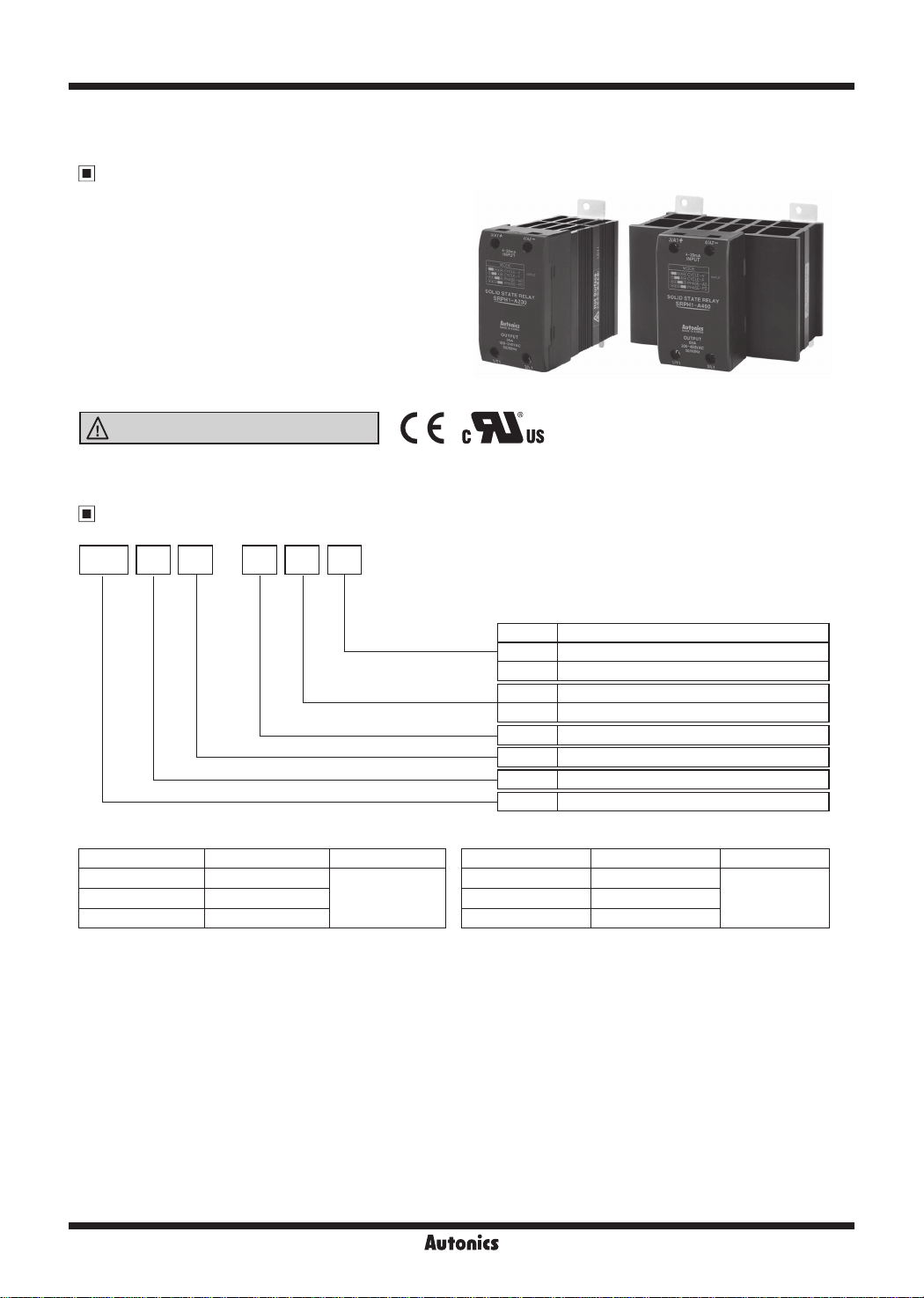

SRPH1 Series

Single-Phase, Analog Input Type SSR

Features

● Phase control and cycle control possible with 4-20 mA

analog input

- Phase control

(output power control / phase angle control)

- Cycle control (xed cycle / variable cycle)

● DIN rail mount or panel mount installation

● Dielectric strength: 4000 VAC

● High heat dissipation efciency with ceramic PCB and

integrated heatsink

● Zero cross turn-on, random turn-on models available

● Input indicator (green LED)

Please read “Safety considerations” in operation

manual before using.

c=..__I&

SRP AH 1 2 30-

__

Ordering Information

I

CE

c'i\lus

Rated load current

(resistive load)

Rated load voltage

Rated input current

Control phase

Type

Item

Model Rated load current Rated load voltage

SRPH1-A220 20A

L__________J___--------'------11------+----------i

SRPH1-A260 60A

100-240VAC SRPH1-A230 30A

20 20A

30 30A

60 60A

2 100-240VAC

4 200-480VAC

A 4-20mA analog input

1 Single-phase

H Integrated heatsink type

SRP Solid State Relay (analog input type)

Model Rated load current Rated load voltage

SRPH1-A420 20A

200-480VAC SRPH1-A430 30A

SRPH1-A460 60A

I-18

Autonics

Single-Phase, Analog Input Type SSR

Specications

Input

Rated input current

Max. allowable input current

Pick-up current Min. 4 2mA

Static off current Max. 0.2mA

Power factor Min. 0 9 (max. 25° of difference between voltage phase and current phase)

Start-up time 60Hz: 200ms, 50Hz: 250ms

Operation time 60Hz: 16.6ms, 50Hz:20ms

※

Operation mode

※

1: You can change operation mode by jumper pin. Default is Phase control (Power equality division type).

Output

0

1

Rated load voltage range 100-240VACrmsᜠ (50/60Hz) 200-480VACrmsᜠ (50/60Hz)

Allowable load voltage range 90-264VACrmsᜠ (50/60Hz) 200-528VACrmsᜠ (50/60Hz)

Rated load

current

Resistive load

(AC-51)

I

Min. load current 0 5Arms 0.5Arms

Max. 1 cycle surge current

(60Hz)

Max. non-repetitive surge

2

current (I

t, t=8.3ms)

Peak voltage (non-repe i ive)

Leakage current (Ta=25℃) Max. 10mArms (240VACᜠ/60Hz) Max. 10mArms (480VACᜠ/60Hz)

Output on voltage drop[Vpk]

(Max. load current)

Static off-state dv/dt 500V/

※

1: AC-51 are utilization category at IEC 60947-4-3.

General Specifications

0

Phase control

(phase equality division type)

Phase control

(power equality division type)

Frequency reading function Ye s

Dielectric strength (Vrms) 4000VACᜠ 50/60Hz for 1min. (Input-Output, Input/Output-Case)

Insulation resistance Over 100MΩ (at 500VDC megger)

Vibra ion 10 to 55Hz double amplitude 0.75mm in each X, Y, Z direction for 1 hour

Indicator Input indicator: Green LED

Environment

Ambient temp.

I

Ambient humi. 45 to 85%RH, storage: 45 to 85%RH

I

Input terminal connection Min. 1×0.5mm

Output terminal connection

Input terminal xed torque 0.75 to 0 95N.m

Output terminal xed torque 1.6 to 2.2N m

Approval

Unit weight

※

Environment resistance is rated at no freezing or condensa ion.

※

For wiring the terminal, an O-ring terminal must be used.

4-20mA

50

mA

Phase control (phase equality division type, power equality division type)

Cycle control (xed cycle, variable cycle)

20Arms 30Arms 60Arms 20Arms 30Arms 60Arms

※

1

300A 500A 1000A 300A 500A 1000A

350A2s 1000A2s 4000A2s 350A2s 1000A2s 4000A2s

600V 1000V

Max. 1.6V

㎲

5 to 99%

10 to 99%

-20 to 70℃, storage: -20 to 100

℃

(The rated load current capacity is different depending on ambient temperature. Refer to '

2

(1×AWG20) Max. 1×1.5mm2 (1×AWG6) or Max. 2×1.5mm2 (2×AWG16)

2

Min. 1×1.5mm

※

Connect appropriate cable for the load current capacity to output terminal.

(€

c'i\lus

(1×AWG16) Max.1×16mm2 (1×AWG6) or Max. 2×6mm2 (2×AWG10)

• SRPH1-A220, SRPH1-A230, SRPH1-A420, SRPH1-A430 : Approx. 410g

• SRPH1-A260, SRPH1-A460 : Approx. 680g

~

SSR Derating Curve'.)

(A)

Photoelectric

Sensors

(B)

Fiber

Optic

Sensors

(C)

Door/Area

Sensors

(D)

Proximity

Sensors

(E)

Pressure

Sensors

(F)

Rotary

Encoders

(G)

Connectors/

Connector Cables/

Sensor Distribution

Boxes/Sockets

(H)

Temperature

Controllers

(I)

SSRs / Power

Controllers

(J)

Counters

(K)

Timers

(L)

Panel

Meters

(M)

Tacho /

Speed / Pulse

Meters

(N)

Display

Units

(O)

Sensor

Controllers

(P)

Switching

Mode Power

Supplies

(Q)

Stepper Motors

& Drivers

& Controllers

(R)

Graphic/

Logic

Panels

(S)

Field

Network

Devices

(T)

Software

Autonics

I-19

SRPH1 Series

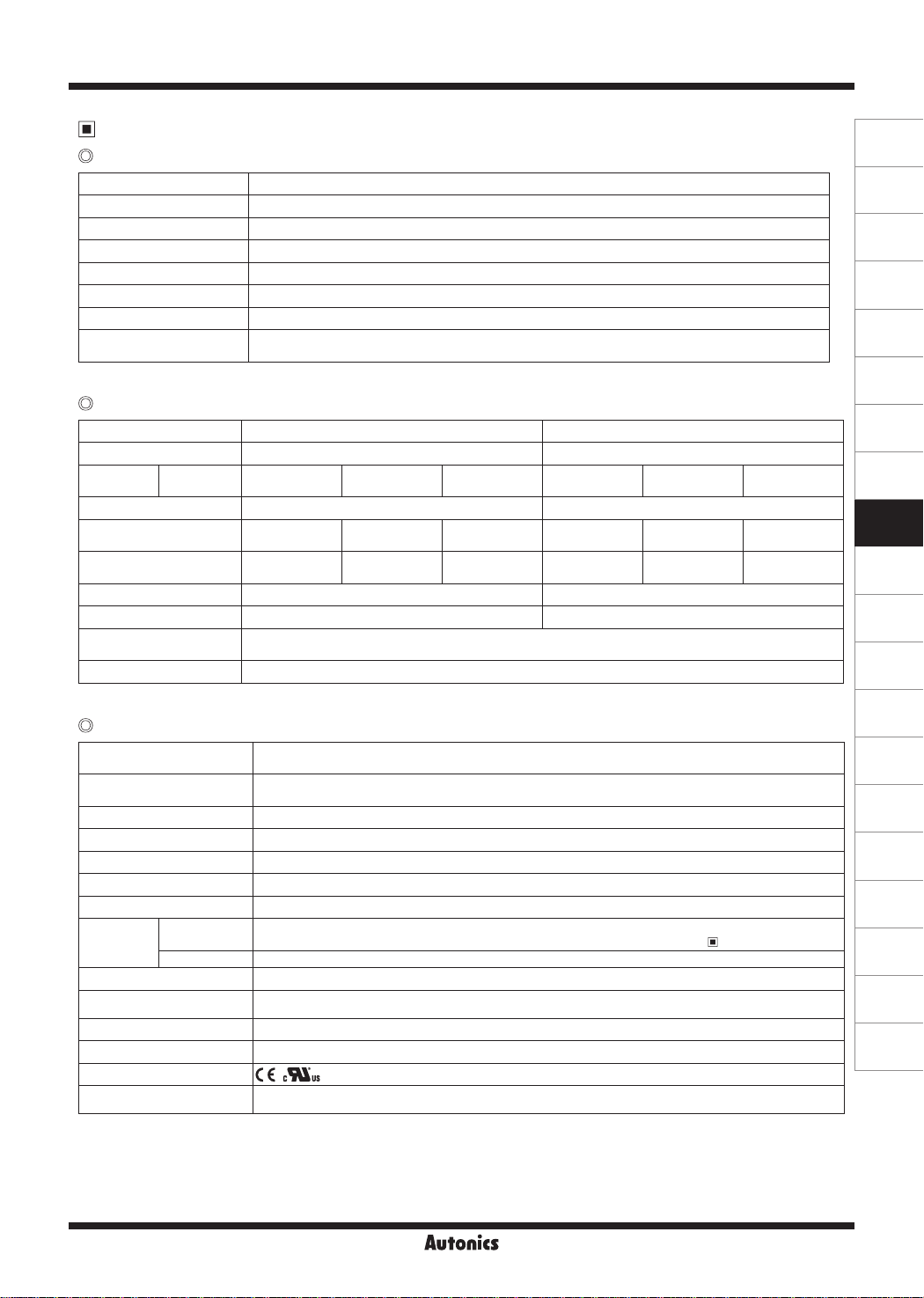

Dimensions & Mounting

Dimensions

● Rated load current 20A/30A

Ø4.5

Input indicator

(green LED)

● Rated load current 60A

Ø4.5

Input indicator

(green LED)

3.5

80

90

4.5

3.5

45

81.5

3.5

100

Ø4.5

I

I

I

I

3.5

(unit: mm)

(()

Hole cut-out for panel front mounting

● Rated load current

20A/30A

2-M4×0.7 Tap

~

I

~~

~

~i

-~

00

0~

.,

~

● Rated load current

60A

81.5

4-M4×0.7 Tap

90

90

<El

I

31

100

-

※

Screw tightening torque for mounting: 1.8 to 2.5N m

~

7 77

'I

I

~

80

90

100

I

~

•ii

~~

-~

00

0~

.,

<El

~

~

4.5

3.5

45

110

4 5

3.5

31

"

DIN rail mounting Installation interval

● DIN rail attachment

②

※

DIN rail must be grounded.

● DIN rail detachment

②

①

35mm DIN rail

35mm DIN rail

①

(-) driver

100100100

20

100

Panel

Panel

-

a

※

For mounting multiple

SSR, please keep certain

installation intervals for

heat prevention.

For horizontal installation

(when the heights of input

part and output part are

equal), it is recommended

to apply 50% of rated

load current.

High temperature

caution

Make sure do not touch the

heat sink or the unit body

while power is supplied or

right after load power is

turned off.

If not, it may cause a burn.

I-20

Autonics

Single-Phase, Analog Input Type SSR

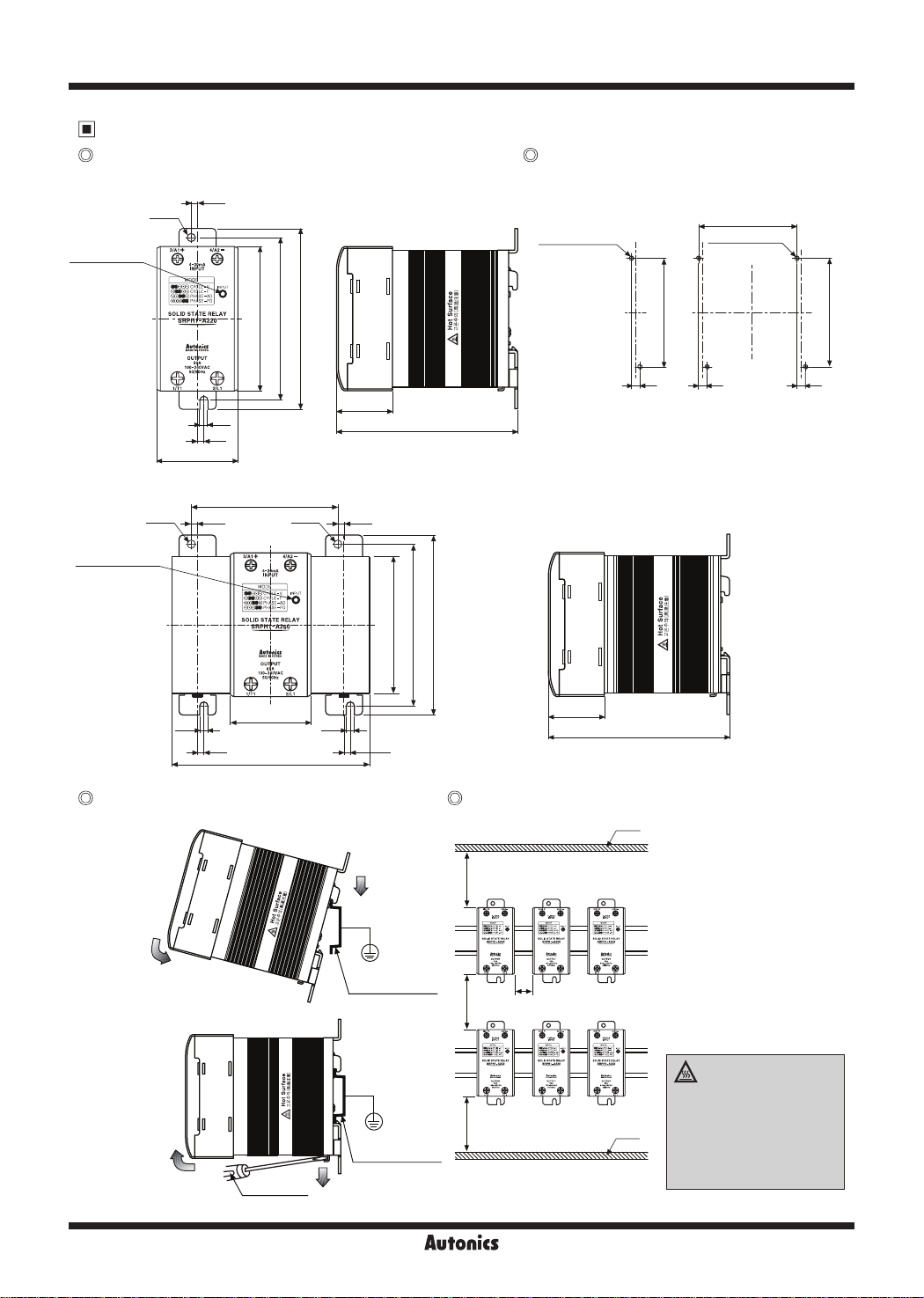

Connections

3/A1+

4-20

mA

4/A2- 2/L1

※

1: As above connection, connect a capacitor. It is proper to EMC.

SSR module

Input Output

SRPH1 Series

CAP: Load voltage 100-240VAC → 1uF/250VAC, Load voltage 200-480VAC → 0.47uF/500VAC

1/T1

Load

CAP

※

1

Rapid fuse

Load Source

(AC)

SSR Derating Curve

SRPH1-A220/A420 SRPH1-A230/A430 SRPH1-A260/A460

60

50

40

Load current [A]

30

20

16

'"

10 10

0

0 0 0

-

10 10 1020 20 2030 30

Ambient temperature [℃] Ambient temperature [℃] Ambient temperature [℃]

,- -

40 40 4050 50 5060 60 6070 70 7080 80 8090 90 90

(Q)

60 60

50 50

40 40

Load current [A]

30

20

r-

- - - - - - - _

16

0 0

...............

...,.

Please supply less than 50% of the rated load current when installing several SSRs closely due to decreasing

effectiveness of protection against heat.

(Q)

Load current [A]

30

...

-

25

20

10

,,

I'-.

I

I

'i'\.

I

-

-

30

-·-

I

I

I

35

-

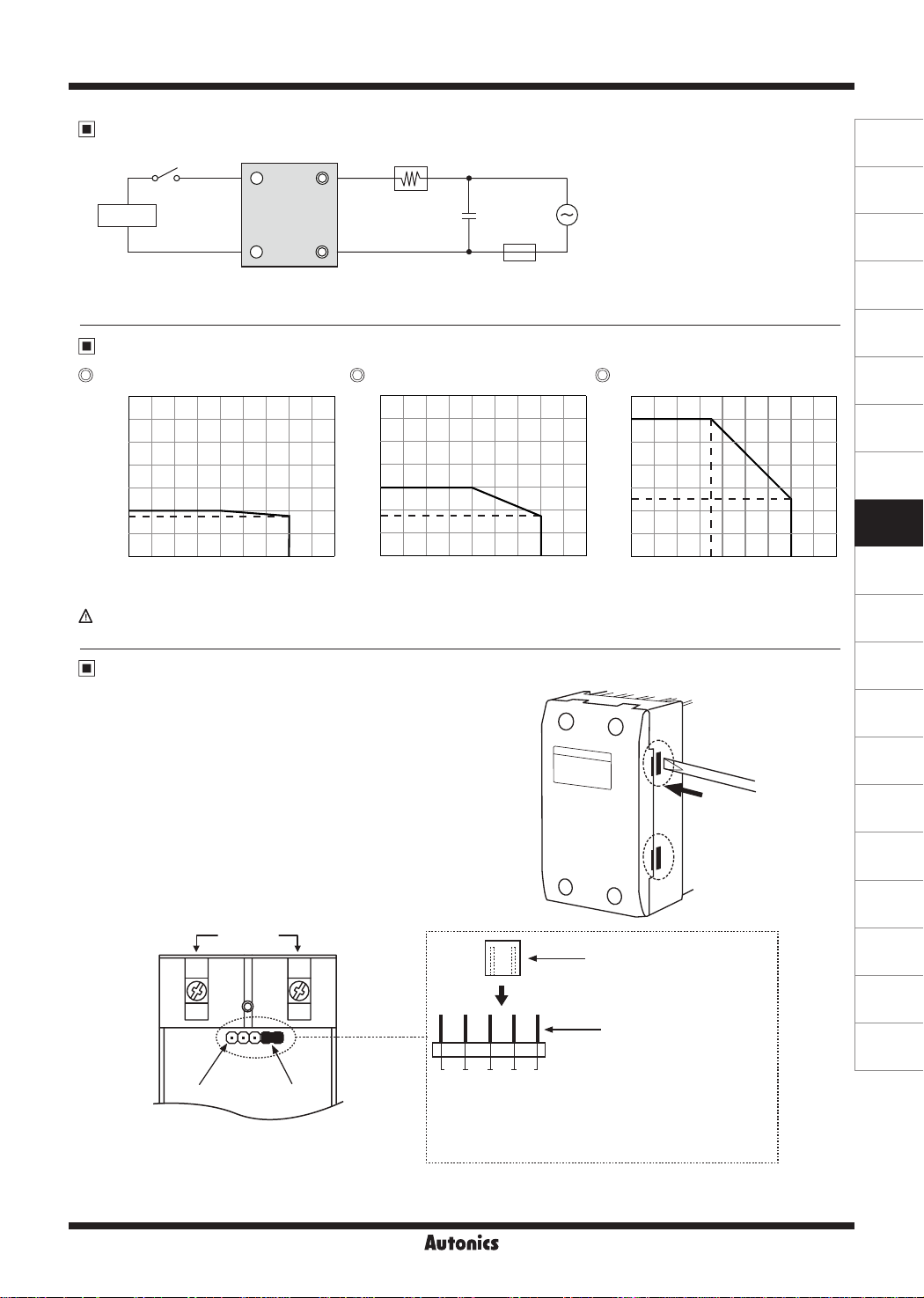

Operation Setting

● Detach front cover

Press front cover connection 4 parts at right and left side

with (-) driver, and front cover is detached.

※

Before detaching front cover, you must cut off load

current and input.

Flat head (-)

driver

'

- -

'

(A)

Photoelectric

Sensors

(B)

Fiber

Optic

Sensors

(C)

Door/Area

Sensors

(D)

Proximity

Sensors

(E)

Pressure

Sensors

(F)

Rotary

Encoders

(G)

Connectors/

Connector Cables/

Sensor Distribution

Boxes/Sockets

(H)

Temperature

'lo

Controllers

(I)

SSRs / Power

Controllers

(J)

Counters

(K)

Timers

(L)

Panel

Meters

(M)

Tacho /

Speed / Pulse

Meters

(N)

Display

Units

● Jumper pin setting

Operation mode is decided by jumper position.

After changing operation mode, re-supply input signal.

4-20mA

input

r 7

@

fr~···

Jumper pin

Jumper

...........

LI-

Jumper

..

Jumper pin

I!

111

1 2 3 4

CYCLE-V: Cycle control (variable cycle)

1.

CYCLE-F: Cycle control (xed cycle)

2.

PHASE-AD: Phase control (phase equality division type)

3.

PHASE-PD: Phase control (power equality division type)

4.

(factory default)

l

1

Autonics

I-21

(O)

Sensor

Controllers

(P)

Switching

Mode Power

Supplies

(Q)

Stepper Motors

& Drivers

& Controllers

(R)

Graphic/

Logic

Panels

(S)

Field

Network

Devices

(T)

Software

SRPH1 Series

Operation Mode

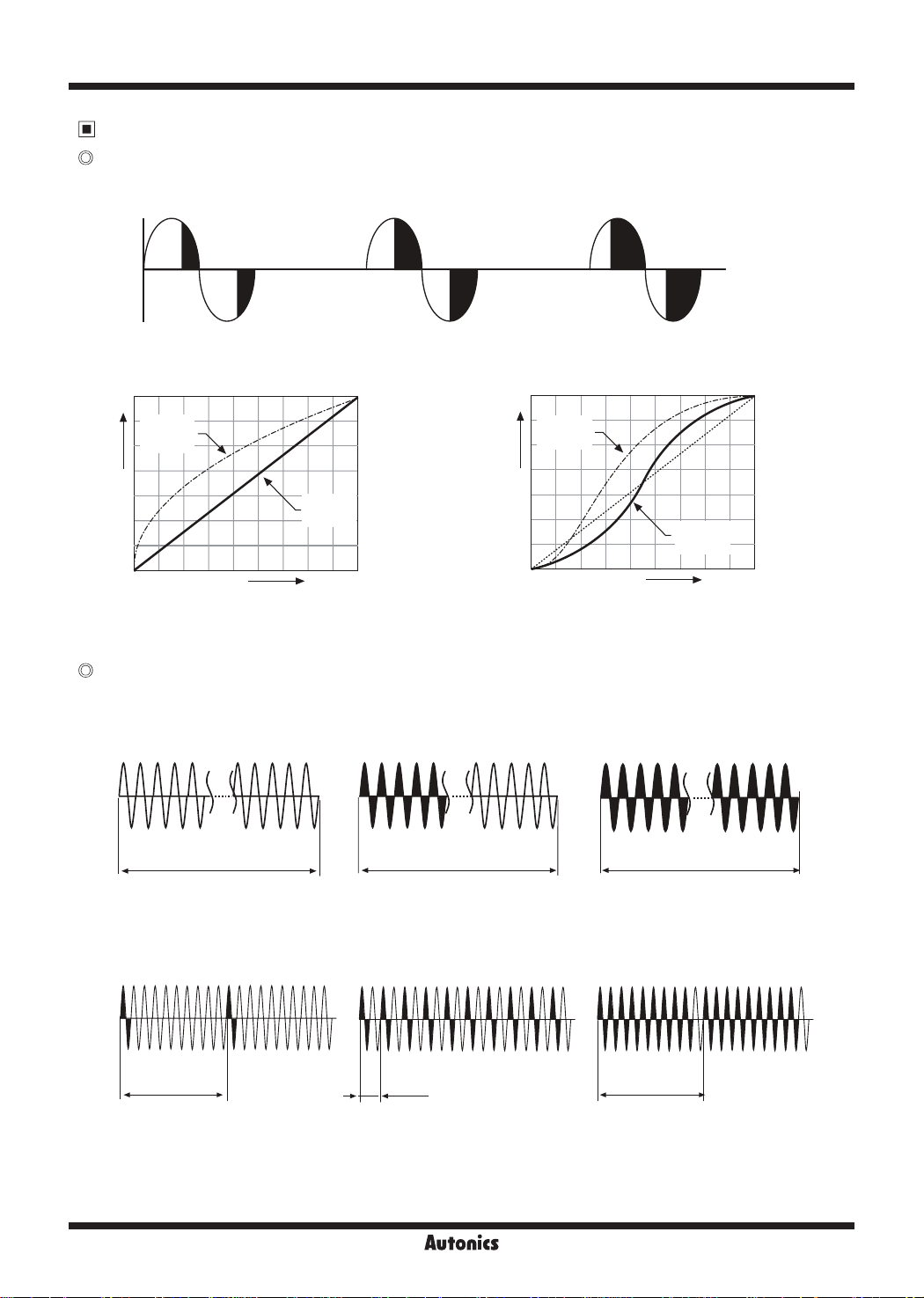

Phase control

● Output waveform of phase control

• When control input signal is 25%

※

1

• When control input signal is 50%

• When control input signal is 75%

,________..,.__F'=,-~C\,-------~

※

1: The black parts of output waveform are output on the load.

● Power equality division type ● Phase equality division type

100%

Output

DC 4

Output

voltage

curve

mA

Control input

Output

power

curve

DC 20

100%

mA

100%

Output

DC 4

Output

voltage

curve

mA

Control input

Output

power

curve

DC 20

100%

mA

Controls output power which is

proportional to control input (4-20mA) level.

(Q)

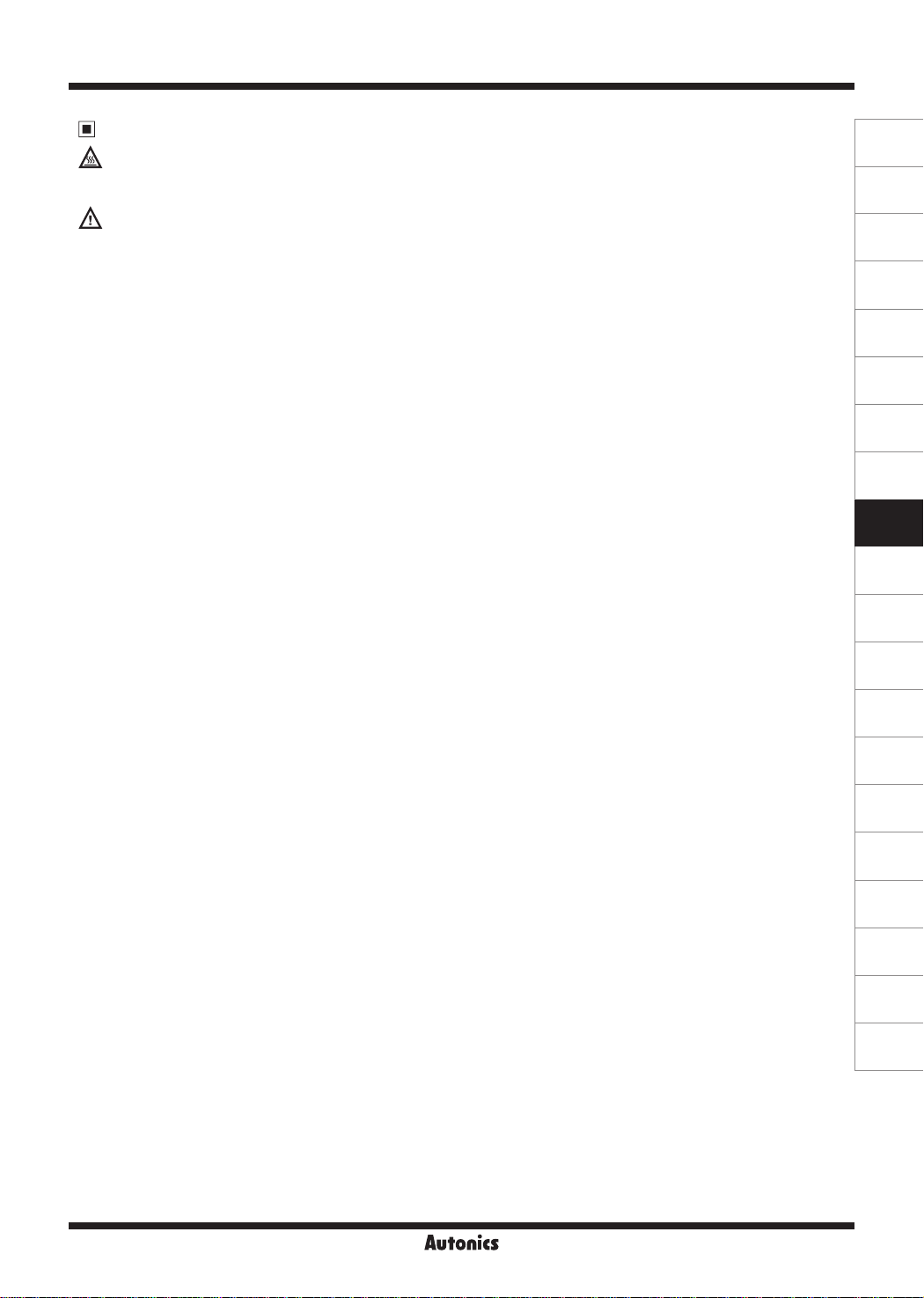

Cycle control

Controls phase angle which is proportional

control input (4-20mA) level.

● Fixed cycle

Controls continuously the number of full cycle which is supplied to load every 1 sec by being proportional to control input

(4-20mA).

• When control input signal is 0%

T: Cycle (1 sec) T: Cycle (1 sec)

• When control input signal is 50%

• When control input signal is 100%

T: Cycle (1 sec)

● Variable cycle

Controls fast and accurately the subject with optimized the number of AC voltage cycle which is supplied to load by being

proportional to control input (4-20mA).

• When control input signal is 10%

T cycle

• When control input signal is 50%

T cycle T cycle

--+

-+----

• When control input signal is 90%

I-22

Autonics

Single-Phase, Analog Input Type SSR

Proper Usage

High temperature caution

Make sure do not touch the heat sink or the unit body while power is supplied or right after load power is

turned off. If not, it may cause a burn.

Cautions during use

1. Ventilate for smooth convection current. If not, congested heat transfer may cause product failure or malfunction.

2. Must ground heatsink or mounted DIN rail. Failure to follow this instruction may cause electric shock.

3. For mounting multiple SSR, please keep certain installation intervals for heat prevention. For horizontal installation (when

the heights of input part and output part are equal), it is recommended to apply less than 50% of the rated load current.

4. Make sure do not touch the heatsink or the unit body while power is supplied or right after load power is turned OFF.

If not, it may cause a burn.

5. Connect the proper cable for the rated load current with output terminal.

6. Use rapid fuse of which I

short-circuit please replace the fuse which has same specication.

7. In case that load's current is lower than SSR min. load current, connect dummy resistance to the load in parallel so as to

make load's current higher than SSR min. load current.

8. Make sure that the screw on output terminal is tightly fastened. Using the unit with loose bolt may cause product failure

or malfunction.

9. Do not touch the load's terminal even if output is OFF. It may cause electric shock.

10. The input of the 4-20mA should be supplied by the insulated and limited voltage/current or by class 2 power supply.

11. Avoid following environments to install this unit.

Where temperature/humidity is beyond the specication

①

Where dew condensation occurs due to temperature change

②

Where inammable or corrosive gas exists

③

Where direct rays of light exist

④

Where severe shock, v bration or dust exists

⑤

Where near facilities generating strong magnetic forces or electric noise

⑥

12. This product may be used in the following environments.

Indoors

①

Max. altitude: 2,000m

②

Pollution degree 2

③

Installation category

④

2

t is under 1/2 of SSR I2t in order to protect the unit from load's short-circuit current. In case of a

Ⅲ

(A)

Photoelectric

Sensors

(B)

Fiber

Optic

Sensors

(C)

Door/Area

Sensors

(D)

Proximity

Sensors

(E)

Pressure

Sensors

(F)

Rotary

Encoders

(G)

Connectors/

Connector Cables/

Sensor Distribution

Boxes/Sockets

(H)

Temperature

Controllers

(I)

SSRs / Power

Controllers

(J)

Counters

(K)

Timers

(L)

Panel

Meters

(M)

Tacho /

Speed / Pulse

Meters

(N)

Display

Units

Autonics

I-23

(O)

Sensor

Controllers

(P)

Switching

Mode Power

Supplies

(Q)

Stepper Motors

& Drivers

& Controllers

(R)

Graphic/

Logic

Panels

(S)

Field

Network

Devices

(T)

Software

Loading...

Loading...