DRW171113AA

Autonics

Solid State Relay

SRPH1 SERIES

I N S T R U C T I O N M A N U A L

Thank you for choosing our Autonics product.

Please read the following safety considerations before use.

Safety Considerations

Please observe all safety considerations for safe and proper product operation to avoid hazards.

※

symbol represents caution due to special circumstances in which hazards may occur.

※

Failure to follow these instructions may result in serious injury or death.

Warning

Failure to follow these instructions may result in personal injury or product damage.

Caution

3.5

® ' ®

'

80~;:.;r~II~ -

3 5

45

----jf~~~~~t~!!'~y

3.5

Ø4.5

Input indicator

(green LED)

0

80

100

4 5

81 5

6

I

!!.¾,~

6

-

-

Input indicator

(green LED)

@,JiB'/®

lilW

~·-rJr•~~

45

110

4.5

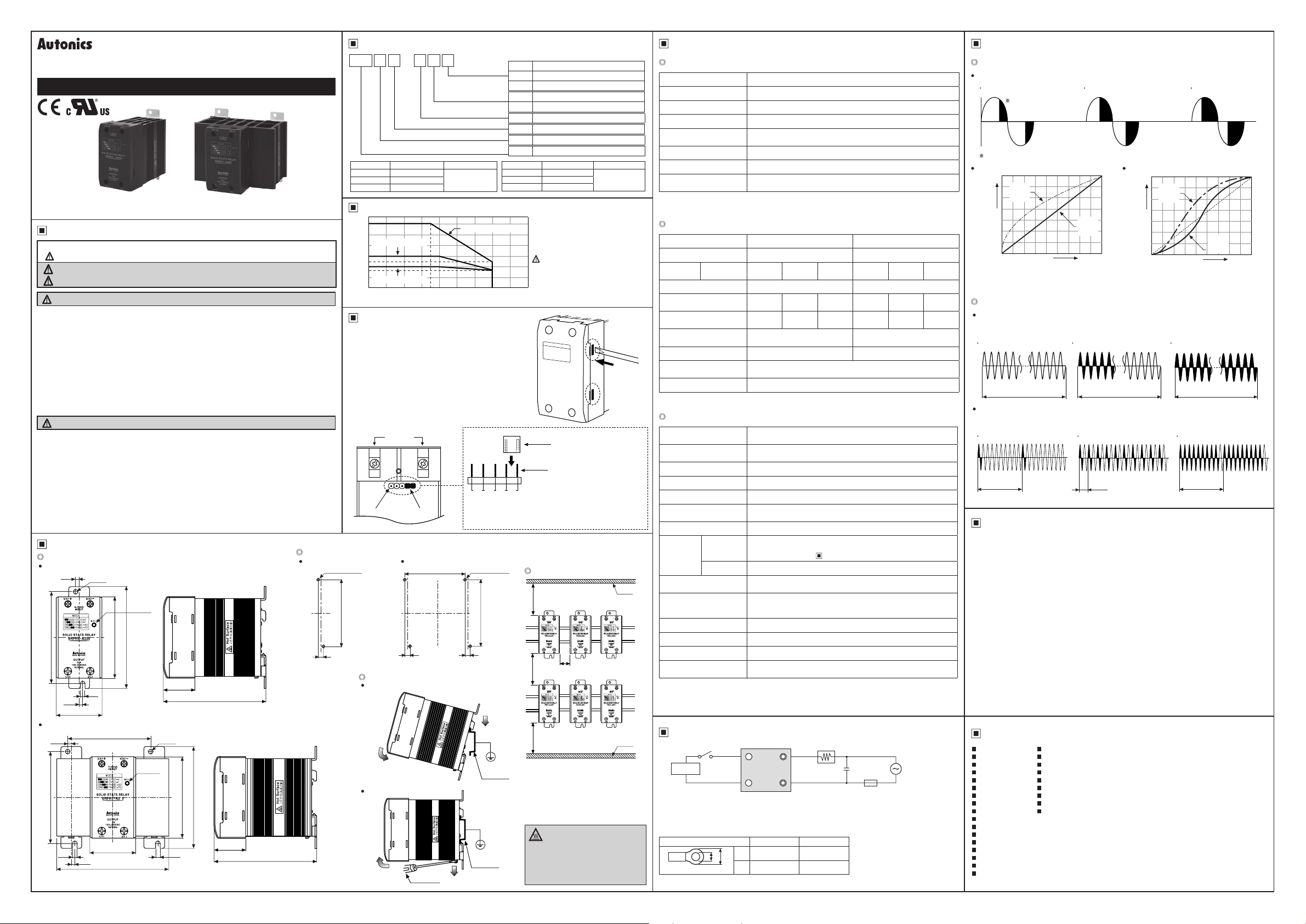

Hole cut-out for mounting on panel

Rated load current 20A/30A Rated load current 60A

•

2-M4×0.7 Tap

90

7

※

tightening torque for mounting: 1.8 to 2.5N m

Screw

31

100

~

I

I

□

80

100

I

□

D

~~

:'El

J

I

31

~

100

Warning

1. Fail-safe device must be installed when using the unit with machinery that may cause

serious injury or substantial economic loss. (e.g. nuclear power control, medical equipment,

ships, vehicles, railways, aircraft, combustion apparatus, safety equipment, crime/disaster

prevention devices, etc.)

Failure to follow this instruction may result in re, personal injury, or economic loss.

2. Install on a device panel or DIN rail to use.

Failure to follow this instruction may result in electric shock or re.

3. Do not connect, repair, or inspect the unit while connected to a power source.

Failure to follow this instruction may result in electric shock or re.

4. Check 'Connections' before wiring.

Failure to follow this instruction may result in re.

5. Do not disassemble or modify the unit.

Failure to follow this instruction may result in electric shock or re.

Caution

1. Use the unit within the rated specications.

Failure to follow this instruction may result in re or product damage.

2. Use dry cloth to clean the unit, and do not use water or organic solvent.

Failure to follow this instruction may result in electric shock or re.

3. Do not use the unit in the place where ammable/explosive/corrosive gas, humidity, direct

sunlight, radiant heat, vibration, impact, or salinity may be present.

Failure to follow this instruction may result in re or explosion.

4. Keep metal chip, dust, and wire residue from owing into the unit.

Failure to follow this instruction may result in re or product damage.

5. Since leakage current still ows right after turning off the power or in the output OFF status,

do not touch the load terminal.

Failure to follow this instruction may result in electric shock.

Dimensions & Mounting

00

Dimensions

Rated load current 20A/30A

90

Rated load current 60A

3.5 Ø4.5

t------j---

90

4.5

※

The above specifications are subject to change and some models may be discontinued without notice.

※

Be sure to follow cautions written in the instruction manual and the technical descriptions (catalog, homepage).

Ordering Information Specications

00

SRP

-

30H 1 A

2

Rated load current

(resistive load)

r2

Rated load voltage

Rated input current

Control phase

Type

Item

Model Rated load current Rated load voltage

SRPH1-A220 20A

SRPH1-A230 30A

SRPH1-A260 60A

SSR Derating Curve

60

50

SRPH1-A230/A430

40

30

Load current [A]

25

---

---

20

16

10

SRPH1-A220/A420

0 10 20 30 35 40 50 60 70 80 90

---

Operation Setting

Detach front cover

●

Press front cover connection 4 parts at right and left side with

(-) driver, and front cover is detached.

※

Before detaching front cover, you must cut off load current

and input.

Jumper pin setting

●

Operation mode is decided by jumper position.

After changing operation mode, re-supply input signal.

4-20mA

input

g

DIN rail mounting

DIN rail attachment

•

②

※

D N rail must be grounded.

DIN rail detachment

②

-L

JumperJumper pin

----j----

(-) driver

'

81 5

i

!

I

i

I

'

100-240VAC

SRPH1-A260/A460

Ambient temperature[℃]

① ② ③ ④

CYCLE-V

①

CYCLE-F: Cycle control (fixed cycle)

②

PHASE-AD: Phase control (phase equality division type)

③

PHASE-PD: Phase control (power equality division type) (default)

④

4-M4×0.7 Tap

90

77

①

35mm

D N rail

35mm

DIN rail

①

20A

20

30A

30

60A

60

I I

100-240VAC

2

200-480VAC

4

I I

4-20mA Analog input

A

Single phase

1

Integrated heatsink type

H

Solid State Relay (analog input type)

SRP

Model Rated load current Rated load voltage

SRPH1-A420 20A

SRPH1-A460 60A

Since effectiveness of the heat rediation

is decreased when multiple SSRs are

installed closely, please supply less than

50% of the rated load current.

※

Above SSR derating curves obtained

approval from the UL certication authority.

Jumper

Jumper pin

: Cycle control (variable cycle)

Spacing

100100100

200-480VACSRPH1-A430 30A

(-) driver

(unit: mm)

Panel

~

·--·

·-·

'=

@'H!

'"""'"""' ""'"'"'..,

Cl,;z;.CI

1%_%_

※

When installing multiple SSRs, please keep

space between SSRs for heat radiation.

When installing SSRs horizontally (input

part and output part on the same height),

please supply less than 50% of the rated

load current.

While supplying power to the load or right

after turning off the power of the load, do

not touch the body and heat sink.

Failure to follow this instruction may result

in a burn due to the high temperature.

~

PII

II

...

El9

20

- -

- -

Cl:;;,;.O

~,J;;Cl

%~

High Temperature Caution

Panel

~,,~

00

Input

Rated input current 4-20mA

Max. allowable input current 50

Pick-up current Min. 4.2mA

Static off current Max. 0 2mA

Power factor

Start-up time 60Hz: 200ms, 50Hz: 250ms

Operation time 60Hz: 16 6ms, 50Hz:20ms

※

Operation mode

1: You can change operation mode by jumper pin.

※

Default is Phase control (power equality division type).

Output

Rated load voltage range 100-240VACrmsᜠ (50/60Hz) 200-480VACrmsᜠ (50/60Hz)

Allowable load voltage range 90-264VACrmsᜠ (50/60Hz) 200-528VACrmsᜠ (50/60Hz)

Rated load

current

Min. load current 0 5Arms 0.5Arms

Max. 1 cycle surge current

(60Hz)

Max. non-repetitive surge

current (I

Peak voltage

(non-repetitive)

Leakage current (Ta=25℃) Max. 10mArms (240VACᜠ/60Hz) Max. 10mArms (480VACᜠ/60Hz)

Output on voltage drop [Vpk]

(max. load current)

Static off-state dv/dt 500V/

※

1: AC-51 are utilization category at EC60947-4-3.

General specications

Phase control

(phase equality division type)

Phase control

(power equality division type)

Frequency reading function Yes

Dielectric strength (Vrms) 4000VAC 50/60Hz for 1min (input-output, input/output-case)

Insulation resistance Over 100MΩ (at 500VDC megger)

Vibration

Indicator Input indicator: green LED

Environment

Input terminal connection

Output terminal connection

Input terminal xed torque 0.75 to 0 95N.m

Output terminal xed torque 1 6 to 2.2N m

Approval

Unit weight

※

Environment resistance is rated at no freezing or condensation.

※

For wiring the terminal, round terminal must be used.

Connections

00

4-20mA

1: As above connection, connect a capacitor. It is proper to EMC.

※

CAP: Load voltage 100-240VAC→1uF/250VAC

※

Use terminals of size specied below.

Terminal type

1

Resistive load

(AC-51)

I

2

t, t=8.3ms)

Ambient temp.

Ambient humi. 45 to 85%RH, storage: 45 to 85%RH

3/A1+ 1/T1

4/A2- 2/L1

Load voltage 200-480VAC→0.47uF/500VAC

a

b

<Round>

mA

Min. 0.9 (max. 25° of difference between voltage phase and current

phase)

Phase control (phase equality division type, power equality division type)

Cycle control (xed cycle, variable cycle)

20Arms 30Arms 60Arms 20Arms 30Arms 60Arms

※

1

300A 500A 1000A 300A 500A 1000A

350A2s 1000A2s 4000A2s 350A2s 1000A2s 4000A2s

600V 1000V

Max. 1.6V

㎲

5 to 99%

10 to 99%

0.75mm amplitude at frequency of 10 to 55Hz in each X, Y, Z direction

for 1 hour

-20 to 70℃, storage: -20 to 100

( The rated load current capacity is different depending on ambient

temperature. Refer to '

Min. 1×0.5mm

max. 1×1.5mm2 (1×AWG6) or 2×1.5mm2 (2×AWG16)

Min. 1×1.5mm

max.1×16mm2 (1×AWG6) or 2×6mm2 (2×AWG10)

※

Use wires compliant with load current capacity to connect to the terminal.

ᜢ ᜧ

• Rated load current 20A/30A : Approx. 410g

• Rated load current 60A: Approx. 680g

SSR Module

SRPH1 Series Output

Input

Input

a Min. 3.5mm Min. 5.0mm

b Max. 7 0mm Max. 12.0mm

2

(1×AWG20),

2

(1×AWG16),

Output

℃

SSR Derating Curve'.)

00

Load

1

※

CAP

Rapid fuse

Load

power source

(AC)

Operation Mode

00

g

Phase control

.

Output waveform of phase control

When control input signal is 50% When control input signal is 25% When control input signal is 75%

1

I

Output

voltage

curve

,'

I

-

:,

II

,

__

,,.,

·:.,r,

{I

Ir

_,

/

If".,,-

f

Output

power

curve

"---

Control input

-

T cycle

(f

,,

~/

,,

/'

,'

,,

~

~

100%

DC 20mA

DR W17 1113A A

Cl

-7

·--

V

Output

power

curve

I I

DC 20mA

T cycle

\J

.

Phase equality division type

100%

Output

r

-

100%

DC 4mA

Controls phase angle which is proportional

to control input (4-20mA) level.

-

-

/~

~

1: The black parts of output waveform are output on the load.

*

.

Power equality division type

100%

I I

Output

-

voltage

Output

r

-

f-

curve

~

/

/

/

/,,

/

f/

DC 4mA

Controls output power which is

proportional to control input (4-20mA) level.

Cycle control

Fixed cycle

Controls continuously the number of full cycle which is supplied to load every 1sec by being

proportional to control input (4-20mA).

When control input signal is 0% When control input signal is 50% When control input signal is 100%

T: Cycle (1 sec) T: Cycle (1 sec) T: Cycle (1 sec)

Variable cycle

Controls fast and accurately the subject with optimized the number of AC voltage cycle which is

supplied to load by being proportional to control input (4-20mA).

When control input signal is 0% When control input signal is 50% When control input signal is 100%

T cycle

Cautions during Use

00

1. Follow instructions in 'Cautions during Use'. Otherwise, it may cause unexpected accidents.

2. Install the unit in the well ventilated place.

3. Ground to the heat sink, panel, or D N rail.

Failure to follow this instruction may result in electric shock.

4. While supplying power to the load or right after turning off the power of the load, do not touch the

body and heat sink.

Failure to follow this instruction may result in a burn due to the high temperature.

5. In order to protect the product from the short-circuit current of the load, use rapid fuse of which I2t is

under the 1/2 of SSR I

the used rapid fuse.

6. Install dummy resistance in parallel with the load, to keep the sum of current owing in the load and

dummy resistance being over SSR minimum load current.

7. Do not use near the equipment which generates strong magnetic force or high frequency noise.

8. This unit may be used in the following environments.

Indoors (in the environment condition rated in 'Specications')

①

Altitude max. 2,000m

②

Pollution degree 2

③

④ Installation category III

Major Products

00

Photoelectric Sensors Temperature Controllers

Fiber Optic Sensors Temperature/Humidity Transducers

Door Sensors SSRs/Power Controllers

Door Side Sensors Counters

Area Sensors Timers

Proximity Sensors Panel Meters

Pressure Sensors Tachometers/Pulse(Rate) Meters

Rotary Encoders Display Units

Connectors/Sockets Sensor Controllers

Switching Mode Power Supplies

Control Switches/Lamps/Buzzers

I/O Terminal Blocks & Cables

Stepper Motors/Drivers/Motion Controllers

Graphic/Logic Panels

Field Network Devices

Laser Marking System(Fiber, Co₂, Nd:YAG)

Laser Welding/Cutting System

■

■

■

■

■

■

■

■

■

2

.v

,/

/

/

1,

/

"---

Control input

-

t. When short-circuited, replace the fuse to those of same specication with

Loading...

Loading...