Autonics SPR1 Series Instruction Manual

DRW171280AC

Autonics

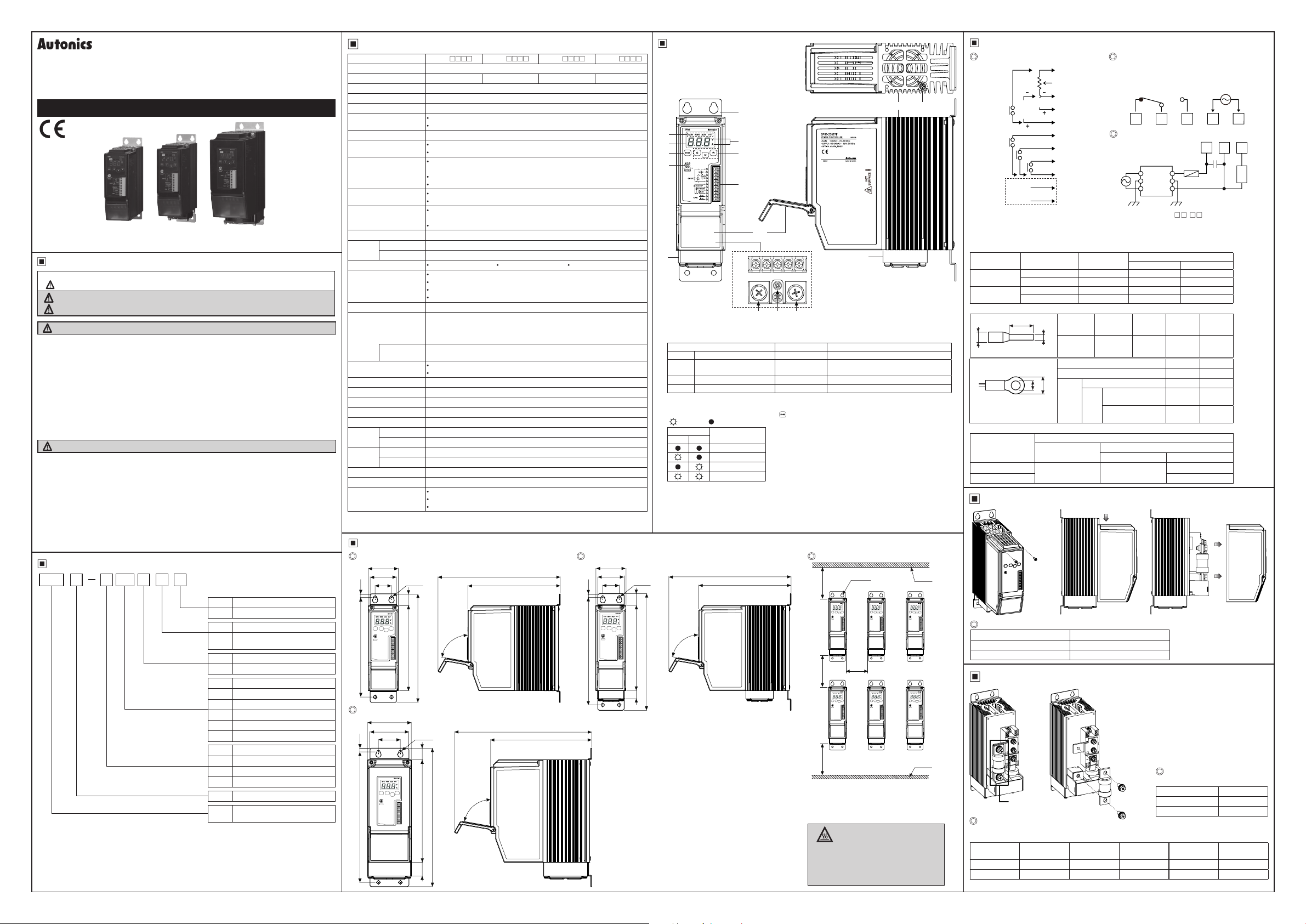

Single-Phase,

LED Display Slim Power Controller

SPR1 Series

INSTRUCTION MANUAL

Please read the following safety considerations before use.

Safety Considerations

00

Please observe all safety considerations for safe and proper product operation to avoid hazards.

※

symbol represents caution due to special circumstances in which hazards may occur.

※

Warning

Caution

Warning

1. Fail-safe device must be installed when using the unit with machinery that may cause

serious injury or substantial economic loss. (e.g. nuclear power control, medical equipment,

ships, vehicles, railways, aircraft, combustion apparatus, safety equipment, crime/disaster

prevention devices, etc.)

Failure to follow this instruction may result in re, personal injury, or economic loss.

2. Install on the device panel, and ground to the bolt for grounding separately.

Failure to follow this instruction may result in electric shock or re.

3. Do not connect, repair, or inspect the unit while connected to a power source.

Failure to follow this instruction may result in electric shock or re.

4. Check 'Connections' before wiring.

Failure to follow this instruction may result in re.

5. Do not disassemble or modify the unit.

Failure to follow this instruction may result in electric shock or re.

Caution

1. Use the unit within the rated specications.

Failure to follow this instruction may result in re or product damage.

2. Use dry cloth to clean the unit, and do not use water or organic solvent.

Failure to follow this instruction may result in electric shock or re.

3. Do not use the unit in the place where ammable/explosive/corrosive gas, humidity, direct

sunlight, radiant heat, vibration, impact, or salinity may be present.

Failure to follow this instruction may result in re or explosion.

4. Keep metal chip, dust, and wire residue from owing into the unit.

Failure to follow this instruction may result in re or product damage.

5. Since leakage current still ows right after turning off the power or in the output OFF status,

do not touch the load terminal.

Failure to follow this instruction may result in electric shock.

L_

Ordering Information

00

Item

※

1: Product is not equipped with a rapid fuse inside. Install the suitable fuse for rated load current of

the model separately.

(The performance of the product is guaranteed only when using the fuse provided by us.)

※

The above specifications are subject to change and some models may be discontinued

without notice.

※

Be sure t o follow cauti ons wr itten in the i nstr ucti on manu al, use r manual, and t he

technical descriptions (catalog, homepage).

Thank you for choosing our Autonics product.

Failure to follow these instructions may result in serious injury or death.

Failure to follow these instructions may result in personal injury or product damage.

______

-

1 T FSPR 702 F

※1

I

Normal/constant current/constant

voltage/constant power control

I

I

I

I

Solid State Power Regulator

(slim type)

I

Rated load voltage

Control phase

Feedback

control

Option output

Rated load current

Fuse

N Non-fuse

F Fuse

I I I

N Normal control

I

F

I

N Alarm output

I

T Alarm+RS485 comm. output

I

25 25A

35 35A

50 50A

70 70A

'

100 100A

'

150 150A

1 110VAC

2 220VAC

3 380VAC

4 440VAC

I

1 Single-phase

J

SPR

I

Specications

00

SPR1-2

SPR1-3

Model SPR1-1

Control phase Single-phase

Rated load voltage (50/60Hz)

Power supply 100-240VACᜠ 50/60Hz

Min. load current 1A

Permissible voltage range 90 to 110% of rated voltage

Power consumption

Display method 3-digit 7-segment LED

Indicator

Control method

Applied load

Control input

Digital input (DI) RUN/STOP switching, AUTO/MAN switching, RESET

Alarm 250VACᜠ 3A, 30VDCᜡ 3A, 1c resistive load

I

Output

Communication

I

Output range

Output accuracy

Set method

I

J

Functions

Alarm

l

Cooling method

Insulation resistance Over 200MΩ (at 500VDC megger)

Dielectric strength 2,000VAC 50/60Hz for 1 min (between input terminals and power terminals)

Output leakage current Max. 10mArms

Noise immunity ±2kV the square wave noise (pulse width: 1㎲) by the noise simulator

Memory retention Approx. 10 years (when using non-volatile semiconductor memory type)

Mechanical

Vibration

Malfunction

Ambient temp. -10 to 55℃, storage: -20 to 80

Environ

ment

Ambient humi. 35 to 85%RH, storage: 35 to 85%RH

Accessory 11-pin connector

Approval

1

※

Weight

-

※

1: The weight includes packaging. The weight in parenthesis is for unit only.

※

Environment resistance is rated at no freezing or condensation.

Dimensions

00

o

Rated load current 25A/35A/50A

55

48

30 168.5

6.8

4-Ø6

21.3

J

J

181

155

197.6

□□ □□

110VAC

ᜠ

Rated load current 25A/35A/50A: max. 7VA

Rated load current 70A/100A/150A: max. 12VA

Operation indicator/Manual control indicator: green LED

Alarm indicator/output indicator/unit (V, A) indicator: red LED

Phase control: normal control mode, constant current/constant voltage/

Cycle control: xed cycle control mode, variable cycle control mode

ON/OFF control

Phase control, ON/OFF control: resistance load, inductive load

Cycle control: resistance load

Auto control: DC4-20mA, 1-5VDC

Manual control: outside adjuster (10kΩ), inside adjuster (output limit)

RS485 communication output (Modbus RTU method), max. connection: 31 units

Phase control: 0 to 98% Cycle control: 0 to 100% ON/OFF control: 0%, 100%

Normal control

Constant current feedback control

Constant voltage feedback control

Constant power feedback control

By front keys, by communication

Output limit (OUT ADJ), AUTO/MAN selection, control method selection, RESET,

SOFT START, SOFT UP/DOWN, output high/low limit, input correction, input

slope correction, monitoring (control input, load voltage/current/power/resistance,

power supply frequency, heatsink temperature)

Overcurrent alarm, overvoltage alarm, fuse break alarm, SCR error alarm,

heater break alarm, heatsink overheat alarm

Rated load current 25A/35A/50A: natural cooling

Rated load current 70A/100A/150A: forced air cooling (with the cooling fan)

0.75mm amplitude at frequency of 5 to 55Hz in each X, Y, Z direction for 2 hours

0.5mm amplitude at frequency of 5 to 55Hz in each X, Y, Z direction for 10 min

ᜢ

Rated load current 25A/35A/50A: approx. 1.6kg (approx. 1.3kg)

Rated load current 70A: approx. 1 65kg (approx. 1.35kg)

Rated load current 100A/150A: approx. 3 2kg (approx. 2 8kg)

pulse voltage (5-12VDCᜡ)

: within ±10% F.S. of rated load voltage

80°

D

ITTI

I

220VAC

ᜠ

I

constant power feedback control mode

ᜡ

: within ±3% F.S. of rated load current

: within ±3% F.S. of rated load voltage

: within ±3% F.S. of rated load power

℃

223

ITIJ

I

380VAC

I

, ON/OFF contact (no-voltage input),

J

SPR1-4

□

I

440VAC

ᜠ

I

Rated load current 70A

6.8

196

J

Rated load current 100A/150A

80

J

71

4-Ø6

40

6.8

21.3

I

238

187

252.6

80°

L

250.1

184.4

~

1//

1\

25

I

I

I

I

55

48

30

□□□□

ᜠ

4-Ø6

21.3

155

15

Unit Description

00

⑬

②

③

⑤

⑦

⑫

0 0

①

④

⑥

⑧

⑨

⑩

⑫

⑪

R U

S

①

Bracket

②

Indicator

Indicator Color Function

RUN Operation indicator Green LED Turns on in the RUN mode.

MAN Manual control indicator Green LED

ALM Alarm indicator Red LED Flashes in alarming status.

OUT Output indicator Red LED Turns on when load control outputs.

f=r==r:==::;::==I

③

Display par t: Displays settings of the front display [

④

Unit indicator

: Light ON/ : Light OFF)

(

Indicator

V A

• •

◊

•

◊ ◊

⑪

R, S, U load output terminals

⑫

Cooling fan: For models with the rated load current of 70A/100A/150A, a cooling fan is attached.

⑬

Heatsink

⑭

Bolt for grounding (M4)

80°

212.6

====t=====t=====E====fl

parameter and setting value in setting mode.

•

Display

Resistance, input

Voltage

•

Current

◊

Power

223

168 5

⑤

key:

⑥

Setting value adjustment key

: Enters SV setting mode and move digits.

⑦

Output limit adjuster (OUT ADJ)

: Limits output from 0 to 100%.

⑧

11-pin connector terminal

⑨

Terminal cover

⑩

Alarm output and power input terminals

Turns on when adjusting load output in

the manual control mode.

==--------==~

] parameter in RUN mode, and displays

DIS

Enters parameter group, returns to RUN mode, moves

parameters, and saves the setting value.

Spacing

4-Ø6

100100100

50

&~~

※

When installing multiple power controllers,

please keep space at least 50mm in

horizontal and 100mm in vertical between

power controllers for heat radiation.

High Temperature Caution

£.

While supplying power to the load or right after

turning off the power of the load, do not touch

the body and heatsink.

Failure to follow this instruction may result in a

burn due to the high temperature.

I

⑭

(unit: mm)

Panel

Panel

Connections

Control input/Comm. output Alarm output/power input

①

VR

rE

1-5

ll

ON/OFF

r4

VDC

L~

RUN/STOP

1

AUTO/MAN

11

(

,

___

l!C

:

※

1

RS485

i

~-

※

1: This is only for models with RS485 communication output (SPR1-

※

2: When connecting noise lter and capacitor, it is appropriate for EMC.

※

Tighten the terminal screw with the below tightening torque.

Rated load

current

25A, 35A,

50A, 70A

100A, 150A

I I I I I I

※

Use crimp terminals or terminals of size specied below.

lroB7

I I

※

Connect the specied wire as the rated load current.

Rated load current

25A/35A/50A/70A

100A/150A AWG 4 to 2/0

I I I I

Rated load current Specication of bolts

25A, 35A, 50A, 70A M3

100A, 150A M4

Recommended fuse specifications

0

For replacing the fuse, please use the recommended fuse which has the below specications.

(manufacture: BUSSMANN)

Rated load

current

25A 50FE 50A 80ET 100A FWH-150B

35A 63ET 70A 100FE 150A FWH-200B

I I I I I I

※

The performance of the product is guaranteed only when using the fuse provided by us.

I

---- ------ -----

CAP : Rated load voltage 110VAC-220VAC → 1uF/250VAC

: Rated load voltage 380VAC-440VAC → 0.47uF/500VAC

Specication

Screw M3 M3 M6

Tightening torque 0.5N.m 0 5N.m 5 5 to 6.0N m

Screw M3 M3 M8

Tightening torque 0.5N.m 0 5N.m 6 5 to 7.0N m

a

c

<Crimp terminal>

~

<Round>

Removing the Case

Specification of case fixing bolts

Replacement of Fuse

Fuse

Model

②

③

4-20mA

~

④

⑤

+

⑥

⑦

'

⑧

RESET

⑨

:

A(+)

------+

:

⑩

B(-)

______...,

!

⑪

--·

Alarm output/

power input

Terminal

type

b

Input

(11-pin)

I I I I I I

Terminal type a b

Alarm output/power input Min. 3.0 Max. 6.0

a

b

I I I I I I

Load

output

Wire specication

Alarm output/

power input

AWG 18 to 14 AWG 18 to 14

Case

xing

bolts

Terminal

number

1 to 11 6 to 7 Max. 1 5 Max. 3.5

S Min. 3.0 Max. 8.0

Rated load current

25A/35A/50A/70A

R, U

Rated load current

100A/150A

Load output

S R, U

·.

•.

Rated load

current

Alarm Output

(250VAC 3A 1c)

(30VDC 3A 1c)

Resistive Load

N.C. N.O. LCOM N

l?°lr87

1 2 3 4 5

□ □

Load output

Noise lter

Load output

S R, U

a b c

①

-~

Fuse

xing bolts

·

..

--

~

Model

□ □

※

2

Rapid fuse

□□

Min. 6.0 Max. 16 0

Min. 8.0 Max. 26 0

AWG 13 to 4

Specification of

0

fuse fixing bolts

Rated load current Spec. of bolts

25A, 35A, 50A, 70A M6

100A, 150A M8

Rated load

current

T ).

□□

100-240VAC

50/60Hz

□

R S U

CAP

※

2

(unit: mm)

②

I

Model

Load

I

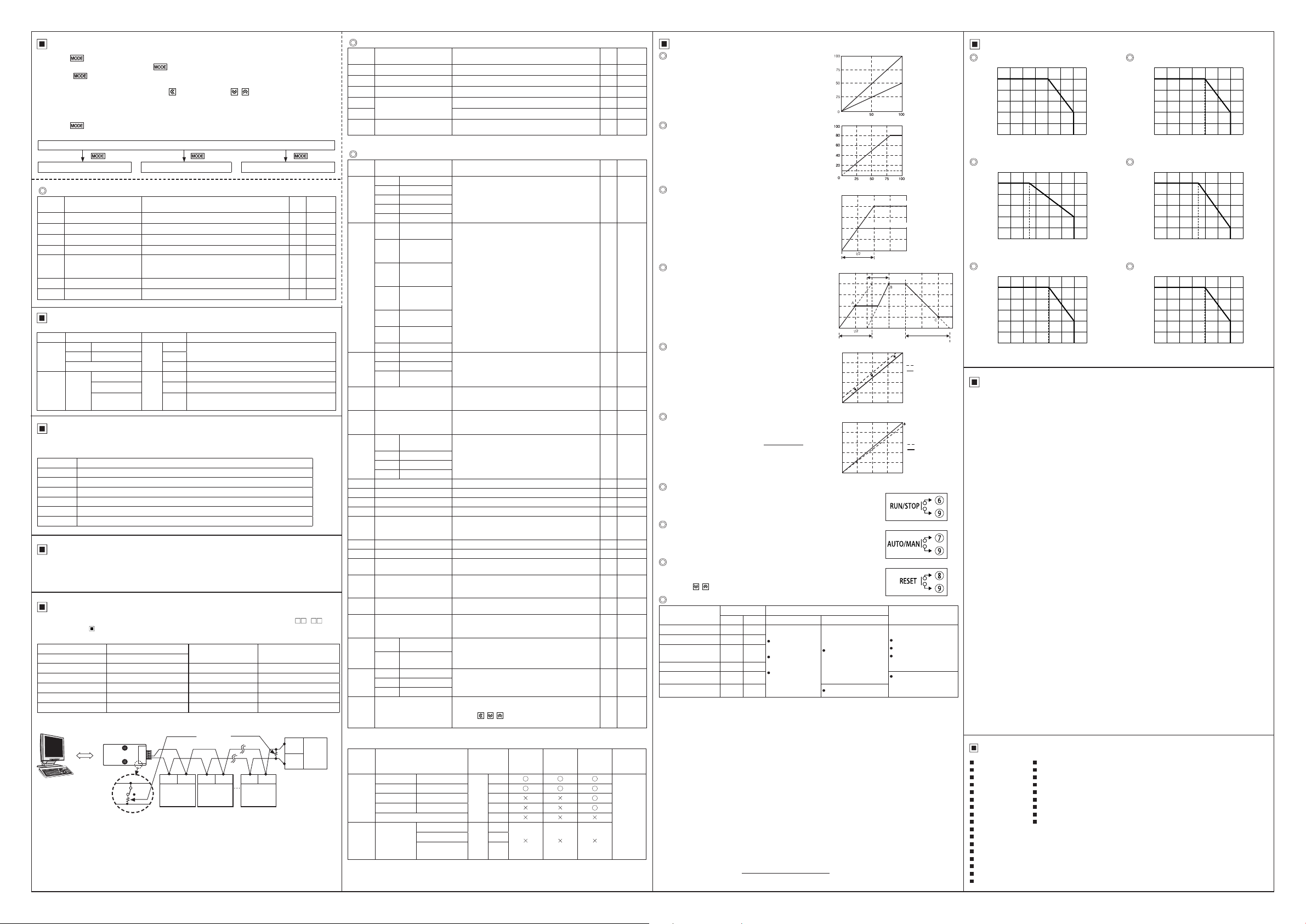

Parameter Group

~

※

Hold the key in RUN mode to enter into parameter group.

~

※

In parameter setting group, press the key to move to other parameter in the group.

※

Press the key once after changing the setting value, to save the setting value and move to the

~

next parameter.

※

When entering to the parameter, press the key to move digit, , keys to change the setting

value.

※

If there is no key input for 30 sec while setting SV or the parameters, the new settings are ignored, and

the unit will return to RUN mode with previous settings.

Hold the key for 3 sec to save the setting value and return to RUN mode after changing the

※

~

setting value.

~

I

Monitoring group Parameter 1 group [

:

~

~

RUN mode

I~

I I I I

~@§]

2 sec 4 sec

] Parameter 2 group [

PA1

I

~

PA2

]

Monitoring group

Display Measuring range Description Unit

0 to 100 Displays the present control input as percentage. %

IN

※

1

0 to rated voltage range Displays the present load voltage. V

L V

※

1

0 to rated current range Displays the present load current. A

L A

※

1

0 to rated power range Displays the present load power. kW

L W

※

1

0 to 100

L R

0 to 100 Displays the present temperature of heatsink.

TMP

50, 60 Displays the present frequency of power supply. Hz

FRQ

Displays the present resistance as percentage

compared to the set resistance of full load auto

recognition.

Factory

default

-

-

-

-

%

-

-

℃

-

Load Output Formula

Type Input Display Formula

Current DC4-20mA

Auto

control

Voltage 1-5VDC

(AUTO)

RS485 communication

Output

limit

Inside adjuster

Outside adjuster

Inside/outside

adjuster

Manual

control

(MAN)

Comprehensive Device Management Program [DAQMaster]

DAQMaster is a comprehensive device management software for setting parameters and

monitoring processes.

Item Minimum specications

System BM PC compatible computer with Pentium Ⅲ or above

Operations Windows 98/NT/XP/Vista/7/8/10

Memory 256MB+

Hard disk 1GB+ of available hard disk space

VGA Resolution: 1024×768 or higher

Others RS232C serial port (9-pin), USB port

User Manual for Communication

For the detail information and instructions, please refer to user manual for communication, and be sure

to follow cautions written in the technical descriptions (catalog, homepage).

RS485 Communication Output

※

Applicable for models with RS485 communication output through option output (SPR1Please refer to '

Ordering Information'.

1. Communication Specifications

Comm. protocol Modbus RTU

Connection method RS485

Application standard

Compliance with EIA RS485 Comm. response time

Max. connections 31 units (address: 1 to 99) Start bit 1-bit (xed)

Synchronization method

Asynchronous Data bit 8-bit (xed)

Comm. method Two-wire half duplex Parity bit None, Even, Odd

Comm. distance Max. 800m Stop bit 1-bit, 2-bit

2. Application of system organization

RS232C/

USB/Wi-Fi

I

Comm.

•=

Computer

※

t is recommended to use Autonics communication converter; SCM-WF48 (Wi-Fi to RS485 USB wireless

communication converter, sold separately), SCM-US48I (USB to RS485 converter, sold separately),

SCM-38I (RS232C to RS485 converter, sold separately). Please use twisted pair wire, which is suitable

for RS485 communication, for SCM-WF48, SCM-US48I and SCM-38I.

converter

RS485

:~\~

,---i,,

B(-)

I

I

ON OFF

\

tJ;

...

____

A(+)

'

...

INT

MAN

,

420

Load output [%]

= Control input [%] × Output slope (

1 5

COM

Load output [%] = RS485 [%]

I R

Load output [%] = Inside adjuster [%]

E R

Load output [%] = Outside adjuster [%]

Load output [%]

E I

= Inside adjuster [%] × Outside adjuster [%]

Comm. speed

2400, 4800, 9600, 19200,

38400 bps

5 to 99ms (default: 20ms)

Terminating

resistance

(100 to 120Ω)

I I

A(+)

DEVICE

RS485

#1

A(+) A(+)B(-) B(-) B(-)

...

RS485

DEVICE

#2

RS485

DEVICE

#30

) [%]

SLP

T

□□ □□

B(-)

RS485

DEVICE

#31

A(+)

).

(Q)

Parameter 1 group [

Display Setting range Description Unit

0 to 100 Set SOFT START time. sec

S T

0 to 100 Set SOFT UP time. sec

U T

0 to 100 Set SOFT DOWN time. sec

D T

L L

~

0 ≤

≤

L L

H L

※

SLP

(Q)

Parameter 2 group [

Display Setting range Description Unit

:

※

INT

C M

※

MAN

※

INB

※

SPN

DIS

※

OCV

※

OCT

※

OVV

※

OVT

※

F L

※

HBV

※

ADR

※

BPS

※

PRT

※

STP

※

RwT

※

CmW

LOC

INI NO

※

Displayed only for feedback control models.

1:

※

2: Set the below parameters available depends on the control input.

Type Input Display

I

H L

2

0 to 100

DC4-20mA

420

1-5VDC

1 5

2

5-12VDC

512

ON/OFF contact

ONF

RS485 comm.

COM

Phase control

PA

- Normal

Phase control

※

1

- Constant voltage

V F

feedback

Phase control

※

1

- Constant current

C F

feedback

Phase control

※

1

- Constant power

W

F

feedback

Cycle control

F

C

- Fixed cycle

Cycle control

V C

- Variable cycle

ON/OFF control

ONF

Inside adjuster

I R

Outside adjuster

E R

2

Inside/Outside

E I

adjuster

2

-99 to 99

2

-99 to 99

Resistance and

IN

input

※

1

Load voltage

L V

※

1

Load current

L A

※

1

Load power

L W

1

0 to 120 Set the overcurrent alarm value. %

1

0 to 100 Set the overcurrent alarm delay time. sec

1

0 to 120 Set the overvoltage alarm value. %

1

0 to 100 Set the overvoltage alarm delay time. sec

1

/

OFF

ON

1

/ 10 to 100 Set the heater break alarm value. %

OFF

3

01 to 99 Assign the unique address when communicating.

3

24, 48, 96, 192, 384

3

/

/

NON

EVE

ODD

3

1, 2

3

5 to 99

Enable

EnA

3

Disable

DsA

Unlock

OFF

lock

lock

LC2 PA2

/

YES

Current DC4-20mA

Voltage 1-5VDC

Auto

control

pulse voltage 5-12VDC

(AUTO)

No-voltage ON/OFF contact

RS485 communication

Manual

control

Output limit

(MAN)

※

3: Displayed only for models with RS485 comm. output.

]

PA1

≤ 100

Set the output low-limit value. %

Set the output high-limit value. %

In case of auto control (AUTO), set the output slop

limit proportional to control input for limit load power.

]

PA2

Set the control input specication.

Set the control method.

In case of manual control (MAN), set the output limit

method.

Set the compensated input value for the offset

between the actual input value and the measured

input value.

Set the compensated input slope value between the

actual input value 100% and the measured input value

100%.

Set the desired value to be displayed at the front

display part.

resistance value recognized automatically as the initial

set when the function is ON.

Set the speed of data transmission. Multiply by 100 to

read the set value. (e.g.: 96=9600bps)

A parity bit is a data communication method that adds

an additional bit to each character in transmitted data

as an indicator used to verify data loss and corruption.

Set the number of bits to mark the end of a transmitted

data string.

Set standby time to prevent communication errors

when communicating with a slow master device (PC,

PLC, etc.).

Enable or disable the setting of parameters stored in

memory via communication from the master system

(PC, PLC, etc.). Reading the set value in parameter is

always possible.

The parameter group settings can not be changed

when the function is ON.

If set the parameter to YES, reset all parameters to

default.

Hold the

reset parameter.

Inside adjuster

Outside adjuster

Inside/outside

adjuster

t executes 100% control output for 3 sec and the load

, keys for 5 sec, to enter parameter

~~§I

INT

MAN

Input

correction

[

INB

420

1 5

512

ONF

COM

I R

f---

E R

~

E I

Input slope

correction

]

[

SPN

0 0

0 0

X X

X X

X X

X X

Functions

Factory

default

3

3

3

0

100

%

100

Output limit (OUT ADJ)

This function will be [Control input (%) × OUT ADJ (%) =

Output] and it controls the power supplied into the load.

Although control input is 100% (5V or 20mA), the output

is the 50% which is proportioned with OUT ADJ.

※

This function can not be used for ON/OFF control method.

Output high limit/low limit value [

This function is to limit output range to protect load.

H-L/L-L

[%]

Output

]

[%]

Output

Control input [%]

' ' '

Setting value 100%

Setting value 50%

Output high limit value [H-]

80%

:Lldf:})_i:

20 -

Factory

default

SOFT START [

-

-

-

%

%

When the power is supplied, this function is able to

420

protect the load when it controls load (molybdan,

white gold, infrared lamp) with inrush current or the

width of rising temperature in big (SV is big).

SOFT START set time (T) is the required time that

output reaches to 100%, and it is differentiated by

OUT ADJ set value.

※

This function can not be used for ON/OFF control method.

SOFT UP/DOWN [

Unlike SOFT START which operates only once at

supplying power, this function protects load from the

PA

inrush current in the RUN mode. When reached to

the target output value, operation stops.

※

This function can not be used for ON/OFF control method.

Input correction [

It compensates the offset between actual input value

and measured input value.

I R

E.g.) When input monitoring value is 5% at 4mA in

DC4-20mA control input, setting

)0

)0

calibrates the input monitoring value to 0%.

Input slope correction [

It compensates the gain of the measured 100% input

for actual 100% input value.

Calibrated monitoring value=Monitoring value+

-

-

-

bps

-

bit

E.g.) When the input monitoring value is 99% at 4mA in

IN

120

5

120

5

OFF

10

01

96

NON

2

DC4-20mA control input,

the input monitoring value to 100%.

RUN/STOP switching

RUN/STOP status of the power controller can be switched with the external

RUN/STOP contact.

In the RUN mode, the operation indicator on the front turns on.

AUTO/MANUAL selection

Operation mode (auto control/manual control) of the power controller can be

selected with the external AUTO/MAN contact.

In the manual control mode, the manual control indicator on the front turns on.

RESET

In the event of system anomalies and alarms, RESET input restarts the

power controller.(Parameters are not initialized.)

Or, hold the

Alarm

Type

ms

20

SCR error alarm

Overcurrent alarm

f-----------+---+------1

-

-

-

Output

slope

]

[

SLP

]

Monitoring

value

[ IN]

0

0

0

The last

control

0

input

X

value

0 to 100%

X

Heatsink overheat

EnA

alarm

Overvoltage alarm

f-----------+---+------io

Fuse break alarm

OFFLC1 PA1

Heater break alarm

※

1: This is only for feedback control models.

※

NO

When multiple alarms occur at the same time, the highest priority error message will be displayed

based on priority.

1) SCR error alarm

Even though output is 0%, if the current of 10% or more of the rated load current ows for over 3 sec

continuously, SCR error alarm occurs.

2) Overcurrent alarm

This function protects the load from overcurrent.

If the current ows over the overcurrent alarm setting value [

overcurrent alarm occurs.

3) Heatsink overheat alarm

When the temperature of a heatsink is over 85℃, heatsink overheat alarm occurs.

4) Overvoltage alarm

This function protects the load from overvoltage.

If the current ows over the overvoltage alarm setting value [

overvoltage alarm occurs.

5) Heater break alarm

Comparing the full load resistance value and the current load resistance value, if the current load

resistivity is maintained under the setting value [

occurs. This alarm operates when control output is over 10% and load current is over 10% of the rated

current. Output does not stop and operates normally.

Current load resistivity(%) =

S-T

]

U-T/D-T

INB

]

setting SP to calibrates

, keys

for 2 sec, to operates RESET.

Display

Error

※

1

※

※

Priority

SCR

1

O C

TEM

1

O V

FUS

※

1

H B

Current load resistance value

]

A SOFT START function nished.

B SOFT UP function nished.

C SOFT DOWN function nished.

INB

to 5

SPN

]

Monitoring value

Operation

Alarm Output

1

2

.

4

5

3

6

Full load resistance value

×

SP

SP

100-

Error messege

ashes.

Alarm indicator

(ALM) ashes.

Alarm output

turns ON

HBV

] for over 3 sec continuously, heater break alarm

Output stops.

Continues operation

---1---r--

~

-~----+---------

0 25 50

[%]

When output applied to load is 100%,

100

Output

When output app ied to load is 50%,

50

0

SOFT START set time

[%]

100

Output

50

0

SOFT START set time

100

[%]

60

40

Measured input signal

0

Actual input signal [%]

100

[%]

60

40

Measured input signal

Actual input signal [%]

(SCR OFF)

] and setting delay time [

OCV

] and setting delay time [

OVV

100

×

Output low limit value [-]

75

100

Control input [%]

Time

SOFT UP set ime

Time

1008075

502025

1008075

5020250

RUN/STOP

I

ON/OFF

AUTO/MANI~

I

ON/OFF

RESET

ON

I

Clear alarm

Re-supply the power

RESET

Switch to STOP mode

Automatically cleared

when returning within

the setting range

10%

SOFT DOWN set time

Actual input signal (%)

Input corrected signal (%)

Actual input signal (%)

Input corrected signal (%)

I~®

<4®

(j) I

<4®

I~®

<4®

],

OCT

],

OVT

I

I

Derating Curve

Rated load current 25A

25

20

15

Load current [A]

10

5

0010 20 30 40 50 60 70

I'\.

\

Ambient temperature [℃]

Rated load current 50A

50

40

30

Load current [A]

20

10

0010

20 30

40 50 60 70

25

Ambient temperature [℃]

Rated load current 100A

100

80

60

Load current [A]

40

20

0010 20 30 40 50 60 70

Cautions during Use

\.

\

Ambient temperature [℃]

Rated load current 35A

35

28

21

Load current [A]

14

7

0010 20 30 40 50 60 70

I'\.

Ambient temperature [℃]

Rated load current 70A

70

56

42

Load current [A]

28

14

0010 20

I\.

30 40

50 60 70

35

Ambient temperature [℃]

Rated load current 150A

150

120

90

Load current [A]

60

30

0010 20 30 40 50 60 70

I\.

Ambient temperature [℃]

\

\

1. Follow instructions in 'Cautions during Use'. Otherwise, it may cause unexpected accidents.

2. Use the product, after 3 sec of supplying power.

3. Before use, set the mode and function according to the specification. Especially, be cautious that the

product does not operate when OUT ADJ. is set to 0%. Since changing the mode/parameter during

operation may result in malfunction, set the mode and function after disconnecting load output.

4. Re-supply the power to the unit after the unit is discharged completely.

Failure to follow this instruction may result in malfunction.

5. To ensure the reliability of the product, install the product on the panel or metal surface vertically to

the ground.

6. Install the unit in the well ventilated place.

7. While supplying power to the load or right after turning off the power of the load, do not touch

the body and heat sink. Failure to follow this instruction may result in a burn due to the high

temperature.

8. Install a power switch or circuit breaker in the easily accessible place for supplying or disconnecting

the power.

9. Do not wire to terminals which are not used.

10. Since inter element can be damaged when using with coil load, inductive load, etc., the inrush

current must be under the rated load current.

11. Do not use near the equipment which generates strong magnetic force or high frequency noise.

12. This unit may be used in the following environments.

①

Indoors (in the environment condition rated in 'Specifications')

②

Altitude max. 2,000m

③

Pollution degree 2

④

Installation category III

Major Products

00

Photoelectric Sensors Temperature Controllers

Fiber Optic Sensors Temperature/Humidity Transducers

Door Sensors SSRs/Power Controllers

Door Side Sensors Counters

Area Sensors Timers

Proximity Sensors Panel Meters

Pressure Sensors Tachometer/Pulse (Rate) Meters

Rotary Encoders Display Units

Connector/Sockets Sensor Controllers

Switching Mode Power Supplies

Control Switches/Lamps/Buzzers

I/O Terminal Blocks & Cables

Stepper Motors/Drivers/Motion Controllers

Graphic/Logic Panels

Field Network Devices

Laser Marking System (Fiber, CO₂, Nd: YAG)

Laser Welding/Cutting System

■

■

■

■

■

■

■

■

■

DRW171280AC

Loading...

Loading...