Page 1

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

V ) Preliminary Specification

(

( ) Final Specification

Module

Model Name

19.0” SXGA

M190EP02 V2

Color TFT-LCD

M190EP02 V2

Customer D

Approved by

This Specification is subject to change without

Note:

notice.

ate

Checked &

Approved

by

CC Chiu

ared by

Prep

Jack CC Hsu

Desktop Display Business Group /

AU Optronics corporation

Date

May

. 2, 2006

May. 2, 2006

d

ocument version 0.1 1/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 2

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

Content

1. Handling Precautions

2. General Description ................................................................................................................ 5

2.1 Display Characteristics .......................................................................................................................5

2.2 Optical Characteristics........................................................................................................................ 6

3. Functional Block Diagram .................................................................................................... 11

4. Absolute Maximum Ratings.................................................................................................. 12

4.1 Absolute Ratings of TFT LCD Module ............................................................................................ 12

4.2 Absolute Ratings of Backlight Unit.................................................................................................. 12

4.3 Absolute Ratings of Environment..................................................................................................... 12

5. Electrical characteristics ...................................................................................................... 14

5.1 TFT LCD Module ............................................................................................................................. 14

.............................................................................................................. 4

s

M190EP02 V2

5.2 Backlight Unit................................................................................................................................... 15

6. Signal Characteristic............................................................................................................. 16

6.1 Pixel Format Image........................................................................................................................... 16

6.2 Signal Description............................................................................................................................. 17

6.3 The input data format........................................................................................................................ 20

6.4 Signal Electrical Characteristics ....................................................................................................... 22

6.5 Interface Timings ..............................................................................................................................25

6.6 Power ON/OFF Sequence.................................................................................................................27

7. Connector & Pin Assignment ............................................................................................... 28

7.1 TFT LCD Module ............................................................................................................................. 28

7.2 Backlight Unit................................................................................................................................... 31

8. Reliability Test ....................................................................................................................... 32

9. Shipping Label....................................................................................................................... 33

10. Mechanical Characteristics ................................................................................................ 34

d

ocument version 0.1 2/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 3

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

Record of Revision

ersion & Date

V

0.1

2006/05/02 All First Edition for Customer -

Page Old Description New

M190EP02 V2

Description

Remark

d

ocument version 0.1 3/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 4

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

M190EP02 V2

1. Handling Precautions

1) Since front polarizer is easily damaged, pay attention not to scratch it.

2) Be sure to turn off power supply when inserting or disconnecting from input connector.

3) Wipe off water drop immediately. Long contact with water may cause discoloration or spots.

4) When the panel surface is soiled, wipe it with absorbent cotton or other soft cloth.

5) Since the panel is made of glass, it may break or crack if dropped or bumped on hard surface.

6) Since CMOS LSI is used in this module, take care of static electricity and insure human earth

when handling.

7) Do not open or modify the Module Assembly.

8) Do not press the reflector sheet at the back of the module to any directions.

9) In case if a Module has to be put back into the packing container slot after once it was taken out

from the container, do not press the center of the CCFL reflector edge. Instead, press at the far

ends of the CCFL Reflector edge softly. Otherwise the TFT Module may be damaged.

10) At the insertion or removal of the Signal Interface Connector, be sure not to rotate nor tilt the

Interface Connector of the TFT Module.

11) After installation of the TFT Module into an enclosure, do not twist nor bend the TFT Module even

momentary. At designing the enclosure, it should be taken into consideration that no

bending/twisting forces are applied to the TFT Module from outside. Otherwise the TFT Module

may be damaged.

12) Cold cathode fluorescent lamp in LCD contains a small amount of mercury. Please follow local

ordinances or regulations for disposal.

13) Small amount of materials having no flammability grade is used in the LCD module. The LCD module

should be supplied by power complied with requirements of Limited Power Source (IEC60950 or

UL1950), or be applied exemption.

14) The LCD module is designed so that the CCFL in it is supplied by Limited Current Circuit (IEC60950 or

UL1950). Do not connect the CCFL in Hazardous Voltage Circuit.

d

ocument version 0.1 4/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 5

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

M190EP02 V2

2. General Description

M190EP02 is a Color Active Matrix Liquid Crystal Display composed of a TFT-LCD panel, a driver circuit,

and backlight system. The screen format is intended to support the SXGA (1280(H) x 1024(V)) screen and

16.2M colors (RGB 6-bits + FRC data). All input signals are Analog RGB interface compatible, DVI

interface optional. Inverter card of backlight is not included. M190EP02 is designed for a display unit of

personal computer.

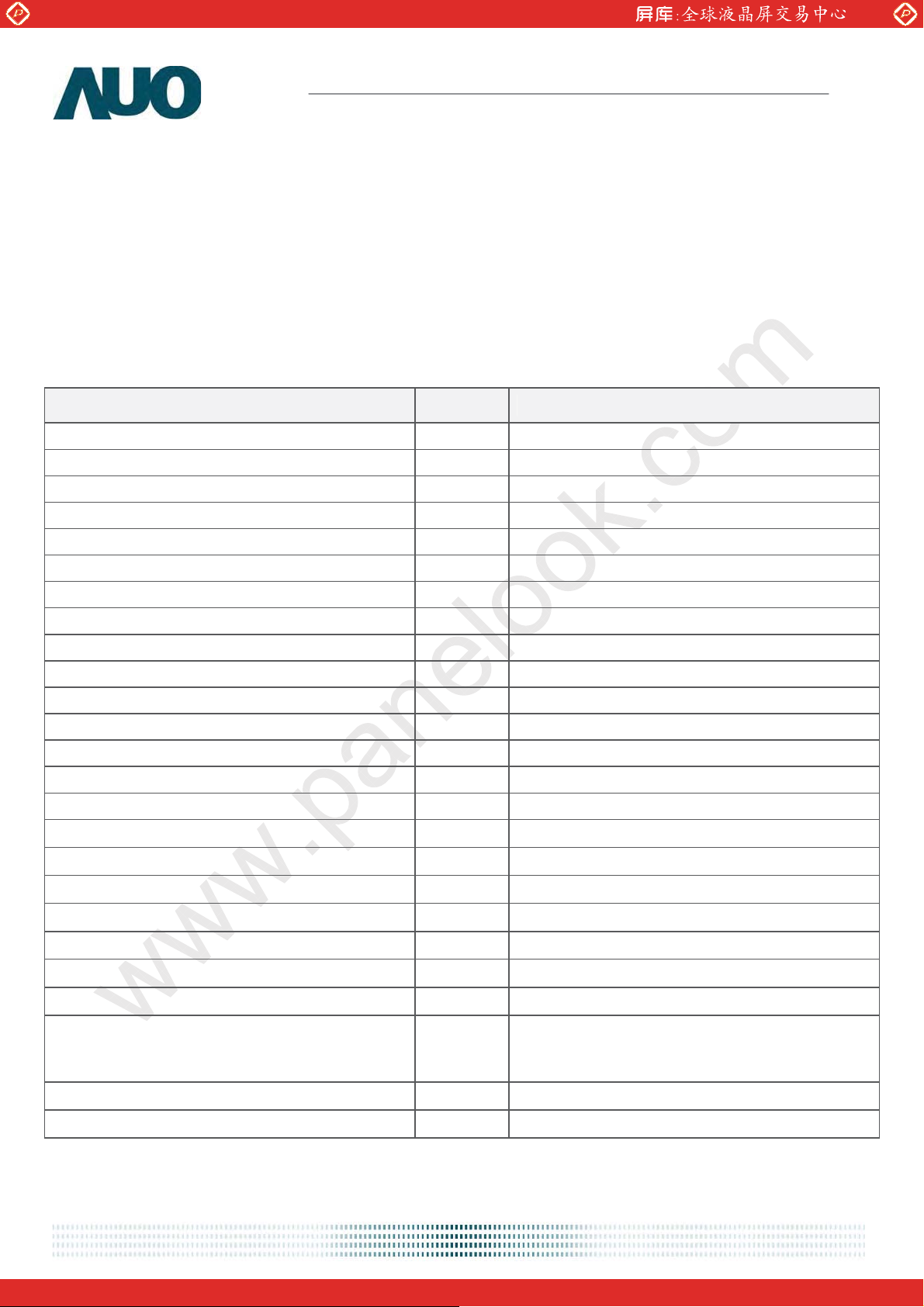

2.1 Display Characteristics

The following items are characteristics summary on the table under 25 к condition:

Items Unit Specifications

Screen Diagonal [mm]

Active Area [mm]

Pixels H x V 1280 × 3(RGB) × 1024

Pixel Pitch [mm]

482.6 (19.0”)

376.320(H) × 301.060(V)

0.294(per one triad) × 0.294

Pixel Arrangement R.G.B. Vertical Stripe

Display Mode Normally White

White Luminance [cd/m2] 250

(Typ)

1

Contrast Ratio 700 : 1 (Typ)

Optical ResponseTime [msec]

Nominal Input Voltage VCC [Volt]

Power Consumption [Watt]

6ms(Typ, on/off) ; 2ms(AVG.,

+5.0 (Typ)

30.6 W (Typ) ; 0.4 W (Stand by)

G

TG)

Weight [Grams] 2500 (Typ)

Physical Size (H x V x D) [mm]

396.0(H) x 324.0(V) x 21.7(D) (Typ)

Electrical Interface VESA standard Analog RGB and DVI 1.0

Surface Treatment Anti-glare type, Harness 3H

Support Color 16.2M colors (RGB 6-bits + FRC data)

Plug & Play VESA DDC1/2B/2Bi/2B+/CI

2

Compability PC/MAC

Max. Firmware Code Size [bit]

Max. Pixel Clock

[MHz] 135.09 MHz

6500K White Point (CIE x,y) (0.313,0.329) +/-0.03

Auto Adjustment Auto Color, Size & Phase

128K

2

2

Temperature Range

Operating

Storage (Non-Operating)

o

[

C]

o

[

C]

0 to +50

-20 to +60

RoHS Compliance RoHS Compliance

TCO ‘03 Compliance TCO ‘03 Compliance

1

At CCFL= 7.5 mA

2

With AUO standard firmware

3

With AUO standard power module & firmware

d

ocument version 0.1 5/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

3

www.panelook.com

Page 6

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

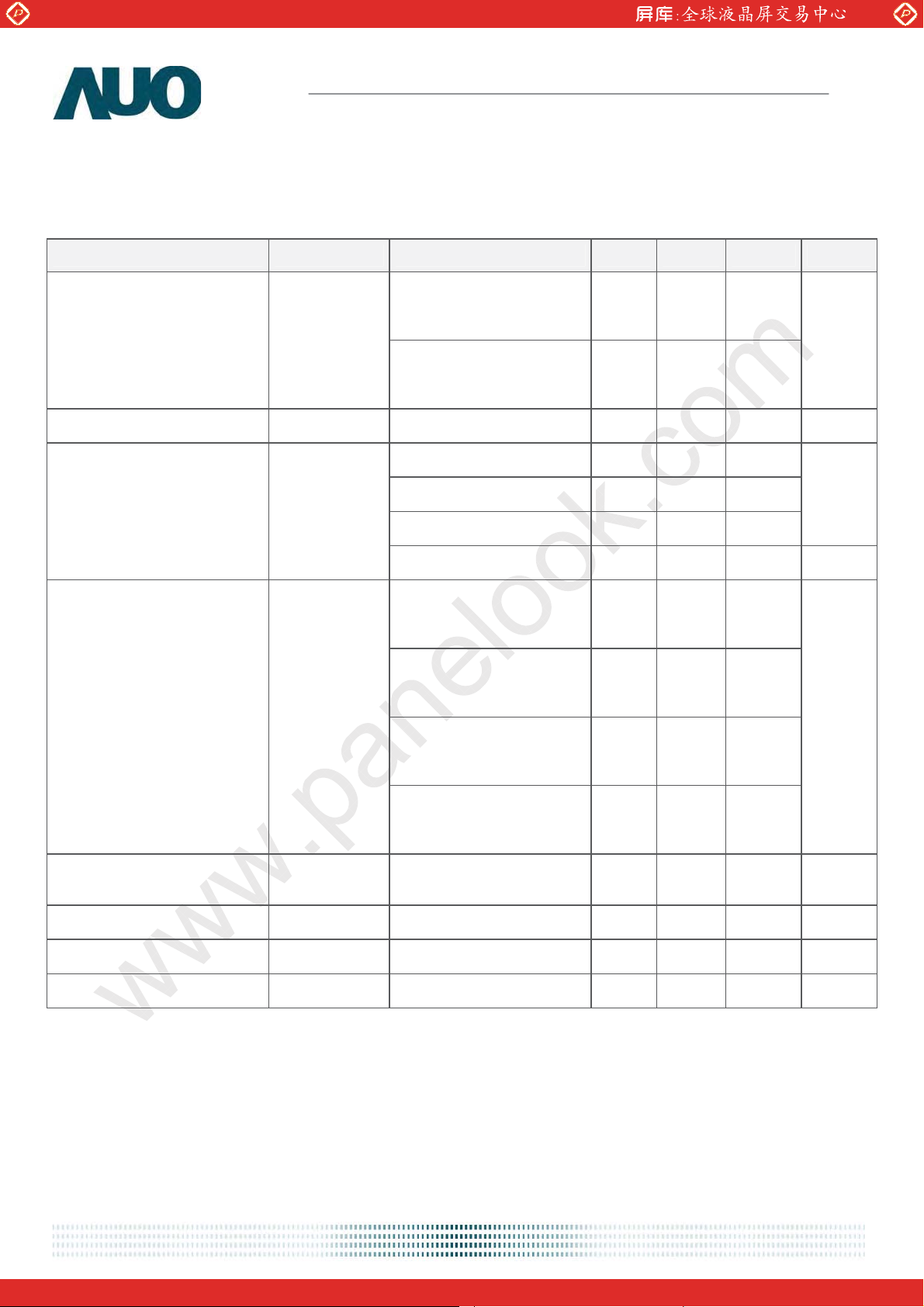

2.2 Optical Characteristics

The optical characteristics are measured under stable conditions at 25к (Room

Item Unit Conditions Min. Ty

Viewing Angle [degree]

Luminance Uniformity [%]

Optical Response Time [msec]

Horizontal (R+L)

CR = 10

Vertical (U+D)

R = 10

C

9 Points 75 80 - 2, 3

Rising - 4.5 7

Falling - 1.5 2

Rising + Falling -

140 160 -

140 160 -

M190EP02 V2

Temperature):

p.

6 9

Max. Note

1

4, 6

Grey to Grey (Avg.) - 2 - 6

Red x 0.61

Red y 0.31

Green x 0.26

Color / Chromaticity

Coordinates

(CIE 1931)

White Luminance

(At CCFL= 7.5mA)

Contrast Ratio

Cross Talk (At 75Hz) [%]

Flicker [dB]

[cd/m2]

Green y 0.58

Blue x 0.11

Blue y 0.04 0.07 0.10

White x 0.28 0.31 0.34

White y 0.30 0.33 0.36

200 250 - 4

0.64 0.67

0.34 0.37

0.29 0.32

0.61 0.64

4

0.14 0.17

500 700 - 4

- - 1.5 5

- - -20

7

Optical Equipment: BM-5A, BM-7, PR880, or equivalent

d

ocument version 0.1 6/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 7

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

M190EP02 V2

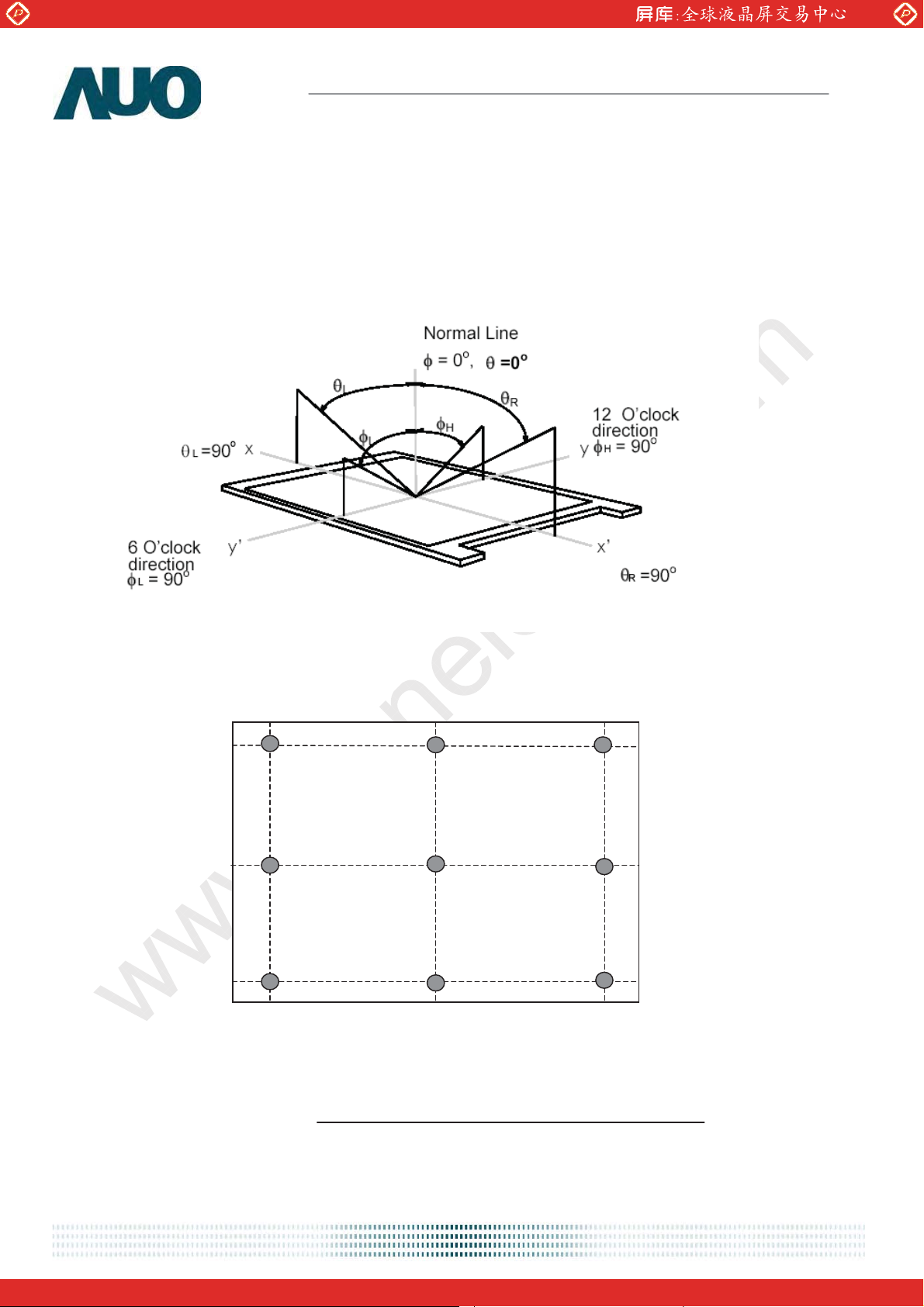

Note 1: Definition of viewing angle

Viewing angle is the measurement of contrast ratio Њ10, at the screen center, over a 180° horizontal and

180° vertical range (off-normal viewing angles). The 180° viewing angle range is broken down as follows;

90° (Ӱ) horizontal left and right and 90° (ӥ) vertical, high (up) and low (down). The measurement

direction is typically perpendicular to the display surface with the screen rotated about its center to

develop the desired

measurement viewing angle.

Note 2: 9 points position

90 %

50 %

10 %

10 %

50 %

90 %

Note 3: The luminance uniformity of 9 points is defined by dividing the maximum luminance values by the

minimum test point luminance

Ӭ

W9

Minimum

=

Maximum

Luminance of 9 points

Luminance of 9 points

d

ocument version 0.1 7/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 8

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

M190EP02 V2

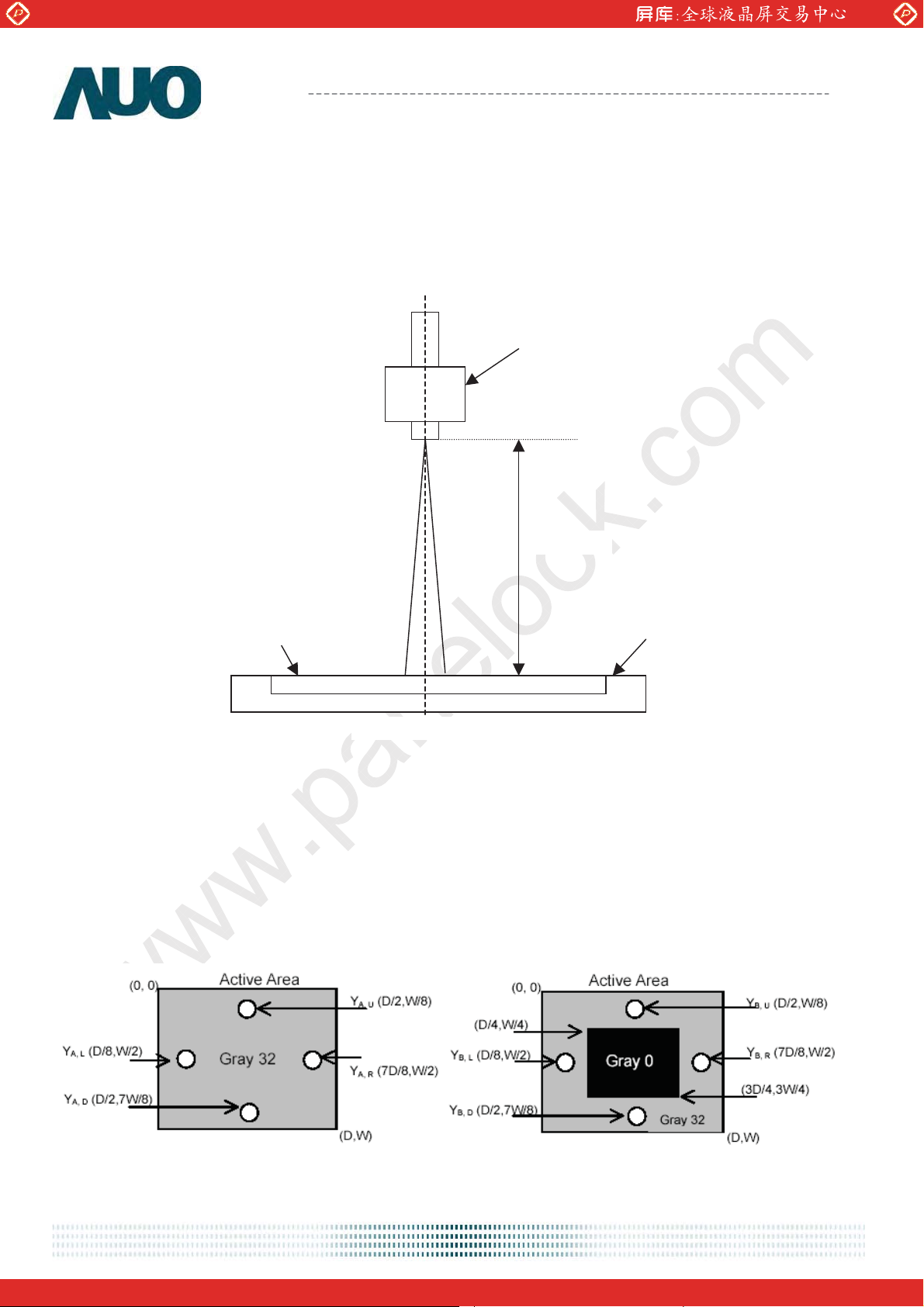

Note 4: Measurement method

The LCD module should be stabilized at given temperature for 30 minutes to avoid abrupt temperature

change during measuring. In order to stabilize the luminance, the measurement should be executed after

lighting Backlight for 30 minutes in a stable, windless and dark room. ʳ

Photo detector

Field=2

50 cm

LCD Panel

Center of the screen

Note 5: Definition of Cross Talk (CT)

CT = |

YB – YA | / YA Ø 100 (%)

Where

YA = Luminance of measured location without gray level 0 pattern (cd/m2)

YB = Luminance of measured location with gray level 0 pattern (cd/m2)

TFT-LCD Module

d

ocument version 0.1 8/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 9

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

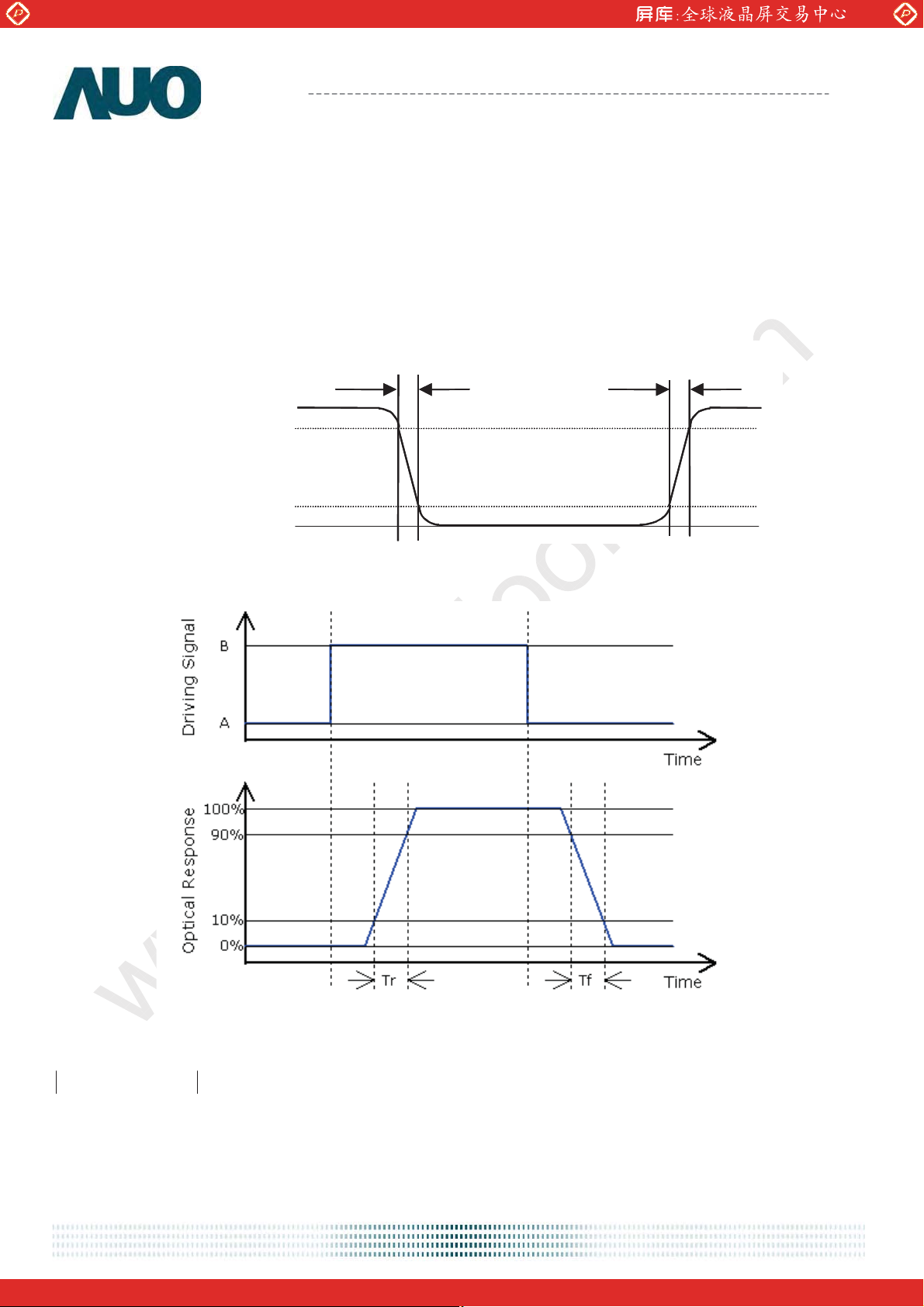

Note 6: Definition of response time:

The output signals of photo detector are measured when the input signals are changed from “Full Black” to

“Full White” (rising time), and from “Full White” to “Full Black ”(falling time), respectively. The response time

is interval between the 10% and 90% of amplitudes. Please refer to the figure as below.

%

Optical

Optical

response

response

10

10

90

90

10

10

%

0

0

White Black White

White Black White

0

0

Tr

Tr

Tr

F

F

Tr

M190EP02 V2

R

R

Over-Drive and Response time:

Algorithm:

B Level -A Level t

32

then the average of Grey-to-Grey response time is 2 ms. ( F= 60 Hz).

Tr (rising time; from “Black” to “White”) + Tf (Falling time; from “White” to “Black”) = 6 ms(typ).

d

ocument version 0.1 9/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 10

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

Note 7: Subchecker Pattern

R G B R G B

Gray Level = L127

R G B R G B

Gray Level = L0

R G B R G B

Method: Record dBV & DC value with (WESTAR)TRD-100

Amplitude

M190EP02 V2

AC

DC

Time

log20(dB)Flicker

Level

DC

Hz) 30Level(at AC

d

ocument version 0.1 10/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 11

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

M190EP02 V2

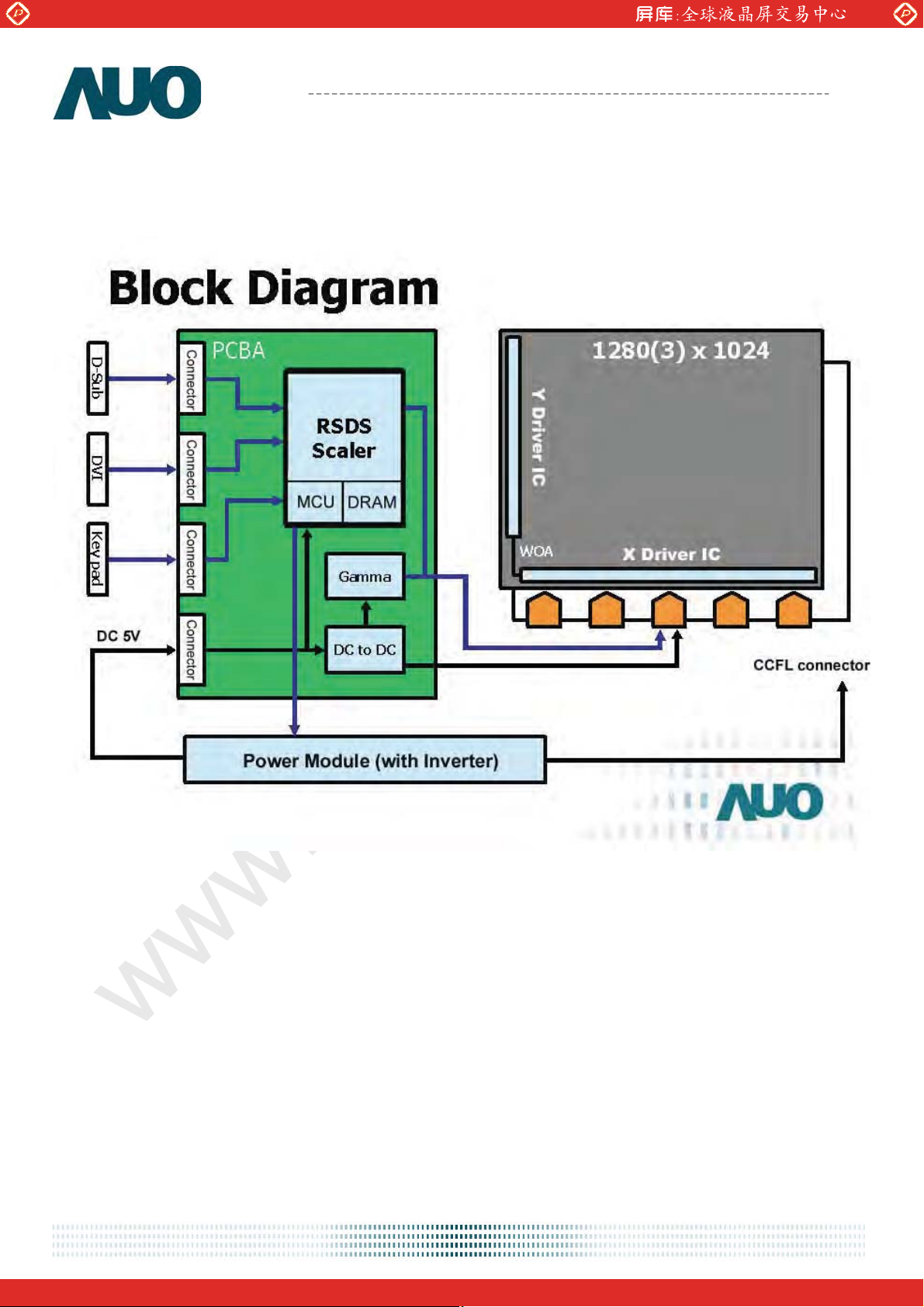

3. Functional Block Diagram

The following diagram shows the functional block of the 19.0 inches Color TFT-LCD Module:

d

ocument version 0.1 11/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 12

Global LCD Panel Exchange Center

g

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

4. Absolute Maximum Ratings

Absolute maximum ratings of the module is as following:

4.1 Absolute Ratings of TFT LCD Module

Item Sy

Logic/LCD Drive

Volta

e

4.2 Absolute Ratings of Backlight Unit

Item Sy

CCFL Current ICFL 0 8.5

mbol

VCC -0.3 +5.25 [Volt] Note 1, 2

mbol

Min. Max. Unit Conditions

Min. Max. Unit Conditions

M190EP02 V2

[mA] rms Note 1, 2

4.3 Absolute Ratings of Environment

Item Sy

Operating Temperature

Operation Humidity

Storage Temperature

Storage Humidity HST

TST -20 +60 [

mbol

TOP 0 +50 [

HOP 5 90 [%RH]

Min. Max. Unit Conditions

5 90

[%RH]

o

C]

o

C]

Note 3

d

ocument version 0.1 12/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 13

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

Note 1: With in Ta= 25к

Note 2: Permanent damage to the device may occur if exceed maximum values

Note 3: For quality performance, please refer to AUO IIS (Incoming Inspection Standard).

M190EP02 V2

Operating

Range

Storage

Range

d

ocument version 0.1 13/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 14

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

5. Electrical characteristics

5.1 TFT LCD Module

5.1.1 Pow

Input power specifications are as follows:

Sy

VCC

ICC Input Current -

PCC VCC

IRush

VCCrp

er Specification

mble

Logic/LCD Drive

Voltage

Inrush Current - - 3.0 [A] Note 2

Allowable

Logic/LCD Drive

Ripple Voltage

Parameter Min. Ty

4.75

Power - 9 9.5 [Watt]

p.

Max. Unit Condition

5.0 5.25 [Volt] Load Capacitance 20uF

1.8 1.81 [A] VCC= 5.0V, All Black Pattern

- -

100

M190EP02 V2

Note 1,

VCC= 5.0V, All Black Pattern

[mV]

p-p

PS Power Saving -

0.4 0.5 [Watt] VCC= 5.0V

Note 1: The variance of VCC power consumption is ±10%.

Note 2: Measurement conditions:

(High to Low)

Control

Signal

SW1

SW MAG-SPST

1 2

+12.0V

+5.0V

C2

1uF/25V

R1

47K

R2

1K

VR1

47K

D6

D5

D2 S

D1

G

C3

0.01uF/25V

Q3

AO6402

D2SD1D5

G

D6

Q3

AO6402

F1

VCC

(LCD Module Input)

C1

1uF/16V

90%

5.0V

10%

0V

VCC rising tim

e

0.5ms

d

ocument version 0.1 14/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 15

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

M190EP02 V2

5.2 Backlight Unit

Parameter guideline for CCFL Inverter is under stable conditions at 25 (Room Temperature):к

Parameter Min.

CCFL Standard Current(ISCFL) 7.0 7.5 8.0 [mA] rms Note 2

CCFL Operation Current(IRCFL) 3.0 7.5 8.0 [mA] rms Note 2

CCFL

CCFL Ignition Voltage(ViCFL, Ta= 0

CCFL Ignition Voltage(ViCF, Ta= 25

CCFL Operation Voltage (VCFL) -

Frequency(FCFL) 40 60 80 [KHz] Note 3,4

)к 1500 - - [Volt] rms

)к 1160 - - [Volt] rms

p.

Ty

720

(@ 7.5mA)

Max.

845

(@ 3.0mA)

Unit Condition

Note 5

[Volt] rms

Note 6

CCFL Power Consumption(PCFL) -

CCFL Life Time(LTCFL) 40,000

Note 1: Typ. are AUO recommended design points.

*1 All of characteristics listed are measured under the condition using the AUO test inverter.

*2 In case of using an inverter other than listed, it is recommended to check the inverter carefully.

Sometimes, interfering noise stripes appear on the screen, and substandard luminance or flicker

at low power may happen.

*3 In designing an inverter, it is suggested to check safety circuit very carefully. Impedance of

CCFL, for instance, becomes more than 1 [M ohm] when CCFL is damaged.

*4 Generally, CCFL has some amount of delay time after applying kick-off voltage. It is

recommended to keep on applying kick-off voltage for 1 [Sec] until discharge.

*5 Reducing CCFL current increases CCFL discharge voltage and generally increases CCFL

discharge frequency. So all the parameters of an inverter should be carefully designed so as not

to produce too much leakage current from high-voltage output of the inverter.

Note 2: It should be employed the inverter which has “Duty Dimming”, if IRCFL is less than 4mA.

Note 3: CCFL discharge frequency should be carefully determined to avoid interference between inverter

and TFT LCD.

Note 4: The frequency range will not affect to lamp life and reliability characteristics.

21.60 23.76 [Watt] Note 6

50,000 - [Hour]

Note 5: CCFL inverter should be able to give out a power that has a generating capacity of over 1,500

voltage. Lamp units need 1,500 voltage minimum for ignition.

Note 6: The variance of CCFL power consumption is ±10%. Calculator value for reference (ISCFL × VCFL ×

4 = PCFL)

d

ocument version 0.1 15/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 16

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

6. Signal Characteristic

6.1 Pixel Format Image

Following figure shows the relationship of the input signals and LCD pixel format.

1 2 1279 1280

1st Line

R G B R G B

M190EP02 V2

R G B R G B

1024th Line

R G B R G B

R G B R G B

d

ocument version 0.1 16/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 17

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

M190EP02 V2

6.2 Signal Description

The LVDS receiver equipped in this LCD module is compatible with SN75LVDS86 standard. LVDS is a

differential signal technology for LCD interface and high speed data transfer device. Transmitter shall be

SN75LVDS84 (negative edge sampling) or compatible.

¾ Power Connector (J1)

PIN# Signal Name Description

1 VCC

2 VCC

3 GND Ground

4 GND

5 NC

DC 5V

DC 5V

Ground

NC

6 GND Ground

7

8

9

10 MUTE

11

12 GND Ground

BKLT_ADJ Light adjust for the DC/AC inverter(PWM)

BKLT_EN Enable for the DC/AC inverter

AUDIO _EN Enable audio power control signal

Mute audio

VOLUME Adjust audio volume(PWM)

d

ocument version 0.1 17/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 18

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

¾ VGA Connector (J2)

PIN# Signal Name Description

1 GND

2VS

3 HS Hsync input from VGA host

4

5 BIN

6 GNDG Ground for the video green signal

7 GIN

8

9 RIN Video red signal

10 GND

GNDB Ground for the video blue signal

GNDR Ground for the video red signal

Ground

Vsync input from VGA host

Video blue signal

Video green signal

Ground

M190EP02 V2

11

12 SCL Clock signal for the DDC2B

13

14

SDA Data signal for the DDC2B

PC5V DC 5V from the PC host

VGA_CON Video cable connected detect signal(host connect this pin to ground)

¾ OSD Connector (J4)

PIN# Signal Name Description

1 GND

2 SOURCE OSD item source function.

3

4

5 LED_A LED Amber for the sleep mode.

6UP

7

8 MINUS OSD minus selection function.

9

SELECT OSD item select function.

LED_G LED Green for the full mode.

DOWN OSD down selection function.

PLUS OSD plus selection function.

Ground

OSD up selection function.

10

11 Power Power on/off function.

12 NC ʳ

13 GND

d

ocument version 0.1 18/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

MENU OSD menu on/off function.

Ground

www.panelook.com

Page 19

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

¾ DVI Connector (J3)

PIN# Signal Name Description

1 GND

2 GND

3 RX2+ TMDS RX2+ signal

4

5RX

6 HPD Host detect for the DVI

7 GND

8 GND

9 RX1+ TMDS RX1+ signal

10

DVI_5V DC 5V from the PC host

2- TMDS RX2- signal

SDA Data signal for the DDC2B

Ground

Ground

Ground

Ground

M190EP02 V2

11

12 SCL Clock signal for the DDC2B

13 GND

14 GND

15 RX0+ TMDS RX0+ signal

16 NC

17

18 NC

19 GND

20 GND

21 RXC+ TMDS RXC+ signal

22

23

24 GND Ground

25 GND

26 NC

27 NC

RX1- TMDS RX1- signal

Ground

Ground

RX0- TMDS RX0- signal

Ground

Ground

DVI_CON DVI cable connected detect

RXC- TMDS RXC- signal

Ground

28 GND

29 GND

30 NC

d

ocument version 0.1 19/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Ground

Ground

www.panelook.com

Page 20

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

M190EP02 V2

6.3 The input data format

The input data format is followed the VESA Vedio Signal Standard. In each RGB termination is described as

following table.

Values

Max Luminance Voltage Input Data = (FFh)

Min Luminance voltage Input Data = (00h)

Video Channel Rise/Fall Time Max 25% of minimum pixel clock period

Maximum Settling Time after

overshoot/undershoot

Monotonic Yes

Resolution 1 LSB

Integral Linearity Error

Differential Linearity Errorʳ

0.700 Volts +0.070 /-0.035 volts

0.000 Volts

30% of minimum pixel clock period averaged over 100

waveforms to 5% final full-scale value.

1

LSB

1

LSB

Video Channel to Video Channel Mismatch

Video Noise injection ratio

Video Channel to Video Channel Output Skew

Overshoot/Undershoot

6% of any video output voltage over the full voltage range

2.5 % of Max Luminance Voltage

50% of minimum pixel clock period

12% of step function voltage level over the full voltage

range

d

ocument version 0.1 20/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 21

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

The Synchronization (Hsync and Vsync) Signal format is described as following table.

M190EP02 V2

Min. Max.

Driver Logic Level “1” 2.4 Volts 5.5 Volts

Driver Logic Level “0” 0.0 Volts 0.5 Vots

Driver High Level Output Current

Driver Low Level Output Current 8mA

Receiver Logic Level “1” 2.0 Volts

Receiver Logic Level “0” 0.8 Volts

Fall Time Max 80% of minimum pixel clock period

Rise Time Max 80% of minimum pixel clock period

Monotonic Rise/Fall Voltage range

Overshoot/Undershoot

8mA

0.5-2.4 Volts

30% of high level signal voltage range No signal

excursions allowed in the 0.5-2.4 volt voltage range

Over the frequency spectrum: One half of the

difference between the maximum and minimum

Jitter

(Measured between Hsync pulses)

LSB

: Least Significant Bit

interval between Hsync pulses measured over

100,000 intervals shall be less than 15% of the pixel

clock, 0Hz to max. horizontal refresh rate at all image

formats, worst-case screen patterns.

Monotonic

1. The property of either never increasing or never decreasing in reference to the slope of a

transient response.

2. A constant slope value containing no inflection points.

Sync: Synchronization Signals

For more details, please refer to VESA (Video Electronics Standards Association) Video Signal

Standard.

d

ocument version 0.1 21/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 22

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

6.4 Signal Electrical Characteristics

¾ Power interface

Pin# Name Ty

1 VCC 4.75 5.0 5.25 V

2 VCC 4.75 5.0 5.25 V

3 GND

4 GND

5 NC

6 GND

7 BKLT_ADJ

8 BKLT_EN

9 AUDIO_EN

10 MUTE

11 VOLUME

12 GND

pe

High (Max.)

Low (Min.)

High (On) VCC V Internal serial 1K Ohm

Low (Off)

High (On)

Low (Off)

High (On)

Low (Off)

High (Max.)

Low (Min.)

Min. Ty

VCC V Internal serial 3.2K Ohm

0.3 V Internal serial 2.2K Ohm

0.3 V

2.65 3.3 V -4mA

GND 0.45 V 5mA

2.65 3.3 V -4mA

GND 0.45 V 5mA

3.2 V

0.1 V 4mA

p.

Max. Unit Remark

M190EP02 V2

1.5A

d

ocument version 0.1 22/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 23

Global LCD Panel Exchange Center

www.panelook.com

¾ VGA interface

Pin# Name Ty

1

2 VS

3 HS

4

5

6

7

8

9

10

11 SDA

12 SCL

13

14

GND

GNDB

BIN 700 mV

GNDG

GIN 700 mV

GNDR

RIN 700 mV

GND

PC5V

VGA_CON

Product Specification

AU OPTRONICS CORPORATION

pe

High 2.5

Low GND 0.8

High 2.5

Low GND 0.8

High 3.5

Low GND 0.8 V

High 3.5

Low GND 0.8 V

Min. Ty

p.

VCC V

VCC V

VCC V

VCC V

Max. Unit

M190EP02 V2

d

ocument version 0.1 23/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 24

Global LCD Panel Exchange Center

www.panelook.com

¾ OSD interface

Pin# Name Ty

1

2 SOURCE

3 SELECT

4

5

6 UP

7 DOWN

8 MINUS

9 PLUS

10 MENU

11 Power

12

13

GND

LED_G 3.3

LED_A 3.3

NC

GND

Product Specification

AU OPTRONICS CORPORATION

pe

High 2.65

Low 0

High 2.65

Low 0

High 2.65

Low 0

High 2.65

Low 0

High 2.65

Low 0 0.45 V

High 2.65

Low 0 0.45 V

High 2.65

Low 0

High 2.65

Low 0 0.45 V

Min. Ty

p.

3.3 V

0.45 V

3.3 V

0.45 V

3.3 V

0.45 V

3.3 V

0.45 V

3.3 V

3.3 V

3.3 V

0.45 V

3.3 V

Max. Unit

M190EP02 V2

d

ocument version 0.1 24/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 25

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

M190EP02 V2

6.5 Interface Timings

The signal interface of the TFT-LCD module is analog RGB compatible.

6.5.1 Timing Characteristics

The timings are supported by the signal interface of M190EP02 are listed as following table.

Horizontal

Resolution

Frequency

(KHz)

640x350 31.47(P)

720x400 31.47(N)

640x480 31.47(N)

640x480 35.00(N)

640x480 37.86(N)

640x480 37.50(N)

800x600 37.88(P) 60.32(P) 40 1280x1024 VESA

800x600 48.08(P) 72.19(P) 50 1280x1024 VESA

800x600 46.86(P) 75.00(P) 49.5 1280x1024 VESA

832X624 49.72(N) 74.55(N) 57.29 1280x1024 Macintosh

1024x768 48.36(N)

1024x768 56.48(N) 70.10(N) 75 1280x1024 VESA

1024x768 60.02(P) 75.00(P) 78.75 1280x1024 VESA

1024X768 60.24(N) 74.93(N) 80 1280x1024 Macintosh

1152x864 67.50(P) 75.00(P) 108 1280x1024 VESA

1152x870 68.68(N) 75.06(N) 100 1280x1024 Macintosh

1152x900 61.80(N) 66.00(N) 94.5 1280x1024 SUN 66

1152x900 71.81(N) 76.14(N) 108 1280x1024 SUN

1280x1024 64.00(P) 60.00(P) 108 1280x1024 VESA

1280x1024 75.83(N) 71.53(N) 128 1280x1024 IBM1

1280x1024 80.00(P) 75.00(P) 135 1280x1024 VESA

1280x1024 81.18(N) 76.16(N) 135.09 1280x1024 SPARC2

Vertical

Frequency

(Hz)

70.08(N) 25.17 1280x943 DOS

70.08(P) 28.32 1280x1024 DOS

60.00(N) 25.18 1280x1024 DOS

67.00(N) 30.24 1280x1024 Macintosh

72.80(N) 31.5 1280x1024 VESA

75.00(N) 31.5 1280x1024 VESA

60.00(N) 65 1280x1024 VESA

Dot Clock

(MHz)

Actually

Resolution

Display

Remark

Note: ϘP”, “N” stands for “Positive”, “Negative” polarity of incoming H-sync/V-sync (input timing). For each

timming detail, please refer to individual video siganl standard.

d

ocument version 0.1 25/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 26

Global LCD Panel Exchange Center

www.panelook.com

6.5.2 Definition of terms

¾ Video Signal Definition

Product Specification

AU OPTRONICS CORPORATION

M190EP02 V2

a) Vmin steady state Amplitude before transition

b) Video Rise Time Delta (t), (measured from the 10% to 90% points of Vmin Steady State to Vmax Steady

State)

c) Overshoot Amplitude

d) Undefined

e) Settling Time - Measured from the end of the overshoot to the point where the amplitude of the video

ringing is down to 5% of the final steady state value

f) Undefined

g) Video Fall Time Delta (t), (measured from the 90% to 10% points of Vmax Steady State to Vmin Steady

State)

h) Undefined here, Note: Undershoot is within this period and with an Amplitude of (j)

i) Settling Time - Measured from the end of the undershoot to the point where the amplitude of the video

ringing is down to 5% of the final steady state value

j) Vmin steady state Amplitude after transition

¾ Synchronization Signal Definition

d

ocument version 0.1 26/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 27

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

M190EP02 V2

6.6 Power ON/OFF Sequence

VCC power and lamp on/off sequence is as follows. Interface signals are also shown in the chart. Signals

from any system shall be Hi-Z state or low level when VCC is off.

T1

Power Supply VCC

LVDS Signal

90%

10%

T2

VALID

DATA

90%

T5

T6

10%

T7

Backlight On

Parameter

T1 -

10 50

T3 200

T4 100

T5 0

T6 -

T3

er Sequence Timing

Pow

Value

Min. Ty

16 50 [ms]

T4

Unit

p.

- 10 [ms]

- 10 [ms]

- - [ms]

- - [ms]

- 50 [ms]

Max.

T7 1000

d

ocument version 0.1 27/36

- - [ms]

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 28

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

M190EP02 V2

7. Connector & Pin Assignment

Physical interface is described as for the connector on module.These connectors are capable of

accommodating the following signals and will be following components

.

7.1 TFT LCD Module

7.1.1 Connector

Connector Name / Designation Pow

Manufacturer STM or compatiable

Type / Part Number STM MS242612R

Mating Housing / Part Number STM P242612

er Connector / J1

Connector Name / Designation VGA Connector / J2

Manufacturer STM or compatiable

Type / Part Number STM MS242614R

Mating Housing / Part Number STM P242614R

Connector Name / Designation OSD Connector / J4

Manufacturer STM or compatiable

Type / Part Number STM MS242613R

Mating Housing / Part Number STM PS242613

Connector Name / Designation DVI Connector / J3

Manufacturer STM or compatiable

Type / Part Number STM MDS240315

Mating Housing / Part Number STM PDS240315

7.1.2 Pin Assignment

d

ocument version 0.1 28/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 29

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

M190EP02 V2

¾ Power Connector (J1)

Pin# Signal Name Pin# Signal Name

1 VCC

3 GND

5 NC

7 BKLT_ADJ

9 AUDIO _EN 10 MUTE

11 VOLUME

Ϥ

1

Share with OSD source key

2 VCC

4 GND

6 GND

8 BKLT_EN

12 GND

¾ VGA Connector (J2)

Pin# Signal Name Pin# Signal Name

1

1 GND

3 HS

2 VS

4 GNDB

5 BIN 6 GNDG

7 GIN 8 GNDR

9 RIN

11 SDA

13 PC5V

10 GND

12 SCL

14 VGA_CON

¾ OSD Connector (J4)

Pin# Signal Name Pin# Signal Name

1 GND

3 SELECT

5 LED_A

7 DOWN

9 PLUS 10 MENU

2 SOURCE

4 LED_G

6 UP

8 MINUS

11 Power 12 NC

13 GND

d

ocument version 0.1 29/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 30

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

M190EP02 V2

¾ DVI connector (J3)

Pin# Signal Name Pin# Signal Name

1 GND

3 RX

5 RX2- 6 HPD

7 GND 8 GND

9 RX

11 RX

13 GND

15 RX0+ 16 NC

17 RX0- 18 NC

19 GND

21 RXC+

2+ 4 DVI_5V

1+ 10 SDA

1- 12 SCL

2 GND

14 GND

20 GND

22 DVI_CON

23 RXC-

25 GND

27 NC 28 GND

29 GND

24 GND

26 NC

30 NC

d

ocument version 0.1 30/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 31

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

M190EP02 V2

7.2 Backlight Unit

Physical interface is described as for the connector on module. These connectors are capable of

accommodating the following signals and will be following components.

Connector Name / Designation Lamp Connector / Backlight Lamp

Manufacturer JST

Type / Part Number BHSR-02VS-1

Mating Type / Part Number SM02(4.0)B-BHS-1-TB

7.2.1 Signal for Lamp connector

Pin # Cable color Signal Name

Upper

er

Low

1 Pink

2 White

3 Pink

4 White

High Voltage

Low Voltage

High Voltage

Low Voltage

Pin # Cable color Signal Name

1 Pink

2 White

3 Pink

4 White

High Voltage

Low Voltage

High Voltage

Low Voltage

d

ocument version 0.1 31/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 32

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

8. Reliability

Environment test conditions are listed as following table.

Temperature Humidity Bias (THB) Ta= 50 , к 80%RH, 300hours

High Temperature Operation (HTO)

Low Temperature Operation (LTO)

High Temperature Storage (HTS) Ta= 60 , 300hoursк

Low Temperature Storage (LTS)

Vibration Test

(Non-operation)

Shock Test

(Non-operation)

Test

Items Required Condition

Ta= 50 , к 50%RH, 300hours

Ta= 0 , 300hoursк

Ta= -20 , 300hoursк

Acceleration: 1.5 G

Wave: Random

Frequency: 10 - 200 - 10 Hz

Sweep: 30 Minutes each Axis (X, Y, Z)

Acceleration: 50 G

Wave: Half-sine

Active Time: 20 ms

Direction: X,ʳY,ʳZ (one time for each Axis)

M190EP02 V2

Note

Drop Test Height: 60 cm, package test

Thermal Shock Test (TST)

On/Off Test On/10sec, Off/10sec, 30,000 cycles

ESD (ElectroS

Altitude Test

Note 1: The TFT-LCD module will not sustain damage after being subjected to 100 cycles of rapid

temperature change. A cycle of rapid temperature

-2˃к to 6˃к, and back again. Power is not applied during the test. After temperature cycling, the

unit is placed in normal room ambient for at least 4 hours before power on.

Note 2: According to EN61000-4-2 , ESD class B: Some performance degradation allowed. No data lost.

Self-recoverable. No hardware failures.

tatic Discharge)

-20к/30min, 60к/30min, 100 cycles

Contact Discharge: ± 8KV, 150pF(330

8 points, 25 times/ point.

Air Discharge: ± 15KV, 150pF(330 ) 1sec

8 points, 25 times/ point.

Operation:10,000 ft

Non-Operation:30,000 ft

change consists of varying the temperature from

) 1sec,

1

2

d

ocument version 0.1 32/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 33

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

9. Shipping Label

The shipping label format is shown as below.

M190EP02 V2

d

ocument version 0.1 33/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 34

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

10. Mechanical Characteristics

M190EP02 V2

d

ocument version 0.1 34/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 35

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

M190EP02 V2

d

ocument version 0.1 35/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 36

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

AU OPTRONICS CORPORATION

M190EP02 V2

d

ocument version 0.1 36/36

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Loading...

Loading...