DR W161011AC

Autonics

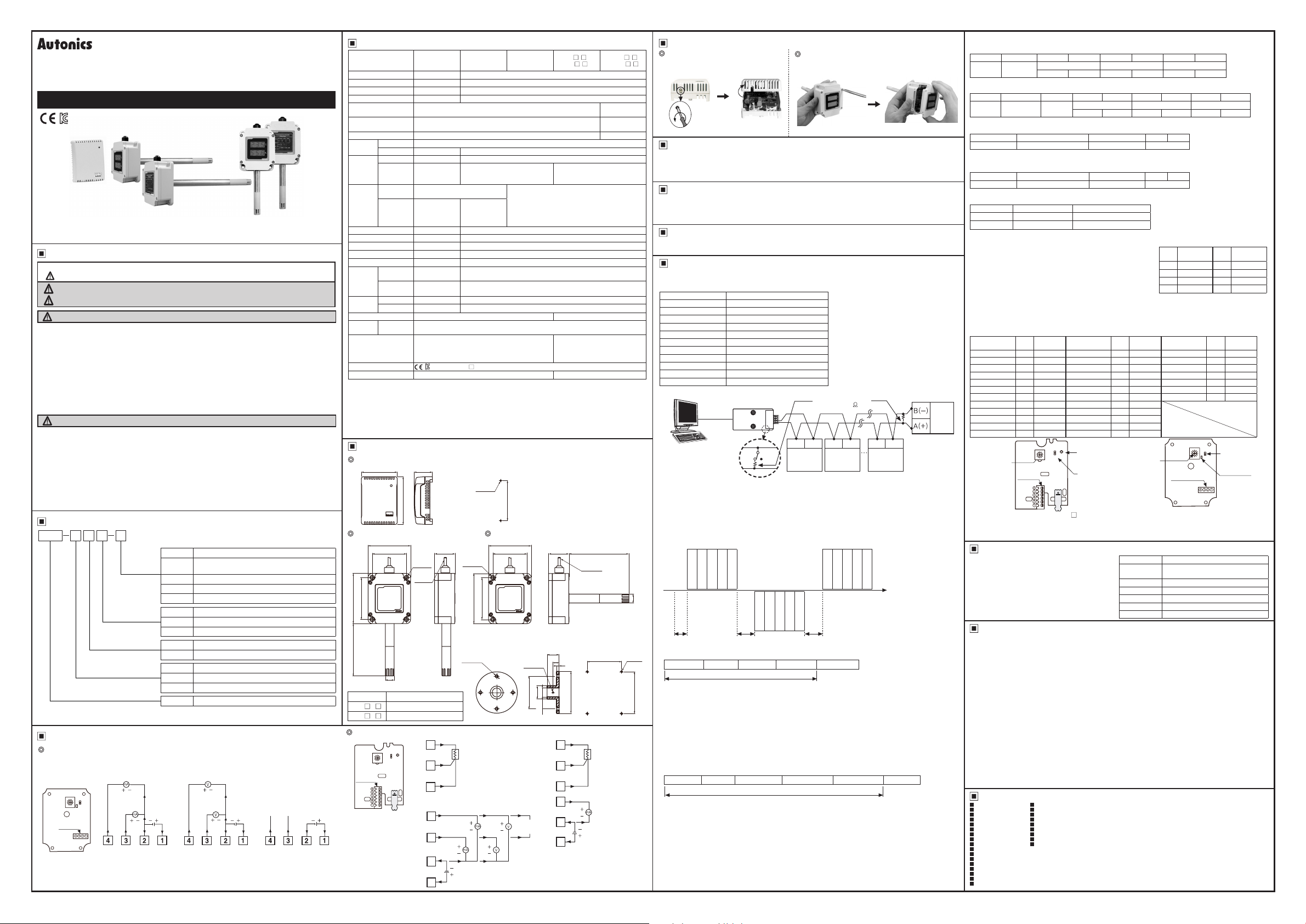

Temperature/Humidity Transducer

THD SERIES

I N S T R U C T I O N M A N U A L

Please read the following safety considerations before use.

Safety Considerations

Please observe all safety considerations for safe and proper product operation to avoid hazards.

※

symbol represents caution due to special circumstances in which hazards may occur.

※

Warning

Caution

Warning

1. Fail-safe device must be installed when using the unit with machinery that may cause

serious injury or substantial economic loss. (e.g. nuclear power control, medical equipment,

ships, vehicles, railways, aircraft, combustion apparatus, safety equipment, crime/disaster

prevention devices, etc.)

Failure to follow this instruction may result in re, personal injury, or economic loss.

2. Do not connect, repair, or inspect the unit while connected to a power source.

Failure to follow this instruction may result in re.

3. Check 'Connections' before wiring.

Failure to follow this instruction may result in re.

4. Do not disassemble or modify the unit.

Failure to follow this instruction may result in re.

Caution

1. Use the unit within the rated specications.

Failure to follow this instruction may result in re or product damage.

2. Use dry cloth to clean the unit, and do not use water or organic solvent.

Failure to follow this instruction may result in re.

3. Do not use the unit in the place where ammable/explosive/corrosive gas, humidity, direct

sunlight, radiant heat, vibration, impact, or salinity may be present.

Failure to follow this instruction may result in re or explosion.

4. Keep metal chip, dust, and wire residue from owing into the unit.

Failure to follow this instruction may result in re or product damage.

Thank you for choosing our Autonics product.

Failure to follow these instructions may result in serious injury or death.

Failure to follow these instructions may result in personal injury or product damage.

Specications

Model THD-R-PT THD-R-PT/C

Power supply

Permissible voltage range

Power consumption

Sensor type

Display type Non-display

Display digit

Character size

Measuring

range

Accuracy

1

※

Output

Resolution

Sampling period

Insulation resistance

Dielectric strength

Noise resistance

Vibration

Shock

Protection IP10 IP65 (except sensor part)

Environ-

ment

Cable

Approval

Weight

1: •Room temperature is 23℃±5℃.

※

2: The weight includes packaging. The weight in parentheses is for unit only.

※

※

Environment resistance is rated at no freezing or condensation.

Dimensions

THD-R

Ordering Information

@ @

- -

THD

D D 1 C

※

PT

DPt100Ω resistance value (Temp.)

※

DPt100Ω resistance value (Temp.) /

PT/C

Current output (Humidity)

C Current output (Temp./Humidity)

V Voltage output (Temp./Humidity)

T

RS485 com. output (Temp /Humidity)

※

No-mark

Built in type

1 100mm

2 200mm

No-mark

I

I

I

I

I

I

Non-display type

I

D

Display type

I

R Room type (for indoor)

I

D

Duct mounting type

7

W

Wall mounting type

I

THD

Temperaure Humidity Double

T

Display

Mounting

Item

※

It is only for THD-R.

Output

Length of

sensor pole

Terminal Connection

@

THD-D/THD-W

Power &Output

terminal

The above specications are subject to change and some models may be discontinued without notice.

※

Be sure to follow cautions written in the instruction manual and the technical descriptions (catalog, homepage).

※

● THD-D-C/

THD-W-C

DC4-20mA (Humi.)

(Temp.)

24VDC 2.4W

White Black Blue Brown

● THD-D-V/

THD-W-V

1-5VDC (Humi.)

(Temp.)

24VDC 2.4W

White Black Blue Brown

● THD-D-T/

THD-W-T

RS485

(Temp. &

Humi.)

A (+)

B (-)

White Black Blue Brown

24VDC 2.4W

THD-W THD-D

85

7

A

l

l

l

I

Model Length of sensor pole (A)

l

THD-

1,-------------,~

THD-

@

THD-R

Power

&Output

terminal

※

Check the terminal

connection diagram

and be sure that

when connecting

the power.

THD-R-C

THD-R-V

I

-

-

Temperature sensor

-

Temp. -19.9 to 60.0

Humidity

Temp. Max. ±0 8℃ ±1ºC (at room temp.)

Humidity

Temp.

Humidity

Mechanical

Malfunction

Mechanical

Malfunction

Ambient

temperature

2

※

• t may cause degree of degradation when the unit is exposed to organic chemicals such as

alcohol gas or sulfuric acid.

• It may cause degree of degradation for humidity when using the unit at high temperature/humidity

environment for a long time.

• It may cause error of humidity value when the unit is used at high humidity environment (over

80%RH) for a long time.

60

-

-

-

DPt100Ω resistance value

(TCR: 3850ppm/

-

-

-

-

-

-

-

-

-

-

-20 to 60℃, storage: -20 to 60

-

(only for THD- -T model)

CE

[\

Approx. 98g (approx. 55g) Approx. 415g (approx. 160g)

30 5

80

24VDC

90 to 110% of rated voltage

Max. 2.4W

Temperature/Humidity sensor

℃

0 0 to 99 9%RH (THD-R is required to attend for using over 90%RH)

±3%RH (30 to 70%RH, at room

temp.), ±4%RH (10 to 90%RH)

℃)

DC4-20mA

(allowable

impedance:

max. 600Ω)

1/1000

0 5 sec

Min. 100MΩ (at 500VDC megger)

500VAC 50/60Hz for 1 minute

±0.3kV the square wave noise (pulse width: 1㎲) by the noise simulator

0.75mm amplitude at frequency of 10 to 55Hz (for 1 min) in each

X, Y, Z direction for 1 hour

0 5mm amplitude at frequency of 10 to 55Hz (for 1 min) in each

X, Y, Z direction for 10 minutes

300m/s2 (approx. 30G) in each X, Y, Z direction for 3 times

100m/s2 (approx. 10G) in each X, Y, Z direction for 3 times

□

THD-R-T

ᜡ

DC4-20mA (allowable impedance: max. 600Ω),

1-5VDCᜡ,

RS485 communication (Modbus RTU)

℃

●

Mounting hole

2-M3

67.8

-

THD-D

THD-W -

I

Typ. ±2%RH

(10 to 90%RH, at room temp.)

Max. ±2.5%RH

※

I

I

Ø4mm, 4-wire, length: 2m

(AWG22, Core diameter: 0.08mm,

number of cores: 60, insulation

out diameter: Ø1.25mm)

I

THD-DD -

□□ □□

THD-WD -

□□ □□

7Segment LED

Display

Each 3 digits for

temp./humi.

W6.2×H10 0mm

I

(unit: mm)

J

72 72

58 58

71

Ø15

1- 100mm

~

I

2- 200mm

-08

D

34.5 34.5 A

4-Ø4.8

Ø4, 2m

●THD-R-PT

3

2

1

●THD-R-C, V, T

4

(Humi.)

3

(Temp.)

2

1

4-Ø4.8

85

71

●

Bracket

4-Ø4.5

A

TEMPERATURE

SENSOR

DPt100Ω SIGNAL OUT

B

B'

DC4-20mA 1-5VDC RS485

24VDC 2.4W

2-M3

55

Ø22

00

Ø15.2

B (-)

A (+)

●

20

10

4

Ø70

●THD-R-PT/C

A

6

B

5

B'

4

3

2

1

Ø4, 2m

Mounting hole

4-M4

58

71

: j

TEMPERATURE

SENSOR

DPt100Ω SIGNAL OUT

DC4-20mA

(Humi.)

24VDC 2.4W

Case Detachment

THD-R

Unfasten the bolt on the bottom of the

product, separate the case from it.

@

THD-D/THD-W

Unfasten 4 bolts on the top of the product, separate

the case cover from it.

Current Output

It transmits current temperature/humidity to other devices (PC, recorder, etc.) and outputs DC4-20mA.

It outputs DC4mA at -19.9℃ of temperature and 0%RH of humidity, DC20mA at 60℃ of temperature

and 99.9%RH of humidity. The temperature and humidity output are separated and the resolution is

divisible by 1,000.

rf

■

~~---------_j

Voltage Output

It transmits current temperature/humidity to other devices (PC, recorder, etc.) and outputs 1-5VDC.

It outputs 1VDC at -19.9℃ of temperature and 0%RH of humidity, 5VDC at 60℃ of temperature

and 99.9%RH of humidity. The temperature and humidity output are separated and the resolution is

divisible by 1,000.

DPt 100Ω Resistance Value Output

It transmits current temperature to other devices (recorder, thermometer, etc.). t outputs 100Ω at 0℃

and 119.40Ω at 50℃. (Temperature coefficient (TCR)=3850ppm/℃)

RS485 Communication Output

It is output transmit current temperature and humidity to other devices (PC, recorder, etc.) by

communication.

●Interface

Comm. protocol Modbus RTU

Connection type RS485

Application standard Compliance with EIA RS485

Max. connection 31 units (address: 01 to 31)

Synchronous method Asynchronous

Comm. method Two-wire half duplex

Comm. distance Max. 800m

Comm. speed 1200 to 115200bps (selectable)

Start bit 1-bit (xed)

Data bit 8-bit (xed)

Parity bit None (xed)

Stop bit 1-bit (xed)

●Application of system organization

Computer

※

It is recommended to use Autonics communication converter; SCM-WF48 (Wi-Fi to RS485 USB

wireless communication converter, sold separately), SCM-US48I (USB to RS485 converter, sold

separately), SCM-38I (RS232C to RS485 converter, sold separately).

Please use twisted pair wire, which is suitable for RS485 communication, for SCM-WF48, SCMUS48I and SCM-38I.

●Ordering of communication control

1. The communication method is Modbus RTU.

2. After 2.0 sec being supplied the power into master system, it is able to start communication.

3. The initial communication is started by master system. When a command comes out from the

master system, THD will respond.

Master

Ø15

THD

A B C

●Communication command and block

The format of query and response.

Query

Address code Command Start address Number of data CRC16

①

Address code: This address code is for identifying THD by master system and able to set within

range of 01 to 31.

②

Command: Read command for input register

③

Start address: The start address of input register to read (start address). It is available to select

0000 and 0001 for start address. 16-bit data in the address 0000 indicates temperature value, 16bit data in the address 0001 indicates humidity value. (refer to Modbus Mapping table.)

④

Number of data: The number of 16-bit data from start address (no. of Points). When start address

is 0000, it is available to read 2 of 16-bit data, or when start address is 0001, it is available to read

1 of 16-bit data.

⑤

CRC16: Checksum for checking the whole frame and it is used for more reliable transmit/receive

to check the error between transmitter and receiver.

Response

Address code Command Number of data Temperature data Humidity data CRC16

①

Address code: This address code is for identifying THD by master system and able to set within

range of 01 to 31.

②

Command: A response for read command of input register

③

Number of data: The number of 8-bit data to send from start address (no. of bytes). When start

address is 0000, it is available to read 4 of 8-bit data, or when start address is 0001, it is available

to read 2 of 8-bit data.

④

Temperature data: This is the value of 16-bit. To get a current temperature value, divide read value

by 100.

E g.)When read data is 0×09B0, decimal value is 2480, the current value is 2480/100=24.80

⑤

Humidity data: This is the value of 16-bit. To get a current humidity value, divide read value by 100.

E g.)When read data is 0×0B68, decimal value is 2920, the current value is 2920/100=29.20%RH.

⑥

CRC16: Checksum for checking the whole frame.

RS232C/

USB/Wi-Fi

Communication

Address code

Command

Start address

Number of data

CRC16

Calculation range of CRC16

RS485

converter

B(-)

ON OFF

Calculation range of CRC16

Address code

Command

Number of data

A(+)

RS485

DEVICE

Data

#1

CRC16

※

It is not possible to change parameter

related to communication of THD

under the communication wth high

order system.

(At communication status, THD and

upper system are available to change

the address.)

※

Match the parameter of

communication to be same as the

high order system.

※

It is not allowed to set overlapping

communication address at the same

communication line.

Terminating resistance

(100 to 120 )

A(+) A(+)B(-) B(-) B(-)

RS485

DEVICE

#2

Address code

Command

※

A→Min. 2.0 sec after supplying power

B→ (Comm. speed × 10-bit) × within 10 times

E.g.) Comm. speed is 9600bps,

(1s/9600-bit

※

C→ (Comm. speed × 10-bit) × over 4 times

Start address

Number of data

CRC16

× 10-bit) = 1.04ms ×

RS485

DEVICE

#30

THD

RS485

DEVICE

within 10 times

●Application for communication command

(Query):

Address code (01), Start address (0000), The number of 16-bit data to read (2), CRC16 (0×71CB)

01 04 00 00 00 02 71 CB

Address

Command

code

(Response): Address code (01), The number of 8-bit data to read (4), Temperature (0×09B0),

01 04 04 09 B0 0B 68 94 DE

Address

Reponse

code

command

●Error processing (Slave → Master)

1. Not supported command

01 8X 01 XX XX

Address code Response command Exception code CRC16

※

Set a received the highest bit and send it to response command and exception code 01.

2. The start address of queried data is inconsistent with the transmittable address or the requested

number of data is bigger than the transmittable address.

01 84 02 C2 C1

F===t======r=====i=:::r:::=::J

Address code Response command Exception code CRC16

※

Set a received the highest bit and send it to response command and exception code 02.

●Modbus Mapping Table

Address Item Remark

30001 (0000) Temperature value Temperature value

30002 (0001) Humidity value Humidity value

●Setting communication speed

1. Turn off the power of the unit.

2. Set SW1 to 0 and supply the power.

3. Operation indicator LED is flashing.

4. Set a communication speed after choosing SW1 within the

range 1 to 8, and hold it for 3 sec.

5. After setting a communication speed, the LED will be ON.

At the moment turn OFF the power.

※

Factory default communication speed is 9600bps.

●Setting communication address

1. Set upper address setting terminal and setting switch (SW1) to the desired address and supply the power.

2. The communication address is changed automatically.

※

Factory default communication address is 01.

(SW1: 1, Up

<

Setting table for address>

Upper address

setting terminal

OPEN 1 01 OPEN D 13 SHORT 9 25

OPEN 2 02 OPEN E 14 SHORT A 26

OPEN 3 03 OPEN F 15 SHORT B 27

OPEN 4 04 SHORT 0 16 SHORT C 28

OPEN 5 05 SHORT 1 17 SHORT D 29

OPEN 6 06 SHORT 2 18 SHORT E 30

OPEN 7 07 SHORT 3 19 SHORT F 31

OPEN 8 08 SHORT 4 20

OPEN 9 09 SHORT 5 21

#31

OPEN A 10 SHORT 6 22

OPEN B 11 SHORT 7 23

OPEN C 12 SHORT 8 24

Communication

(speed/address)

setting switch

1

※

(SW1)

※

1

Only when communication setting, remove the case cover and adjust communication setting switch

to set address and communication speed.

※

2 Short terminal as upper address setting terminal, the lower address setting is available.

Start address Amount of data CRC16

High Low High Low High Low

Humidity (0×0B68), CRC16 (0×94DE)

Temperature data Humidity data CRC16

Number

of data

High Low High Low High Low

0 01

×

0.01

×

per

address setting terminal: OPEN)

CJ

I

so~

485

'

Upper address

setting terminal

Operation

indicator

(Red LED)

Upper

"-

address

setting

※

terminal

□

SW1 Address

Communication

(speed/address)

setting switch

(SW1)

2

<Inner PCB of THD-D/THD-W Series>

SW1 Address

~~

[i]

Power

&Output

terminal

~

<Inner PCB of THD-R- >

<

Setting table for

communication speed>

Comm.

SW1

speed (bps)

1 1200 5 19200

2 2400 6 38400

3 4800 7 57600

4 9600 8 115200

11

Upper address

setting terminal

~

/o

[ilns:~

1

※

Power &Output

terminal

~

\o

0

SW1

I I

SW1 Address

Upper address

setting terminal

485

Operation

indicator

~

(Red LED)

0

Comm.

speed (bps)

Comprehensive Device Management Program

[DAQMaster]

DAQMaster is comprehensive device management

program. t is available for temperature and humidity

monitoring.

For more information, please refer to the DAQMater

user manual.

Cautions during Use

1. Follow instructions in 'Cautions during Use'. Otherwise, t may cause unexpected accidents.

2. Keep away from high voltage lines or power lines to prevent inductive noise.

In case installing power line and input signal line closely, use line lter or varistor at power line and

shielded wire at input signal line.

Do not use near the equipment which generates strong magnetic force or high frequency noise.

3.

Install a power switch or circuit breaker in the easily accessible place for supplying or disconnecting the power.

4. 24VDC power supply should be insulated and limited voltage/current or Class 2, SELV power supply

device.

5. Do not overlapping communication line and power line.

Use twisted pair wire for communication line and connect ferrite bead at each end of line to reduce

the eect of external noise.

6. Do not touch TDH-W/D sensor part at the bottom of the sensor pole by hands.

It may cause malfunction.

7. THD-R must be installed on the wall.

It may cause malfunction.

8. Make a required space around the unit for radiation of heat.

For accurate temperature measurement, warm up the unit over 20 min after turning on the power.

9.

Make sure that power supply voltage reaches to the rated voltage within 2 sec after supplying power.

10. Do not wire to terminals which are not used.

11. This unit may be used in the following environments.

Indoors (in the environment condition rated in 'Specications')

①

Pollution degree 2

③

Major Products

~

Photoelectric Sensors Temperature Controllers

■

Fiber Optic Sensors Temperature/Humidity Transducers

■

Door Sensors SSRs/Power Controllers

■

Door Side Sensors Counters

■

Area Sensors Timers

■

Proximity Sensors Panel Meters

■

Pressure Sensors Tachometer/Pulse (Rate) Meters

■

Rotary Encoders Display Units

■

Connector/Sockets Sensor Controllers

■

Switching Mode Power Supplies

■

Control Switches/Lamps/Buzzers

■

I/O Terminal Blocks & Cables

■

℃.

Stepper Motors/Drivers/Motion Controllers

■

Graphic/Logic Panels

■

Field Network Devices

■

Laser Marking System (Fiber, Co₂, Nd: yag)

■

Laser Welding/Cutting System

■

■

■

■

■

■

■

■

■

■

Item Minimum specications

System

Operations Windows 98/NT/XP/Vista/7/8/10

Memory 256MB+

Hard disk 1GB+ of available hard disk space

VGA Resolution: 1024×768 or higher

Others RS232C serial port (9-pin), USB port

I

IBM PC compatible computer with

Pentium Ⅲ or above

Altitude max. 2,000m

②

Installation category II

④

DR W161011AC

2

※

Loading...

Loading...