1 Product Introduction

USER MANUAL

© Copyright Reserved Autonics Co., Ltd. 1

1 Product Introduction

2 © Copyright Reserved Autonics Co., Ltd.

1 Product Introduction

Preface

Thank you for purchasing an Autonics product.

Please familiarize yourself with the information contained in the Safety Precautions section

before using this product.

This user manual contains information about the product and its proper use, and should be kept

in a place where it will be easy to access.

© Copyright Reserved Autonics Co., Ltd. 3

1 Product Introduction

User Manual Guide

Please familiarize yourself with the information in this manual before using the product.

This manual provides detailed information on the product's features. It does not offer any

guarantee concerning matters beyond the scope of this manual.

This manual may not be edited or reproduced in either part or whole without permission.

A user manual is not provided as part of the product package.

Visit our web site (www.autonics.com) to download a copy.

The manual's content may vary depending on changes to the product's software and other

unforeseen developments within Autonics, and is subject to change without prior notice.

Upgrade notice is provided through out homepage.

We contrived to describe this manual more easily and correctly. However, if there are any

corrections or questions, please notify us these on our homepage.

4 © Copyright Reserved Autonics Co., Ltd.

1 Product Introduction

Symbol

Description

User Manual Symbols

Supplementary information for a particular feature.

Failure to follow instructions can result in serious injury or death.

Failure to follow instructions can lead to a minor injury or product damage.

An example of the concerned feature's use.

※1

Annotation mark.

© Copyright Reserved Autonics Co., Ltd. 5

1 Product Introduction

Safety Precautions

Following these safety precautions will ensure the safe and proper use of the product and

help prevent accidents, as well as minimizing possible hazards.

Safety precautions are categorized as Warnings and Cautions, as defined below:

Warning

Caution

Failure to follow the instructions may lead to a serious injury

or accident.

Failure to follow the instructions may lead to a minor injury

or accident.

Fail-safe device must be installed when using the unit with machinery that may cause

serious injury or substantial economic loss. (e.g. nuclear power control, medical equipment,

ships, vehicles, railways, aircraft, combustion apparatus, safety equipment, crime/disaster

prevention devices, etc.)

Failure to follow this instruction may result in personal injury, fire, or economic loss.

The unit must be installed on a device panel before use.

Failure to follow this instruction may result in electric shock.

Do not connect, repair, or inspect the unit while connected to a power source.

Failure to follow this instruction may result in electric shock.

Check the terminal numbers before connecting the power source.

Failure to follow this instruction may result in fire.

Do not disassemble or modify the unit. Please contact us if necessary.

Failure to follow this instruction may result in electric shock or fire.

Do not use the unit outdoors.

Failure to follow this instruction may result in shortening the life cycle of the unit, or electric

shock.

2

When connecting the power input and relay output cables, use AWG20 (0.05mm

) cables

and make sure to tighten the terminal screw bolt above 0.74N.m to 0.90N.m.

Failure to follow this instruction may result in fire due to contact failure.

Use the unit within the rated specifications.

Failure to follow this instruction may result in shortening the life cycle of the unit, or fire.

Do not use loads beyond the rated switching capacity of the relay contact.

Failure to follow this instruction may result in insulation failure, contact melt, contact failure,

relay broken, or fire.

Do not use water or oil-based detergent when cleaning the unit. Use dry cloth to clean the

unit.

Failure to follow this instruction may result in electric shock or fire.

Do not use the unit where flammable or explosive gas, humidity, direct sunlight, radiant heat,

vibration, or impact may be present.

Failure to follow this instruction may result in fire or explosion.

6 © Copyright Reserved Autonics Co., Ltd.

1 Product Introduction

Keep dust and wire residue from flowing into the unit.

Failure to follow this instruction may result in fire or product damage.

Check the polarity of the measurement input contact before wiring the temperature sensor.

Failure to follow this instruction may result in fire or explosion.

For installing the unit with reinforced insulation, use the power supply unit which basic level

is ensured.

The above specifications are subject to change and some models may be discontinued without

notice.

© Copyright Reserved Autonics Co., Ltd. 7

1 Product Introduction

8 © Copyright Reserved Autonics Co., Ltd.

1 Product Introduction

Table of Contents

Preface ................................................................................................................................. 3

User Manual Guide ................................................................................................................ 4

User Manual Symbols ............................................................................................................ 5

Safety Precautions ................................................................................................................. 6

Table of Contents ................................................................................................................... 9

1 Product Introduction................................................................................. 13

1.1 Features .................................................................................................................. 13

1.2 Components and Accessories ................................................................................. 14

1.3 Ordering information ............................................................................................... 20

1.4 Parts descriptions .................................................................................................... 22

2 Specifications ............................................................................................ 25

3 Dimensions ................................................................................................ 27

4 Connections .............................................................................................. 33

4.1 Precautions for wiring .............................................................................................. 35

4.1.1 Sensor connection ..................................................................................... 35

4.1.2 Communication connection ........................................................................ 35

5 Preparation and Startup ........................................................................... 37

5.1 Initial display when power ON ................................................................................. 37

5.2 Basic controls .......................................................................................................... 38

5.2.1 Parameter setting sequence ...................................................................... 38

5.2.2 Set value (SV) setting ................................................................................ 38

5.2.3 MV monitoring and manual control ............................................................ 39

5.3 Parameter group ..................................................................................................... 41

5.4 Parameter groups .................................................................................................... 44

5.4.1 Parameter 1 group [PAR1] ......................................................................... 44

5.4.2 Parameter 2 group [PAR2] ......................................................................... 45

5.4.3 Parameter 3 group [PAR3] ......................................................................... 47

5.4.4 Parameter 4 group [PAR4] ......................................................................... 49

5.4.5 Parameter 5 group [PAR5] ......................................................................... 52

6 Parameter Settings and Functions .......................................................... 55

6.1 Input ........................................................................................................................ 55

6.1.1 Input types and temperature ranges .......................................................... 55

6.1.2 Input type [PAR3 → IN-T] .......................................................................... 56

6.1.3 Sensor temperature unit [PAR3 → UNIT] ................................................... 56

6.1.4 Analog input/scale value ............................................................................ 57

6.1.5 Input correction [PAR3 → IN-B]................................................................. 59

6.1.6 Input digital filter [PAR3 → MAvF] ............................................................... 59

6.1.7 High/Low-limit value of setting value(SV) [PAR3 → H-SV/ L-SV] ............. 60

6.2 Control output .......................................................................................................... 61

6.2.1 Control output mode [PAR3 → O-FT] ......................................................... 61

© Copyright Reserved Autonics Co., Ltd. 9

1 Product Introduction

6.2.2 MV High/Low-limit value settings [PAR2 → H-MV / L-MV] ......................... 66

6.2.3 Ramp settings [PAR2 → RAMU/ RAMD/ rUNT] ............................................ 67

6.2.4 Auto/Manual control settings ...................................................................... 69

6.2.5 Output settings ........................................................................................... 72

6.3 Temperature control ................................................................................................ 73

6.3.1 Temperature control mode [PAR3 → C-MD] ............................................... 73

6.3.2 ON/OFF control [PAR3 → C-MD → ONOF] .................................................. 74

6.3.3 PID control [PAR3 → C-MD → PID] ............................................................ 75

6.3.4 Auto-tuning ................................................................................................. 77

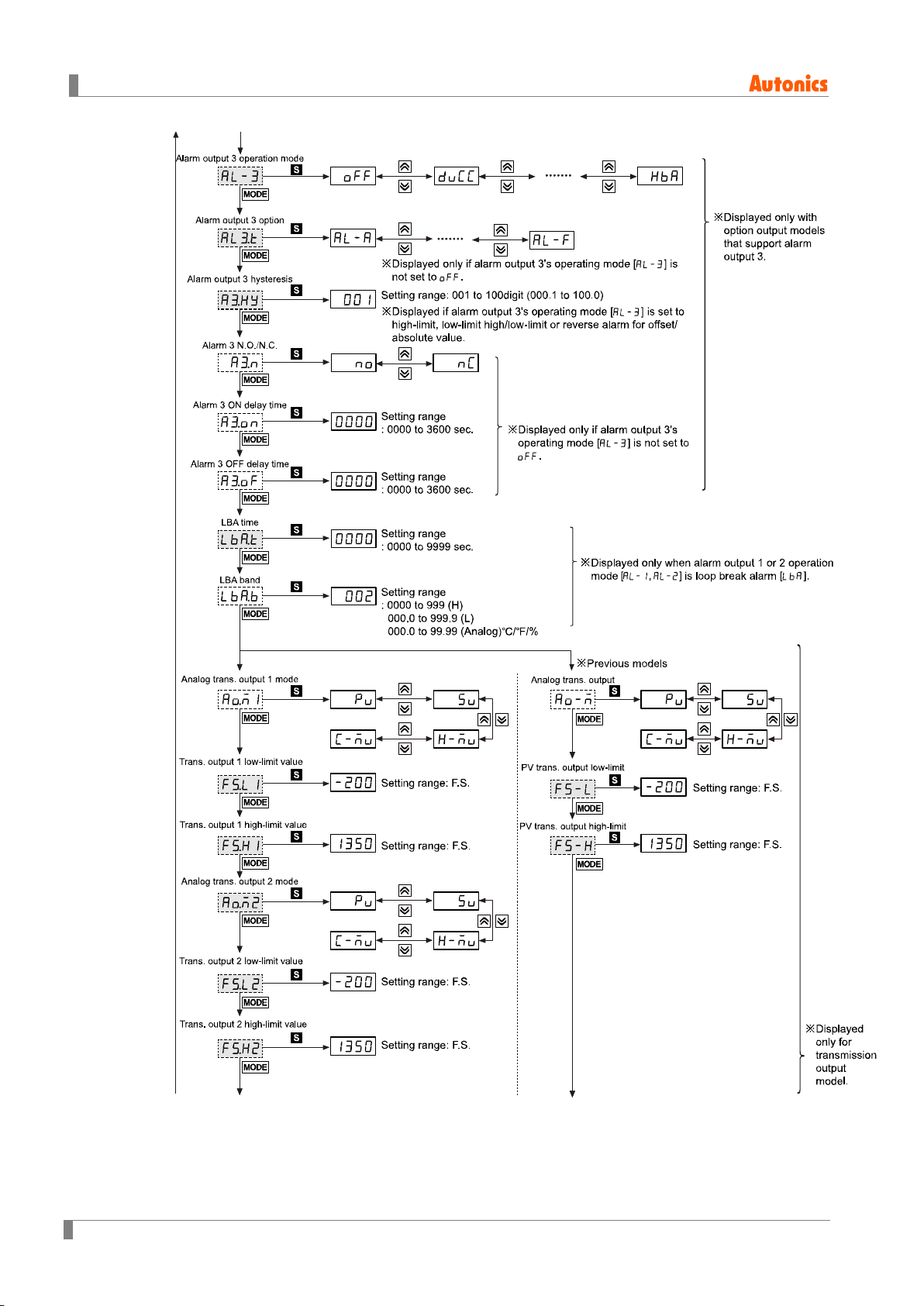

6.4 Alarm output ............................................................................................................ 79

6.4.1 Alarm operation [PAR4 → AL-1/AL-2/AL-3] ............................................ 79

6.4.2 Alarm output options [PAR4 → AL!T/AL@T] .............................................. 81

6.4.3 Alarm SV settings [PAR1 → AL!L/AL!H/AL@L/AL@H/AL#L/AL#H] .......... 82

6.4.4 Alarm output hysteresis [PAR4 → A!HY/A@HY/A#HY] ............................... 82

6.4.5 Alarm N.O./N.C. [PAR4 → A!N/A@N/A#N] .................................................. 83

6.4.6 Alarm output delay settings

[PAR4 → A!ON / A!OF/ A@ON / A@OF/ A#ON / A#OF] .................................. 84

6.4.7 Loop break alarm(LBA) [PAR4 → AL-1/AL-2/AL-3 → LBA] .................... 85

6.4.8 Sensor break alarm [PAR4 → AL-1/AL-2/AL-3 → SBA] .......................... 87

6.4.9 Heater burnout alarm [PAR4 → AL-1/AL-2/AL-3 → HBA] ....................... 88

6.4.10 Alarm output deactivation [PAR5 → DI-K→ AlRE] .................................... 89

6.4.11 Alarm output examples ............................................................................... 90

6.5 Analog transmission ................................................................................................ 93

6.5.1 Analog transmission output value settings [PAR4 → AoM1/ AoM2] ............ 93

6.5.2 Transmission output high/low-limit value settings

[PAR4 → FsL1/ FsH1→ FsL2/ FsH2] .......................................................... 93

6.6 Communication settings .......................................................................................... 95

6.6.1 Unit address settings [PAR4 → ADRS] ........................................................ 95

6.6.2 BPS (bits per second) settings [PAR4 → BPS] ........................................... 95

6.6.3 Communication parity bit [PAR4 → PRTY] .................................................. 96

6.6.4 Communication stop bit settings [PAR4 → STP] ......................................... 96

6.6.5 Response wait time settings [PAR4→ RSwT].............................................. 96

6.6.6 Enable/Disable communication write[PAR4→ COMW] ................................. 97

6.6.7 USB to Serial communication connection .................................................. 97

6.7 Additional features ................................................................................................... 98

6.7.1 Monitoring ................................................................................................... 98

6.7.2 RUN/STOP [PAR1 → R-S] ......................................................................... 99

6.7.3 Multi SV .................................................................................................... 100

6.7.4 Digital input ............................................................................................... 101

6.7.5 Error .......................................................................................................... 103

6.7.6 User level setting [PAR5 → USER] ............................................................ 104

6.7.7 Lock settings ............................................................................................ 104

6.7.8 Parameter reset [INIT] ........................................................................... 105

6.7.9 Password settings [PAR5 → PWD]............................................................. 105

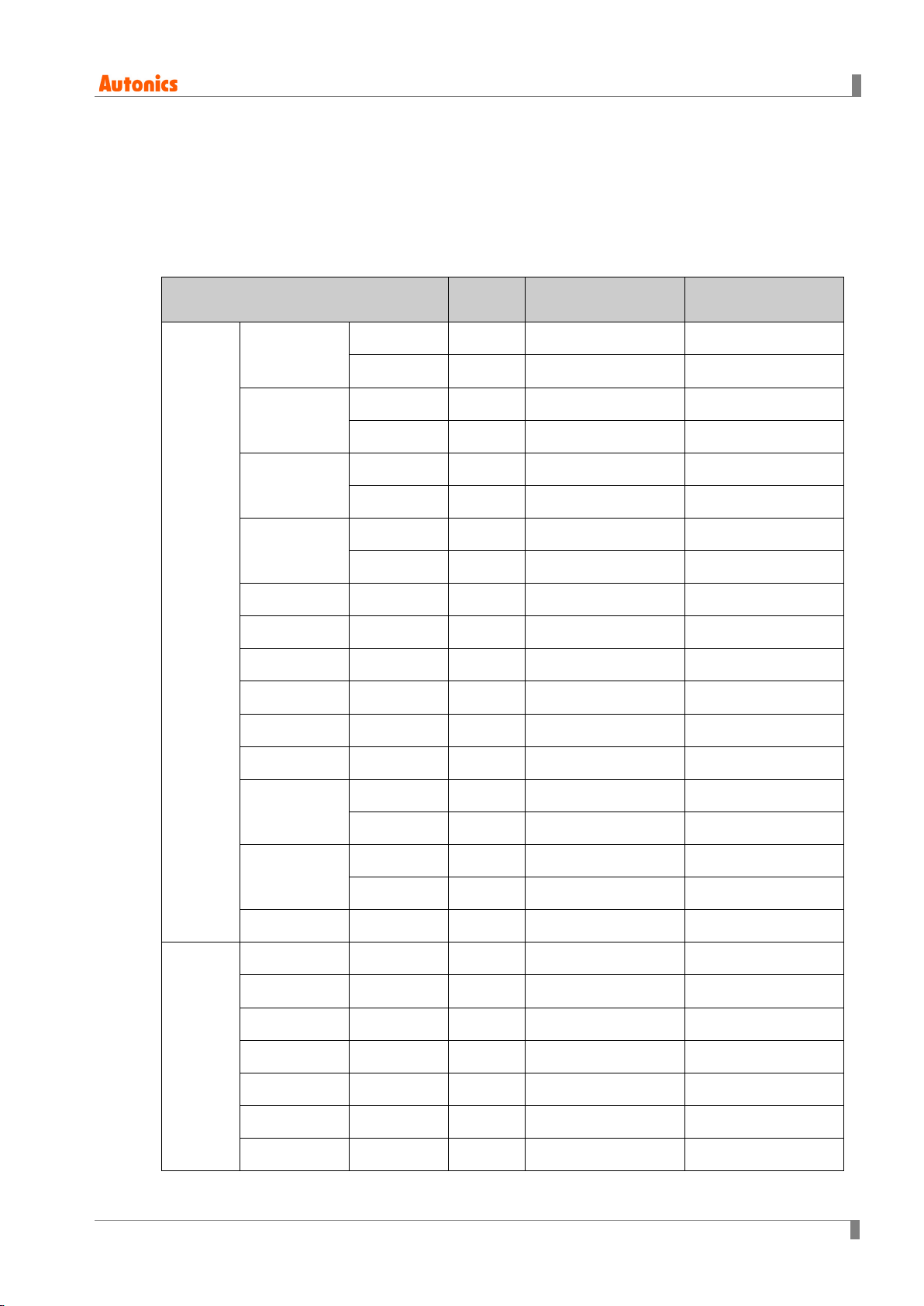

7 Setting group parameter description .................................................... 107

7.1 Setting group [ SV ] ............................................................................................... 107

7.2 MV monitoring/manual control setting group [ MV ] ............................................... 107

7.3 Parameter 1 setting group [ PAR1 ]....................................................................... 108

10 © Copyright Reserved Autonics Co., Ltd.

1 Product Introduction

7.4 Parameter 2 setting group [PAR2 ] ....................................................................... 109

7.5 Parameter 3 setting group [ PAR3 ] ....................................................................... 111

7.6 Parameter 4 setting group [ PAR4 ] ...................................................................... 113

7.7 Parameter 5 setting group [ PAR5 ] ...................................................................... 115

7.8 Password entry parameter .................................................................................... 116

7.9 Parameter change reset parameters .................................................................... 116

8 DAQMaster .............................................................................................. 117

8.1 Overview ............................................................................................................... 117

8.2 Major features ....................................................................................................... 118

8.3 Special feature for TK Series ................................................................................ 120

8.3.1 Parameter mask ....................................................................................... 120

8.3.2 User parameter group [PARU] .................................................................. 122

© Copyright Reserved Autonics Co., Ltd. 11

1 Product Introduction

12 © Copyright Reserved Autonics Co., Ltd.

1 Product Introduction

1 Product Introduction

1.1 Features

TK Series – standard PID temperature controller – realizes more powerful control with super

high-speed sampling cycles of 50 ms and ±0.3% display accuracy. It supports diverse control

modes including heating & cooling simultaneous control, and automatic/manual control and

communication functions. In addition, TK Series covers all necessary features for high

performance temperature controllers – that is, diverse input sensor support, multi SV setting,

SSR drive output + current output, high resolution display and compact size.

Improves convenience for parameter setting (using DAQMaster)

Parameter mask

To hide parameters which are not unnecessary or not used frequently

User parameter group

To group parameters which are used frequently as one group for more convenient

setting

Super high-speed sampling cycle (10 times faster compared to existing models);

50 ms sampling cycle and ±0.3% display accuracy

Improved visibility with wide display and high luminance LED

High performance control with heating & cooling control and automatic/manual control

modes

Communication function supported: RS485 (Modbus RTU type)

PC parameter setting (USB and RS 485 communication)

Free download comprehensive device management program (DAQMaster)

※Communication converter, sold separately

: SCM-WF48 (Wi-Fi to RS485·USB wireless communication converter),

SCM-US48I (USB to RS485 converter), SCM-38I (RS232C to RS485 converter),

SCM-US (USB to serial converter)

Current output or SSR drive output selectable

ON/OFF, Cycle, Phase control by SSRP function

Heater burn-out alarm (CT input) (except TK4SP)

※CT, sold separately: CSTC-E80LN, CSTC-E200LN, CSTS-E80PP

Multi SV setting function (Max. 4 ) – selectable via digital input terminals

Space saving mounting possible with compact design ; downsized by 38% (depth-based)

Multi-input/multi-range

© Copyright Reserved Autonics Co., Ltd. 13

1 Product Introduction

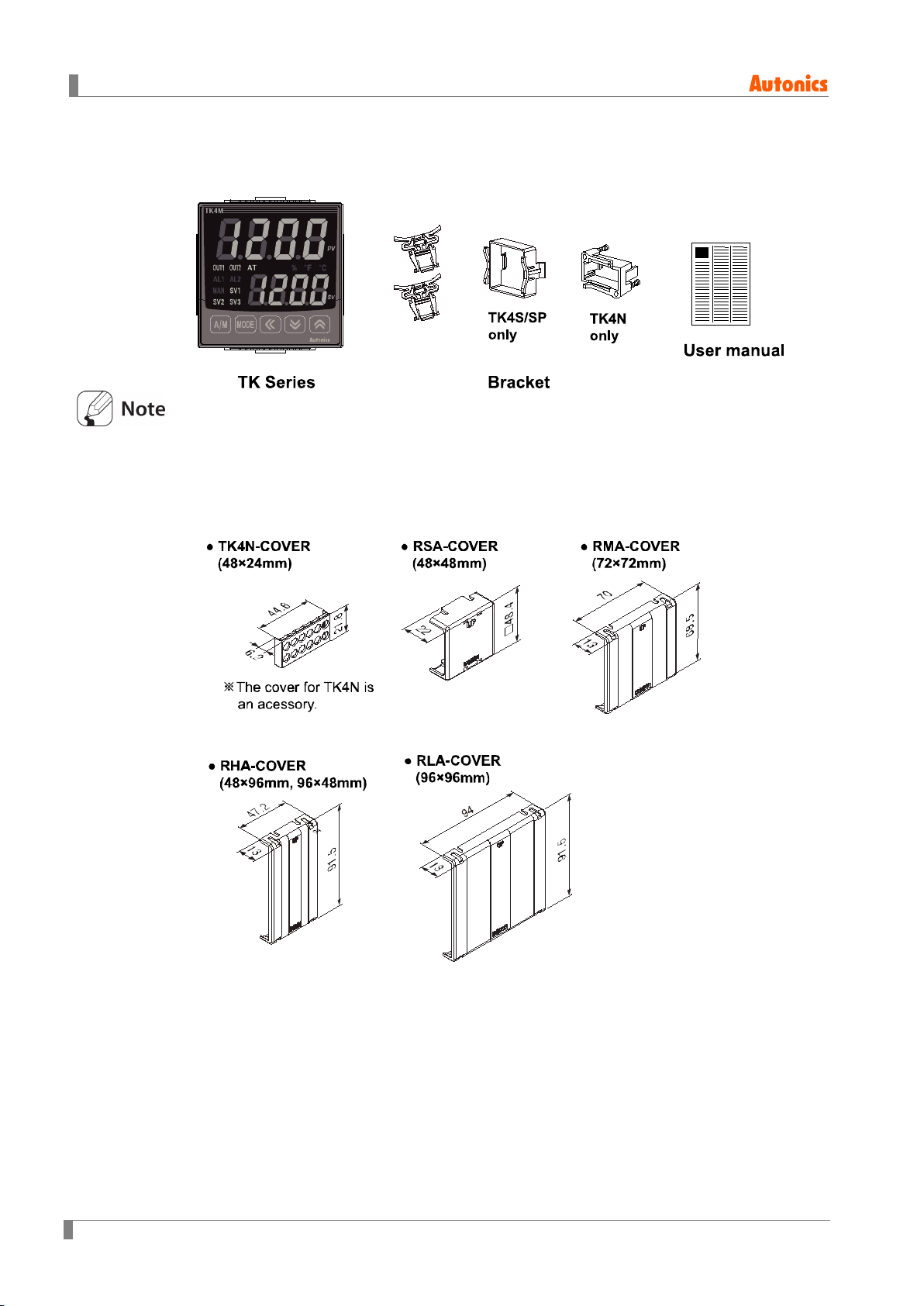

1.2 Components and Accessories

(1) Components

Make sure all of the above components are included with your product package before use.

If a component is missing or damaged, please contact Autonics or your distributor.

Visit www.autonics.com to download a copy of the user manual.

(2) Sold separately

Terminal cover (unit: mm)

14 © Copyright Reserved Autonics Co., Ltd.

1 Product Introduction

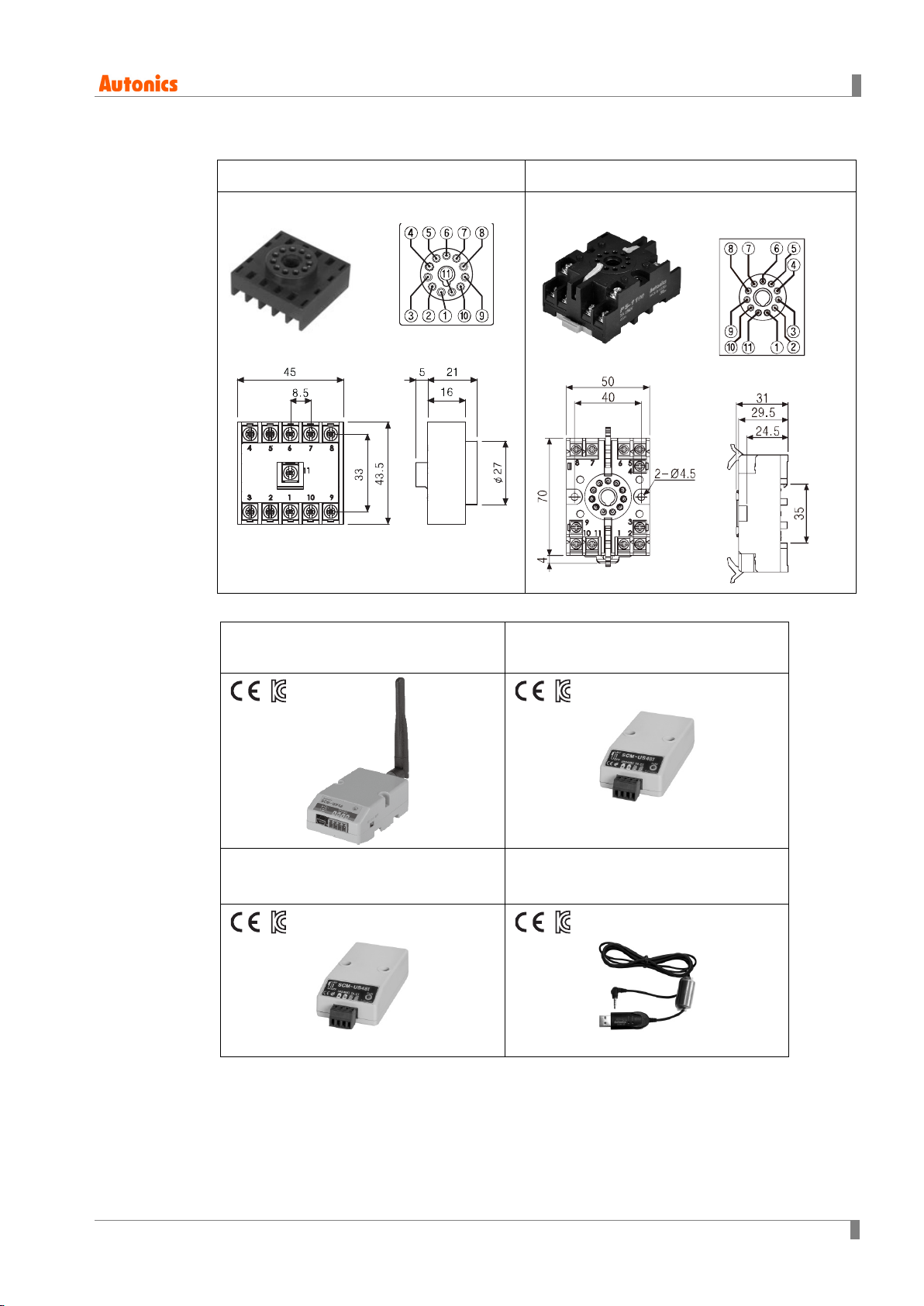

Socket (for TK4SP) (unit: mm)

PG-11 PS-11(N)

(unit: mm)

Communication converter

SCM-WF48 (Wi-Fi to RS485·USB

wireless communication converter)

(unit: mm)

SCM-US48I

(USB to RS485 converter)

SCM-38I

(RS232C to RS485 converter)

SCM-US

(USB to Serial converter)

© Copyright Reserved Autonics Co., Ltd. 15

1 Product Introduction

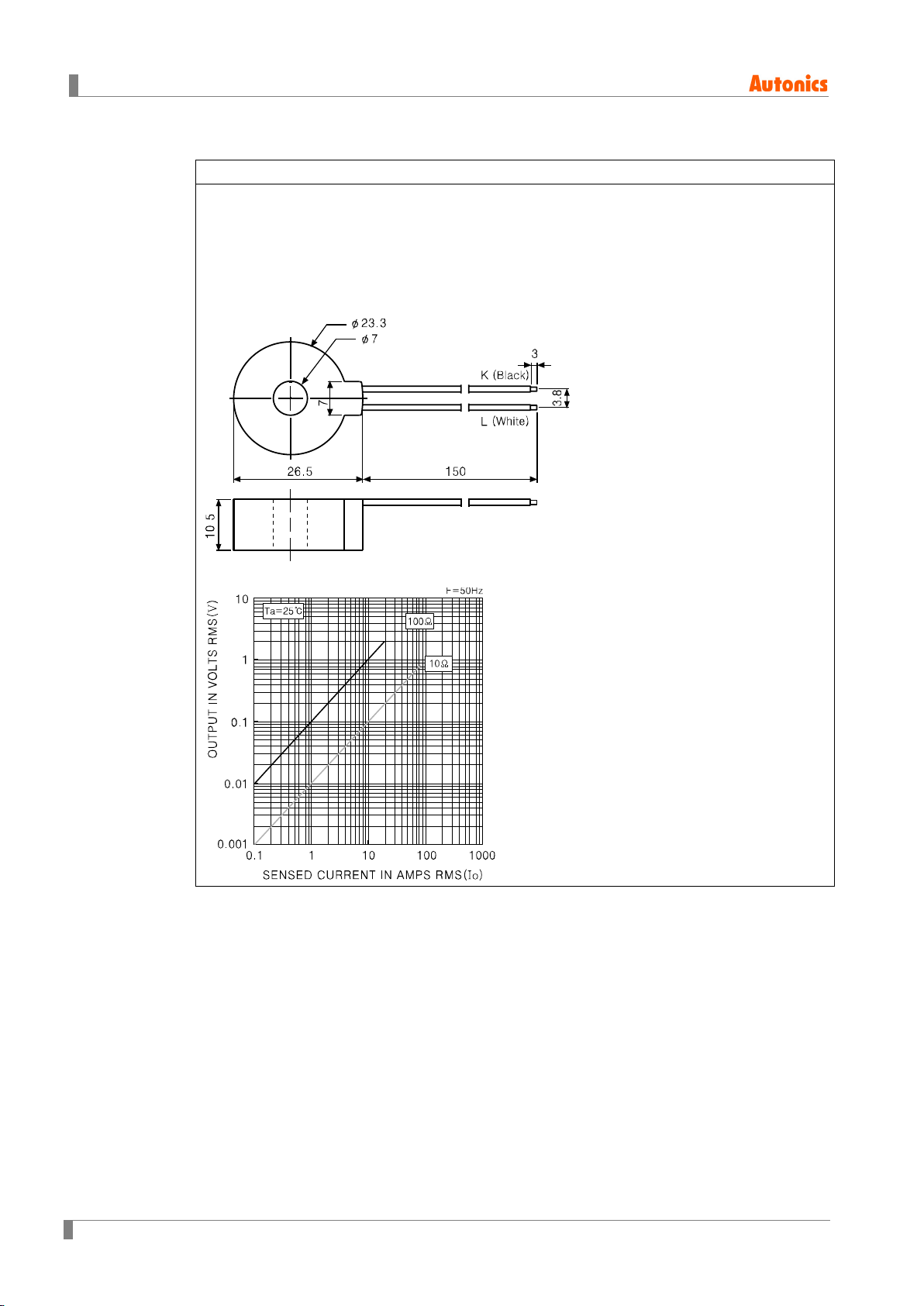

Current transformer(CT)

CSTC-E80LN

Max. load current: 80A (50/60Hz)

※Max. load current for TK4 Series is 50A.

Current ratio: 1/1000

Wire wounded resistance: 31Ω ±10%

(unit: mm)

16 © Copyright Reserved Autonics Co., Ltd.

1 Product Introduction

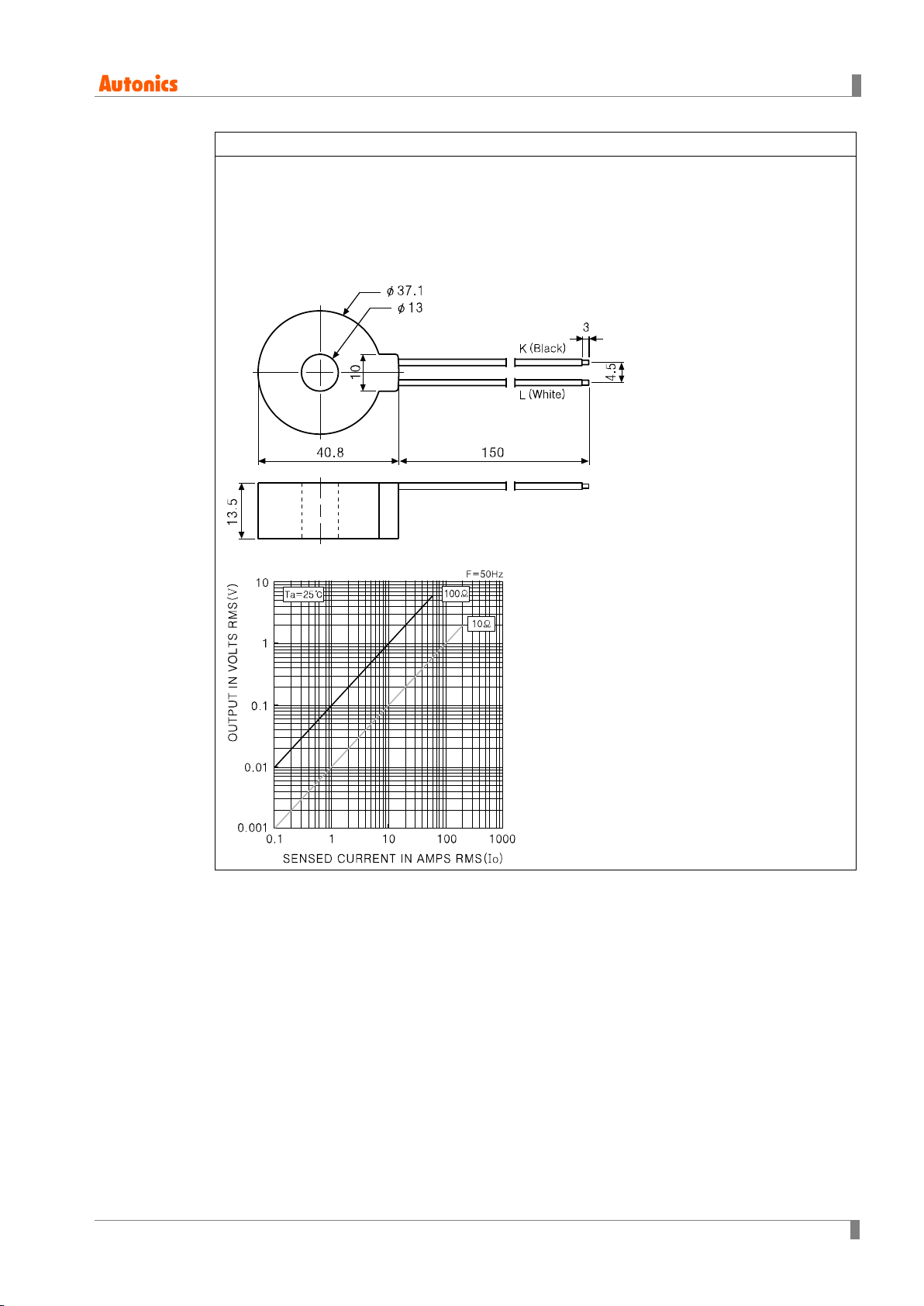

CSTC-E200LN

Max. load current: 200A (50/60Hz)

※Max. load current for TK4 Series is 50A.

Current ratio: 1/1000

Wire wounded resistance: 20Ω±10%

(unit: mm)

© Copyright Reserved Autonics Co., Ltd. 17

1 Product Introduction

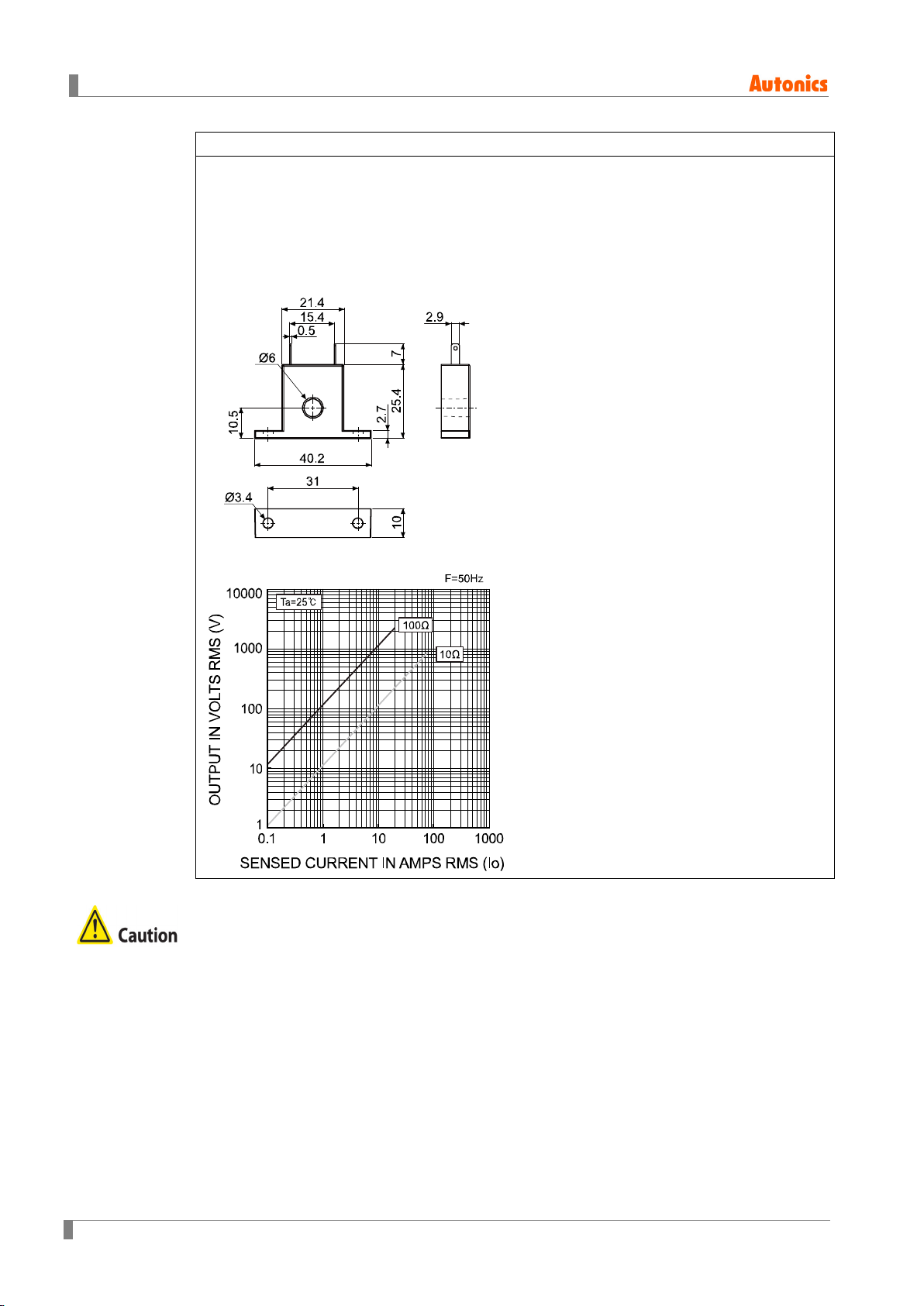

CSTS-E80PP

Max. load current: 80A (50/60Hz)

※Max. load current for TK4 Series is 50A.

Current ratio: 1/1000

Wire wounded resistance: 31Ω ±10%

(unit: mm)

For using CT, do not supply first part current when opening CT output.

It occurs high voltage at CT output part.

Using current of above CTs are same as 50A. But be sure that inner hole sizes are different.

Select it properly for the environment.

18 © Copyright Reserved Autonics Co., Ltd.

1 Product Introduction

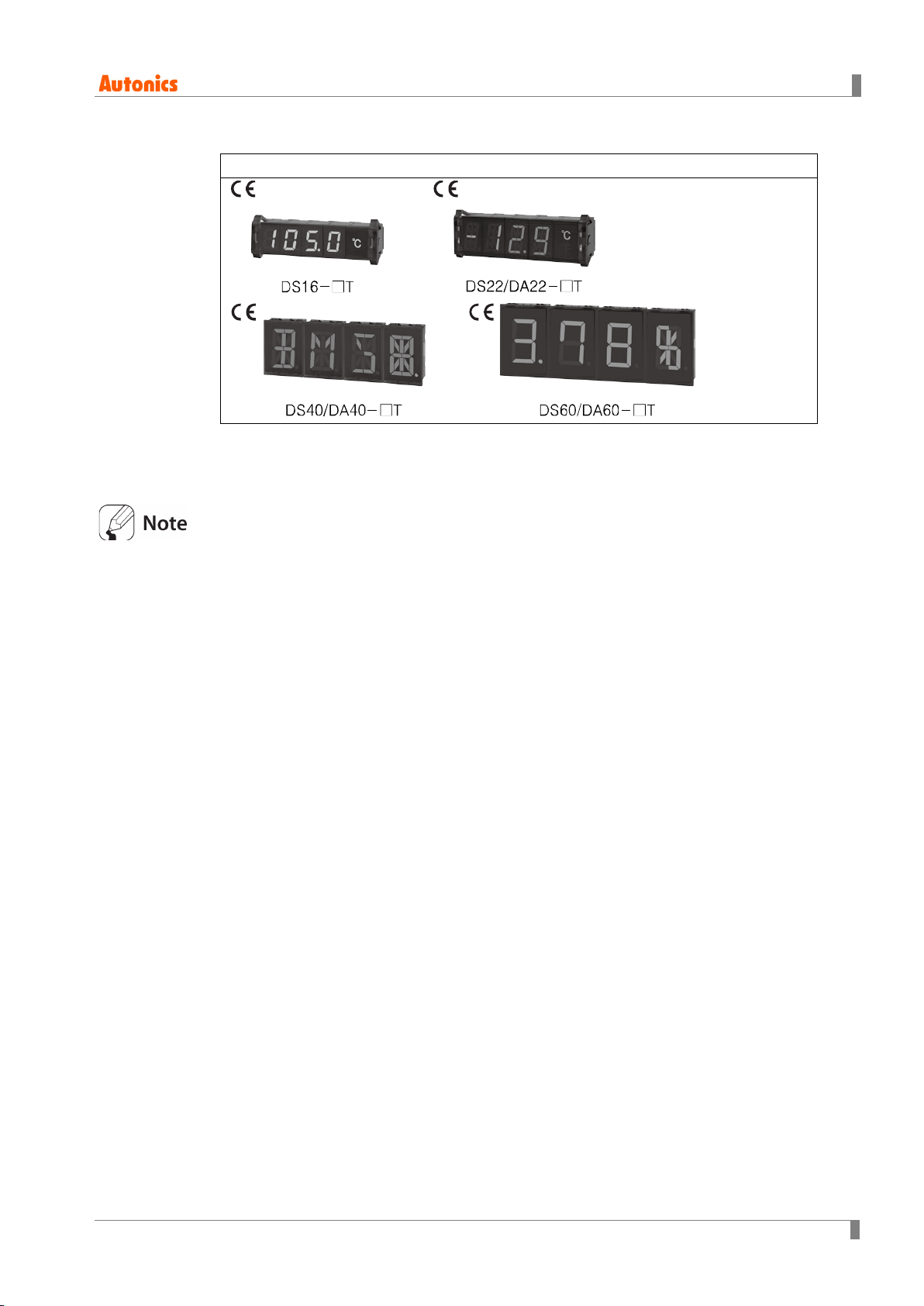

Display unit

DS/DA-T Series (RS485 communication input type display unit)

Connect RS485 communication input type display unit (DS/DA-T Series) and TK Series, the

display unit displays present value of the device without PC/PLC.

Images of components and accessories may differ from actual products.

For detailed information about any of the above products, please refer to the concerned

product's user manual.

Visit our website (www.autonics.com) to download copies of the user manuals.

© Copyright Reserved Autonics Co., Ltd. 19

1 Product Introduction

①

Category

Description

Standard: Alarm output 1+RS485com. output

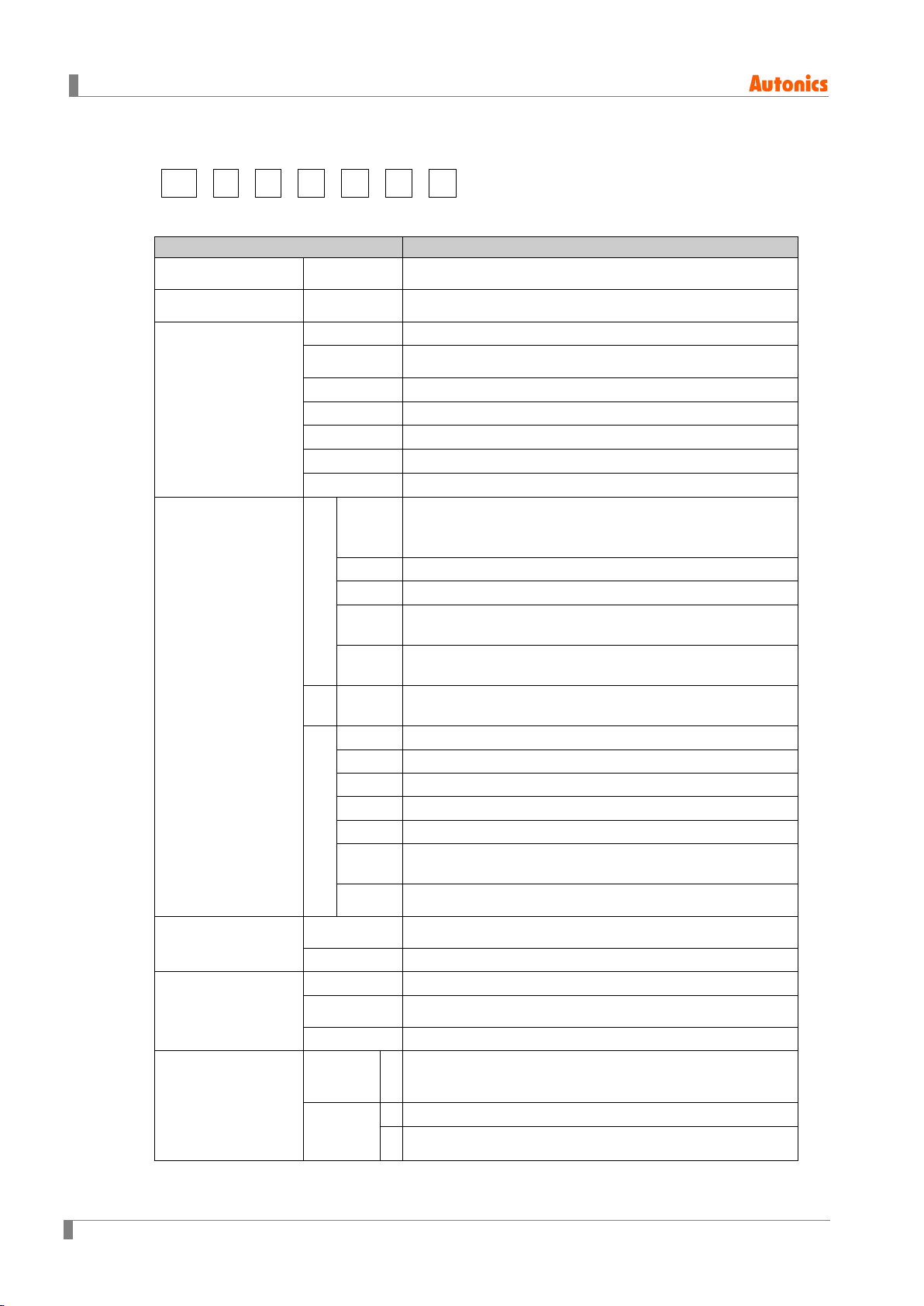

1.3 Ordering information

TK 4 S - 1 4 R R

② ③ ④ ⑤ ⑥ ⑦

① Item

② Digit

③ Size

④ Input/Output

Option

1

※

⑤ Power Supply

⑥ OUT1 Control

Output

2

※

⑦ OUT2 Control

3

※

Output

TK Temperature/Process controller

4 9999(4digit)

N

SP

DIN W48×H24mm

DIN W48×H48mm (11 pin plug type

9

※

)

S DIN W48×H48mm (terminal block type)

M DIN W72×H72mm

W DIN W96×H48mm

H DIN W48×H96mm

L DIN W96×H96mm

6,

1

Standard: Alarm output 1+CT input

Heating&Cooling: Alarm output 2

※

7

※

2 Standard: Alarm output 1+Alarm output 2

N

D Standard: Alarm output 1+Digital input(DI-1, DI-2)

R

T

S

1 Alarm output 1

P

Standard: Alarm output 1+Digital input, Heating&Cooling:

Trans. output

Heating&Cooling: RS485com. output

1 Alarm output 1

2 Alarm output 1+Alarm output 2

S

R Alarm output 1+Trans. output

M

T Alarm output 1+RS485com. output

W

A Alarm output 1+Alarm output 2+Trans. output

H

L

2

B

D

5

※

Alarm output 1+Alarm output 2+

RS485 com. output

Alarm output 1+Alarm output 2+Digital input(DI-1, DI-2)

24VAC 50/60Hz, 24-48VDC

4 100 to 240VAC, 50/60Hz

R Relay output

4

※

S

SSR drive output(standard ON/OFF, cycle, phase control)

C Current output or SSR drive output selectable

None

Standard

Heating

&

Cooling

N

※Select in case of standard control (heating or cooling)

R Relay output

C Current output or SSR drive output selectable

8

※

20 © Copyright Reserved Autonics Co., Ltd.

1 Product Introduction

※1. In case of TK4N/SP Series, option control output selection and digital input will be

limited due to number of terminals.

※2. “S” represents SSR drive output support models which SSRP function (standard

ON/OFF, cycle, phase)control are available. “C” represents selectable current and

SSR drive output support models.

※3. Select “R” or “C” type in case of using heating & cooling control. “N” type in case fo

using standard control.

※4. Does not support in AC/DC voltage type model.

※5. Does not support in TK4N.

※6. The CT input model of TK4N is selectable only for standard model which has alarm 1.

※7. The Heaing & Cooling model of TK4N-1□□□ has only alarm output 2.

※8. Only for TK4S-D□□□, OUT2 output terminal is used as DI-2 input terminal.

※9. 11Pin socket(PG-11, PS-11(N)): Sold separately

CT (Current Transformer) input is supported by all models.

However, TK4SP (11 pin plug type) does not support CT input due to its limited number of

terminal blocks.

© Copyright Reserved Autonics Co., Ltd. 21

1 Product Introduction

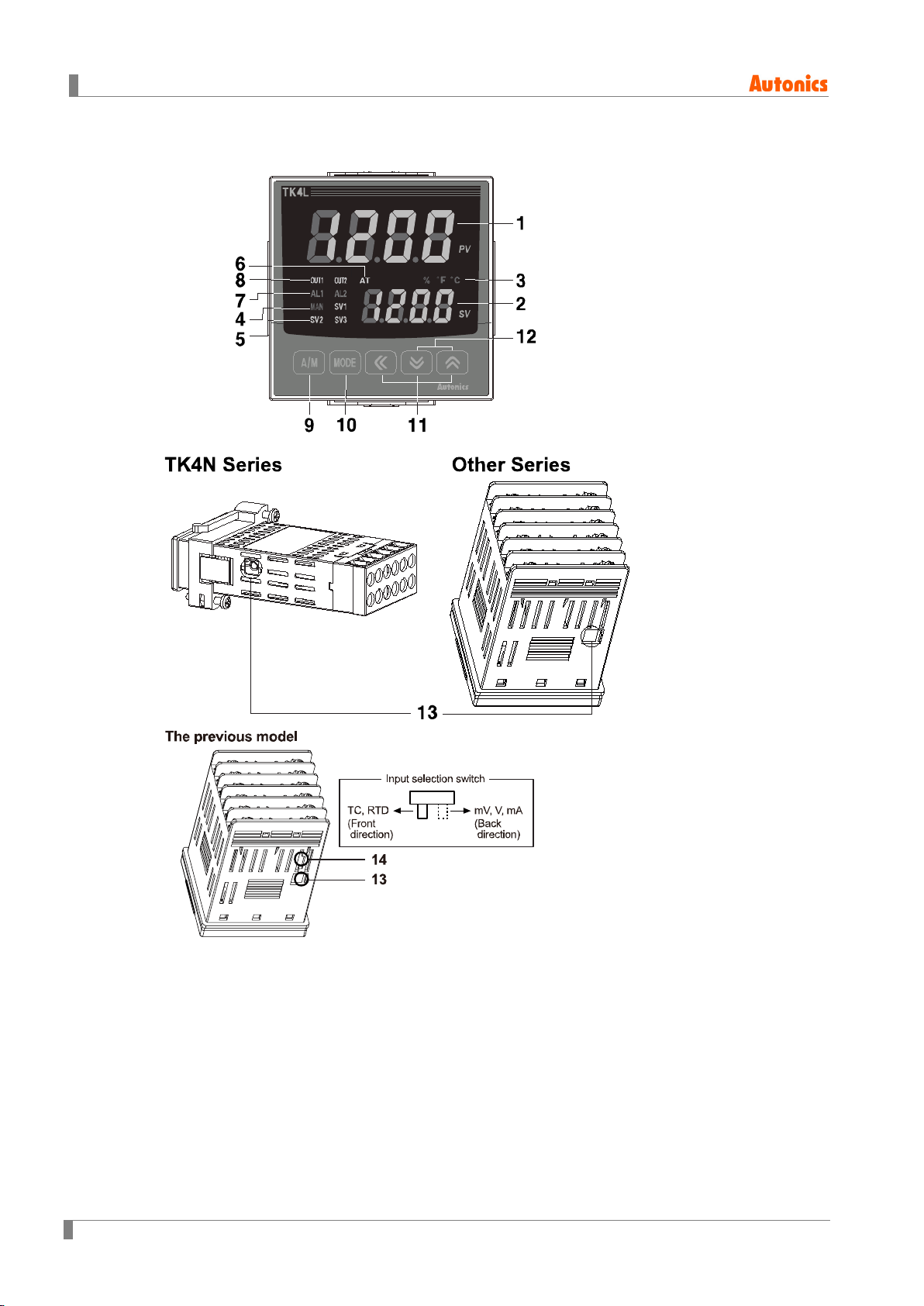

1.4 Parts descriptions

① Measured value(PV) display part:

RUN mode: It displays currently measured value (PV).

Setting mode: It displays the parameter.

② Set value (SV) display part:

RUN mode: It displays the set value (SV).

Setting mode: It displays the set value of the parameter.

③ Unit(℃/℉/%) indicator: It displays the unit set at display unit [UNT] in parameter 3 group.

(TK4N Seires does not support ‘%’ unit.)

④ Manual control indicator: It turns ON during manual controlling.

⑤ Multi SV indicator: One of SV1 to 3 indicator will be ON in case of selecting multi SV

function.

⑥ Auto tuning indicator: It flashes by 1 sec. when executing auto tuning.

22 © Copyright Reserved Autonics Co., Ltd.

1 Product Introduction

⑦ Alarm output (AL1, AL2) indicator: It turns ON when the alarm output is ON.

⑧ Control output (OUT1, OUT2) indicator: It turns ON when the control output is ON.

During cycle/phase controlling in SSRP function model (TK4□-□4S□)type, when MV is

over 5.0%, it turns ON.

※ To use current ouput, when MV is 0.0% in manual control, it turns OFF. Otherwise, it

always turns ON. When MV is over 3.0% in auto control, it turns ON and when MV is

below 2.0%, it turns OFF.

⑨ key: It is used when switching auto control to manual control.

※ TK4N/S/SP do not have the key. The key operates switching

simultaneously.

⑩ key: It is used when entering parameter group, returning to RUN mode, moving

parameter, saving the set value.

⑪ key: It is used when entering the set value changing mode and moving or

changing up/down digit.

⑫ Digital input key: When pressing the keys for 3 sec. at the same time, it operates

the function (RUN/STOP, alarm clear,auto tuning) set at digital input key [DI-K] in

parameter 5 group.

⑬ PC loader port: It is the PC loader port for serial communication to set parameter and

monitoring by DAQMaster installed in PC. Use this for connecting SCM-US(USB to Serial

converter, sold separately).

⑭ Input selection switch: Used when switching sensor (TC, RTD) input ↔ analog input(mV,

V, mA) (only the previous models)

7-Segment Display Characters

A B C D E F G H I J K L M

A B C D E F G H I J K L M

N O P Q R S T U V W X Y Z

N O P Q R S T U V W X Y Z

0 1 2 3 4 5 6 7 8 9 0 ` /

0 1 2 3 4 5 6 7 8 9 0 -1 /

© Copyright Reserved Autonics Co., Ltd. 23

1 Product Introduction

24 © Copyright Reserved Autonics Co., Ltd.

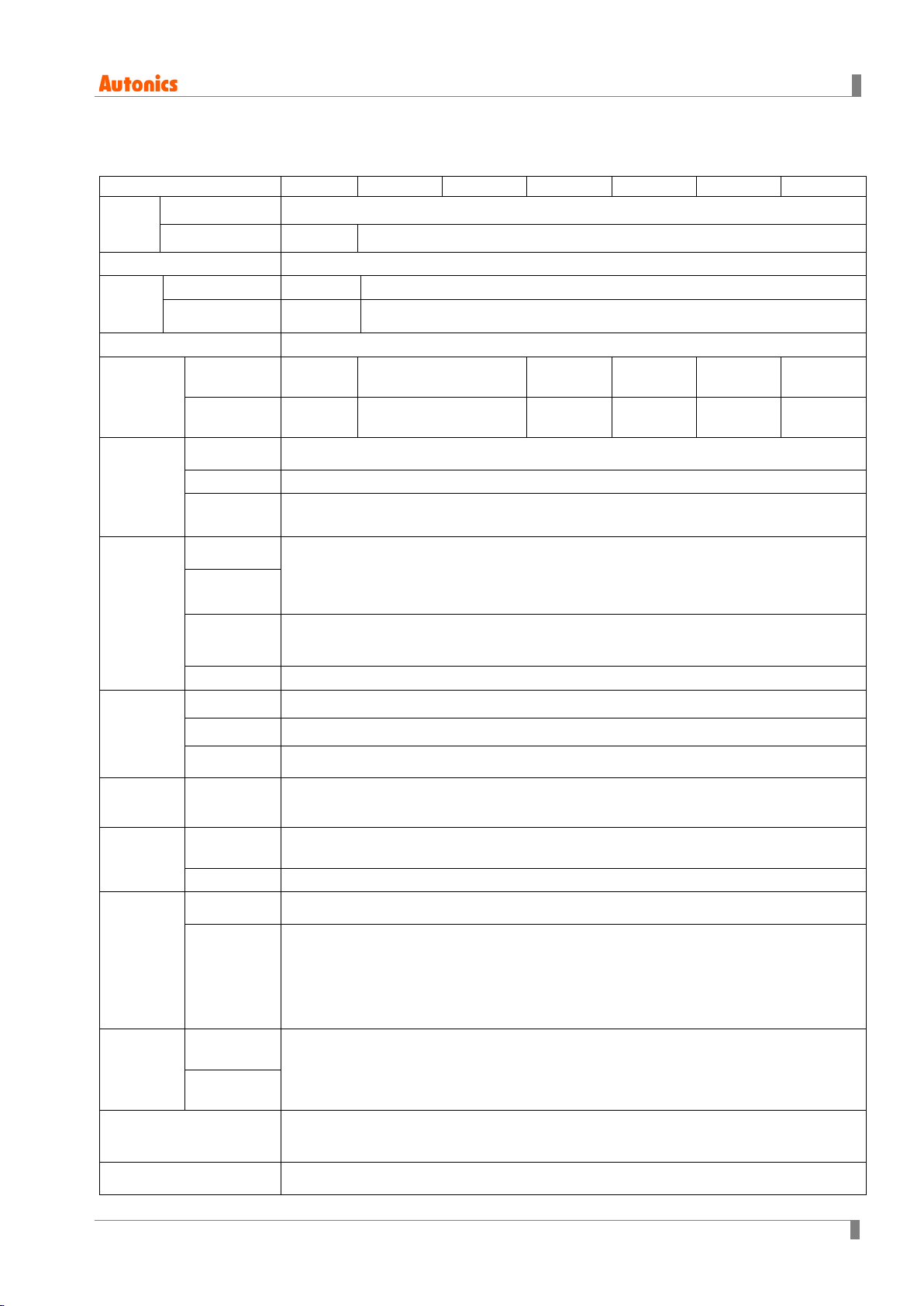

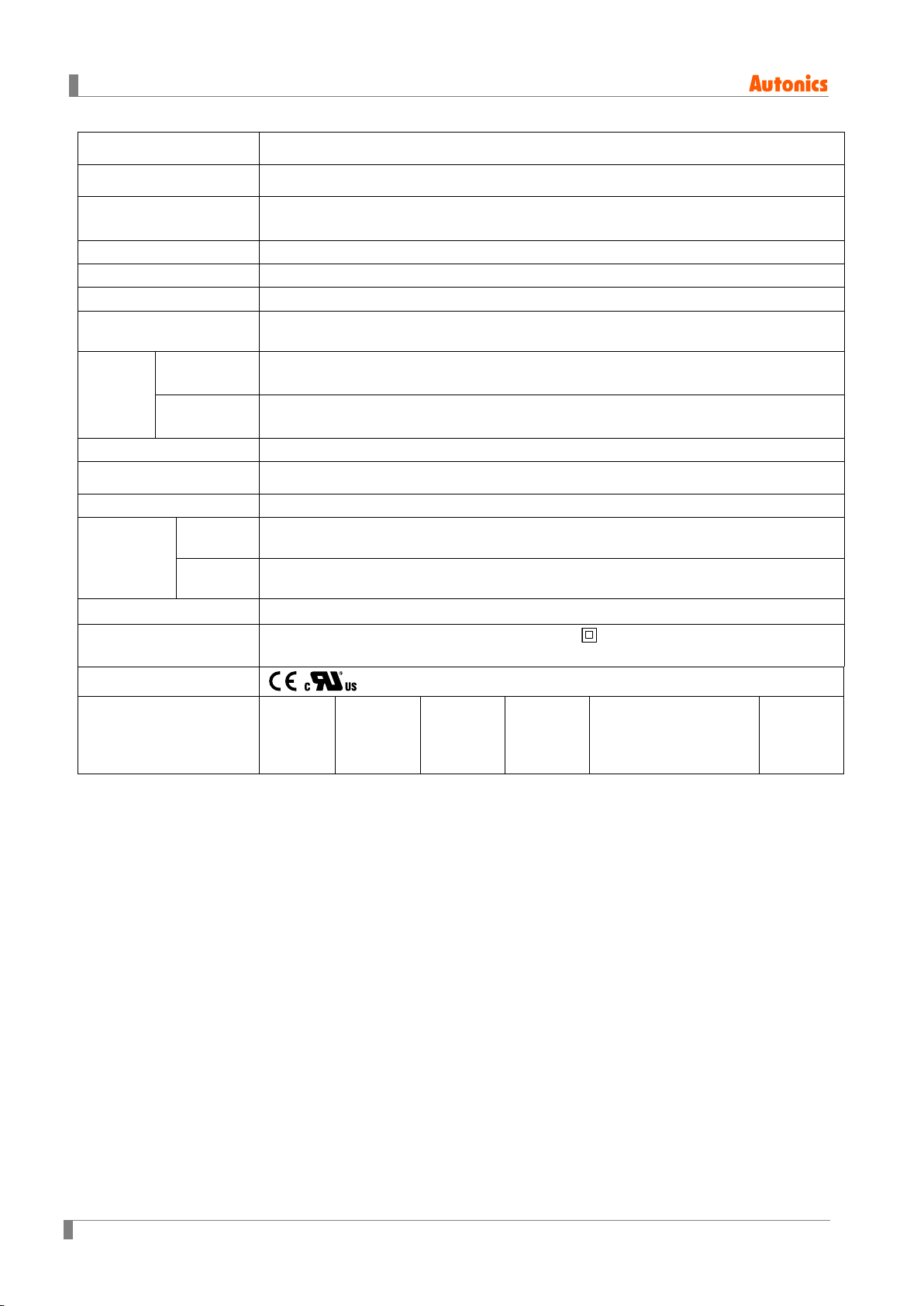

2 Specifications

Series

TK4N

TK4SP

TK4S

TK4M

TK4W

TK4H

TK4L

2 Specifications

Power

supply

AC voltage

AC/DC voltage -

100-240VACᜠ, 50/60Hz

24VACᜠ 50/60Hz, 24-48VDCᜡ

Allowable voltage range ±10% of rated voltage

Power

consu

mption

AC voltage Max. 6VA Max. 8VA

AC/DC voltage -

Max. 8VA(24VACᜠ 50/60Hz), Max. 5W(24-48VDCᜡ)

Display method 7 segment (PV: red, SV: green), all other displays (green, yellow, red) LED

Character

size

Input type

PV(W×H)

SV(W×H)

RTD

4.5 × 7.2

mm

3.5 × 5.8

mm

7.0×14.0mm

5.0×10.0mm

JPt 100Ω, DPt 100Ω, DPt 50Ω, Cu 100Ω, Cu 50Ω, and Nikel 120Ω (6 types)

TC K, J, E, T, L, N, U, R, S, B, C, G, and PLII (13 types)

Analog

RTD

Voltage: 0-100mV, 0-5V, 1-5V, and 0-10V (4 types)

Current: 0-20mA and 4-20mA (2 types)

At room temperature (23℃ ± 5℃): (PV ± 0.3% or ± 1℃, select the higher one) ± 1 digit

9.5×20.0

mm

7.5×15.0

mm

8.5×17.0

mm

6.0×12.0

mm

7.0×14.6

mm

6.0×12.0

mm

Out of room temperature ranges: (PV ± 0.5% or ± 2℃, select the higher one) ± 1 digit

Display

TC

accuracy

Analog

In case of TK4SP Series, ±1℃ will be added.

At room temperature (23℃ ± 5℃): ± 0.3% F.S. ± 1 digit

Out of room temperature ranges: ± 0.5% F.S. ± 1 digit

CT Input ± 5% F.S. ± 1 digit

OUT1, OUT2: 250VACᜠ 3A 1a

Max.11VDCᜡ ± 2V 20mA

DC4-20mA or DC0-20mA selectable (resistance load max. 500Ω)

Control

output

Relay

SSR

Current

11.0×22.0

mm

7.0×14.0

mm

1

※

Alarm

output

Option

output

Option

input

Relay

Transmissio

n output

Comm. RS485 Communication Output (Modbus RTU)

CT

Digital input

AL1, AL2 Relay: 250VACᜠ 3A 1a

(TK4N AL2: 250VACᜠ 0.5A 1a (max. 125VA), TK4SP has only AL1)

DC4-20mA (resistance load max. 500Ω, output accuracy: ±0.3% F.S)

0.0-50.0A (primary heater current reading range) ※CT Ratio is 1/1000 (except TK4SP)

Contact input - ON: Max. 2kΩ, OFF: Min. 90kΩ

Non-Contact input - ON: Residual voltage max. 1.0VDCᜡ, OFF: Leakage current min. 0.1mA

Leakage current: Approx. 0.5mA per input

※TK4S/M: 1 (TK4S-D□□□: 2, TK4SP: None), TK4N/H/W/L: 2 (except TK4SP)

Heating &

Control

type

cooling

Heating or

ON/OFF, P, PI, PD, PID control mode

Cooling

Hysteresis

RTD/ Thermocouples: 1 to 100℃/℉ (0.1 to 100.0℃/℉) variable

Analog: 1 to 100 digit

Proportional band (P)

0.1 to 999.9℃/℉ (0.1 to 999.9%)

© Copyright Reserved Autonics Co., Ltd. 25

2 Specifications

Manual reset value

0.0 to 100.0%

Ambient

Integral time (I) 0 to 9999sec.

Derivative time (D) 0 to 9999sec.

Control period (T)

Relay output, SSR drive output: 0.1 to 120.0 sec.

Current output+SSR drive output: 1.0 to 120.0 sec.

Sampling period 50 ms

Dielectric strength 2,000 VAC 50/60 Hz for 1 min. (between power source terminal and input terminal)

Vibration resistance

Relay

Mechanical

life

cycle

Electrical

0.75mm amplitude at frequency of 5 to 55 Hz (for 1 min.) in each of X, Y, Z directions

for 2 hours

OUT1/OUT2: Min. 5,000,000 operations

AL1/2: Min. 20,000,000 operations (TK4H/W/L: Min. 5,000,000 operations)

OUT1/OUT2: Min. 200,000 operations

AL1/2: Min. 100,000 operations(TK4H/W/L: Min. 200,000 operations)

Insulation resistance Min. 100MΩ (at 500VDC megger)

Noise resistance

Square shaped noise by noise simulator (pulse width 1 ㎲) ±2 kV R-phase, S-phase

Memory retention Approx. 10 years (non-volatile semiconductor memory type)

Environ

-ment

Ambient

temp.

humi.

-10 to 50℃, Storage: -20 to 60℃

35 to 85% RH, Storage: 35 to 85% RH

Protection IP65 (front panel) ※TK4SP: IP50 (front panel)

Insulation type

Double insulation or reinforced insulation (mark: , dielectric strength between the

measuring input part and the power part: 2kV)

Approval

※

Weight

Approx.

2

140 g

(Approx.

70 g)

Approx.

130 g

(Approx.

85 g)

Approx.

150 g

(Approx.

105 g)

Approx.

210 g

(Approx.

140 g)

Approx. 211 g

(Approx. 141 g)

Approx.

249 g

(Approx.

198 g)

※1. At room Temperature range(23℃ ± 5℃)

TC K, J, T, N, E type , below -100℃ / TC L, U, PLⅡ, RTD Cu50

Ω, DPt50Ω:

(PV ±0.3% or ±2℃, select the higher one) ± 1digit

TC C, G, R, S type bellow 200℃: (PV ±0.3% or ±3℃, select the higher one)

± 1 digit

TC B type, below 400℃: There is no accuracy standard.

Out of room temperature range

RTD Cu50

Ω, DPt50Ω: (PV ±0.5% or ±3℃, select the higher one) ±1digit

TC R, S, B, C, G type: (PV ±0.5% or ±5℃, select the higher one) ±1digit

Others, Below -100℃, Within ±5℃

In case of TK4SP Series, ±1℃ will be added to the degree standard.

26 © Copyright Reserved Autonics Co., Ltd.

※2. The weight is with packaging and the weight in parentheses is only unit weight.

※Environment resistance is rated at no freezing or condensation.

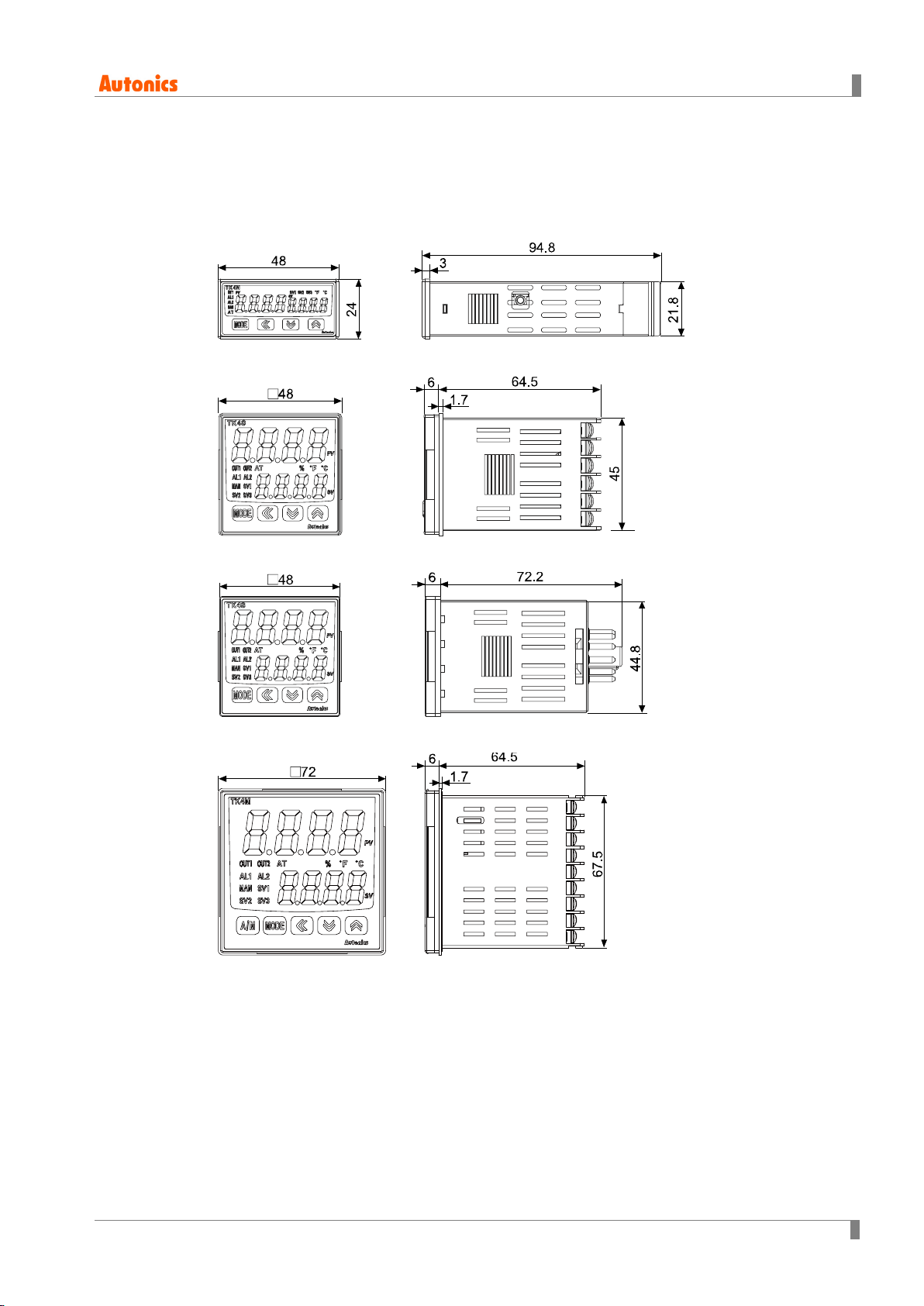

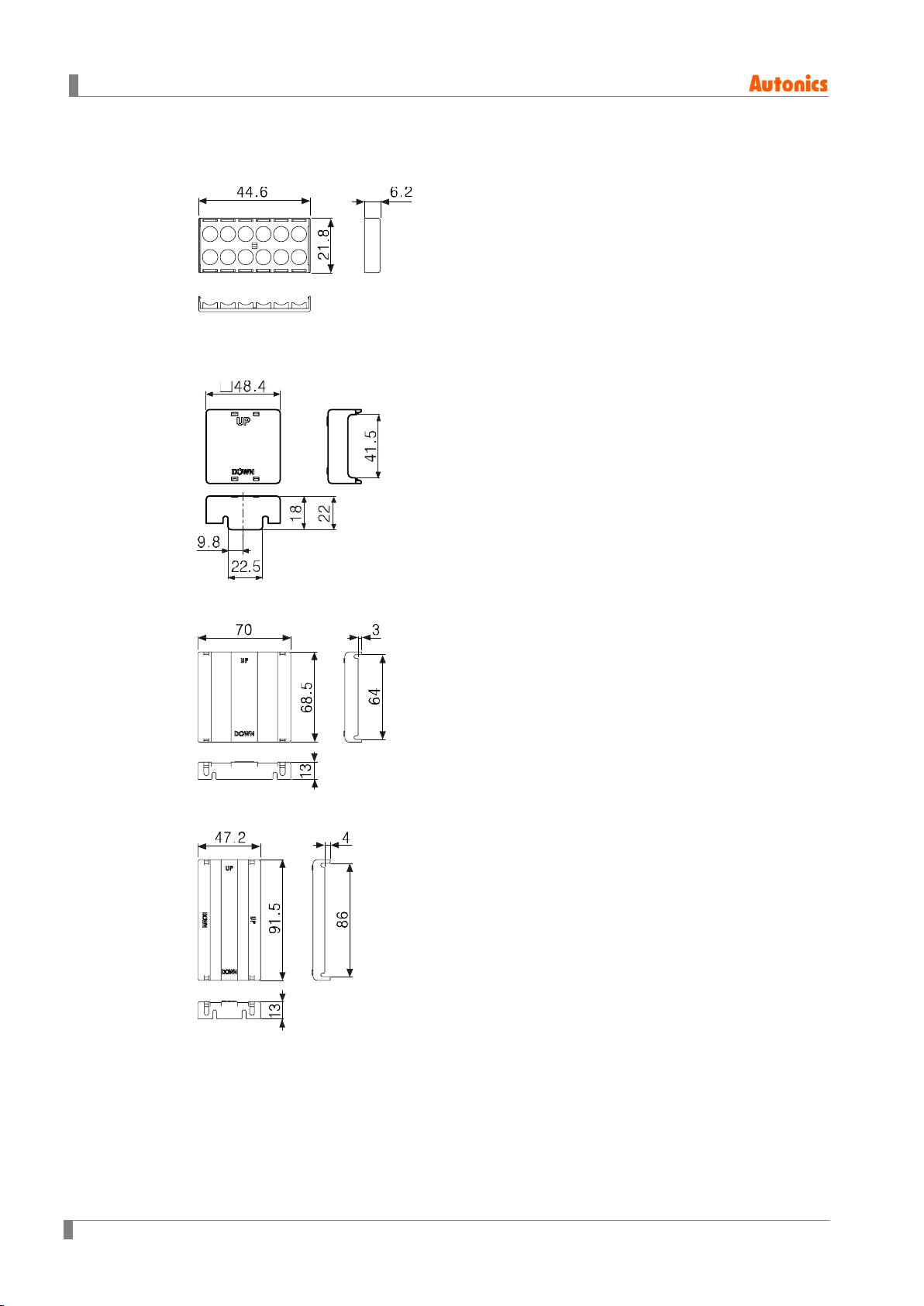

3 Dimensions

3 Dimensions

(1) TK4N Series

(2) TK4S Series

(unit: mm)

(3) TK4SP Series

(4) TK4M Series

© Copyright Reserved Autonics Co., Ltd. 27

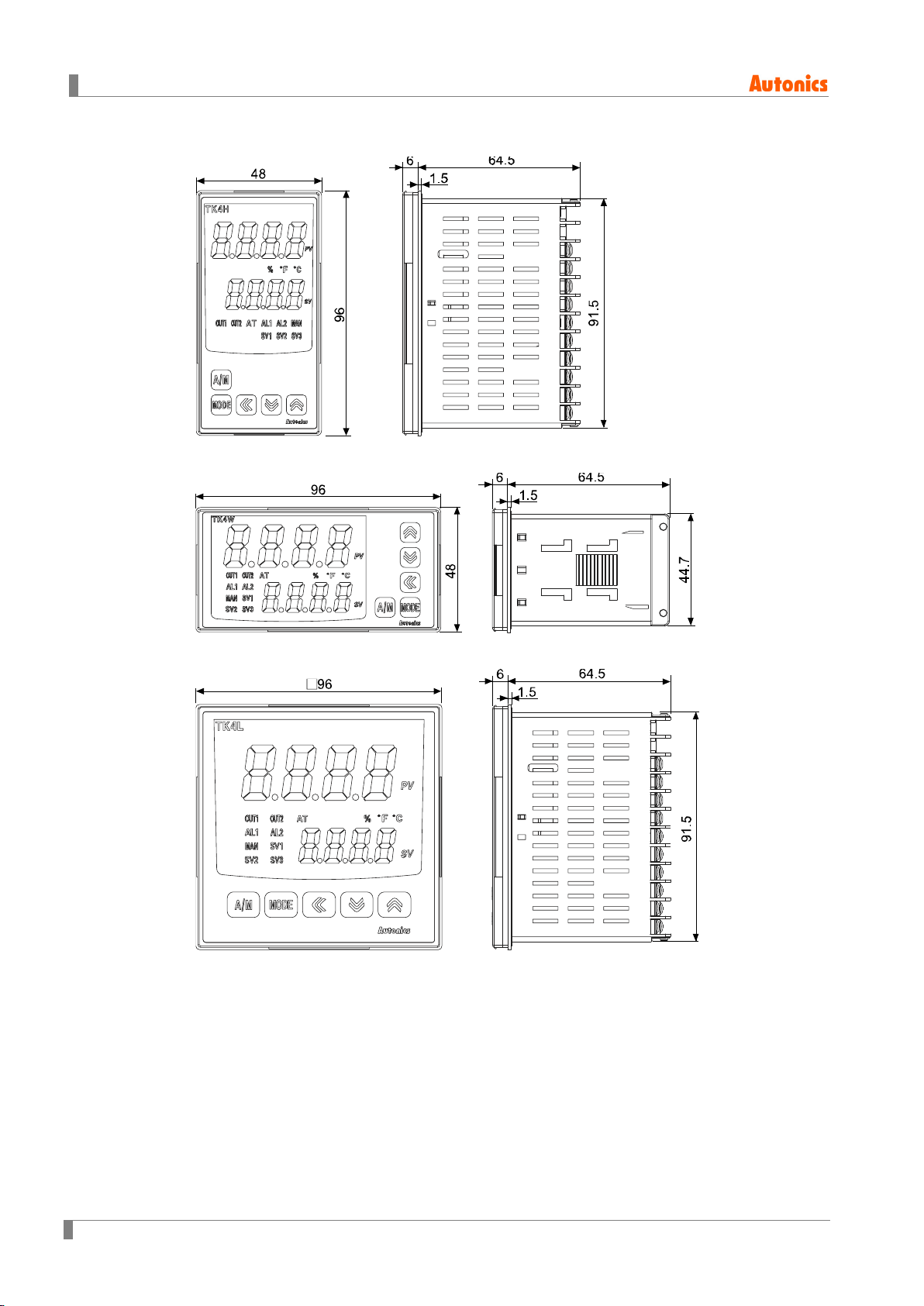

3 Dimensions

(5) TK4H Series

(6) TK4W Series

(7) TK4L Series

28 © Copyright Reserved Autonics Co., Ltd.

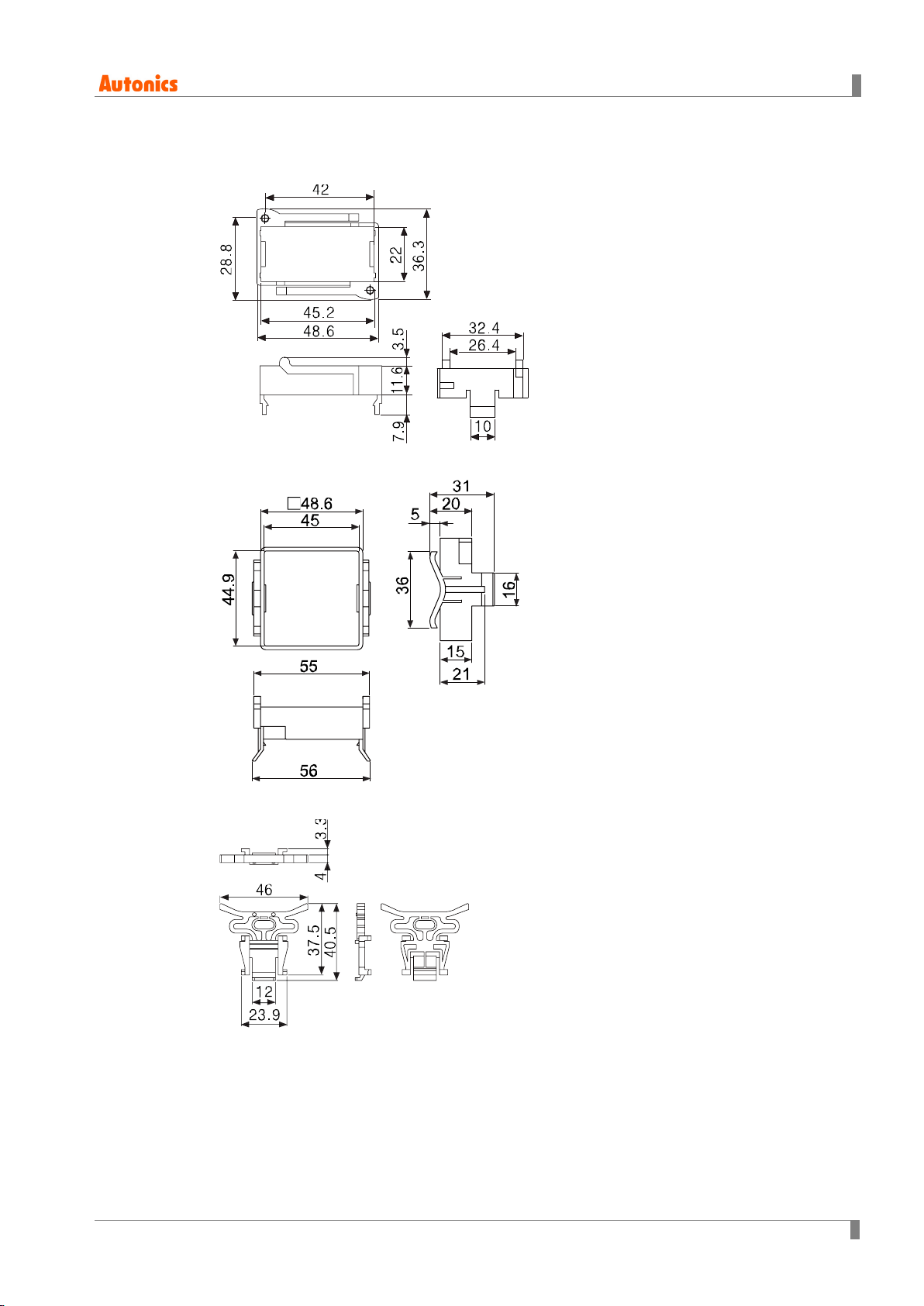

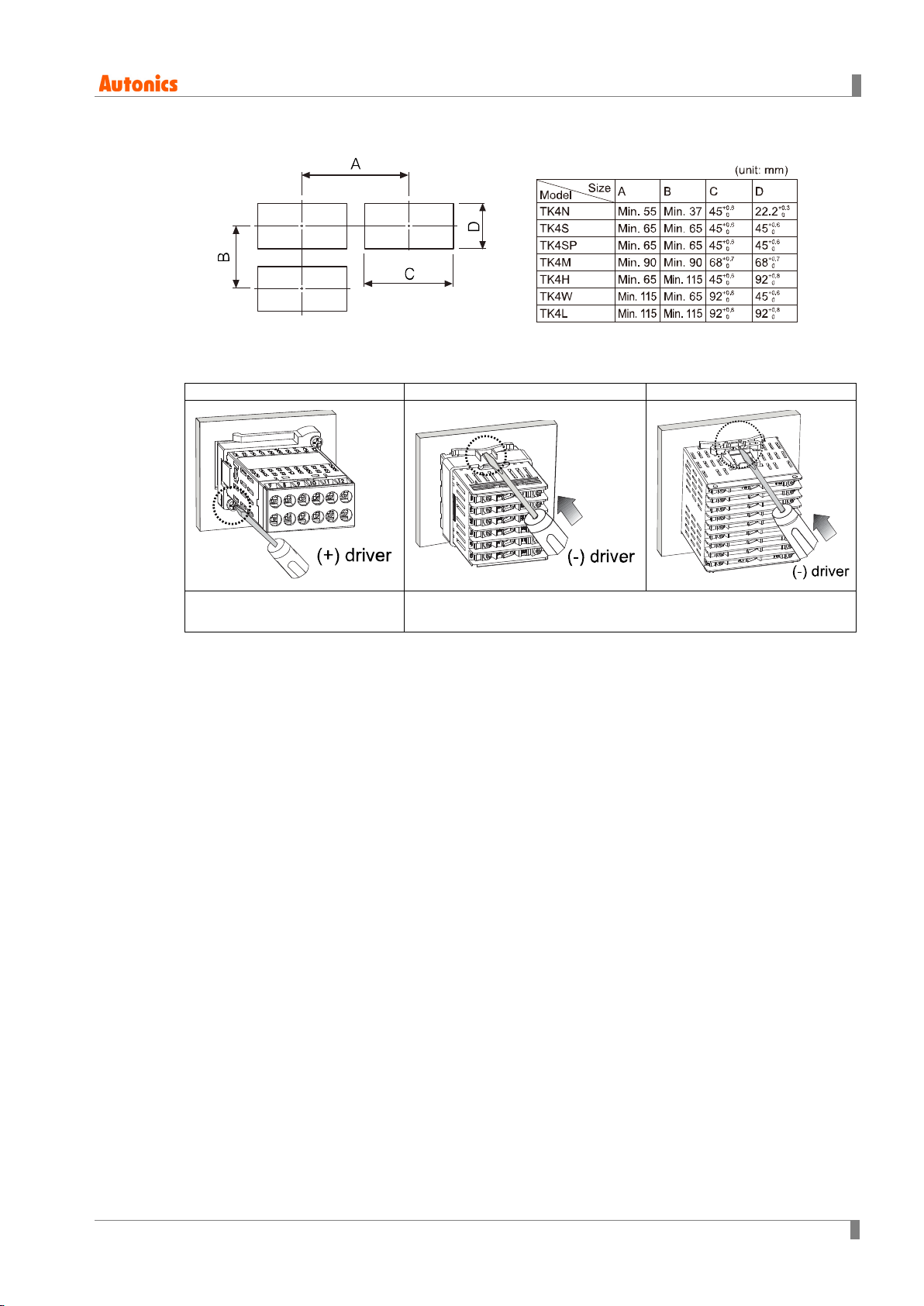

3 Dimensions

(8) Bracket

TK4N Series

TK4S, TK4SP Series

TK4M/W/H/L Series

© Copyright Reserved Autonics Co., Ltd. 29

3 Dimensions

(9) Terminal cover (sold separately)

TK4N COVER (48×24mm)

※TK4N COVER is accessory.

RSA-COVER (48×48mm)

RMA-COVER (72×72mm)

RHA-COVER (48×96mm, 96×48mm)

30 © Copyright Reserved Autonics Co., Ltd.

3 Dimensions

TK4N

TK4S/SP

Other Series

(10) Panel cut-out

Installation

Insert the unit into a panel

fasten the bolt with a (+) driver.

Insert the unit into a panel fasten the bracket by pushing with tools

with a (-) driver.

© Copyright Reserved Autonics Co., Ltd. 31

3 Dimensions

32 © Copyright Reserved Autonics Co., Ltd.

4 Connections

4 Connections

Be sure that the polarity for input connectiong a temperature sensor or analog input.

Standard model has shaded terminals only.

When the operation mode of heating&cooling OUT2 relay output model is heating or cooling

control, the OUT2 is usable as alarm output 3(except TK4N).

When the operation mode of heating & cooling OUT2 current model is heating or cooling control,

the OUT2 is usable as transmisstion output 2.

(1) TK4N Series

(2) TK4S Series

Features one digital input terminal (DI-1) due to limited number of terminal blocks. Supports

two multi SVs (SV1 and SV2) only.

© Copyright Reserved Autonics Co., Ltd. 33

4 Connections

(3) TK4SP Series

Does not feature any digital input terminal due to limited number of terminal blocks.

11Pin Socket(PG-11, PS-11): Sold separately

(4) TK4M Series

Features one digital input terminal (DI-1) due to limited number of terminal blocks. Supports

two multi SVs (SV1 and SV2) only.

(5) TK4W, TK4H, TK4L Series

※ Digital input is not electrically insulated from internal circuits, so it sholud be insulated when

connecting other circuits. (photocoupler, relay, independent switch)

34 © Copyright Reserved Autonics Co., Ltd.

4 Connections

4.1 Precautions for wiring

Mixing up the input terminals with output terminals and vice versa can lead to product

damage.

Use only sensors supported by the product.

Make sure to connect rated SSRs or loads to the output terminals. Make sure to connect

communication cable with correct communication terminals (A, B).

Make sure to observe correct polarity of power source terminals. (+ and -).

Make sure to connect correct polarity of temperature sensor and analog input.

4.1.1 Sensor connection

Compensation Wire Connection

For thermocouple sensors, use compensation wire of the same specification as input

sensors. Using an extension wire of different specifications and/or material will increase

inaccuracy of temperature sensing. It is recommended to choose high performance

compensation wire for more reliable sensing.

Measurement Error

Do not mix up the direction of the input sensor connector.

Carefully adjust both load and sensor positions.

Make sure the sensor is securely attached to the input connector.

AC Power Cable and Wiring

Do not put the sensor lines in close proximity of the AC power lines.

4.1.2 Communication connection

Do not tie together with the AC power line and communication line. Only use twisted pair wires

for the communication lines. Do not allow the communication line to exceed 800m in length.

For further details, please refer to ‘6.6 Communication ’.

© Copyright Reserved Autonics Co., Ltd. 35

4 Connections

36 © Copyright Reserved Autonics Co., Ltd.

5 Preparation and Startup

twice

Standard: Alarm output1+Digital input(DI-1, DI-2)

Heating & Cooling: Digital input (DI-1, DI-2)

Standard: Alarm output1+Trans. output

Heating & Cooling: Trans. output

Standard: Alarm output1+RS485 com. output

Heating & Cooling: RS485 comm. output

Alarm output1+ Trans. output

Alarm output1+RS485 com. output

Power

supply

SSR drive output

(standard ON/OFF, cycle, phase control)

Current + SSR drive output

5 Preparation and Startup

5.1 Initial display when power ON

When power is supplied, whole display parts flash for 1 sec. Afterwards, model name and input

sensor type will be flash twice and then in enters into RUN mode.

①Whole display part ②Model type display

SV display part Display type Type

1, 2, D, R, T TK4N

Option

Input/

Output

1, 2, R, T, A,

B, D

TK4S/SP/

M/W/H/L

③Input type display

Standard: Alarm output1+CT input

1

Heating & Cooling: Alarm output2

2 Standard: Alarm output1+Alarm output2

D

R

T

1 Alarm output1

2 Alarm output1+Alarm output2

R

T

A Alarm output1/2+ Trans. output

④RUN mode

4

R, S, C

N, R, C

© Copyright Reserved Autonics Co., Ltd. 37

OUT1

control

output

OUT2

control

output

B Alarm output1/2+RS485 com. output

D Alarm output1/2+ Digital input(DI-1, DI-2)

100-240VAC 50/60Hz

R Relay contact

S

C

N None

R Relay contact

C Current + SSR drive output

5 Preparation and Startup

5.2 Basic controls

5.2.1 Parameter setting sequence

Parameters of each group are connected each other. Therefore, follow the below parameter

order.

Parameter 3 Group [PAR3] → Parameter 4 Group [PAR4] → Parameter 5 Group [PAR5] →

Parameter 2 Group [PAR2] → Parameter 1 Group [PAR1] → SV Setting [SV]

Changing Parameter 3 Group's parameters can sometimes reset other associated parameters.

Always make sure to check if such parameters have been affected.

5.2.2 Set value (SV) setting

①

②

③

Press any key among , , in RUN mode to enter SV

setting mode. Last digit (10

Press the key to move digit.

0

→ 101 → 102 → 103 → 100)

(10

Press the , keys to raise or lower the set value.

0

digit) on SV display part flashes.

④

Press the key to save the set value. If there is no additional

key operations in 3 sec., the changed SV is automatically saved.

38 © Copyright Reserved Autonics Co., Ltd.

5 Preparation and Startup

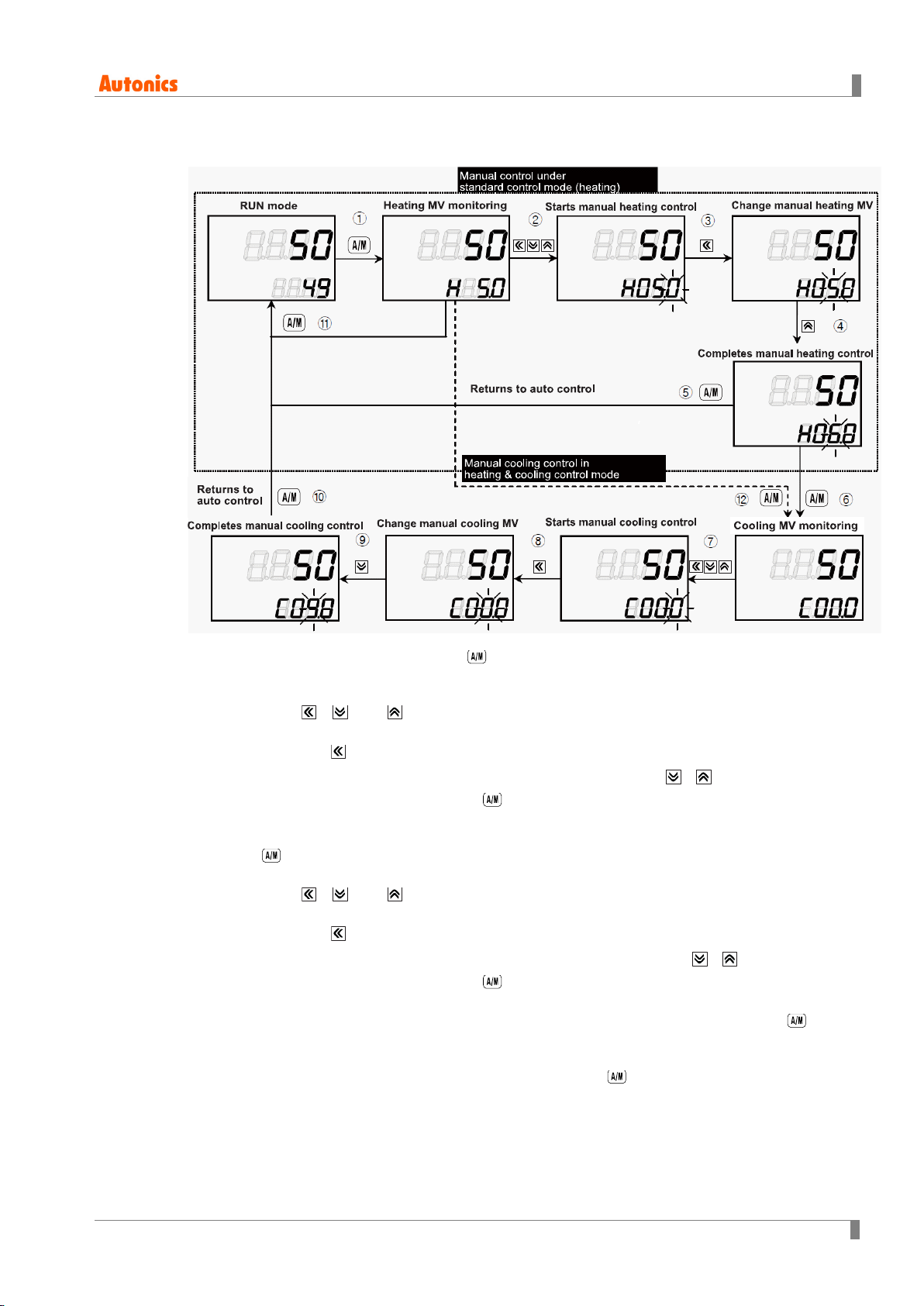

5.2.3 MV monitoring and manual control

① While in RUN mode, press the key to commence manual control. The SV display will

then show H (heating control) or C (cooling control) and simultaneously display the MV to

indicate commencement of MV monitoring.

② If the , , or is pressed while MV monitoring is in progress, the MAN indicator

will turn on and the last digit will start to flash to indicate activation of manual control.

0

③ Press the key to change the flashing digit (10

→ 101 → 102 → 103 → 100).

④ Select the digit and configure the desired MV value using the , keys.

⑤ To end manual control, press the key. The MAN indicator will turn off, and the system

will revert to auto control mode.

⑥ While in heating & cooling control mode, set the manual heating MV and then press the

key to see C (cooling control) and the current cooling MV value on the SV display

indicating commencement of cooling MV monitoring.

⑦ If the , , or is pressed while MV monitoring is in progress, the MAN indicator

turns on and the last digit starts to flash to indicate activation of manual control.

0

⑧ Press the key to change the flashing digit (10

→ 101 → 102 → 103 → 100).

⑨ Select the digit and configure desired cooling MV value using the , keys.

⑩ To end manual control, press the key. The MAN indicator will turn off, and the system

will revert to auto control mode.

⑪ While in standard control mode (heating control or cooling control), pressing the key

once from the MV monitoring stage, or any other stage, will revert the system to auto

control mode.

⑫ During heating & cooling control mode, pressing the key once from the MV

monitoring stage, or any other stage, will skip the system to the cooling MV monitoring

stage.

© Copyright Reserved Autonics Co., Ltd. 39

5 Preparation and Startup

Control status

MV

Monitoring

AUTO

Not changed

MANUAL

Changeable

For heating & cooling control, the system reverts to auto control after going through heating

monitoring, manual heating control, cooling monitoring, and manual cooling control stages in

sequence.

Heating MV remains in effect during cooling monitoring and manual cooling control.

When setting ditial input function as AUTO/MANUAL, MV monitoring and control status

Avaliable

TK4N/S/SP model’s the key alternates the ke y.

40 © Copyright Reserved Autonics Co., Ltd.

5 Preparation and Startup

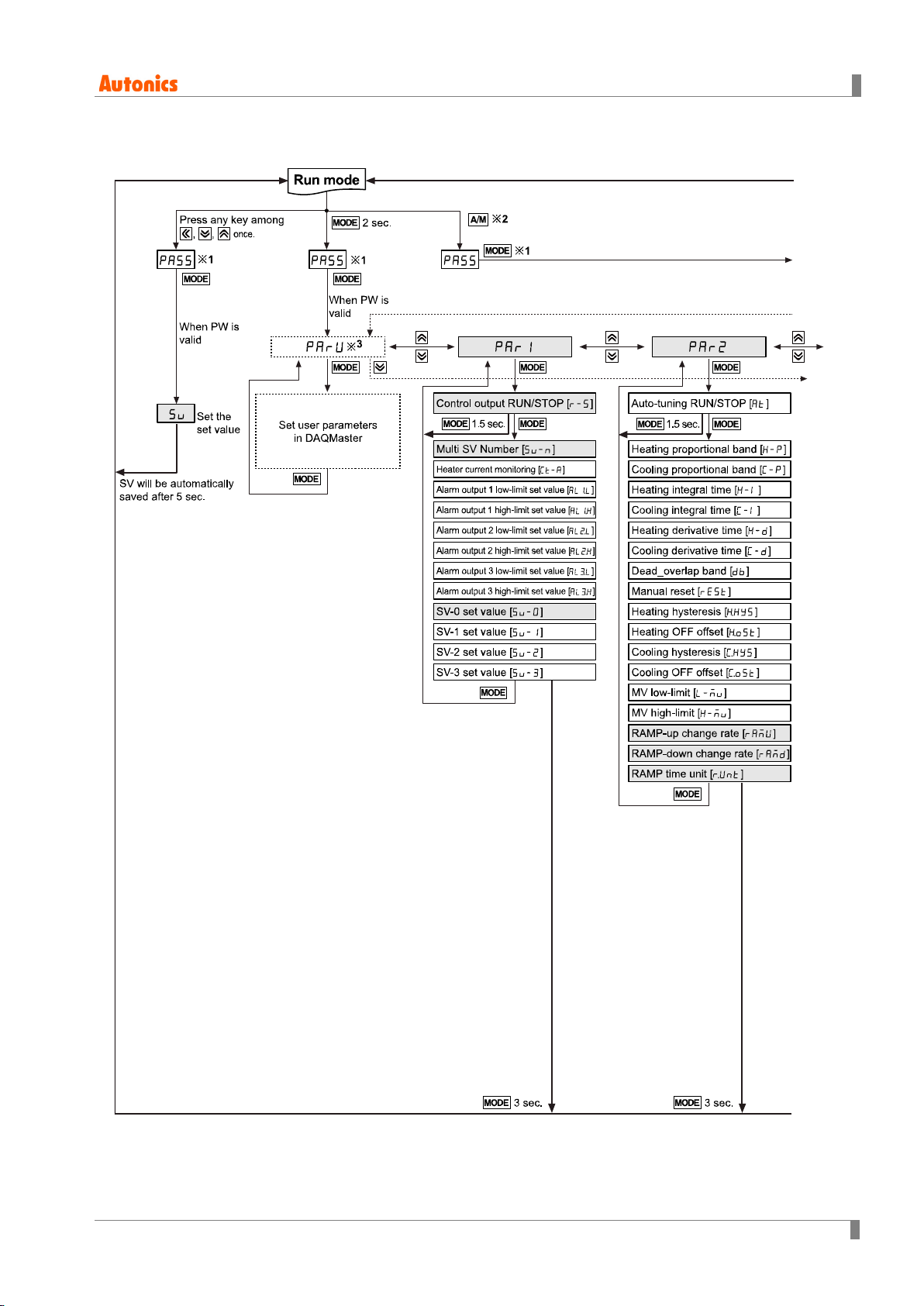

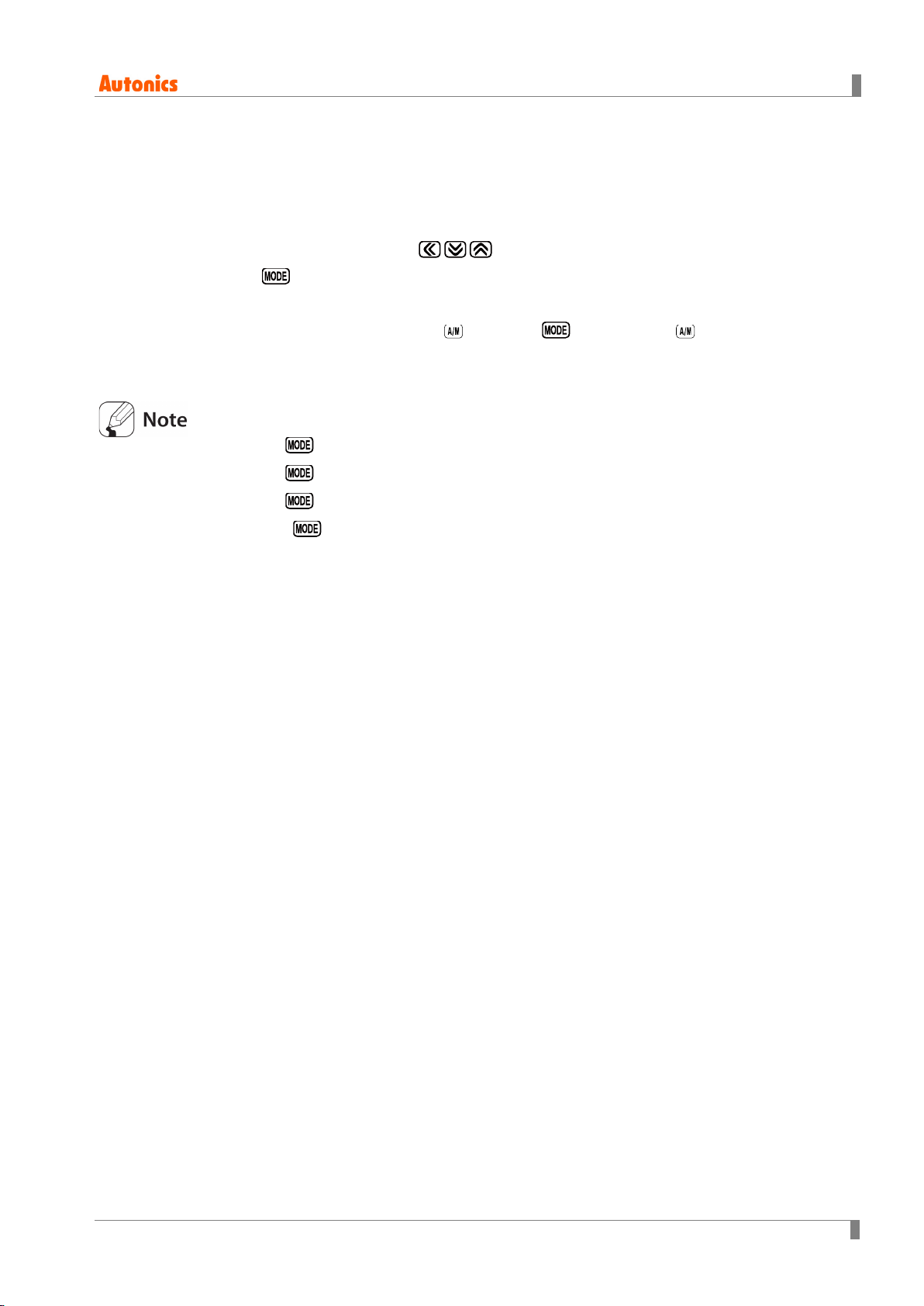

5.3 Parameter group

© Copyright Reserved Autonics Co., Ltd. 41

5 Preparation and Startup

42 © Copyright Reserved Autonics Co., Ltd.

5 Preparation and Startup

※1.

parameter will be displayed only when password is set. It is not displayed when

PASS

purchasing the unit since default password is set to

0000

.

If password is not valid, the screen will be shifted to password code required window.

Press any key among to return to password entering window. Press

key to return to RUN mode.

In case you forget password, contact Autonics after checking password code.

※2. TK4N/4S/4SP do not have key. The key replaces key.

※3. It is displayed when setting user parameter group in the comprehensive device

management program (DAQMaster).

Hold the key over 2 sec in RUN mode to enter into setting mode.

Hold the key for 1.5 sec while in setting mode to move to other parameter group.

Hold the key over 3 sec while in setting mode to return to RUN mode.

Press the key at the last parameter of each parameter, it moves to that parameter

name. You can move to other groups.

If there is no additional key operation within 30 sec after entering into setting mode, it will be

automatically returned to RUN mode and previous setting value will be remained

The shaded parameters are displayed in common.

The others may not be displayed by the specifications of the product, other parameter’s

setting, or parameter mask setting.

© Copyright Reserved Autonics Co., Ltd. 43

5 Preparation and Startup

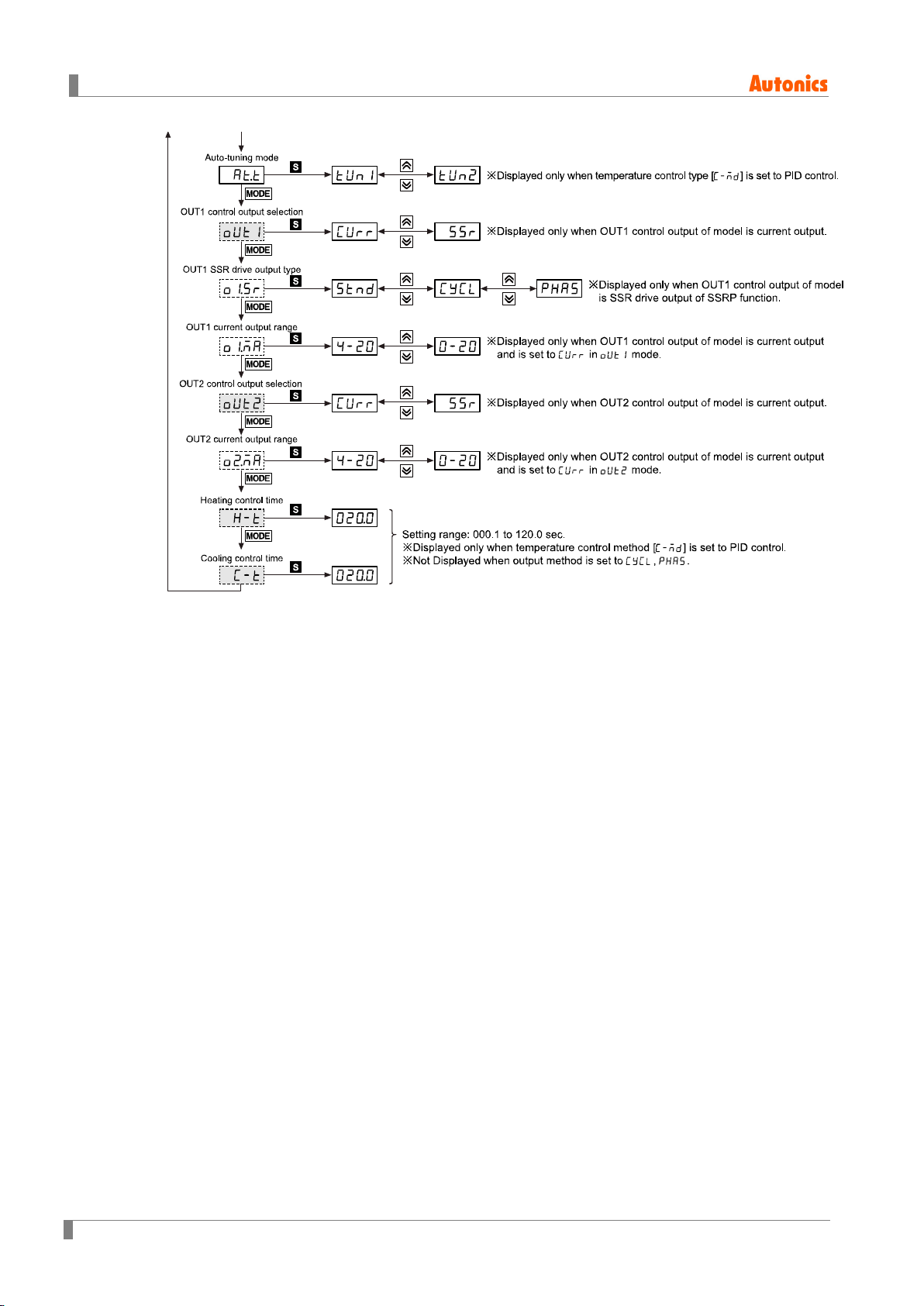

5.4 Parameter groups

5.4.1 Parameter 1 group [PAR1]

44 © Copyright Reserved Autonics Co., Ltd.

5 Preparation and Startup

5.4.2 Parameter 2 group [PAR2]

© Copyright Reserved Autonics Co., Ltd. 45

5 Preparation and Startup

46 © Copyright Reserved Autonics Co., Ltd.

5 Preparation and Startup

5.4.3 Parameter 3 group [PAR3]

© Copyright Reserved Autonics Co., Ltd. 47

5 Preparation and Startup

※ OUT1, OUT2 output:

In case that OUT1, OUT2 output is relay output type

: OUT1

, O!SR, O!MA, OUT2, O@SR, O@MA parameters are not displayed.

In case that OUT1,OUT2 output is current + SSR drive output type, when OUT1,OUT2

output is set to SSR

: Output method of O!SR

, O@SR is held in STND and parameter is not displayed.

In case that OUT1, output is SSR drive output model of SSRP function and OUT2 output is

current + SSR drive output

OUT1, O!MA are not displayed.

-

- O!SR can set to STND

, CYCL, PHAS

-When O@SR is set to SSR it is held in STND and parameter is not displayed.

48 © Copyright Reserved Autonics Co., Ltd.

5 Preparation and Startup

5.4.4 Parameter 4 group [PAR4]

© Copyright Reserved Autonics Co., Ltd. 49

5 Preparation and Startup

50 © Copyright Reserved Autonics Co., Ltd.

5 Preparation and Startup

© Copyright Reserved Autonics Co., Ltd. 51

5 Preparation and Startup

5.4.5 Parameter 5 group [PAR5]

52 © Copyright Reserved Autonics Co., Ltd.

5 Preparation and Startup

© Copyright Reserved Autonics Co., Ltd. 53

5 Preparation and Startup

54 © Copyright Reserved Autonics Co., Ltd.

6 Parameter Settings and Functions

Temperature range

Temperature range

6 Parameter Settings and Functions

6.1 Input

6.1.1 Input types and temperature ranges

Input types Display

1 KCaH -200 to 1350 -328 to 2463

K (CA)

0.1 KCaL -199.9 to 999.9 -199.9 to 999.9

1 JIcH -200 to 800 -328 to 1472

J (IC)

0.1 JIcL -199.9 to 800.0 -199.9 to 999.9

1 ECrH -200 to 800 -328 to 1472

E (CR)

0.1 ECrL -199.9 to 800.0 -199.9 to 999.9

1 TCcH -200 to 400 -328 to 752

T (CC)

0.1 TCcL -199.9 to 400.0 -199.9 to 752.0

B (PR) 1 B PR 0 to 1800 32 to 3272

Thermoc

ouple

(TC)

R (PR) 1 R PR 0 to 1750 32 to 3182

S (PR) 1 S PR 0 to 1750 32 to 3182

N (NN) 1 N NN -200 to 1300 -328 to 2372

1

C (TT)

G (TT)

※

2

※

1 C TT 0 to 2300 32 to 4172

1 G TT 0 to 2300 32 to 4172

(℃)

(℉)

1 LIcH -200 to 900 -328 to 1652

L (IC)

0.1 LIcL -199.9 to 900.0 -199.9 to 999.9

1 UCcH -200 to 400 -328 to 752

U (CC)

0.1 UCcL -199.9 to 400.0 -199.9 to 752,0

Platinel II 1 PLII 0 to 1390 32 to 2534

Cu 50Ω

Cu 100Ω

JPt 100Ω

RTD

© Copyright Reserved Autonics Co., Ltd. 55

JPt 100Ω

DPt 50Ω

DPt 100Ω

DPt 100Ω

0.1 CU 5 -199.9 to 200.0 -199.9 to 392.0

0.1 CU10 -199.9 to 200.0 -199.9 to 392.0

1 JPtH -200 to 650 -328 to 1202

0.1 JPtL -199.9 to 650.0 -199.9 to 999.9

0.1 DPt5 -199.9 to 600.0 -199.9 to 999.9

1 DPtH -200 to 650 -328 to 1202

0.1 DPtL -199.9 to 650.0 -199.9 to 999.9

6 Parameter Settings and Functions

Temperature range

Temperature range

Setting

group

Factory

default

Refer to 6.1.1. Input types and

temperature

Setting

group

Factory

default

Input types Display

Nickel 120Ω

Voltage

Analog

Current

1 NI12 -80 to 200 -112 to 392

0 to 10V AV1

0 to 5V AV2

1 to 5V AV3

0 to 100mV AMV1

0 to 20mA AMA1

4 to 20mA AMA2

(℃)

-1999 to 9999

(Display point will be changed according to

decimal point position)

(℉)

※1. C (TT): Same temperature sensor as former W5 (TT).

※2. G(TT): Same temperature sensor as former W (TT).

Temperature sensors are to convert subject temperature to electrical signals for the temperature

controller allowing it to control output.

SV (Setting Value) can only be set within the input range and do not set over the input range.

6.1.2 Input type [PAR3 → IN-T]

This product supports multiple input types, making it possible for the user to choose from

thermocouples, resistors, and analog voltage/current.

If you change the input specification, the SV's upper/low-limits are automatically set to the new

specification's max/min values for temperature sensors. As for analog inputs, analog upper/lower

input values are set to the max/min temperature range and the SV upper/low-limits set to

upper/lower scale values. Therefore, you need to reconfigure the settings.

Parameter Setting range

PAR3 IN-T

6.1.3 Sensor temperature unit [PAR3 → UNIT]

When selecting the input temperature sensor, you can set the desired units (℃, ℉) of

temperature/scale value to be displayed.

Parameter Setting range

PAR3 UNIT ?C / ?F ?C -

This parameter will not be displayed if analog input has been selected.

Unit

KCaH -

Unit

56 © Copyright Reserved Autonics Co., Ltd.

6 Parameter Settings and Functions

No.

PV

Display

Setting

group

Factory

default

Setting

group

Factory

default

6.1.4 Analog input/scale value

With analog input selected, you can set the analog input range (high/low limit input values) and

the display scale (high/low limit scale values) within the designated input range.

The decimal point positions remain fixed when configuring the high/low limit input values. You

can change the input values at AV1: 00.00, AV2/AV3: 0.000, AMV1: 000.0, AMA1/ AMA2: 00.00

decimal points.

If the upper and lower limit scale settings are identical, ERRflashes twice and setting mode is

displayed.

For analog input, ±5% of the set high/low limit input value is extended. Analog output is also

extended compairing input value. (For temperature sensor input, ±5% extension is applied

within the temperature range.)

① ±5% section

② ±5 to 10% section

③ Over ±10% section

Flashes PV

Flashes HHHH or LLLL

Flashes OPEN

This parameter is not displayed for temperature sensor input.

6.1.4.1 Low-limit input value [PAR3 → L-RG]

You can set the low limit input values for actual use within the analog input range.

Parameter Setting range

PAR3 L-RG

Minimum temperature range to high-limit

input value [H-RG] - F. S . 10%

6.1.4.2 High-limit input value [PAR3 → H -RG]

You can set high limit input values for actual use within the analog input range.

Parameter Setting range

PAR3 H-RG

Low-limit input value [L-RG] + F.S. 10% to

maximum temperature range

Unit

0)00 -

Unit

1)00 -

© Copyright Reserved Autonics Co., Ltd. 57

6 Parameter Settings and Functions

Setting

group

Factory

default

PAR3

DOT

0 / )0/ )00 / )000

)0

-

Setting

group

Factory

default

PAR3

L-SC

`999 to 9999

00)0

-

Setting

group

Factory

default

PAR3

H-SC

`999 to 9999

10)0

-

Setting

group

Factory

default

Setting

Parameter description

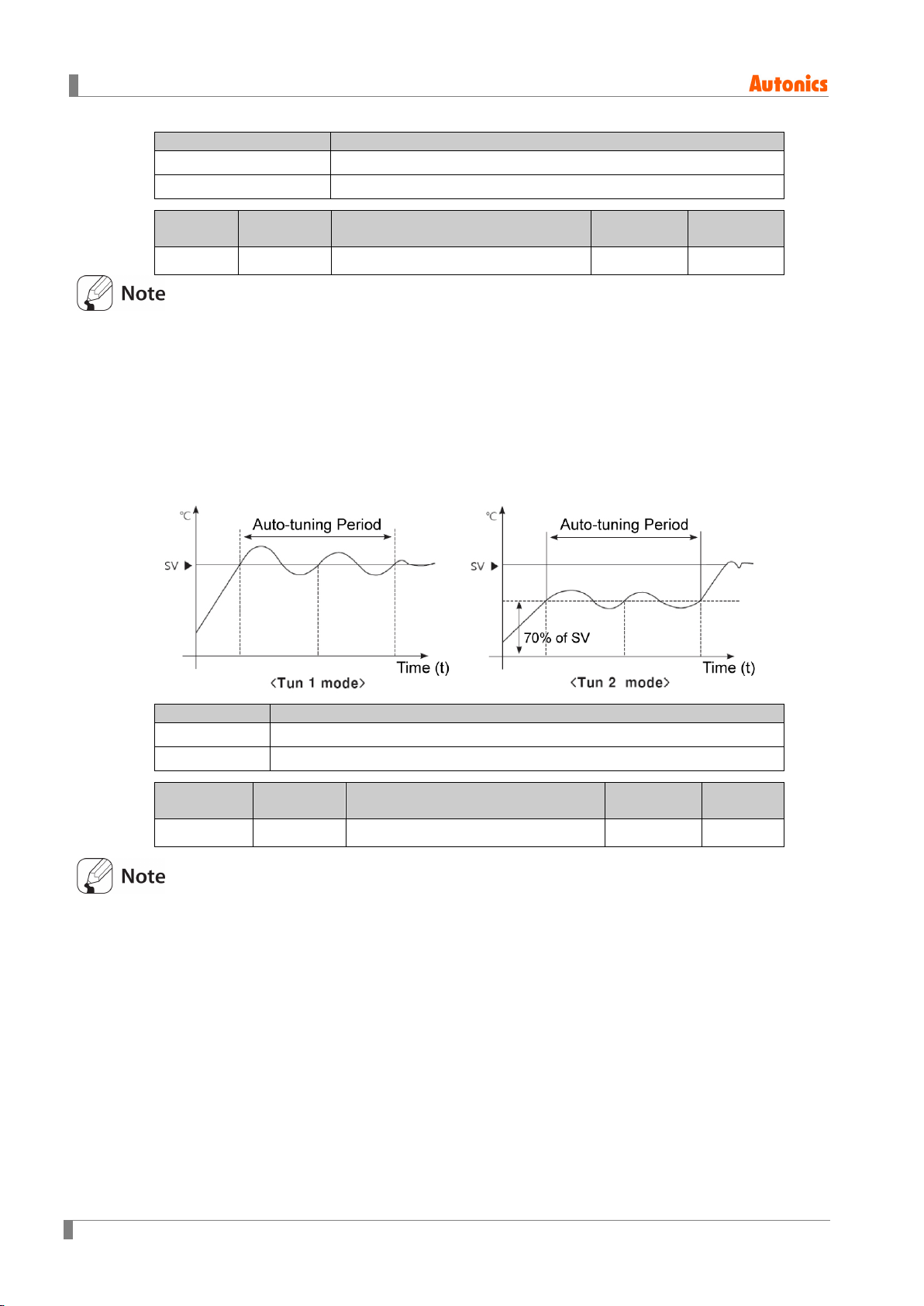

6.1.4.3 Scale decimal point position [PAR3 → DOT]

You can set the decimal point positions for present value (PV) and set value(SV) within high and

low limit scale values.

Parameter Setting range

6.1.4.4 Low-limit scale value [PAR3 → L-SC]

You can set the display scales of low-limit values for analog input [L-RG]. (Based on the decimal

point position setting.)

Parameter Setting range

6.1.4.5 High-limit scale value [PAR3 → H-SC]

You can set the display scales of high-limit values for analog input [H-RG]. (Based on the

decimal point position setting.)

Parameter Setting range

6.1.4.6 Display unit for front panel [PAR3 → dUNT]

When you select an analog input type, you can set the display units.

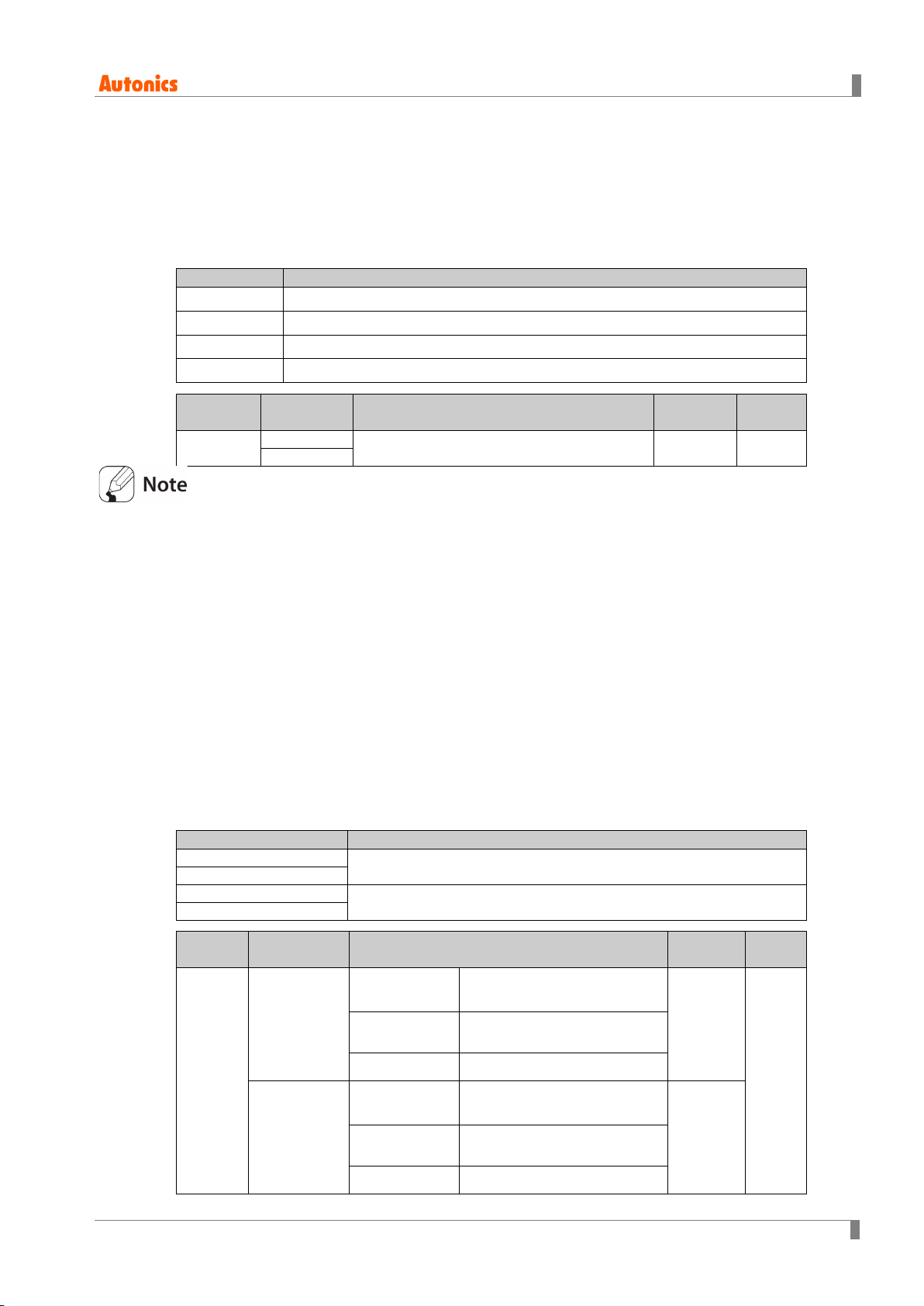

Parameter Setting range

Unit

Unit

Unit

Unit

PAR3 dUNT ?C / ?F / ?/O / OFF ?/O -

?C

?F

?/O Sets the display unit to % and turns on the % of front unit indicator.

OFF

Sets the display unit to ℃ and turns on the ℃ of front unit indicator.

Sets the display unit to ℉ and turns on the ℉ of front unit indicator.

Sets the display unit to an undefined unit. The LED unit indicator will not turn on.

58 © Copyright Reserved Autonics Co., Ltd.

6 Parameter Settings and Functions

Setting

group

Factory

default

-999 to 0999 (temperature H, analog)

`9(9 to 99(9 (temperature L)

Setting

group

Factory

default

to

Sec

6.1.5 Input correction [PAR3 → IN-B]

This feature is used to compensate for input correction produced by thermocouples, RTDs, or

analog input devices, NOT by the controller itself.

The Input correction function is mainly used when the sensor cannot be attached directly to

controlled objects. It is also used to compensate for temperature variance between the sensor's

installation point and the actual measuring point.

Parameter Setting range

PAR3 IN-B

If the controller displays 78℃ when the actual temperature is 80℃, set the input correction [IN-

B] as ‘002’ in order to adjust the controller's display temperature to 80℃.

If present value after input correction is out of the input range by each input sensor, it displays

‘HHHH’ or ‘LLLL’.

Make sure that an accurate temperature variance measurement is taken before set values of

input correction. An inaccurate initial measurement can lead to greater variance.

Many of today's temperature sensors are graded by their sensitivity. Since higher accuracy

usually comes at a higher cost, most people tend to choose sensors with medium sensitivity.

Measuring each sensor's sensitivity correction for input correction feature in order to ensure

higher accuracy in temperature reading.

6.1.6 Input digital filter [PAR3 → MAvF]

It is not possible to perform stable control if the present value (PV) fluctuates because of fast

changes of input signal. Using the Input digital Filter function can stabilize PV to realize more

reliable control.

0000

Unit

℃/℉/-

Parameter Setting range

PAR3 MAvF 00)1

12)0

)1

Unit

If the input digital filter is set to 0.4 sec., digital filtering is applied to a sampling value collected

over 0.4 sec. (400 ms).

When the input digital filter is used, present value (PV) can vary from the actual input value.

© Copyright Reserved Autonics Co., Ltd. 59

6 Parameter Settings and Functions

Setting

group

1350(temperature)

-200(temperature)

Parameter

Parameter Description

6.1.7 High/Low-limit value of setting value(SV) [PAR3 → H-SV/ L-SV]

You can limit the Set value(SV) range within the temperature range of the temperature sensor or

analog input type in order to prevent the system from controlling with improper SV.

Parameter Setting range Factory default Unit

SV low-limit + 1 digit to sensor

H-SV

PAR3

L-SV

input high-limit or analog highlimit scale value

Sensor low-limit or analog lowlimit scale value to SV high-limit 1 digit

00)0(analog)

10)0(analog)

℃/℉

℃/℉

L-SV

H-SV Set value(SV) high-limit

Set value(SV) low-limit

Attempts to set the limits outside the min/max input range, or analog's high/low-limits, are not

accepted. Instead, the previous settings are retained.

Set value(SV) can only be set within the SV low-limit [L-SV] and SV high-limit [H-SV] range.

SV lower-limit [L-SV] cannot exceed SV high-limit [H-SV].

60 © Copyright Reserved Autonics Co., Ltd.

6 Parameter Settings and Functions

Setting

group

Factory

default

Standard model:

-

Heating/Cooling model: HEAT / COOL / H-C

H-C

-

6.2 Control output

6.2.1 Control output mode [PAR3 → O-FT]

Control output modes for general temperature control include heating, cooling, and heating

& cooling.

Heating control and cooling control are mutually opposing operations with inverse outputs.

The PID time constant varies based on the controlled objects during PID control.

Parameter Set range

PAR3 O-FT

6.2.1.1 Heating control [PAR3 → O-FT → HEAT]

Heating control mode: the output will be provided in order to supply power to the load (heater) if

present value (PV) falls below set value(SV).

6.2.1.2 Cooling control [PAR3 → O-FT → COOL]

Cooling control mode: the output will be provided in order to supply power to the load (cooler) if

present value (PV) rises above set value(SV).

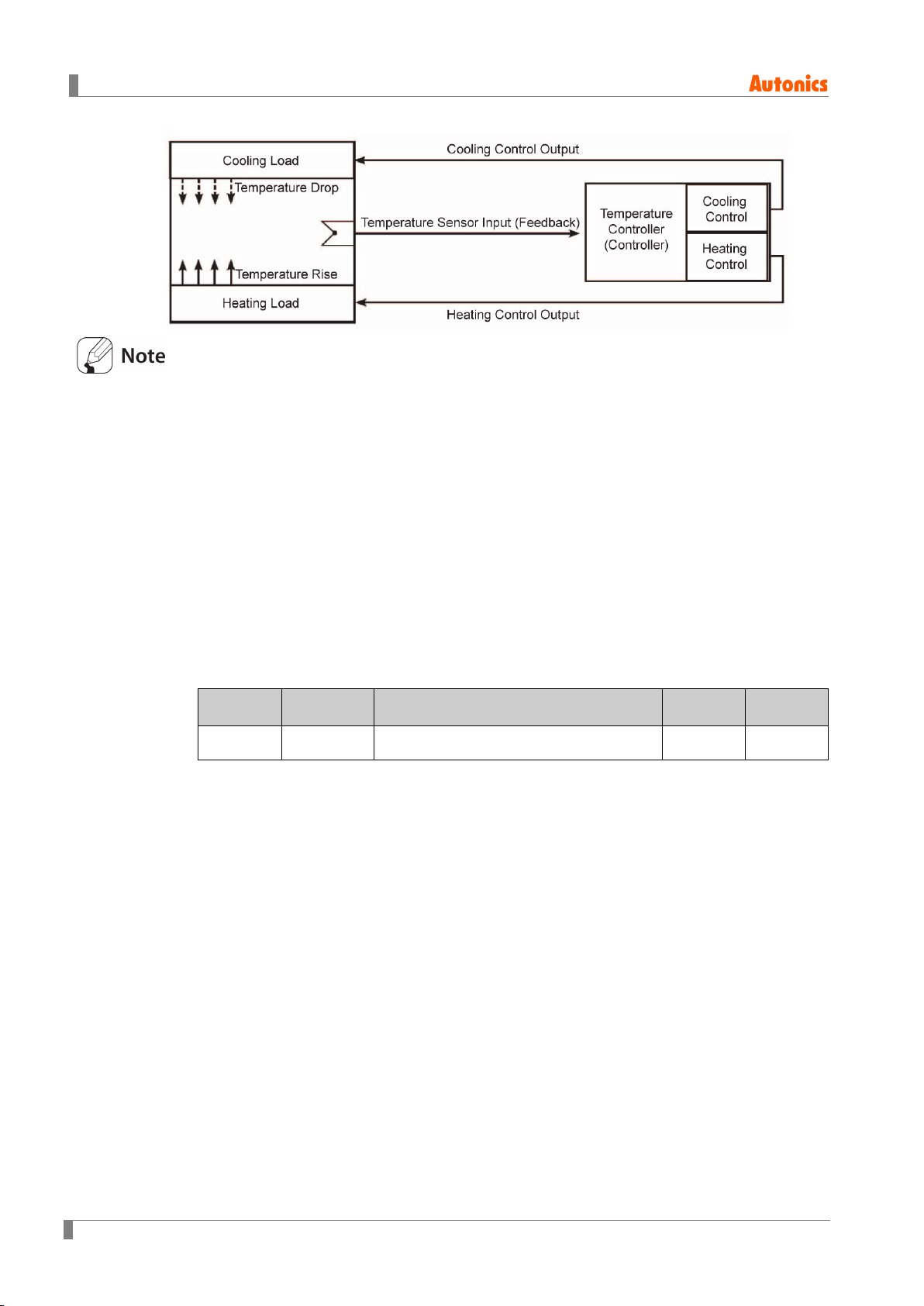

6.2.1.3 Heating & Cooling control [PAR3 → O-FT → H-C]

Heating & Cooling control mode: heating & cooling with a single temperature controller when it is

difficult to control subject temperature with only heating or cooling.

Heating & Cooling control mode controls the object using different PID time constants for each

heating & Cooling.

It is also possible to set heating & cooling control in both PID control or ON/OFF control mode.

Heating/cooling output can be selected among Relay output, SSR drive output and current

output depending on model types choosen according to your application environment. (Note that

SSR drive output of OUT2 operates standard control.)

HEAT / COOL

Unit

HEAT

© Copyright Reserved Autonics Co., Ltd. 61

6 Parameter Settings and Functions

Setting

group

Factory

default

See

below.

For heating & cooling control, OUT1 control output is dedicated to heating control and OUT2

control output to cooling control.

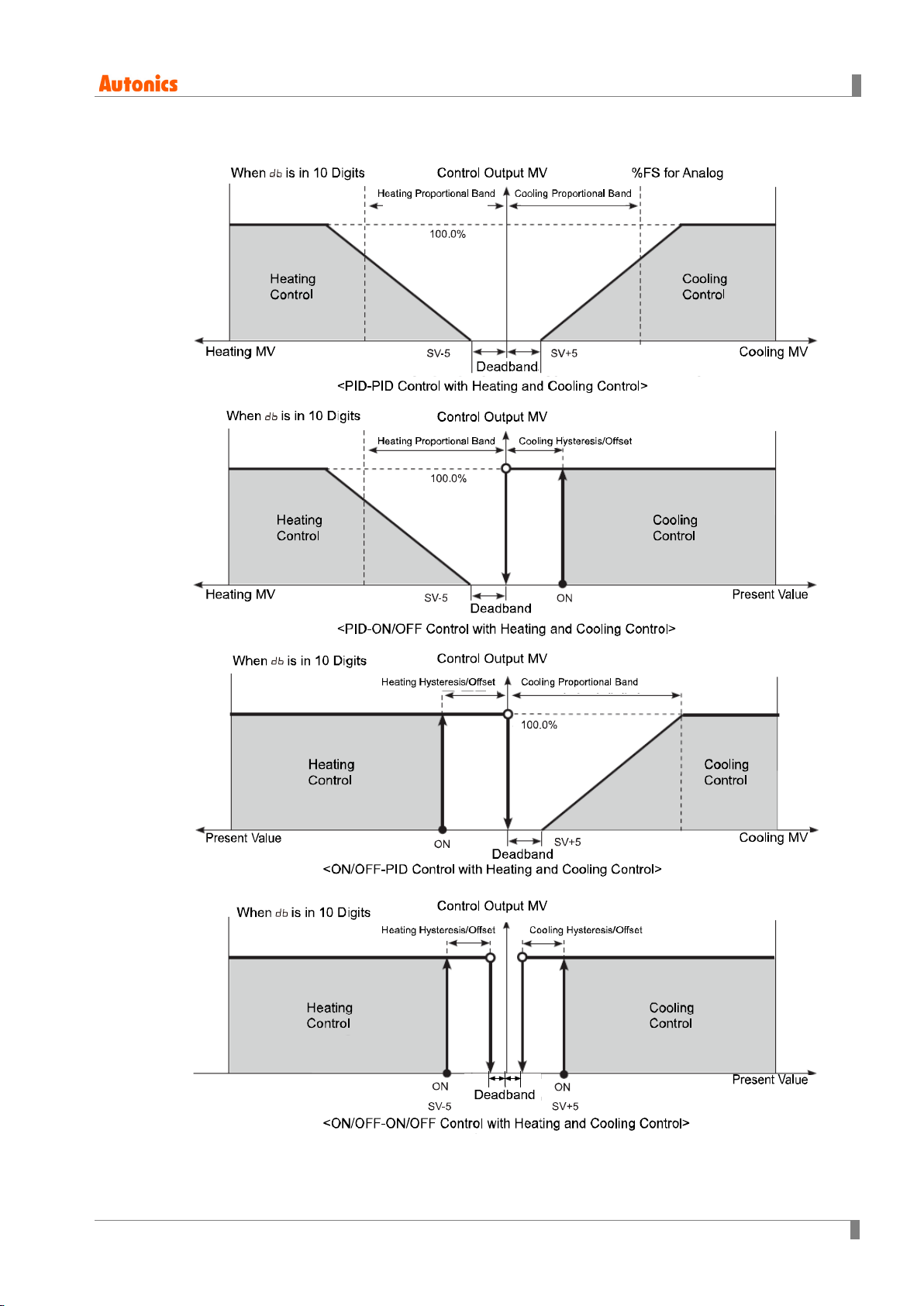

6.2.1.3.1. Dead band/Overlap band [PAR2 → DB]

In heating & cooling control, it is possible to designate a dead band between heating & cooling

control bands based on set value(SV).

A dead band forms around the SV when positive (+) value is set. No control occurs in the dead

band area. Therefore, heating & cooling MVs become 0.0% in the formed dead band.

An overlap band (simultaneous application of heating & cooling MVs) forms around the SV when

negative (-) value is set.

Set as 0 when a dead band or an overlap band is not used.

When setting integration time, it is applied when the intengration time of heating control and

cooling control is set. In case of PI-P control and P-PI control, it also operates as P-P control.

Parameter Setting range

PAR2 DB See below.

Unit

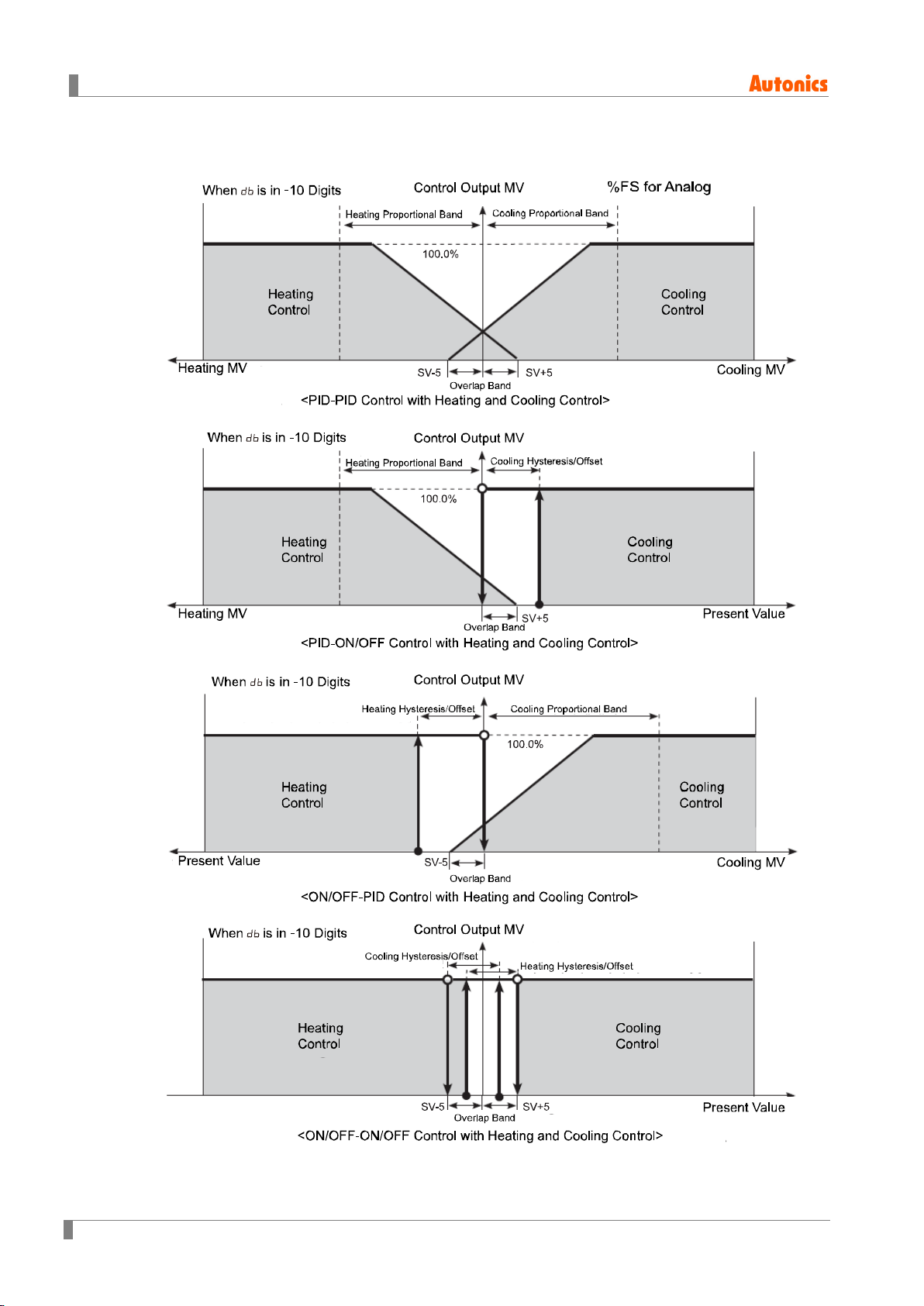

PID/PID, PID/ON-OFF, and ON-OFF/PID Control

Set range (temperature): -(proportional band) to +(proportional band) (the lower value

when using different proportional bands)

Set range (analog): -99.9 to 099.9

Factory default: 0000 (temperature H), 000.0 (temperature L, analog),

(unit: temperature ℃/℉, analog % F. S. )

ON-OFF/ON-OFF Control

Set range (temperature):

-999 (overlap band) to 0000 (not used) to 0999 (dead band) (temperature H)

-199.9 (overlap band) to 000.0 (not used) to 999.9 (dead band) (temperature L)

Set range (analog): -99.9 (overlap band) to 000.0 (not used) to 099.9 (dead band)

Factory default: 0000 (temperature H), 000.0 (temperature L, analog),

(unit: temperature ℃/℉, analog % F. S. )

62 © Copyright Reserved Autonics Co., Ltd.

6 Parameter Settings and Functions

(1) Using a Deadband

© Copyright Reserved Autonics Co., Ltd. 63

6 Parameter Settings and Functions

(2) Using an Overlap Band

64 © Copyright Reserved Autonics Co., Ltd.

6 Parameter Settings and Functions

(3) Using neither a Dead band nor an Overlap Band

Depends on the set value of the heating integration time[H-I], cooling integration time[C-I],

actual operation may be different.

© Copyright Reserved Autonics Co., Ltd. 65

6 Parameter Settings and Functions

Setting

group

Factory

default

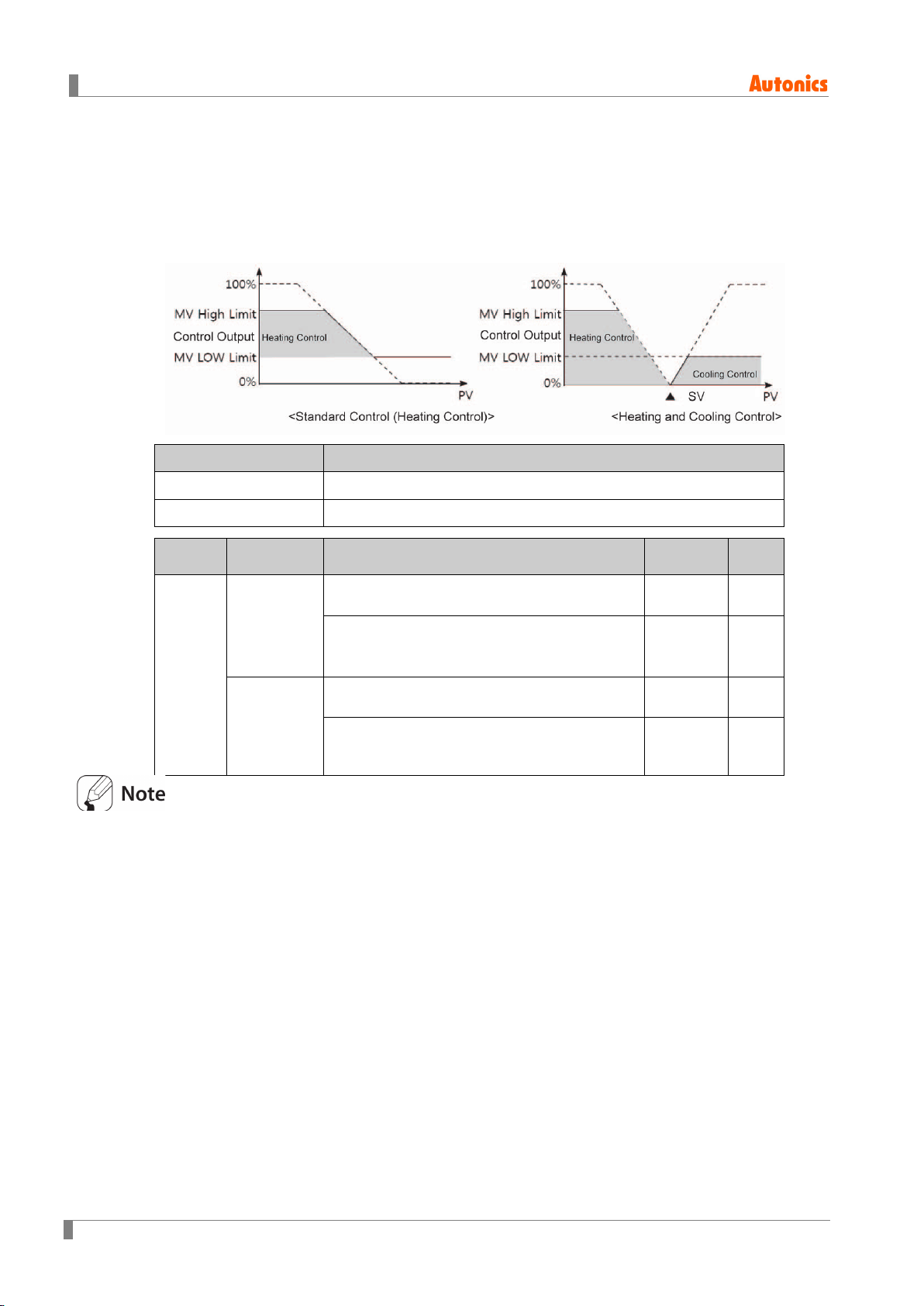

6.2.2 MV High/Low-limit value settings [PAR2 → H-MV / L-MV]

MV high/low-limit values [H-MV / L-MV] for control output can be configured to the actual MV,

provided the temperature controller's MV calculation exceeds the limits.

During heating & cooling control, cooling MV carries a "-" prefix. Therefore, the high-limit is

expressed as a + value on the heating side and the low-limit as a - value on the cooling side.

Parameter Description

L-MV

H-MV MV High-limit value setting

Parameter Set range

H-MV

PAR2

L-MV

MV Low-limit value setting

Standard Control: MV Low-limit value [L-MV]

+ )1 to 10)0

Heating & Cooling Control: 00)0 to 10)0

(PID control)

)0 (OFF)/10)0 (ON) (ON/OFF control)

Standard Control: 00)0 to MV high-limit value

[H-MV] – )1

Heating & Cooling Control: `0)0 to 00)0

(PID control), `0)0 (ON)/ )0 (OFF) (ON/OFF

control)

Unit

10)0 %

10)0 %

)0 %

`0)0 %

Same MV limits applied during auto-tuning.

MV limits are not applied to manual control, MV upon control stop, MV upon a sensor error, and

initial manual control MV.

MV high/low-limit configuration is not available for ON/OFF control in standard control mode

(heating or cooling control).

66 © Copyright Reserved Autonics Co., Ltd.

6 Parameter Settings and Functions

Parameter

Description

Setting

group

Factory

default

Operation Status

Ramp Up/Down

Ramp

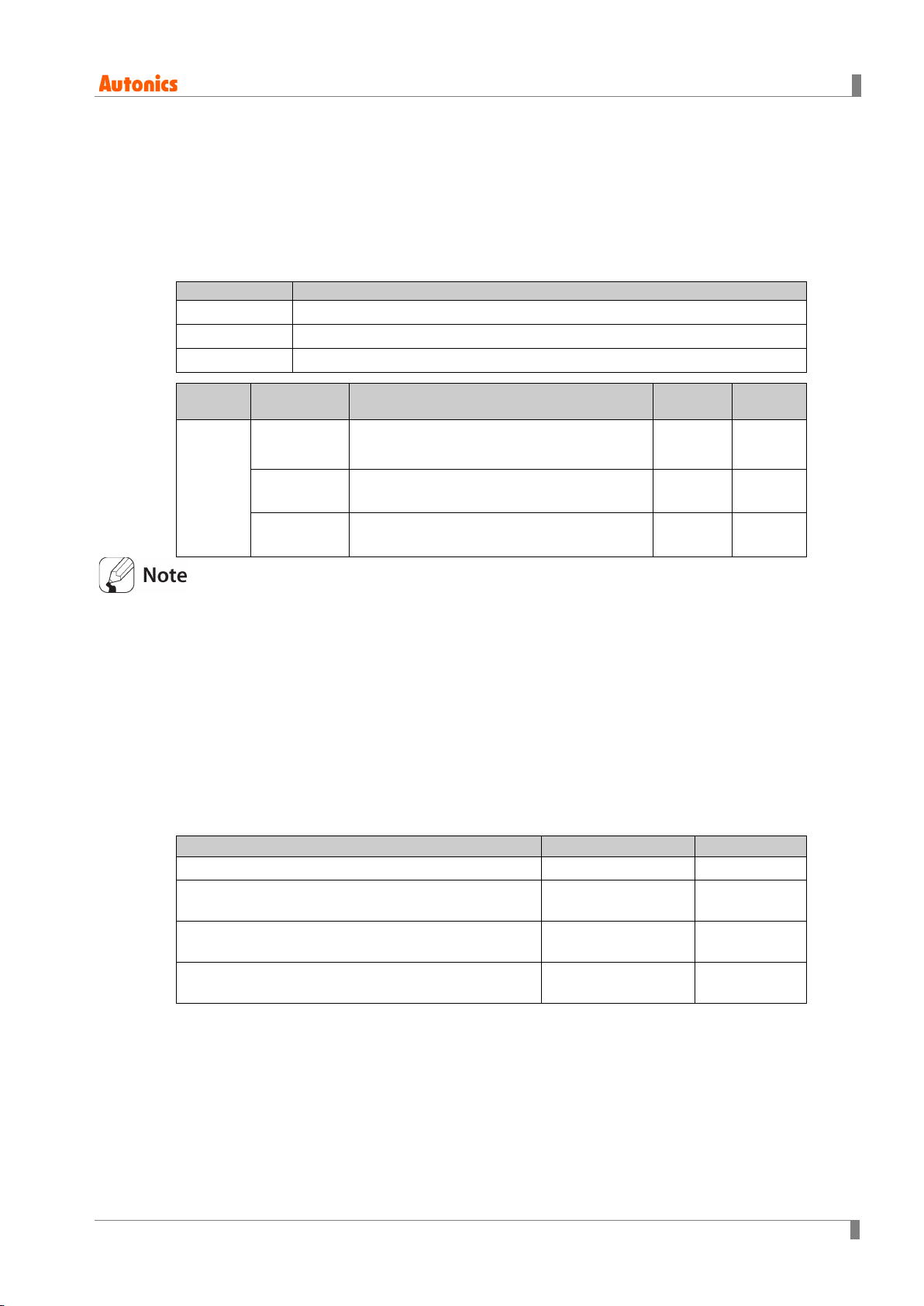

6.2.3 Ramp settings [PAR2 → RAMU/ RAMD/ rUNT]

Ramp is a feature used to configure the slope toward set value(SV). The feature limits change

rate of set value(SV) and thereby restricts sudden temperature changes (increase and decrease)

in the control subject.

Ramp is commonly used in applications where rapid temperature changes (increase and

decrease) could impact negatively on the control subject.

RAMU

RAMD Settings for Ramp-down change rate.

rUNT

PAR2

Settings for Ramp-up change rate.

Settings for Ramp time unit.

Parameter Setting range

RAMU

RAMD

rUNT

000 to 999 (temperature H, analog),

00)0 to 99(9 (temperature L)

000 to 999 (temperature H, analog),

00)0 to 99(9 (temperature L)

SEC (seconds), MIN (minutes),

HOUR (hours)

Unit

000

000

MIN -

Activating the ramp feature when the ramp is not in operation limits the change rate of Set

value(SV) based on present value (PV). Changing SV or ramp parameters while the ramp is in

operation limits the change rate of SV based on SV at the point of the change.

Control will be carried out based on changed SV (hereinafter referred to as RAMP SV) changed by preset change rate (slope). RAMP-Up Change Rate and RAMP-Down Change Rate

can be configured independently.

Alarm operation during RAMP will be made based on final SV.

Setting the rate of ramp change to 0 deactivates the ramp feature.

If the ramp feature has been activated, RAMP SV will be displayed on SV display part.

Ramp depending on operation status

All operations When it is 0. Inactive

OPEN, HHHH, LLLL, Auto-tuning, Switching from

Auto to Manual, Switching from Run to Stop

OPEN, HHHH, LLLL, After Auto-tuning completed, PV

= SV

Power On, SV Change, Switching from Stop to Run,

Switching from Manual to Auto, Ramp Rate Change

Irrespective of

conditions.

Irrespective of

conditions.

When it is not 0. Active

Inactive

Inactive

© Copyright Reserved Autonics Co., Ltd. 67

6 Parameter Settings and Functions

(1 to 9999

(1 to 9999

Ramp operation graph

digit)

digit)

68 © Copyright Reserved Autonics Co., Ltd.

6 Parameter Settings and Functions

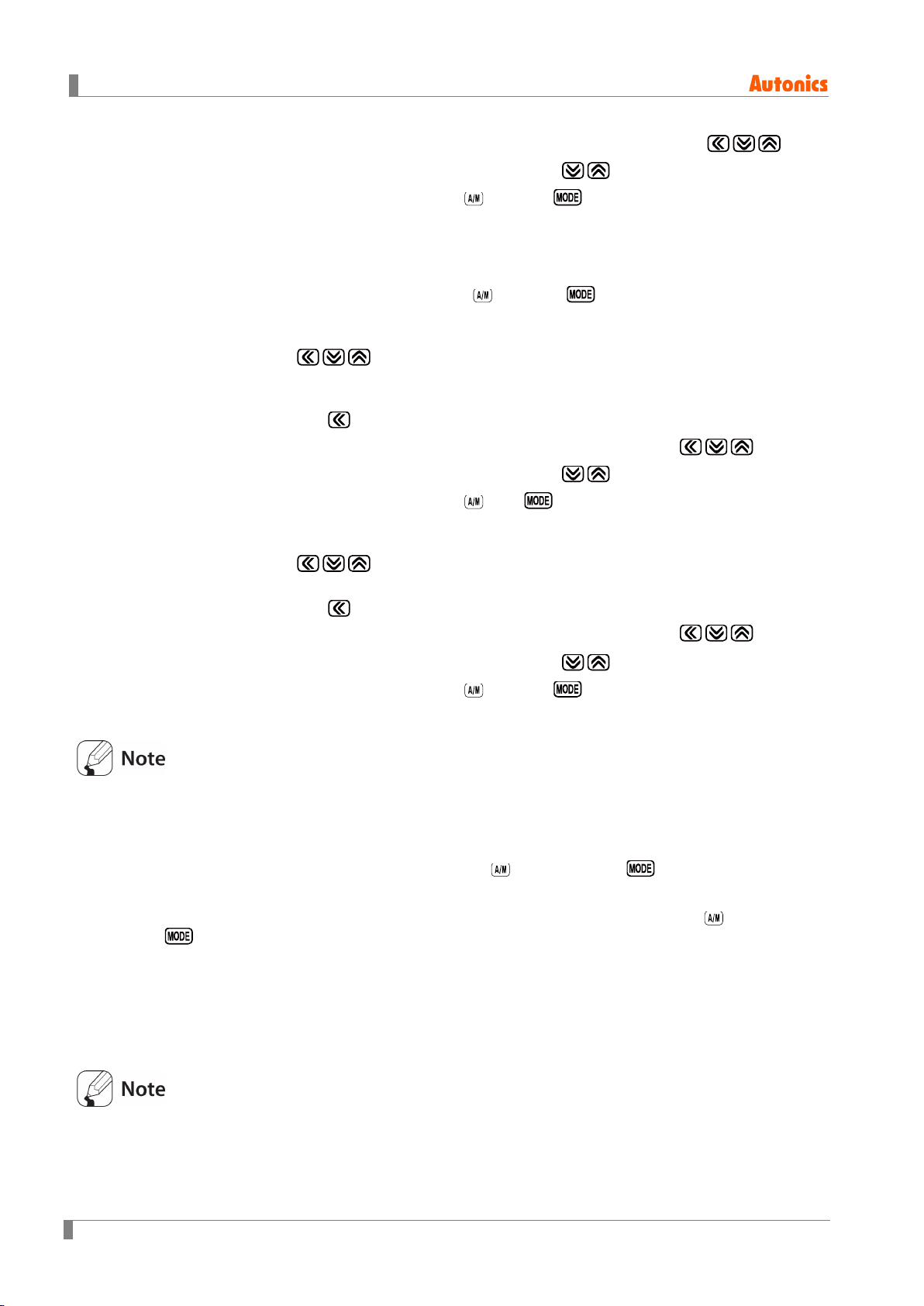

6.2.4 Auto/Manual control settings

Auto control mode is to make temperature reach SV with MV calculated by PID control. Manual

control mode is to make temperature reach SV with user’s defined MV.

When in manual control mode, parameter settings can only be viewed and cannot be modified

(except for lock parameters). When digital input terminal function is set as Auto/Manual control,

the key (the key for TK4N, TK4S, TK4SP) and the Auto/Manual swithcing by

communication do not operate. When the unit is powered on following a power interruption or

shutdown, previous control mode (auto or manual) will be maintained.

If switching to manual control during Auto-tuning, Auto-tuning will be terminated. It is still possible

to switch to manual control mode while in STOP. When a sensor break alarm [SBA] occurs in

standard control mode, the sensor error MV [ErMV] is applied. In this state, manual and auto

control MV settings can be modified. It is still possible to switch auto/manual control mode while

in controlling operation.

Operation Priority: Manual Control > Stop > Open (Sensor Disconnection)

6.2.4.1 Manual/Auto control switching

(1) Manual control switching for standard control (heating or cooling control)

①, ⑤: When in RUN mode, press the key (the key for TK4N, TK4S, TK4SP

model) and it enters MV monitoring mode. The SV display shows H (heating control) or

C (cooling control), and shows MV to indicate the start of MV monitoring.

②, ⑥: If the is pressed when MV monitoring is in progress, the MAN

0

indicator comes on and the lowest digit (10

digit) starts to flash, indicating activation of

manual control.

0

③, ⑦: Press the key to change the flashing digit (10

© Copyright Reserved Autonics Co., Ltd. 69

→ 101 → 102 → 103 → 100).

6 Parameter Settings and Functions

④, ⑧: Select the digit and configure the desired MV value using the keys

moving to 0→1→2→3→4→5→6→7→8→9→0 by the keys.

⑨: In ① to ⑧ status, press the key(the key for TK4N, TK4S, TK4SP

model) to end manual control. The MAN indicator goes off and the system reverts to

auto control mode.

(2) Manual control switching for heating & cooling control

①: When in RUN mode, press the key (the key for TK4N, TK4S, TK4SP

model) and it enters heating MV monitoring mode. The SV display shows ‘H’ and

shows MV to indicate the start of heating MV monitoring.

②: If the is pressed when heating MV monitoring is in progress, the MAN

0

indicator comes on and the lowest digit (10

digit) starts to flash, indicating activation of

manual control.

0

③: Press the key to change the flashing digit (10

→ 101 → 102 → 103 → 100).

④: Select the digit and configure the desired MV value using the keys

moving to 0→1→2→3→4→5→6→7→8→9→0 by the keys.

⑤: In ① to ④ status, press the key( key for N, S, SP model) and it enters

cooling MV monitoring mode. The SV display shows ‘C’ and shows MV to indicate the

start of cooling MV monitoring.

⑥: If the is pressed when cooling MV monitoring is in progress, the lowest

0

digit (10

⑦: Press the key to change the flashing digit (100 → 101 → 102 → 103 → 100).

digit) starts to flash.

⑧: Select the digit and configure the desired MV value using the keys

moving to 0→1→2→3→4→5→6→7→8→9→0 by the keys.

⑨: In ⑤ to ⑧ status, press the key(the key for TK4N, TK4S, TK4SP

model) to end manual control. The MAN indicator goes off and the system reverts to

auto control mode.

After heating & cooling control, the system reverts to auto control in sequence of heating

monitoring, manual heating control, cooling monitoring, and manual cooling control.

Heating MV remains in effect during cooling monitoring and manual cooling control.

TK4N/S/SP (W48×H48mm) does not have the key. Press the key once to change

between auto and manual controls.

If the digital Input [DI-1, DI-2] feature has been set for AUTO/MANUAL, the key ( the

key for TK4N, TK4S and TK4SP model) key located on the front and automatic/manual

control functions via communication do not act.

(3) Manual/Auto Control switching with the digital input (DI) terminal

If the digital Input (DI) feature has been configured for manual/auto control switching, turn

on the DI to activate manual control (MAN indicator goes on) and turn off the DI to activate

auto control. If the digital Input feature is automatic control status, you can be only to

monitor. In case it is manual control status, modifying MV and monitoring are possible.

See 6.7.4 Digital input, for detailed information on digital Input (DI) terminal settings.

When MV parameter is masked, MV parameter cannot be monitored and changed.

70 © Copyright Reserved Autonics Co., Ltd.

6 Parameter Settings and Functions

Auto-MV[AUTO]

Preset MV[PrMV]

Setting

group

Setting

group

Factory

default

6.2.4.2 Baseline MV for manual control [PAR5 → ItMV]

When switching from auto control [AUTO] to manual control [PrMU] you can set the initial MV.

AUTO: Controlling with auto control MV as an initial MV for manual control

PrMV: Controlling with preset manual MV [PrMV] as an initial M V.

Parameter Setting range Factory default Unit

PAR5 ItMV AUTO / PrMV AUTO -

When re-supplying the power, it controls with the MV which is at the power OFF.

6.2.4.3 Initial MV for manual control [PAR5 → PrMV]

If the baseline MV for manual control is configured to PrMV (Preset Manual MV), you can set the

initial MV for manual control.

Parameter Setting range

00)0 (OFF)

/10)0 (ON)

00)0 to10)0

`0)0 (Cooling ON)

/ 00)0(OFF)

/10)0 (Heating ON)

`0)0 (Cooling) to

00)0 (OFF) to

10)0 (Heating)

PAR5 PrMV

Standard

control

Heating

&

Cooling

control

ON/OFF

control

PID

control

ON/OFF

control

PID

control

Unit

00)0 %

© Copyright Reserved Autonics Co., Ltd. 71

When in heating & cooling control mode, a setting between )1 and 10)0 will be applied as

heating MV and a setting between )1 and `0)0 will be applied as cooling MV.

6 Parameter Settings and Functions

Setting

group

Factory

default

Setting

group

Factory

default

6.2.5 Output settings

6.2.5.1 Control output (OUT1/OUT2) selection [PAR3 → OUT1/OUT2]

In case of selecting the Models with current control output, both current and SSR drive

outputs are available. You can therefore choose the right output type depending on

application environments.

OUT1: Selects OUT1 control output.

OUT2: Selects OUT2 control output.

Parameter Setting range

PAR3

OUT1

SSR / CURR SSR -

OUT2

6.2.5.2 SSRP function [PAR3 → O!SR]

SSRP function of SSR drive output is selectable one of standard ON/OFF control, cycle, phase

control. By parameter setting, standard SSR drive is available. Also, cycle control connecting

with a zero cross turn-on method SSR, phase control connectiong with a random turn-on method

SSR are available.

Realizing high accuracy and cost effective temperature control with both current output (4-20mA)

and linear output(cycle control and phase control).

(1) Standard ON/OFF control [STND]

A mode to control the load in the same way as Relay output type.(ON: output level 100%,

OFF: output level 0%)

(2) Cycle control [CYCL]

A mode to control the load by repeating output ON / OFF according to the rate of output

within setting cycle. Having improved ON / OFF noise feature by Zero Cross type.

Unit

(3) Phase control [PHAS]

A mode to control the load by controlling the phase within AC half cycle. Serial control is

available. Random turn-on SSR must be used for this mode.

Parameter Setting range

PAR3 O!SR STND / CYCL/ PHAS STND -

72 © Copyright Reserved Autonics Co., Ltd.

Unit

6 Parameter Settings and Functions

Description

Heating

Cooling

Standard

Control

PID

PID control

ONOF

ON/OFF control

pP

PID control

PID control

pON

PID control

ON/OFF control

OnP

ON/OFF control

PID control

OnON

ON/OFF control

ON/OFF control

Setting

group

Factory

default

Standard

Control

Heating &

Control

Make sure that SSRP function is not available for OUT2. In case of current type models,

SSR is fixed to standard output [STND] only.

When selecting cycle output [CYCL] or phase output [PHAS], the power supply for the load

and temperature controllers must be the same.

In case of selecting SSRP function whether cycle output [CYCL] or phase output [PHAS]

with PID control type, control cycle is not available to set.

6.2.5.3 Current output range settings [PAR3 → O!MA/O@MA]

If the control output is set to current output, you can select upper and low-limit range for the

current output as either 4-20mA or 0-20mA.

O!MA: Sets OUT1's current output range.

O@MA: Sets OUT2's current output range.

This parameter is only available on models supporting current output [OUT1, OUT2].

6.3 Temperature control

6.3.1 Temperature control mode [PAR3 → C-MD]

You can choose the type of temperature control method.

Setting

Heating &

Cooling

Control

Parameter Setting range

PID / ONOF PID

PAR3 C-MD

Cooling

pP / pON / OnP / OnON pP

Unit

-

© Copyright Reserved Autonics Co., Ltd. 73

6 Parameter Settings and Functions

Parameter

Description

Setting

group

Factory

default

6.3.2 ON/OFF control [PAR3 → C-MD → ONOF]

Controls the temperature by comparing present value (PV) with set value(SV) and turning power

to the load on or off.

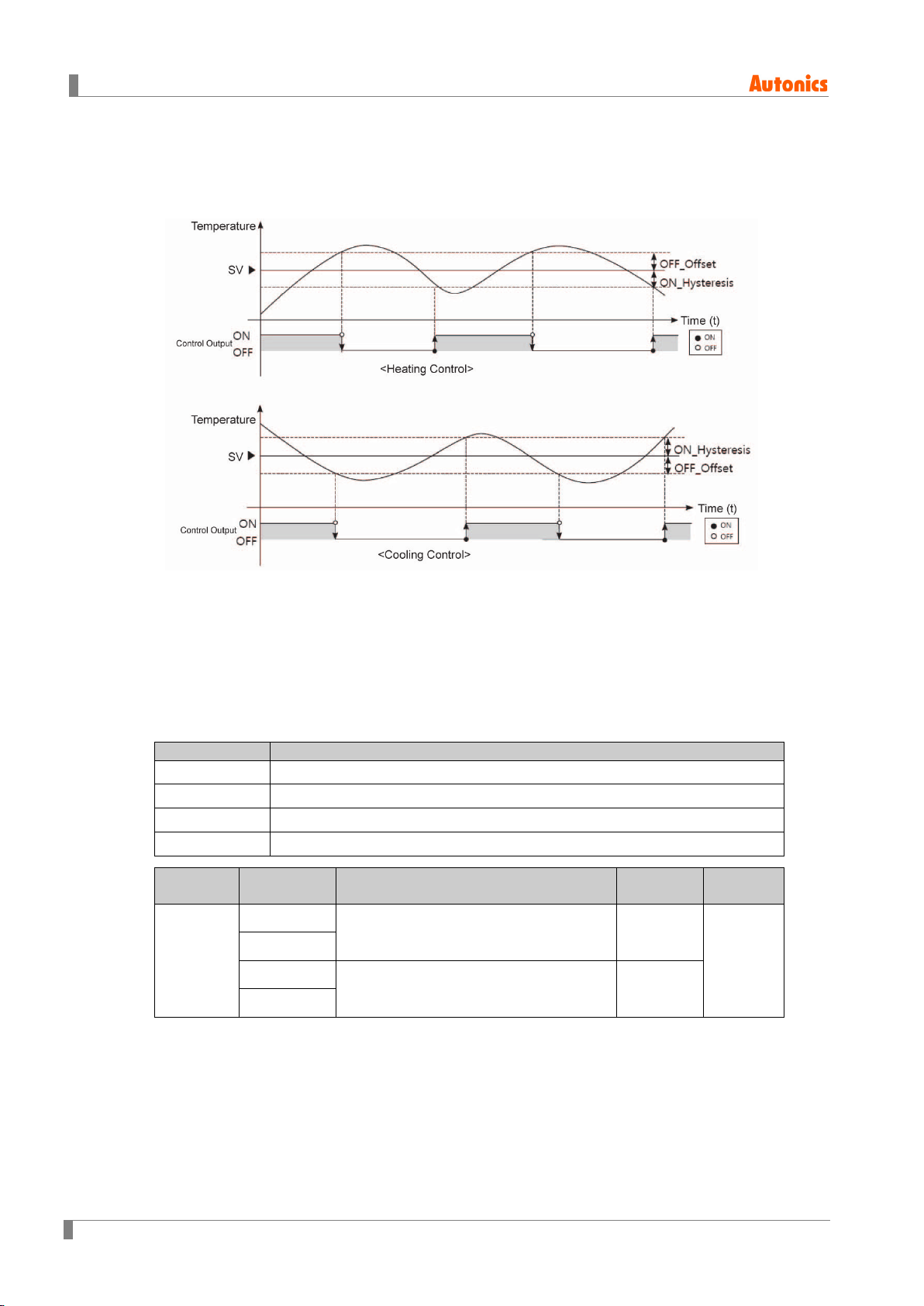

6.3.2.1 Hysteresis [PAR2 → hHYS/hOFT/cHYS/cOFT]

Hysteresis is to adjust control output ON/OFF point in ON/OFF control mode. ON_Hysteresis

sets the output on point and OFF_Offset sets the off point.

Setting hysteresis too low can result in hunting induced by disturbance (noise, chattering, etc.).

To minimize hunting, set ON_Hysteresis and OFF_Offset values with consideration to the heater

or cooler's capacity and thermal characteristics, the control subject's response characteristics,

the sensor's response characteristics and installation conditions, and other defining factors.

hHYS Configures ON_Hysteresis for heating control.

hOFT

cHYS Sets ON_Hysteresis for cooling control.

cOFT

Configures OFF_Offset for heating control.

Sets OFF_Offset for cooling control.

Parameter Setting range

hHYS

cHYS

PAR2

hOFT

cOFT

Temperature H, Analog: 001 to100

Temperature L: 0)1 to1)0

Temperature H, Analog: 001 to100

Temperature L: 0)1 to1)0

Unit

002

℃/℉/-

000

74 © Copyright Reserved Autonics Co., Ltd.

6 Parameter Settings and Functions

Parameter

Description

Setting

group

Factory

default

Analog: %

Parameter

Description

Setting

group

Factory

default

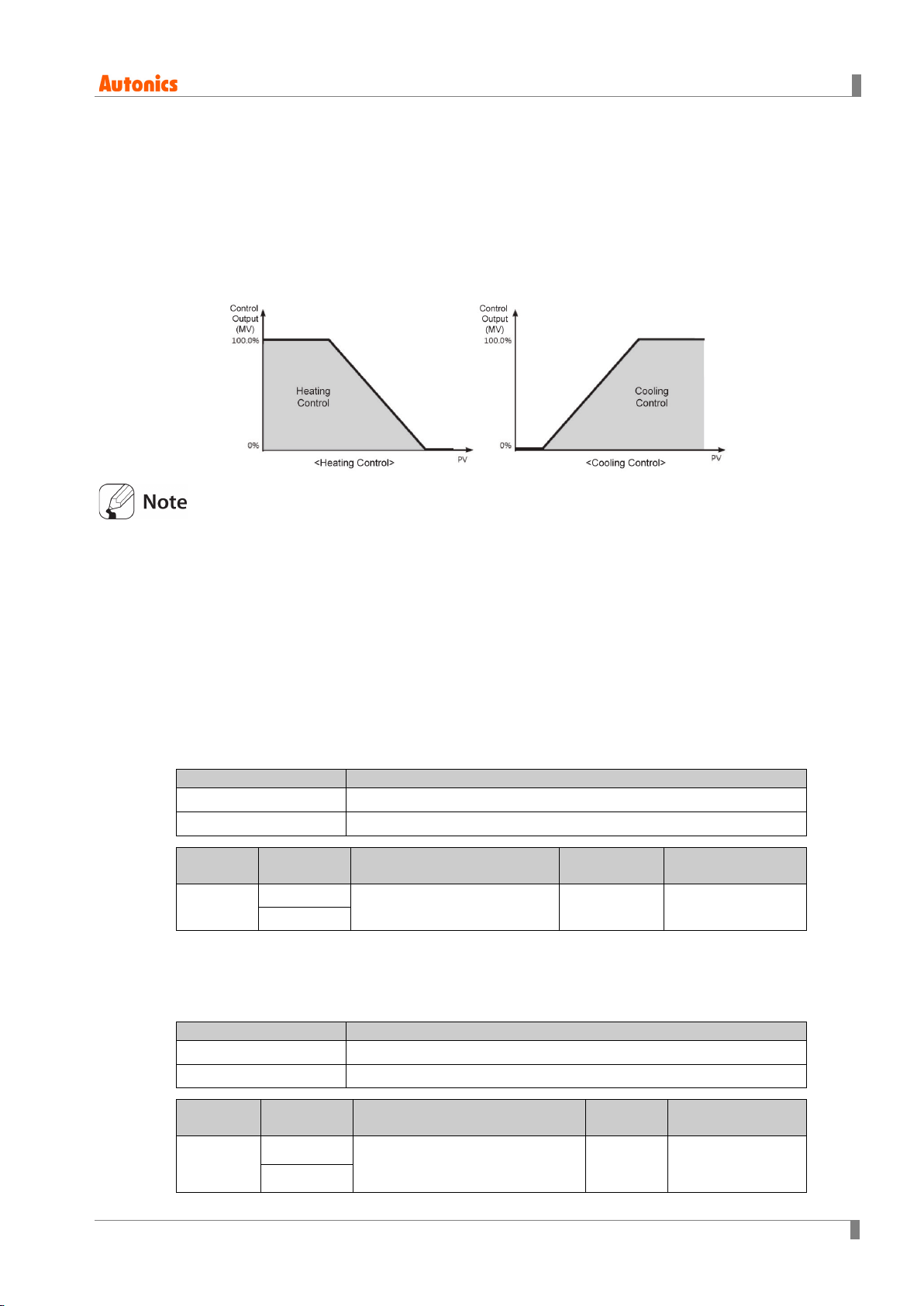

6.3.3 PID control [PAR3 → C-MD → PID]

PID control is a combination of proportional (P), integral (I), and derivative (D) controls and offers

superb control over the control subjects, even with a delay time.

Proportional control (P) implements smooth,

hunting-free control; integral control (I) automatically corrects offsets;

and derivative control (D) speeds up the response to disturbance. Through these actions, PID

control realizes ideal temperature control.

Applied PID Control Technique

Proportional Control (P): Select PID control and set the integral and derivative time to 0000.

Proportional Integral Control (PI): Select PID control and set the derivative time to 0000.

Proportional Derivative Control (PD): Select PID control and set the integral time to 0000.

Multi SV: Use the same PID time constant for the values of SV0 to SV3.

6.3.3.1 Proportional band settings [PAR2 → H-P/C-P]

When present value (PV) is within the Proportional Band (P), the ON/OFF ratio needs to be

adjusted during the proportional period (T). The defined proportional control (time proportional

control) section is called as the proportional band.

H-P

C-P

Heating proportional band

Cooling proportional band

Parameter Setting range

PAR2

H-P

C-P

00)1 to 99(9 01)0

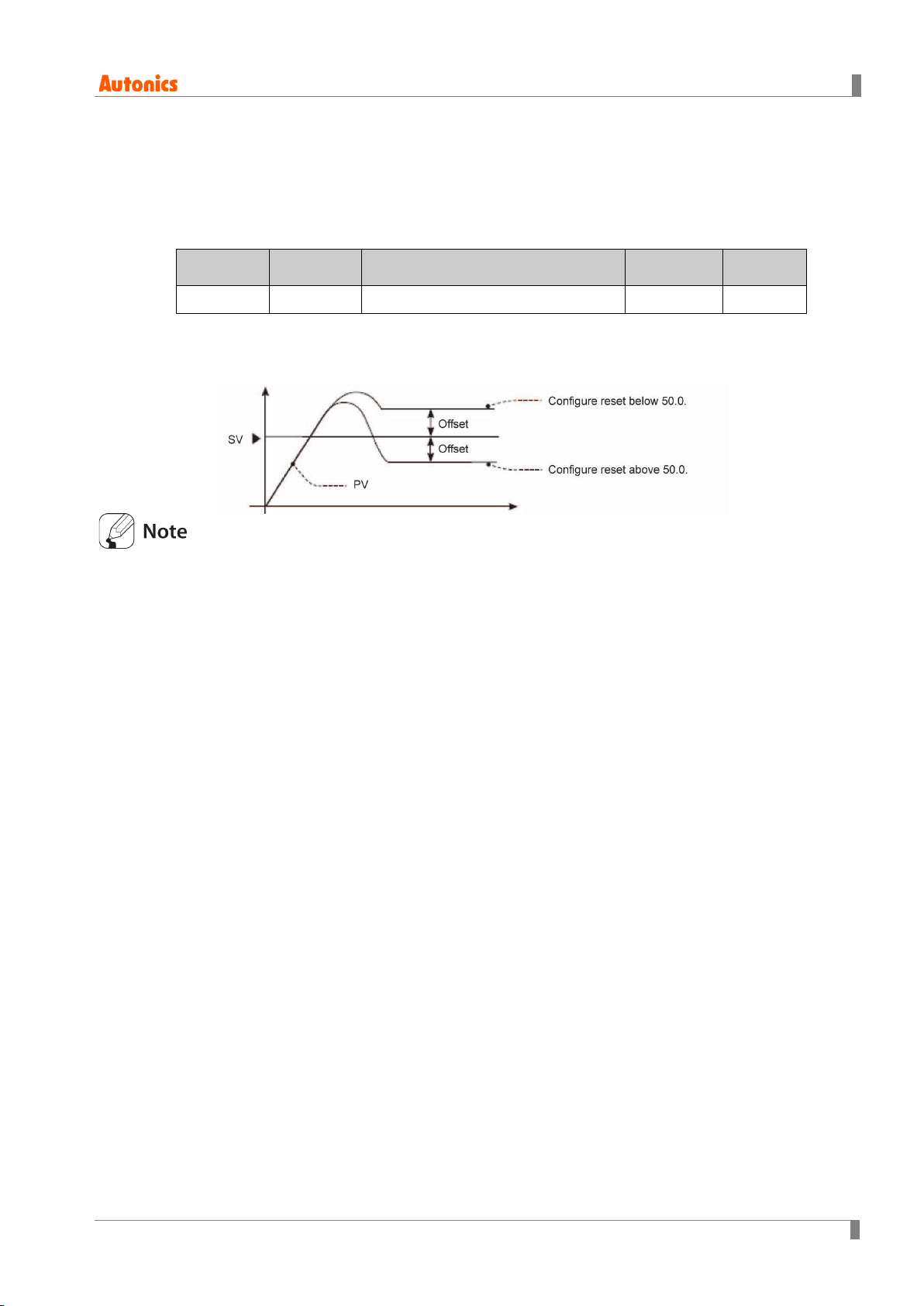

6.3.3.2 Integral time settings [PAR2 → H-I/C-I]

MVs from integral and proportional operation become the same when deviation is consistent.

The time taken for the two MVs to match is called the integral time.

Unit

Temperature: ℃/℉

H-I

C-I Cooling integral time

Parameter Setting range

H-I

PAR2

C-I

© Copyright Reserved Autonics Co., Ltd. 75

Heating integral time

Unit

0000 to 9999 0000 Sec

6 Parameter Settings and Functions

Parameter

Description

Setting

group

Factory

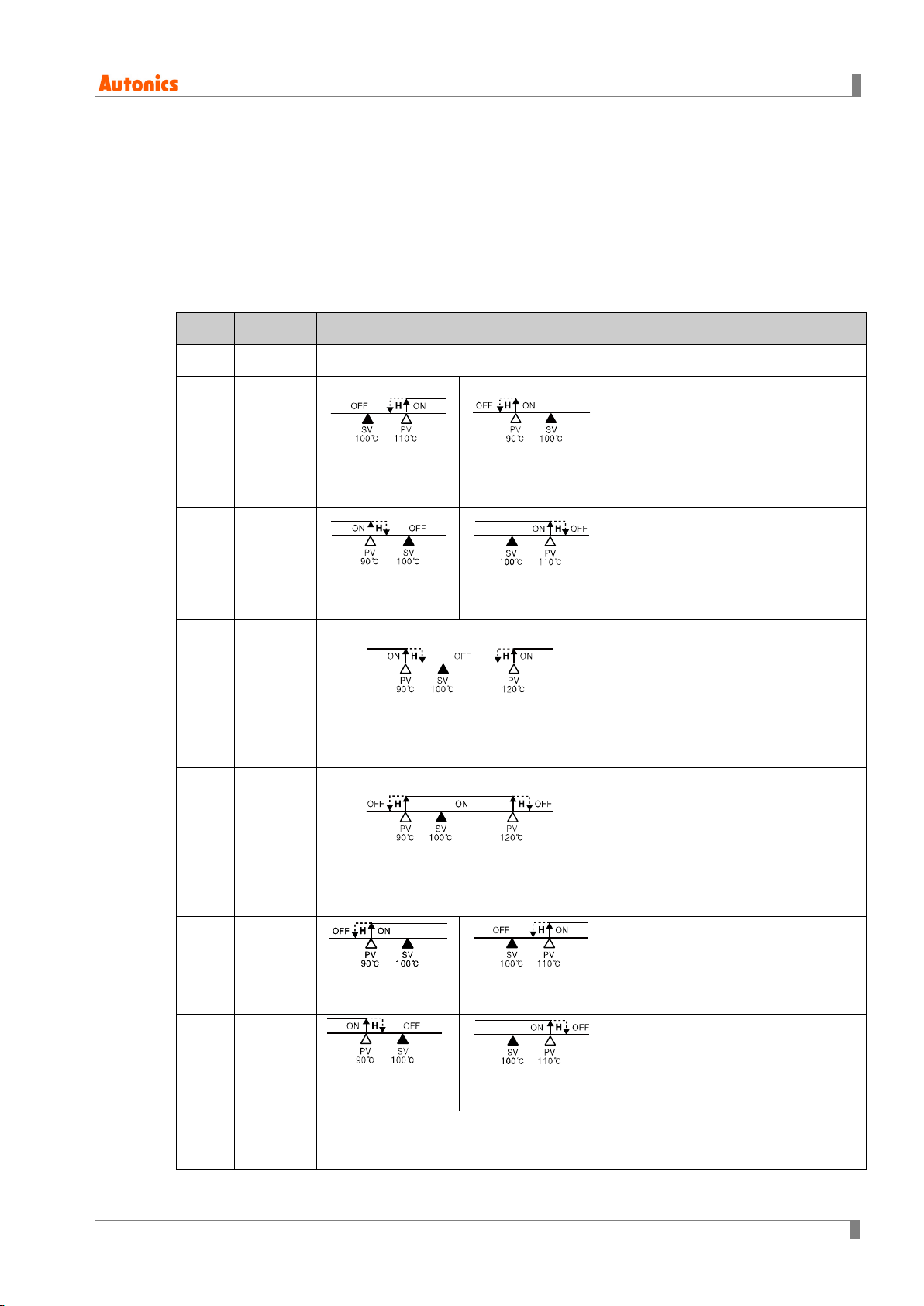

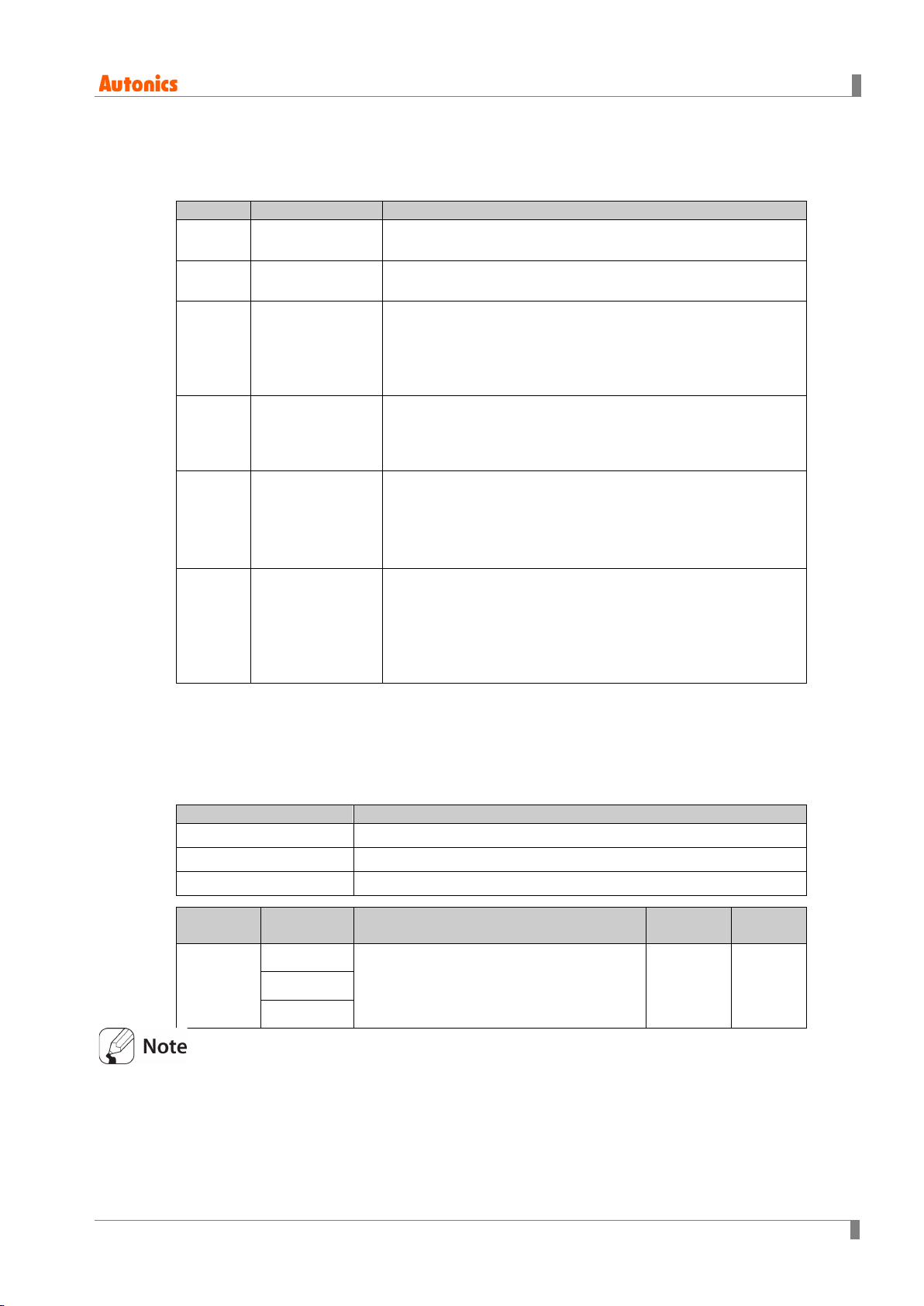

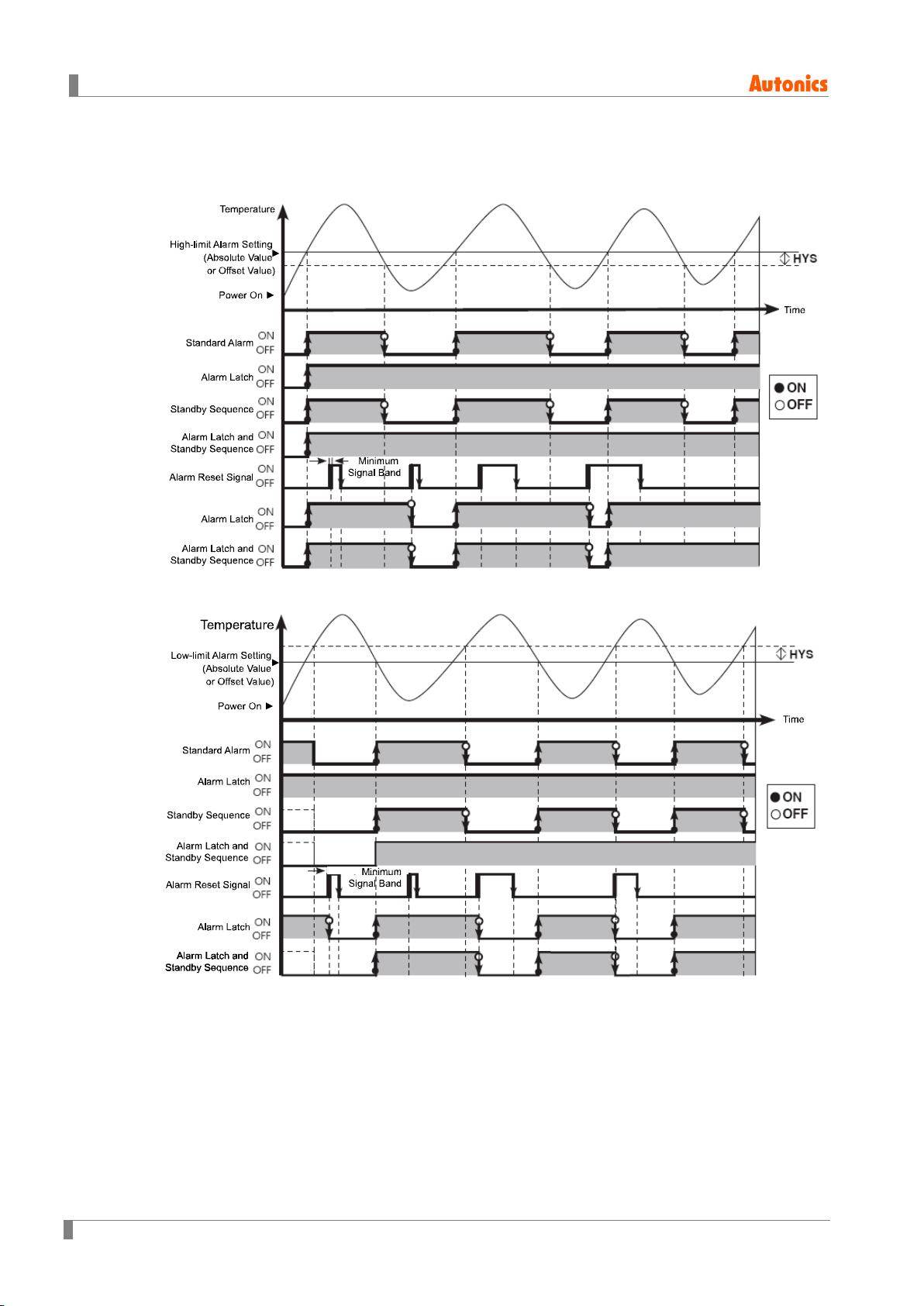

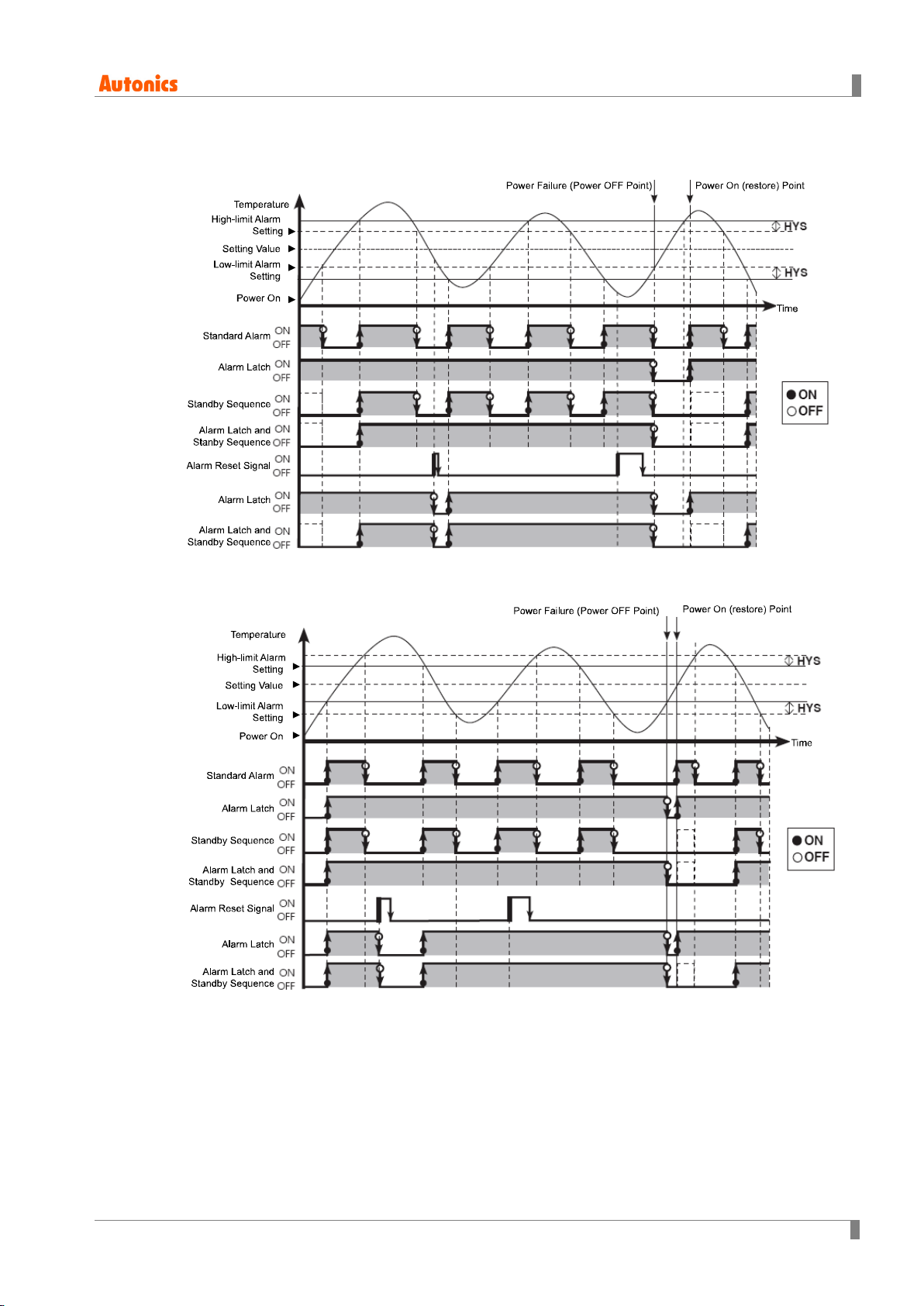

default