TEMPERATURE CONTROLLER

TAS/TAM/TAL SERIES

M A N U A L

Thank you very much for selecting Autonics products.

For your safety, please read the following before using.

Caution for your safety

Please keep these instructions and review them before using this unit.

※

Please observe the cautions that follow;

※

Warning

Caution

The following is an explanation of the symbols used in the operation manual.

※

Warning

1. In case of using this unit with machinery(Ex: nuclear power control, medical equipment, ship, vehicle,

train, airplane, combustion apparatus, safety device, crime/disaster prevention equipment, etc) which

may cause damages to human life or property, it is required to install fail-safe device.

It may cause a re, human injury or damage to property

2. It must be mounted on Panel.

It may give an electric shock.

3. Do not connect, inspect and repair terminals when it is power on.

It may give an electric shock.

4. Please check the number of terminal when connecting power or input.

It may cause a re.

5. Do not disassemble or modify this unit, please contact us when it is required.

It may cause a re and give an electric shock.

Caution

1. This unit shall not be used outdoors.

It might shorten the life cycle of the product or give an electric shock.

2. When wire connection, AWG 20(0.50mm²) should be used and screw bolt on terminal block with 0.74

to 0.90N·m strength.

It may result in malfunction or re due to contact failure.

3. For crimpled terminal, select following shaped terminal.

4. Please observe specication rating.

It might shorten the life cycle of the product and cause a re.

5. Do not use the load beyond rated switching capacity of Relay contact.

It may cause insulation failure, contact melt, contact failure, relay broken, re etc.

6. In cleaning the unit, do not use water or an oil-based detergent.

It might cause an electric shock or re that will result in damage to the product.

7. Do not use this unit at place where there are ammable or explosive gas, humidity, direct ray of the

sun, radiant heat, vibration, impact etc.

It may cause a re or explosion.

8. Do not inow dust or wire dregs into inside of this unit.

It may cause a re or mechanical trouble.

9. Please wire properly after checking the polarity of terminals when connect thermocouples.

It may cause a re or explosion.

10. In order to install the units with reinforced insulation, use the power supply unit which basic

insulation level is ensured.

Ordering information

TA S B 4 R P 4 C

Item

1: Socket(PG-08, PS-08) is sold separately.

※

The above specifications are subject to change without notice.

※

Serious injury may result if instructions are not followed.

Product may be damaged, or injury may result if instructions are not followed.

Caution: Injury or danger may occur under special conditions.

Max. 5.8mm Max. 5.8mm

Unit

C Celsius(℃)

F Fahrenheit(℉)

Celsius(℃) Fahrenheit(℉)

Temperature

range

for each sensor

0 -50 to 100 -58 to 212 Pt

1 0 to 100 32 to 212 Pt

2 0 to 200 32 to 392 Pt J K

3 0 to 300 32 to 572

4 0 to 400 32 to 752 Pt J K

6 0 to 600 32 to 1,112

8 0 to 800 32 to 1,472

C 0 to 1,200 32 to 2,192

Sensor input type

P DPt100Ω

J J(IC)

K K(CA)

Control output

Power supply

Control method

Size

R Relay output

S SSR drive output

4 100-240VAC 50/60Hz

B ON/OFF control & PID control combined

S DIN W48 x H48mm(8 pin plug type)

M DIN W72 x H72mm

L DIN W72 x H72mm

TA Analog setting type temperature controller

Temperature sensor

- -

-

-

J

- -

- -

- -

1

※

Specication

Series TAS TAM TAL

Power supply 100-240VAC 50/60Hz

Allowable voltage range 90 to 110% of rated voltage

Power consumption Max. 4VA

Size DIN W48 x H48mm DIN W72 x H72mm DIN W96 x H96mm

Display method Deviation LED(red, green), Output LED(red)

Setting type Dial setting

Setting accuracy F.S. ±2% (room temperature 23℃ ±5℃)

RTD DPt 100Ω(allowable line resistance max. 5Ω per a wire)

Input

type

Thermocouples K(CA), J(IC)

ON/OFF Control Hysteresis: 2℃ Fixed

Control

PID Control Control period: Relay output 20 sec./SSR drive output 2 sec.

Relay 250VAC 3A 1c

Control

output

SSR Max. 12VDC±2V 20mA

Functions PV deviation indication, Error indication

Dielectric strength 2,000VAC 50/60Hz for 1minute(between input terminal and power terminal)

Vibration 0.75mm amplitude at frequency of 5 to 55Hz in each of X, Y, Z directions for 2hours

Mechanical Min. 10,000,000 operation(18,000 times/hr)

Relay life

cycle

Electrical Min. 100,000 operation(900 times/hr)

Insulation resistance Min. 100MΩ(at 500VDC megger)

Noise strength Square shaped noise by noise simulator(pulse width 1㎲) ±2kV R-phase and S-phase

Memory retention Approx. 10 years (when using non-volatile semiconductor memory type)

Ambient temperature

Environ

-ment

Ambient humidity 35 to 85%RH, Storage: 35 to 85%RH

Insulation type

Approval

2

※

Weight

1: <Except normal temperature range> Below 100℃ model is F.S. ±4%, Over 100℃ model is F.S. ±3%

※

2: The weight is with packaging and the weight in parentheses is only unit weight.

※

Environment resistance is rated at no freezing or condensation.

※

-10 to 50℃ , Storage: -20 to 60

Double insulation or reinforced insulation

(mark: , dielectric strength between the measuring input part and the power part: 2kV)

Approx. 112g(approx. 74g) Approx. 176g(approx. 114g) Approx. 237g(approx. 152g)

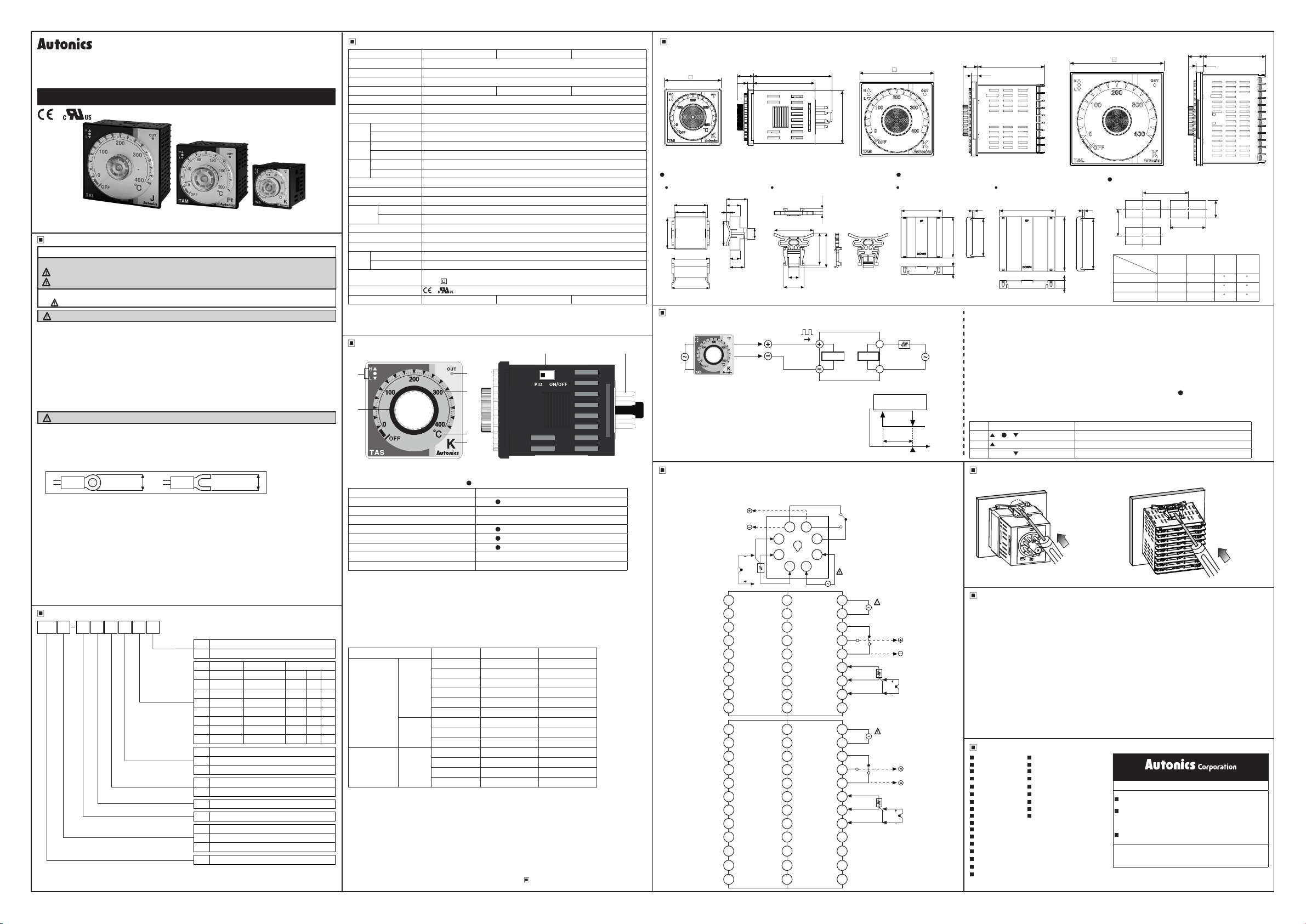

Front panel Identication

1

2

1. Deviation indicator

It shows deviation of present temperature(PV) based on set temperature(SV) by LED.

Input deviation indicator[Deviation indicator:

PV deviation temperature Deviation indicator

Input sensor OPEN ▲ +

Exceed max. input value ▲ indicator ashes(every 0.5 sec.)

More than 10

℃

More than 2℃ to less than or equal to 10℃▲ +

Less than or equal to ±2

℃

More than -2℃ to less than or equal to -10℃

More than -10

℃

Less than min. input value ▼ indicator ashes(every 0.5 sec.)

This is the same as Fahrenheit(℉).

※

When power is on, all indicators light for 2 sec., then all indicators turn off and control

operation starts.

2. Set temperature(SV) dial

Dial to change set temperature (SV). When changing set temperature, it is applied after 2 sec. for the stable

input.

3. Input sensor

Indicates sensor type of present value.

Input sensor type or input range each product is shown in the below table.

Input Sensor Range No. Input range(℃) Input range(℉)

1 0 to 100 32 to 212

2 0 to 200 32 to 392

K

-

K

K

K

K(CA)

Thermocouple

J(IC)

4 0 to 400 32 to 752

6 0 to 600 32 to 1,112

8 0 to 800 32 to 1,472

C 0 to 1,200 32 to 2,192

2 0 to 200 32 to 392

3 0 to 300 32 to 572

4 0 to 400 32 to 752

0 -50 to 100 -58 to 212

RTD DPt100Ω

1 0 to 100 32 to 212

2 0 to 200 32 to 392

4 0 to 400 32 to 752

Set temperature within input range each sensor.

※

4. Temperature unit

Indicates temperature unit(℃, ℉) of set temperature(SV) and present value(PV).

5. Temperature range

Indicates temperature range of set temperature(SV)

6. Control output indicator

Turns ON when control output (Relay Output/SSR Output)

7. Control mode selection switch

Select PID control or ON/OFF control using switch.

8. Terminal block

Terminals for external connections. For more information, refer to '

6

5

4

3

(green), ▲/▼(red)]

+ ▼ indicators ash(every 0.5 sec.)

▲ indicator turns ON

+ ▼ indicators turn ON

▼ indicator turns ON

1

※

℃

7 8

indicators turn ON

indicator turns ON

Connections'.

Dimensions

1. TAS Series

48

14

5.2

Bracket

TAS Series TAM, TAL Series

□48.6

45

44.9

55

56

31

20

5

36

16

15

21

66.7

52

46

12

23.9

37.5

3.34

40.5

2. TAM Series

72

44.8

Terminal cover(sold separately)

RMA-COVER(72×72mm)

Functions

1. SSR drive output

SSR drive output

12VDC

Power

Temperature

controller

2. ON/OFF control

ON/OFF control function is for controlling temperature by comparing

present temperature(PV) to set temperature(SV). ON/OFF control is

xed on reverse operation(Heating). Output turns on to supply power

temperature(SV) and the output turns off to turn off heater when present

temperature(PV) is higher then set temperature(SV).

Hysteresis is xed at 2℃ during ON/OFF control.

※

SSR module

INPUT

SRH1 Series

LOAD

Reverse operation

(Heating)

Hysteresis

Control output

Load

Connections

RTD(Platinum resistance thermometer): DPt100Ω(3-wire) ※T.C.(Thermocouple): K(CA), J(IC)

※

1. TAS Series

2. TAM Series

3. TAL Series

SSR

12VDC±2V

20mA Max

T.C.

SENSOR

RTD

1 19 10

2 20 11

3 21 12

4 22 13

5 23 14

6 24 15

7 25 16

8 26 17

9 27 18

1 25 13

2 26 14

3 27 15

4 28 16

5 29 17

6 30 18

7 31 19

8 32 20

9 33 21

10 34 22

11 35 23

12 36 24

B'

B

A

RELAY OUT

250VAC 3A 1c

RESISTIVE LOAD

3

2

148

RELAY OUT

250VAC 3A 1c

RESISTIVE LOAD

RELAY OUT

250VAC 3A 1c

RESISTIVE LOAD

(※Socket(PG-08, PS-08) is sold separately.)

COM

5

N.C.

N.O.

6

7

SOURCE

100-240VAC

4VA 50/60Hz

SOURCE

100-240VAC

4VA 50/60Hz

N.C.

N.O.

B

B'

N.O.

B

B'

COM

RTDA

N.C.

COM

RTDA

T.C.

SENSOR

SOURCE

100-240VAC

4VA 50/60Hz

T.C.

SENSOR

SSR

12VDC±2V

20mA Max

SSR

12VDC±2V

20mA Max

70

Power

SV

Temperature

68.5

13

14.7

6.5

3

64

3. TAL Series

64.5

RLA-COVER(96×96mm )

94

91.5

13

96

Panel cut-out

3

B

86

Size

Series

TAS Min. 65 Min. 65 45 45

TAM Min. 90 Min. 90 68 68

14.7 64.5

6.5

A

D

C

A B C D

TAL Min. 115 Min. 115 92 92

3. PID Control

PID constants are suggested and implemented based on self tuning from supply power until reaching set

temperature(SV), then self tuning is over after reaching set temperature(SV). When power supply, in case that

set temperature(SV) dial points at OFF or self tuning can not be started because present temperature(PV) is

higher than set temperature(SV) or hunting occurs during self tuning, output control is switched to proportion

band(P) because that is considered to error. At that time, proportion band is xed at 10℃.

Control cycle of PID control and proportion control is 20 sec. in relay output model and 2 sec. in SSR drive

※

output model.

4. STOP

Control output could stop without power off by setting the front setting volume to below min. setting range.

If control output stops by STOP function, green indicator in deviation indicator( ) will ash every 1 sec.

5. Error

Error mark will ash(every 1 sec.) in PV indicator when error occurs during the control operation.

It will operate normally, if input sensor is connected or temperature is returned to normal range.

No Display Description

1

+ + indicators ash If input sensor is broken or sensor is not connected.

2

indicator ashes If measured sensor input is higher than temperature range.

3

indicator ashes If measured sensor input is lower than temperature range.

Installation

1. TAS Series

Mount the product on the panel and securely push the bracket in using a tool, as shown in the diagram.

※

2. TAM, TAL Series

Caution for using

1. Please use separated line from high voltage line or power line in order to avoid inductive noise.

2. Install power switch or circuit-breaker in order to on/off the power.

3. The switch or circuit-breaker should be installed nearby users for safety.

4. Do not use this product as Volt-meter or Ampere-meter, this is a temperature controller.

5. In case of using RTD sensor, 3-wire type must be used. If you need to extend the line, 3 wires must be used

with the same thickness as the line. It might cause the deviation of temperature if the resistance of line is

different.

6. In case of making power line and input signal line closely, line lter for noise protection should be installed at

power line and input signal line should be shielded.

7. Keep away from the high frequency instruments. (High frequency welding machine & sewing machine, large

capacity SCR controller)

8. Installation environment

It shall be used indoor.

①

Altitude Max. 2,000m

②

Pollution Degree 2

③

Installation Category

④

It may cause malfunction if above instructions are not followed.

※

Major products

Photoelectric sensors Temperature controllers

Fiber optic sensors Temperature/Humidity transducers

Door sensors SSR/Power controllers

Door side sensors Counters

Area sensors Timers

Proximity sensors Panel meters

Pressure sensors Tachometer/Pulse(Rate) meters

Rotary encoders Display units

Connector/Sockets Sensor controllers

Switching mode power supplies

Control switches/Lamps/Buzzers

I/O Terminal Blocks & Cables

Stepper motors/drivers/motion controllers

Graphic/Logic panels

Field network devices

Laser marking system(Fiber, CO₂, Nd:YAG)

Laser welding/soldering system

Ⅱ

http://www.autonics.com

Satisable Partner For Factory Automation

HEAD QUARTERS:

116, Ungbigongdan-gil, Yangsan-si, Gyeongsangnam-do, Korea

OVERSEAS SALES:

#402-404, Bucheon Techno Park, 655, Pyeongcheon-ro,

Wonmi-gu, Bucheon, Gyeonggi-do, Korea

TEL: 82-32-610-2730 / FAX: 82-32-329-0728

E-mail: sales@autonics.com

The proposal of a product improvement and

development: product@autonics.com

EP-KE-03-0340C

0.6

0.6

0

0

0.7

0.7

0

0

0.8

0.8

0

0

Loading...

Loading...