Casual contact requires no immediate attention. Short term contact requires no

immediate attention.

INGESTION:

Seek medical attention immediately. DO NOT induce vomiting.

EYES:

Irrigate immediately with water for several minutes. Although NOT a primary irritant, minor irritation may occur following contact.

Fire

Flash point 232°C. Not classified as flammable.

Suitable extinguishing media: CO

2

, dry powder, foam or water fog. DO NOT use water jets.

Environment

WASTE DISPOSAL: Through authorised contractor to a licensed site. May be incinerated. Used product may be sent for reclamation.

SPILLAGE: Prevent entry into drains, sewers and water courses. Soak up with absorbent material.

Handling

Wear eye protection, impervious gloves (e.g. of PVC) and a plastic apron. Use in well ventilated area.

Storage

No special precautions.

To enable you to follow the priming procedure opposite, you will need to obtain a Priming Kit:

Oil Details

Hyspin®VG 32 Oil Safety Data

Priming Kit

26

PRIMING KIT : 07900-00688

PART Nº DESCRIPTION

07900-00351 3mm ALLEN KEY

07900-00700 PRIMING PUMP

07900-00224 4mm ALLEN KEY

07900-00698 STOP NUT

07900-00734 STOP NUT - MAXLOK

®

27

Priming Procedure

Priming

IMPORTANT

DISCONNECT THE TOOL FROM THE AIR SUPPLY OR SWITCH OFF AT VALVE 55.

REMOVE NOSE ASSEMBLY OR SWIVEL HEAD COMPONENTS.

All operations should be carried out on a clean bench, with clean hands in a clean area.

Ensure that the new oil is perfectly clean and free from air bubbles.

Care MUST be taken at all times, to ensure that no foreign matter enters the tool, or serious damage may result.

• Switch OFF air supply at ON/OFF Valve Assembly 62.

• Remove all nose equipment. (see pages 9 and 14)

• Remove Bleed Screw 1 and Bonded Seal 6.

• Invert tool over suitable container, switch ON air supply at ON/OFF Valve Assembly 62 and actuate tool.

• Residual oil in the tools hydraulic system will empty through bleed screw orifice.

CARE SHALL BE TAKEN TO ENSURE THAT THE BLEED HOLE IS NOT DIRECTED TOWARDS THE OPERATOR OR OTHER

PERSONNEL.

• Switch air supply OFF at ON/OFF Valve Assembly 62.

• Screw priming pump (07900-00700) into bleed screw port, utilising Bonded Seal 6.

• Actuate Priming Pump by pressing down and releasing several times until resistance is evident and the Head Piston starts to move

rearward.

ENSURE PUMP IS KEPT ‘SQUARE’ TO BLEED SCREW PORT DURING PRIMING OPERATION TO PREVENT BREAKAGE OF BLEED

NIPPLE ON PRIMING PUMP.

• Remove the Priming Pump, surplus oil will expel from bleed screw port.

• Replace the Bleed Screw 1 together with Bonded Seal 6.

• Switch ON air supply at ON/OFF Valve Asembly 62.

• Check that the stroke of the Head Piston reaches specification. If not repeat above procedure.

• Switch OFF air supply and refit nose equipment. (see pages 9 to 14).

Item numbers in bold refer to the general assembly drawing and parts list on pages 24 and 25.

English

Item numbers in bold refer to the general assembly drawing and parts list on pages 24 and 25.

SYMPTOM POSSIBLE CAUSE REMEDY PAGE REF

Other symptoms or failures should be reported to your local Avdel authorised distributor or repair centre.

Symptom Possible Cause Remedy Page Ref

Fault Diagnosis

More than one Air leak Tighten joints or replace components

operation of the Insufficient air pressure Adjust air pressure to within specification 5

trigger needed to Worn or broken jaws Fit new jaws 9 to 14

place fastener Low oil level or air in oil Prime tool 26, 27

Build up of dirt inside the nose assembly Service nose assembly 14

Tool will not grip Worn or broken jaws Fit new jaws 9 to 14

stem of fastener Build up of dirt inside the nose assembly Service nose assembly 14

Loose jaw housing Tighten against locking ring 8

Weak or broken spring in nose assembly Fit new spring 9 to 14

Incorrect component in nose assembly Identify and replace 9 to 14

Jaws will not release Build up of dirt inside the nose assembly Service nose assembly 9

broken stem of Jaw housing, nose tip or nose casing

fastener not properly seated Tighten nose assembly 9 to 14

Weak or broken spring in nose assembly Fit new spring 9 to 14

Air or oil leak Tighten joints or replace components

Low oil level or air present in oil Prime tool 26, 27

Cannot feed next Broken stems jammed inside tool Empty stem collector 7

fastener Check jaw spreader is correct 9 to 14

Adjust air pressure to within specification 5

Slow cycle Low air pressure Adjust air pressure to within specification 5

Build up of dirt inside the nose assembly Service nose assembly 14

Tool fails to operate No air pressure Connect and adjust to within specification 5

Damaged Trigger Valve 21 Replace 21

Fastener fails to break Insufficient air pressure Adjust air pressure to within specification 5

Fastener outside tool capability Use more powerful Genesis tool.

Contact Avdel

Low oil level or air present in oil Prime tool 26, 27

28

Notes

29

Notes

30

31

Declaration of Conformity

We, Avdel UK Limited, Watchmead Industrial Estate, Welwyn Garden City, Herts, AL7 1LY

declare under our sole responsibility that the product:

Model nG4

Serial No. ................................................

to which this declaration relates is in conformity with the following standards:

EN ISO 12100 - parts 1 & 2

BS EN ISO 8662 - part 6 BS EN ISO 11202

BS EN ISO 3744 BS EN 982

ISO EN 792 part 13 - 2000 BS EN 983

following the provisions of the Machine Directive 98/37/EC

This box contains a power tool which is in

conformity with Machines Directive

98/37/EC. The ‘Declaration of Conformity’ is

contained within.

A. Seewraj - Product Engineering Manager - Automation Tools

Date of issue

33

Règles de sécurité 34

Caractéristiques de l’outil

Caractéristiques de l'outil 35

Dimensions de l’outil 35

Utilisation prévue

Gamme de fixations 36

Numérotation des pièces 36

Mise en service

Alimentation pneumatique 37

Procédure d'utilisation - toutes fixations sauf

Avtainer®et Maxlok

®

37

Procédure d'utilisation - Avtainer®et Maxlok

®

38

Équipement

Sélection du nez 39

Instructions de montage - Tous équipements sauf

Avtainer®et Maxlok

®

39

Nez 40-43

Type 1 Standard 40

Nez Avseal

®

II 41

Type 2 Accès limité 42

Type 3 Aerospace 42

Type 6 Hemlok®/Interlock

®

42

Type 5 Avtainer

®

43

Maxlok

®

43

Instructions de montage pour les ensembles de nez

Maxlok®et Avtainer

®

44

Instructions d'entretien pour tous les ensembles de nez 44

Accessoires

Déflecteur de tiges 45

Préparation de l'outil de base en vue d'une utilisation 45

avec le déflecteur de tiges

Rallonge 45

Entretien de l’outil

Journalier / hebdomadaire 46

Graisse au bisulfure de Molybdène EP 3753 46

informations de sécurité

Informations de sécurité, graisse Molykote

®

55m 47

Informations de sécurité, graisse Molykote®111 47

Kit d’entretien 48

Entretien 48

Equipement de pose 48

Démontage de l'outil 49

Ensemble tête 49

Ensemble piston pneumatique 50

Soupape à air 50

Valve rotative 51

Gâchette 51

Ensemble plaque de butée (71213-03900) 52

Assemblage général de l’outil de base

Assemblage général 54

Liste de pièces 55

Plein d’huile

Huile recommandée 56

Informations de sécurité, huile Hyspin

®

VG 32 56

Kit de plein d’huile 56

Procédure de plein d’huile 57

Diagnostic des pannes

Symptôme, cause possible & remède 58

Avdel UK Limited poursuit une politique de développement et d'amélioration continue et se réserve le droit de modifier les caractéristiques de ses produits sans préavis.

GARANTIE LIMITEE.

Les termes de la garantie limitée Avdel confirment l'engagement de cette dernière vis-à-vis

de produits exempts de vices de fabrication et de matériaux et ce dans des conditions

d'utilisation normales. Cette garantie limitée tient compte des restrictions suivantes : (1) le

produit sera installé, entretenu et exploité conformément à la documentation et au mode

d'emploi y afférents et (2) Avdel aura confirmé le vice signalé après inspection et tests. La

garantie limitée Avdel susdite est valable douze (12) mois, à compter de la livraison du

produit par Avdel à l'acheteur direct du produit Avdel. Le renvoi des marchandises

défectueuses constitue le recours exclusif en cas de manquement à la garantie susdite ;

celles-ci seront remplacées ou remboursées au prix d'achat, la décision en la matière

appartenant à Avdel. LA GARANTIE LIMITEE EXPRESSE ET LE RECOURS SUSDITS SONT

EXCLUSIFS ET SE SUBSTITUENT A TOUS AUTRES GARANTIES ET RECOURS. AVDEL

DESAVOUE ET EXCLUT SPECIFIQUEMENT TOUTE GARANTIE IMPLICITE DE QUALITE,

D'APTITUDE A L'EMPLOI ET DE COMMERCIABILITE DU PRODUIT.

Sommaire Français

34

Règles de sécurité

1 Ne pas employer pour d'autres usages que celui prévu.

2 Ne pas utiliser avec cet outil / cette machine d'autres matériels que ceux recommandés et fournis par Avdel UK Limited.

3 Toute modification apportée par le client à l'outil ou à la machine, aux équipement, aux accessoires ou à tout autre matériel fourni par

Avdel UK Limited ou ses représentants relève de la seule et entière responsabilité du client. Avdel UK Limited donnera volontiers son avis

sur toute modification envisagée.

4 L'outil ou la machine doivent être maintenus en permanence en état de fonctionner sans danger et leur bon état et fonctionnement doivent être

vérifiés à intervalles réguliers par un personnel compétent et ayant reçu la formation adéquate. Toute opération de démontage ne doit être

entreprise que par des personnes formées aux procédures Avdel UK Limited. Ne pas démonter cet outil/cette machine avant d'avoir consulté

les instructions de maintenance. Prière de consulter Avdel UK Limited pour ce qui concerne vos besoins en formation.

5 L'outil ou la machine doivent à tout moment être utilisés conformément à la législation d'hygiène et de sécurité conforme aux règlements

du Ministère du Travail en application de l'article R233-69 du code du travail. Toute question relative à la bonne utilisation de l'outil ou de la

machine et à la sécurité de l'opérateur doit être adressée à Avdel UK Limited.

6 Il appartient au client d'expliquer à chaque opérateur les précautions à respecter lors de l'utilisation de l'outil ou de la machine.

7 Toujours débrancher le tuyau d'air du raccord d'arrivée de l'outil ou de la machine avant tout réglage, montage ou démontage d'un

ensemble de nez.

8 Ne pas actionner un outil/une machine orientés vers une/des personne(s) ou l’opérateur.

9 L’opérateur veillera à adopter une position équilibrée et stable avant d’utiliser l’outil/la machine.

10 S’assurer que les orifices de mise à l’atmosphère ne viennent pas à être obstrués ou masqués.

11 La pression de service ne doit pas dépasser 7 bars.

12 Ne pas utiliser l’outil si celui-ci n’est pas muni d’un équipement complet ou d’une tête pivotante, à moins d’une consigne contraire explicite.

13 L’on veillera à faire en sorte que les tiges usagées ne risquent pas de constituer un danger.

14 La fonction d’élimination de l’air DOIT être désactivée à l’aide de la gâchette avant d’ôter le vase récupérateur de tiges qui DOIT être vidé

lorsqu’il est à moitié plein.

15 L'outil NE DOIT PAS être utilisé lorsque le vase de récupération des tiges est enlevé.

16 Si l’outil nG4 est muni d’un déflecteur de tiges, l’on veillera à faire pivoter le déflecteur de manière à ce que l’ouverture soit tournée du

côté opposé à l’opérateur et, le cas échéant, à des personnes travaillant à proximité.

17 Lors de l'utilisation de l'outil, l'opérateur et les personnes se trouvant à proximité doivent impérativement porter des lunettes de sécurité

pour se protéger contre l'éjection des fixations en cas de pose ‘en l'air’. Nous recommandons le port de gants en cas de présence

d'arêtes ou d'angles vifs sur l'application.

18 Veiller à ne pas laisser des vêtements amples, cravates, cheveux longs, chiffons de nettoyage, etc. se prendre dans les parties mobiles

de l'outil. L'outil doit être maintenu sec et propre pour donner la meilleure prise.

19 Lors du transport de l'outil, éloigner les mains de la gâchette ou du levier pour éviter un déclenchement intempestif de l'outil.

20 Tout contact excessif avec de l’huile hydraulique doit être évité. Veiller à bien se laver pour éviter tout risque d’éruption cutanée.

21 Les données C.O.S.H.H. de sécurité et d'hygiène professionnelle se rapportant aux fluides hydrauliques et lubrifiants sont disponibles sur

demande auprès du fournisseur de l'outil.

Toute personne participant à l'installation, à l'utilisation ou à l'entretien de cet outil doit lire attentivement ce manuel.

Caractéristiques de l'outil

Spécifications

35

Pression pneumatique Minimum - Maximum 5 à 7 bars

Volume d’air libre nécessaire à 5,5 bars 4,3 litres (0,15 cu ft)

Course Minimum 17 mm

Force de traction à 5,5 bars 18,68 kN (4200 lbf)

Cycle de pose Approximativement 1,2 seconde

Niveau sonore 75 dB(A)

Poids Equipement de pose inclus 2.3 kg

Vibrations Inférieures à 2,5 m/s

2

Dimensions en millimètres

Dimensions de l’outil

Remarque: tiges à vase de

récupération : version courte est un

accssoire référence 71213-03810

Français

DÉTAIL DU RÉCUPÉRATEUR

DE TIGES VERSION COURTE

36

Utilisation prévue

Le nG4 est un outil oléo-pneumatique destiné à la

pose à cadence rapide de rivets à rupture de tige

Avdel

®

, qui convient parfaitement au travail en lots ou

en chaîne continue pour une grande diversité

d’applications dans tous les secteurs industriels. Les

fixations qu’il permet de poser sont indiquées cicontre.

L'outil comporte un dispositif à dépression qui sert à

maintenir la fixation et à récupérer facilement les tiges

brisées quelle que soit l'orientation de l'outil.

Un outil complet se compose de trois éléments

individuels fournis séparément. Voir le schéma

ci-dessous.

L'EQUIPEMENT DE POSE DOIT ETRE INSTALLE

CONFORMEMENT AUX INSTRUCTIONS DE LA

PAGE 39.

.

La référence de l’outil de base reste la même, quel que soit l’équipement ou le nez monté. Voir l’assemblage général pages

54 et 55.

La référence du nez correspond à une fixation particulière. En cas de difficulté d'accès,

il existe certains nez allongés. Voir le tableau de la page 42.

L’équipement universel permet de poser des fixations non aéronautiques en choisissant simplement le

modèle voulu dans la gamme de nez de type 1. Il existe d’autre équipements pour les applications à accès

limité et pour les fixations aéronautiques et spéciales. Voir le tableau de la page 42.

Gamme de fixations

Numérotation des pièces

* Pour l'équipement

3

/16(4,8) et 1/4(6,4) Lockbolt référez-vous à la fiche de

données séparée 07900-00795.

NOM DE LA

FIXATION

AVEX

STAVEX

AVINOX II

AVIBULB

BULBEX

T-LOK

AVDEL® SR

INTERLOCK

HEMLOK

MAXLOK

AVTAINER

AVDEL

MBC

MBC®/LC

AVSEAL

TM

RIVET

Q

TM

T

RIVET

CHERRYMATE

KLAMPTITE

KLAMPTITETMKTR

LOCKBOLT

*

4.3 4.8 5 5.2 6 6.4 6.5 7 8 9 9.5 10 11 12

–3/16 –––1/4 ––––3/8 – – –

®

®

®

®

®

®

®

®

®

®

®

®

®

II

TM

TM

. .

. .

.

. .

.

. .

. .

. .

. .

.

.

.

. .

. .

. .

. .

. .

. .

DIMENSION DE LA FIXATION ( )

.

. . . . . .

MM

Pouce

.

1

2

2

71210-15000

OUTIL DE BASE

1

71233-02000

3

3

ÉQUIPEMENT

NEZ

voir note 3

1

*AJOUTER LES 3 CHIFFRES

TROUVES DANS LA DERNIERE

COLONNE D'UN DES TABLEAUX

DE NEZ DES PAGES 40 OU 43.

2

++=

3

OUTIL COMPLET

71233-00 . . .

*

37

Tous les outils fonctionnent à l'air comprimé, à une pression optimale de 5,5 bars. Nous préconisons l'utilisation de régulateurs de pression

et de systèmes de filtration sur le circuit d'alimentation pneumatique. Ces appareils doivent être montés à 3 mètres au plus de l'outil (voir le

schéma ci-dessous) afin d'assurer à l'outil une durée de vie maximum et une maintenance minimum.

Les flexibles d'alimentation en air doivent être compatibles avec une pression de service active minimum équivalente à 150% de la pression

maximum produite par le système ou de 10 bars, selon la plus élevée de ces valeurs. Ces flexibles doivent résister à l'huile, avoir une paroi

extérieure résistant à l'abrasion, et ils doivent être armés si les conditions d'utilisation présentent un risque de détérioration. Tous les

flexibles d'air DOIVENT IMPERATIVEMENT avoir un diamètre intérieur minimum de 6,4 millimètres.

• Veiller à bien monter l’équipement ou la tête pivotante qui

conviennent à la fixation.

• Raccorder l’outil à l’alimentation pneumatique.

• Introduire la tige de la fixation dans le nez de l’outil. Dans le cas

d’un équipement, la fixation doit rester maintenue par le système à

dépression.

• Présenter sur l'application l'outil portant la fixation de telle sorte