AVANT 630, 635, 640 Operator's Manual

English

630/635/640

Operator’s Manual

2016-

Table of contents

600 Series

2

TABLE OF CONTENTS

Table of contents...............................................2

Introduction, warranty .....................................3

Safety instructions ........................................... 4

Description of the loader..................................7

Main parts of the loader..................................8

Signs and decals...............................................9

Technical specification...................................10

Load diagram ................................................12

Transporting instructions and tie down points .12

Operating instructions....................................13

Controls........................................................14

Control of loader boom, auxiliary

hydraulics and other functions ......................15

Attachment control switch pack...................15

Dashboard ....................................................16

Controls in the footwell................................16

Suspension seat.............................................17

Seat heater....................................................17

Battery disconnect switch.............................17

Telescopic boom...........................................17

Boom self levelling ........................................17

Boom floating................................................17

Smooth drive ................................................17

Joystick..........................................................18

Engine block heater ......................................18

Trailer coupling .............................................18

Hydraulic lifting device in the rear ................18

Extra counterweights....................................18

Drive release valve .......................................18

Anti slip valve ................................................18

Work light kit ................................................18

Headlight, beacon, blinker & reflector kit.....18

Tilt adapter ...................................................19

Extra auxiliary hydraulics outlets,

front and rear................................................19

Drive speed range selection switch (640).....19

Parking brake switch.....................................19

Snow chains ..................................................19

Light bar........................................................19

Starting the engine ........................................20

Stopping the engine ......................................20

Drive control ................................................21

Steering of the machine ................................22

Loader control ..............................................22

Using the auxiliary hydraulics........................22

Cabs ..............................................................23

Requirements for attachments......................24

Coupling the attachments.............................24

Hydraulic attachment coupling plate ............24

Coupling the hydraulic hoses of the attachment

......25

Service and maintenance instructions ...........26

Safety instructions for maintenance ..............26

Releasing the pressure of hydraulic system...26

Installing of service support and frame lock..27

Daily inspections ...........................................27

Maintenance schedule...................................27

Cleaning of the machine ...............................28

Greasing of the machine ...............................28

Battery check................................................28

Hydraulic oil level..........................................28

Changing of hydraulic oil filters.....................28

Hydraulic oil change......................................28

Check and tightening of bolts, nuts etc.........28

Check pressure of hydraulic system .............28

Adjust pressure of hydraulic system .............29

Adjust and change of slide pads on telescopic boom

29

Calibration of load sensor.............................30

Service, engine ..............................................30

Storage of the machine .................................30

Fuse box........................................................30

Jump start and auxiliary power .....................30

Safety instructions when handling the battery..30

Greasing points .............................................31

Refueling........................................................31

Light bulbs.....................................................31

Metal structures of the loader ......................31

Filters ............................................................32

Troubleshooting............................................33

Service history ..............................................34

EC Declaration of Conformity ........................35

Original instructions

Introduction, warranty

600 Series

3

Introduction

AVA NT TECNO OY wants to thank you for purchasing this AVANT loader. It is the result of Avants long

experience in design and manufacturing of compact loaders.

We ask you that you read and understand the contects of this manual completely before operating the loader.

This will improve your operating and maintenance efficiency, help avoid breakdowns and damage and extend

your machines life.

Contact your local AVANT dealer for any questions, service, spare parts or about any problems that may occur

with the operation of your machine.

Keep this Operators Manual with the machine at all times. If this Manual gets lost, ask for a new copy from

your Avant dealer. Remember also to give this Manual to the new owner when the machine changes ownership.

AVANT 600 series warranty

This warranty specifically applies to the AVANT 600 series loader only and not to any attachments used with

this product.

Any repairs or modifications performed without the prior authorisation of Avant Tecno Oy will cancel this

warranty.

During the first two years of operation or first 1000 hours (whichever is the soonest) Avant Tecno Oy warrants

to replace any part or repair any defect which may occur, subject to the terms detailed below:

1) The product has received regular maintenance in accordance with schedules given by the manufacturer.

2) Any damage caused by operation in a negligent manner or exceeding the approved specifications detailed

in this manual is excluded.

3) Avant Tecno Oy accepts no responsibility for interruption to working or any other consequential losses

resulting from any failure of the product.

4) Only Avant Tecno Oy approved replacement or original quality parts shall be used during routine maintenance.

5) Any damage caused by the use of incorrect fuel, lubricants, cooling liquid or cleaning solvents is excluded.

6) The Avant Warranty excludes any consumable parts (e.g. tyres, batteries, filters, belts etc.) except where

it can be clearly shown that these parts were defective on original supply.

7) Any damage caused resulting from the use of attachments not approved for use with this product is excluded.

8) In the event a fault occurs which is attributable to manufacturing or assembly defect you should arrange

to return your AVANT to your authorised dealer for repair. Travel and freight costs are excluded.

Intended use

AVANT 600 series loader is an articulated compact loader, designed and manufactured for both professional

and private use. The loader can be equipped with attachments offered by Avant Tecno Oy, which enables

doing of several different jobs. Because of this multi purpose nature of the machine and the various attachments

and tasks, read always not only this Manual but also the Operators Manual of the attachment, and follow all

instructions. Every person who has to do with this machine must follow work safety regulations, all other

generally accepted rules related to work health and safety, and all road traffic regulations.

Remember that safety consists of several factors. The loader, equipped with an attachment is very powerful

and can cause serious personal injuries or property damages if it is operated in a wrong or careless way. Do

not operate an attachment unless you have familiarised yourself with the use of it and the eventual dangers

related to it.

These operating instructions are intended to help to:

operate this machine safely and efficiently

observe and prevent situations that may cause a risk or danger

keep the machine in good condition and its life span as long as possible

This loader has been designed to require as little maintenance as possible. The operator can perform the most

common maintenance operations. There are however more demanding service operations that can be done

by professional service personnel only. It is allowed to perform service operations only when wearing appropriate

protective equipment. Original spare parts must be used. Familiarise yourself with the service and maintenance

instructions in this Manual.

Contact your local AVANT dealer, if you are uncertain of anything concerning the operation and maintenance

of this loader, or for any questions, service or spare parts.

Safety first

Following symbols are used throughout this Manual

to point out important things related to safety:

This safety symbol indicates important

safety instructions in this Manual. It warns

of an immediate hazardous situation that

can cause serious personal injuries or

property damages. Read carefully the

warning text next to this symbol and

make sure that all other operators are

aware of the warnings as well. It is a

question of safety of persons.

This attention symbol indicates important

instructions concerning correct use and

maintenance of this machine. If these

instructions are not followed, the

consequence can be breakdown of the

machine or property damage.

An incorrect or careless operation of the

loader may be the origin of a serious accident.

Before putting the machine into operation,

familiarise yourself with the use of the machine

and read and understand this Operators

Manual as well as the safety instructions.

Understand the limitations of speed, braking, steering

and stability as well as loading capacity of the machine

before starting operation. Make sure that every one

who operates or works with this equipment is familiar

with these safety precautions.

If you have no previous experience of the machine,

make sure to do all testing at a safe and open place

with no persons in the area of operation.

Read this Operators Manual, and also the

Operators Manual of the attachment(s) and

other safety instructions before starting operation.

General instructions

1. Remember the correct working position. When

driving be comfortably seated in the driver's seat,

fasten seat belt and keep it fastened always when

driving and working with the machine, keep your

feet in their proper place in the footwell and at

least one hand on the steering wheel.

2. Start the operation slowly and carefully. Practice

driving of the machine at a safe and open place

before connecting any attachment, follow the

instructions in this Manual.

3. Operate the control levers with ease and without

hesitation. Avoid abrupt movements when handling

the load, in order to prevent the load from falling

and to keep the machine stable.

4. Keep away from the danger zone of the lifted

boom and dont let anyone go there.

5. Keep your hands, feet and clothing away from all

moving parts, hydraulic components and hot surfaces.

6. Make sure that there is enough open space around

the machine for safe driving.

7. Do not transport the load with the boom lifted.

Always carry bucket or attachment as low as

possible, and put the load down whenever you

leave the machine.

8. Before leaving drivers seat:

Lower the loader boom and place attachment

flat on ground

Engage the parking brake

Stop the engine, remove the ignition key

9. It is not allowed to transport persons with this

machine. Do not transport or lift persons in the

bucket or in any other attachment. Lifting of persons

is only allowed with the attachment designed for

this purpose: Avant Leguan 50, following the

instructions in the Operators Manual of Leguan 50.

10. Do not exceed rated operating capacity. Familiarise

yourself with and follow the load diagrams in this

Manual.

11. When turning with the machine, remember that

the driver´s seat extends beyond the turning

radius of the wheels (collision risk).

12. Do not operate the loader in an explosive

environment or in a place where dust or/and gases

can create a fire or explosion hazard.

13. Keep the engine area clean of flammable materials.

14. Read the transportation instructions on page 12.

15. Switch off the battery disconnect switch during storage.

16. Follow all inspection, service and maintenance

instructions. If you notice any faults or damages

on the machine, these must be repaired before

starting operation.

17. Before any maintenance or repair operation always

stop the engine, lower the boom down and release

pressure from hydraulic system. Read safety

instructions for maintenance on page 26.

18. Do not let any person operate this loader who

has not read safety instructions and is not familiar

with the safe and correct use of this loader.

Operation on gradients

19. Load, unload, and turn on flat level ground only.

Drive slowly on uneven terrains. Do not drive on

too steep a gradient - watch out for ditches,

manholes and steep gradients.

20. Do not park the machine on a surface with a

gradient. Should this be necessary, engage the

parking brake and preferably turn the machine

sideways and put down the load. If needed, use

chocks behind the wheels.

Safety instructions

4

600 Series

Safety instructions

5

Handling of heavy loads and load sensor

The loader is equipped with a load sensor system. It

gives an audible warning signal and at the same time

an indicator lights in the dashboard when there is a risk

that the machine tips over its front axle. When the

system gives a warning signal the load that is being lifted

is too heavy in relation with the lift capacity of the

loader. In this case one has to either put more counterweights

on the loader or relieve the load that is being lifted.

When the load sensor starts to warn, there is

a risk that the machine tips over its front axle.

In this case stop lifting of the boom, retract

the telescopic boom and lower down the boom

slowly. When the load sensor is warning do

not steer the machine before the boom is

lowered down close to ground level. Lift the

boom only when the loader chassis is straight.

Keep the load as close to ground as possible.

Never take a heavy load on the loader from

high level e.g. from truck, shelf etc. risk

of tipping over!

Always put the load down on the ground before

leaving the machine. When loading, always

keep the loader chassis as straight as possible.

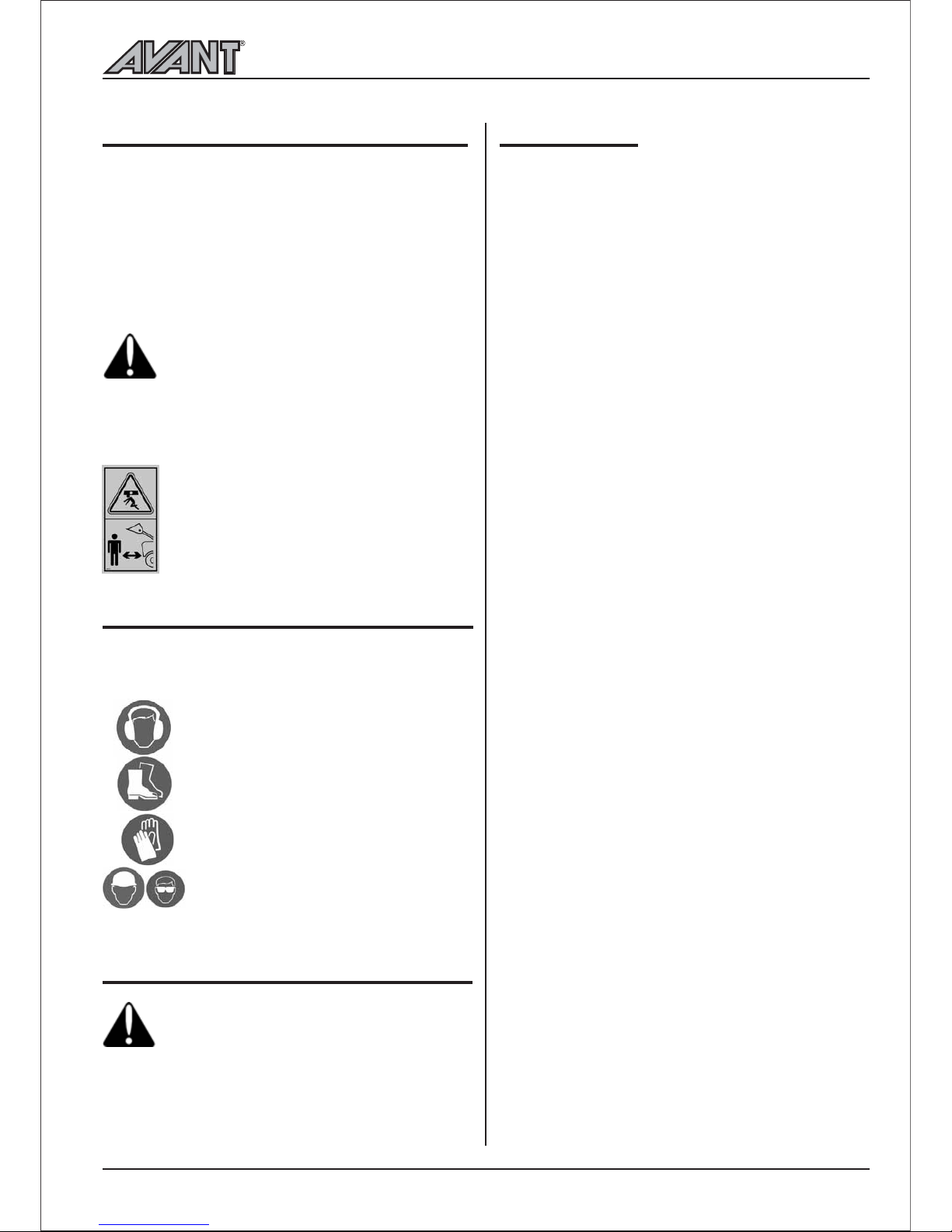

Personal safety and protective equipment

Wear safe clothing and personal protective equipment

(PPE). Protect yourself against work hazards like noise,

ejecting debris or dust for example.

Noise level at drivers seat can exceed

85 dB(A). Wear hearing protection

when working with the loader.

It is recommended to wear safety

footwear when working with the loader.

Wear protective gloves when handling

hydraulic hoses.

Follow regulations regarding

protective equipment. Wear eye

protection and hard hat or other

protective equipment as needed.

Read Operators Manual of the attachment for more information

about protective equipment needed in the work.

Safety frame (ROPS) and safety canopy (FOPS)

Safety frame (ROPS) protects the operator in

case the machine tips over. Always fasten the

seat belt in order to stay inside the safety frame

protective area. Never take off the safety frame.

The loader is also equipped with a falling objects

protective canopy (FOPS).

Electric system

Lead acid batteries can produce flammable and

explosive gases. Make sure that the ventilation is

sufficient and keep arcs, sparks, flames and lighted

tobacco away from battery.

Battery acid causes severe burns. In case of acid

contact, wash immediately with water for several

minutes and get medical attention in case of eye

contact.

Read the instructions for jump start on page 30.

Never charge a frozen battery.

600 Series

Safety instructions

6

600 Series

Description of the loader

600 Series

Description of the loader

7

Identification of the loader

Write down the identification information of your loader in the following

fields, it facilitates ordering of spare parts etc.

1. Loader model___

__________________________________________

2. Loader serial no.___________

________________________________

3. Engine serial no.___________________________________________

Serial number of the loader is printed on the type plate (see page 9),

which also indicates the loader model.

Location of engine serial number can be found in the Operators Manual

of the engine.

Dealer:____________________________________________________

Contact information:__________________________________________

__________________________________________

Multi connector

Pressure 2

Tank line

Pressure 1

Attachment

control switch

pack socket

(option)

l

j

k

m

n

o

p

q

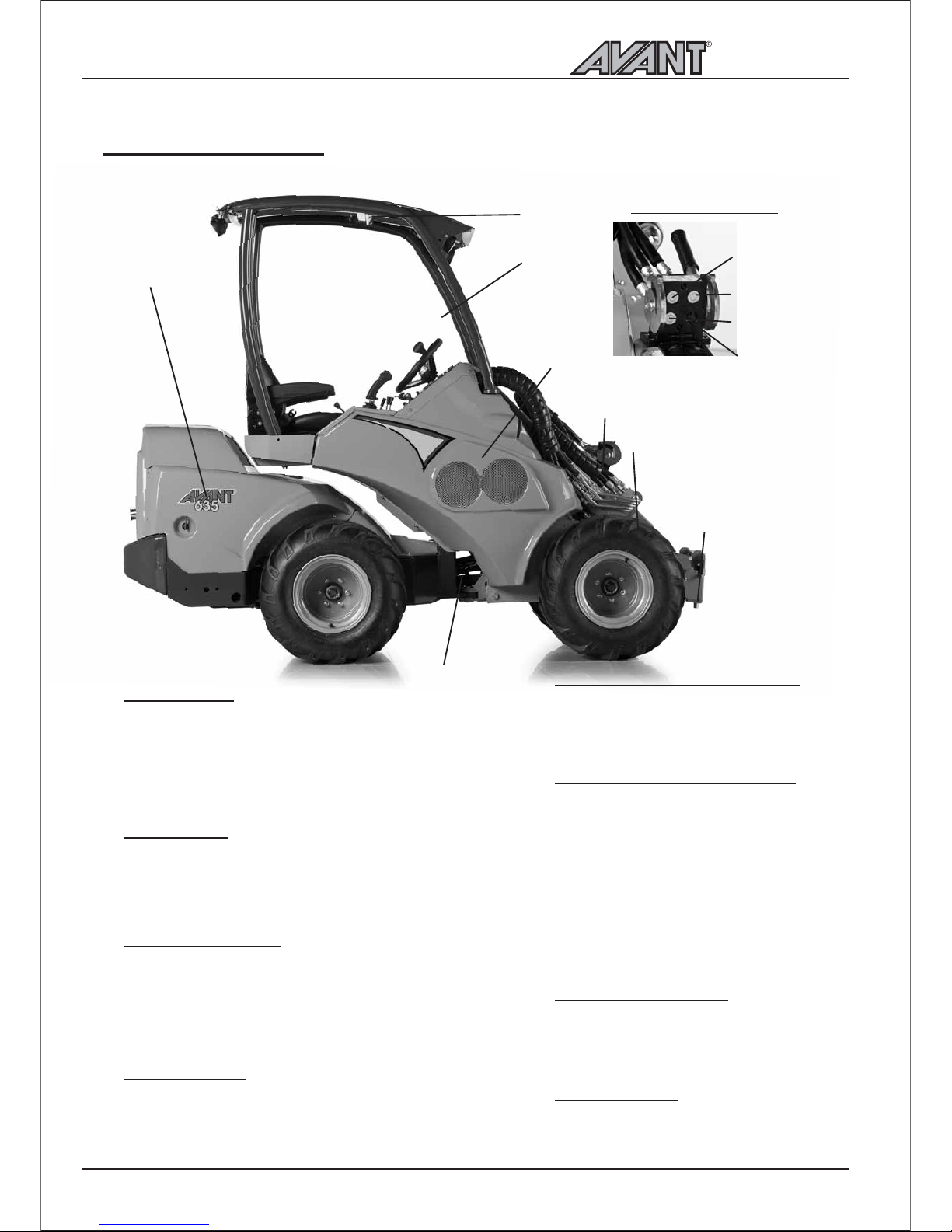

Main parts of the loader

Following picture shows the main parts of the loader:

l

j

k

m

Front frame

On the front frame are mounted: drivers seat,

operating controls, parking brake, hydraulic control

valves, hydraulic oil tank, auxiliary hydraulics outlet,

front wheels, hydraulic motors and the loader boom

with attachment coupling plate.

Back frame

On the back frame are mounted: engine with

accessories, battery, fuel tank, hydraulic pumps, rear

wheels, hydraulic motors.

Articulation joint

Articulation joint connects the front and back frame.

The loader is steered hydraulically by the steering

cylinder which is mounted between the front and

back frames. Hydraulic hoses and electric wires are

conducted through the articulation joint.

n

o

Attachment coupling plate

Attachments are mounted on the

attachment coupling plate. The locking pins

on the plate can be operated manually

(standard) or hydraulically (option).

Auxiliary hydraulics outlet

The hydraulic hoses of hydraulically operated

attachments are mounted on this outlet. The

outlet is equipped with the multi connector

quick coupling system and is double acting: it

has two pressure lines and one tank line. Also

the optional attachment control switch pack

socket is mounted on the multi connector. In

addition, as an option, it is also possible to install

a single or double acting auxiliary hydraulics

outlet in the rear of the machine, or a double

acting outlet in the front under the multi connector.

p

q

ROPS safety frame

ROPS frame (Roll-over protective structure)

complies with the standard ISO 3471:1994

with Amendment 1:1997 and Technical

Corrigendum 1:2000.

FOPS canopy

FOPS canopy (Falling objects protective

structure) mounts on the ROPS. It meets

the ISO 3449:1992 (1365 J) criteria.

Loader boom

The attachment coupling plate is mounted on the

lower end of the boom. The boom is telescopic,

extending 600 mm hydraulically.

Description of the loader

8

600 Series

l

A417273

m

r

A414690

A414664

n

o

p

q

A415591

l

p

q

j

k

m

n

o

r

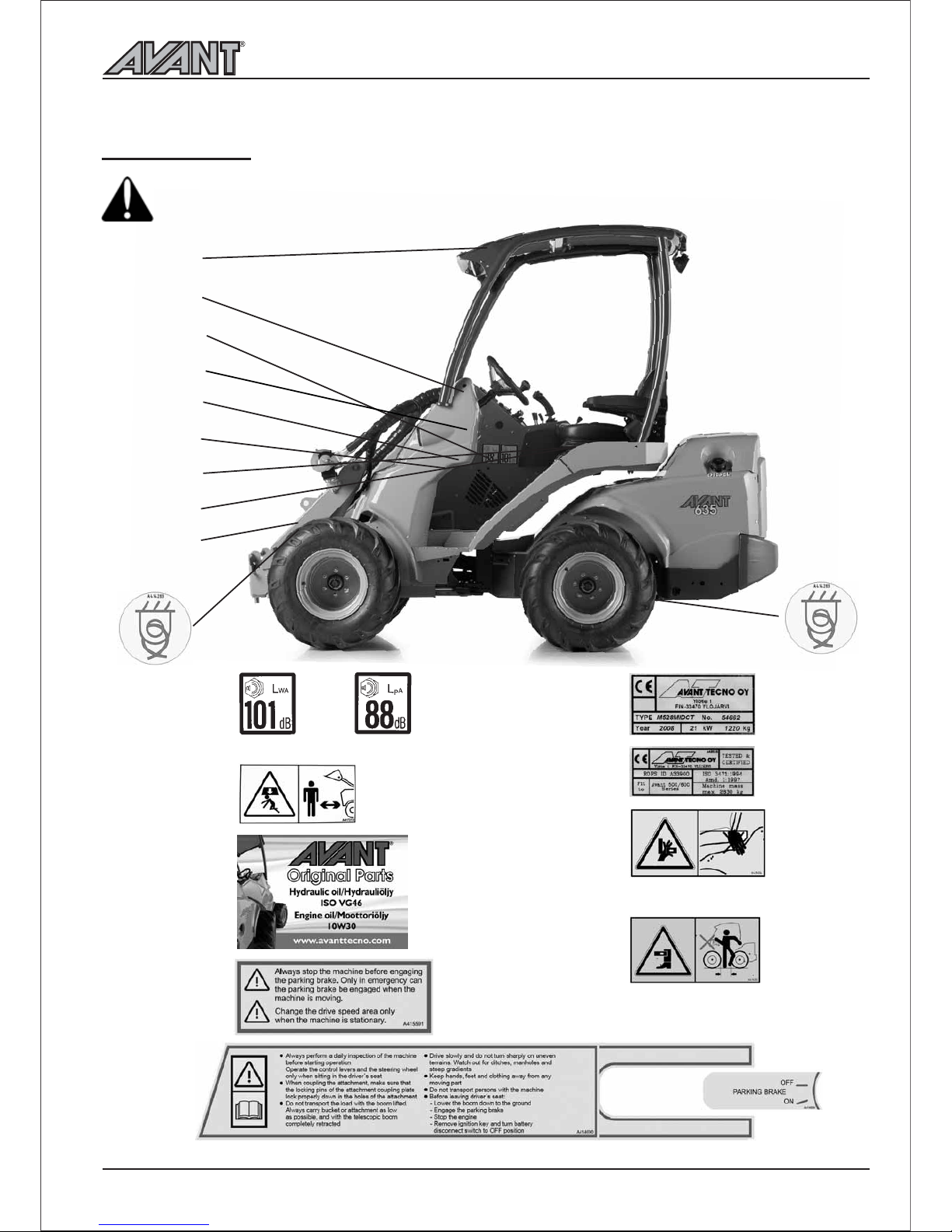

Signs and decals

Make sure that the following signs and decals clean, undamaged and readable. If any of these

decals is missing or is unreadable it should be replaced without delay. Ask for new decals

from your local Avant dealer.

j

k

600 Series

Description of the loader

9

Risk of crushing, keep hands and feet within

the drivers area

Risk of crushing, do not grip the steering

wheel from outside the machine or when

getting into the drivers seat.

Sound power level / Sound pressure level at drivers seat

Keep out from the danger zone of

the machine 2 pcs

A43600

A411047

A411456

A411455

Technical specification

Model

Engine make & type

Function

Cooling system

Number of cylinders

Starter

Bore * stroke

Displacement

Max. output (ISO Gross)

Fuel

Fuel tank capacity

Engine oil type

Engine oil capacity

Charging current max.

Battery

Tipping load, see diagram on page 11.

Tyr e

23x10.50-12

23x10.50-12

27 x 8.50-15

26x12.00-12

320/60-12

26,5x14.00-12

Tyre pressure

2,5 bar

2,5 bar

2,5 bar

2,0 bar

2,0 bar

2,0 bar

Part no.

65997 TR

65996 Grass

65414 TR

65739 TR

65212 Grass

65224 TR

65787 Grass *)

Machine width

1130 mm

1130 mm

1030 mm

1290 mm

1290 mm

1480 mm

AVANT 630

Kubota D 1105

4 stroke

water

3

electric

78,0 * 78,4 mm

1124 cm

³

19 kW (26 hp)

diesel

30 l

API CC SAE 10W-30

5,1 l

40 A

12V 60Ah

AVANT 635/640

Kubota V1505

4 stroke

water

4

electric

78,0 * 78,4 mm

1498 cm

³

28 kW (37,5 hp)

diesel

30 l

API CC SAE 10W-30

6,4 l

40 A

12V 60Ah

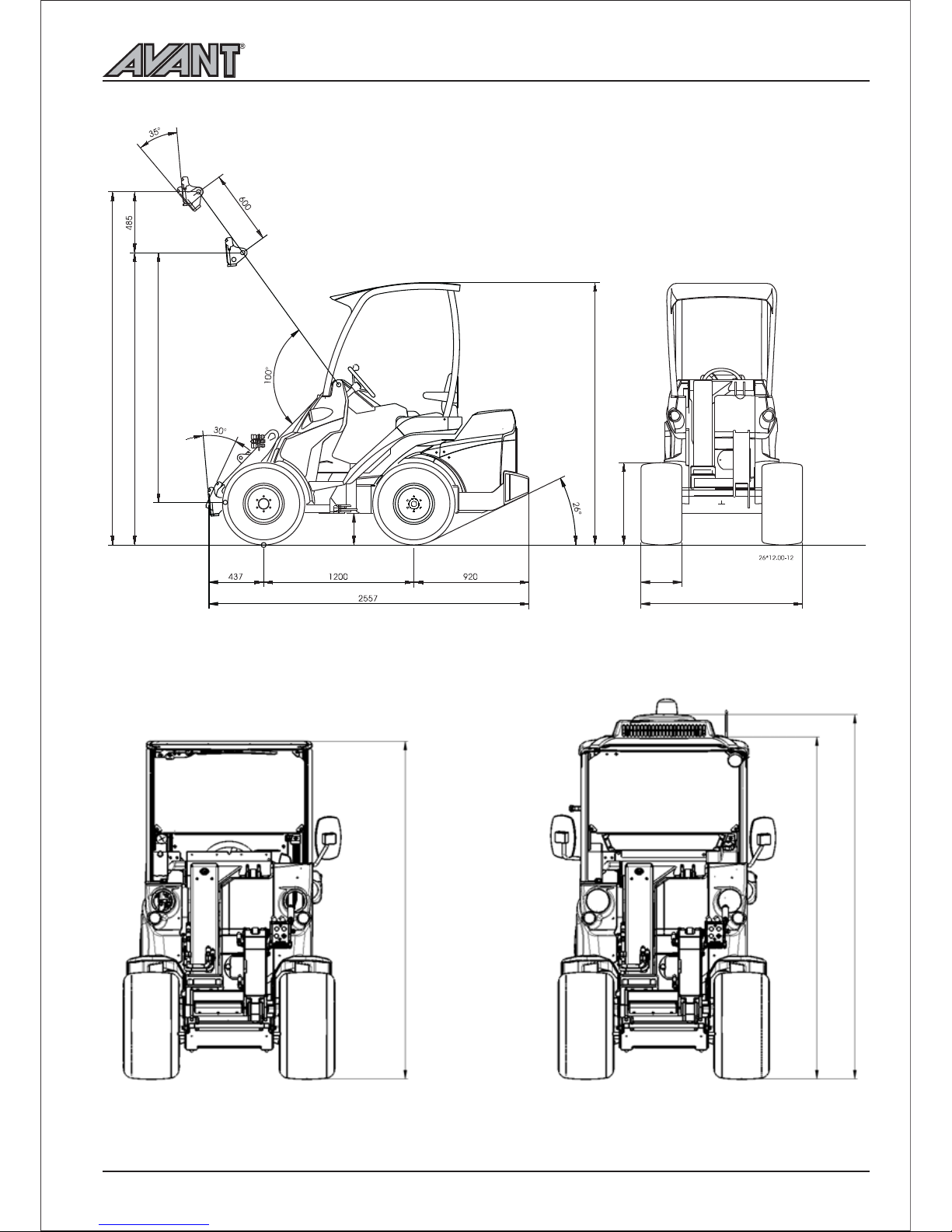

AVANT 630/635/640

2557 mm

1290 mm

2034 mm

252 mm

1500/1530/1590 kg

26x12.00-12 tractor/grass

0 - 22 km/h

hydrostatic

38 l

AVANT 630: 44 l/min 200 bar

AVANT 635/640: 66 l/min 200 bar

900 / 2190 mm

2835 mm

1180 -1390 daN

1400 kg

1250 kg

88 dB (A)

101 dB (A)

< 2,5 m/s

²

< 0,5 m/s

²

Model

Length

Width

(with 26x12.00-12 wheels)

Height

Ground clearance

Weight, starting from

Standard wheels

Drive speed (depending on model)

Transmission, drive

Hydraulic oil tank capacity

Auxiliary hydraulics

Turning radius inside/outside

Max. lifting height

Max. pulling force

(depending on model)

Max. lifting capacity (hydr.)

Max. breakout force / 50 cm

Sound power level 2000/14/EC Lp

Sound pressure level 2000/14/EC Lw

Hand-arm vibration, total

Whole-body vibration, max.

Description of the loader

10

600 Series

Auxiliary hydraulics oil flow

1 pump

2 pump

0

10

20

30

40

50

60

70

80

1500

1600

1700

1800

1900

2000

2100

2200

2300

2400

2500

2600

2700

2800

2900

3000

3100

3200

3300

rpm

l/min

Max. auxiliary hydraulics oil flow can not

be used with all attachments. Check correct

engine rpm and auxiliary hydraulics pump

configuration for the attachment with the

help of this table and Operators Manual of

the attachment.

1 pump

2 pump

Avant 635/640

Avant 630

*) Requires spacer kit A418958 on the machine

(4 pcs 40 mm spacers, 5-bolt, part. no A417486)

600 Series Description of the loader

11

2835

1995

2034

252

620

300

2350

1030-1480

LX Cab, 2056

DLX Cab, 2083

DLX Cab with A/C on the roof, 2219

Loading...

Loading...