Audi A6 242, A6 Service Manual

Service.

For internal use only

Pneumatic suspension system

Par t 1

Selflevelling suspension

in the Audi A6

Design and Function

Self-study programme 242

242

2

242_067

Pneumatic self-levelling suspension system

The 4-level air suspension of the Audi

allroad quattro is described in selfstudy program 243.

You will find further information on the

Audi allroad quattro in self-study

programme 241.

Principles of spring suspension, damping and

air suspension

Self-levelling suspension, A6

The rear axle air suspension system for the

Audi A6 Avant is described here.

242_046

242_048

This self-study programme is divided into two

parts:

3

Contents

Principles

Vehicle suspension.................................................................. 4

The suspension system .......................................................... 6

Vibration................................................................................... 8

Characteristic values of springs .......................................... 12

Conventional running gear without self-levelling ............ 14

The self-study programme is not intended as a workshop manual.

The self-study programme will provide you with

information on design and functions.

New

Note

Important:

Note

Page

For maintenance and repairs please refer to the current

technical literature.

Principles of air suspension

Self-levelling air suspension ............................................... 16

Characteristic values of air spring ...................................... 21

Vibration damping................................................................. 23

Shock absorbers (vibration dampers) ................................ 25

PDC shock absorbers ........................................................... 33

System overview ................................................................... 38

Air springs.............................................................................. 40

Air supply unit........................................................................ 42

Diagram of pneumatic system............................................. 43

Compressor ........................................................................... 44

Air dryer ................................................................................. 47

Discharge valve N111 ........................................................... 48

Valve for suspension struts N150 and N151....................... 51

Self-levelling suspension sender G84 ................................ 52

Self-levelling suspension control unit J197 ....................... 54

Self-levelling suspension warning lamps K134 ................ 55

Function diagram ...................................................................56

Interfaces................................................................................ 57

The control concept .............................................................. 58

Other features of the control concept ................................ 60

Self-levelling suspension, A6

4

Vehicle suspension

When a vehicle travels over irregular road

surfaces, impact forces are transmitted to the

wheels. These forces pass to the bodywork

via the suspension system and the wheel

suspension.

The purpose of the vehicle suspension is to

absorb and reduce these forces.

Principles

Wheel contact with the road surface, which

is essential for braking and steering, is

maintained.

The vehicle components are protected

against excessive stresses.

Unpleasant and unhealthy stresses to vehicle

passengers are minimised, and damage to

fragile loads is avoided.

242_003

Driving safety

Operating safety

Driving comfort

When we talk about the vehicle suspension

we can basically distinguish between the

suspension system and the vibration

damping system .

By means of the interaction of the two

systems, the following is achieved:

5

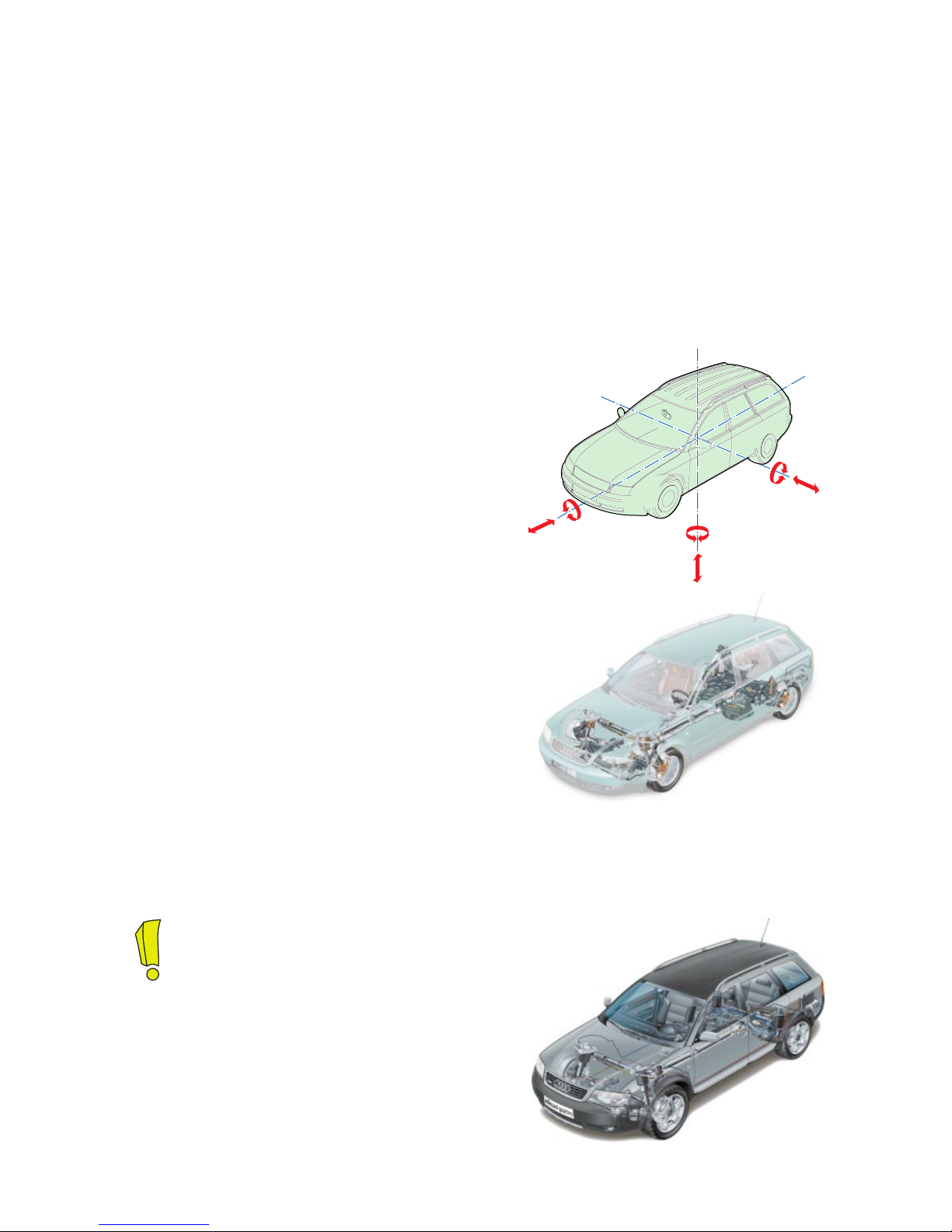

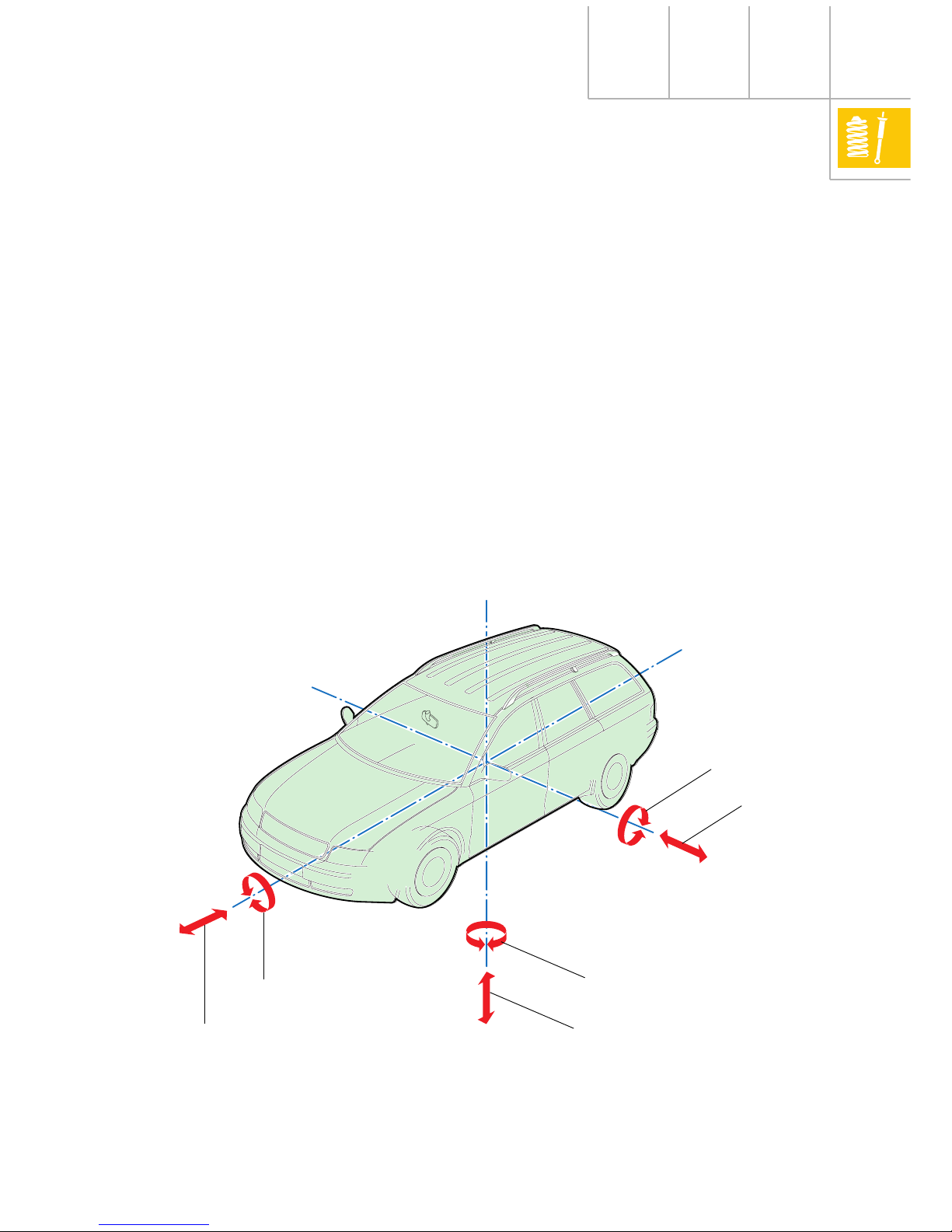

During driving operation, the vehicle body is

subject not only to the forces which cause the

upward and downward motion of the vehicle,

but also the movements and vibrations in the

direction of the three spatial axes.

Along with the axle kinematics, the vehicle

suspension has a significant influence on

these movements and vibrations.

242_048

Longitudinal axis

Transverse axis

Vertical axis

Drift

Pitch

Swerving (yaw)

Rising and sinking

Tipping (roll)

Jerking

The correct matching of the springs and

vibration damping system is therefore of

great significance.

6

Principles

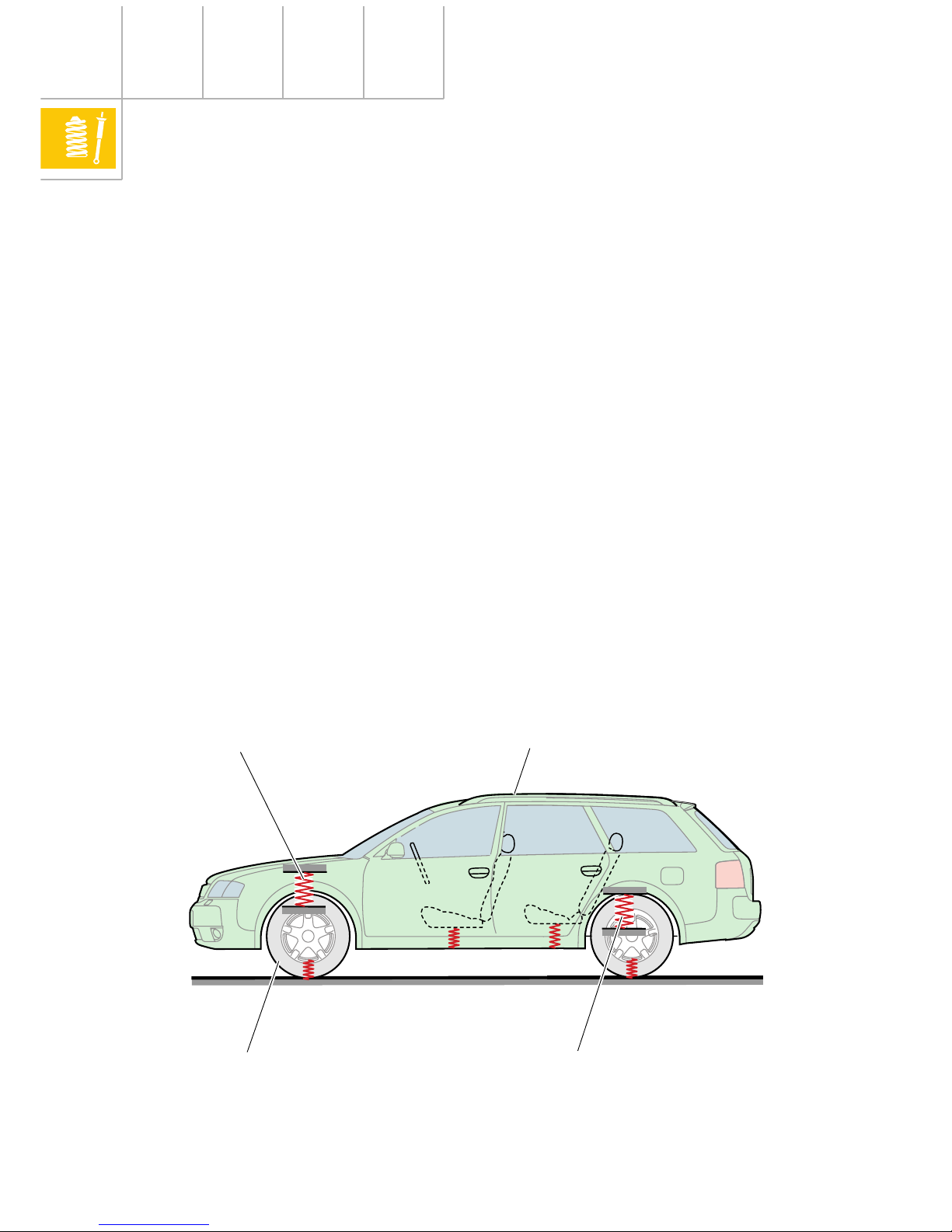

The suspension system

As ”supporting” components of the

suspension system, the suspension elements

form the connection between the wheel

suspension and the bodywork. This system is

complemented by the spring action of the

tyres and vehicle seats.

The suspension elements include steel

springs, gas/air and rubber/elastomers or

combinations of the above.

Steel spring suspensions have become well

established in passenger vehicles. Steel

springs are available in a wide variety of

designs, of which the coil spring has become

the most widespread.

Air suspension, which has been used for

many years in heavy goods vehicles, is

finding increasing application in passenger

vehicles due to its system-related

advantages.

242_047

In the case of the passenger vehicle we can

differentiate between sprung masses (body

with drive train and parts of the running gear)

and unsprung masses (the wheels, brakes

and parts of the running gear and the axle

shafts).

As a result of the suspension system, the

vehicle forms an oscillatory unit with a

natural frequency of the bodywork

determined by the sprung masses and the

matching of the suspension system (see

”Vibration” chapter).

Sprung mass

Unsprung mass

Suspension element

Suspension element

7

The unsprung masses

The aim in principle is to minimise the volume

of unsprung masses and their influence on

the vibration characteristics (natural

frequency of the bodywork). Furthermore, a

low inertia of masses reduces the impact load

on the unsprung components and

significantly improves the response

characteristics of the suspension. These

effects result in a marked increase in driver

comfort.

Examples for the reduction of unsprung

masses:

• Aluminium hollow spoke wheel

• Running gear parts (swivel bearing, wheel

carrier, links etc.) made of aluminium

• Aluminium brake callipers

• Weight-optimised tyres

• Weight optimisation of running gear parts

(e.g. wheel hubs)

213_091

213_068

See also SSP 213, chapter “Running

gear”.

213_041

8

Principles

The natural frequency of the bodywork

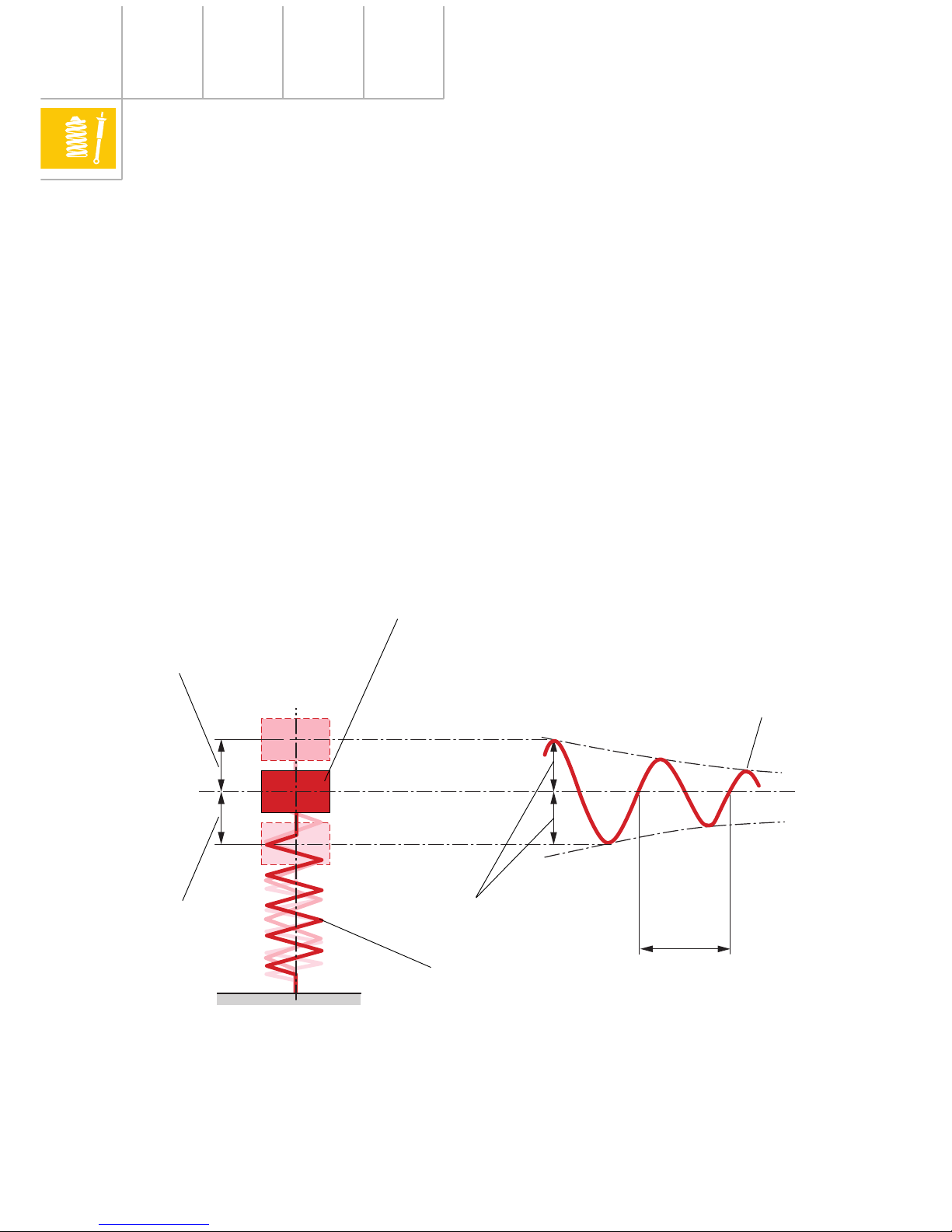

The vibrations are defined by the degree of

amplitude and its frequency. The natural

frequency of the bodywork is particularly

important during matching of the

suspension.

The natural frequency of unsprung parts is

between 10 Hz and 16 Hz for a medium-size

vehicle. Appropriate matching of the

suspension system reduces the natural

frequency of the bodywork (sprung mass) to

between 1 Hz and 1.5 Hz.

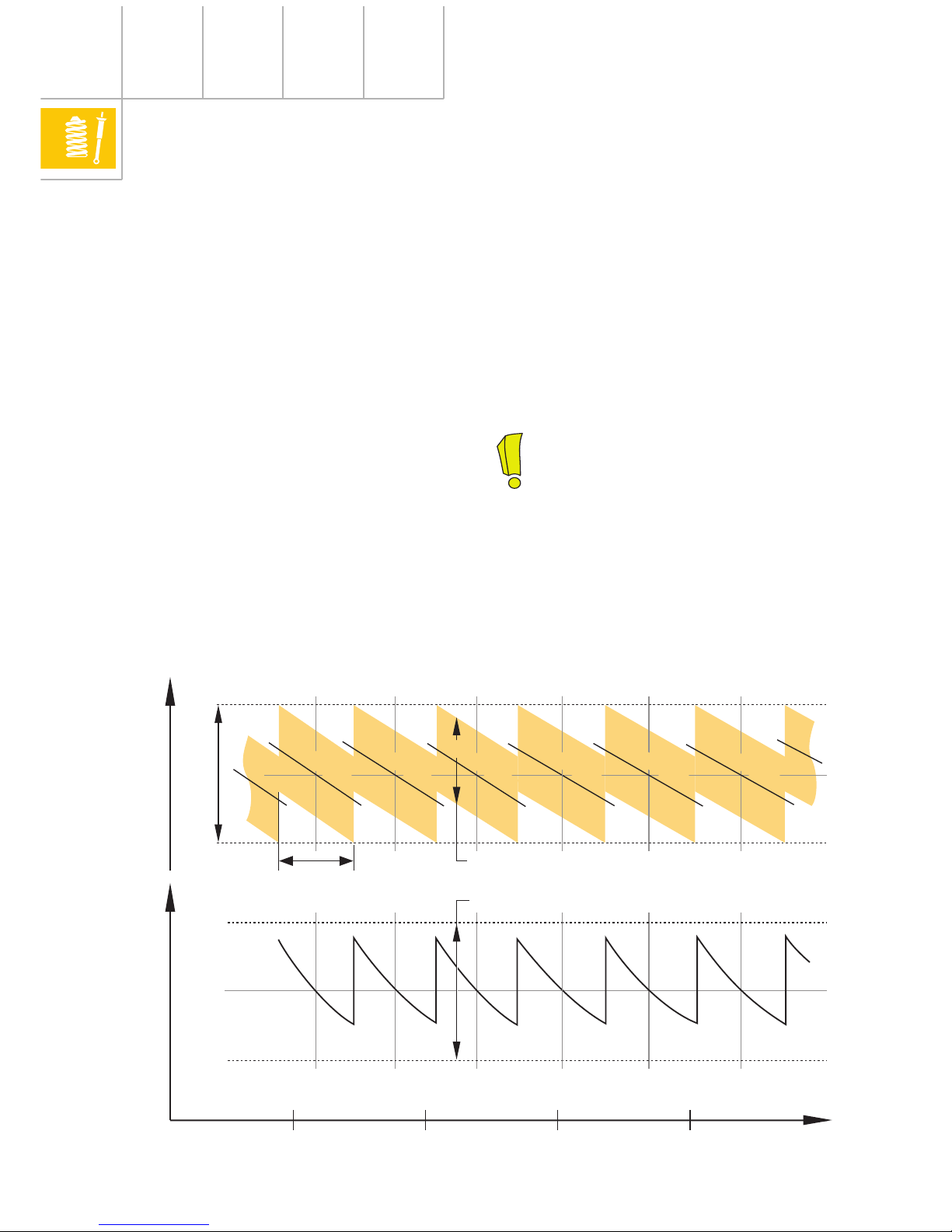

Vibration

If a mass on a spring is deflected from its rest

position by a force, a restoring force develops

in the spring which allows the mass to

rebound. The mass oscillates beyond its rest

position which results in a further restoring

force being exerted. This process is repeated

until air resistance and the internal friction of

the spring causes the vibration to cease.

242_021

Rest position

Mass

Spring

Vibration

Rebound

Compression

1 cycle

Amplitude

9

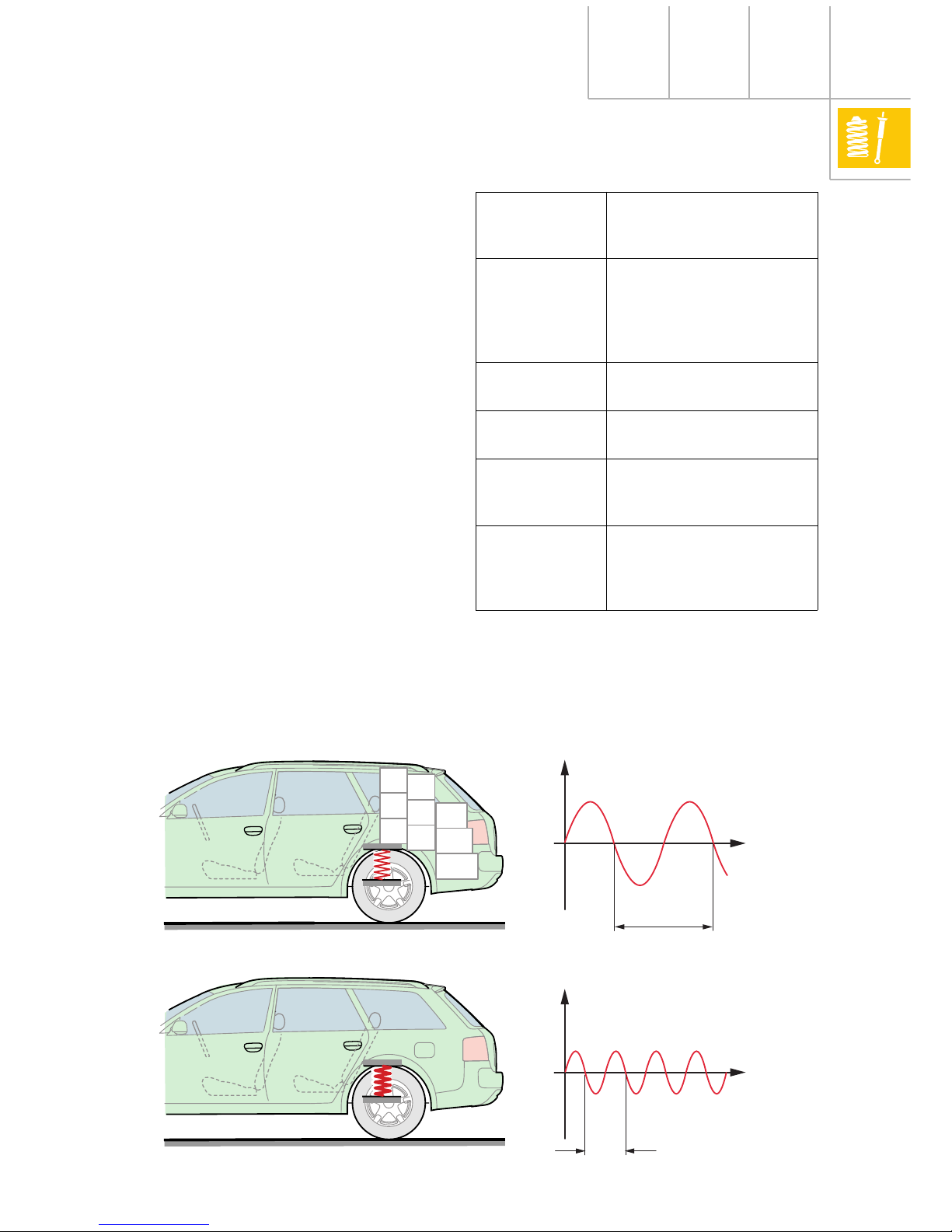

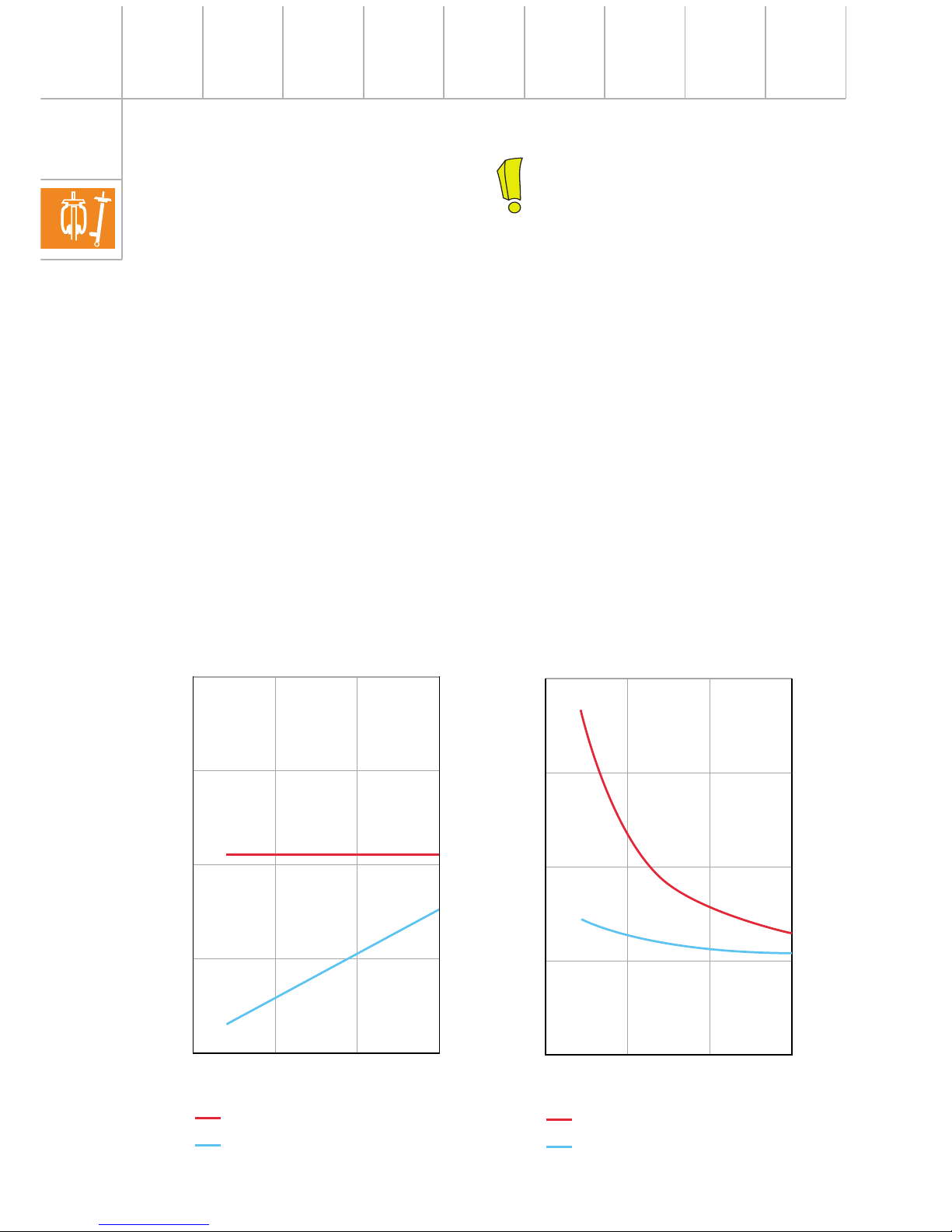

The natural frequency of the bodywork is

essentially determined by the characteristics

of the springs (spring rate) and by the sprung

mass.

Greater mass or softer springs produce a

lower natural frequency of the bodywork and

a greater spring travel (amplitude).

Smaller mass or harder springs produce a

higher natural frequency of the bodywork and

a lesser spring travel.

Depending on personal sensitivity, a natural

frequency of the bodywork below 1 Hz can

cause nausea. Frequencies above 1.5 Hz

impair driving comfort and are experienced

as shudders above around 5Hz.

242_072

Definitions

Vibration Upward and downward

motion of the mass

(body)

Amplitude The greatest distance of

the vibrating mass from

the rest position

(vibration extent, spring

travel)

Cycle Duration of a single

vibration

Frequency Number of vibrations

(cycles) per second

Natural

frequency of

the bodywork

Number of vibrations of

the sprung mass (body)

per second

Resonance The mass is disturbed in

its rhythm by a force

which increases the

amplitude (build-up).

Greater mass or softer springs

Smaller mass or harder springs

Spring travelSpring travel

Low natural frequency of the

bodywork

High natural frequency of the

bodywork

1 cycle

1 cycle

Time

Time

10

The degree of damping of the vibration

damper has no significant influence on the

value of the natural frequency of the

bodywork. It influences only how quickly the

vibrations cease (damping coefficient). For

further information, see chapter “Vibration

damping”.

Matching of the natural frequency of the

bodywork

The axle loads (sprung masses) of a vehicle

vary, at times considerably, depending on the

engine and equipment installed.

To ensure that the bodywork height

(appearance) and the natural frequency of the

bodywork (which determines the driving

dynamics) remains practically identical for all

vehicle versions, different spring and shock

absorber combinations are fitted to the front

and rear axles in accordance with the axle

load.

For instance, the natural frequency of the

bodywork of the Audi A6 is matched to 1.13Hz

on the front axle and 1.33Hz on the rear axle

(design position).

The spring rate of the springs therefore

determines the value of the natural frequency

of the bodywork.

The springs are colour-coded to differentiate

between the different spring rates (see table).

Principles

For standard running gear without selflevelling, the rear axle is always

matched to a higher natural frequency

of the bodywork because when the

vehicle is loaded, it is principally the

load to the rear axle which increases,

thus reducing the natural frequency of

the bodywork.

242_073

Vehicle heightNatural frequency of the bodywork

Component tolerance band

Natural frequency tolerance band

Usable load range

of a spring

Height tolerance

Axle load800 kg 850 kg 900 kg 950 kg

1.13 Hz

c

F1

= 33.3 N/mm

c

F2

= 35.2 N/mm

c

F3

= 37.2 N/mm

c

F4

= 39.3 N/mm

c

F5

= 41.5 N/mm

c

F6

= 43.7 N/mm

Spring rate levels of the front axle for the A6

11

OJL

1BA

OYF

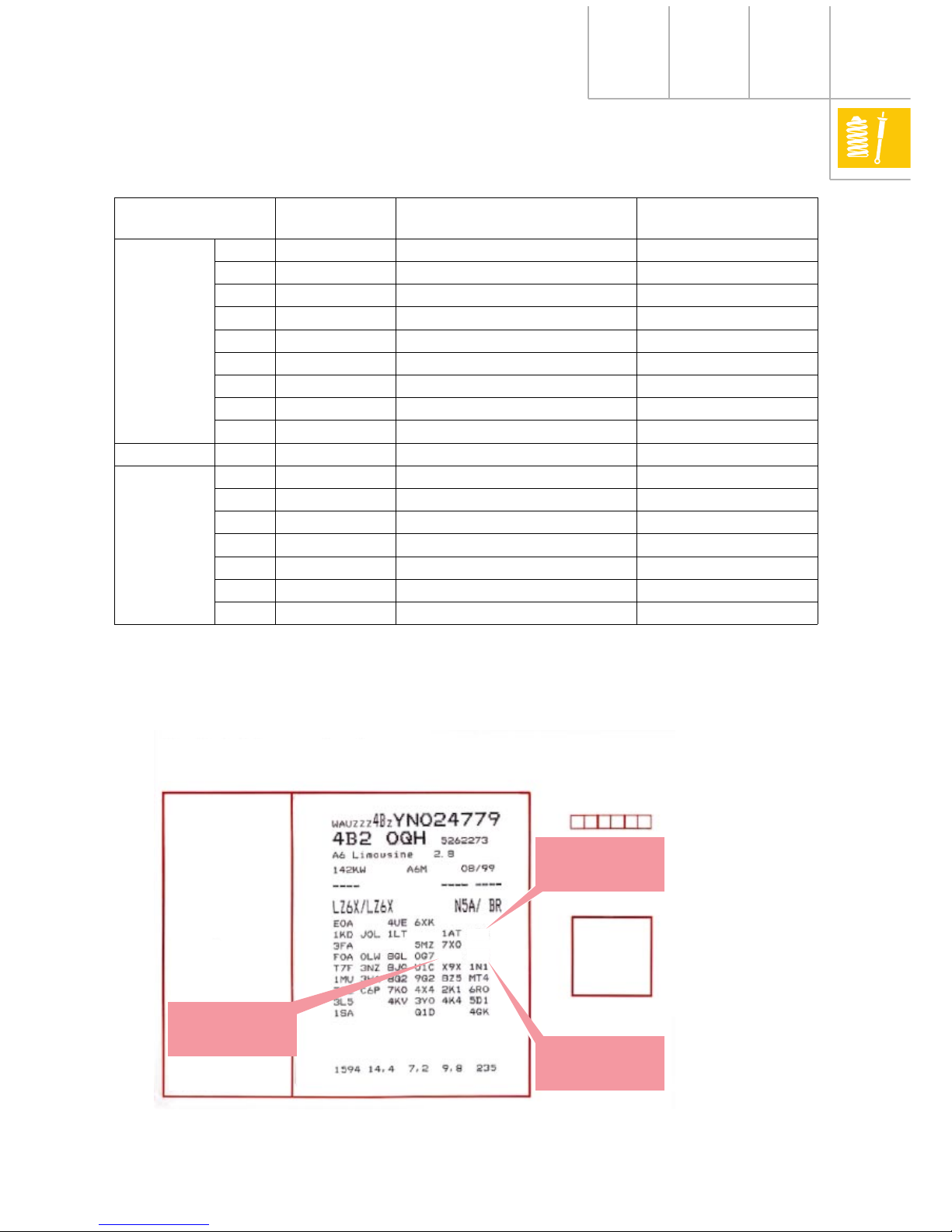

Spring allocation table (e.g. A6 front axle 1BA)

PR-No. weight

class, front axle

Axle load (kg) Suspension, left and right

(spring rate)

Colour coding

Standard

running

gear

e.g. 1 BA

OJD 739 - 766 800 411 105 AN (29.6 N/mm) 1 violet, 3 brown

OJE 767 - 794 800 411 105 AP (31.4 N/mm) 1 white, 1 brown

OJF 795 - 823 800 411 105 AQ (33.3 N/mm) 1 white, 2 brown

OJG 824 - 853 800 411 105 AR (35.2 N/mm) 1 white, 3 brown

OJH 854 - 885 800 411 105 AS (37.2 N/mm) 1 yellow, 1 brown

OJJ 886 - 918 800 411 105 AT (39.3 N/mm) 1 yellow, 2 brown

OJK 919 - 952 800 411 105 BA (41.5 N/mm) 1 yellow, 3 brown

OJL 953 - 986 800 411 105 BM (43.7 N/mm) 1 green, 1 brown

OJM 987 - 1023 800 411 105 BN (46.1 N/mm) 1 green, 2 brown

Sports

running

gear

e.g. 1BE

OJD 753 - 787 800 411 105 P (40.1 N/mm) 1 grey, 3 violet

OJE 788 - 823 800 411 105 Q (43.2 N/mm) 1 green, 1 violet

OJF 824 - 860 800 411 105 R (46.3 N/mm) 1 green, 2 violet

OJG 861 - 899 800 411 105 S (49.5 N/mm) 1 green, 3 violet

OJH 900 - 940 800 411 105 T (53.0 N/mm) 1 yellow, 1 violet

OJJ 941 - 982 800 411 105 AA (56.6 N/mm) 1 yellow, 2 violet

OJK 983 - 1027 800 411 105 AB (60.4 N/mm) 1 yellow, 3 violet

Weight class of

front axle

Running

gear

Weight class of

the rear axle

242_108

Proof of warranty

Vehicle data

Vehicle identification number

Type description

Engine capacity / gearbox / month/

year of manufacture

Engine code / gearbox

code letters

Paint no. / interior equipment no.

M-equipment number

Un-laden weight / consumption

figures / CO

2

emissions

Date of

Delivery

Stamp of the

Audi delivery

centre

12

0

0

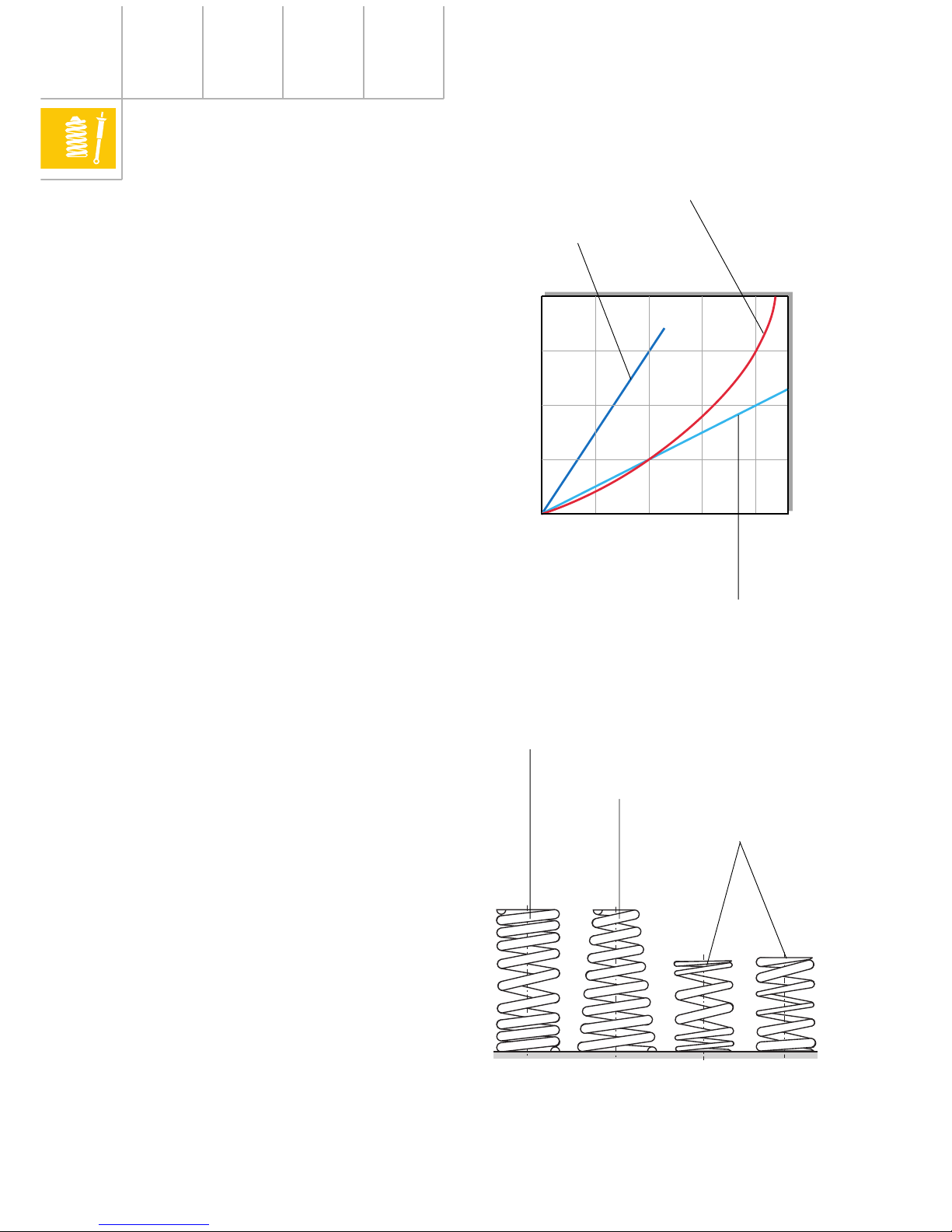

Characteristic values of

springs

Characteristic curve/spring rate of springs

We can obtain the characteristic curve of a

spring by producing a forces/travel diagram.

The spring rate is the ratio between the

effective force and the spring travel. The unit

of measurement for the spring rate is N/mm.

It informs us whether a spring is hard or soft.

If the spring rate remains the same

throughout the entire spring travel, the spring

has a linear characteristic curve.

A soft spring has a flat characteristic curve

while a hard spring has a steep curve.

A coil spring is harder due to:

• a greater wire diameter

• a smaller spring diameter

• a lower number of coils

Principles

242_018

If the spring rate becomes greater as the

spring travel increases, the spring has a

progressive characteristic curve.

Coil springs with a progressive characteristic

curve can be recognised as follows:

a) uneven coil pitch

b) conical coil shape

c) conical wire diameter

d) combination of two spring elements

(example, see next page)

242_019

Spring travel s

Resilience F

Linear characteristic curve

Hard spring

Progressive characteristic

curve

a

b

c

Linear characteristic curve

Soft spring

13

-120 -80-400

0

3

6

9

12

15

40 80 120

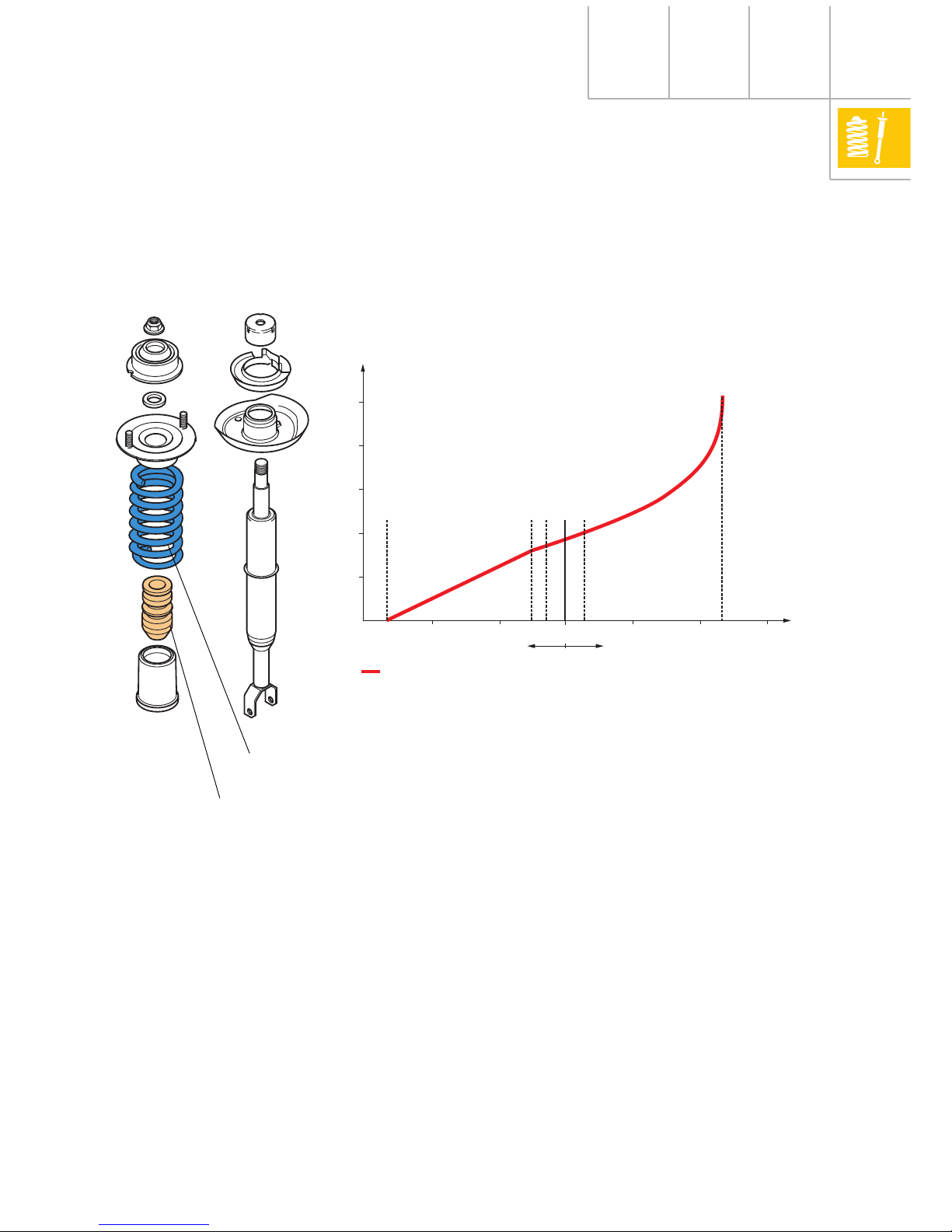

(Example: Suspension strut with auxiliary

polyurethane springs).

Advantages of progressive characteristic

curve of spring:

• Better matching of the suspension system

from normal to full load.

• The natural frequency of the bodywork

remains practically constant during

loading.

• The suspension is not so prone to impacts

in the case of significant irregularities in

the road surface.

• Better use of the available spring travel.

Rebound in mm Compression in mm

Parallel springing

Lower stop

Upper stop

Rebound stop insert (in shock absorber)

Un-laden position

Design position

Auxiliary spring insert

Lower stop

242_020

Spring

Auxiliary spring

14

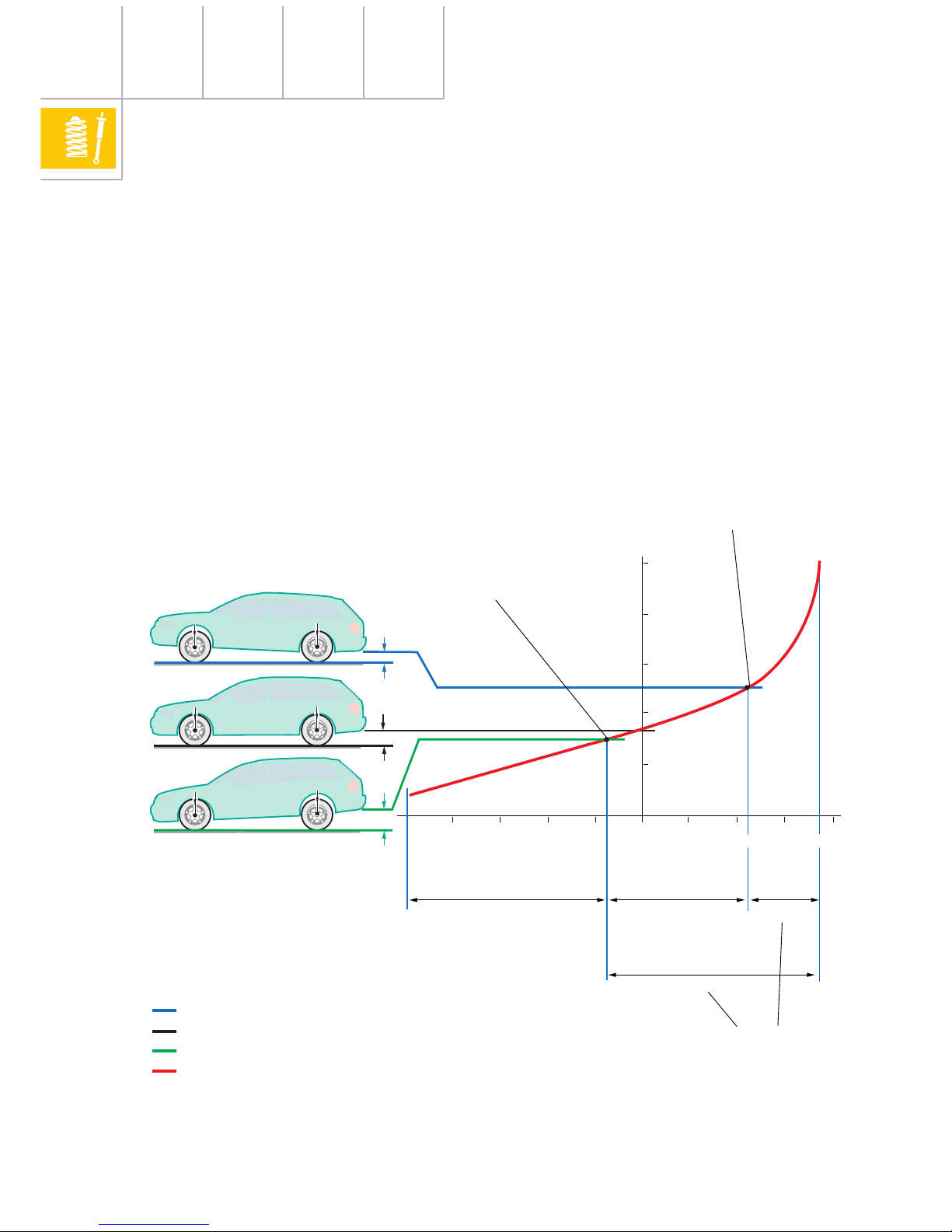

When the vehicle is stationary, the vehicle

body retracts by a certain spring travel

depending upon the load. In this case, we

speak of static compression: s

stat

.

The disadvantage of conventional running

gear without self-levelling is its reduced

spring travel at full load.

Conventional running gear

(steel springs) without selflevelling

Spring travel

The overall spring travel s

tot

required for

running gear without self-levelling is

comprised of the static compression s

stat

and

the dynamic spring travel caused by vehicle

vibrations s

dyn

for both laden and un-laden

vehicles.

s

tot

= s

stat

+ s

dyn(un-laden)

+ s

dyn(fully laden)

Principles

242_075

Steel suspension

fully laden

Design position

Un-laden position

Supporting force in kn.

H

V

H

H

L

dyn. rebound

s

stat

(un-laden)

dyn. compression

(un-laden)

(fully laden)

10

8

6

4

2

+80 mm

-40 mm-80 mm

H

V

= height when fully laden

H

= design position height

H

L

= height when un-laden

Characteristic curve of spring

s

stat(un-laden)

s

stat(fully laden)

+40 mm

0

15

Definitions:

The un-laden position ...

... is the compression exerted onto the wheels

when the vehicle is ready for the road (fuel

tank completely filled, spare wheel and

vehicle tools present).

The design position ...

... is defined as the un-laden position plus the

additional load of three persons, each

weighing 68 kg.

The static compression ...

... is the starting point (zero) for the dynamic

spring movements, compression travel (plus)

and rebound travel (minus).

... is dependant upon the spring rate and the

load (sprung masses).

... results from the difference between the

static compression when un-laden

s

stat(un-laden)

and the static compression when

fully laden s

stat(fully laden)

.

s

stat

= s

stat(fully laden)

- s

stat(un-laden)

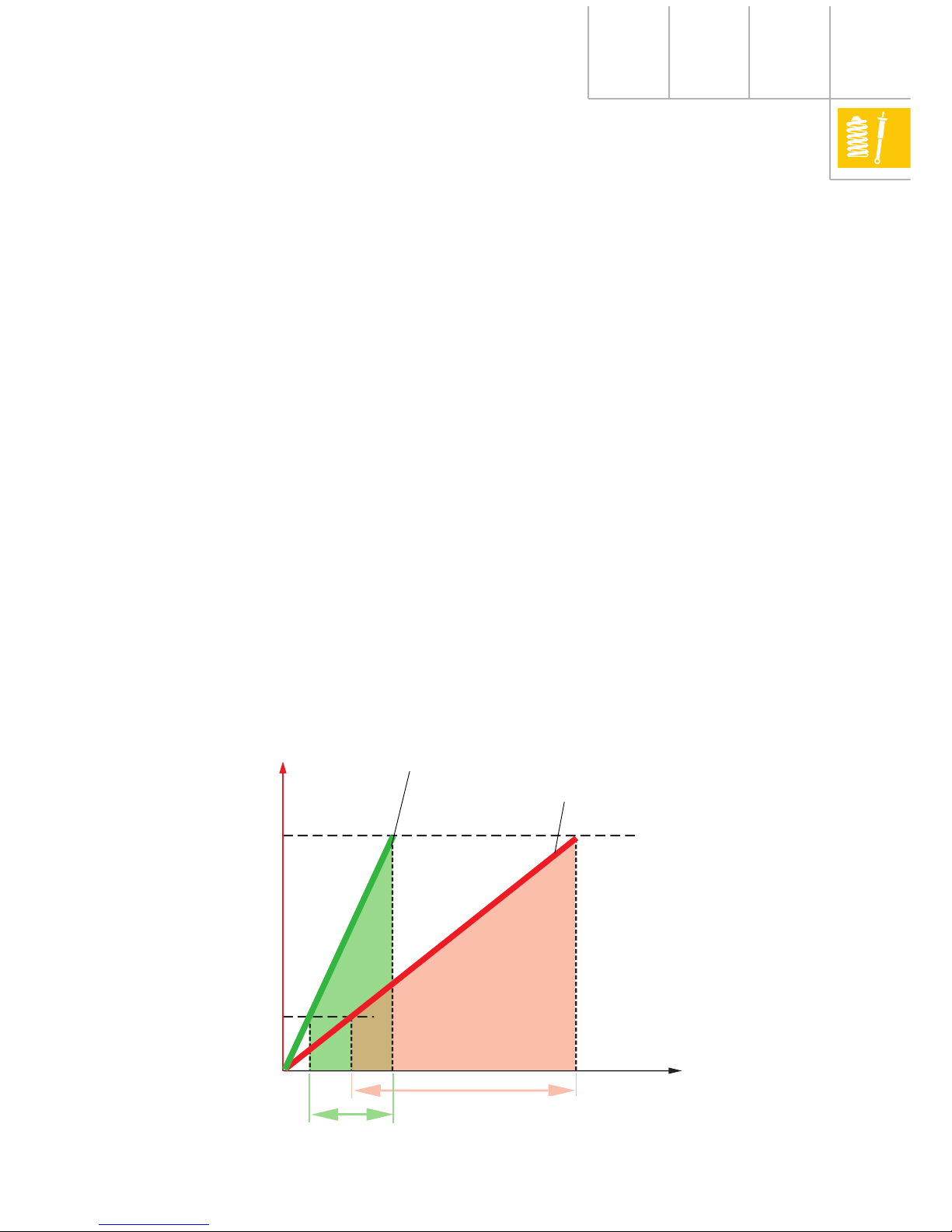

In the case of a flat characteristic curve (soft

springs), the difference and thereby the static

compression between full and un-laden is

very great.

242_076

In the case of a steep characteristic spring

curve, this state of affairs is reversed and is

coupled with an excessive increase of the

natural frequency of the bodywork.

Fully laden

Un-laden position

Hard springs

Soft springs

s

stat

soft springs

s

stat

hard springs

16

Principles of air suspension

Self-levelling air

suspension

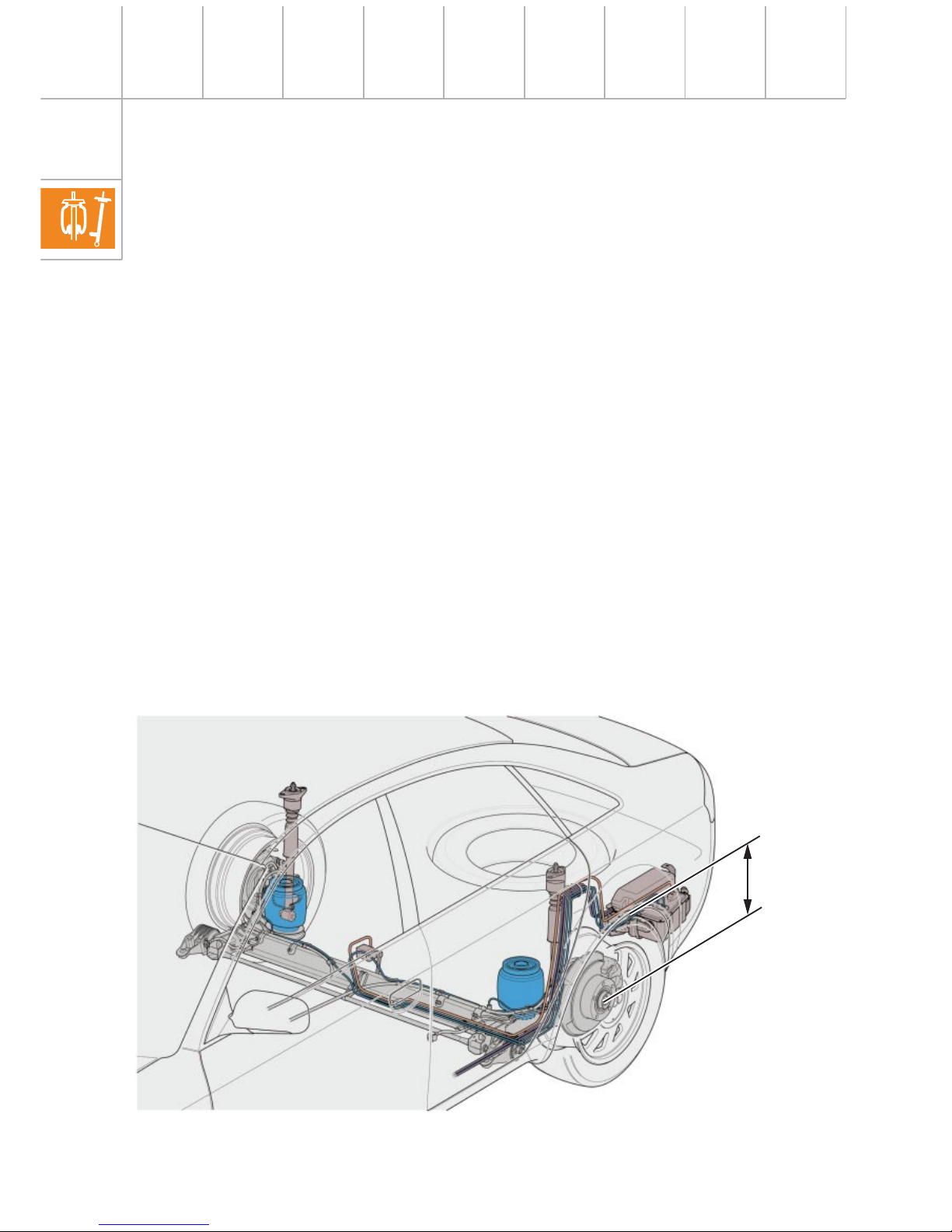

Air suspension is a controllable form of

vehicle suspension.

With air suspension, it is simple to achieve

self-levelling and it is therefore generally

integrated into the system.

The basic advantages of self-levelling are:

• Static compression remains the same,

irrespective of vehicle loads (see overleaf).

The space requirement in the wheel

arches for free wheel movement kept to a

minimum, which has benefits for the

overall use of available space.

• The vehicle body can be suspended more

softly, which improves driving comfort.

• Full compression and rebound travel is

maintained, whatever the load.

242_074

• Ground clearance is maintained, whatever

the load.

• There are no track or camber changes

when vehicle is laden.

• The c

w

value is maintained, as is the visual

appearance.

• Less wear to ball joints due to reduced

working angle.

• Greater loads are possible if required.

= constant

17

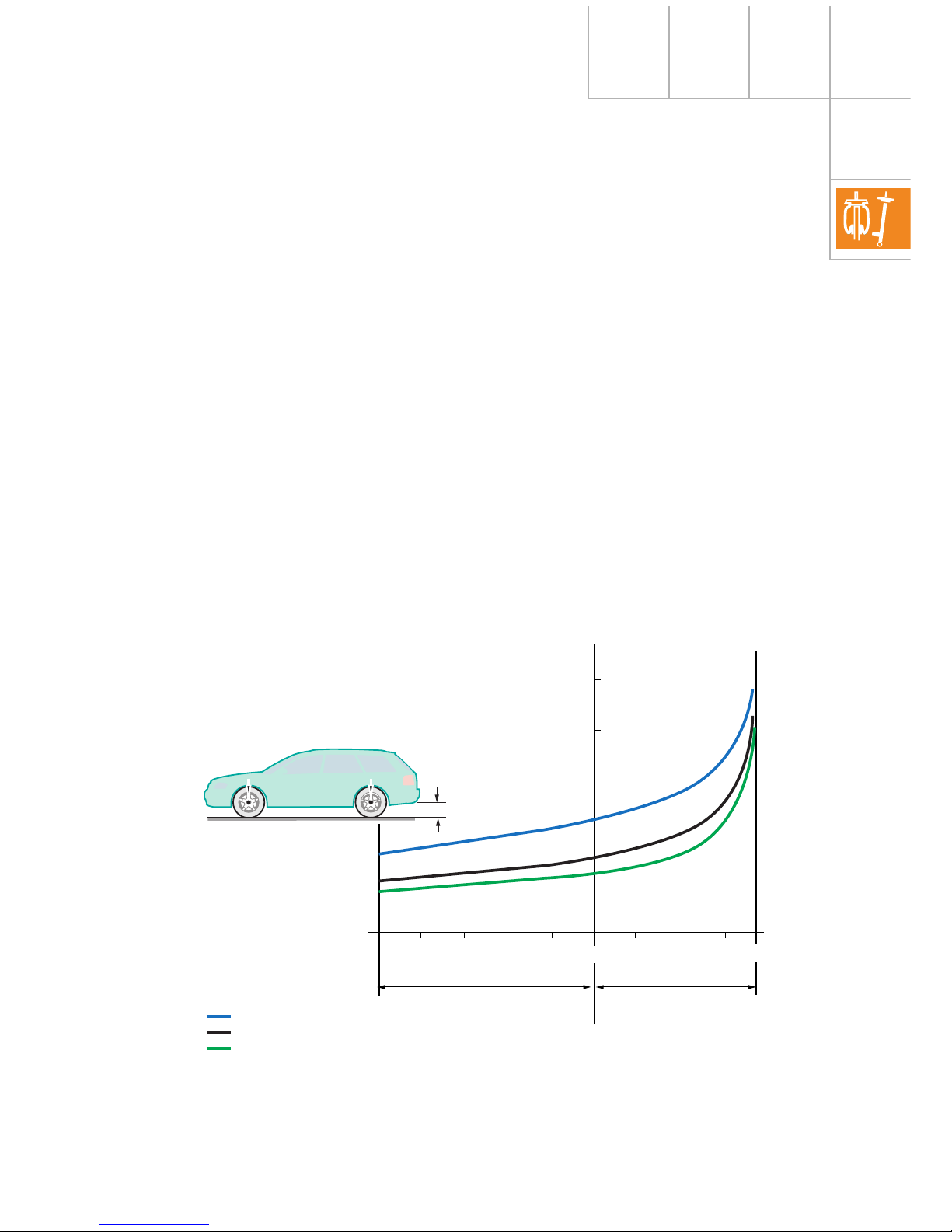

In addition to the main advantages offered by

self-levelling, its realisation by means of air

suspension (Audi A6) offers another

significant advantage.

As the air pressure in the air springs is

adapted in accordance with the load, the

spring rate alters proportionally to the sprung

mass. The positive outcome is that the natural

frequency of the bodywork and thereby

driving comfort remain virtually constant,

irrespective of the load.

With the aid of self-levelling, the vehicle

(sprung masses) remains at one level (design

position) because the air spring pressure is

adapted accordingly.

Static compression is thus the same at all

times thanks to the self-levelling system and

need not be accounted for when designing

the wheel clearances.

s

stat

= 0

Another feature of self-levelling air

suspension is that the natural frequency of

the bodywork is kept virtually constant

between un-laden and full-load (see chapter

“Air spring characteristic values” page 21).

242_077

H = constant

fully laden

Design position H

un-laden

s

stat

0

Supporting force in kN.

10

8

6

+80 mm+40 mm-40 mm-80 mm

4

2

Air suspension

dyn. rebound dyn. compression

Spring travel

Characteristic curves

of springs

18

Principles of air suspension

Another benefit is the principle-related

progressive characteristic curve of an air

spring.

With fully supporting air suspension on both

axles (Audi allroad quattro), different vehicle

levels can be set, e.g.:

• Normal driving position for city driving.

• Lowered driving position for high speeds

to improve driving dynamics and air

resistance.

• Raised driving position for travel off-road

and on poor road surfaces.

You can find further details in SSP 243

“4-Level air suspension in the Audi allroad

quattro”.

Fully supporting means:

Self-levelling systems are often

combined with steel or gas-filled spring

devices with hydraulic or pneumatic

control. The supporting force of these

systems results from the sum of both

systems. We therefore call them

“partially supporting” (Audi 100/

Audi A8).

In the self-levelling suspension systems

in the Audi A6 (on the rear axle) and in

the Audi allroad quattro (rear and front

axles) air springs are the only

supporting suspension elements and

these systems are therefore described

as “fully supporting”.

0

1

2

3

4

0 102030

242_030

Spring rate

0

1

2

3

4

0 102030

Natural frequency of the bodywork

Supporting force

242_031

Supporting force

Steel springs (linear)

Air springs

Steel springs (linear)

Air springs

19

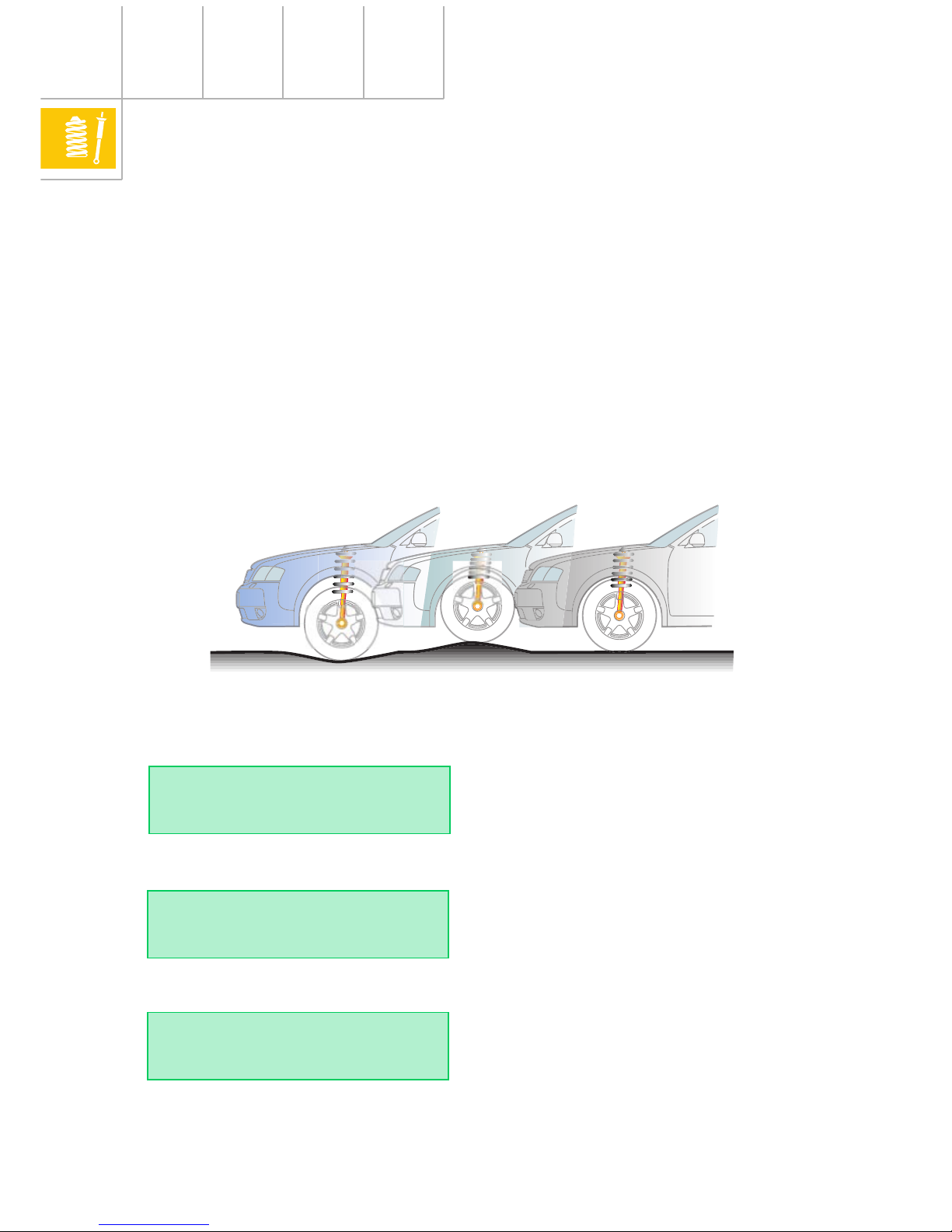

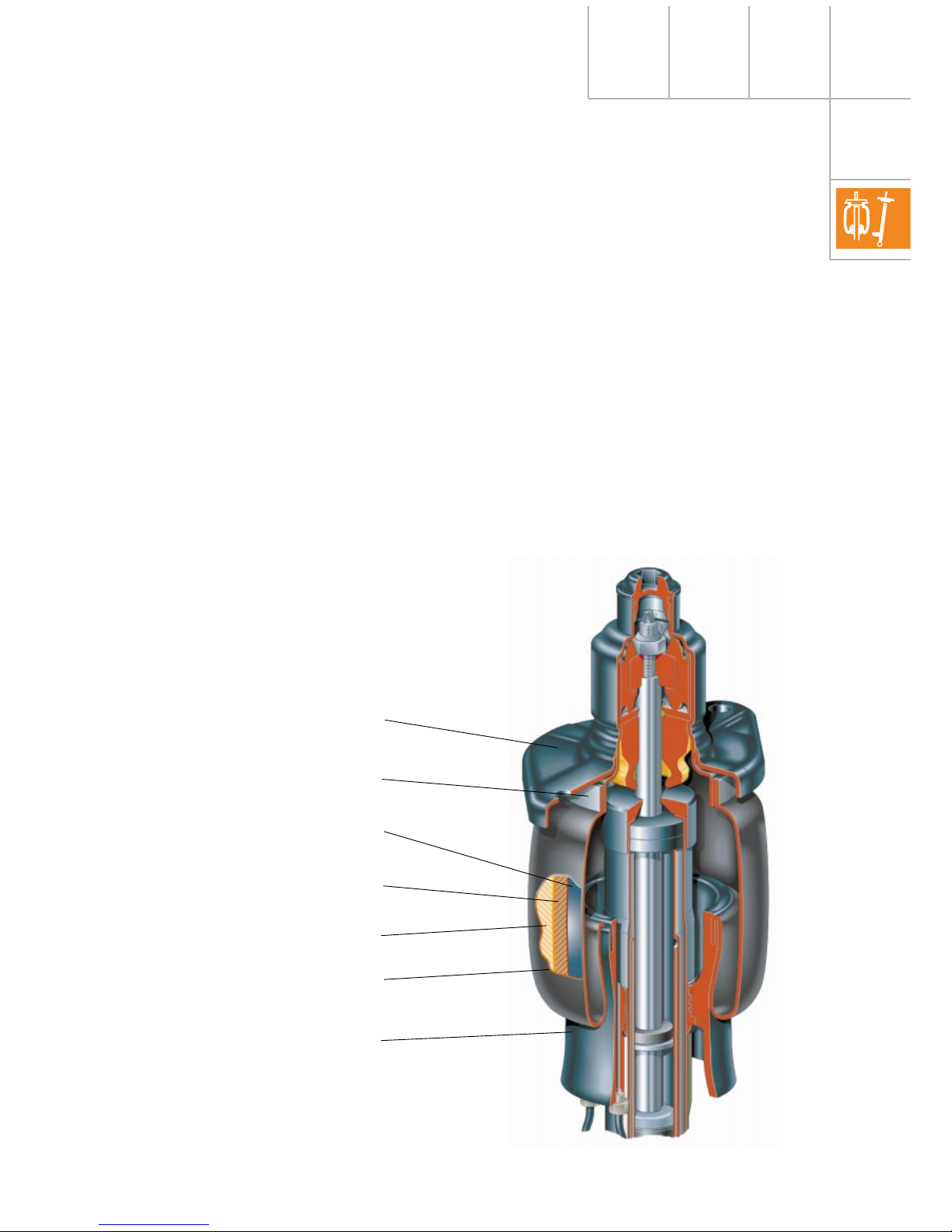

Design of the air springs:

In passenger vehicles, air springs with

U-bellows are used as suspension elements.

These allow greater spring travel in restricted

spaces.

The air springs consist of:

• Upper housing closure

• U-bellows

• Piston (lower housing closure)

• Retaining rings

The construction of the U-bellows can be

seen in fig. 242_032.

242_032

The outer and inner surfaces are made of an

elastomer material. The material is resistant

to all weather influences and is largely oilresistant. The inner surface finish is designed

to be particularly air-tight.

The stability supports absorb the forces

produced by the internal pressure in the air

springs.

Upper housing closure

Retaining ring

Internal surface coating

Woven insert 1

Woven insert 2

External surface coating

Piston

Coaxial arrangement of the air springs

20

Principles of air suspension

High-quality elastomer material and

polyamide cord woven inserts (stability

supports) provide the U-bellows with good

unrolling characteristics and a sensitive

response of the spring system.

The necessary properties are ensured over a

wide temperature range between

-35 °C and +90 °C.

Metal retaining rings tension the U-bellows

between the upper housing closure and the

piston. The retaining rings are machinepressed by the manufacturer.

The U-bellows unrolls onto the piston.

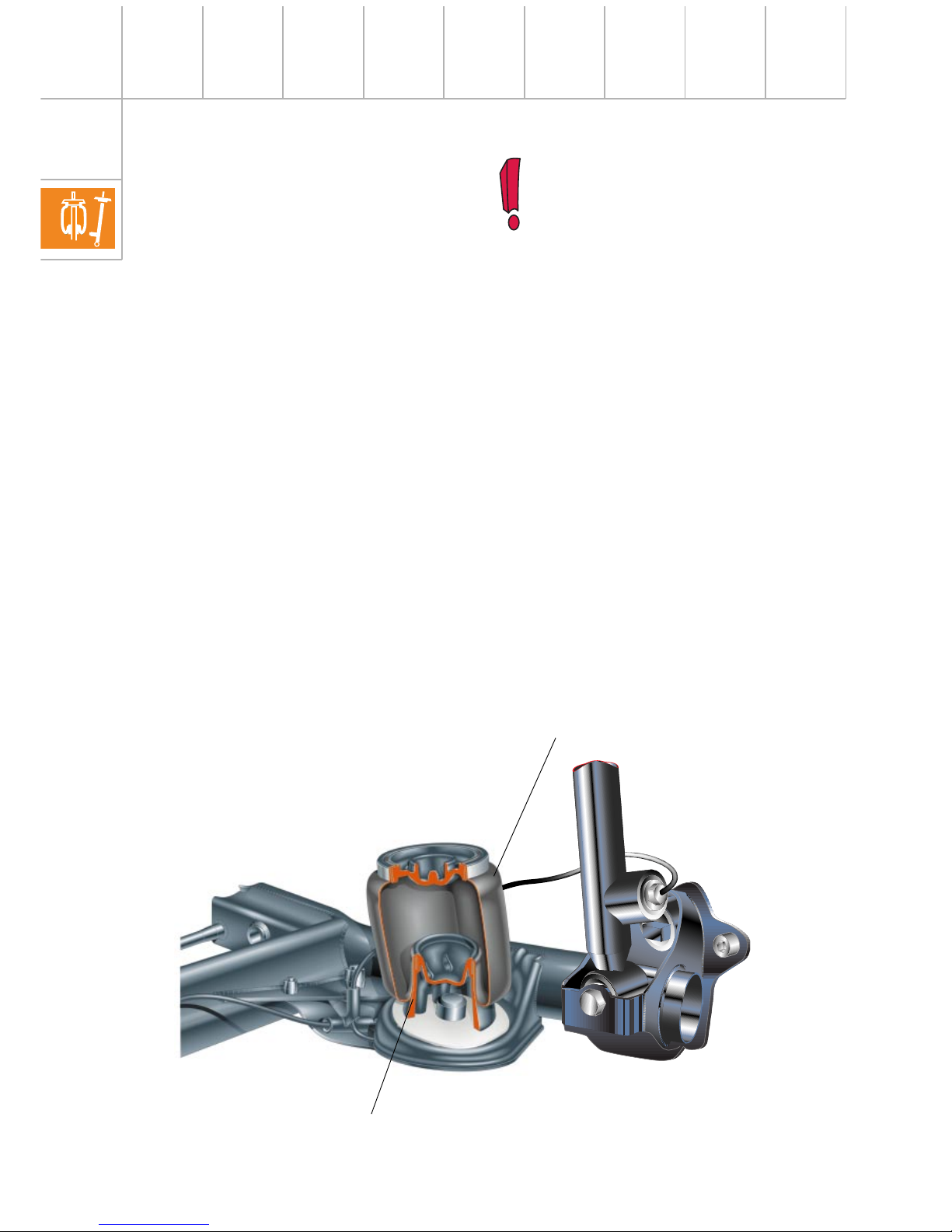

Depending on the axle design, the air springs

are either separate from the shock absorbers

or combined as a suspension strut (coaxial

arrangement).

Air springs must not be moved in an

unpressurised condition since the air

bellows cannot unroll on the piston and

would be damaged.

In a vehicle in which the air springs are

unpressurised, the relevant air springs

must be filled with the aid of the

diagnostic tester (see Workshop

Manual) before raising or lowering the

vehicle (e.g. vehicle lifting platform or

vehicle jack).

242_042

Separate arrangement of the air springs

Piston

Air springs

Loading...

Loading...