AVANT 220, 225, 225LPG Operator's Manual

English

Operator's Manual

2016-

www.avanttecno.com

Avant 220/225 2017 1

2

TABLE OF CONTENTS

INTRODUCTION ....................................................... 3

Foreword ................................................................................... 3

Make sure all relevant manuals are available ..................... 4

Intended use .............................................................................. 5

Avant warranty ......................................................................... 7

SAFETY FIRST ............................................................ 8

General safety instructions .................................................... 8

Operation on uneven surfaces, gradients, and near

excavations ................................................................................ 11

Personal safety and protective equipment......................... 11

Electric system and handling the battery ........................... 13

Handling fuel (220/225) .......................................................... 14

LPG Fuel - Safety (225LPG) ................................................... 15

Safety of LPG systems ............................................................. 15

DESCRIPTION OF THE LOADER ............................ 17

Identification of the loader .................................................... 17

Main parts of the loader ......................................................... 18

Signs and decals ........................................................................ 19

Technical specifications .......................................................... 23

General specifications ............................................................. 24

Tyres............................................................................................ 25

Wheel spacers .......................................................................... 25

Wheel weights (optional extra) ........................................... 25

Fuel requirements .................................................................... 26

Engine oil requirements .......................................................... 27

Auxiliary hydraulics oil flow .................................................. 27

Tipping load ............................................................................... 28

CONTROLS OF THE LOADER ................................ 30

Parking brake lever .................................................................. 30

Dashboard .................................................................................. 31

Indicator lights .......................................................................... 31

Control of loader boom, auxiliary hydraulics and

other functions ......................................................................... 32

Engine compartment ............................................................... 34

Battery disconnect switch ...................................................... 34

Trailer coupling ......................................................................... 34

Rear auxiliary hydraulics outlet (option) ............................ 35

Engine heater (option) ............................................................ 35

Electric 12 V outlet .................................................................. 35

Seat - Seat belt and seat adjustments .................................. 36

Seat heater ................................................................................. 36

Lights ........................................................................................... 37

CAB L (optional extra) ........................................................... 38

OPERATING INSTRUCTIONS ................................. 39

Starting the engine ................................................................... 40

Ignition key ................................................................................. 40

Stopping the engine (Safe stopping procedure) ................ 41

Drive control ............................................................................. 42

In case the machine tips over ................................................ 44

Material handling ....................................................................... 45

Refuelling (220/225) ................................................................. 46

Replacing a gas bottle (225LPG) ........................................... 47

Transporting instructions and tie down points ................ 48

Storage ........................................................................................ 49

WORKING WITH ATTACHMENTS ........................ 51

Requirements for attachments ............................................. 51

Coupling the attachments ...................................................... 52

Coupling the hydraulic hoses of the attachment ............. 54

Using the auxiliary hydraulics ................................................ 55

Releasing the residual pressure of hydraulic systems ..... 56

SERVICE AND MAINTENANCE ............................... 57

Installing of service support and frame lock ...................... 59

Daily inspections ....................................................................... 60

Maintenance schedule ............................................................. 61

Loader maintenance ................................................................ 62

Engine maintenance ................................................................. 67

Engine service ............................................................................ 67

Fuel system, gasoline 220/225 ............................................... 70

Fuel system, 225LPG ............................................................... 71

Jump start and auxiliary power ............................................. 73

TROUBLESHOOT ...................................................... 74

SERVICES MADE ........................................................ 76

INDEX .......................................................................... 82

Original instructions

Avant 220/225

3

Introduction

Foreword

AVANT TECNO OY wants to thank you for purchasing this AVANT loader. It is the result of Avant’s long

experience in design and manufacturing of compact loaders. We ask you that you read and understand the

contents of this manual completely before operating the loader. This operator’s manual is intended to help you to:

operate this machine safely and efficiently

observe and prevent situations that may cause a risk of physical injury or danger

keep the machine in good condition and its life span as long as possible

The following warning symbols and signal words are used throughout this manual to indicate factors that must be

taken into account to reduce the risk of personal injury or damage to property:

WARNING:

This safety symbol refers to important safety information in this manual.

It warns of an immediate hazard that could cause serious personal

injury.

Read the warning text accompanying the symbol carefully and ensure

that other operators are also familiar with the warnings, since personal

safety is at stake.

DANGER:

This signal word indicates a hazardous situation which, if not avoided, will cause death or

serious injury.

WARNING:

This signal word indicates a potentially hazardous situation which, if not avoided, could

cause serious injury or death.

CAUTION:

This signal word is used when minor injury could result if the instructions are not followed

properly.

This signal word indicates information about the correct operation and maintenance

of the equipment.

Failure to observe the instructions accompanying the symbol can lead to equipment

breakdown or other property damage.

Avant 220/225

4

.

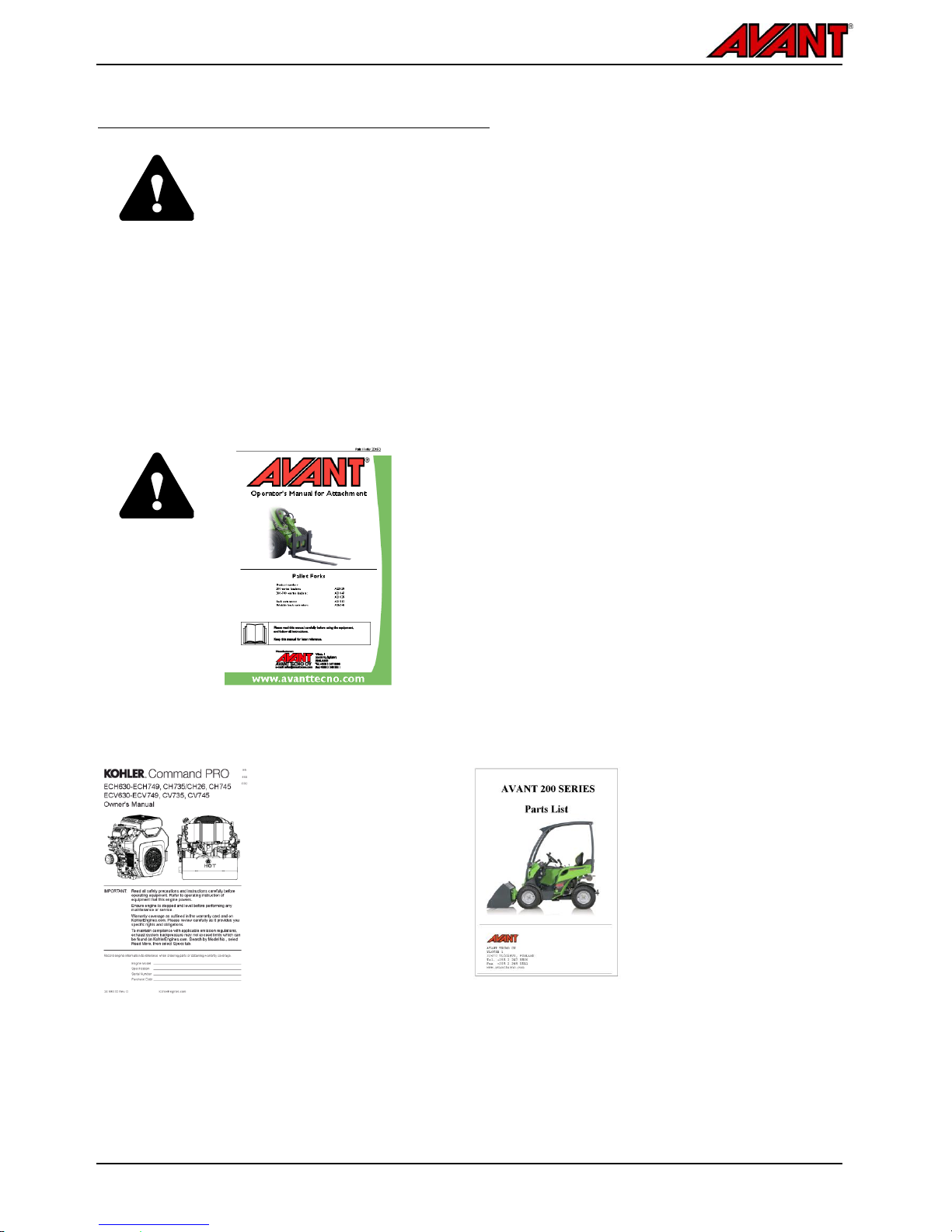

Make sure all relevant manuals are available

DANGER

Wrong use of the equipment can cause death or severe injuries - Make sure to read

all relevant manuals and instructions thoroughly and keep them available for all

operators.

Using each attachment requires specific information about correct use, mounting

procedure, safety, and how to avoid hazardous situations. An attachment may introduce

risks that are not present when operating the loader with other kinds of attachments.

Always read the operator's manual of each attachment carefully.

Manuals of attachments

DANGER

Attachments can create significant risks that are not

covered by this Operator's manual of the loader.

Make sure you have all attachments manual available.

Wrong use of an attachment can cause serious injuries or

death.

Each attachment is accompanied by its own respective

Operator’s Manual. The manual will show important

information related to safety, and how to attach, use, and

maintain each attachment correctly.

Engine manual

Spare parts list

In addition to this

Operator’s manual of

the loader, ensure that

you have received and

read also the original

Engine owner’s

manual.

The instructions

concerning the engine

must be followed. If

conflicting information

is found, the

information shown in

the Operator’s Manual

of the loader must be

followed.

All spare parts of the loader are

listed in a separate spare parts

list. Engine related parts are

listed in the spare parts list of

the engine.

Avant 220/225

5

.

Intended use

Avant 220/225/225LPG are articulated compact loaders, designed and manufactured for both private and

professional use. The loader can be equipped with attachments offered by Avant Tecno Oy, which enables

performing several different jobs. Because of this multi-purpose nature of the machine and the various

attachments and tasks, read always not only this Manual but also the Operator's Manual of the attachment, and

follow all instructions. Every person who has to do with this machine must follow work safety regulations, all other

generally accepted rules related to work health and safety, and all road traffic regulations.

Remember that safety consists of several factors. The loader, equipped with an attachment is very powerful and

can cause serious personal injuries or property damages if it is operated in a wrong or careless way. Do not

operate an attachment unless you have familiarised yourself with the use of it and the eventual dangers related to

it. The loader is not intended to lift or transport people or be used as a work platform. Different jobs require

different attachments, and it is not allowed to handle loads without any attachment fitted. The loader must not be

used in underground or tunneling work.

Contact your local AVANT dealer, if you are uncertain of anything concerning the operation and maintenance of

this loader, or for any questions, service or spare parts.

In addition to the safety instructions included in this manual, you must observe all occupational safety regulations,

local laws, and other regulations concerning the use of the equipment. Particularly the regulations concerning the

use of the equipment on public road areas must be observed. Contact your Avant dealer for more information

about local requirements before you operate the loader on road areas. The use of LPG equipment on road areas

may be restricted or regulated.

This loader has been designed to require as little maintenance as possible. The operator can perform the routine

maintenance tasks. There are however more demanding service operations that must be done by professional

service personnel only. It is allowed to perform service operations only when wearing appropriate protective

equipment. Original spare parts must be used. Familiarise yourself with the service and maintenance instructions

in this Manual. Operating a loader that is in poor condition, or that has received unauthorised modifications, can be

hazardous to the operator and bystanders.

Gas operated 225LPG

The gas evaporation capability of the LPG cylinder limits the lowest operating temperature. Engine performance

may decrease significantly at temperatures below 0ºC (32ºF) and engine may not run. Even though the LPG

engine runs cleaner and produces less harmful emissions than gasoline engines, it is not intended or suitable to

be used in enclosed spaces or areas with poor ventilation. See warnings in this manual.

The gasoline and LPG engines have fundamental differences between each other. In addition to fuel delivery

system differences include engine valves and other major parts. The gasoline engine of the 225 cannot be

converted to LPG engine. Any attempt to modify the engine can cause risk of fire, poor performance, short service

life, and will void all warranties.

Avant 220/225

6

.

Operator qualification

Only operators who have studied this manual, and all relevant attachment manuals, are allowed to use this loader.

Regardless of your possible previous experience with lawn-mowers, loaders, ATVs, or other equipment, it is

important that you learn the driving principle of this loader. Practise how to operate the loader and its attachments

safely at an open area before you use the loader near other persons.

You must be in good physical and mental condition with the ability to stay alert and to observe the surrounding

area. Never use the equipment while under influence of medication which could impair your abilities to operate the

equipment safely. Do not operate the loader if you are under the influence of alcohol or any other intoxicant during

the work shift.

Depending on operating area, you may also be required to read, understand and comply with all applicable

Employer, Industry and Governmental rules, standards and regulations.

You can replace an empty gas bottle with a full one by yourself with the instructions shown in this manual. Any

other gas related service or repair, such as replacing a hose or a fitting, must be left to qualified service personnel.

Gas related service tasks may require a registered professional.

Versions of this manual

Avant has a policy on continuous product development. Updated versions of the manual replace the previous

versions of this manual as long as the year on the cover page matches with the original manual. You can ask for

the latest manual from your dealer. Some of the features or technical details presented in this manual may change

without notice. The pictures in this manual may show optional equipment or features that are not currently

available in your market area. We reserve the right to change the contents of the manual without notification.

Keep this Operators Manual with the machine at all times. If this Manual gets lost, ask for

a new copy from your Avant dealer. Remember also to give this Manual to the new owner

when the machine changes ownership.

Avant 220/225

7

.

Avant warranty

This warranty specifically applies to the Avant 220/225/225LPG loader only and not to any attachments used with

this product. Any repairs or modifications performed without the prior authorisation of Avant Tecno Oy will cancel

this warranty. During the first two years of operation or first 500 hours (whichever is the soonest) Avant Tecno Oy

warrants to replace any part or repair any defect which may occur, subject to the terms detailed below:

1. The product has received regular maintenance in accordance with schedules given by the manufacturer.

2. Any damage caused by operation in a negligent manner or exceeding the approved specifications detailed in

this manual is excluded.

3. Avant Tecno Oy accepts no responsibility for interruption to working or any other consequential losses

resulting from any failure of the product.

4. Only Avant Tecno Oy approved replacement or original quality parts shall be used during routine

maintenance.

5. Any damage caused by the use of incorrect fuel, lubricants, cooling liquid or cleaning solvents is excluded.

6. The Avant Warranty excludes any consumable parts (e.g. tyres, batteries, filters, belts etc.) except where it

can be clearly shown that these parts were defective on original supply.

7. Any damage caused resulting from the use of attachments not approved for use with this product is

excluded.

8. In the event a fault occurs which is attributable to manufacturing or assembly defect you should arrange to

return your AVANT to your authorised dealer for repair. Travel and freight costs are excluded.

.

..

Avant 220/225

8

Safety First

DANGER

Incorrect or careless operation of the loader may cause a serious accident. Before putting

the machine into operation, familiarise yourself with the use of the machine and read and

understand this Operator's Manual, as well as all relevant safety instructions, local

regulations, and safe working practices.

Understand the limitations of speed, braking, steering and stability as well as loading

capacity of the machine before starting operation. Make sure that everyone who operates

or works with this equipment is familiar with these safety precautions.

If you have no previous experience of the machine, make sure to do all testing at a safe

and open place with no persons in the area of operation.

General safety instructions

1. Remember the correct working position. When

driving, be comfortably seated in the driver´s

seat, keep your feet in their proper place in the

footwell and at least one hand on the steering

wheel.

2. When seated, always keep the seat belt

fastened and keep hands and feet inside the

operator’s area.

3. Before leaving driver’s seat, always:

Lower the loader boom and place attachment

flat on ground

Engage the parking brake

Stop the engine, remove the ignition key

4. Start the operation slowly and carefully.

Practise driving of the machine at a safe and

open place before connecting any attachment,

and follow the instructions in this Manual and

also the operator's manual of the attachment.

5. Operate the control levers with careful and

deliberate movements. Avoid abrupt

movements when handling the load, in order to

prevent the load from falling and to keep the

machine stable.

6. Keep away from the danger zone of the lifted

boom and don’t let anyone go there.

7. Keep your hands, feet and clothing away from

all moving parts, hydraulic components, and

hot surfaces.

8. Make sure that there is enough open space

around the machine for safe driving.

9. Do not transport the load with the boom lifted.

Always carry bucket or attachment as low as

possible, and put the load down whenever you

leave the machine.

10. It is not allowed to transport persons with this

machine. Do not transport or lift persons in the

bucket or in any other attachment.

11. Do not exceed the tipping load. Familiarise

yourself with and follow the load diagrams in

this Manual.

12. When turning with the machine, remember that

the driver´s seat extends beyond the turning

radius of the wheels (collision risk).

13. Do not operate the loader in an explosive

environment or in a place where dust or/and

gases can create a fire or explosion hazard.

14. Keep the engine area clean of flammable

materials.

15. Read the lifting, towing and transportation

instructions on page 48.

16. Switch off the battery disconnect switch

whenever leaving the machine unattended.

17. Follow all inspection, service and maintenance

instructions. If you notice any faults or

damages on the machine, these must be

repaired before starting operation.

18. Before any maintenance or repair operation

always stop the engine, lower the boom down

and release pressure from hydraulic system.

Read safety instructions for maintenance on

page 57.

Avant 220/225

9

19. Do not let any person operate this loader who

has not read safety instructions and is not

familiar with the safe and correct use of this

loader.

20. Never operate the loader or attachments while

under the influence of alcohol, drugs,

medication that may impair judgement or

cause drowsiness, or if not otherwise medically

fit to operate the equipment.

.

..

Suffocation hazard - Ensure ventilation

DANGER

Make sure that ventilation is

sufficient in the working area, even

when using a loader equipped with

an LPG engine. Using a loader in

poorly ventilated areas can cause

loss of consciousness and death

as carbon monoxide (CO) and

carbon dioxide (CO2) can be at

dangerous level within minutes.

Never operate the loader indoors or in partly

enclosed areas unless you've made sure there is

special ventilation system installed. Even LPG

engines are not safe to operate in enclosed or poorly

ventilated indoor areas. They produce carbon dioxide

(CO2) and can also emit carbon monoxide (CO)

under some conditions that can concentrate quickly

to a dangerous level. Never leave the engine

running in garages or sheds. Operate the loader

only outdoors and far from windows, doors, and

vents.

Elevated level of carbon dioxide or carbon monoxide

in breathing air can not be noticed without dedicated

measuring equipment. Signs of carbon monoxide

poisoning include nausea, headache, dizziness,

drowsiness, and lack of consciousness.

Get fresh air if anyone shows signs of carbon

monoxide poisoning and see a doctor.

.

..

Articulated frame - Risk of overturning

WARNING

Turning articulated frame can lead

to overturning of the loader on

inclined terrain or when driving at

high speed. Never turn frame

towards the slope while operating

on inclined ground.

Always drive slowly when carrying

load or when turning with the

machine.

.

..

Sudden movements can tip the machine over Risk of overturning

WARNING

Movements, such as stopping,

turning, or lowering the boom

abruptly, can cause loss of

stability. Always drive slowly and

operate the controls of the loader

very carefully, especially when

handling heavy loads.

.

..

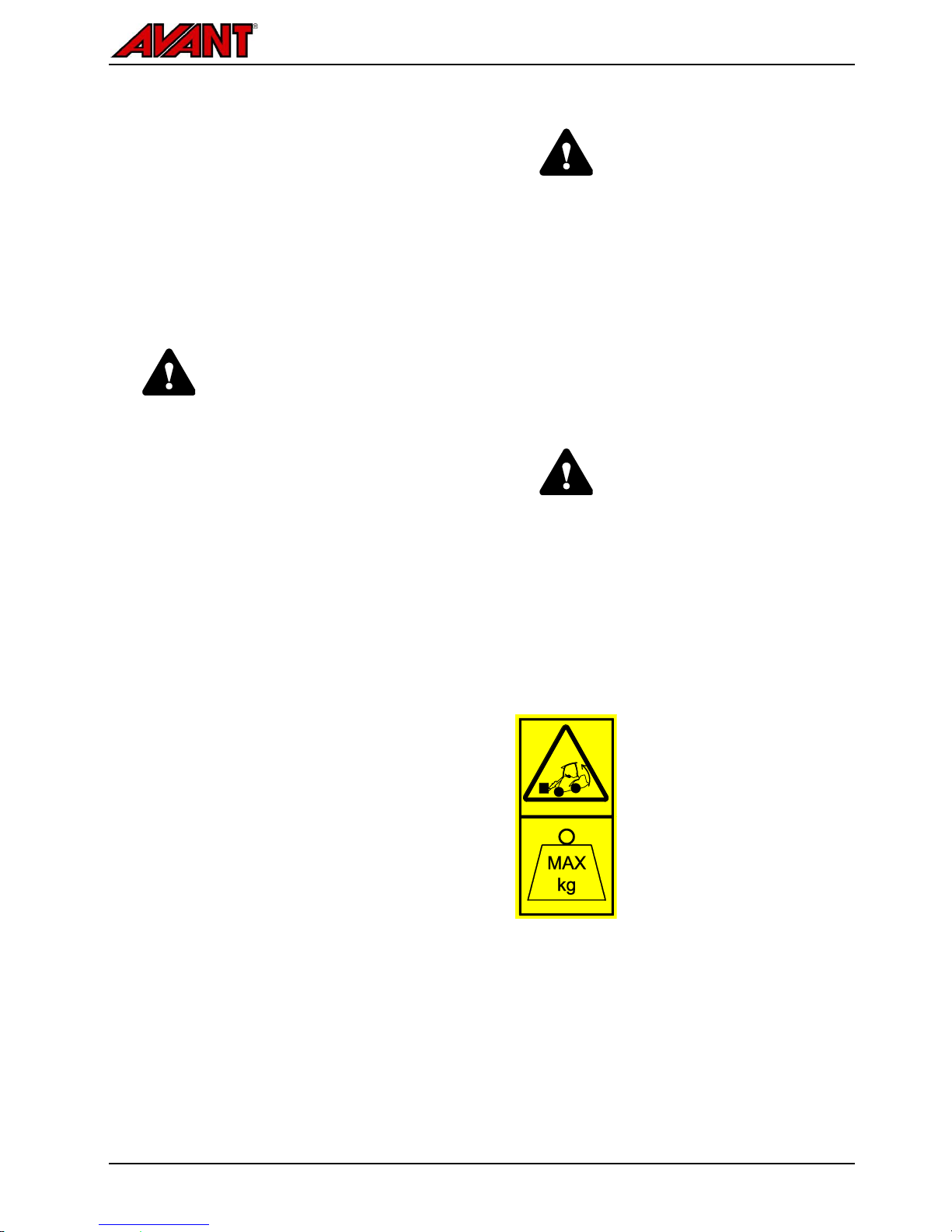

Overload - Risk of overturning

CAUTION

The high lift capacity of the loader

makes it possible to exceed the

stability of the loader when

handling loads. Read the

instructions regarding maximum lift

capacity and load handling in this

Operator's Manual. Following the

instructions reduces the risk of

tipping the machine over its front

axle, but the operator must be

aware of the limits of the machine

and follow safe working practises

to avoid overturning of the

machine.

.

..

Avant 220/225

10

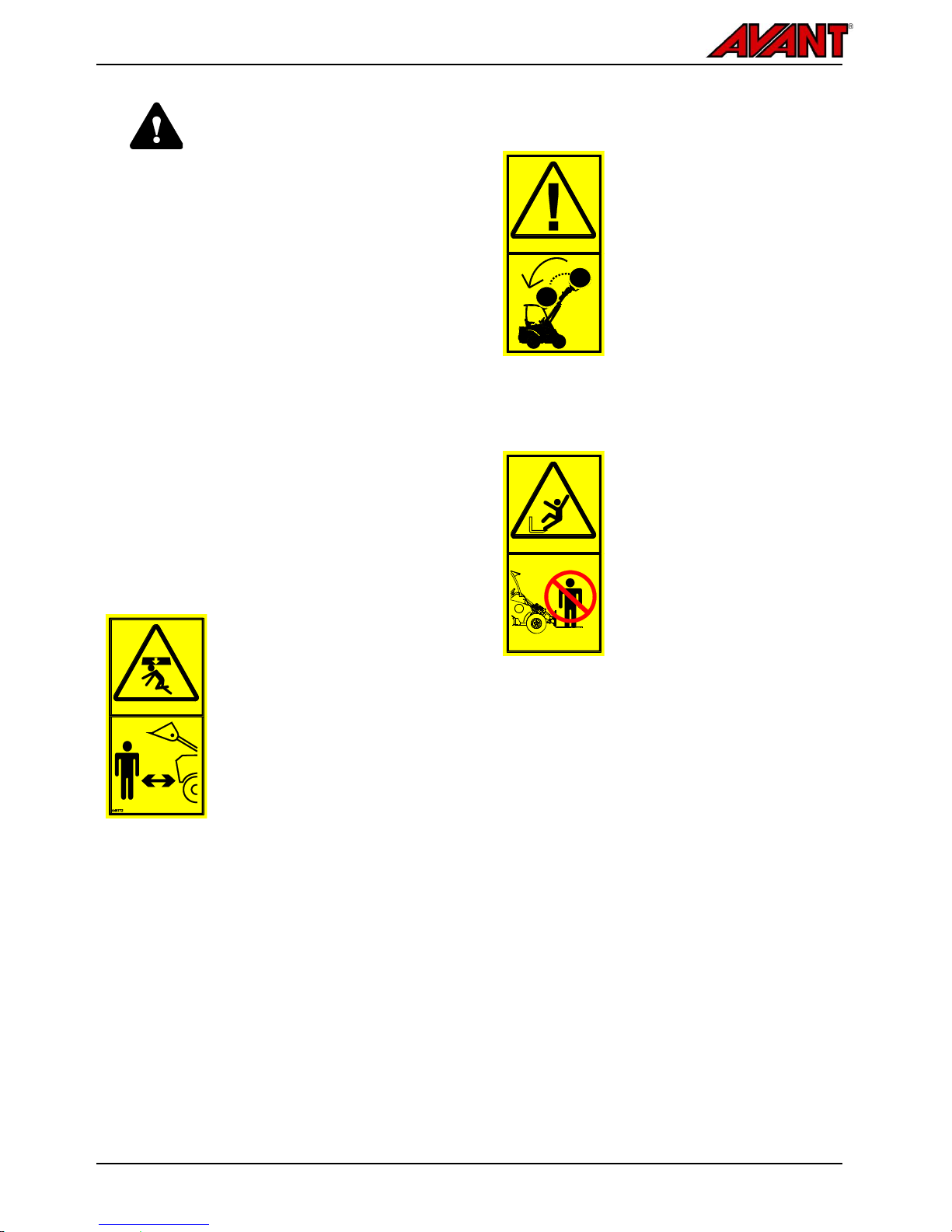

WARNING

Never take a heavy load on the

loader from high level – e.g. from

truck, shelf etc. – risk of tipping

over!

If the load is too heavy when lifting

load from a high level, the loader

could tip forward when reversing

with the loader.

Never reverse and drag with the

loader before you make sure that

the loader can handle the load that

is being lifted.

When loading, always keep the

loader frame as straight as

possible.

.

..

Falling of load or unexpected lowering of loader

boom - Risk of crushing

WARNING

Always remember that the boom

may lower unexpectedly due to

loss of stability, mechanical fault,

or if another person operates the

controls of the loader, leading to

crushing hazard. The attachment

or the loader are not intended to be

left to keep a load elevated for

longer periods. Lower the

attachment before leaving the

driver's seat. The stability of the

loader may change when leaving

the driver’s seat, leading to tipping

over of the machine.

.

..

Risk of falling objects

WARNING

Make sure load is securely on the

attachment. Never tilt the

attachment back when it is lifted

high. Operate only with machines

equipped with ROPS and FOPS

structures.

.

..

Falling of persons - Risk of crushing

WARNING

Never use the loader or its

attachments to lift persons or as

any kind of work platform even

temporarily. Never climb on the

loader or on the attachment.

Seating capacity: one person only.

.

..

Avant 220/225

11

Operation on uneven surfaces,

gradients, and near excavations

Extra caution is needed when using the equipment

on inclined terrains and slopes. Drive slowly

especially on inclined, uneven, or slippery surfaces,

and avoid sudden changes in speed or direction.

Operate the controls of the loader with careful and

smooth movements. Watch out for ditches, holes on

the ground, and other obstacles, as hitting an

obstacle may cause the loader to tip over.

Overturning of machine can lead to death or

serious injury

WARNING

The stability and the load handling

capacity of the loader are

significantly reduced on inclined

terrains and maximum lifting

capacity can be achieved only on

firm, level ground. On horizontally

tilted terrain the load must be kept

close to the ground and must

never be lifted high.

.

..

Handle heavy loads only on even surfaces.

Drive very slowly on uneven terrains. Load,

unload, and turn the machine on flat level ground

only. Lifting a load or turning on uneven surfaces

can lead to loss of stability.

Do not drive on too steep a gradient - watch out

for ditches, manholes and steep gradients, which

may cause the loader to tip over.

Never drive along an excavation. Note that the

excavation or trench may suddenly cave in.

Exercise extreme caution when driving near

ditches or embankments, and avoid driving along

a ditch or trench, as the machine could suddenly

tip over if an edge caves in. Avoid driving along

trenches and keep at least a distance equal to

width of a trench.

Do not park the machine on a surface with a

gradient. Should this be necessary, engage the

parking brake and preferably turn the machine

sideways and put down the load. If needed, use

chocks behind the wheels.

Personal safety and protective

equipment

Wear safe clothing and personal protective

equipment.

Protect yourself against work hazards like noise,

ejecting debris or dust for example.

Follow regulations regarding protective

equipment. Wear eye protection and hard hat or

other protective equipment as needed.

Read Operator's Manual of the attachment for

more information about protective equipment

needed in the work.

The noise level at the driver's

seat may exceed 85 dB(A).

Wear hearing protection while

working with the loader.

Wear protective gloves.

Wear safety boots whenever

working with the loader.

Wear safety glasses when

handling hydraulic components.

Always fasten seat belt while

operating the machine.

When working at construction

sites, a safety helmet is

recommended and may be

mandatory in addition to the

falling objects protective

structure (FOPS) on the loader.

Depending on work and working

area, also a respirator mask may

be required. Find out about other

necessary safety equipment at

your specific work site.

Avant 220/225

12

CAUTION

Silica dust warning. Prolonged

exposure to crystalline silica can

cause a lung disease called

silicosis. Occupational health and

safety officials recommend limiting

exposure to dust that is present at

most earth-moving and many other

work sites. Avoid spreading of dust

where possible, keep loader cabin

clean from dust, use respiration

mask when necessary.

Safety frame (ROPS) and safety

canopy (FOPS)

The loader is equipped with a Rolling Over Protective

Structure (ROPS) and a Falling Object Protective

structure (FOPS). These safety structures are

important parts of operator safety, and they must be

fitted on the machine.

Safety frame (ROPS) protects the operator in case

the machine tips over. Fasten seat belt while

operating a machine with a ROPS. All cab versions

are ROPS & FOPS tested and certified.

Crushing hazard - Always keep safety structures

installed

WARNING

Never take off the safety

structures, modify them, or attempt

to repair. If damaged, contact

service.

Always fasten the seat belt in order

to stay inside the protected area of

the safety frame.

Modifications

Any modification to this machine must be approved

beforehand by an authorised Avant representative. If

you modify the loader or attachment, it can become

dangerous and cause serious injuries or even death.

Unauthorised modifications can increase the risk of

accidents and damage or shorten the service life of

the machine. Modifications to engine can make it no

longer compliant with emission regulations. Use only

original spare parts to make sure that the product is

kept in safe operating condition.

Avant 220/225

13

.

Electric system and handling the battery

Always handle the battery with care. Follow the

safety instructions given below. The battery of the 12

v electric system of the loader is located under a

cover plate under the floor of the loader. See page

63 for more information about battery and

maintenance instructions.

WARNING

Short-circuit of the battery can

create fire or explosion. Disconnect

the battery with the battery

disconnect switch before working

on the engine or equipment. Never

lay metal objects on the battery.

WARNING

Battery acid can cause severe skin

burns. Handle damaged battery

with extreme care and wear

appropriate safety gloves and

clothing. Battery is a sealed type

battery, meaning that you should

never attempt to open the battery.

WARNING

Lead acid batteries produce

flammable and explosive gases

during charging. Make sure that

ventilation is sufficient when

charging the battery. Keep arcs,

sparks, flames, and lighted

tobacco away from battery.

Never charge a frozen battery. A

frozen battery can explode during

charging.

CAUTION

Battery and its terminals contain

lead, a harmful substance which

should not be handled more than

what is necessary. Wash hands

with soap and water after handling

the battery.

Battery contains corrosive sulphuric acid which

causes serious burns upon skin contact. Avoid

contact with skin or clothes. If electrolyte gets on

your skin or clothes, flush with a lot of water. In

case of contact with eyes, flush with a lot of

water for at least 15 minutes and see a doctor

immediately.

In order to avoid spark emissions, always

disconnect the negative (-) cable first and

connect it last.

Before connecting the battery cables make sure

that the polarity is correct: Faulty connection will

seriously damage the electric system of the

engine and may cause sparks, fire, or explosion

of the battery.

If fuse is blown repeatedly, find out the cause.

Always use fuses with correct rating.

Read the instructions for jump start, see page

72

Avant 220/225

14

Working near powerlines

Digging may expose buried electric cables, and

some attachments may make it possible to reach

overhead powerlines with the loader, creating hazard

of electric shock and electrocution.

Plan work ahead and take necessary safety

precautions.

Stay away from electric cables - Electrocution

hazard

DANGER

Electric shock hazard - Contact

with or working too close to electric

wires can result in lethal electric

shock. Keep the loader and any

attachment at a sufficient distance

from all electric cables, see table

below.

Table 1 - Safety distance from powerlines

Voltage level

Safety distance

0 - 1000 V

2 m

1 - 45 kV

3 m

110 kV

4 m

220 kV -

5 m

Unknown voltage

5 m

If electric cables are exposed during digging, or in

case of inadvertent contact or proximity with live

electric source:

Do not leave the loader until the electricity has

been disconnected by qualified technicians,

usually local electric company.

If absolutely necessary, jump out from the

loader, keeping feet next to each other, until at a

safe distance.

Warn others not to approach the loader until safe

to do so.

Handling fuel (220/225)

Refuel with correct type of fuel specified in this

manual, and follow refuelling instructions on page

46. Store fuel carefully in an approved container

away from heat and sources of ignition.

Always have correct type of fuel tank cap fitted and

avoid spilling of fuel.

Risk of fire or explosion - Handle fuel with care

DANGER

Always stop the engine and allow it

to cool before refuelling.

Refuel only in a well ventilated area.

Do not overfill the fuel tank. Leave at

least 50 mm below the neck of the

fuel tank to avoid spilling of fuel.

Avoid spilling fuel when refuelling.

Should this happen, wipe the fuel

away immediately in order to avoid

risk of fire.

Keep fuel away from sources of

ignition. Do not smoke during

refuelling.

Avant 220/225

15

LPG Fuel - Safety (225LPG)

Liquefied Petroleum Gas is extremely flammable and

is heavier than air and tends to settle in low areas

where a spark or flame could ignite gas.

Do not start or operate this engine in a poorly

ventilated area where leaking gas could accumulate

and endanger safety of persons in area.

Handle the LPG equipment with care and stop the

use of the loader immediately if you think that it may

be damaged. Contact authorised service to sort out

the problem.

See storage instructions on page 49.

Fuel can explode or burn, risk of severe burns and

personal injury - No smoking or open flames near

fuel

DANGER

Always stop the engine and allow

it to cool before changing a gas

cylinder.

Close the manual valve of the gas

cylinder and let the engine run

until gas hoses are empty before

disconnecting any fitting.

Make sure you use correct type of

LPG gas and that hose fittings are

correct for the bottle type.

Always keep LPG cylinders in

upright position. Store LPG gas

bottles correctly. See page 49.

Keep fuel away from heat and

sources of ignition. Do not smoke

when handling gas.

Leaking gas is heavier than air.

Safety of LPG systems

Keep the entire LPG system in good condition to

keep the LPG system safe and to avoid leaks. Use

only correct type of gas bottles, refer to page 26.

Improperly installed and maintained gas equipment

can cause fuel supply system or other components

to malfunction, causing gas leaks. It is recommended

to have the LPG system inspected annually (hoses,

fittings, pressure regulator). Propane fuel supply

systems must be installed and serviced only by

qualified service professionals. Observe all local

regulations concerning the handling of LPG

equipment.

Handling of LPG bottles

Always keep gas bottle upright. This ensures that the

overpressure relief of the bottle can function as

intended.

Stop the engine and switch off the main current with

the battery disconnect switch before changing the

gas bottle.

Make sure the gas bottle has an overpressure relief

valve fitted. Pressure inside the gas bottle depends

on ambient temperature. In case of overpressure in

the cylinder, the overpressure relief valve will vent

out propane to keep pressure inside the tank at a

safe level.

Close the manual shut off valve on the gas bottle

carefully, do not overtighten the valve. Typically the

valve needs to be opened about 2-3 rounds to be

fully open.

Notice the inspection year that has been marked on

the bottle. The gas bottle must be inspected by a

licenced professional before the year marked on the

bottle. If there are no markings on the bottle, or the

inspection date has passed, the gas bottle must be

taken out of service and returned to the retailer.

Avant 220/225

16

WARNING

Risk of gas leak, fire or

explosion - Handle gas bottles

with care. Disconnect the gas

cylinder from the loader and store

it separately in an area designated

for safe propane storage, see page

49. If the gas bottle is damaged, or

if damage is otherwise suspected,

remove it from service and take it

to exchange point or qualified

inspector.

Filling of gas bottle

In some areas empty gas bottles are exchanged to

full ones, and in other areas they are filled. Filling of

a gas bottle requires special equipment and training.

If filling a bottle, the condition of the bottle and the

valve must be checked by a qualified specialist. Only

professionals who have been trained to fill gas

bottles and have a valid licence are allowed to fill a

gas bottle. Never attempt to fill a gas bottle without

special equipment needed to avoid risk of explosion.

Use with LPG only

Do not use natural gas or any other gas that contains

methane (common names for these include biogas

EPG / CBG and CNG). In addition to the differences

in composition between these and other gases, the

working pressures and the gas systems themselves

can be very different. This loader is intended to be

used only with a gas bottle that contains propane.

WARNING

Risk of fire or explosion - Use

only correct LPG gas and gas

bottle. If you use other gas types,

there is a serious risk of fire and

explosion, or engine damage at

minimum.

In an event of a gas leak

In case you suspect a leak in the gas system:

Close the manual shut off valve of the gas bottle

immediately if suspecting a leak.

Stop the engine with ignition key and switch off

the main current.

Ventilate well before investigating the cause of

the leak.

To check components for gas leaks, see page

16.

If a leak in a propane fuel system occurs, the heavier

than air gas will sink to lowest parts of the room and

remain there, creating a risk of explosion and fire.

Therefore it is very important to ventilate enclosed

areas well to remove all remaining gas. Replace

faulty components with new ones, never attempt to

repair damaged components. Contact authorised

Avant service if necessary.

Avant 220/225

17

Description of the loader

.

..

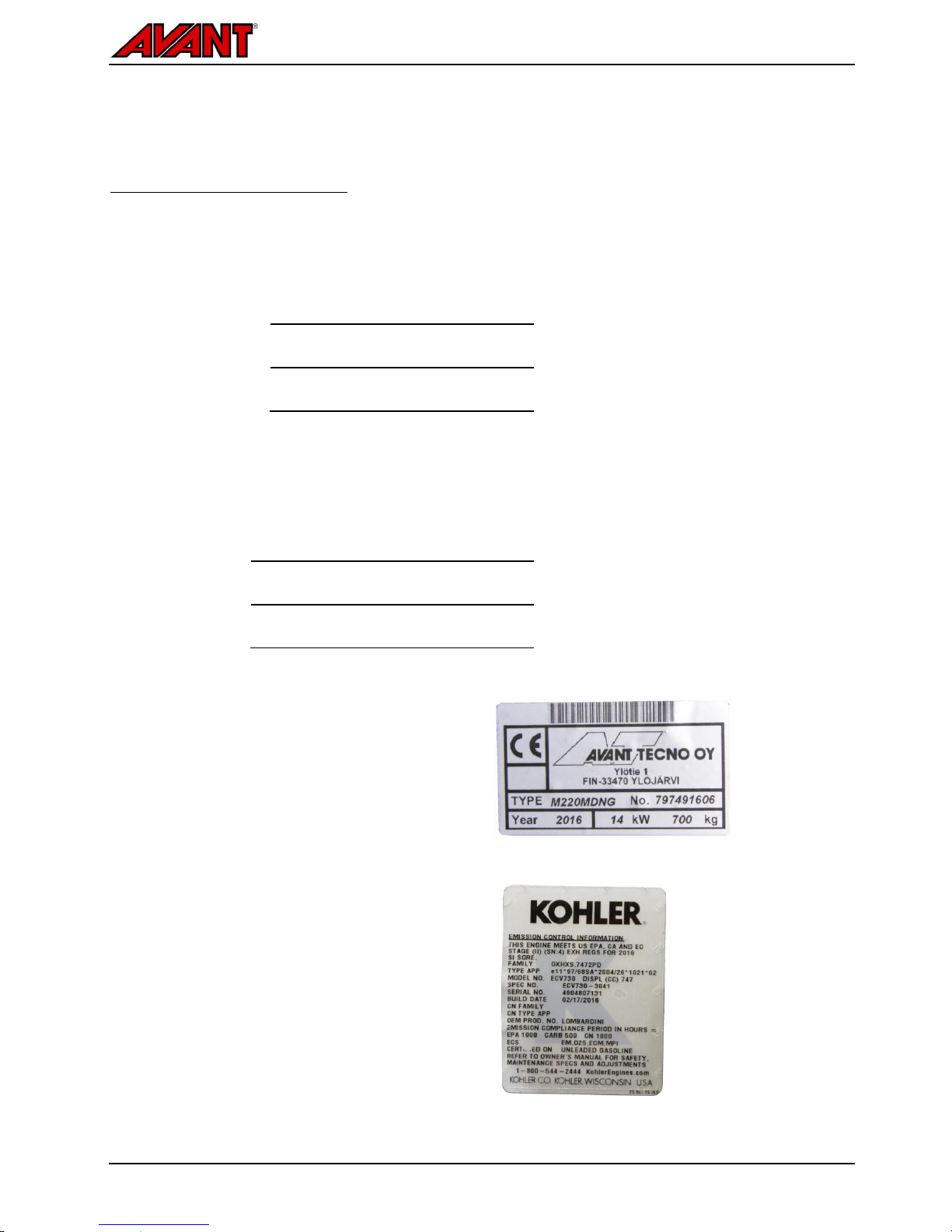

Identification of the loader

Write down the identification information of your loader in the following fields, it facilitates ordering of spare parts

etc.

1.

Loader model

2.

Loader serial no.

3.

Engine serial no.

Serial number of the loader is printed on the type plate, which also indicates the loader model. Location of engine

serial number can be found in the Operators Manual of the engine.

Dealer:

Contact information

Loader identification

Loader identification plate is located near the left

knee of the driver.

Engine identification

Engine identification plate is visible under the

seat on the side of the engine. Further details are

shown in the engine operator’s manual.

Avant 220/225

18

.

Main parts of the loader

Following picture shows the main parts of the loader:

.

..

1. Front frame

On the front frame are mounted: driver’s seat,

operating controls, engine with accessories, battery,

hydraulic components, fuel tank, oil tank, front

wheels with hydraulic motors, and loader boom with

attachment coupling plate.

2. Back frame

On the back frame are mounted: rear wheels with

hydraulic motors, counterweights, trailer coupling.

3. Articulation joint

Articulation joint connects the front and back frame.

The loader is steered hydraulically by the steering

cylinder which is mounted between the front and

back frames. Hydraulic hoses and electric wires are

conducted through the articulation joint.

4. Loader boom

Loader boom is mounted on the front frame and is

controlled with control lever from the driver's seat.

The attachment coupling plate is mounted at the end

of the boom. The boom is fitted with a mechanical

parallel linkage.

5. Attachment coupling plate

Attachments are mounted on the attachment

coupling plate. The locking pins on the plate are

manually operated type.

6. Auxiliary hydraulics outlet

The hydraulic hoses of hydraulically operated

attachments are mounted on this outlet. The outlet is

equipped with the multi connector quick coupling

system and is double acting: it has two pressure

lines and one tank line, see page 55. If the loader is

equipped with the optional Attachment control switch

pack, its electric socket is integrated in the multi

connector.

7. ROPS safety frame

ROPS frame (Roll-over protective structure)

complies with the standard ISO 3471:1994 with

Amendment 1:1997 and Technical Corrigendum

1:2000 for a maximum machine configuration mass

of 1200 kg.

8. FOPS canopy

FOPS canopy (Falling objects protective structure)

mounts on the ROPS. It meets the ISO 3449:2005

(1365 J) criteria.

9. LPG Gas bottle (225LPG)

Vertically installed gas bottle, from which gas is

drawn in vapour form. See page 26.

Avant 220/225

19

.

Signs and decals

Shown in the figure below and listed on the following page are the labels and markings, which must be visible on

the equipment. Replace any warning label which has become unclear, or has detached completely. New labels are

available via your retailer or contact information provided on the cover.

Before applying a new decal, clean the surface from dirt, dust, grease, or other material. Peel small portion of the

decal backing paper and apply exposed adhesive to cleaned surface, aligning the decal properly. Peel rest of

backing paper and press with hands to smooth out the decal.

The warning labels contain important safety information and they help to identify and

remember the hazards related to the equipment.

Make sure that the following signs and decals are clean, undamaged and readable. If any

of these decals is missing or is unreadable it should be replaced without delay. Ask for

new decals from your local Avant dealer.

Avant 220/225

20

.

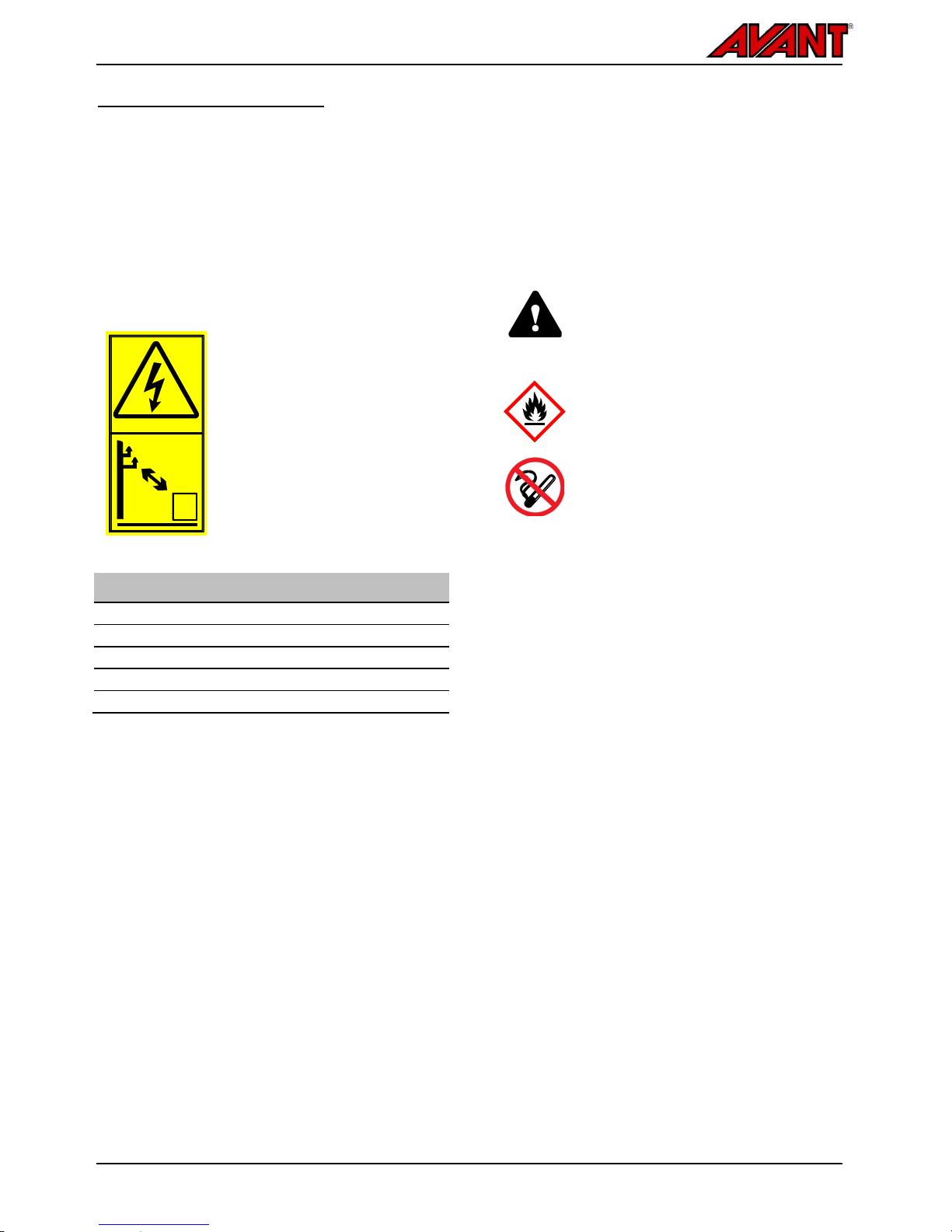

Table 2 - List of safety labels and markings on the machine (continued on following pages)

Label

Location

Product code

1

Dashboard,

around/ behind

steering wheel

A420546

Symbol

Safety message

a b

WARNING

a Wrong use, misuse, or careless use can cause hazards that

could be prevented with following the instructions properly.

Read all instructions carefully before operating the loader.

b Lowering of loader boom can crush, causing death or

serious injury.

Keep out from the danger zone of the machine.

c Risk of falling of persons and getting run over.

Never carry passengers with the loader or its attachments.

d High pressure fluid injection hazard.

Never use hands to search for leaks.

e Risk of dropping of attachment.

Make sure both locking pins are locked.

f Risk of getting crushed by moving loader.

Apply parking brake and lower attachment on the ground.

Make sure loader will not move when leaving the driver's

seat.

c d

e f

Avant 220/225

21

.

Symbol

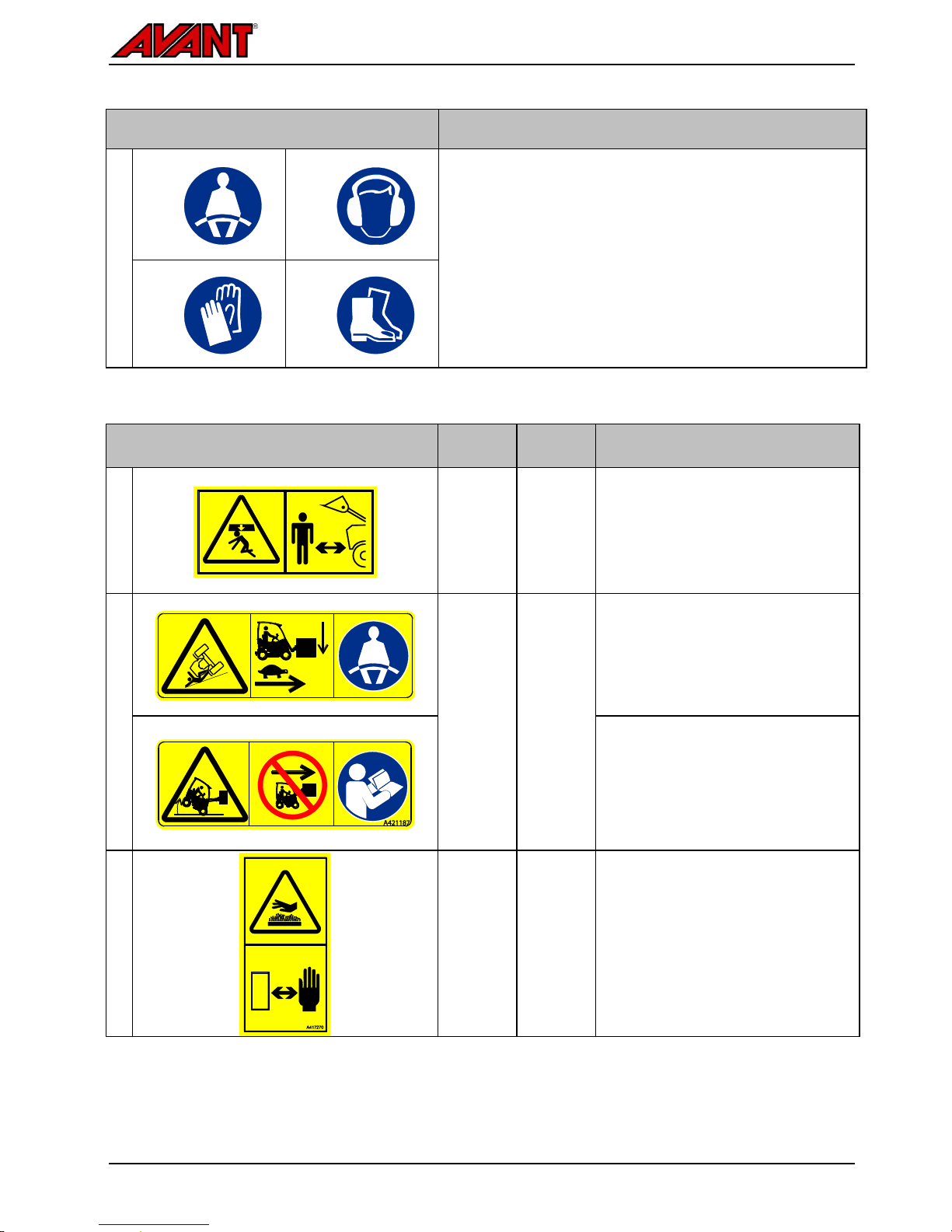

Safety message

g h

g

Always wear seat belt.

h

Wear hearing protection. Depending on use, noise level at

driver's seat and around the loader and its attachments may

be high enough to cause hearing damage.

i j

i

Wear protective gloves with good grip.

j

Wear safety boots with good grip and feet protection.

Label

Location

Product

code

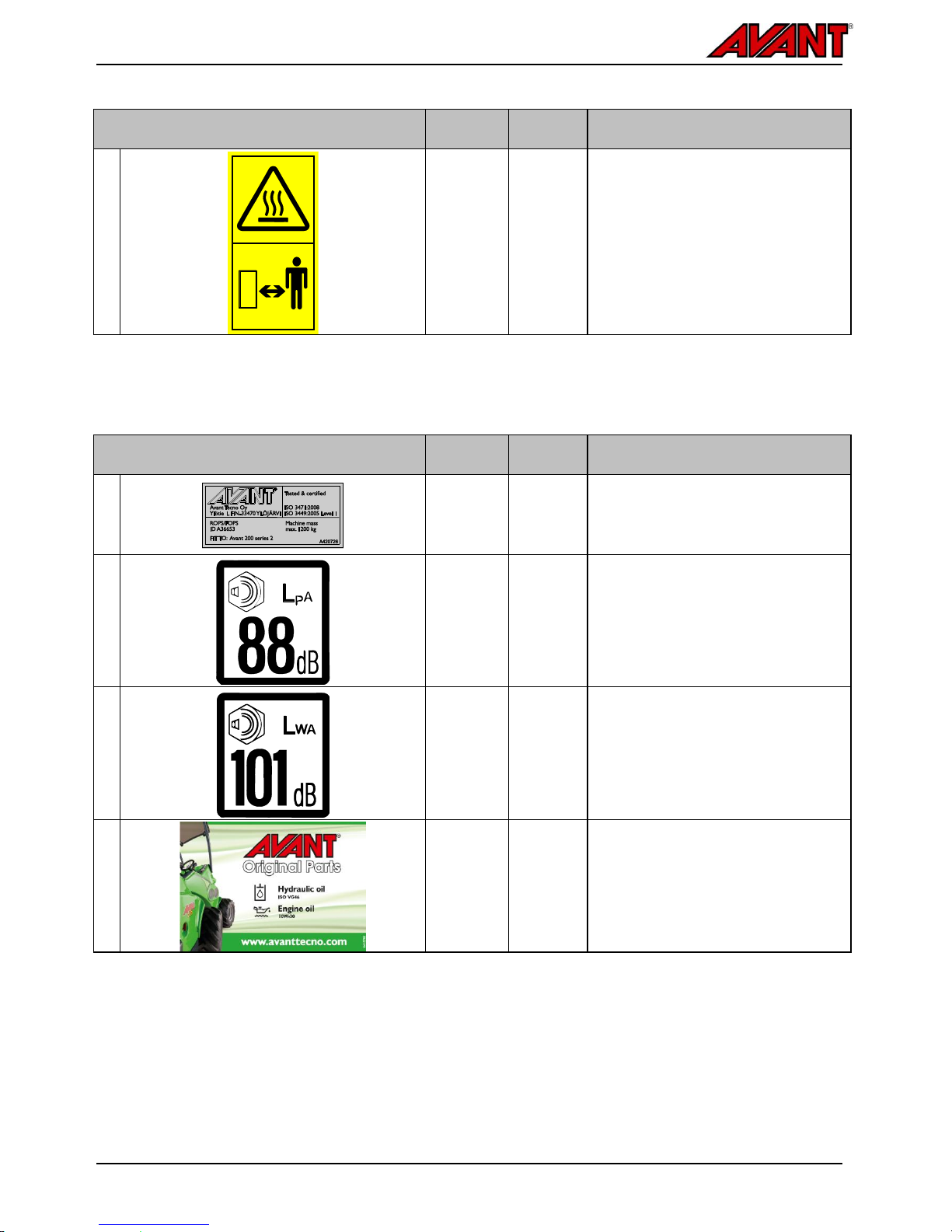

Safety message

2

Boom, on

both sides

A417273

(2 pcs)

DANGER

Lowering of loader boom can crush,

causing death or serious injury.

Keep out from the danger zone of the

machine.

3

Panel

below

steering

wheel

A421187

WARNING

Risk of rolling over - Keep loads close

to ground, drive slow when carrying

load.

Always use seat belt.

WARNING

Risk of tipping over (front direction) -

Keep load close to ground, drive

slowly.

Read operator's manual carefully.

4

On engine

A417270

WARNING

Risk of burns - Extremely hot surfaces.

Keep clear.

Allow loader to cool completely before

maintenance.

Avant 220/225

22

.

Label

Location

Product

code

Safety message

5

Rear

ROPS

posts

A414244

(2 pcs)

WARNING

Hot exhaust - Keep clear.

Exhaust gases and all parts of exhaust

system become extremely hot during

use.

Stay clear of any exhaust part until

engine is allowed to cool, avoid also

reversing or leaving loader near

flammable materials.

Table 3 - Information labels

Label

Location

Product

code

Message

6

ROPS

frame

A420726

ROPS/FOPS Approval

7

Right

panel near

driver's

seat

A43600

Sound pressure level 88 dB(A) at

driver's seat

8

Right

panel near

driver's

seat

A411047

Sound power level 101 dB(A)

2000/14/EC

9

Front

panel

below

driver's

seat

A415780

Correct type of hydraulic and engine oil

Avant 220/225

23

.

Technical specifications

Dimensions

General dimensions

Length

1910 mm

225LPG: 1940 mm

Width

1025 mm (with standard tyres)

995 mm (see page 25)

Height

1880 mm (with standard tyres)

Mass (empty)

220

225

225 LPG

700 kg

700 kg

760 kg

Tyres

Standard:

20 x 8.00-10 TR /

20 x 8.00-10 GR

Lifting height

1400 mm

Max reach

810 mm

Turning radius,

inside/outside

910 mm / 2220 mm

Ground clearance

150 mm

Drive speed and pulling force

Tyre

Drive

speed

Pulling

force

220

20 x 8.00-10 TR

10 km/h

6200 N

20 x 8.00-10 GR

10 km/h

6200 N

225

225

LPG

20 x 8.00-10 TR

10 km/h

6400 N

20 x 8.00-10 GR

10 km/h

6400 N

Height and Width

Tyre

Height

Width

20 x 8.00-10 TR

1880 mm

995 mm

20 x 8.00-10 GR

1880 mm

995 mm

.

..

.

..

.

..

.

..

.

..

.

..

.

..

Avant 220/225

24

.

General specifications

220

225

225LPG

Category

Earth-moving machinery / Loader/ Compact loader EN ISO 6165

Product code

A21675

A21687

A21698

Drive system

Hydrostatic 4WD

Tipping load ISO 14397-1

(see also page 28)

320 kg

320 kg

350 kg

Rated operating capacity

175 kg

175 kg

200 kg

Auxiliary hydraulics

*See also page 27

Max 20,0 MPa (200 bar)

Max 20,0 MPa (200 bar)

Max 20,0 MPa (200 bar)

Max flow

Front: 30 l/min

Rear: 7 l/min

Max flow

Front: 43 l/min

Rear: 7 l/min

Max flow

Front: 43 l/min

Rear: 7 l/min

Hydraulic pumps 2 2

2

Auxiliary hydraulics

Standard: Faster multiconnector system on front

Attachment coupling

Avant quick coupling attachment plate

Hydraulic oil capacity

23 l

Hydraulic oil type

ISO VG 46, mineral oil only

Fuel tank capacity

14 l

14 l

Steel propane tank

See page 26

Sound pressure level

2000/14/EC Lp, ISO 6396

101 dB(A)

101 dB(A)

100 dB(A)

Sound power level

2000/14/EC Lp, ISO 6395

88 dB(A)

88 dB(A)

88 dB(A)

Hand-arm vibration, total

< 2,5 m/s2

< 2,5 m/s2

< 2,5 m/s2

Whole-body vibration, max.

< 0,5 m/s2

< 0,5 m/s2

< 0,5 m/s2

Engine

Model

220

225

225LPG

Engine

Kohler CV640

Kohler ECV730 EFI

Kohler PCV740 EFI

Engine max output

14,9 kW (20,5 hp),

3600 rpm

18,6 kW (25 hp)

3600 rpm

17,9 kW (24 hp)

3600 rpm

Operating principle:

4-stroke V2, OHV

4-stroke V2, OHV

Electronic fuel injection

4-stroke V2, OHV

Electronic fuel injection

Fuel (see page 26)

Gasoline

Gasoline

Propane (Propane/Butane)

Cooling

Air

Air

Air

Starting system

Electric

Electric

Electric

Displacement

674 cm3

747 cm3

747 cm3

Bore * stroke

77*67 mm

83*69 mm

83*69 mm

Engine oil

wet, oil pump, filter

wet, oil pump, filter

wet, oil pump, filter

Oil capacity (refill)

1.9 l

1.6-1.9 l

1.6-1.9 l

Engine oil:

SAE 10W-30

API CF-4/SG

SAE 10W-30

API CF-4/SG

SAE 10W-30

API CF-4/SG

Valve clearance

Hydraulic tappet

Hydraulic tappet

Hydraulic tappet

Avant 220/225

25

.

Tyres

The loader can be equipped with different type of

tyres for different operating conditions. Grass pattern

(GR) tyres will damage the ground surface less than

tractor (TR) tyres, but provide less traction.

Tyre

Tread

pattern

Code

Fill

pressure

Max

pressure

20 x 8.00-10

TR

66231

2,3 bar

2,9 bar

20 x 8.00-10

GR

66252

2,3 bar

2,9 bar

For the best stability and controllability, always use

the largest tyres possible.

Use only tyres and rims that meet the original

specifications and dimensions to avoid potential

issues with load capacity, tyre size, or bearing load

on drive motors. Special tyres, such as studded

wheels may also be available. Consult your dealer

for further information.

Snow chains will not fit and are not available for the

loader.

WARNING

Risk of tipping over - Make sure

tyres are not damaged. Loss of

tyre pressure can cause loader to

tip over. Make sure there are no

visible damages on tyres. Keep

tyre pressure within

recommendations.

Wheel spacers

The wheels are fitted with spacers that increase the

width of the loader for better stability. In special

cases where the width of the loader is restricted, the

wheel spacers can be removed. Remove only if

operating on flat areas. The spacers A44337 are 15

mm thick.

WARNING

Wheel spacers improve the lateral

stability of the loader. Do not

remove the wheel spacers unless

operating the loader on flat areas,

where the total width of the loader

must be reduced to as narrow as

possible.

Use only spacers recommended by

the manufacturer. Too thick spacers

may damage the hydraulic motors.

Contact your Avant dealer for more

information.

Wheel weights (optional extra)

Extra wheel weights can be fitted to improve stability

of the loader. If fitting only two weights, they should

be fitted to rear wheels.

The 14 kg weights are installed to wheel rim with two

special bolts included in the kit as shown below.

Avant 220/225

26

.

Fuel requirements

Gasoline requirements (220/225)

Gasoline fuel must meet the following

requirements:

Clean, fresh, unleaded gasoline from a clean

container. Do not use gasoline older than 30

days.

Minimum octane rating:

EU: Min 90 (RON)

North America: 87 (R+M)/2

Bio fuel mixed with ethanol (max 10%) can be

used.

Gasoline blend with max 15% MTBE additive by

volume (Methyl Tertiary Butyl Ether) is approved.

Do not add oil to gasoline.

E15, E20 and E85 are not

approved for use with the engine

in the loader. Effects of old, stale

or contaminated fuel are not

covered by warranty.

LPG gas requirements (225LPG)

Avant 225LPG is intended to operate with gas that

flows as vapour from the bottle, not liquid. Regular,

commonly available gas bottles that are also used for

i.e. heating, grilling etc. and used in vertical position

are correct type of gas bottles.

NOTE: The Avant 525LPG, another Avant loader

model, uses different type of gas system with

external vaporizer. This means that the gas bottles

are not interchangeable between these two loader

models.

The Avant 225LPG is intended to be

used with gas bottles that are used in

upright position and supply gas in

vapour form, not liquid.

Make sure to use correct type of gas

bottles, contact your local dealer for

more information.

The exact type of gas bottle will depend on the area

where the loader is used, but the following general

instructions and requirements apply.

When replacing a gas bottle, take the following into

account:

The loader engine is certified to operate with

commercial propane that complies with USA

standard GPA STD 2140. This standard

specifies that the maximum amount of butane is

limited to a low level. If you operate the loader in

cold climate, use LPG gas that is only propane.

Bottle must supply LPG in vapor form, not liquid.

Hose coupling must be threaded fitting, not any

quick coupling type. Hose threading must match

perfectly the hose threads. See page 27 for

standard hose fittings and typical, available fitting

options.

Overpressure valve must be fitted and in

functioning condition. Bottle itself and its valve

must be inspected periodically by qualified

technician. With bottles that are exchanged to

full ones, this is usually managed by businesses

offering exchange bottle service.

Physical dimensions of the bottle must be within

the following limits:

300 mm in diameter

700 mm height

Stainless steel, steel, and aluminium bottle

absorb heat the best. Do not use plastic /

composite bottle, they will not absorb heat from

surrounding air effectively

Larger bottles absorb more heat than smaller

ones.

Loading...

Loading...