AVANT 313S, 314S, 320S Operator's Manual

Operators Manual

2005-

Table of contents

2

TABLE OF CONTENTS

INTRODUCTION ...............................................................................................................3

AVANT 300S SERIES WARRANTY ...................................................................................3

EC DECLARATION OF CONFORMITY ............................................................................4

HOW TO WORK SAFELY ................................................................................................. 5

DECAL LOCATIONS ..........................................................................................................6

MAIN PARTS OF THE LOADER ........................................................................................7

TECHNICAL SPECIFICATION ..........................................................................................8

TECHNICAL SPECIFICATION, ENGINES ........................................................................9

LOAD DIAGRAM ..............................................................................................................10

CONTROLS ......................................................................................................................11

STARTING THE ENGINE.................................................................................................14

STOPPING THE ENGINE ................................................................................................15

DRIVE CONTROL.............................................................................................................15

DOUBLE SPEED FUNCTION ..........................................................................................16

USING THE AUXILIARY HYDRAULICS.........................................................................16

COUPLING THE ATTACHMENTS..................................................................................17

300S SERIES SERVICE TABLE.........................................................................................18

SAFETY INSTRUCTIONS FOR MAINTENANCE ..........................................................19

MAINTENANCE INSTRUCTIONS..................................................................................20

REFUELING.......................................................................................................................21

FILTER LOCATION...........................................................................................................22

FILTER TABLE...................................................................................................................22

GREASING POINTS 300S SERIES ..................................................................................22

TROUBLESHOOTING .....................................................................................................23

ATTACHMENT LISTING .................................................................................................24

300S Series

Introduction, warranty

3

300S Series

INTRODUCTION

AVA NT TECNO OY wants to thank you for purchasing an AVANT loader. It is the result of Avants long

experience in design and manufacturing of compact loaders.

We ask you that you read and understand the contects of this manual completely before operating the loader.

This will improve your operating and maintenance efficiency, help avoid breakdowns and damage and extend

your machines life.

Contact your local AVANT dealer for any questions, service, spare parts or about any problems that may occur

with the operation of your machine.

AVANT 300S SERIES WARRANTY

This warranty specifically applies to the AVA NT 300S series loaders only and not to any attachments used

with this product.

Any repairs or modifications performed without the prior authorisation of AVA NT Tecno Oy will cancel this

warranty.

During the first year of operation or the first 750 hours (whichever is the soonest) AVA NT Tecno Oy warrants

to replace any part or repair any defect which may occur, subject to the terms detailed below:

1) The product has received regular maintenance in accordance with schedules given by the manufacturer.

2) Any damage caused by operation in a negligent manner or exceeding the approved specifications detailed

in this manual is excluded.

3) AVA NT Tecno Oy accepts no responsibility for interruption to working or any other consequential losses

resulting from any failure of the product.

4) Only AVA NT Tecno Oy approved replacement or original quality parts shall be used during routine

maintenance.

5) Any damage caused by the use of incorrect fuel, lubricants, cooling liquid or cleaning solvents is exclude

6) The Avant Warranty excludes any consumable parts (e.g. tyres, spark plugs, batteries, filters, belts etc.)

except where it can be clearly shown that these parts were defective on original supply.

7) Any damage caused resulting from the use of attachments not approved for use with this product is excluded.

8) In the event a fault occurs which is attributable to manufacturing or assembly defect you should arrange

to return your AVANT to your authorised dealer for repair. Travel and freight costs are excluded.

IDENTIFICATION OF THE LOADER

Write down the following information about your loader, it will help you when ordering parts etc.

1. Model: AVA NT_____________________Purchase date:______________________________

2. Serial number:________________________________________________________________

3. Engine serial number:__________________________________________________________

The serial number and model of the loader are printed on the manufacturers plate which is located

in the footwell (decal no. 8, see page 6). Location of engine serial number can be found in the

operating manual of the engine.

EC declaration of conformity

4

300S Series

EC DECLARATION OF CONFORMITY FOR MACHINERY

Manufacturer: AVANT TECNO OY

Address:Ylötie 1, 33470 YLÖJÄRVI, FINLAND

We hereby declare that the machines listed below conform to EC Directives: 98/37/EC

(Machinery), 89/336/EEC (EMC) and 2000/14/EC (Noise Emission).

Category: EARTH-MOVING MACHINERY/LOADERS/COMPACT

Models: AVANT 313S, 314S, 320S and 320S+

Ylöjärvi, Finland, 07.01.2003

Risto Käkelä

Managing Director

300S Series

How to work safely

5

HOW TO WORK SAFELY

An incorrect or careless operation of the loader may

be the origin of a serious accident. Before putting the

machine into operation, familiarise yourself with the

use of the machine and read and understand this

Operators Manual as well as the safety instructions.

THIS SYMBOL INDICATES

THE IMPORTANT

SAFETY FACTORS.

Understand the limitations of speed, braking, steering

and stability as well as loading capacity of the machine

before starting operation.

If you have no previous experience of the machine,

make sure to do all testing at a safe and open place

with no persons in the area of operation.

SAFETY INSTRUCTIONS

Never use the loader without instructions. Read loader

signs (decals), and this manual.

Start the operation slowly and carefully.

Do not wear loose clothing, long uncovered hair or

jewelry near machine.

When driving be comfortably seated in the driver´s

seat, keep your feet in their proper place in the footwell

and both hands on the control levers.

Operate the control levers and the lever of auxiliary

hydraulics only when sitting in the driver´s seat.

Operate the control levers with ease and without

hesitation.

When coupling the attachment, make sure that the

locking pins lock in positively.

Never put any part of the body or let anyone go under

the lifted boom.

Do not transport persons in the bucket. The machine

is not designed to lift or to transport persons.

Keep hands, feet and clothing away from any moving

part and/or hydraulic cylinder.

Never carry passengers. Keep other bystanders away

from the work area.

Drive slowly on uneven terrains. Watch out for ditches,

manholes and steep gradients.

Do not drive on too steep a gradient. Load, unload, and

turn on flat level ground.

Make sure that the ventilation is sufficient when working

indoors or otherwise confined area.

Do not use loader in an atmosphere with explosive dust

or gases or where exhaust can contact flammable

material, explosion or fire can result.

Do not transport the load with the boom lifted.

Always carry bucket or attachment as low as possible,

and put the load down whenever you leave the machine.

When lifting or lowering the load, do not operate the

boom control lever abruptly. Turn the lever smoothly

and with care.

Do not exceed rated operating capacity - follow the

load diagrams.

Do not park the machine on a surface with a gradient.

Should this be necessary, use the parking brake and

preferably turn the machine sideways and put down

the bucket. If needed, use chocks behind the wheels.

Before leaving driver´s seat:

- Lower the loader boom

- Place attachment flat on ground

- Stop the engine, remove the key

- Engage the parking brake

Never perform any maintenance or repair operation

when the engine is running.

Stop and cool the engine before adding fuel.

Never use ether or starting fluid on diesel engines with

glow plugs. Use only starting aids as approved by engine

manufacturer.

Keep the engine area clean of flammable materials.

Wear eye protection when servicing, and hard hat or

other protective equipment as needed.

When connecting a booster battery for "jump" start,

always make last connection (negative cable) to engine,

never at battery. When removing the "jump" start cable,

always remove the negative cable (-) from engine first.

Never charge a frozen battery.

Lead acid batteries produce flammable and explosive

gases. Keep arcs, sparks, flames and lighted tobacco

away from battery.

Battery acid causes severe burns. In case of acid contact,

wash immediately with water for several minutes and

get medical attention in case of eye contact.

Use a piece of cardboard to check for hydraulic leaks.

Leaking fluids under pressure can enter the skin and

cause serious injury. Medical attention is required if

hydraulic or other fluids contact skin.

Never modify the loader or add attachments not

approved by AVA NT Tecno Oy.

Do not smoke during refueling or driving.

Read this Operator's Manual carefully, especially if you

are unfamiliar with the safe use and operation of the

machine.

Decal locations

6

300S Series

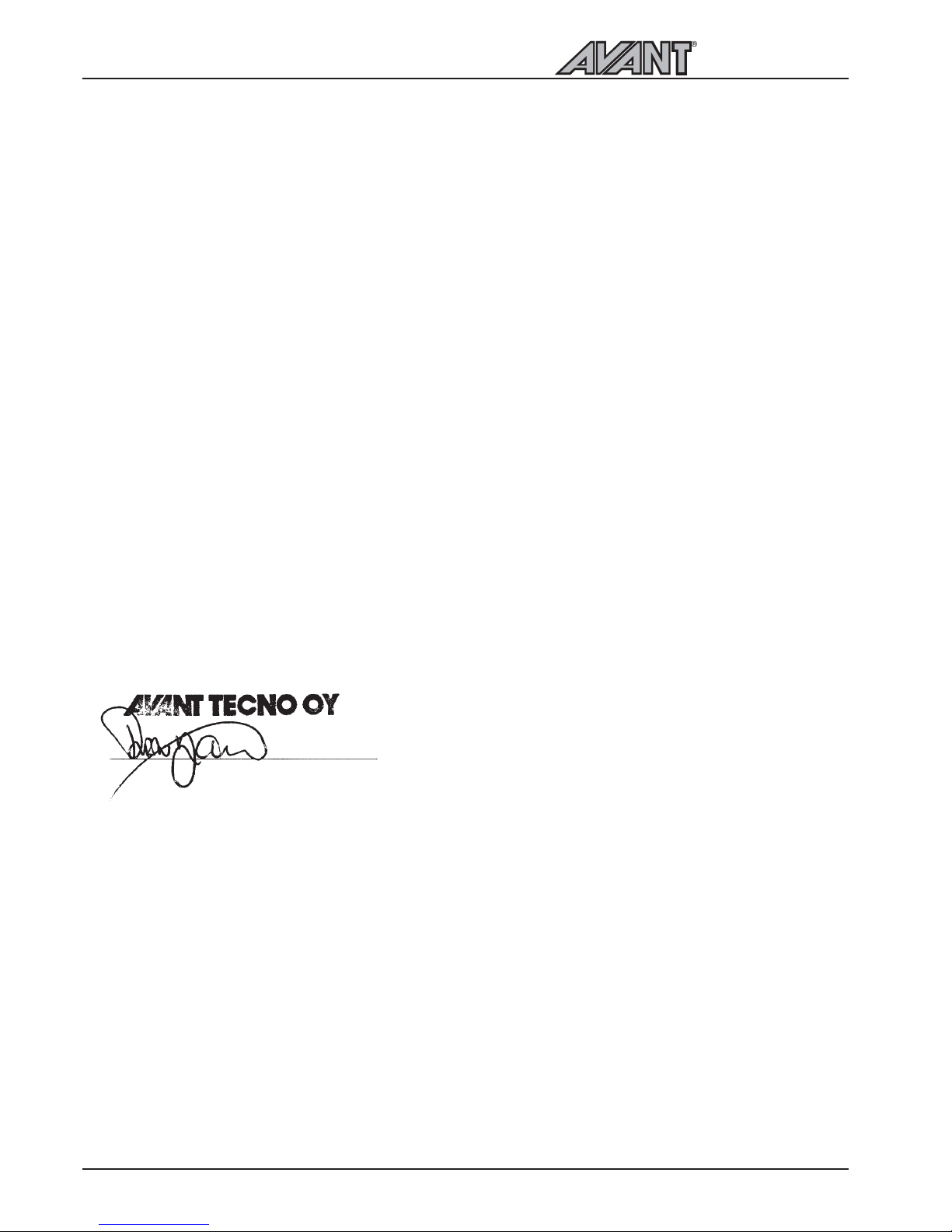

DECAL LOCATIONS

The following decals and signs should always be installed on the loader. If any of these decals has been

removed or is unreadable it should be replaced without delay.

l

j

k

m

no

r

l

j

k

m

n

o

p

q

r

p

q

300S Series

Main parts of the loader

7

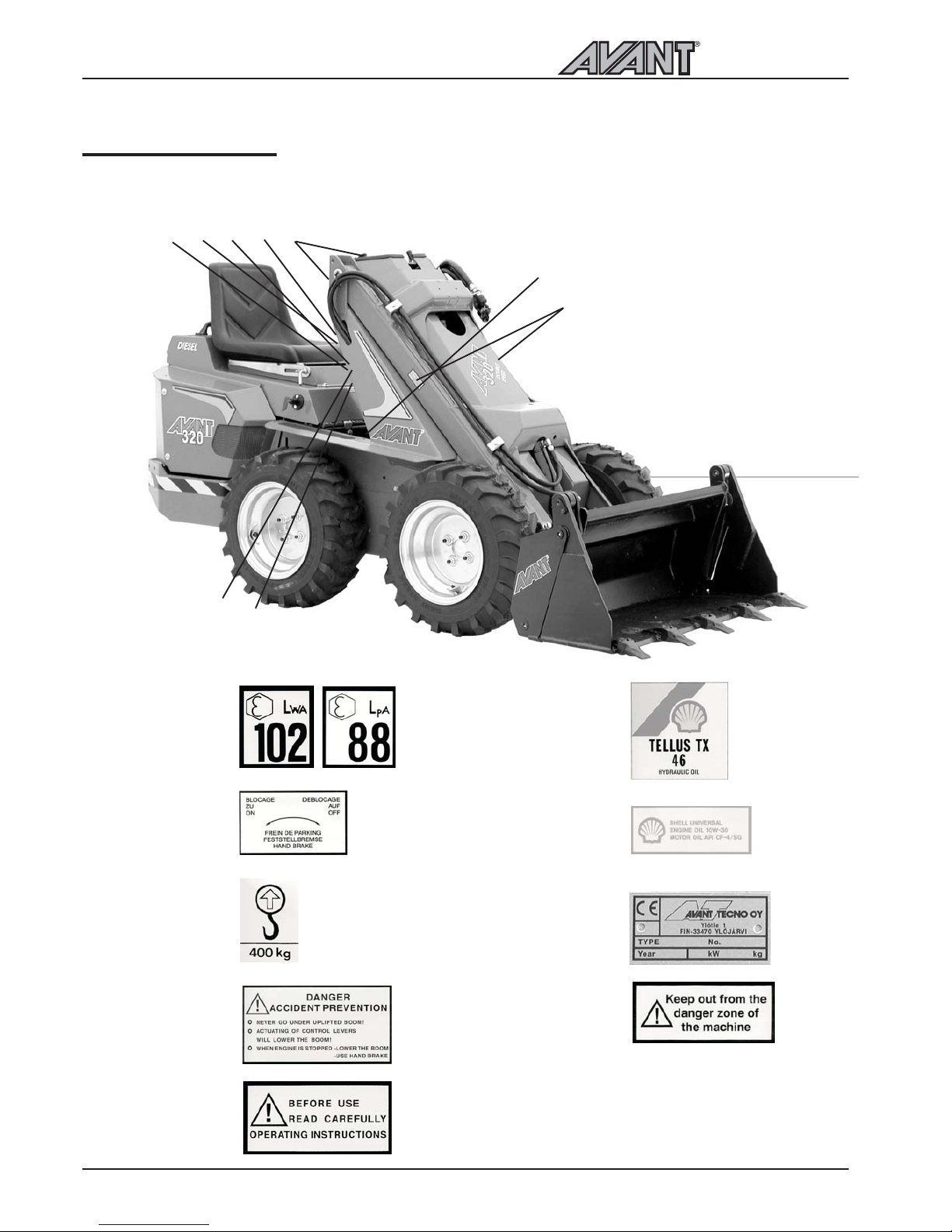

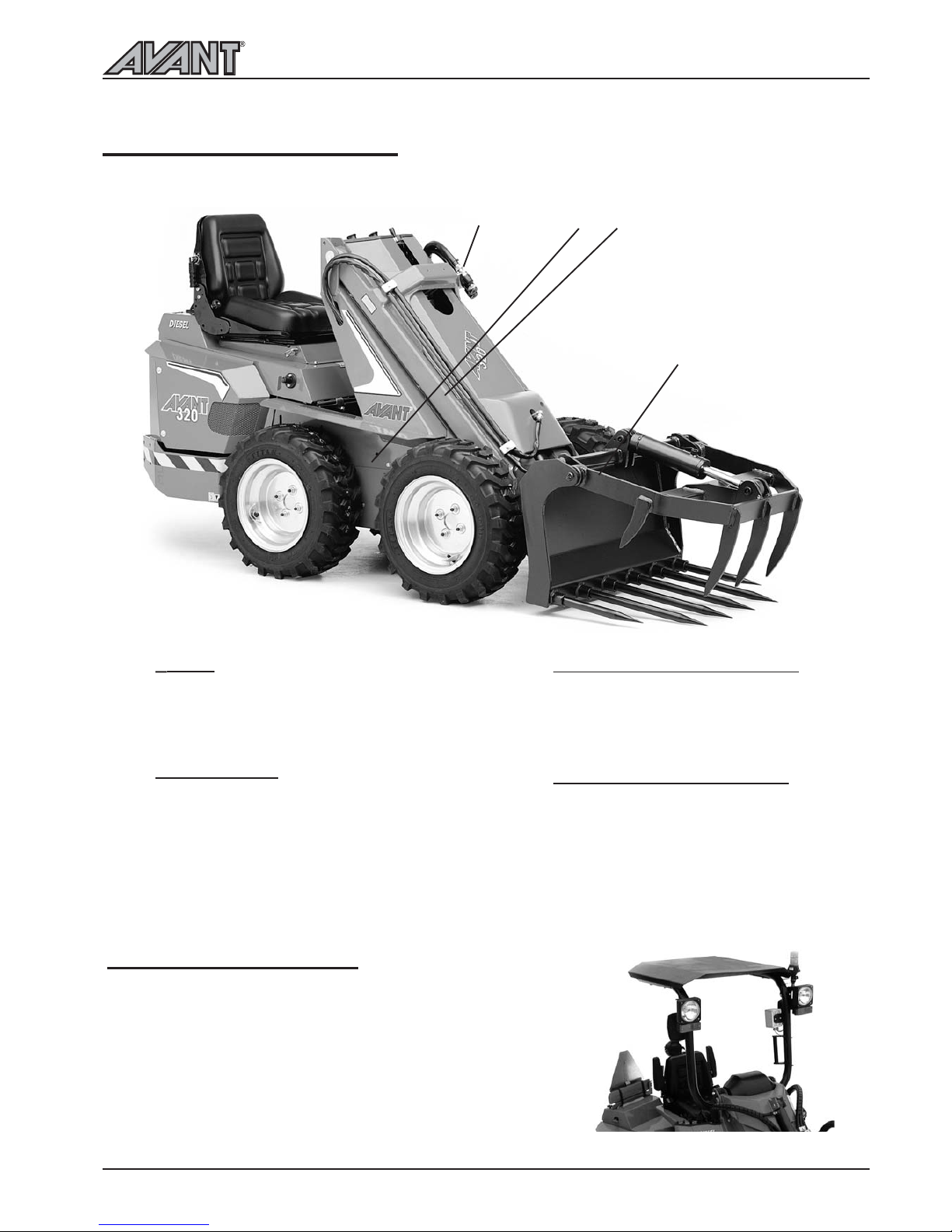

MAIN PARTS OF THE LOADER

Following picture shows the main parts of the loader:

j

k

m

l

j

k

m

Frame

The machine has a rigid frame, on which

all the hydraulic components, engine,

control valves, loader boom, wheels etc.

are mounted.

Loader boom

Loader boom is mounted on the front

frame with two pivot pins. The attachment

coupling plate is mounted on the lower

end of the boom. There are two types of

booms: standard boom with fixed length

and the optional telescopic boom which

extends 500 mm hydraulically.

Attachment coupling plate

Attachments are mounted on the

attachment coupling plate.

Auxilary hydraulics outlet

The hydraulic hoses of hydraulically

operated attachments are mounted on

this outlet with quick couplers. The outlet

is double acting: it has two pressure lines

and one return line. It is also possible to

install an auxiliary hydraulics outlet in the

rear of the machine (optional extra).

l

ROPS AND FOPS (Option)

1. ROPS frame

ROPS frame complies with the ISO 3471 / SAE J1040 standard.

Total machine height with ROPS frame is 1990 mm.

1. FOPS canopy, mounts on the ROPS

FOPS safety canopy exceeds the ISO 3449 Level 1 / SAE J1043

FOPS criteria. Total machine height with FOPS is 2050 mm.

Technical specification

8

300S Series

TECHNICAL SPECIFICATION

Model AVANT 313S AVANT 314S AVANT 320S

AVANT

320S+

Length 1680 mm 1950 mm 1950 mm 1950 mm

Width 790-1050 mm

(depending on

tyre size)

790-1050 mm

(depending on

tyre size)

790-1050 mm

(depending on

tyre size)

790-1050 mm

(depending on

tyre size)

Standard tyre size

Width

5x10 TR

940 mm

23*8.50-12

1020 mm

23*8.50-12

1020 mm

23*8.50-12

1020 mm

Height 1200 mm 1250 mm 1250 mm 1250 mm

Axle width 795 mm 795 mm 795 mm 795 mm

Ground clearance

206 mm 206 mm 206 mm 206 mm

Weight 530 kg 610 kg 720 kg 720 kg

Single speed model

Drive speed:

Double speed model

0 5 km/h

0 9 km/h 0 9 km/h 0 9 km/h 0 9 km/h

0 5 km/h

Drive hydraulics hydraulic four wheel drive hydraulic four wheel drive

Auxiliary hyraulics

flow and pressure

28 l/min single pump, 22,5 + 22,5 l/min

double pump, 175 bar

22,5+22,5 l/min

200 bar

22,5+22,5 l/min

220 bar

Turning radius

same as the length

of the machine

same as the length

of the machine

same as the length

of the machine

same as the length

of the machine

Lifting height with

standard boom

2100 mm 2100 mm 2100 mm 2100 mm

Lifting height with

telescopic boom

(Option)

2400 mm 2400 mm 2400 mm 2400 mm

Max. pulling force 6500 N 6500 N 7700 N 10 000 N

Max. lifting capacity

(hydr.)

750 daN 750 daN 850 daN 880 daN

Tipping load*) 600 kg 650 kg

700 kg

700 kg

Engine Honda GX 390

petrol

Kubota Z 482

diesel

Kubota D 722

diesel

Kubota D 722

diesel

Engine output 10 kW (13 hp) 10,5 kw (14 hp) 14 kW (20 hp) 14 kW (20 hp)

*) with standard lift arm, 80 kg driver and 30 kg extra back weight, on flat even surface

Loading...

Loading...