Autonics ERB Series Catalog Page

ERB Series

Flexible coupling

Features

● Zero (0) Backlash

● High torsional stiness by high strength aluminum alloy

AL 7075-T6

● High corrosion resistance with alumite treated surface

● Two connection types (clamp type, set screw type)

Please read “Safety Considerations”

in the instruction manual before using.

Applications

● Stepper motor, Servo motor, Precision motor, high-precision encoder, dynamometer driver,

high speed/precision position control system

Ordering Information

ERB d1/d

A 19 C- -

Type

Item

Connection type

External diameter

2

Bore diameters

Number/Number Bore diameters

S Set screw

C Clamp

Number External diameter (mm)

A Double beam (normal type)

ERB Radial beam type coupling

Specifications

Model ERB-A-19C-

Connection type Clamp Set screw Clamp Set screw

Max. revolutions 8000rpm 20000rpm 6000rpm 15000 rpm

Max. torque 1.2N·m (12.17kgf·cm) 3.0N·m (30.42kgf·cm)

Rated torque 0.6N·m (6.08kgf·cm) 1.5N·m (15.21kgf·cm)

Mounting bolt

(mounting torque)

Torsional stiness 140N·m/rad 240N·m/rad

Moment of inertia 6.4×10

Angular

Max.

allowable

misalignment

Standard bore diameter

(tolerance h7)

Min. allowable bore

diameter

Max. allowable bore

diameter

Material Aluminum (AL 7075-T6), Alumite surface

Weight Approx. 14 9g (approx. 14.4g) Approx. 37.3g (approx. 36.7g)

misalignment

Parallel

misalignment

End-play ±0.3mm ±0.4mm

M2.5 (1N·m) M3 (0.7N·m) M3 (0.7N·m) M4 (1.7N·m)

2.5°

0.15mm 0.2mm

Ø4, Ø5, Ø6mm Ø6, Ø8mm

Ø4mm Ø5mm

Ø8mm Ø12mm

□ □

2

-7

kg·m

ERB-A-19S- ERB-A-26C- ERB-A-26S-

3.4×10-6kg·m

□ □

2

H-102

Autonics

Flexible Coupling

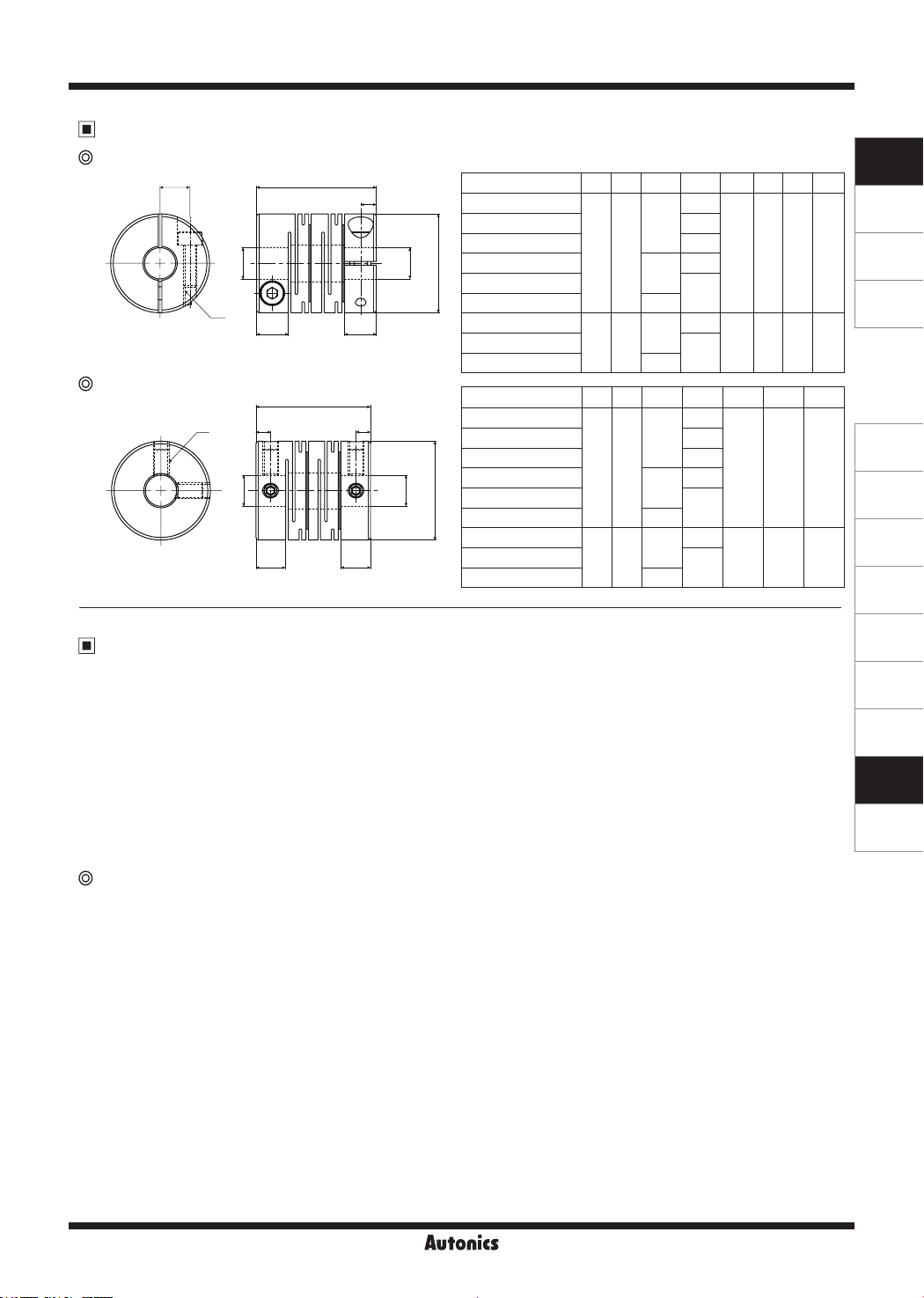

Dimensions

Clamp type

K

2

ØD

M

L

B

1

ØA

ØD

C

C

Set screw type

L

M

B

2

ØD

C C

B

1

ØA

ØD

Proper Usage

The flexible coupling is available in the places where

v bration or misalignment occurs. It must be used within the

rated allowable misalignment range.

When using the flexible coupling over the rated

misalignment range, it may cause vibration or shorten the

life cycle.

When there are more than two misalignments, each

allowable value is 50%.

It is recommended to use the flexible coupling below 1/3 of

the allowable misalignment value to extend the life of the

coupling and the applied equipment.

(unit: mm)

Model ØA L ØD1ØD2M C B K

ERB-A-19C-04/04

ERB-A-19C-04/05

ERB-A-19C-04/06

ERB-A-19C-05/05

19 23

ERB-A-19C-05/06

ERB-A-19C-06/06

ERB-A-26C-06/06

26 31.4

ERB-A-26C-08/08

1---

Model ØA L ØD1ØD2M C B

ERB-A-19S-04/04

ERB-A-19S-04/05

ERB-A-19S-04/06

ERB-A-19S-05/05

19 22

ERB-A-19S-05/06

ERB-A-19S-06/06

ERB-A-26S-06/06

26 30

ERB-A-26S-08/08

1---

4

0

5

0

6

0

6

0

8

0

0.018

4

0

0.018

0.018

5

0

0.018

6

0

M2.5 6.1 3 5.75

0.018

5

0

0.018

1---

0.018

6

0

0.018

0.018

6

0

0.018

0.018

0.018

4

0

0.018

5

0

0.018

6

0

0.018

6

0

0.018

8

0

0.018

8

0

0 018

4

0

0 018

5

0

0 018

6

0

0 018

5

0

1---

0 018

6

0

0 018

6

0

0 018

8

0

M3 7.4 3.7 8.55ERB-A-26C-06/08

M3 5.7 2.8

M4 6.8 3.4ERB-A-26S-06/08

● This product is for transferring rotation power. If there is a

risk of human contact, attach the caution label or install a

safety cover in a prominent position.

● Rated torque is available to transfer the power

continuously. Check the rated capacity before using this

product.

● Max. torque is available to transfer the power in a

moment. Check the rated capacity before using this

product.

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(A)

Photoelectric

Sensors

(B)

Fiber Optic

Sensors

(C)

LiDAR

(D)

Door/Area

Sensors

(E)

Vision

Sensors

(F)

Proximity

Sensors

(G)

Pressure

Sensors

(H)

Rotary

Encoders

(I)

Connectors/

Connector Cables/

Sensor Distribution

Boxes/ Sockets

Caution for using

● Couplings are for transferring rotation angle and power

between shafts. Before using this, make sure to check

the purpose and appropriacy.

● This product uses high strength aluminum alloy and

has spring power as Radial beam type. However, if the

coupling is dropped, hit or applied excessive power, it

may be damaged or transformed.

● If the coupling is applied over the rated misalignment, or

the tolerance of the shaft is over the allowable value, it

may cause plastic deformation, damage of the product or

shorten the life cycle.

● When it occurs abnormal sound during operating the

equipment with this coupling, stop the operation and

remove the cause such as misalignment, unscrewing, or

rotation hazard.

● If this coupling is applied to the equipment which has big

fluctuation of load, shaft may be loose by unscrewing.

Tighten the screw securely and prevent from unscrewing.

Autonics

H-103

Loading...

Loading...