Audi A6 Quattro 2008 User Manual

Accessories and Body, Cab

2008 Audi A6 Quattro

2008 Audi A6 Quattro

Accessories and Body, Cab Body Collision Repair

Accessories and Body, Cab Body Collision Repair

Body Collision Repair

01 - BODY COLLISION REPAIR - GENERAL INFORMATION

SAFETY INSTRUCTIONS

--> Removing Components

--> Battery, Welding Procedures

--> Electronic Control Modules

--> Paint, Glass, Upholstery, Trim

--> Fuel Tank or Fuel Lines

--> Air Conditioning

--> Airbag System

--> Seat Belts, Inspecting

--> Working on Vehicles with Belt Tensioners

--> Separating Work, Straightening Work and/or Dent Removal on Vehicles with Airbags

--> Seats with Side Airbags, Removing

Removing Components

The vehicle must be secured on the hoist before its center of gravity changes due to disassembly.

Battery, Welding Procedures

NOTE:

Before disconnecting battery ensure that radio code is available. Ensure

radio is in an operational condition by inputting radio code before

releasing vehicle to customer.

Before welding, you must disconnect both battery terminals and cover both battery poles.

You must remove the vehicle battery before performing work near the battery that could produce sparks.

CAUTION: Switch off ignition before connecting battery! --> 27

GENERATOR, CRUISE CONTROL

FIXYOURCAR

FIXYOURCAR

1:34:58 AM Page 1

1:35:03 AM Page 1

- STARTER,

No other vehicles may be parked unprotected in areas used for body repairs. (Fire hazard due to flying sparks,

No parts of the charged air conditioner system may be welded, brazed or soldered. This also applies to any part

2008 Audi A6 Quattro

Accessories and Body, Cab Body Collision Repair

On vehicles with electronic ignition lock, ignition must be switched off

before removal

There should not be any people inside the vehicle when connecting the

battery!

Electronic Control Modules

Connect the ground (GND) connection of the electric welding appliance directly to the part to be welded. When

doing this, make sure that no electrically insulated parts are between the ground (GND) connection and the

welding point..

Do not allow the ground (GND) connection or the welding electrode to touch the electronic control units and

electrical wiring.

Procedure for Electronic Control Modules after accident repairs

It is only necessary to install new electronic control units after an accident where at least one of the following

conditions is present:

The function check results in the message "Control module faulty".

If electronic components, e.g. ABS control modules, were removed for servicing and then reused, these are to

be checked for function according to the available documentation after installing. To do this, check all DTC

memories with a tester and correct any possible malfunctions present.

Paint, Glass, Upholstery, Trim

battery, damage to paintwork and glass).

Fuel Tank or Fuel Lines

Use extreme care when performing sanding and welding work near the tank or other components carrying fuel.

Where there are doubts regarding safety, these parts must be removed.

Air Conditioning

of the vehicle if there is a risk that the parts of the air conditioner system could heat up. After paint repairs, the

vehicle must not be heated up to more than 176 F (80 C) in the drying booth or preliminary heating zone,

because heat causes a pressure increase which can burst the system..

NOTE:

The system must be evacuated when it is necessary to weld electrically

near the refrigerant hoses. During the electrical welding process invisible

ultraviolet rays are given off which penetrate the refrigerant hoses and

FIXYOURCAR

1:34:59 AM Page 2

The battery Ground (GND) strap must be disconnected when working on the airbag system or when performing

2008 Audi A6 Quattro

Accessories and Body, Cab Body Collision Repair

decompose the refrigerant.

Solution

Evacuate air conditioning system: --> 87 - AIR CONDITIONING Only extract system if it is required by the

safety precautions.

If it is necessary to evacuate the refrigerant when carrying out repairs to a vehicle, avoid all contact with liquid

refrigerant or refrigerant vapor!

Wear rubber gloves to protect the hands and goggles to protect the eyes! If the refrigerant comes into contact

with unprotected parts of the body it will cause frostbite..

CAUTION: It is advisable to have a rinsing bottle for the eyes handy at all times. If

liquid refrigerant gets into the eyes, they should be rinsed thoroughly with

water for about 15 minutes.

Then use eye drops and obtain medical attention immediately even if no

pain is felt in the eyes. The doctor should be informed that the cause of

the frostbite was R12 or R134a refrigerant.

If the refrigerant comes into contact with other parts of the body despite

compliance with safety measures, the part of the body concerned must be

rinsed immediately with cold water for at least 15 minutes. --> 87

- AIR

CONDITIONING

Although refrigerant does not present a fire hazard, smoking is not permitted in rooms containing refrigerant

vapors. The high temperature of a burning cigarette causes a chemical breakdown of the refrigerant vapor. The

products of this breakdown are poisonous and cause violent coughing and sickness when inhaled.

Airbag System

Repair notes --> 69

- PASSENGER PROTECTION - AIRBAGS, SEAT BELTS

straightening work when repairing the body.

CAUTION: Switch off ignition before connecting battery! --> 27 - STARTER,

GENERATOR, CRUISE CONTROL

On vehicles with electronic ignition lock, ignition must be switched off

before removal

There should not be any people inside the vehicle when connecting the

battery!

FIXYOURCAR

1:34:59 AM Page 3

Airbag components must not even briefly be subjected to temperatures above 100C (212F).

Audi 100 sedan From MY 1982

straightening work or dent removal, the belt tensioners with load detection

2008 Audi A6 Quattro

Accessories and Body, Cab Body Collision Repair

Additional notes --> 69 - PASSENGER PROTECTION - AIRBAGS, SEAT BELTS

Airbag components must not come into contact with grease, cleaning agent, oil or similar.

Mechanically damaged airbag components must be replaced --> Airbag

Wash hands after touching deployed airbag units.

Seat Belts, Inspecting

CAUTION: After every accident, seat belt system must be checked systematically. If

damage is determined when checking the test points, customer must be

informed regarding necessity of changing belts..

Additional notes --> 69 - PASSENGER PROTECTION - AIRBAGS, SEAT

BELTS

Working on Vehicles with Belt Tensioners

CAUTION: Before beginning separation work, straightening work or dent removal,

remove mechanically activating belt tensioners without load detection

(release lock). With electrically activating belt tensioners, the battery

Ground (GND) strap must be disconnected.

Additional notes --> 69

- PASSENGER PROTECTION - AIRBAGS, SEAT

BELTS

NOTE:

If the belt webbing is completely unrolled, the load detection (release lock)

hinders the release of the mechanically activated belt tensioner in an

accident.

CAUTION: With belt tensioners with load detection, the belt webbing must not be

pulled out when performing separation work, straightening work or dent

removal. If strong shaking motions are generated by separating work,

must be removed.

Additional notes --> 69 - PASSENGER PROTECTION - AIRBAGS, SEAT

BELTS

The following vehicles with no load detection on belt tensioners:

FIXYOURCAR

1:34:59 AM Page 4

AIRBAGS,

The battery Ground (GND) strap must be disconnected when working on the airbag system or when performing

--

>

2008 Audi A6 Quattro

Accessories and Body, Cab Body Collision Repair

Audi 200/V8 From MY 1983

Safety belts with belt tensioners, removing and installing --> 69 - PASSENGER PROTECTION SEAT BELTS

Separating Work, Straightening Work and/or Dent Removal on Vehicles with Airbags

straightening work when repairing the body.

CAUTION: Switch off ignition before connecting battery!

There should not be any people inside the vehicle when connecting the

battery!

Repair notes --> 69 - PASSENGER PROTECTION - AIRBAGS, SEAT BELTS

Seats with Side Airbags, Removing

CAUTION: You must always follow safety precautions when removing seats.

You can find the safety precautions in the repair information belonging to each vehicle model --> 69 PASSENGER PROTECTION

- AIRBAGS, SEAT BELTS .

GENERAL INFORMATION

--> Diagnosis of Accident Vehicles

--> General Information

--> Conditions in which Body and/or Parts are Passed for Painting

--> Straightening

--> Separating Cuts

--> Replacement Body Sub-Parts and Part Sections

--> Original Joint

--> Galvanized Body Parts

Removing Remaining Material

FIXYOURCAR

1:34:59 AM Page 5

--

>

New Parts

--> Replacement Parts

reshaping of accident damaged areas should be carried out in the same manner.

Diagnosis of Accident Vehicles

2008 Audi A6 Quattro

Accessories and Body, Cab Body Collision Repair

Damage to the running gear and assembly mountings, which could have very serious effects later

on is

sometimes not discovered when accident vehicles are being repaired. Where the accident damage indicates

over-stressing of the vehicle, special attention must be paid to the following components, completely

independent of the axle geometry check which must be done in all cases:

Check steering and steering linkages using steering wheel angle for problem-free function, visual

inspection for bends or cracks.

Check suspension, all suspension parts such as links, struts, steering knuckle, stabilizer, subframe, axle

body and their securing parts for bends or cracks.

Check rims and tires for damage, true running and imbalance. Check tires for cuts in the profile and the

sides, check tire pressure.

Check mounts for engine, transmission, axles and exhaust system for damage.

Finally, a proper road test after repairs ensures that the vehicle is safe to drive and can be handed over to

the customer.

General Information

When repairing, the original connection should always be restored.

tandard repairs are described in the repair information. Further descriptions are not given because if there are

S

more extensive repairs, the damaged area should be removed at the original connection. Where this is possible,

the joining techniques can be implemented according to the preceding comparison.

All repairs with special separating cuts and joining techniques that do not correspond to the original connection

(production status) checked and approved by the Technical Development by means of calculation, strength

testing and crash.

Conditions in which Body and/or Parts are Passed for Painting

Before a repaired vehicle or part is handed over to the paint shop for painting, the repaired or beaten out, and

where necessary, filled surfaces must be prepared for painting by rubbing-down with abrasive paper having a

grade of P 80 - P 100.

This preparatory work is the job of the sheet metal worker and is included in the time allowed for the repair.

Straightening

Body and floor sections are produced mainly from cold formed deep drawn sheet metal. For this rea

FIXYOURCAR

1:34:59 AM Page 6

son the

If the size of the damage does not allow it to be reshaped against the direction of damage, the damaged part

information, e.g with pressure hammer V.A.G 1577 or body repair saw V.A.G 1523 A , drill out most spot weld

connections with spot weld remover V.A.G 1731.

2008 Audi A6 Quattro

Accessories and Body, Cab Body Collision Repair

must be removed after straightening the connecting surfaces.

Separating Cuts

In areas where cutting and the subsequent joining affect the rigidity of the body and also the operational safety

and serviceability of the vehicle, the parting cuts must be made in accordance with the Repair Information

instructions.

Replacement Body Sub-Parts and Part Sections

"Sub-parts" include sections of individual parts (e.g. front and rear end points) that are del

ivered pre-cut from

the parts depot.

In contrast to this, "partial sections" are to be cut out from replacement parts. In individual cases, work is

to be performed exactly according to the methods described and represented in the body repair

information.

Because the use of "sub-parts" or "partial sections" as well as special resources influence repair times, the

special resources are included separately in the repair description.

Original Joint

"Original joint" refers to welding that is used by the vehicle manufacturer.

These welds should be reconstructed when performing body repairs.

When doing so, ensure that the production number of weld points is not exceeded when making repairs.

Methods and procedures differing from the original connection are described in the applicable body repair

information.

Galvanized Body Parts

Fully galvanized panels provide a high level of bodywork anti-corrosion protection during manufacture. To be

able to maintain the warranty guarantee against perforation rusting when carrying out repairs, the repair

information from --> Galvanized Body Parts

CAUTION: Because toxic galvanized oxide develops in welding emissions when

welding galvanized sheet steel panels, there must be good workplace

ventilation and flue-gas removal through appropriate means, e.g. welding

emission exhaust system V.A.G 1586 A.

Removing Remaining Material

If the damaged body piece is removed roughly according to the separating cuts in the applicable repai

FIXYOURCAR

1:34:59 AM Page 7

r

In addition, we recommend the degree sander V.A.G 1529 as well as an angle sander to remove the weld

New parts which are not accessible from the inside after a repair, e.g. side members, should, to prevent

painted in the color of the vehicle before being welded in. Here it is recommended to mask the

Cut out side part from roof with the body repair saw V.A.G 1523 A , observing prominent contours, e.g. a

After painting vehicle, preserve cavities in repair area.

2008 Audi A6 Quattro

Accessories and Body, Cab Body Collision Repair

connections that cannot be removed with the spot weld remover.

New Parts

corrosion, be prewelding flanges.

Replacement Parts

In many cases, replacement parts are delivered only in the "basic version" for parts reduction.

Examples:

Audi 100 from MY 1991 roof without roof rail holes.

In these cases, we recommend that the workshop creates "patterns" from damaged parts.

Example: from MY Audi 100 1991 roof rail holes:

part of the depression (rain gutter), when doing so. Deburr cut edges and protect with fabric-reinforced

adhesive tape.

Apply patterns before painting and allow for the material strength of the pattern when marking the bore holes.

Check new replacement parts, such as doors, panels or fenders for transport damage before sending to paint

shop. This prevents double painting, if transport or accident damage to the vehicle is noticed during assembly.

EXPANDED FOAM INSERTS

CAUTION: Expanded foam inserts expand only after reaching 180 C. Because of this,

filler foam is used for repairs

Filler foam D 506 000 A2 is required for repairs.

Insert replacement expanded foam inserts.

Foam D 506 000 A2 must be applied before fitting replacement part.

The foam hardens within 25 minutes

Do not do perform welding within 15 mm on either side of molded foam element.

FIXYOURCAR

1:34:59 AM Page 8

SYMBOLS

2008 Audi A6 Quattro

Accessories and Body, Cab Body Collision Repair

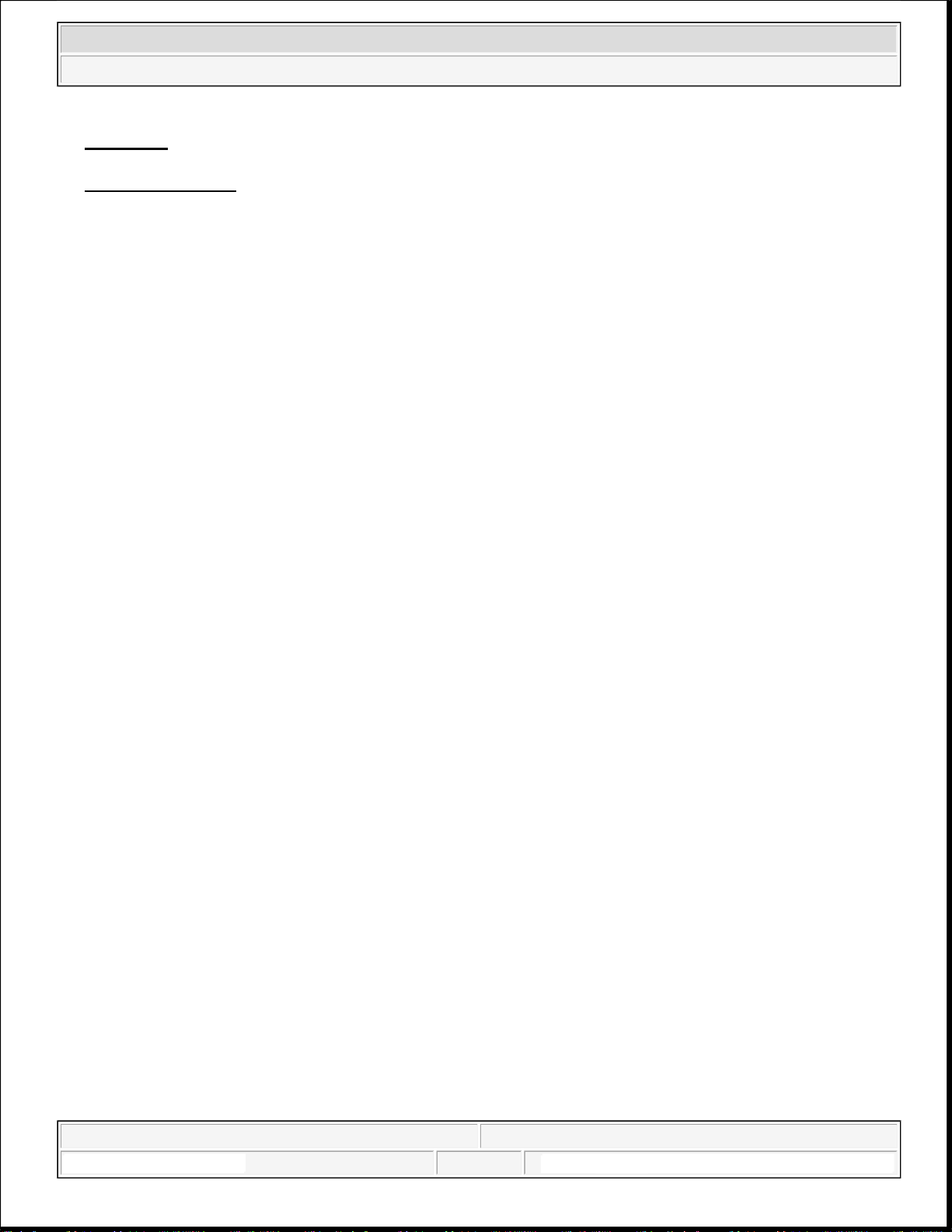

Welding Legend

Straight-line spot weld seam (single row) RP = Spot weld

Straight-line spot weld seam (double row)

Straight-line spot weld seam (double row, staggered)

Fig. 1: Spot Weld Symbols

Courtesy of VOLKSWAGEN UNITED STATES, INC.

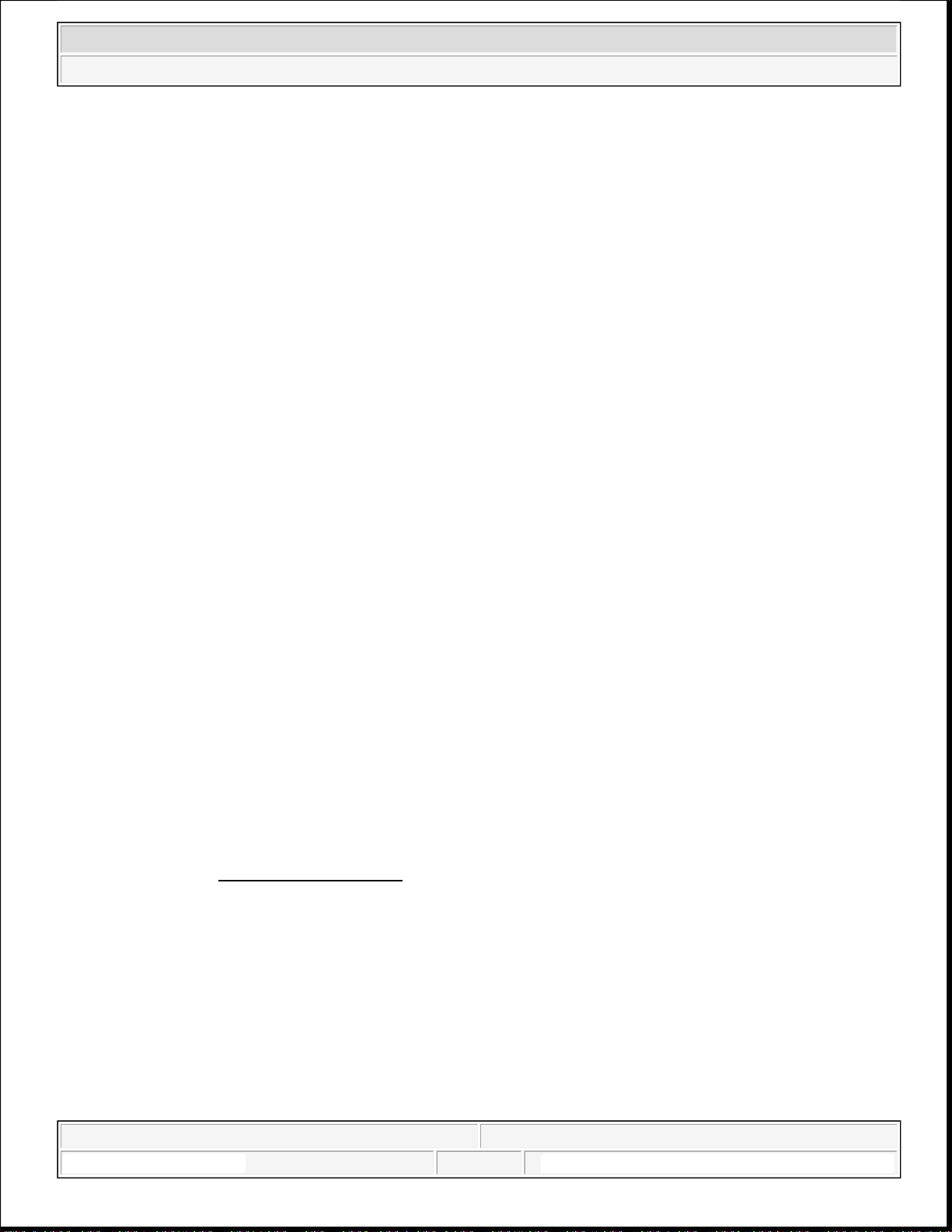

Gas-shielded arc plug weld seam SG = gas-shielded welding

Gas-shielded arc stitch weld seam

Gas-shielded arc continuous weld seam

Gas-shielded arc continuous weld seam (intermittent)

Fig. 2: Seam Weld Symbols

Courtesy of VOLKSWAGEN UNITED STATES, INC.

FIXYOURCAR

1:34:59 AM Page 9

Hard soldering

--> Work Procedures Legend

Work Procedures Legend

Sanding

2008 Audi A6 Quattro

Accessories and Body, Cab Body Collision Repair

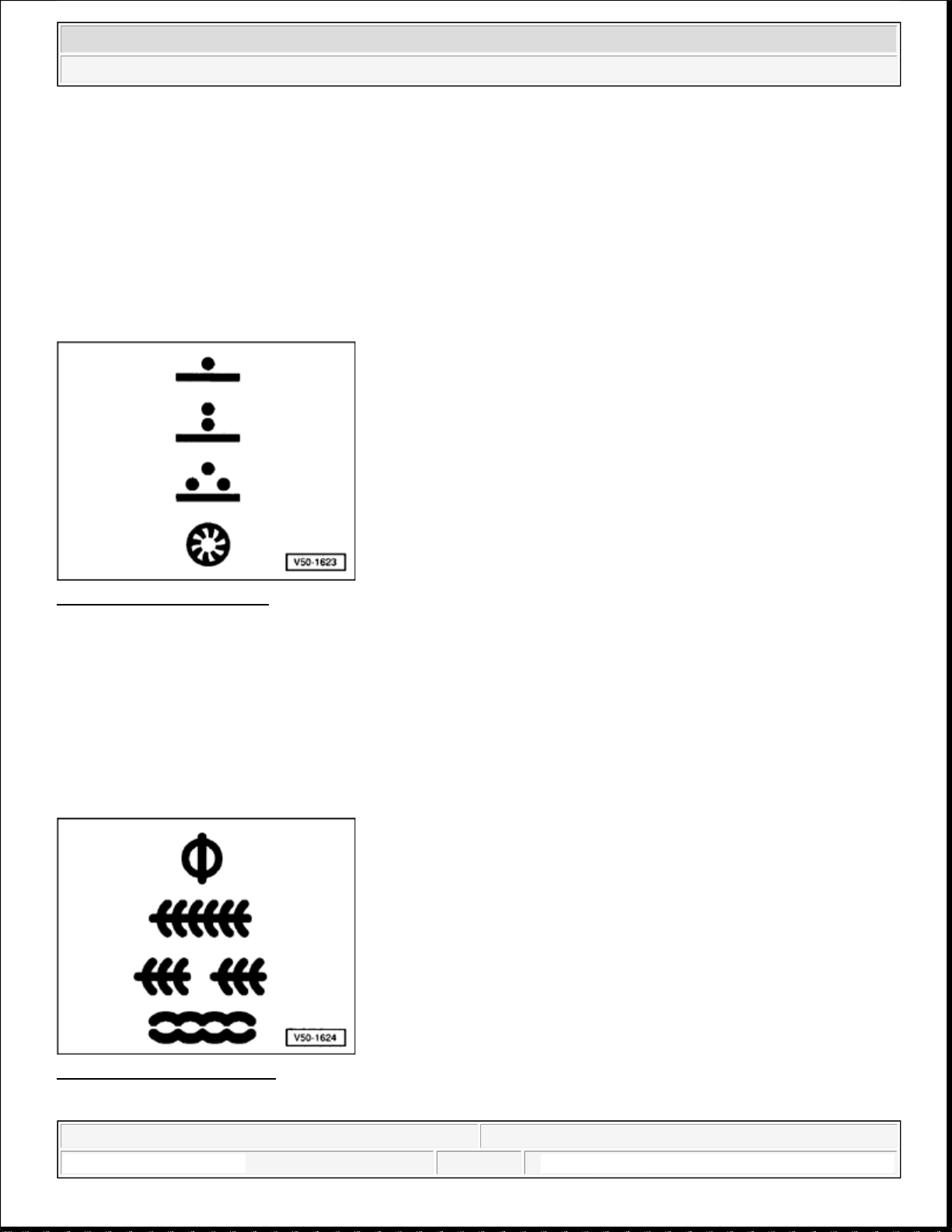

ig. 3: Grind Symbol

F

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Wear away weld seam with a grinder around material application.

NOTE:

The weld seams must be sanded so that the panel strength of the exterior

panels is not or only slightly weakened.

Set an Edge

To perform an overlapping weld.

Perforate

To perform a gas-shielded arc plug weld later.

Drill

FIXYOURCAR

1:34:59 AM Page 10

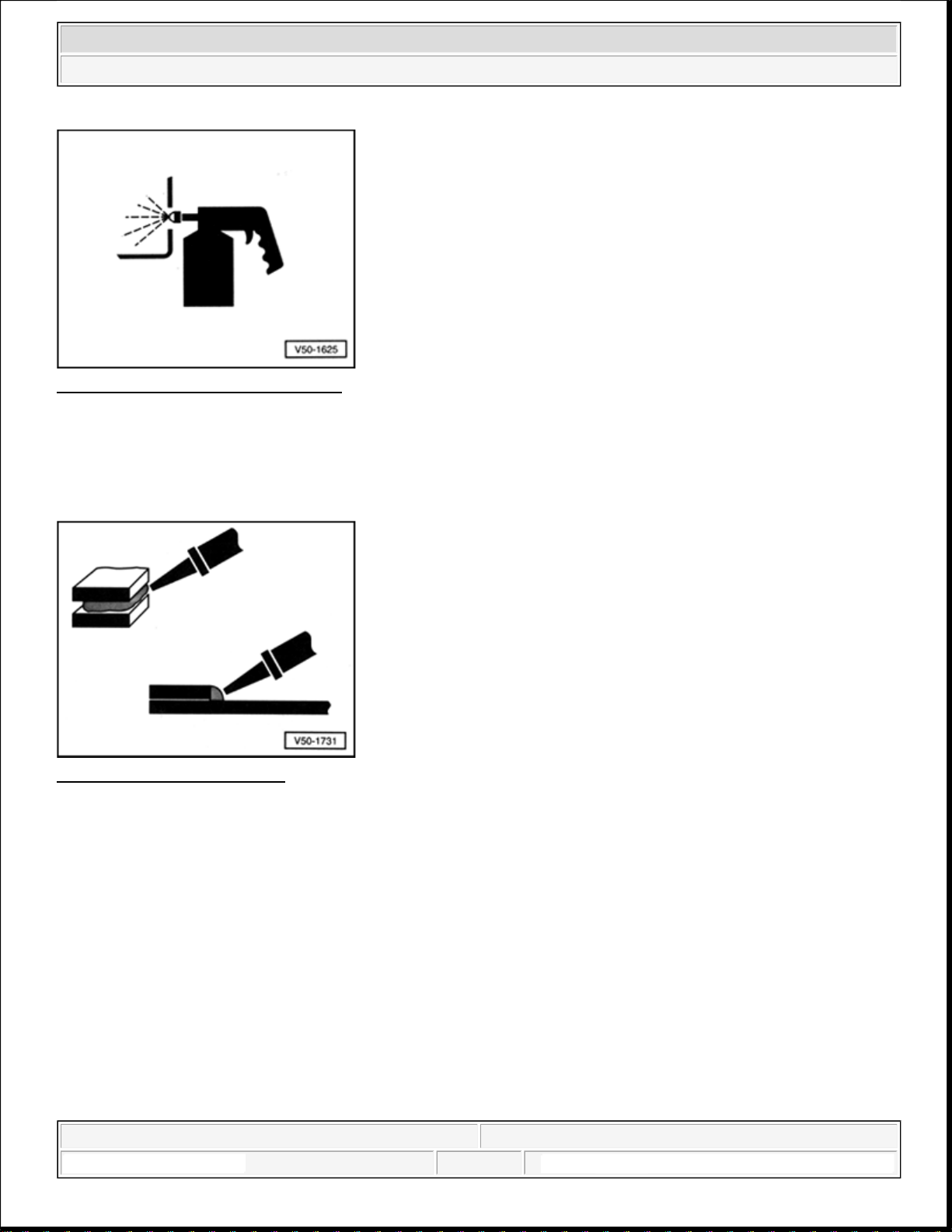

Removing paint on hard

-to-

reach areas (e.g. interior roof frame) with brush VAS 5182.

2008 Audi A6 Quattro

Accessories and Body, Cab Body Collision Repair

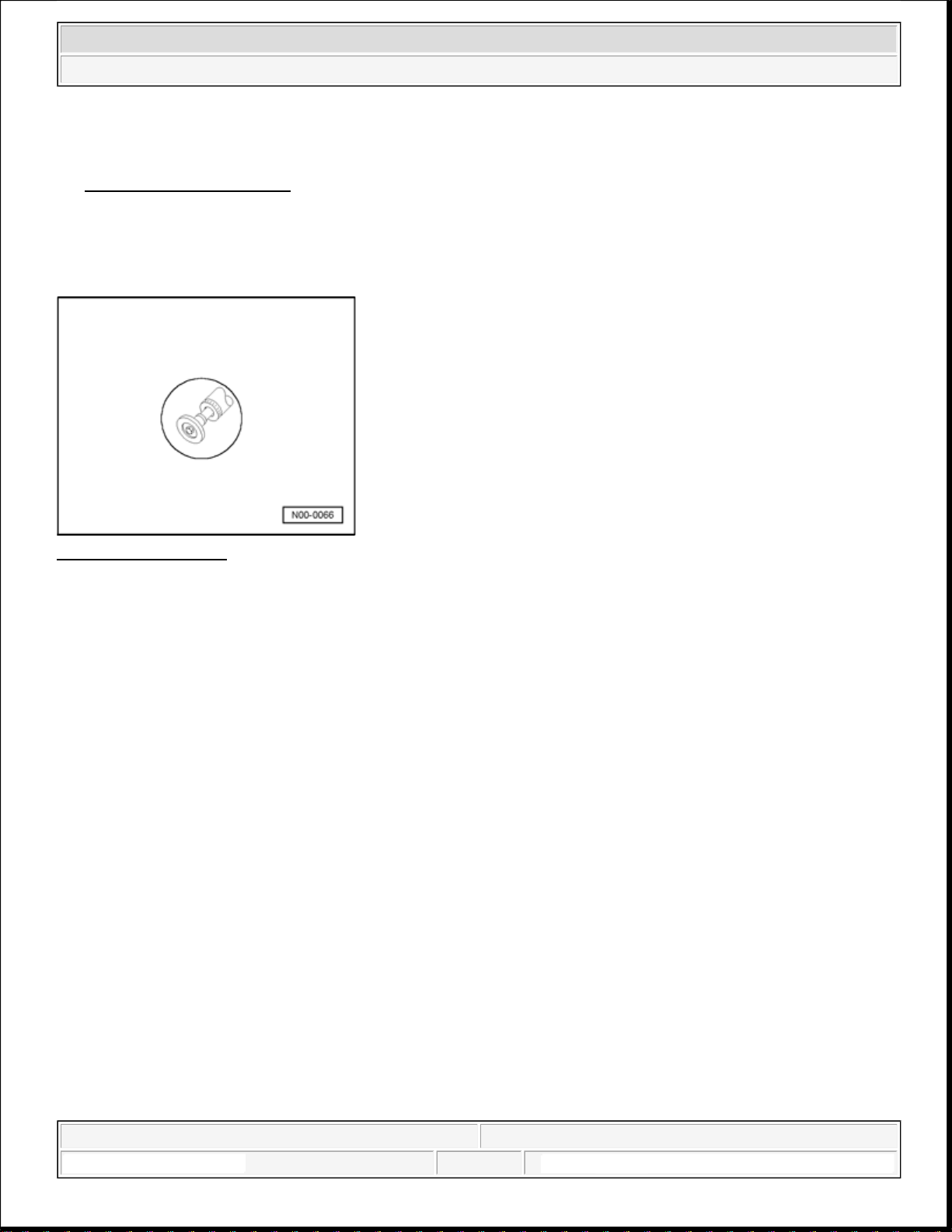

Fig. 4: Offset, Punch And Drill Symbols

Courtesy of VOLKSWAGEN UNITED STATES, INC.

To perform a gas-shielded arc plug weld later or drill out spot welds (original connection).

Fig. 5: Removing Paint On Hard

-To-Reach Areas With Brush VAS 5182

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Sanding

FIXYOURCAR

1:34:59 AM Page 11

Hole pliers V.A.G 1329

The following tools are organized according to V.A.G / VAS numbers.

2008 Audi A6 Quattro

Accessories and Body, Cab Body Collision Repair

Fig. 6: Cavity Conservation Symbol

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Cavity Sealant

Adhesives

Fig. 7: Bond & Seal Symbols

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Fine Seal

BODY REPAIR TOOLS

NOTE:

Special tools, testers and auxiliary items required

FIXYOURCAR

1:34:59 AM Page 12

2008 Audi A6 Quattro

Accessories and Body, Cab Body Collision Repair

Fig. 8: Basic Equipment V.A.G 1366/3

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Basic equipment V.A.G 1366/3

Fig. 9: Undersealant Spray Gun V.A.G 1379

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Undersealant spray gun V.A.G 1379

Fig. 10: Identifying Heat Gun V.A.G 1416

Courtesy of VOLKSWAGEN UNITED STATES, INC.

FIXYOURCAR

1:34:59 AM Page 13

Heat gun V.A.G 1416

Body tool trolley V.A.G 1439

2008 Audi A6 Quattro

Accessories and Body, Cab Body Collision Repair

Fig. 11: Door Tensioner V.A.G 1438

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Door tensioner V.A.G 1438

Fig. 12: Body Tool Trolley V.A.G 1439

Courtesy of VOLKSWAGEN UNITED STATES, INC.

FIXYOURCAR

1:34:59 AM Page 14

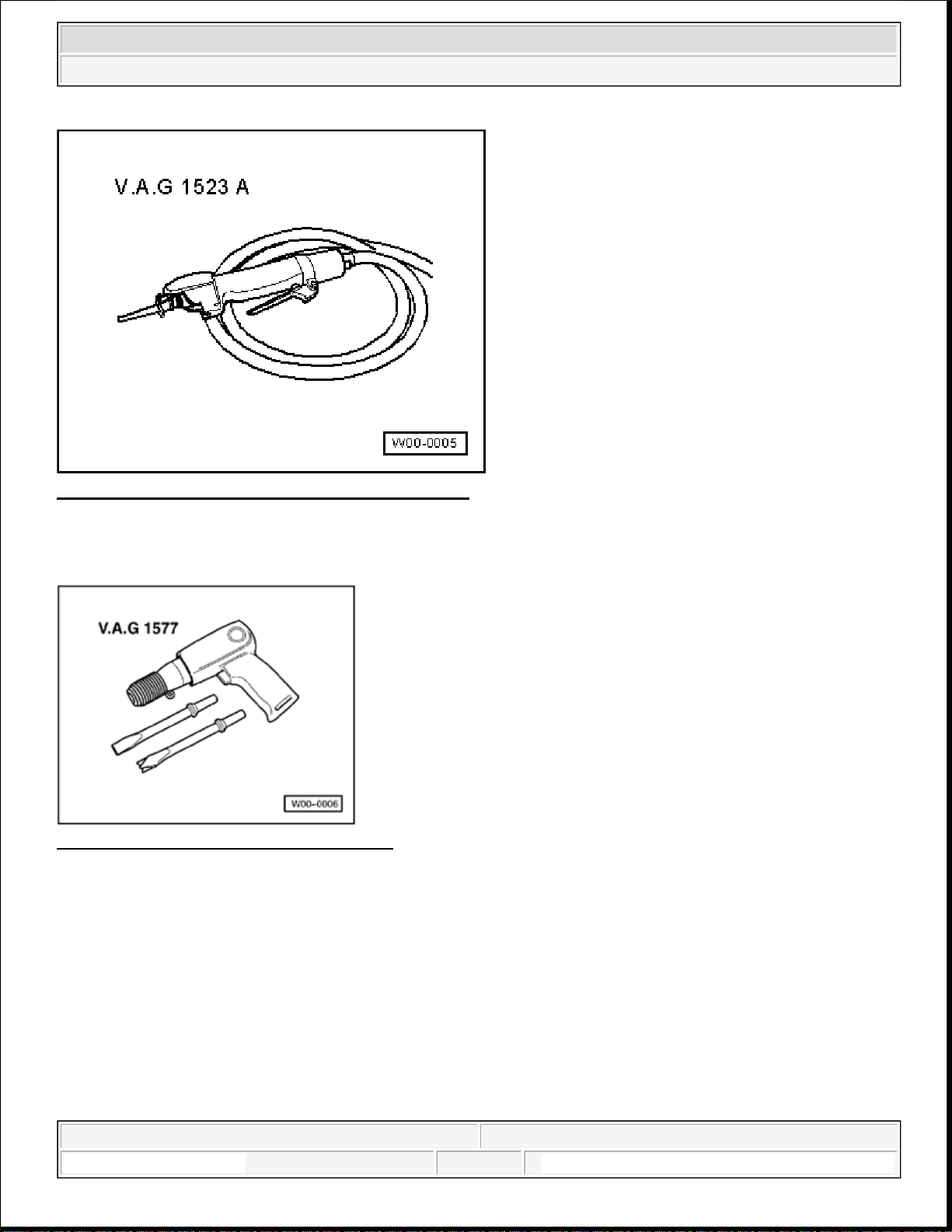

Compressed

-

air chisel V.A.G 1577

2008 Audi A6 Quattro

Accessories and Body, Cab Body Collision Repair

Fig. 13: Identifying Body Repair Saw V.A.G 1523 A

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Body repair saw V.A.G 1523 A

Fig. 14: Pneumatic Hammer (V.A.G 1577)

Courtesy of VOLKSWAGEN UNITED STATES, INC.

FIXYOURCAR

1:34:59 AM Page 15

2008 Audi A6 Quattro

Accessories and Body, Cab Body Collision Repair

Fig. 15: Flange Finishing Iron V.A.G 1585

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Flange finishing iron V.A.G 1585

Fig. 16: Welding Emission Exhaust System V.A.G 1586

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Welding emission exhaust system V.A.G 1586

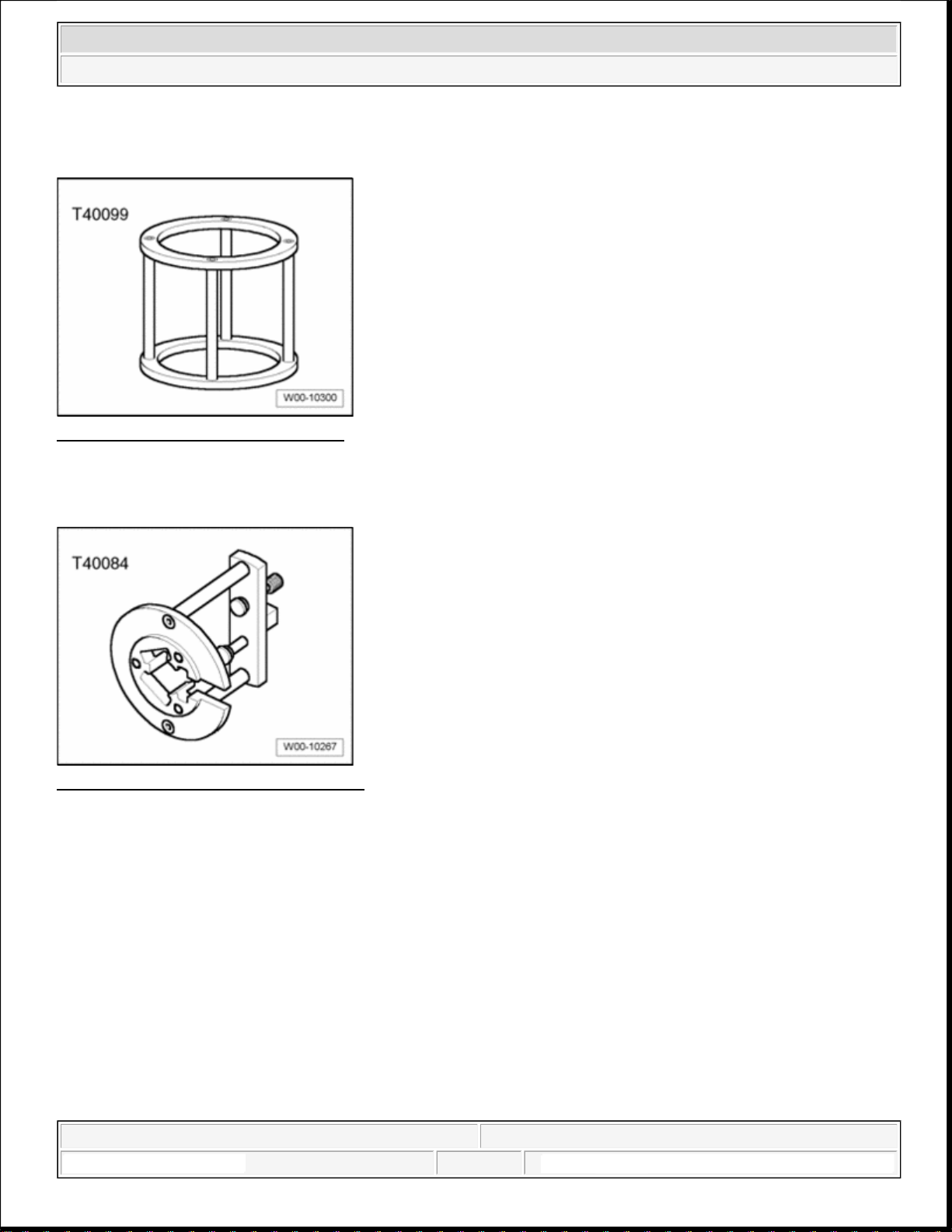

Fig. 17: Spot Weld Remover V.A.G 1731

Courtesy of VOLKSWAGEN UNITED STATES, INC.

FIXYOURCAR

1:34:59 AM Page 16

Compressed air punch pliers and edge setter VAS 1996

Accessories and Body, Cab Body Collision Repair

Spot weld remover V.A.G 1731

2008 Audi A6 Quattro

Fig. 18: Compressed Air Gun V.A.G 1761/1

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Compressed air gun V.A.G 1761/1

Compressed air gun for producing seals and undercoating with factory-original optical characteristics.

Also, all 310 ml cartridges can be used with this gun.

Fig. 19: Compressed Air Punch Pliers And Edge Setter VAS 1996

Courtesy of VOLKSWAGEN UNITED STATES, INC.

FIXYOURCAR

1:34:59 AM Page 17

Fig. 22: Hose Packet (VAS 5023)

2008 Audi A6 Quattro

Accessories and Body, Cab Body Collision Repair

Fig. 20: Compressed-Air Adhesive Gun V.A.G 2005

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Compressed-air adhesive gun V.A.G 2005

For body adhesive

Fig. 21: Door Hinge Replacement Stud 3114

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Door hinge replacement stud 3114

FIXYOURCAR

1:34:59 AM Page 18

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Hose package VAS 5023

Nozzle set 5023/1

Angle sander VAS 5174

710 Watt; 115 mm

Angle sander VAS 5175

1500 Watt; 180 mm

2008 Audi A6 Quattro

Accessories and Body, Cab Body Collision Repair

Fig. 23: Wire Brush VAS 5182

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Brush VAS 5182

For removing paint in hard-to-reach places (e.g. interior roof frame)

BONDED BODY JOINTS

--> Supporting Bonds

--> Types of Bonding

--> Repair Methods for Replacing Parts

Supporting Bonds

The following procedure is used when repairing bonded points:

Separating procedure:

FIXYOURCAR

1:34:59 AM Page 19

2008 Audi A6 Quattro

Accessories and Body, Cab Body Collision Repair

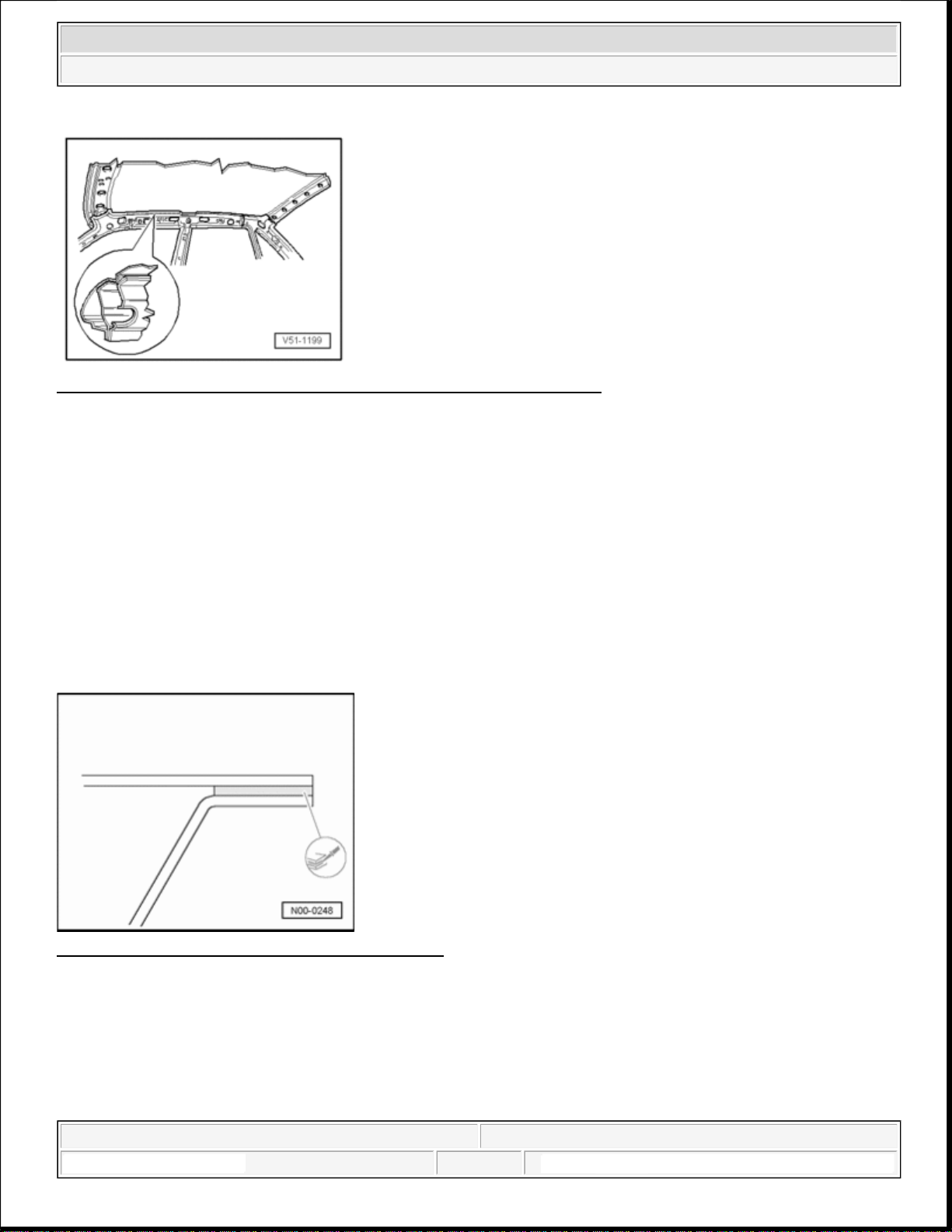

Fig. 24: Roughly Cutting Out Roof To Gain Access To Bonded Point

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Roughly cut out roof to gain access to the bonded point.

Cut through bonded point with oscillating knife.

Types of Bonding

To increase body rigidity and strength, adhesive and spot-weld bonded joints are being increasingly used in

production. They are differentiated as follows:

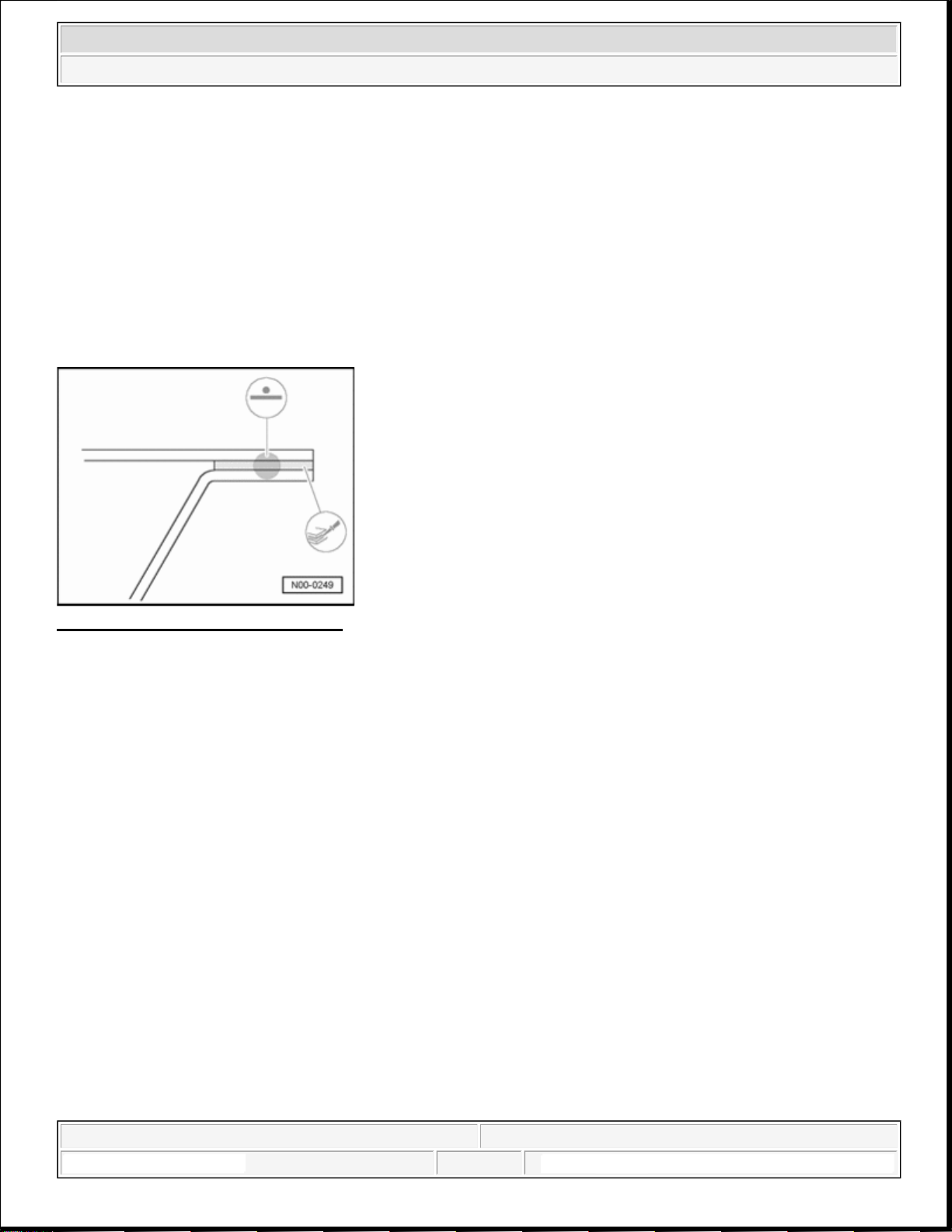

High-Strength bonded joints

In bonded joints, the sheet metal parts are only bonded by adhesive.

Fig. 25: Strength Bonded Joints (Adhesive Only)

Courtesy of VOLKSWAGEN UNITED STATES, INC.

The distance of the high-strength adhesive surfaces to each should not be less than 2 mm or greater than 4 mm.

If necessary, the adhesive surfaces must be prepared.

Repair measures

FIXYOURCAR

1:34:59 AM Page 20

2008 Audi A6 Quattro

Accessories and Body, Cab Body Collision Repair

The bonded joints are restored with the materials specified in the repair information or replacement parts

program.

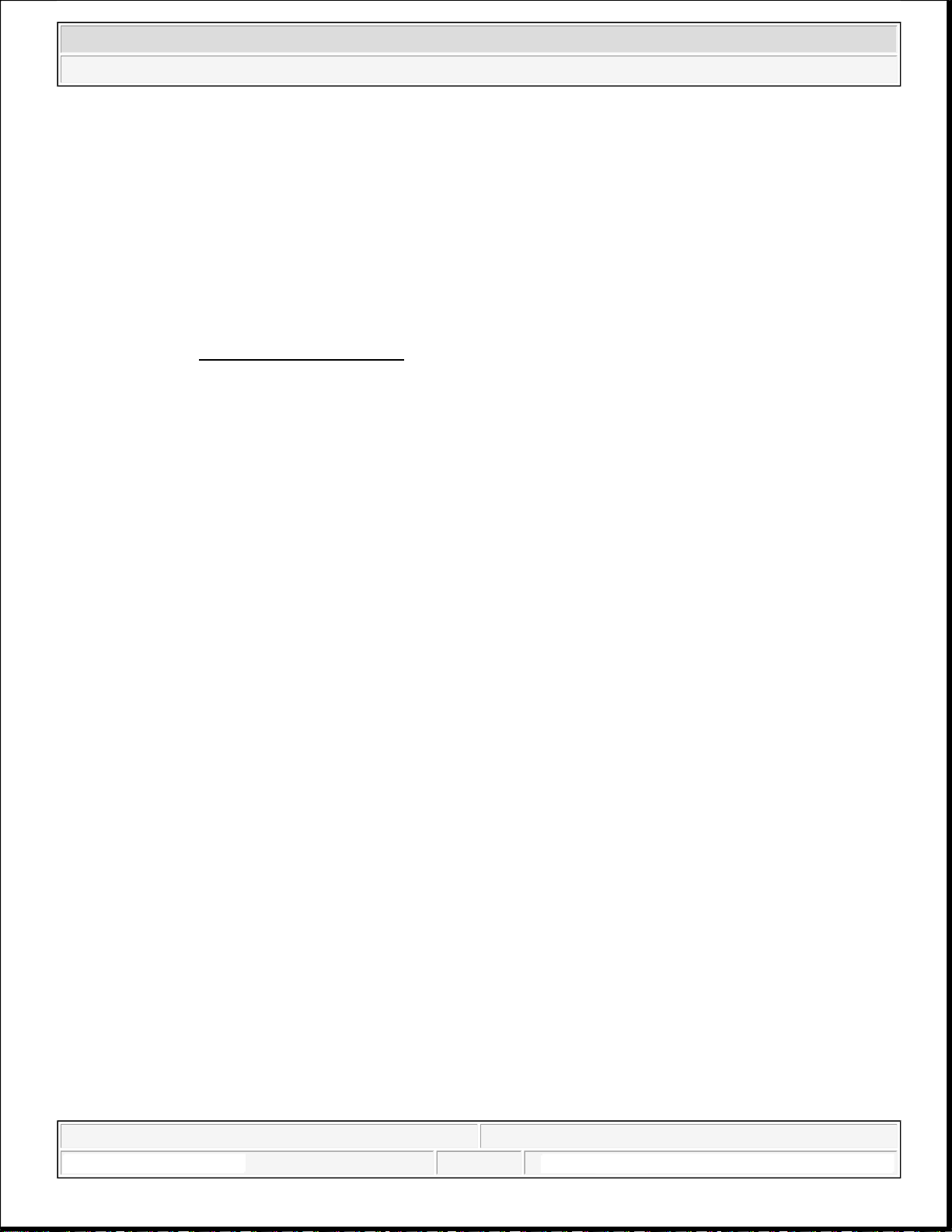

Spot-weld bonded joints

In spot-welded bonded joints, an electrically conductive adhesive is used between the panels, allowing good

root penetration for spot welding.

The distance of the spot-weld surfaces to each other should not be greater than 1 mm. If necessary, the adhesive

surfaces must be prepared.

Fig. 26: Spot Welded Bonded Joints

Courtesy of VOLKSWAGEN UNITED STATES, INC.

The welding current must not be increased for spot-weld bonding operations. The pre-press period must be

extended to approx. 30 - 50 cycles because of the displacement of the adhesive. The fumes produced must be

exhausted.

Repair Methods for Replacing Parts

Adhesive DA 001 730 A should be used in connection with compressed-air adhesive gun V.A.G 2005 as

eplacement for spot-weld adhesive.

r

For simultaneous bonding and welding, the procedures are differentiated according to the type of weld (spot

weld, gas-shielded weld) as follows:

Straight-line spot weld and bonding

With spot welding and bonding, the entire area of spot welds and bonding is replaced when making repairs, as

in production.

With welding problems, e.g. there is a 3-layer panel connection and only the outer panel is replaced, the repair

spot weld should be placed on the "old" spot weld.

Gas-shielded welding and bonding (if spot welding is not possible)

FIXYOURCAR

1:34:59 AM Page 21

If an adhesion area is not accessible with a straight

-

line spot welding device, the area is welded with a gas

-

On vehicles with highest strength steel, spot welding devices with inverter technology (see workshop equipment

press out a bead about 5 cm. long. Then apply adhesive to adhesive surface.

2008 Audi A6 Quattro

Accessories and Body, Cab Body Collision Repair

shielded arc plug weld seam.

In this case, adhesive is done without in order to maintain the welding bead. The gas-shielded arc plug weld

distance is 15 mm.

Gas-shielded welding

SG 2 welding wire is suitable all steel types.

For variations, see 00

- TECHNICAL DATA .

and special tools catalog) are to be used.

Welding emission exhaust system

For spot welding in conjunction with spot weld adhesive, the same standard exhaust system is used as with

welding galvanized panels.

Preparation

The panels to be welded must be fitted before applying adhesive.

Due to adhesive displacement when spot welding, the bare spot weld flange is coated with adhesive and thus

protected from corrosion.

The adhesive surfaces in the welding area must be free of primer and adhesive residue and well as dust and

grease.

Our vacuum device VAS 6216 is recommended for this.

Reconditioning

Wipe escaping adhesive.

Corrosion protection measure Surface technology / chemical materials binder

Paint structure Surface technology / chemical materials binder

DA 001 730 A1 instructions for use

If the adhesive escapes on both sides along the entire length, too much was applied.

On large parts, such as the roof, it is necessary to perform the work with a helper. Otherwise the adhesive

will dry before work is complete.

Before inserting mixing nozzle, ensure double cartridge openings are clean. Secure mixing nozzle and

FIXYOURCAR

1:34:59 AM Page 22

Loading...

Loading...