DRW1707 75AB

Autonics

TEMPERATURE CONTROLLER

TC4 Series

INSTRUCTION MANUAL

n;.,...,_ ----._.,,

~·

-,

,

...

- J .

Ii

1

IIID , ,

..

an

Cl

l'i:I

f

uu

'2""

~

,~·

-~

~

~ -

73:

=~

I

:aoa

t::l

~

_,,,

.'

Q:,

Ql'J~

,., /J

,,,,

Thank you for choosing our Autonics product.

Failure to follow these instructions may result in personal injury or product damage.

2

) cable or over and tighten

7r

7-

Control output

l?

Power supply

Sub output

Size

Digit

N Indicator - Without control output

R Relay output+SSR drive output

2 24VAC 50/60Hz, 24-48VDC

4 100-240VAC 50/60Hz

I I I

N No alarm output

1 Alarm1 output

2 Alarm1 + Alarm2 output

S D N W48 H48mm (terminal block type)

SP D N W48

Y D N W72 H36mm

M D N W72

H D N W48

W D N W96

L D N W96

4 9999 (4 Digit)

C Set by touch switch

T Temperature controller

X

H48mm (11pin plug type)

X

X

H72mm

X

X

H96mm

H48mm

X

H96mm

X

1

※

2

※

/J

3

※

.

rcn

0.JU

Please read the following safety considerations before use.

Safety Considerations

00

Please observe all safety considerations for safe and proper product operation to avoid hazards.

※

Safety considerations are categorized as follows.

※

Warning Failure to follow these instructions may result in serious injury or death.

Caution

※

The symbols used on the product and instruction manual represent the following

symbol represents caution due to special circumstances in which hazards may occur.

Warning

1. Fail-safe device must be installed when using the unit with machinery that may cause serious injury

or substantial economic loss. (e.g. nuclear power control, medical equipment, ships, vehicles,

railways, aircraft, combustion apparatus, safety equipment, crime/disaster prevention devices, etc.)

Failure to follow this instruction may result in personal injury, re or economic loss.

2. Do not use the unit in the place where ammable/explosive/corrosive gas, humidity, direct sunlight,

radiant heat, vibration, impact, or salinity may be present.

Failure to follow this instruction may result in explosion or re.

3. Install on a device panel to use.

Failure to follow this instruction may result in electric shock or re.

4. Do not connect, repair, or inspect the unit while connected to a power source.

Failure to follow this instruction may result in electric shock or re.

5. Check 'Connections' before wiring.

Failure to follow this instruction may result in re.

6. Do not disassemble or modify the unit.

Failure to follow this instruction may result in electric shock or re.

Caution

1. When connecting the power input and relay output, use AWG 20(0.50mm

the terminal screw with a tightening torque of 0.74~0.90N.m.

When connecting the sensor input and communication cable without dedicated cable, use AWG

28~16 cable and tighten the terminal screw with a tightening torque of 0.74~0.90N.m.

Failure to follow this instruction may result in re or malfunction due to contact failure.

2. Use the unit within the rated specications.

Failure to follow this instruction may result in re or product damage.

3. Use dry cloth to clean the unit, and do not use water or organic solvent.

Failure to follow this instruction may result in electric shock or re.

4. Keep metal chip, dust, and wire residue from owing into the unit.

Failure to follow this instruction may result in re or product damage.

Ordering Information

T C 4 S 1 4 R

I

II II

Setting type

Item

※

1 In case of the AC voltage model, SSR drive output method (standard ON/OFF control, cycle control,

phase control) is available to select.

※

2 t is unavailable for TC4SP, TC4Y.

※

3 Sockets for TC4SP (PG-11, PS-11(N)) are sold separately.

The above specications are subject to change and some models may be discontinued

※

without notice.

Be sure to follow cautions written in the instruction manual and the technical descriptions

※

(catalog, homepage).

Specications

00

Series

AC power 100-240VACᜠ 50/60Hz

Power

I

supply

AC/DC Power 24VACᜠ 50/60Hz, 24-48VDC

Allowable voltage range 90 to 110% of rated voltage

Power

consumption

Display method 7Segment (Red), Other display (Green, Yellow, Red LED)

Character size (W×H) 7 0×15.0mm

Input

type

Display

accuracy

Control

output

Alarm output AL1, AL2 Relay: 250VACᜠ 1A 1a (※TC4SP, TC4Y have AL1 only.)

Control method ON/OFF and P, PI, PD, PID control

Hysteresis 1 to100℃/℉ (0.1 to 50 0℃/℉) variable

Proportional band (P) 0.1 to 999.9℃/

Integral time (I) 0 to 9999 sec.

Derivative time (D) 0 to 9999 sec.

Control period (T) 0 5 to 120.0 sec.

Manual reset 0 0 to 100.0%

Sampling period 100ms

Dielectric

strength

Vibration 0.75mm amplitude at frequency of 5 to 55Hz in each X, Y, Z direction for 2 hours

Relay

life cycle

Insulation resistance Min. 100MΩ (at 500VDC megger)

Noise immunity

Memory retention Approx. 10 years (When using non-volatile semiconductor memory type)

Environ

-ment

Insulation type

Approval

Weight

※

Out of room temperature range: (PV ±0 5% or ±3

In case of TC4SP Series, ±1℃ will be added.

※

※

00

1. Present temperature (PV) display

2. Deviation indicator, Auto-tuning indicator

3. Set temperature (SV) indicator

4. Temperature unit

00

I

00

•

※

AC power Max. 5VA (100-240VAC 50/60Hz)

AC/DC Power

I

RTD DPt100Ω, Cu50Ω (Allowable line resistance max.5Ω per a wire)

TC K (CA), J (IC), L (IC)

RTD

1

※

TC

Relay 250VACᜠ 3A 1a

SSR 12VDCᜡ ± 2V 20mA Max.

AC power 2,000VAC 50/60Hz for 1min. (between input terminal and power terminal)

AC/DC Power 1,000VAC 50/60Hz for 1min. (between input terminal and power terminal)

Mechanical OUT: Min. 5,000,000 operations, AL1/2: Min. 5,000,000 operations

Electrical

Ambient temp.

I

Ambient humi.

I

2

※

1: Thermocouple L (IC) type, RTD Cu50Ω

At room temperature (23℃ ±5℃): (PV ±0.5% or ±2

2: The weight includes packaging. The weight in parentheses is for unit only.

Environment resistance is rated at no freezing or condensation.

Unit Description

1

3

2

6

RUN mode: Present temperature (PV) display.

Parameter setting mode: Parameter or

parameter setting valuedisplay.

It shows current temperature (PV) deviation

based on set temperature (SV) by LED.

No.

PV deviation temp. Deviation display

1

Over 2

2

Below ±2

3

Under -2

11

The deviation indicators (

every 1 sec. when operating auto tuning.

Press any front key once to check or change

current set temperature (SV), the set

temperature (SV) indicator is ON and preset set

value is flashed.

t shows current temperature unit.

Input Sensor and Temperature Range [

Input sensor Display Temperature range (℃) Temperature range (℉)

Thermocouple

RTD

Installation

TC4S/SP (48 48mm) Series TC4Y (72 36mm) Series

Mount the product on the panel, fasten bracket by pushing with tools as shown above.

(In case of TC4Y, fasten bolts for bracket.)

TC4 Series

I

TC4S TC4SP TC4Y TC4M TC4W TC4H TC4L

Max. 5VA (24VAC 50/60Hz), Max. 3W (24-48VDC)

.

At room temperature (23℃±5℃): (PV ±0 5% or ±1℃, select the higher one) ±1digit

.

Out of room temperature range: (PV ±0 5% or ±2℃, select the higher one) ±1digit

※ For TC4SP, add ±1

OUT: Min. 200,000 operations (250VAC 3A resistive load),

AL1/2: Min. 300,000 operations (250VAC 1A resistive load)

Square-wave noise by noise simulator (pulse width 1㎲) ± 2KV R-phase and S-phase

-10 to 50℃, Storage: -20 to 60

35 to 85%RH, Storage: 35 to 85%RH

Double insulation or reinforced insulation (mark:

measuring input part and the power part: AC power 2kV, AC/DC Power 1kV)

CE

,'Nus

Approx. 141g

(approx. 94g)

℃

℃

(℃/℉)

indicator ON

indicator ON

indicator ON

, ) flash by

indicator

℃

℉

rn[

@

Approx. 123g

(approx. 76g)

l

4

5

8

7

1

2

℃ by accuracy standard.

I

I

ᜡ

7.4×15.0mm 9.5×20.0mm 9.5×20.0mm 7.0×14.6mm

l

I

℃

Approx. 174g

(approx. 85g)

l

I

℃, select the

℃, select the

3 5 4

5. Control/alarm output indicator

OUT: t will turn ON when control output (Main Control

※

In case of CYCLE/PHASE control of SSR drive

output, it will turn ON when MV is over 3.0%.

(only for AC power type)

AL1/AL2: t will light up when alarm output Alarm1/

6.

Used when entering into parameter group, returning

to RUN mode, moving parameter, and saving setting

values.

7. Adjustment

Used when entering into set value change mode, digit

moving and digit up/down.

8. FUNCTION key

Press

STOP, alarm output cancel, auto-tunning) set in inner

parameter [

※

Press

operation to move digit.

I

I

, Dielectric strength between the

[g]

Approx. 204g

Approx. 194g

(approx. 133g)

(approx. 122g)

I

higher one) ±1digit

higher one) ±1digit

Output) is ON.

Alarm2 are on.

key

+ keys for 3 sec. to operate function (RUN/

].

DI K

+ keys at the same time in set value

IN-T

K (CA)

J (IC)

L (IC)

DPt100Ω

Cu50Ω

X • X

KCA

JIC

LIC

DPtH

DPtL

CUsH

CUsL

-50 to 1200 -58 to 2192

-30 to 500 -22 to 932

-40 to 800 -40 to 1472

-100 to 400 -148 to 752

-100 0 to 400.0 -148 0 to 752.0

-50 to 200 -58 to 392

-50 0 to 200.0 -58 0 to 392.0

Other Series

•

I

I

Approx. 194g

(approx. 122g)

I

6 7, 8

]

I

I

11.0×22.0mm

Approx. 254g

(approx. 155g)

l

~

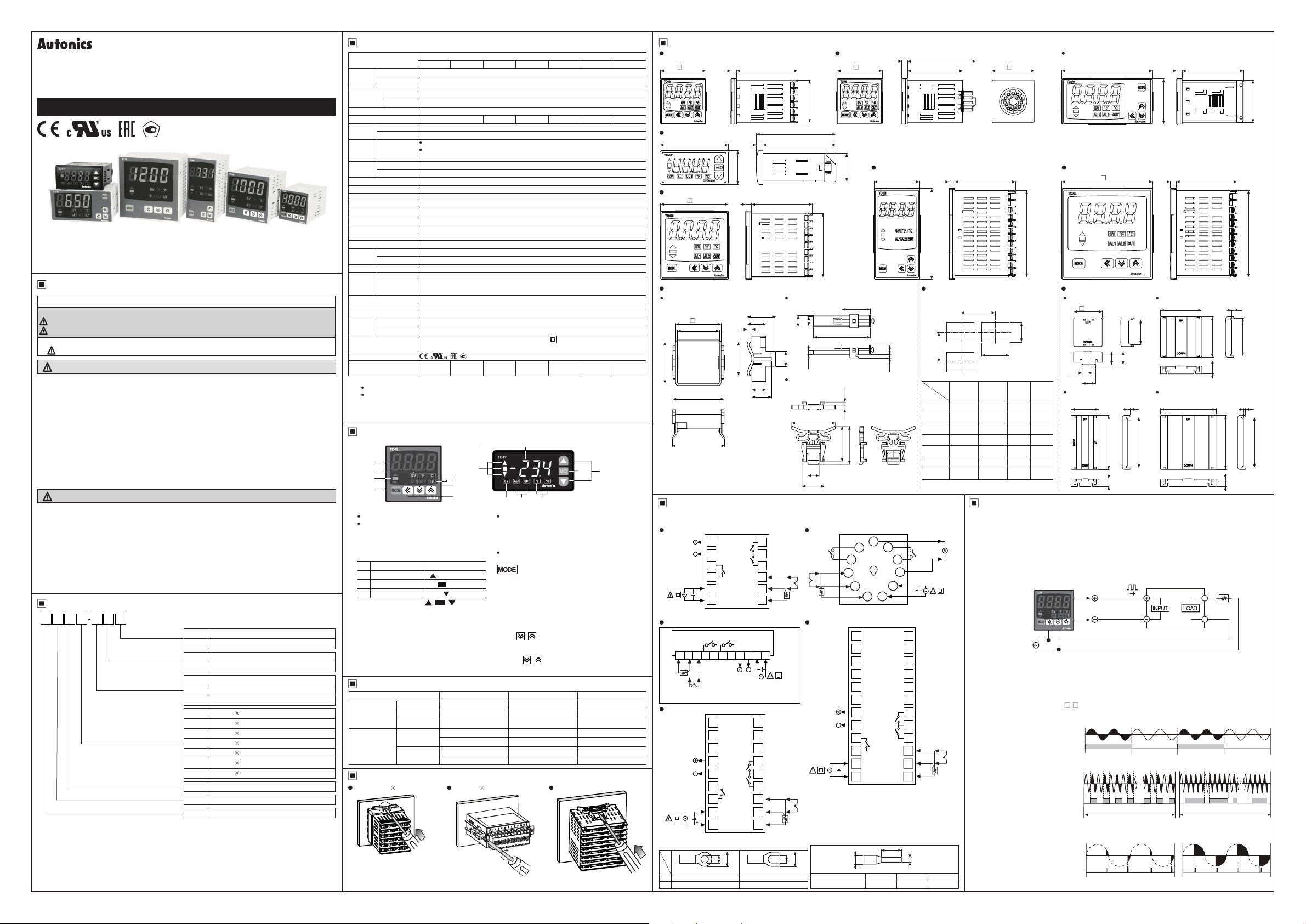

Dimensions

00

TC4S Series

• •

48

□

TC4Y Series

•

72 77

TC4M Series

•

72 6

□

64.56 48 58 5 45

I

84

7

36

64 5

....

10111

L,.

Iii]

D

'v

~

Bracket

•

TC4S/TC4SP Series TC4Y Series

44 9

IT]~

l!Y

1/llli

!!!!I

0000~

I};,._,,,

48 6

45

55

56

31

20

5

36

15

21

104.4

12

0 1

16

TC4M, TC4W, TC4H, TC4L Series

11'P

:=:

JlHV

Connections

00

※

TC4 Series has selectable control output; Relay output, and SSR drive output.

AC/DC power type does not have SSRP function.

TC4S Series

• •

SSR OUT:

+

1 7

12VDC ±2V

20mA Max

Allll-

※

1

SOURCE

100-240VAC 5VA 50 60Hz

24VAC 5VA 50/60Hz

24 48VDC 3W

TC4Y Series

• •

AL1 OUT:

250VAC 1A 1a

1 2 3 4 5 6 7 8 9 10 11

w-sy;~I

RTD

SENSOR

w

TC4M Series

•

SSR OUT:

12VDC ±2V

20mA Max

A§-

SOURCE

100-240VAC 5VA 50 60Hz

24VAC 5VA 50/60Hz

24-48VDC 3W

※Use crimp terminals or teminals of size specied below.

~

Nc@I]l~I

a Min. 3.0mm Min. 3.0mm

b Max.5.8mm Max.5.8mm

□

2 8

□

3 9

4 10

BJ

5 11

-

□

+

6 12

□

B'

BA

TC

1 10

□

2 11

□

3 12

□

4 13

+

□

5 14

□

6 15

8}

7 16

8 17

□

:

9 18

□

<Round>

AL1 OUT:

250VAC 1A 1a

AL2 OUT:

250VAC 1A 1a

Relay OUT:

250VAC 3A 1a

Relay OUT:

250VAC 3A 1a

SSR OUT:

12VDC ±2V

20mA Max

AL1 OUT:

250VAC 1A 1a

AL2 OUT:

250VAC 1A 1a

Relay OUT:

250VAC 3A 1a

a

b

{a

t{J

I 1

8

tl

SOURCE

100-240VAC 5VA 50/60Hz

24VAC 5VA 50 60Hz

24-48VDC 3W

□

□

□

18

\B

□

□

□

RTD

B'

□

B

□

A

SENSOR

□

i

- +

-&[Q]

※

1

B'

RTD

B

A

33

SENSOR

a

<Forked>

Relay OUT

250VAC 3A 1a

TC

-

+

SOURCE

100-240VAC 5VA 50/60Hz

24VAC 5VA 50/60Hz

24-48VDC 3W

TC

※

-

+

b

TC4SP Series

45

I

67.5

~

60

I.

f'

~~

T~

46

37 5

12

23 9

TC4SP Series

TC

RTD

B'

+

B

A

SENSOR

TC4H, TC4W, TC4L Series

SSR OUT:

+

12VDC ±2V

20mA Max

-

&[Q]-

+

※

1

1: AC power: 100-240VAC 5VA 50/60Hz

AC/DC power: 24VAC 5VA 50/60Hz

Terminal number

1 to N 6 Max. 1.9 Max. 4.0

6

30

•

48

,..,

,,,

llllll'l'll'l:l

-

D

v'

l!!ll!!ll!!!I

@~

~

30

.I

3 5 10

3.34

40.5

6

7

5

4

3

2

1

□ □

2

□ □

3

□ □

4 16

□ □

5 17

□ □

6 18

□ □

7 19

□

8 20

□

9 21

8}

10

11

□ □

12

□ □

24-48VDC 3W

c

t=o:B=i

8

9

10

11

1

13

14

15

AL1 OUT:

250VAC 1A 1a

{a

AL2 OUT:

250VAC 1A 1a

LO

Relay OUT:

250VAC 3A 1a

<Crimp terminal>

a b c

I I

a

22

□

23

24

72 2

==

===

96

~

Panel cut-out

B

Size

A B C D

Model

I~

TC4S Min. 65 Min. 65 45

TC4SP Min. 65 Min. 65 45

TC4Y Min. 91 Min. 40 68

TC4M Min. 90 Min. 90 68

TC4H Min. 65 Min. 115 45

TC4W Min. 115 Min. 65 92

TC4L Min. 115 Min. 115 92

00

● SSRP function is selectable one of standard ON/OFF control, cycle control, phase control by utilizing

● Realizing high accuracy and cost effective temperature control as linear output(cycle control and

AL1 OUT:

250VAC 1A 1a

SSR OUT:

12VDC ±2V

20mA Max

+

※

1

SOURCE

100-240VAC 5VA 50 60Hz

24VAC 5VA 50 60Hz

24-48VDC 3W

B'

RTD

B

A

SENSOR

b

(unit: mm)

● Select one of standard ON/OFF control [

+

※

※

※

1)Standard ON/OFF control [

TC

-

+

2)Cycle control [

3)Phase control [

TC4W Series

□

~

IIJJRI

L',.

~CEoo

D

~~!!!!I

"'

TC4L Series TC4H Series

64.56

•

@~~

□

~

48

64.596 6

Dc::::Jc::::J

C,

.,==

•

64.5696

(unit: mm)

_1,

=,

7

-

~

91 5

A

D

C

0.6

0.6

45

0

0

0.6

0.6

45

0

0

0.7

0.5

31.5

0

0

0.7

0.7

68

0

0

0.6

0.8

92

0

0

0.8

0.6

45

0

0

0.8

0.8

92

0

0

1111

f::,.

lm!IITICTill

D

V IWIWll!!!I

@~~

~

Terminal cover (sold separately)

•

RSA-COVER (48×48mm) RMA-COVER (72×72mm)

48.4

□

9.8

22 5

~

RHA-COVER

(48×96mm, 96×48mm )

47.2

I

~

,~

.,,.

-,_

,

41 5

w

18

22

4

86

91 5

LI

13

SSR Drive Output Selection Function (SSRP Function)[

standard SSR drive output.

phase control).

parameter of Parameter group 2. For cycle control, connect zero cross turn-on SSR or random

turn-on SSR. For phase control, connect random turn-on SSR.

Temperature controller

(TC4Series)

Power

100-240VAC

50/60Hz

When selecting cycle or phase control mode, the power supply for a load and a temperature

controller must be the same.

In case of selecting cycle [

not allowed to set.

For AC/DC power model (TC4

standard control by relay or SSR.

A mode to control the load in the

same way as Relay output type.

(ON: output level 100%,

OFF: output level 0%)

]

A mode to control the load by

repeating output ON / OFF

according to the rate of output

within setting cycle.

Having improved ON / OFF noise

feature by Zero Cross type.

A mode to control the load by

controlling the phase within

AC half cycle. Serial control is

available.

Random turn-on SSR must be

used for this mode.

CYCL

PHAS

]

] or phase [

CYCL

- 2 R), this parameter [

□□

]

STND

AC

OUT

AC

OUT

OUT

], cycle control [

STND

SSR voltage output

(12VDC)

] control mode for PID control, control cycle [T] is

PHAS

SSrM

ON ONOFF OFF

50Cycle 50Cycle

50% 80%

AC

10% 50%

===

===

===

===

70

mru

~

.

RLA-COVER (96×96mm )

94

mm

lfil~-nG

] , phase control [

CYCL

SSR module

] is not displayed and it is available only

3

68 5

m

13

91 5

ITT

13

] at [

PHAS

Load

44.7

91 5

64

3

86

SSrM

SSrM

]

]

me

~

I

※

※

※

①

②

③

④

⑤

※

※

※

※

※

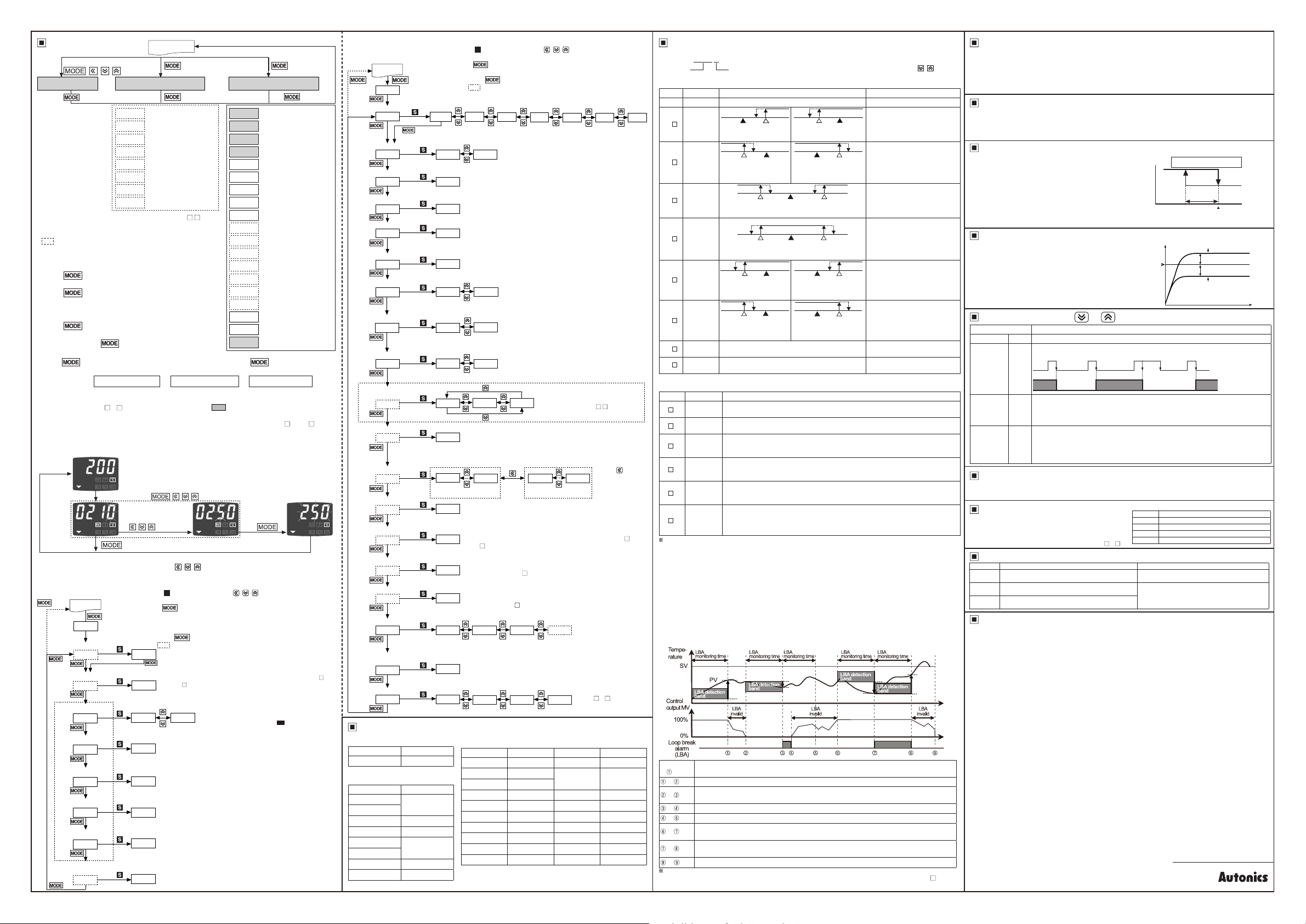

● Flow Chart For SV Setting Group

※

● Parameter Reset

Reset all parameters as factory default. Hold the front

parameter. Select '

maintained. If setting parameter lock [

● Parameter Group 1

Parameter Groups

Press any key among

, , , .

llMODEI

I~

~

§]

SV setting Parameter group 1[

~

1: t is not displayed for AC/DC power model (TC4 - 2R).

If no key entered for 30 sec., it returns to RUN mode

automatically and the set value of parameter is not be saved.

This parameter might not be displayed depending on

other parameter settings.

Press any key once in RUN mode, it advances to set value

setting group.

Press

parameter group 1.

Press

Parameter group 2.

First parameter will be displayed on viewer when it

advances to the setting group.

Press

to RUN mode.

※

Exception: Press

returns to RUN mode.

Press

advances to the first parameter of previous setting group.

Parameter setup Parameter group 2

• Set parameter as the above considering parameter relation of each setting group.

• Check parameter set value after change parameter of Parameter group 2.

Indicator model (TC4

,

AL 1

AL 2

If alarm operation mode[

parameter is not displayed.

In case of changing set temperature from 210℃ to 250

④Check SV

3 sec.

AL1 alarm temperature

AL2 alarm temperature

※

3

Proportional band

Derivation time

I

I

④

•:::::::::::::

key over 2sec. in RUN mode, it advances to

key over 4sec. in RUN mode, it advances to

key over 3sec. in the setting group, it returns

key once in SV setting group it

key again within a sec after return to RUN mode by press key over 3sec., it

1~--~1

-N N)displays shaded parameter ( ) of Parameter group 2.

□ □

parameters of Parameter group 2 is decided whether to display according by alarm output type.

Run mode

PAR1

AL1

AL2

Auto-tuning

Integral time

Manual reset

REST

ON/OFFcontrol

hysteresis

HYS

AL 1

①RUN mode (display current temperature)

Press any key among

' and all parameters are reset as factory default. Select ‘NO’ and previous settings are

YES

2 sec.

AT

P

I

D

RUN mode

I

②①

1~

I~

AL1 alarm temperature

AL1

AL2 alarm temperature

AL2

Auto tuning

AT

Proportional band

P

Integral time

I

Derivative time

D

Manual reset (Normal

REST

deviation correction)

ON/OFF

HYS

→ Parameter group 1 → SV setting

,

] of Parameter group 2 is set to

AL 2

②Set value change mode

Change set value

, , keys.

by

] or processing auto-tuning, parameter reset is unavailable.

LOC

※

1:

※

2: After checking/changing set value at each parameter, and press

※

3: t is displayed when control type parameter [

※

1

1250

1250

01)0

0000

0000

05)0

Press

※

parameter settings.

Setting range: Deviation alarm (-[F.S] to [F.S],

※

2

※

Setting range: 0.1 to 999.9

Setting range: 0 to 9999 sec.

※

Setting range: 0 to 9999 sec.

※

Setting range: 0 0 to 100.0%

※

Setting range: 1 to 100

※

002

※

I

I

IN T

c=J

UNIT

c=J

IN B

c=J

MAvF

c=J

L SV

c=J

H SV

c=J

O FT

c=J

C MD

c=J

OUT

c=J

SSrM

AL 1

AL 2

AHYS

LBaT

LBaB

DI K

c=J

ErMV

c=J

LOC

c=J

1~

③

T

1~

I

Input type

Temperature unit

Input correction

Input digital lter

SV low-limit value

SV high-limit value

Control output operation

Control type

Control output

SSR drive output method

Control cycle

AL1

AL2

Alarm output hysteresis

LBA

LBA

Digital input key

Control output MV in case

of input break error

Parameter lock

__

2sec.

] Parameter group 2[

PAR1

I

3sec.

i

control hysteresis

□□

l~--~I

CJ

/

AM)

SBa

℃

, , , .

+ +

keys for 5 sec., to enter parameter reset [

S

: Press any key among , , .

■

key, set value flashes twice and it moves to next parameter

automatically.

group 2 is set

This parameter might not be displayed depending on other

In case alarm operation mode [

/

LBa

parameters is displayed.

Integral operation will be OFF when set value is "0".

Derivative operation will be OFF when set value is "0".

It is displayed in P/PD control.

It is displayed when control type parameter [

group 2 is set

.

PID

key for 3 sec. to return RUN mode at any parameter.

Absolute value alarm (temperature range)

of Parameter group 2 is set to [

※

It starts to operate auto-tuning when it is ON and

set as OFF automatically after finish the operation

ONOFF

※

Deviation indicators (▲,

sec.) during auto tuning function.

ONOF

℃/℉

.

℃/℉

(For

AL 1, AL 2

AL 1, AL 2

DPtL/CUsL

⑤

4sec.

]

PAR2

I

3sec.

~

alarm operation mode

alarm operation mode

monitoring time

detection range

____,1

,

AHYS

LBa

/

□ □

③Finish the setup.

]

INIT

] of parameter

C MD

],

AM)/ SBa

□

], no

▼) flash (cycle:1

-

: 0.1 to 50 0

℃/℉)

] of Parameter

C MD

● Parameter Group 2

Run mode

3 sec.

PAR2

Input type

IN T

Temperature unit

UNIT

Input correction

IN B

Input digital lter

MAvF

1

※

SV low-limit value

L SV

SV high-limit value

H SV

Control output operation

O FT

Control type

C MD

Control output

OUT

SSR drive

output method

SSrM

'

imf

j "

Control cycle

,----------~

~

1-·

AL1 alarm operation

AL 1

~

:i_::::

AL2 alarm operation

AL 2

~-i----~

Alarm output hysteresis

AHYS

~-i----~

LBA monitoring time

LBaT

~-i----~

LBA detection band

LBaB

~

-i----~

Digital input key

DI K

Control output MV in case

of input break error

ErMV

Parameter lock

LOC

Factory Default

● SV setting

Parameter Factory default

-

● Parameter Group 1

Parameter Factory default

AL1

AL2

AT OFF

P 01)0

I

D

REST 05)0

HYS 002

4 sec.

※

T

0

S

※

1:

: Press any key among , .

■

※

2: After checking/changing set value at each parameter, and press

key, set value flashes twice and it moves to next parameter

automatically.

※

Press

※

※

1

KCA JIC

2

※

When changing input type, SV,

LBaB, AHYS

000

Setting range: -999 to 999 (

Setting range: 0.1 to 120.0 sec.

)1

※

Setting range: Within the rated temperature

050

range by input sensor [

When changing SV low-limit value,

if SV <

Setting range: Within the rated temperature

range by input sensor [

1200

When changing SV high-limit value,

if SV >

HEAT

PID

RLY

STND

·~

Setting range:0 5 to 120.0 sec.

※

02)0

※

AM!A

1

※

Alarm operation mode

~

i~

~~~~~~~~~~~~~~~~~~~~~j·

※

AM@A

※

Setting range: 1 to 100

※

001

Setting range: 0 to 9999sec. (Automatically setting with Auto-tunning)

※

0

Setting range: 0 to 999

(Automatically setting with Auto-tunning)

※

002

※

is not displayed for not alarm output model.

AlRE

※

AT is not displayed

Setting range: 0 0 to 100.0%

※

00)0

※

OFF

● Parameter Group 2

Parameter Factory default Parameter Factory default

key for 3 sec. to return RUN mode at any parameter.

This parameter might not be displayed depending on other

parameter settings.

LIC

DPtH

DPtL

parameters are initialized.

?F?C

Set input digital filter time for average input value affected control,

and display value.

, SV is initialized as

L S

, SV is initialized as

H S

※

COOL

※

ONOF

※

SSR

CYCL PHAS

If control output [

set as

, factory default is 2.0 sec.

SSR

This T will not be displayed when SSR drive output method [

is set as

CYCL, PHAS

LBaA

Same with the above [

When changing alarm operation AL1, AL2, alarm temperature of

AL1, AL2 is initialized.

If alarm operation mode [

□

,

AHYS

LBA

parameter is displayed when alarm operation mode [

LBaT

] is set as

AL 2

When alarm operation mode [

alarm (LBA) [

parameter is displayed.

LBaB

STOP AlRE ATOFF

when control type parameter [

0 0/100 0% is displayed when control type parameter [

set

.

ONOF

When changing P D control to ON/OFF control, if MV is below

100 0%, it is initialized as 0 0%.

LOC1 LOC2 LOC3

IN B, H SV, L SV, AL1, AL2, LBaT

※

Front temperature unit indicator will flash when

selecting the unit.

※

When changing temperature unit, SV,

L SV, AL1, AL2, LBaT, LBaB, AHYS

are initialized.

When changing control output operation,

initialized.

When changing control type,

(control output MV is below 100%) and

OFF automatically.

Operates only selected output between Relay or SSR.

OUT

~

parameter is not displayed.

LBA

LBA

□

/

DPtL

CUsL

≤ (

L S

H S

] is set as

.

t~~~~------~~~----------'

℃/℉

□

℃/℉

], and

-1digit)]

H S

.

L S

≥ (

+1digit)]

L S

.

H S

※

It is displayed when selecting control

output [

OUT

DC power type (TC4

parameter [

RLY

AM!A AM!B

※

Alarm option

].

AL 1

(

DPtL/ CYsL

AL 1, AL 2

.

(

DPtL/ CUs

AL 1, AL 2

parameter does not set as 0,

LBaT

~

---------:

~

,

__________

CU%H CU%L

IN B, H SV

parameters

: -199.9 to 999 9)

※In case of [

IN T

input sensor type,

low/high-limit setting

temperature (SV) is

also set as max./min.

temperature range of

input sensor.

is

ErMU

is initialized

ErMU

] as

SSR

] is not displayed.

SSrM

, factory default is 20.0 sec, or

※

: 0.1 to 50 0℃)

] is set to

: 0 0 to 999.9

] is set as loop break

turns

DI K

. For AC/

- 2R), this

□□

Press

key to

convert alarm

operation mode

into alarm option.

AM), SBa

□

AL 1

)

℃/℉

SSrM

,

] is set

C MD

※

For indicator model

(TC4

LOC1

.

ONOF

C MD

-N N), only

□

□

are available.

] is

OFF

,

IN-T KCA T 02)0

UNIT ?C

IN-B 0000

AL-1 AM!A

MAvF 00)1 AL-2 AM@A

1250

L-SV -050 AHYS 0001

H-SV 1200 LBaT 0000

O-FT HEAT LBaB 002

C-MD PID DI-K STOP

0000

OUT RLY ErMV 00)0

SSrM STND LOC OFF

※

AC/DC power type has no SSR drive output method [

supports only ON/OFF output when selecting

[

].

OUT

SSR

] and

SSrM

in control output

Alarm [

Alarm

operation

1)Alarm operation

Mode Name Alarm operation Description

AM)

AM!

□

,

AM@

□

AM#

□

]

AM$

□

AM%

□

AM^

□

SBa

□

LBa

□

※

H: Alarm output hysteresis[

2)Alarm opetion

Option Name Description

AM

.A

□

AM

.B

□

AM

.C

□

]

AM

.D

□

AM

.E

□

AM

.F

□

Condition of re-applied standby sequence for standby sequence 1, alarm latch and standby sequence 1: Power ON

*

Condition of re-applied standby sequence for standby sequence 2, alarm latch and standby sequence 2: Power ON,

changing set temperature, alarm temperature [AL, AL] or alarm operation [AL,

to RUN mode.

,

3)Sensor break alarm

The function that alarm output will be ON when sensor is not connected or when sensor's disconnection is

detected during temperature controlling. You can check whether the sensor is connected with buzzer or other

units using alarm output contact. t is selectable between standard alarm [

4)Loop break alarm (LBA)

t checks control loop and outputs alarm by temperature change of the subject. For heating control (cooling

control), when control output MV is 100% (0% for cooling control) and PV is not increased over than LBA

detection band [

control) and PV is not decreased below than LBA detection band

[

LBaB

Tempe-

rature

,

Contrd

ClllputMV

100% t

Loop

alann

(LBA)

Start control

G)

to

to

G)

®

to

Q)

®

to

Q)

©

to

©

®

(JJ

to

®

to

(jJ

®

to

®

®

When executing auto-tuning, LBA detection band[

*

on auto tuning value. When alarm operation mode [

detection band [

AL-1/ AL-2

AM!A

- -

Deviation

high-limit

alarm

Deviation

low-limit

alarm

Deviation

high/lowlimit

alarm

Deviation

high/lowlimit

reserve

alarm

Absolute

value high

limit alarm

Absolute

value low

limit alarm

Sensor

break alarm

Loop break

alarm

Standard

alarm

Alarm latch

Standby

sequence 1

Alarm latch

and standby

sequence 1

Standby

sequence 2

Alarm latch

and standby

sequence 2

] during LBA monitoring time [

LBA.

monitoring

sv

>---------------C-----C

-1■:

0%

break

When control output MV is 100%, PV is increased over than LBA detection band [

LBA monitoring time [

The status of changing control output MV (LBA monitoring time is reset.)

When control output MV is 0% and PV is not decreased below than LBA detection band [

during LBA monitoring time [

Control output MV is 0% and loop break alarm (LBA) turns and maintains ON.

The status of changing control output MV (LBA monitoring time is reset.)

When control output MV is 100% and PV is not increased over than LBA detection band [

during LBA monitoring time [

When control output MV is 100% and PV is increased over than LBA detection band [

during LBA monitoring time [

The status of changing control output MV (LBA monitoring time is reset.)

Alarm

option

OFF ONH

i * r=

SV

100℃PV110℃

High deviation: Set as 10℃ High deviation: Set as -10℃

PV

90℃SV100℃

Lower deviation: Set as

10℃

High/Lower deviation: Set as 10℃

OFF OFFONH H

High/Lower deviation: Set as 10℃

OFF ONH

PV

90℃SV100℃

Absolute-value Alarm:

Set as 90℃

,6.

PV

90℃

Absolute-value Alarm:

Set as 90℃

-

-

AHYS

If it is an alarm condition, alarm output is ON. If it is a clear alarm condition, alarm output

is OFF.

If it is an alarm condition, alarm output is ON and maintains ON status.

(Alarm output HOLD)

First alarm condition is ignored and from second alarm condition, standard alarm

operates. When power is supplied and it is an alarm condition, this rst alarm condition

is ignored and from the second alarm condition, standard alarm operates.

If it is an alarm condition, it operates both alarm latch and standby sequence. When

power is supplied and it is an alarm condition, this rst alarm condition is ignored and

from the second alarm condition, alarm latch operates.

First alarm condition is ignored and from second alarm condition, standard alarm

operates. When re-applied standby sequence and if it is alarm condition, alarm output

does not turn ON. After clearing alarm condition, standard alarm operates.

Basic operation is same as alarm latch and standby sequence1. It operates not only by

power ON/OFF, but also alarm setting value, or alarm option changing. When re-applied

standby sequence and if it is alarm condition, alarm output does not turn ON. After

clearing alarm condition, alarm latch operates.

] during LBA monitoring time [

LBaB

LBA.

time

, ,

rroniloring

~'

t

-

LBaB

1•:c ,'

-.

----

: lBA :

1

1

invalk:1

N

i i

<D

®

] and LBA monitoring time [

Set both alarm operation and alarm option by combining.

] Input Correction [

Each alarm operates individually in two alarm output models.

When the current temperature is out of alarm range, alarm

clears automatically. If alarm option is alarm latch or alarm latch

and standby sequence 1/2, press digital input key(

digital input key[

turn OFF the power and turn ON to clear alarm.

OFF ONH

--'·'-1--'-' --....

OFFON H

100℃PV110℃

Lower deviation: Set as

OFFON ONH H

,6. .... ,6.

PV

SV

90℃

100℃

,6. .... ,6.

PV

SV

90℃

100℃

OFF ONH

Absolute-value Alarm:

OFFON H

....

SV

100℃

]

LBaT

LBaT

Absolute-value Alarm:

LBaT

], alarm output turns ON.

LBA LBA LBA

time , rroniloring

].

LBaT

LBaT

LBaT

time

: : •

ury1k:I

' ' '

··

CM

: i : :

@©

], loop break alarm (LBA) turns ON after LBA monitoring time.

], loop break alarm (LBA) turns ON after LBA monitoring time.

], loop break alarm (LBA) turns OFF after LBA monitoring time.

] and LBA monitoring time are automatically set based

LBaB

AL 1, AL 2

] parameter is displayed.

LBaT

] of Parameter group 2 set as

DI K

No alarm output

If deviation between PV and SV

--

PV

90℃SV100℃

....

SV

-10℃

PV

110℃

PV

110℃

SV

100℃PV110℃

Set as 110℃

.... ,6.

SV

100℃PV110℃

Set as 110℃

], or when control output MV is 0% (100% for cooling

, ,

ulA

.:

® ® ® ®

] is set as loop break alarm (LBA)[

as high-limit is higher than set

value of deviation temperature,

the alarm output will be ON.

OFFON H

If deviation between PV and SV

as low-limit is higher than set

value of deviation temperature,

the alarm output will be ON.

If deviation between PV and SV

as high/low-limit is higher than set

value of deviation temperature,

the alarm output will be ON.

If deviation between PV and SV

as high/low-limit is higher than set

value of deviation temperature,

the alarm output will be OFF.

If PV is higher than the absolute

value, the output will be ON.

OFFON H

If PV is lower than the absolute

value, the output will be ON.

It will be ON when it detects

sensor disconnection.

It will be ON when it detects loop

break.

AL

] or alarm latch [

SBaA

mcTlitaing

time , rronitoring

'

----C-

"

"'""··I

' ,

'

---C-

I.,.--¥-

;~;

+ 3 sec.,

AlRE

], switching STOP mode

].

SBaB

time

, ,

'?-,...._-"-'

:

.

] during

LBaB

LBaB

LBaB

LBaB

], LBA

LBa

□

Controller itself does not have errors but there may be error by external input temperature sensor. This function

is for correcting this error.

E.g.) If actual temperature is 80℃ but controller displays 78℃, set input correction value [

), or

controller displays 80℃.

※

As the result of input correction, if current temperature value (PV) is over each temperature range of input

sensor, it displays '

Input Digital Filter [

If current temperature (PV) is uctuating repeatedly by rapid change of input signal, it re ects to MV and stable

control is impossible. Therefore, digital lter function stabilizes current temperature value.

For example, set input digital lter value as 0.4 sec, and it applies digital lter to input values during 0.4 sec and

displays this values. Current temperature may be dierent by actual input value.

Hysteresis [

~

● If Hysteresis is too narrow, hunting (oscillation,

chattering) could occur due to external noise.

● In case of ON / OFF control mode, even if PV reaches

stable status, there still occurs hunting. t could be due

to Hysteresis [

or sensor’s location. In order to reduce hunting to a

minimum, it is required to take into following factors

consideration when designing temp. controlling;

proper Hysteresis [

characteristics, sensor’s response and location.

Manual Reset [

~

When selecting P/PD control mode, certain temperature difference

exists even after PV reaches stable status because heater's rising

and falling time is inconsistent due to thermal characteristics of

controlled objects, such as heat capacity, heater capacity. This

temperature difference is called offset and manual reset [

function is to set/correct offset.

When PV and SV are equal, reset value is 50 0%. After control

is stable, PV is lower than SV, reset value is over 50.0% or PV is

higher than SV, reset value is below 50.0%.

Digital Input Key ( + 3sec.) [

~

Parameter

OFF

RUN/STOP

Clear alarm

Auto-tuning

Control Output MV When Input Sensor Line Is Broken [

~

The function to set control output MV in case of open error. Users are able to set by ON/OFF setting or MV

setting. t executes control output by set MV regardless of ON/OFF or PID control output.

Parameter Lock [

~

A function to prevent changing SV and parameters of

each setting group. Parameter setting values are still

possible to check when parameter lock is set.

※

OFF, LOC1

Error

~

Display Description Troubleshooting

OPEN

HHHH

LLLL

HHHH

] SV, load’s response characteristics

HYS

], heater’s capacity, thermal

HYS

Operation

It does not use digital input key function.

OFF

Pauses control output. Auxiliary output (except loop break alarm, sensor break alarm)

except Control output operates as setting. Hold the digital input keys for 3 sec. to restart.

STOP

RUN RUN

Clears alarm output by force.

(only when alarm option is alarm latch, or alarm latch and standby sequence 1/2 .)

AlRE

This function is applied when present value is out of alarm operation range but alarm

output is ON. Alarm operates normally right after clearing alarm.

Starts/Stops auto-tuning. This function is same as auto-tuning[AT] of parameter group 1.

(You can start auto-tuning [AT] of parameter group 1 and stop it by digital input key.)

This parameter AT appears only when control method [

※

AT

is set as

parameter is changed as

are available only for indicator (TC4

Flashes if input sensor is disconnected or sensor

is not connected.

Flashes if measured sensor input is higher than

temperature range. When input is within the rated temperature

Flashes if measured sensor input is lower than

temperature range.

Cautions during Use

1. Follow instructions in 'Cautions during Use'. Otherwise, It may cause unexpected accidents.

2. Check the polarity of the terminals before wiring the temperature sensor.

For RTD temperature sensor, wire it as 3-wire type, using cables in same thickness and length.

For thermocouple (CT) temperature sensor, use the designated compensation wire for extending wire.

3. Keep away from high voltage lines or power lines to prevent inductive noise.

In case installing power line and input signal line closely, use line lter or varistor at power line and shielded

wire at input signal line.

Do not use near the equipment which generates strong magnetic force or high frequency noise.

Install a power switch or circuit breaker in the easily accessible place for supplying or disconnecting the power.

4.

5. Do not use the unit for other purpose (e g. voltmeter, ammeter), but temperature controller.

6. When changing the input sensor, turn o the power rst before changing.

After changing the input sensor, modify the value of the corresponding parameter.

Ti

7. 24VAC, 24-48VDC power supply should be insulated and limited voltage/current or Class 2, SELV power

supply device.

8. Make a required space around the unit for radiation of heat.

For accurate temperature measurement, warm up the unit over 20 min after turning on the power.

9. Make sure that power supply voltage reaches to the rated voltage within 2 sec after supplying power.

10. Do not wire to terminals which are not used.

11. This unit may be used in the following environments.

]

]

]

Indoors (in the environment condition rated in 'Specications')

①

Altitude max. 2,000m

②

Pollution degree 2

③

Installation category II

④

IN-B

]

' or '

'.

LLLL

MAvFMAvF

]

HYSHYS

]

REST

]

REST

@

~

t t tt

STOP STOP RUN

. When control method [

PID

LOC

]

.

OFF

-N N).

□ □

Heating operation

SV

]

●Manual reset [

►

I

ON OFF

f

Hysteresis

[

HYS

L.------------.

REST

Set below 50.0 as reset value

/ I

I

Set over 50.0 as reset value

Control

output

I

DI-KDI-K

]

D

] Parameter group 2

C MD

] Parameter group 2 is set as

C MD

Display Description

Unlock

OFF

Lock parameter group 2

LOC1

Lock parameter group 1 2

LOC2

Lock parameter group 1 2 SV setting

LOC3

Check input sensor state.

range, this display disappears.

] as '

IN B

t

]

SV

] by control result

Oset

Oset

Digital input key

(t: over 3 sec.)

ONOF

Autonics

002

I

Temp.

ErMV

' and

, this

]

Loading...

Loading...