Programmable Counter/Timer

CT Series

User Manual

CT Series

CT Series

내

ii © Copyright Reserved Autonics Co., Ltd.

Preface

Thank you for purchasing Autonics product.

Please familiarize yourself with the information contained in the Safety Precautions section

before using this product.

This user manual contains information about the product and its proper use, and should be kept

in a place where it will be easy to access.

나 Preface

© Copyright Reserved Autonics Co., Ltd. iii

User Manual Guide 나

User Manual Guide

Please familiarize yourself with the informati on i n this manual before using the product.

This manual provides detailed information on the product's features. It does not offer any

guarantee concerning matters beyond the scope of t his manual.

This manual may not be edited or reproduced in eith er part or whole without permission.

A user manual is not provided as part of the product package. Visit our web site

(www.aut onics.com) to download a copy.

The manual's content may vary depending on changes to the product's software and other

unforeseen developments within Autonics, and is subject t o change without prior notice.

Upgrade notice is provided through out homepage.

We contrived to describe this manual more easily and correctly. However, if there are any

corrections or questions, please notify us these on our homepage.

iv © Copyright Reser ved Autonics Co., Ltd.

나 User Manual Symbols

User Manual Symbols

Symbol Description

※1

Supplementary information for a particular feature.

Failure to follow instructions can result in serious injury or death.

Failure to follow instructions can lead to a minor injury or product damage.

An example of the concerned feature's use.

Annotation mark.

© Copyright Reserved Autonics Co., Ltd. v

Safety Precautions 나

Safety Precautions

Following these safety precautions will ensure the safe and proper use of the product and

help prevent accidents, as well as minimizing possible hazards.

Safety precautions are categorized as Warnings and Cautions, as defined below:

Warning

Caution

Failure to follow these instructions may result in serious

injury or death.

Failure to follow these instructions may result in personal

injury or product damage.

Fail-safe device must be installed when using the unit with machinery that may cause

serious injury or substantial economic loss. (e.g. nuclear power control, medical equipment,

ships, vehicles, railways, aircraft, combustion apparatus, safety equipment, crime/disaster

prevention devices, etc.)

Failure to follow this instruction may result in personal injury, fire, or economic loss.

The unit must be installed on a device panel before use.

Failure to follow this instruction may result in elect ric shock.

Do not connect, repair, or inspect the unit while connected to a power source.

Failure to follow this instruction may result in electric shock.

Do not disassemble or modify the unit. Please cont act us if necessary.

Failure to follow this instruction may result in electric shock or fire.

Do not use the unit outdoors.

Failure to follow this instruction may result in shortening the life cycle of the unit, or electric

shock.

When connecting the power input and relay out put cables, use AWG20 (0.50mm

and make sure to tighten the terminal screw bolt ab ove 0.74N·m to 0.90N·m.

Failure to follow this instruction may result in fi re due to contact failure.

2

) cables

Use the unit within the rated specifications.

Failure to follow this instruction may result in shortening the life cycle of the unit, or fire.

Do not use loads beyond the rated switching capa cit y of the relay contact.

Failure to follow this instruction may result in insulat ion failure, contact melt, contact failure,

relay broken, or fire.

Do not use water or oil-based detergent w hen clean ing the unit. Use dry cloth to clean the un it.

Failure to follow this instruction may result in electric shock or fire.

Do not use the unit where flammable or explosive gas, humidity, direct sunlight, radiant heat,

vibration, or impact may be present.

Failure to follow this instruction may result in fi re or explosion.

Keep dust and wire residue from flowing into the unit.

Failure to follow this instruction may result in fi re or pr oduct damage.

The specifications and dimensions of user manual are subject to change and some

models may be discontinued without notice.

vi © Copyright Reserved Autonics Co., Ltd.

나 Cautions During Use

Cautions During Use

Power ON/OFF

The inner circuit voltage rises within 100ms after supplying the power to the unit.

The input is unavailable at this period. Be sure that the i nner circuit voltage drops

within 500ms after turning OFF the power.

In case of 24VAC / 24-48VDC model, power supply should be insulated and limited

voltage/current or Class 2 power supply device.

Input signal line

① Shorten the cable from the sens or t o the unit.

② Use shield cable when input cable is longer .

③ Wire the input signal line separat ely from power line.

Input logic selection

Before selecting input logic, must cut off the power to counter/timer. Select the input logic

following the instruction.

Contact counting input (counter operation)

If counting speed for counter is high speed mode (1k, 5k, 10kcps) and counting input is

contact, it may cause input signal error by chatt eri ng of contact switching.

Set counting speed as low speed mode (1cps or 30cps) for contact counting input.

T esting dielectric voltage or insulation resistance when the unit is installed at control panel

① Isolate the unit from the circuit of control panel.

② Short all terminals of the unit .

Do not use the unit in the following environments.

① Environments with high v i brat ion or shock.

② Environments with strong alk al i or strong acid materials

③ Environments with exposure to direct sunlight

④ Near machinery which produc e st rong magnetic force or electric noise

This product may be used in the following environments.

① Indoors

② Max. altitude: 2,000m

③ Pollution degree 2

④ Installation category II

Failure to follow these instructions may result in product damage.

© Copyright Reserved Autonics Co., Ltd. vii

Cautions During Use 나

viii © Copyright Reserved Autonics Co., Ltd.

나 Table of Contents

Table of Contents

Preface .......................................................................................................................... iii

User Manual Guide ....................................................................................................... iv

User Manual Symbols .................................................................................................... v

Safety Precautions ........................................................................................................ vi

Cautions During Use ..................................................................................................... vii

Table of Contents .......................................................................................................... ix

1 Product Overview ..................................................................................... 11

1.1 Features .......................................................................................................... 11

1.2 Components and Accessories ......................................................................... 11

1.2.1 Components ............................................................................................... 11

1.2.2 Sold separately .......................................................................................... 12

1.3 Ordering information ........................................................................................ 13

1.4 Part description ................................................................................................ 14

1.4.1 CTS Series ................................................................................................. 14

1.4.2 CTY Series ................................................................................................. 14

1.4.3 CTM Series ................................................................................................ 14

2 Specifications ............................................................................................ 17

3 Communication Specification .................................................................. 19

4 Dimensions ................................................................................................ 21

4.1 CTS Series ...................................................................................................... 21

4.2 CTY Series ...................................................................................................... 21

4.3 CTM Series ...................................................................................................... 21

4.4 Panel cut-out dimensions ................................................................................ 22

4.4.1 CTS Series ................................................................................................. 22

4.4.2 CTY Series ................................................................................................. 22

4.4.3 CTM Series ................................................................................................ 22

4.5 Bracket ............................................................................................................ 23

4.5.1 CTS Series ................................................................................................. 23

4.5.2 CTY Series ................................................................................................. 23

4.5.3 CTM Series ................................................................................................ 23

5 Guide For Connection .............................................................................. 25

5.1 Connections ..................................................................................................... 25

5.1.1 CTS Series ................................................................................................. 25

5.1.2 CTY Series ................................................................................................. 27

5.1.3 CTM Series ................................................................................................ 29

5.2 Input and Output connection ............................................................................ 32

5.2.1 Input logic selection [no-voltage(NPN)/voltage(PNP)] ............................. 32

5.2.2 Input connection ......................................................................................... 34

5.2.3 Output connection ...................................................................................... 35

© Copyright Reserved Autonics Co., Ltd. ix

Table of Contents 나

6 Basic Operations (Counter/Timer/Communication) ............................ 37

6.1 Operations and functions ................................................................................. 37

6.1.1 Setting value change mode (Counter/Timer) ............................................. 37

6.1.2 Setting value check mode .......................................................................... 38

6.1.3 Switching display function in preset indicator ............................................. 38

6.1.4 RESET ........................................................................................................ 38

6.2 BATCH counter (only for CT6M-1P□□/CT6M-2P□□ model) ................... 38

6.2.1 BATCH counter operation .......................................................................... 39

6.2.2 BATCH counting operation ........................................................................ 39

6.2.3 BATCH output operation ............................................................................ 39

6.2.4 BATCH RESET input ................................................................................. 39

6.2.5 Example of BATCH counter ....................................................................... 40

6.3 Setting mode ................................................................................................... 41

7 Counter Mode ............................................................................................ 43

7.1 Parameter Setting ............................................................................................ 43

7.2 Input mode ...................................................................................................... 45

7.3 Output mode .................................................................................................... 48

7.4 Counter operation for indicator model ............................................................. 51

7.5 Output operation for other conditions .............................................................. 52

7.5.1 Start point ................................................................................................... 52

7.5.2 When start point value is larger than setting val ue,

(UP, UP-1, UP-2, UD-A, UD-B, UD-C mode) ........................................... 52

7.5.3 When PRESET 1 is larger or equal than PRESET 2 at at down mode ..... 53

7.6 Prescale .......................................................................................................... 54

8 Timer Mode ................................................................................................ 55

8.1 Parameter setting ............................................................................................ 55

8.2 Output mode .................................................................................................... 57

8.3 Timer operation for indicator model ................................................................. 65

8.4 Timer ‘0’ Time Setting ...................................................................................... 68

8.4.1 Available output mode to set ‘0’ time setting .............................................. 68

8.4.2 Operation by each output mode (‘0’ time setting) ...................................... 68

9 Factory Default .......................................................................................... 75

9.1 Common .......................................................................................................... 75

9.2 Counter ............................................................................................................ 75

9.3 Timer ............................................................................................................... 76

x © Copyright Reserved Autonics Co., Ltd.

나 1 Product Overview

1 Product Overview

1.1 Features

Prescale value setting range

- 6-digit model: 0.00001 to 99999.9/ 4-digit model: 0.001 to 999.9

Communication function supported (communication model): RS485 (Modbus RTU)

One-shot output time setting range: 0.01 sec to 99.99 sec by setting per 10ms

[Counter]

9 input modes/ 11 output modes

BATCH counter, Count start point (counting initial value) setting function

[Timer]

13 output modes

Various time setting range

- 6-digit model: 0.001 sec to 99999.9 hour/

'0' time setting function

Selectable timer memory retention function for indicator model

4-digit model: 0.001 sec to 9999 hour

1.2 Components and Accessories

1.2.1 Components

Make sure all of the above components are included with your product package before use.

If a component is missing or damaged, please conta ct Autonics or your distributor.

© Copyright Reserved Autonics Co., Ltd. 11

1 Product Overview

1.2.2 Sold separately

(1) Communication converter

SCM-38I

(RS232C to RS485 converter)

(2) Display unit (DS/DA-T Series)

(RS485 communication input type display unit)

SCM-US48I

(USB to RS485 converter)

Connect RS485 communication input type display unit (DS/DA-T Series) and RS485

communication output model of CT Series, the display unit displays present val ue of the device

without PC/PLC.

12 © Copyright Reserved Autonics Co., Ltd.

나 1 Product Overview

6 M

4

②

③

⑤

⑥

Item

Description

1.3 Ordering information

CT

- 2P

T

①

① Item

② Display digit

③ Size

④ Output

⑤ Power supply

⑥ Communication

④

CT Counter/Timer

4 9999 (4-digit)

6 999999 (6-digit)

S DIN W48 × H48mm

Y DIN W72 × H36mm

M DIN W72 × H72mm

1P 1-stage preset

2P 2-stage preset

I※1

2 24VAC 50/60Hz, 24-48VDC

4 100-240VAC 50/60Hz

No-mark None

T RS485 communication output

Indicator

※1: CT4S model does not support indicator type.

© Copyright Reserved Autonics Co., Ltd. 13

1 Product Overview

1.4 Part description

1.4.1 CTS Series

1.4.2 CTY Series

1.4.3 CTM Series

14 © Copyright Reserved Autonics Co., Ltd.

나 1 Product Overview

Model

Changed

Note

① Counting value display component (red)

RUN mode: Displays counting value for counter operation or time progress value for timer

operation.

Setting mode: Displays parameter.

② Setting value display component (green)

RUN mode: Displays setting value.

Setting mode: Displays parameter setting value.

③ Key lock indicator (LOCK): Turns ON for key lock setting.

④ Counter indicator (CNT): Turns ON for counter operation.

⑤ Timer indicator (TMR): Flashes (progressing time) or Turns ON (stoping time) for timer

operation.

⑥ Setting value checking and changing indicator (PRESET1, PRESET2)

: Turns ON when checking and changing setting value.

⑦ Output indicator (OUT1, OUT2): Turns ON for the dedicated control output ON.

⑧ key

RUN mode: Press the key to reset the counting value.

BATCH counter mode (CTM Series)

: Press the

⑨ key

RUN mode: Enters parameter setting mode or communication setting mode.

Setting mode: Saves setting value and return to RUN mode.

⑩

⑪ key

⑫ BATCH output indicator (BA.O) (red)

⑬ BATCH setting value checking and changing indicator (BA.S) (green)

, ,

- key

RUN mode: Enters setting value change mode.

Setting value change mode: Moves setting value digits.

- key

Setting value change mode, Setting mode: Changes setting value.

Setting value check mode: Checks setting value of the previous parameter.

- key

RUN mode: Enters setting value check mode.

Setting value change mode, Setting mode: Changes setting value.

Setting value check mode: Check setting value of the next parameter.

RUN mode: Enters BATCH counter indication mode.

: Turns ON when BATCH output is ON.

: Turns ON when checking or changing BATCH setting value.

key to reset the batch counting value.

CT4S-1P

CT6S-1P

CT6Y-1P

CT6M-1P

CT6S-I

CT6Y-I

CT6M-I

PRESET2 → PRESET

OUT2 → OUT

PRESET2 → PRESET

No PRESET1, OUT1 LEDs

No PRESET1, OUT1, OUT2 LEDs

No PRESET1, OUT1, OUT2, BA.S, BA.O LEDs.

No key.

※ CT4S model does not support indicator type.

© Copyright Reserved Autonics Co., Ltd. 15

1 Product Overview

16 © Copyright Reserved Autonics Co., Ltd.

나 2 Specifications

Series

CTS

CTY

CTM

Counting value

6.5 × 10mm

4.5 × 10mm

4.2 × 9.5mm

6.6 × 13mm

counting speed

Decimal point

2 Specifications

1-stage preset

Model

Display digit 4-digit 6-digit 6-digit 6-digit

Display method 7-segment (counting value: red, setting value: green) LED method

Character

size

(W × H)

Power

supply

Permissible voltage range 90 to 110% of rated voltage

Power

consumption

Counter

Timer

Input method

One-shot output time 0.01s to 99.99s setting

2-stage preset

indicator

Setting value 4.5 × 8mm 3.5 × 7mm 3.5 × 7mm 5 × 9mm

AC voltage 100-240VAC 50/60Hz

AC/DC voltage 24VAC 50/60Hz, 24-48VDC

AC voltage Max. 12VA

AC/DC voltage AC: Max. 10VA, DC: Max. 8W

INA/INB max.

Counting range -999 to 9999 -99999 to 999999

Scale

Min. signal width RESET signal: Selectable 1ms/20ms

Time

range

Operation method Count up, Count down, Count up/down

Min. signal width INA, INH, RESET signal: Selectable 1ms/20ms

Repeat error

SET error

Voltage error

Temperature error

4-digit 9.999s, 99.99s, 999.9s, 9999s, 99m59s, 999.9m, 9999m, 99h59m, 9999h

6-digit

CT4S-1P□□ CT6S-1P□□ CT6Y-1P□□ CT6M-1P□□

CT4S-2P□□ CT6S-2P□□ CT6Y-2P□□ CT6M-2P□□

-

Selectable 1cps/30cps/1kcps/5kcps/10kcps

up to third digit

999.999s, 9999.99s, 99999.9s, 999999s, 99m59.99s, 999m59.9s, 9999m59s,

99999.9m, 999999m, 99h59m59s, 9999h59m, 99999.9h

In case of power ON start: Max. ±0.01% ±0.05s

In case of signal ON start: Max. ±0.01% ±0.03s

Selectable voltage input or no-voltage input

[Voltage input]-input impedance: 5.4kΩ, [H]: 5-30VDC, [L]: 0-2VDC

[No-voltage input]-short-circuit impedance: Max. 1kΩ, short-circuit residual

CT6S-I□□ CT6Y-I□□ CT6M-I□□

Decimal point up to fifth digit

INA, INHIBIT,

RESET, BATCH

RESET signal:

Selectable 1ms /

20ms

voltage: Max. 2VDC

© Copyright Reserved Autonics Co., Ltd. 17

2 Specifications

(1c): 1

Series CTS CTY CTM

Model

1-stage preset

2-stage presert

Indicator

CT4S-1P□□

CT4S-2P□□

-

CT6S-1P□□ CT6Y-1P□□ CT6M-1P□□

CT6S-2P□□ CT6Y-2P□□ CT6M-2P□□

CT6S-I□□ CT6Y-I□□ CT6M-I□□

Standard Comm. Standard Comm. Standard Comm.

1-stage

SPDT(1c): 1 SPDT(1c) : 1 SPDT(1c) : 1

SPST

Contact

(Relay)

Control

output

Solid

state

(NPN

open

collector)

Type

Capacity

Type

Capacity

External power supply

2-stage

1-stage

2-stage

SPST(1a): 2

250VAC 5A resistive load

1

-

Max. 30VDC, 100mA

Max. 12VDC ±10%, 100mA

(1a): 1,

SPDT

250VAC 3A

resistive load

1

SPST

(1a): 2

1 2

-

SPST(1a): 1,

SPDT(1c): 1

250VAC 5A

resistive load

3

2

Memory retention Approx. 10 years (non-volatile memory)

Insulation resistance

Over 100MΩ (at 500VDC megger)

Dielectric strength 2,000VAC 50/60Hz for 1 min

Noise

immunity

Vibration

AC voltage

AC/DC voltage

Mechanical

Malfunction

Mechanical

Square-wave noise by noise simulator (pulse width 1µs) ±2kV

Square-wave noise by noise simulator (pulse width 1µs) ±500V

0.75mm amplitude at frequency of 10 to 55Hz (for 1 min) in each

X, Y, Z direction for 1 hour

0.5mm amplitude at frequency of 10 to 55Hz (for 1 min) in each X, Y, Z

direction for 10 minutes

300m/s² (approx. 30G) in each X, Y, Z direction for 3 times

Shock

Relay

life cycle

Malfunction

Mechanical Min. 10,000,000 operations

Malfunction Min. 100,000 operations

100m/s² (approx. 10G) in each X, Y, Z direction for 3 times

Protection structure Front part: IP65 (IEC standards)

Environ-

ment

Ambient temp.

Ambient humi. 35 to 85% RH, storage: 35 to 85% RH

-10 to 55℃, storage: -25 to 65℃

Approval

Weight※1

※

1: The weight includes packaging. The weight in parentheses is for unit only.

※

Environment resistance is rated at no freezing or condensation.

Approx. 212g

(approx. 159g)

Approx. 228g

(approx. 140g)

Approx. 322g

(approx. 252g)

18 © Copyright Reserved Autonics Co., Ltd.

나 3 Communication Specification

3 Communication Specification

Comm. protocol Modbus RTU (16bit CRC)

Connection type RS485

Application standard Compliance with EIA RS485

Max. connection 31 units (address: 1 to 127)

Synchronous method Asynchronous

Comm. type Two-wire half duplex (half duplex)

Comm. distance Max. 800m

Comm. speed 2400, 4800, 9600 (factory default), 19200, 38400bps

Comm. response time 5 to 99ms (factory default: 20ms)

Start bit 1-bit (fixed)

Data bit 8-bit (fixed)

Parity bit None (factory default), Even, Odd

Stop bit 1, 2-bit (factory default: 2bit)

It is recommended to use communication converter RS232C to RS485 (SCM-38I, sold

separately), USB to RS485 (SCM-US48I, sold separately). Communication cable should be

twisted pair cable for RS485 communication.

© Copyright Reserved Autonics Co., Ltd. 19

3 Communication Specification

20 © Copyright Reserved Autonics Co., Ltd.

4 Dimensions

4.1 CTS Series

4.2 CTY Series

나 4 Dimensions

(unit: mm)

4.3 CTM Series

© Copyright Reserved Autonics Co., Ltd. 21

4 Dimensions

4.4 Panel cut-out dimensions

(unit: mm)

4.4.1 CTS Series

4.4.2 CTY Series

4.4.3 CTM Series

22 © Copyright Reserved Autonics Co., Ltd.

4.5 Bracket

4.5.1 CTS Series

4.5.2 CTY Series

나 4 Dimensions

(unit: mm)

4.5.3 CTM Series

© Copyright Reserved Autonics Co., Ltd. 23

4 Dimensions

24 © Copyright Reserved Autonics Co., Ltd.

나 5 Guide For Connecti on

5 Guide For Connection

5.1 Connections

5.1.1 CTS Series

(1) CT□S-1P□

(2) CT□S-1P□T

(3) CT□S-2P□

© Copyright Reserved Autonics Co., Ltd. 25

5 Guide For Connection

(4) CT□S-2P□T

(5) CT6S-I□

(6) CT6S-I□T

Be sure that connection is varied by supporting RS485 communication.

※1: AC voltage: 100-240VAC 50/60Hz

AC/DC voltage: 24-48VDC, 24VAC 50/60Hz

※2: Counter operation: If INHIBIT sig nal is applied, count input will be prohibited.

Timer operation: If INHIBI T signal is applied, time progressing will stop.(HOLD)

26 © Copyright Reserved Autonics Co., Ltd.

나 5 Guide For Connecti on

5.1.2 CTY Series

(1) CT6Y-1P□

(2) CT6Y-1P□T

(3) CT6Y-2P□

© Copyright Reserved Autonics Co., Ltd. 27

5 Guide For Connection

(4) CT6Y-2P□T

(5) CT6Y-I□

(6) CT6Y-I□T

Be sure that connection is varied by supporting RS485 communication.

※1: AC voltage: 100-240VAC 50/60Hz

AC/DC voltage: 24-48VDC, 24VAC 50/60Hz

※2: Counter operation: If INHIBIT sig nal is applied, count input will be prohibited.

Timer operation: If INHIBIT signal is applied, time progressing will stop.(HO LD)

28 © Copyright Reserved Autonics Co., Ltd.

나 5 Guide For Connecti on

5.1.3 CTM Series

(1) CT6M-1P□

(2) CT6M-1P□T

© Copyright Reserved Autonics Co., Ltd. 29

5 Guide For Connection

(3) CT6M-2P□

(4) CT6M-2P□T

Be sure that connection is varied by supporting RS485 communication.

※1: AC voltage: 100-240VAC 50/60Hz

AC/DC voltage: 24-48VDC, 24VAC 50/60Hz

※2: Counter operation: If INHIBIT sig nal is applied, count input will be prohibited.

Timer operation: If INHIBIT signal is applied, time progressing will stop.(HO LD)

30 © Copyright Reserved Autonics Co., Ltd.

나 5 Guide For Connecti on

(5) CT6M-I□

(6) CT6M-I□T

Be sure that connection is varied by supporting RS485 communication.

※1: AC voltage: 100-240VAC 50/60Hz

AC/DC voltage: 24-48VDC, 24VAC 50/60Hz

※2: Counter operation: If INHIBIT signal is applied, count input will be prohibited.

Timer operation: If INHIBIT signal is applied, time progressing will stop.(HOLD)

© Copyright Reserved Autonics Co., Ltd. 31

5 Guide For Connection

5.2 Input and Output connectio n

5.2.1 Input logic selection [no-voltage(NPN)/voltage(PNP)]

1. The power must be cut OFF.

2. Squeeze toward ① and pull toward ② as the figure. (CTS/CTY Series)

3. Select input logic by using input logic switch (SW1 ) inside Counter/Timer.

4. Push a case in the opposite direction of ②.

5. Then supply the power to counter/timer.

32 © Copyright Reserved Autonics Co., Ltd.

나 5 Guide For Connecti on

(1) CTS Series

(2) CTY Series

(3) CTM Series

Turn OFF the power to select or change input logic (PNP/NPN).

© Copyright Reserved Autonics Co., Ltd. 33

5 Guide For Connection

5.2.2 Input connection

(1) No-voltage input (NPN)

Solid state input (standard sensor: NPN output type sensor)

Contact input

(2) Voltage input (PNP)

Solid state input (standard sensor: PNP output type sensor)

Contact input

※1: INA, INB/INH, RESET, INHIBIT, BATCH RESET input part

※2: For contact input, counting speed should be set 1cps or 30cps. (Counter)

34 © Copyright Reserved Autonics Co., Ltd.

나 5 Guide For Connecti on

5.2.3 Output connection

(1) Contact output

Select the load which capacity is not over contact cap acity.

(2) S olid state output

For solid state output, select load power and load not to be over (max. 30VDC, 100mA),

switching capacity.

Do not supply reverse polarity voltage.

※1: For using inductive load (relay, etc), connect surge absorber (diode, varistor, etc) at the both

ends of load.

© Copyright Reserved Autonics Co., Ltd. 35

5 Guide For Connection

36 © Copyright Reserved Autonics Co., Ltd.

6 Basic Operations (Counter/Timer/Co mmunication)

6 Basic Operations (Counter/Timer/Communication)

6.1 Operations and functions

※1: If no key is touched for 60 sec,the counter will return t o RUN mode without being restored

setting value in setting value change mode.

6.1.1 Setting value change mode (Counter/Timer)

In RUN mode, press the key to enter setting value chang e m ode.

Even if changing the setting value, input operation and output control will continue. In

addition, the setting value could be set to 0 and the output of 0 setting value turn s ON.

When entering the setting value change mode, the counting value display component

displays present value and the setting value display c om ponent displays the setting value.

According to the output mode, setting value could not be set to 0. (When setting to 0,

setting value "0" will flash 3 times.)

※In case of 1-stage preset, indicator model, PRESET2 displays PS and PRESET1 does not

displayed.

※Press the key to save the changing setting value at each parameter and it moves the next

parameter or returns in RUN mode.

© Copyright Reserved Autonics Co., Ltd. 37

6 Basic Operations (Counter/Timer/Communication)

6.1.2 Setting value check mode

Setting value of setting mode can be confirmed using the and keys.

6.1.3 Switching display function in preset indicator

Setting value 1(PS1) and setting value 2(PS2) are displayed each time pressing key in dual

setting value change model. (In timer, it is available for OND, ONd1, ONd2 output mode.)

6.1.4 RESET

In RUN mode or function setting mode, if pressing key or applying the signal to the RESET

terminal on the back side, present value will be reset and output will maintain off status. When

selecting voltage input (PNP), short no.10 and no. 12 terminals, or when selecting no-voltage

input (NPN), short no.11 and no.12 terminals to reset.

6.2 BATCH counter (only for CT6M-1P□□/CT6M-2P□□ model)

BATCH counter displays the repeat same operation to the set ting value.

In RUN mode, press the key to enter BATCH counter indication mode.

In BATCH counter indication mode, 'BATCH counter value' is displayed in count indicator

and 'BATCH counter setting value' is displayed in preset indicator.

In BATCH counter indication mode, press the key to set BATCH setting value change

mode.

Press the key to return BATCH counter indication mode.

※If setting BATCH counter setting value as ‘0’, BATCH output does not turn ON.

※In BATCH counter indication mode, press the key to return RUN mode.

38 © Copyright Reserved Autonics Co., Ltd.

6.2.1 BATCH counter operation

6.2.2 BATCH counting operation

BATCH counting value is increasing until BATCH reset signal applied. BATCH counting

value will be circulated when it is over 999999.

BATCH counting operation in Counter: Counts the number of reaching setting value.

BATCH counting operation in Timer: Counts the number of reaching sett ing t i m e. (in case of

'FLK' output mode, it counts the number of reaching T.off setting time and T.on setting time.)

6 Basic Operations (Counter/Timer/Co mmunication)

6.2.3 BATCH output operation

If input signal is applied while changing BATCH setting value, counting operation and output

control will be performed.

If BATCH count value equals to BATCH setting value, BATCH output will be ON and

maintain ON status until BATCH reset signal is applied.

When the power is cut off then resupplied in status of BATCH output is ON, BATCH output

maintains ON status until BATCH reset signal is applied.

※In case of from ‘BATCH setting value>BATCH counting value’ to ‘BATCH setting

value≤BATCH counting value’ and returning to RUN mode, BATCH output turns ON.

※In case of from turning ON BATCH output to ‘BATCH setting value>BATCH counting value’,

BATCH output maintains ON until BATCH RESET input applied.

6.2.4 BATCH RESET input In BATCH counter indication mode, press the key or applying the signal to BATCH

reset terminal on the back side panel, BATCH counting value will be reset.

When selecting voltage input (PNP), short termi nals 10 and 14, or when selecting

no-voltage input (NPN), short terminals 11 and 14 to reset.

When BATCH reset is applied, BATCH countin g value maintains at 0 and BATCH output

maintains in the OFF status.

© Copyright Reserved Autonics Co., Ltd. 39

6 Basic Operations (Counter/Timer/Communication)

6.2.5 Example of BATCH counter

(1) Counter

In case, putting 5 products in a box then packing the boxes when they reach to 200.

Counter setting: Preset setting value=5, BATCH setting value =200

When the count value of counter reaches to the setting value "5", the control output

(OUT) will be on, and at this time the count value of the B ATCH counter will be

increased by "1". The control box which is re ceived the control output (OUT) repeatedly

controls conveyor to move the full box and to place t he next empty box for standby.

When the BATCH count value reaches to "200", BATCH output will be ON. Then the

control box stops conveyor and provides a control signal for packing.

(2) Timer

Fills milk into the bottle for 3 sec (setting time) When 500 bottles ar e filled, BATCH counting

finish lamp is turned on.

(setting time: 3 sec, BATCH setting value: 500)

40 © Copyright Reserved Autonics Co., Ltd.

6.3 Setting mode

In RUN mode, hold the key for 3 sec/5 sec to enter parameter 1 group, parameter 2

group.

In setting mode, hold the key for 3 sec to return RUN mode.

6 Basic Operations (Counter/Timer/Communication)

※Counter counting and output control operates c ontinuously even entering setting mode.

※When changing the setting values of parameter 1 group via communication, the display value

and output are reset.

※Parameter 2 group is not available to non-communication models.

© Copyright Reserved Autonics Co., Ltd. 41

6 Basic Operations (Counter/Timer/Communication)

42 © Copyright Reserved Autonics Co., Ltd.

7 Counter Mode

(fixed as HOLD)

7.1 Parameter Setting

( key: Moves parameters, , key: changes parameter setti ng value)

Parameter Parameter setting value

7 Counter Mode

Counter/Timer

[C-T]

Input mode

[IN]

Output mode

[OUtM]

Indication mode

[DSpM]

Max. counting

speed [

CPS

]

TIME: Timer

● Input mode is UP, UP-1, UP-2 or DN, DN-1, DN-2,

※COUN: Counter

● Input mode is UD-A, UD-B, UD-C,

※ If max. counting speed is 5kcps or 10kcps, and output mode is D,

max. counting speed is automatically changed as 30cps, factory default.

● In case of indicator model,

※In case of the indicator type, indicate mode selection [DSP. M] is displayed.

※It is the added function to set the setting value when selecting HOLD.

※Max. counting speed is when duty ratio of INA or INB input signal is 1:1.

It is applied for INA, or INB input as same.

※When output mode is D, set max . counting speed one among 1cps, 30cps, or

1kcps.

OUT2 output

※1

time

[OUT2]

OUT1 output

※1

time

[

]

OUT1

OUT output

※1

[OUtT]

time

Decimal point

[DP]

※Set one-shot output time of OUT2.

※Setting range: 0.01 to 99.99 sec

※

When output mode is F, N, S, T, D, OUT2 does not appear.

※Set one-shot output time of OUT1.

※Setting range: 0.01 to 99.99 sec, Hold

※When 1st digit is flashing, press the key once and HOLD appears.

※When output mode is S, T, D, OUT1 does not appear. (fixed as HOLD)

※Setting range: 0.01 to 99.99 sec

※When output mode is F, N, S, T, D, OUtT does not appear. (fixed as HOLD)

● 6-digit model

※2

● 4-digit model

※Decimal point is applied to counting value and setting value.

© Copyright Reserved Autonics Co., Ltd. 43

7 Counter Mode

Parameter Parameter setting value

Min. reset time

[RST]

Input logic

[SIG]

Prescale

decimal point

※2

[ScDP]

Prescale value

[SCL]

Start point

value

[STRT]

Memory

protection

[DATA]

, unit: ms

※Set min. width of external reset signal input.

NPN: no-voltage input, PNP: voltage input

※Check input logic (NPN, PNP).

● 6-digit model

● 4-digit model

※Decimal point of prescale should not set smaller than decimal point [DP].

※Setting range of prescale value

6-digit model: 0.00001 to 99999.9, 4-digit model: 0.001 to 999.9

※Setting range is linked with decimal point [DP].

6-digit model: 0.00000 to 999999, 4-digit model: 0.000 to 9999

※When input mode is DN, DN-1, DN-2, start point value does not appear.

※CLR: Resets the counting value when power OFF.

REC: Maintains the counting value when power OFF. (memory protection)

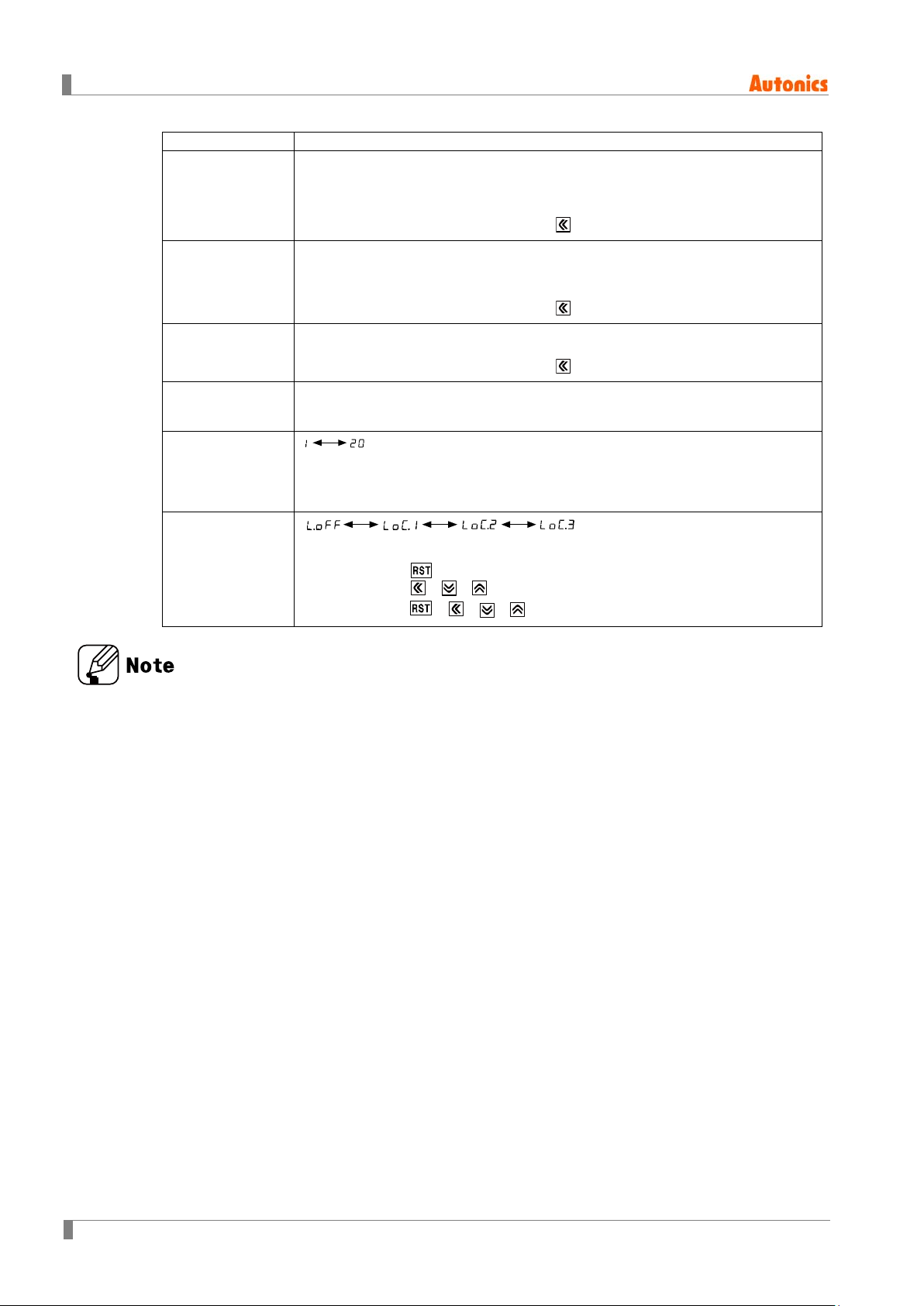

lOFF: Unlock keys, key lock indicator turns OFF

Key lock

[LOCK]

※

LOc1: Locks key, key lock indicator turns ON

LOc2: Locks

LOc3: Locks ,

, ,

, ,

keys, key lock indicator turns ON

keys, key lock indicator turns ON

※1: For 1-stage setting value change model, OUT1 does not appear. The output time of OUT2 is

displayed as OUtT.

※2: Decimal point and prescale decimal point

Decimal point: Set the decimal point for display value regardless of prescale v alue.

Prescale decimal point: Set the decimal point for prescale value of counting value

regardless of decimal point of display value.

44 © Copyright Reserved Autonics Co., Ltd.

7.2 Input mode

Input

mode

Counting chart

Up

[UP]

※When INA is counting input, INB is no counting input.

When INB is counting input, INA is no counting input.

Up-1

[

]

UP-1

7 Counter Mode

Up-2

[

UP-2

Down

[DN]

※When INA input signal is rising ( ), it counts.

※INA: Counting input

※INB: No counting input

]

※When INA input signal is falling ( ), it counts.

※INA: Counting input

※INB: No counting input

※When INA is counting input, INB is no counting input.

When INB is counting input, INA is no counting input.

© Copyright Reserved Autonics Co., Ltd. 45

7 Counter Mode

Input

mode

it maintains previous counting value.

Counting chart

Down-1

[DN-1]

※When INA input signal is rising ( ) , it counts.

※INA: Counting input

※INB: No counting input

Down-2

[

DN-2]

Up/

Down-A

[UD-A]

※When INA input signal is falling ( ) , it counts.

※INA: Counting input

※INB: No counting input

※INA: Counting input

INB: Counting command input

※When INB is "L", counting command is up.

When INB is "H", it is counting command is down .

Up/

Down-B

[UD-B]

46 © Copyright Reserved Autonics Co., Ltd.

※INA: Up counting input

INB: Down counting input

※

INA: When INA and INB input signals are rising ( ) at the same time,

Input

mode

Counting chart

Up/

Down-C

[UD-C]

※When connecting encoder output A, B phase with counter input, INA, INB, set input

mode [InM] as phase different input [UD-C] for counter operation.

※ : over min. signal width, : over than 1/2 of min. signal width.

If the signal is smaller than these width, it may cause counting error (±1)

※The meaning of "H", "L"

7 Counter Mode

Input method

Character

H 5-30VDC Short

L 0-2VDC Open

※Min. signal width by counting speed (1cps = 1Hz)

Counting speed Min. signal width

1cps 500ms

30cps 16.7ms

1kcps 0.5ms

5kcps 0.1ms

10kcps 0.05ms

Voltage input

(PNP)

No-voltage input

(NPN)

© Copyright Reserved Autonics Co., Ltd. 47

7 Counter Mode

Input mode

counting display value increases or decreases until reset signal is

up, counting display value and retained output are maintained until

reset signal is applied.

7.3 Output mode

Output

mode

Up, Up-1, 2 Down, Down-1, 2

Up/Down A, B, C

F [F]

N [N]

※After count-up,

applied and retained output is maintained.

※After count-

C [C]

R [R]

※When count-up, counting display value will be reset and count simultaneously.

※OUT1 retained output will be off after OUT2 one- shot time.

※The one-shot output time of OUT1 one-shot output time is operated regardless

of OUT2 output.

※After count-up, counting value display is reset after one-shot output time of OUT2

and it counts simultaneously.

※OUT1 retained output will be off after OUT2 one-shot time.

※OUT1 one-shot output time is operated regardless of OUT2 output.

48 © Copyright Reserved Autonics Co., Ltd.

Output

Input mode

mode

Up, Up-1, 2 Down, Down-1, 2

7 Counter Mode

Up/Down A, B, C

K [K]

P [P]

※After count-up, counting display value increases or decreases until RESET input is

applied.

※OUT1 retained output is off after OUT2 one-shot time.

※OUT1 one-shot output time is operated regardless of OUT2 output.

※After count-up, counting dis play value is m aintained while OUT2 outpu t is on.

Counting value is internally reset a nd counts simultan eousl y.

※When OUT2 output is off, displays counting value while OUT2 is ON,

and it increases or decreases.

※OUT1 retained output is off after OUT2 one-shot time.

※OUT1 one-shot output time is operated regardless of OUT2 output.

Q [Q]

※After count-up, counting display value increases or decreases during OUT2

one-shot time.

※OUT1 retained output is off after OUT2 one-shot time.

※OUT1 one-shot output time is operated regardless of OUT2 output.

A [A]

.

※After count-up, counting display value and OUT1 retained output are maintained

until RESET input is applied.

※OUT1 one-shot output time is operated regardless of OUT2 output.

© Copyright Reserved Autonics Co., Ltd. 49

7 Counter Mode

≧

≧

≧

Output

mode

S [S]

Up/Down A, B, C

※OUT1 and OUT2 keep ON status in following condition:

Counting display value

Counting display value

PRESET1

PRESET2

T [T]

D [D]

※OUT1 output is off: Counting display value ≧ PRESET1

(when PRESET 1 is 0, OUT1 output maintains ON state.)

※

OUT2 keeps ON status in following condition:

Counting display value

PRESET2

※When counting display value is equal to setting value [PRESET1, PRESET2)

only, OUT1 or OUT2 output keeps ON status.

※When setting 1kcps for counting speed, solid state contact output should

be used.

(When using contact output, it is difficult to execute normal output operation due

to contact reaction time.)

※OUT output as 1-stage setting value change model operates as output of OUT 2 as 2-stage

setting value change model.

※In case of 2-stage setting value change model, OUT1 output operates as as one-shot output or

retained output. (except S, T, D mode)

※OUT1 output is available to set as ‘0’ at every output mode. The output for ‘0’ setting executes.

※In case of C[C], R[R], P[P], Q[Q] output mode, OUT2 output is not available to set as ‘0’.

50 © Copyright Reserved Autonics Co., Ltd.

7.4 Counter operation for indicator model

DSpM

Counting chart

Down input mode

input is

※Only for indicator model.

Indication

mode

[

]

TOTAL

[TOTAL]

Up input mode

(Up, Up-1, Up-2)

Count value increases or decreases until RESET input is applied.

When input is over max./min. counting value, it displays 0. When Reset input is applied,

it displays 0(Up)/999999(Down).

(Down, Down-1, Down-2)

7 Counter Mode

HOLD

[HOLD]

Count value increases or decreases until RESET input is applied. When input is

reaching setting value(Up)/0(Down), the display value is hold. When Reset

applied, it displays 0(Up)/setting value(Down).

※When the command input [UD-A], individual input [UD-B], phase difference input [UD-C] mode,

※In case of UP/DOWN [UD-A, UD-B, UD-C] input mode, indication mode [DSpM] parameter

does not appear.

© Copyright Reserved Autonics Co., Ltd. 51

7 Counter Mode

7.5 Output operation for other conditi on s

7.5.1 Start point

In case of counter operation, set start point [STRT] t o count from the set value.

It is not available for DN, DN-1, DN-2 input mode for count er.

When RESET input is applied, the present value i s r eset as start point value.

In case of C, R, P, Q output mode, it counts up and the present res et as start point value.

7.5.2 When start point value is larger t han setting value,

(UP, UP-1, UP-2, UD-A, UD-B, UD-C mode)

(1) PRESET2 > Start Point > PRESET1

UP, UP-1, UP-2 mode: Output of OUT1 does not execute.

When the present value counts as PRESET 2, output of OUT2 turns ON.

UD-A, UD-B, UD-C mode: When the present value counts down as PRESET 1, output

of OUT1 turns ON.

※Output mode: F

Input mode: UP, UP-1, UP-2

※Output mode: F

Input mode: UD-A, UD-B, UD-C

(2) PRESET2 > Start Point = PRESET1

In case of UP, UP-1, UP-2, UD-A, UD-B, UD-C mode, output of OUT1 turns ON when

RESET OFF.

52 © Copyright Reserved Autonics Co., Ltd.

7 Counter Mode

7.5.3 When PRESET 1 is larger or equal than PRESET 2 at at down

mode

(1) PRESET1 > PRESET2

Output of OUT1 does not execute.

(2) PRESET1=PRESET2

Output of OUT1 turns ON for RESET OFF.

© Copyright Reserved Autonics Co., Ltd. 53

7 Counter Mode

7.6 Prescale

This function is to set and display calculated unit for actual length, liquid, position, etc. It i s called

“prescale value” for measured length, liquid, or posit ion, etc per 1 pulse. For example, when

moving L, the desired length to be measured, and P, the number of pulses per 1 revolution of a

rotary encoder, occurs, prescale value is L/P.

Positioning control by counter and encoder

[ Diameter (D) of pulley connected with encoder= 2 2mm,

the number of pulses by 1 rotation of encoder=1,000]

Prescale value =

=

= 0.069mm/pulse

Set decimal point [DP] as [-----.-], prescale decimal point [sCDP] as [---.---], prescale

value [SCL] as [

0.1mm unit.

0.069

The number of pulses by 1 rotaiton of encoder

3.1416 ×22

1000

] at function setting mode. It is available to c ontrol conveyer position by

π × Diameter (D) of pulley

54 © Copyright Reserved Autonics Co., Ltd.

8 Timer Mode

Parameter

Parameter setting value

8.1 Parameter setting

( key: Moves parameters, , key: changes parameter setting value)

8 Timer Mode

Counter/Timer

[C-T]

Time range

[HOUR/MIN/ SEC]

● 6-digit model

● 4-digit model

※COUN: Counter

TIME: Timer

UP/DOWN mode

[U-D]

Indication mode

[DSpM]

Memory

protection

[DATA]

Output mode

[OUtM]

© Copyright Reserved Autonics Co., Ltd. 55

※UP: Time progresses from ‘0’ to the setting time.

DN: Time progresses from the setting time to ‘0’.

※Used for the indicator model only.

※It is added that the feature which set the setting time when selecting HOLD

or ONtD.

※Used for the indicator model only.

※CLR: Reset time value when power is off.

REC: Memorizes time value at the moment of power off.

8 Timer Mode

Parameter

Parameter setting value

OUT2 output

※Set one-shot output time of OUT2.

time

※1

[

OUT2

※Setting range: 0.01 to 99.99 sec, Hold

]

※When 1st digit is flashing, press the key once and HOLD appears.

OUT1 output

※1

time

[OUT1]

OUT output

※1

[OUtT]

time

Input logic

[SIG]

Input signal

time

[InT]

※Set one-shot output time of OUT1.

※Setting range: 0.01 to 99.99 sec, Hold

※When 1st digit is flashing, press the key once and HOLD appears.

※Setting range: 0.01 to 99.99 sec, Hold

※When 1st digit is flashing, press the key once and HOLD appears.

NPN: no-voltage input, PNP: voltage input

※Check input logic value (NPN, PNP).

, unit: ms

※CTS/CTY: Set min. width of INA, INH, RESET signal.

※CTM: Set min. width of INA, RESET, INHIBIT, BATCH RESET signal.

lOFF: Unlock keys, key lock indicator turns OFF

※

Key lock [LOCK]

LOc1: Locks key, key lock indicator turns ON

LOc2: Locks

LOc3: Locks ,

, ,

, ,

keys, key lock indicator turns ON

keys, key lock indicator turns ON

※1: When output mode is FLk1, FLk2, INTG and OND, ONd1, ONd2 of 1-stage setting value

change model, OUT1does not appear. The output time of OUT2 is displayed as OUtT.

When output mode is OND, ONd1, ONd2, INt2, OUT1 appears.

※2: INt2 mode is available only for 2-stage setting value change m odel.

56 © Copyright Reserved Autonics Co., Ltd.

8.2 Output mode

Output

mode

Time chart

Signal ON Delay (Power RESET)

OND

[OND]

8 Timer Mode

1) Time starts when INA signal turns ON.

2) When INA signal turns OFF, time resets.

3) When INA signal is ON: Power ON Time S tart is ope rated.

RESET OFF Time Start is operated.

OND.1

[ONd1]

4) Control output operates as retained or one-shot output.

Signal ON Delay 1 (Power RESET)

1) Time starts when INA signal turns ON.

2) When INA signal is ON: Power ON T ime S tart is ope rated

RESET OFF Time Start is operated.

3) Control output operates as retained or one-shot output.

4) Only first INA input signal is valid in case INA input signal is

repeatedly applied.

© Copyright Reserved Autonics Co., Ltd. 57

8 Timer Mode

Output

mode

Power ON Delay 2 (Power Hold)

Flicker (Power RESET)

Time chart

OND.2

[ONd2]

1) Power ON Time Start (There is no INA function.)

2) RESET ON: Time RESET

RESET ON→OFF: Time Start

3) Control output operates as retained or one-shot output.

4) It memorizes display value at the moment of power

OFF.

FLK

[FLK]

1) Time starts when INA signal turns on.

2) When INA signal is ON: Power ON Time S tart is ope rated.

RESET OFF Time Start is operated.

3) Control output operates as retained output, output turns

off for the T.off time and turns off for the T.off time and

turns on for the T.on time repeatedly.

Ta+Tb = T.off setting time

4) The T.on time and T.off time must be set individually.

5) In case of using the contact output, min. setting time

must be set over 100ms.

58 © Copyright Reserved Autonics Co., Ltd.

8 Timer Mode

Output

mode

must be set over 100ms.

FLK.1

[FLk1]

Time chart

Flicker 1 (Power RESET)

Hold output

1) Time starts when INA signal turns on.

2) When INA signal is ON: Power ON Time Start is operate d.

RESET OFF Time Start is operated.

3) Control output operates as retained output.

4) In case of using the contact output, min. setting time

One-shot output

1) Time starts when INA signal turns on.

2) When INA signal is ON: Power ON Time Start is operated.

RESET OFF Time Start is operated.

3) Control output operates as one-shot output.

4) In case of using the contact output, min. setting time must

be set over 100ms.

© Copyright Reserved Autonics Co., Ltd. 59

8 Timer Mode

Output

mode

Flicker 2 (Power Hold)

1) Time starts when INA signal turns ON and the display

Time chart

Hold output

value at the moment when power is off is memorized.

2) When INA signal is ON: Power ON Time Start is operated.

RESET OFF Time Start is operated.

3) Control output operates as retained output.

FLK.2

[FLk2]

4) Control output will be reversed when it reaches to setting

time. (At the initial start, OUT2 control output is OFF).

5) In case of using the contact output, min. setting time must

be set over 100ms.

One-shot output

1) Time starts when INA signal turns ON and the display

value at the moment when power is off is memorized.

2) When INA signal is ON: Power ON Time Start is operated.

RESET OFF Time Start is operated.

3) Control output operates as one-shot output.

4) In case of using the contact output, min. setting time must

be set over 100ms.

※Power RESET: There is no memory protection. (resets the display value when power is off)

※Power Hold: There is memory protection. (mem orizes the display value at the moment of

power off, indicates the memorized di splay value when power is resupplied.)

60 © Copyright Reserved Autonics Co., Ltd.

8 Timer Mode

Output

mode

INT

[INT]

Time chart

Interval (Power RESET)

1) Control output turns ON and time starts when INA signal

turns ON.

2) When INA signal is OFF, time is reset.

3) When INA signal is ON: Power ON Time St art is op erated.

RESET OFF Time Start is operated.

4) When it reaches setting time, indication value and control

output are reset automatically.

5) Control output is ON when time is progressing.

Interval 1 (Power RESET)

INT.1

[INt1]

1) Control output turns ON and time starts when INA signal turnsn

ON.

2) When INA signal is ON: Power ON Time St art is op erated.

RESET OFF Time Start is operated.

3) When it reaches setting time, indication value and control

output are reset automatically.

4) Control output is ON when time is progres sing.

5) INA input is ignored while time is progressing.

© Copyright Reserved Autonics Co., Ltd. 61

8 Timer Mode

Output

mode

1) Time starts when INA input is ON and resets when

1) If INA is ON, control output remains ON.

Time chart

Interval 2 (Power RESET)

INT.2

[INt2]

INA input is OFF.

2) INA input is ON, OUT1 output is ON during T1 (hold)

or t1.

3) When it reaches setting time1, display value resets

and OUT2 output is ON during T 2 (hold) or t2 output

time.

※Output turns OFF when reaching the setting time even if

one-shot time is longer than setting time.

Signal Off Delay1 (Power RESET)

OFD

[OFD]

(except when power is off and reset is on)

2) When INA signal is OFF, time processes.

When it reaches setting time, indication value and

control output are reset automatically.

※Power RESET: There is no memory protection. (resets the display value when power is off)

※Power Hold: There is memory protection. (mem orizes the display value at the moment of

power off, indicates the memorized display value when power is resupplied.)

62 © Copyright Reserved Autonics Co., Ltd.

8 Timer Mode

Output

mode

NFD

[NFD]

Time chart

On-Off Delay (Power RESET)

1) When INA input is ON, output is ON and time is

progressing, then output is OFF after On_Delay time.

2) When INA input is OFF, output is ON and ti me is

progressing, then output is OFF after Off_Delay ti me.

3) If INA input is OFF within On_Delay time, step 2 starts again.

4) If INA input is ON within Off_Delay time, step 1 st arts ag ain.

On-Off Delay1 (Power Hold)

NFD.1

[NFd1]

1) When INA input turns ON, time progresses and

output turns ON after On_Delay time.

2) When INA input turns OFF, time pro gresses an d

output turns OFF after Off_Delay time.

3) If INA input turns OFF within On_Delay time,

output will turn ON and step 2 operate.

4) If INA input turns ON within Off_Delay time,

output will turn OFF and step 1 operate.

© Copyright Reserved Autonics Co., Ltd. 63

8 Timer Mode

Output

mode

Time chart

Integration Time (Power RESET)

INTG

[INTG]

1) Time is progressing while INA input is ON.

2) Time progress stops while INA input is OFF.

3) When it reaches the setting time, output is ON.

※Power RESET: There is no memory protection. (resets the display value when power is off)

※Power Hold: There is memory protection. (mem orizes the display value at the moment of

power off, indicates the memorized display value when power is resupplied.)

64 © Copyright Reserved Autonics Co., Ltd.

8.3 Timer operation for indicator model

※Only for indicator model.

8 Timer Mode

TOTAL

[TOTAL]

When memory protection setting is OFF

1) Time starts when INA input is ON.

2) Setting value is initialized when Reset input is ON.

3) Time progress stops when INHIBIT input is ON.

4) Resets when power is OFF.

When memory protection setting is ON

1)Time starts when INA input is ON.

2) Setting value is initialized when Reset input is ON.

3) Time progress stops when INHIBIT input is ON.

4) Display value at the moment of power OFF is memorized.

© Copyright Reserved Autonics Co., Ltd. 65

8 Timer Mode

HOLD

[HOLD]

When memory protection setting is OFF

1) Time progresses when INA input is ON.

2) Time progress stops while INA input is OFF.

3) When time reaches setting time, display value will stop and flash.

4) When reset input is applied, display value is initialized.

5) Resets when power is OFF.

When memory protection setting is ON

1) Time progresses when INA input is ON.

2) Time progress stops while INA input is OFF.

3) When time reaches setting time, display value will stop and flash.

4) When reset input is applied, display value is initialized.

5) Display value the moment when power is OFF is memorized.

66 © Copyright Reserved Autonics Co., Ltd.

8 Timer Mode

display value flashes and operation stops until reset signal is applied.

On Time

Display

[ONtD]

When memory protection setting is OFF

※ON time indicate mode of INA input

1) Time reset start operates when INA input turns ON.

2) Time progress stops while INA input is OFF.

3) When time progress stops and power i s off, th e display value is initi alized.

4) If progress time is greater than setting time when INA input turns off,

When memory protection setting is ON

※ ON time indicate mode of INA input

1) Time reset start operates when INA input turns ON.

2) Time progress stops while INA input is OFF.

3) When time progress stops and power is off, the display value is memorized.

4) If progress time is greater than setting time when INA input turns off,

display value flashes and operation stops until reset signal is applied.

※TMR mark flashes during timer operating.

※TMR mark turn ON for timer stop or hold.

※The present value is zero blank format for highest unit.

E.g.)In case of time range is 99m59.99s and the present value is 00m04.05s, zero blank is

applied for the highest unit, minute. In case of the below digit of decimal point, zero blank

is not applied. Therefore, it displays “0.0$05”.

※In case of timer , it is available for PRESET to set as ‘0’ and the output operates.

© Copyright Reserved Autonics Co., Ltd. 67

8 Timer Mode

8.4 Timer ‘0’ Time Setting

8.4.1 Available output mode to s et ‘0’ time setting

OND, ONd1, ONd2, NFD, NFd1

8.4.2 Operation by each output mode (‘0’ time setting)

(1) OND (Signal ON Delay) mode [OND]

Setting time 1 is set as ‘0’.

1) UP mode

2) DOWN mode

Setting time 2 is set as ‘0’.

68 © Copyright Reserved Autonics Co., Ltd.

(2) OND.1 (Signal ON Delay 1) mode [OND.1]

Setting time 1 is set as ‘0’.

1) UP mode

2) DOWN mode

8 Timer Mode

Setting time 2 is set as ‘0’.

© Copyright Reserved Autonics Co., Ltd. 69

8 Timer Mode

(3) OND.2 (Power ON Delay 2) mode [OND.2]

Setting time 1 is set as ‘0’.

1) UP mode

2) DOWN mode

Setting time 2 is set as ‘0’.

70 © Copyright Reserved Autonics Co., Ltd.

(4) NFD (ON-OFF Delay) mode [NFD]

1) Off_Delay setting time 1 is set as ‘0’.

2) On_Delay setting time 1 is set as ‘0’.

8 Timer Mode

© Copyright Reserved Autonics Co., Ltd. 71

8 Timer Mode

(5) OFD.1 (ON-OFF Delay 1) mode [NFD.1]

1) Off_Delay setting time 1 is set as ‘0’.

2) On_Delay setting time 1 is set as ‘0’.

72 © Copyright Reserved Autonics Co., Ltd.

8 Timer Mode

(6) When setting value 1(PRESET 1) is greater than setting value 2(PRESET 2),

In case of OND[OND], OND.1[ONd1], OND.2[ONd2] output mode,

UP mode: Ti mer s etting v alu e 1 (PRE SET 1 ) is g reate r than setting value 2 (PRE SET 2),

OUT 1 output does not turn ON.

DOWN mode: Timer setting value 1 (PRESET 1) is greater than s etting value2 (PRES ET 2),

as setting value 2 (PRESET 2), OUT1 output turns ON immediately when

applied start signal.

1) OND (Signal On Delay) output mode

OUT1 output does not turn ON. The setting value 1(PRESET 1) is same

2) ONd1 (Signal ON Delay 1) output mode

3) ONd2 (Signal On Delay 2) output mode

© Copyright Reserved Autonics Co., Ltd. 73

1

74 © Copyright Reserved Autonics Co., Ltd.

9 Factory Default

9.1 Common

Parameter Factory default

LOCK lOFF

9 F actory Default

PRESET1

PRESET2

9.2 Counter

Parameter Factory default

IN UD-C

OUtM F

DSpM TOTAL

CPS 30

OUT2 [OUtT] HOLD (fixed)

OUT1 00.10

DP ------

RST 20

SIG NPN

1000

5000

ScDP

SCL

STRT 000000

DATA CLR

6-digit model

4-digit model

6-digit model

4-digit model

-.-----

-.---

1.00000

1.000

© Copyright Reserved Autonics Co., Ltd. 75

9 Factory Default

Parameter

Factory default

9.3 Timer

HOUR/MIN/SEC

U-D UP

DSpM TOTAL

DATA CLR

OUtM OND

OUT2[OUtT]

OUT1 00.10

SIG NPN

InT 20

6-digit model 0.001s-999.999s

4-digit model 0.001s-9.999s

HOLD

76 © Copyright Reserved Autonics Co., Ltd.

■ Major Products

·

Photoelectric Sensors·Fiber Optic Sensors·Door Sensors·Door Side Sensors·Area Sensors

·Proximity Sensors·Pressure Sensors·Connectors/Sockets·Rotary Encoders·Panel Meters

·Counters·Timers·Temperature Controllers·SSRs/Power Controllers·Sensor Controllers

·Graphic/Logic Panels·Temperature/Humidity Transducers·Switching Mode Power Supplies

·Stepper Motors/Drivers/Motion Controllers·I/O Terminal Blocks & Cables·Display Units

·Control Switches/Lamps/Buzzers·Field Network Devices·Tachometer/Pulse(Rate) Meters

·Laser Marking System(Fiber, CO2, Nd:YAG)·Laser Welding/Cutting System

■ Corporate Headquarters

18 Bansong-ro, 513 Beon-gil, Haeundae-gu, Busan, South Korea 48002

■ Overseas Business Headquarters

#402-303, Bucheon Techno Park, 655, Pyeongcheon-ro, Wonmi-gu, Bucheon, Gyeonggi-do,

South Korea 14502

Tel: 82-32-610-2730 / Fax: 82-32-329-0728 / E-mail: sales@autonics.com

■ Brazil − Autonics do Brasil Comercial Importadora Expor tadora Ltda

Tel: 55-11-2307-8480 / Fax: 55-11-2309-7784 / E-mail: comercial@autonics.com.br

■ China − Autonics electronic(Jiaxing) Corporation

Tel: 86-21-5422-5969 / Fax: 86-21-5422-5961 / E-mail: china@autonics.com

■ India − Autonics Automation India Private Limited

Tel: 91-22-2781-4305 / Fax: 91-22-2781-4518 / E-mail: india@autonics.com

■ Indonesia − PT. Autonics Indonesia

Tel: 62-21-8088-8814/5 / Fax: 62-21-8088-4442(4440) / E-mail: indonesia@autonics.com

■ Japan − Autonics Japan Corporation

Tel: 81-3-3950-3111 / Fax: 81-3-3950-3191 / E-mail: ja@autonics.com

■ Malaysia − Mal-Autonics Sensor Sdn. Bhd.

Tel: 60-3-7805-7190 / Fax: 60-3-7805-7193 / E-mail: malaysia@autonics.com

■ Mexico − Autonics Mexico S.A. DE C.V

Tel: 52-55-5207-0019 / Fax: 52-55-1663-0712 / E-mail: ventas@autonics.com

■ Russia − Autonics Corp. Russia Representative Office

Tel/Fax: 7-495-660-10-88 / E-mail: russia@autonics.com

■ Turkey − Autonics Otomasyon Ticaret Ltd. Sti.

Tel: 90-216-365-9117/3/4 / Fax: 90-216-365-9112 / E-mail: infotr@autonics.com

■ USA − Autonics USA, Inc.

Tel: 1-847-680-8160 / Fax: 1-847-680-8155 / E-mail: sales@autonicsusa.net

■ Vietnam − Cong Ty Tnhh Autonics Vina

Tel: 84-8-3771-2662 / Fax: 84-8-3771-2663 / E-mail: vietnam@autonics.com

Dimensions or specifications on this manual are subject to change and

some models may be discontinued without notice.

MCC-CTU1-V1.0-1609US

Loading...

Loading...