Features

• Internal Frequency-to-voltage Converter

• Externally Controlled Integrated Amplifier

• Overload Limitation with “Fold Back” Characteristic

• Optimized Soft-start Function

• Tacho Monitoring for Shorted and Open Loop

• Automatic Retriggering Switchable

• Triggering Pulse Typically 155 mA

• Voltage and Current Synchronization

• Internal Supply-voltage Monitoring

• Temperature Reference Source

• Current Requirement ≤ 3 mA

1. Description

The integrated circuit U211B is designed as a phase-control circuit in bipolar technology with an internal frequency-to-voltage converter. The device includes an internal

control amplifier which means it can be used for speed-regulated motor applications.

Amongst others, the device features integrated load limitation, tacho monitoring and

soft-start functions, to realize sophisticated motor control systems.

Phase Control

IC with

Overload

Limitation

for Tacho

Applications

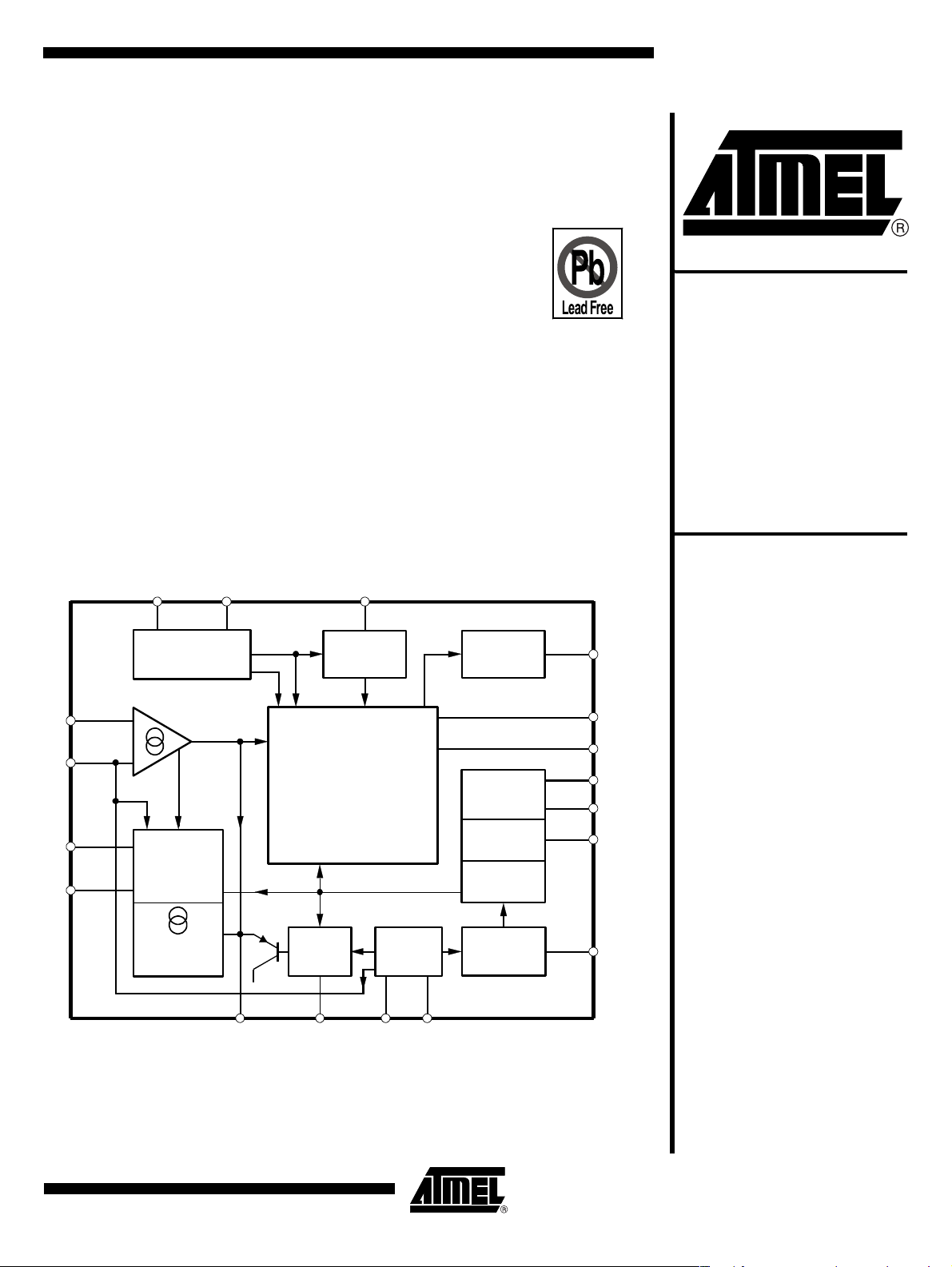

Figure 1-1. Block Diagram

1(1)

11(10)

10(9)

14(13)

15(14)

17(16)

Voltage/current

detector

Control

amplifier

+

-

Load limitation

speed/time

controlled

Controlled

current sink

5*

Automatic

retriggering

Phase-

control unit

ϕ = f (V12)

Soft start

-V

Ref

12(11) 13(12) 9(8)

Frequency-

to-voltage

converter

limitation

Reference

monitoring

Pulse-blocking

monitoring

8(7)

Output

pulse

Supply

voltage

voltage

Voltage

tacho

4(4)

6(5)

7(6)

3(3)

2(2)

16(15)

18*

-V

S

GND

U211B

Pin numbers in brackets refer to SO16

* Pins 5 and 18 connected internally

Rev. 4752B–INDCO–09/05

2. Pin Configuration

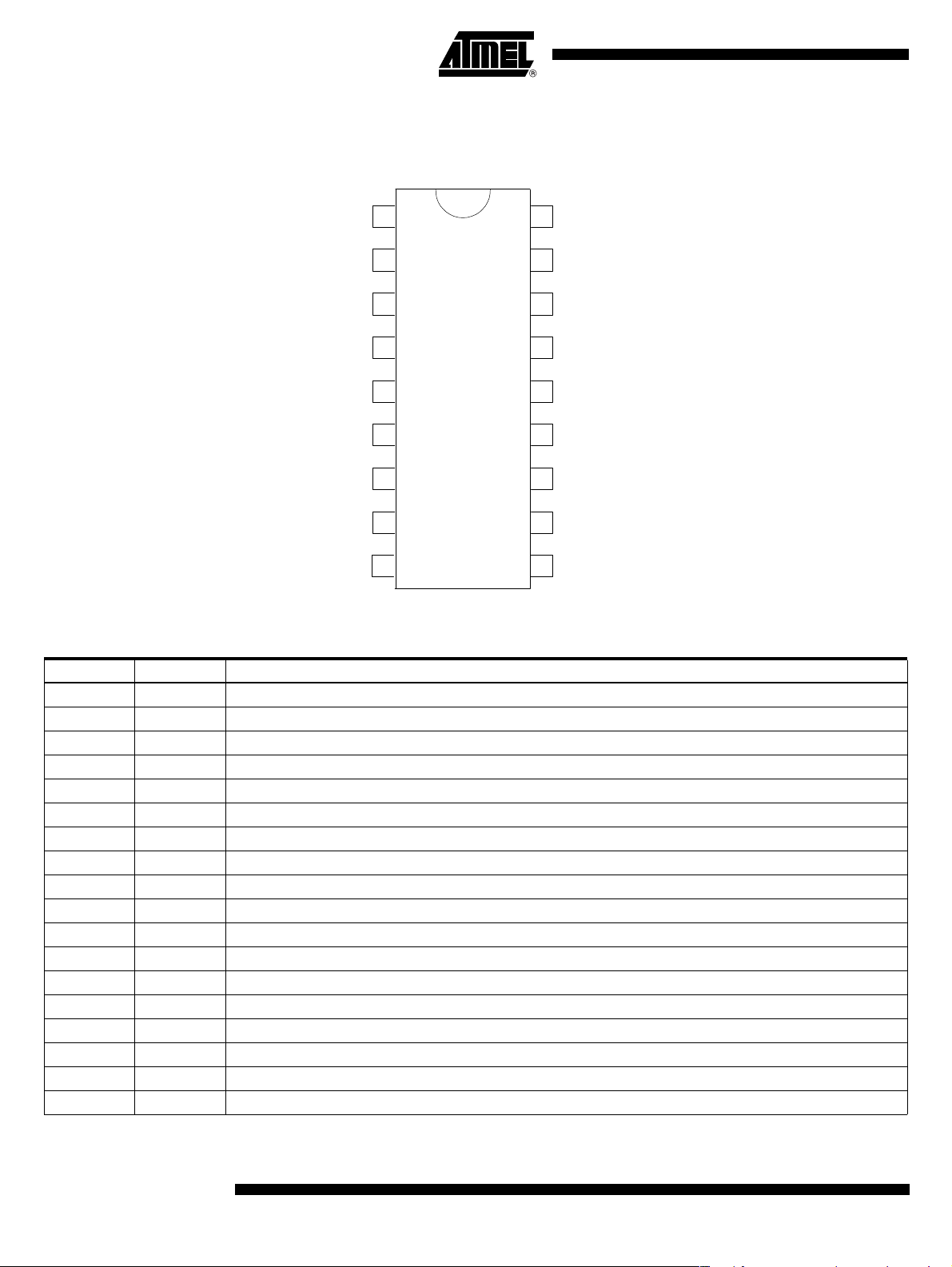

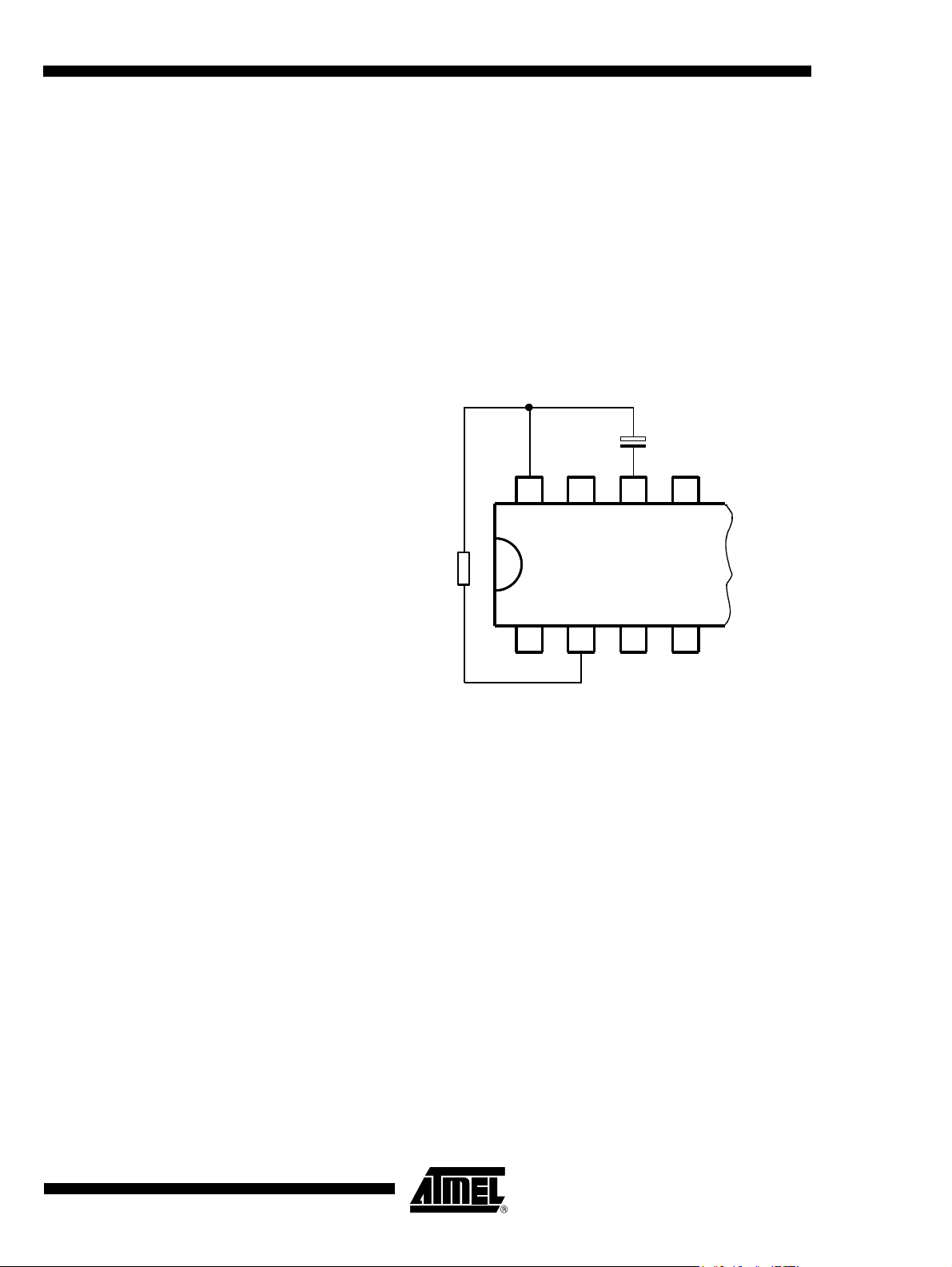

Figure 2-1. Pinning DIP18

I

sync

1

18

PB/TM

GND

Output

Retr

V

F/V

C

Table 2-1. Pin Description

Pin Symbol Function

1I

sync

2 GND Ground

3V

S

4 Output Trigger pulse output

5 Retr Retrigger programming

6V

7C

RP

P

8 F/V Frequency-to-voltage converter

9C

RV

10 OP- OP inverting input

11 OP+ OP non-inverting input

12 CTR/OPO Control input/OP output

13 C

14 I

soft

sense

15 OVL Overload adjust

16 V

17 V

Ref

sync

18 PB/TM Pulse blocking/tacho monitoring

Current synchronization

Supply voltage

Ramp current adjust

Ramp voltage

Charge pump

Soft start

Load-current sensing

Reference voltage

Voltage synchronization

2

V

3

S

4

5

6

RP

C

7

P

U211B

8

9

RV

V

17

V

16

OVL

15

I

14

C

13

CTR/OPO

12

OP+

11

OP-

10

sync

Ref

sense

soft

2

U211B

4752B–INDCO–09/05

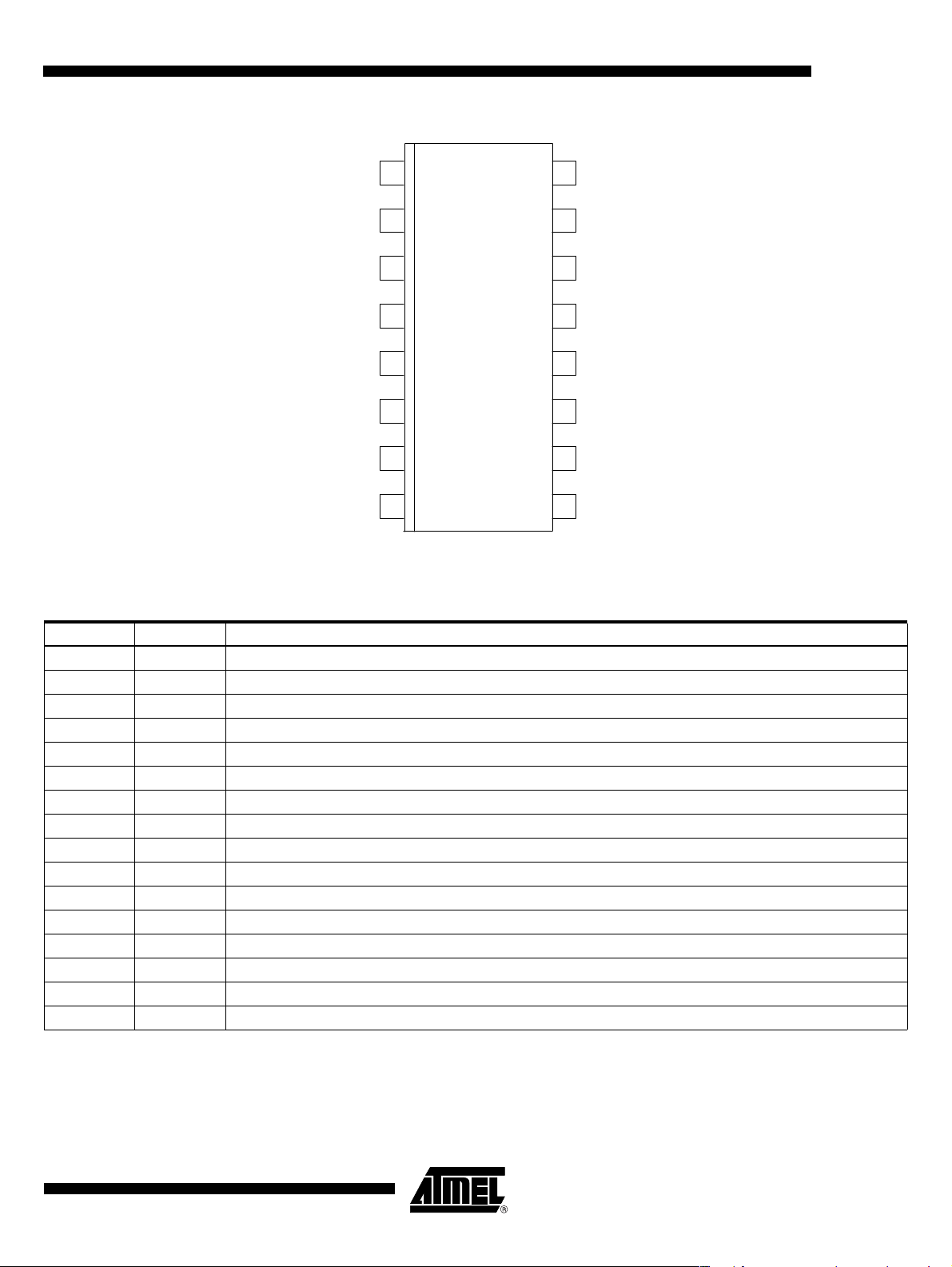

Figure 2-2. Pinning SO16

I

sync

U211B

1

16

V

sync

GND

Output

Table 2-2. Pin Description

Pin Symbol Function

1I

sync

2 GND Ground

3V

S

4 Output Trigger pulse output

5V

6C

RP

P

7 F/V Frequency-to-voltage converter

8C

RV

9 OP- OP inverting input

10 OP+ OP non-inverting input

11 CTR/OPO Control input/OP output

12 C

13 I

soft

sense

14 OVL Overload adjust

15 V

16 V

Ref

sync

Current synchronization

Supply voltage

Ramp current adjust

Ramp voltage

Charge pump

Soft start

Load-current sensing

Reference voltage

Voltage synchronization

V

V

C

F/V

C

RP

RV

2

3

S

4

15

14

13

V

Ref

OVL

I

sense

U211B

5

6

P

7

8

12

11

10

9

C

soft

CTR/OPO

OP+

OP-

4752B–INDCO–09/05

3

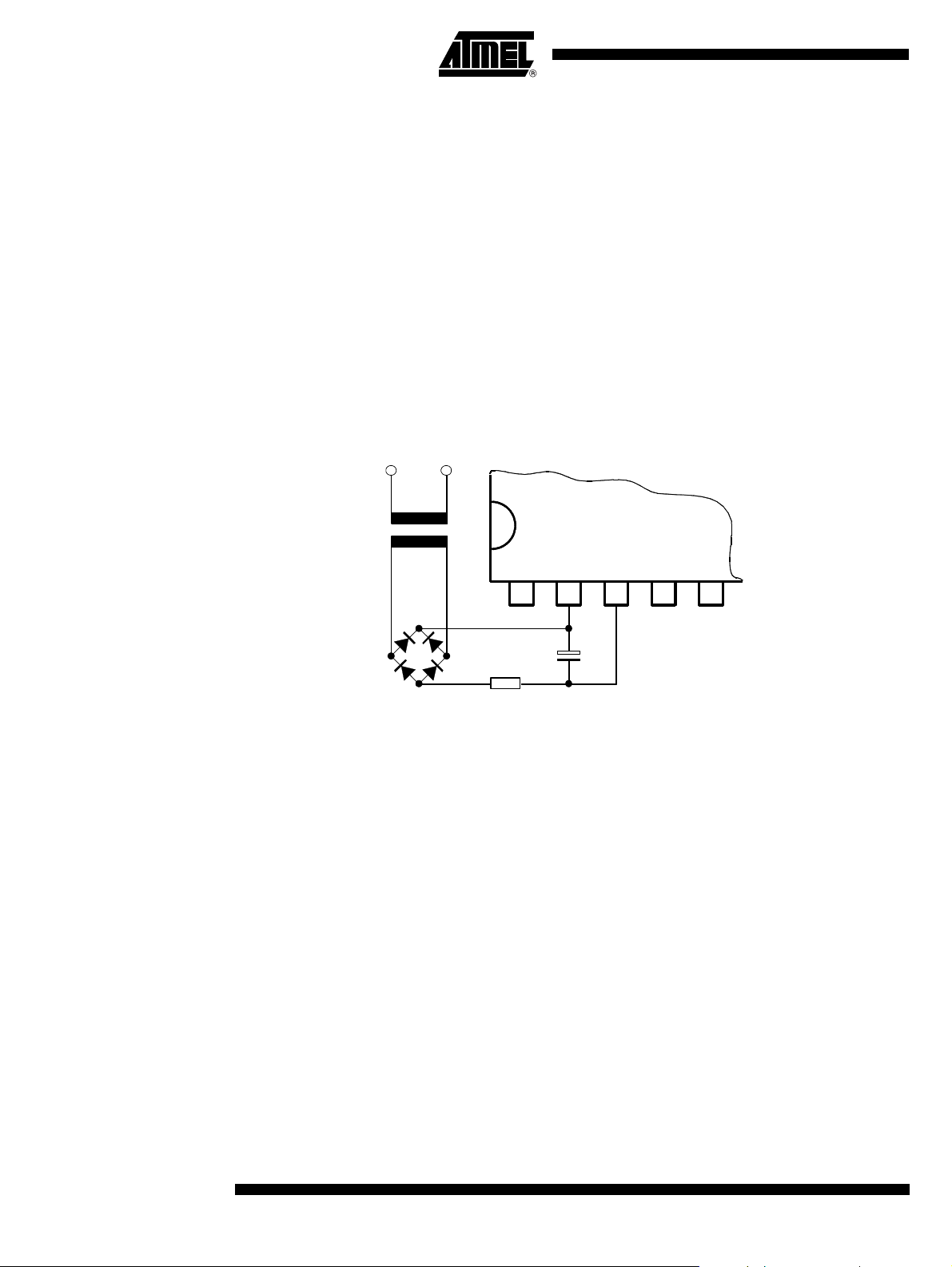

3. Mains Supply

The U211B is equipped with voltage limiting and can therefore be supplied directly from the

mains. The supply voltage between pin 2 (+ pol/_|_) and pin 3 builds up across D

smoothed by C

VMVS–

---------------------=

R

1

2 I

. The value of the series resistance can be approximated using:

1

S

and R1 and is

1

Further information regarding the design of the mains supply can be found in the section “Design

Hints” on page 9. The reference voltage source on pin 16 of typically -8.9 V is derived from the

supply voltage and is used for regulation.

Operation using an externally stabilized DC voltage is not recommended.

4. Phase Control

If the supply cannot be taken directly from the mains because the power dissipation in R

would

1

be too large, the circuit as shown in Figure 3-1 should be used.

Figure 3-1. Supply Voltage for High Current Requirements

~

24 V~

123

C

R

1

1

4

5

The phase angle of the trigger pulse is derived by comparing the ramp voltage (which is mains

synchronized by the voltage detector) with the set value on the control input pin 12. The slope of

the ramp is determined by C

R

on pin 6. The maximum phase angle α

2

and its charging current. The charging current can be varied using

2

can also be adjusted by using R

max

.

2

When the potential on pin 7 reaches the nominal value predetermined at pin 12, a trigger pulse

is generated whose width t

is determined by the value of C2 (the value of C2 and hence the

p

pulse width can be evaluated by assuming 8 µs/nF). At the same time, a latch is set, so that as

long as the automatic retriggering has not been activated, no more pulses can be generated in

that half cycle.

The current sensor on pin 1 ensures that, for operations with inductive loads, no pulse will be

generated in a new half cycle as long as a current from the previous half cycle is still flowing in

the opposite direction to the supply voltage at that instant. This makes sure that “gaps” in the

load current are prevented.

The control signal on pin 12 can be in the range of 0 V to -7 V (reference point pin 2).

If V

= -7 V, the phase angle is at maximum (α

12

The phase angle is minimum (

4

U211B

α

min

) when V

12

), i.e., the current flow angle, is at minimum.

max

= V2.

4752B–INDCO–09/05

5. Voltage Monitoring

As the voltage is built up, uncontrolled output pulses are avoided by internal voltage surveillance. At the same time, all latches in the circuit (phase control, load limit regulation, soft start)

are reset and the soft-start capacitor is short circuited. Used with a switching hysteresis of

300 mV, this system guarantees defined start-up behavior each time the supply voltage is

switched on or after short interruptions of the mains supply.

6. Soft Start

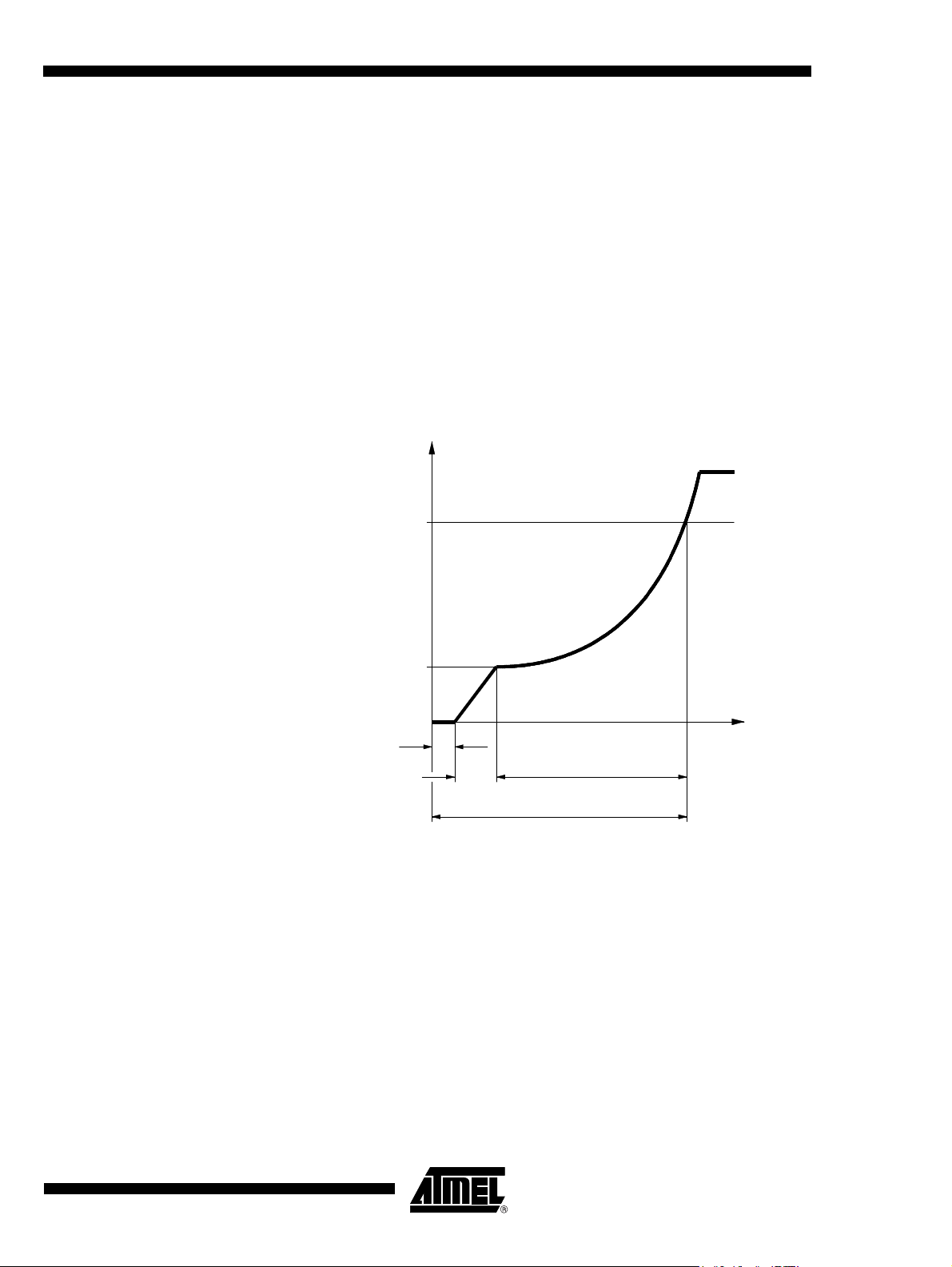

As soon as the supply voltage builds up (t1), the integrated soft start is initiated. Figure 6-1

shows the behavior of the voltage across the soft-start capacitor, which is identical with the voltage on the phase-control input on pin 12. This behavior guarantees a gentle start-up for the

motor and automatically ensures the optimum run-up time.

Figure 6-1. Soft Start

U211B

V

C3

V

12

V

0

t

1

t

2

t

3

t

tot

t

t1 = Build-up of supply voltage

t

= Charging of C3 to starting voltage

2

+ t2 = Dead time

t

1

= Run-up time

t

3

= Total start-up time to required speed

t

tot

C

is first charged up to the starting voltage V0 with a current of typically 45 µA (t2). By reducing

3

the charging current to approximately 4 µA, the slope of the charging function is also substantially reduced, so that the rotational speed of the motor only slowly increases. The charging

current then increases as the voltage across C

increases, resulting in a progressively rising

3

charging function which accelerates the motor more and more with increasing rotational speed.

The charging function determines the acceleration up to the set point. The charging current can

have a maximum value of 55 µA.

4752B–INDCO–09/05

5

7. Frequency-to-voltage Converter

∆

The internal frequency-to-voltage converter (f/V converter) generates a DC signal on pin 10

which is proportional to the rotational speed, using an AC signal from a tacho generator or a light

beam whose frequency is in turn dependent on the rotational speed. The high-impedance input

pin 8 compares the tacho voltage to a switch-on threshold of typically -100 mV. The switch-off

threshold is -50 mV. The hysteresis guarantees very reliable operation even when relatively simple tacho generators are used.

The tacho frequency is given by:

n

------

f

where: n = Revolutions per minute

The converter is based on the charge pumping principle. With each negative half-wave of the

input signal, a quantity of charge determined by C

C

6

transfer voltage of V

G

i

p (Hz)×=

60

p = Number of pulses per revolution

at the converter output on pin 10. The conversion constant is determined by C5, its charge

, R6 (pin 10) and the internally adjusted charge transfer gain.

ch

I

10

-------

I

8.3=

9

is internally amplified and then integrated by

5

k = G

× C5 × R6 × V

i

ch

The analog output voltage is given by

V

= k × f

O

The values of C

mum output voltage V

and C6 must be such that for the highest possible input frequency, the maxi-

5

does not exceed 6 V. While C5 is charging up, the Ri on pin 9 is

O

approximately 6.7 kΩ. To obtain good linearity of the f/V converter, the time constant resulting

from R

and C5 should be considerably less (1/5) than the time span of the negative half-cycle for

i

the highest possible input frequency. The amount of remaining ripple on the output voltage on

pin 10 is dependent on C

GiVch× C5×

V

-------------------------------------=

O

The ripple ∆V

C

6

can be reduced by using larger values of C6. However, the increasing speed will

O

, C6 and the internal charge amplification.

5

then also be reduced.

The value of this capacitor should be chosen to fit the particular control loop where it is going to

be used.

6

U211B

4752B–INDCO–09/05

7.1 Pulse Blocking

U211B

The output of pulses can be blocked by using pin 18 (standby operation) and the system reset

via the voltage monitor if V

output is released when V

Monitoring of the rotation can be carried out by connecting an RC network to pin 18. In the event

of a short or open circuit, the triac triggering pulses are cut off by the time delay which is determined by R and C. The capacitor C is discharged via an internal resistance R

charge transfer process of the f/V converter. If there are no more charge transfer processes, C is

charged up via R until the switch-off threshold is exceeded and the triac triggering pulses are cut

off. For operation without trigger pulse blocking or monitoring of the rotation, pin 18 and pin 16

must be connected together.

Figure 7-1. Operation Delay

≥ -1.25 V. After cycling through the switching point hysteresis, the

18

≤ -1.5 V, followed by a soft start such as after turn-on.

18

= 2 kΩ with each

i

C = 1 µF

10 V

7.2 Control Amplifier

The integrated control amplifier (see Figure 10-17 on page 21) with differential input compares

the set value (pin 11) with the instantaneous value on pin 10, and generates a regulating voltage

on the output pin 12 (together with the external circuitry on pin 12). This pin always tries to keep

the actual voltage at the value of the set voltages. The amplifier has a transmittance of typically

1000 µA/V and a bipolar current source output on pin 12 which operates with typically ±110 µA.

The amplification and frequency response are determined by R

out). For open-loop operation, C

connected with pin 12 and pin 8 with pin 2. The phase angle of the triggering pulse can be

adjusted by using the voltage on pin 11. An internal limitation circuit prevents the voltage on

pin 12 from becoming more negative than V

R = 1 MΩ

18

, C5, R6, R7, C7, C8 and R11 can be omitted. Pin 10 should be

4

17 16 15

123

+ 1 V.

16

4

, C7, C8 and R11 (can be left

7

7.3 Load Limitation

The load limitation, with standard circuitry, provides full protection against overloading of the

motor. The function of load limiting takes account of the fact that motors operating at higher

speeds can safely withstand larger power dissipations than at lower speeds due to the increased

action of the cooling fan. Similarly, considerations have been made for short-term overloads for

the motor which are, in practice, often required. These behaviors are not damaging and can be

tolerated.

4752B–INDCO–09/05

7

In each positive half-cycle, the circuit measures, via R10, the load current on pin 14 as a potential

drop across R

available on pin 15 and is integrated by C

angle for current flow, the voltage on C

and produces a current proportional to the voltage on pin 14. This current is

8

. If, following high-current amplitudes or a large phase

9

exceeds an internally set threshold of approximately

9

7.3 V (reference voltage pin 16), a latch is set and load limiting is turned on. A current source

(sink) controlled by the control voltage on pin 15 now draws current from pin 12 and lowers the

control voltage on pin 12 so that the phase angle α is increased to α

max

.

The simultaneous reduction of the phase angle during which current flows causes firstly a reduction of the rotational speed of the motor which can even drop to zero if the angular momentum of

the motor is excessively large, and secondly a reduction of the potential on C

which in turn

9

reduces the influence of the current sink on pin 12. The control voltage can then increase again

and bring down the phase angle. This cycle of action sets up a “balanced condition” between the

“current integral” on pin 15 and the control voltage on pin 12.

Apart from the amplitude of the load current and the time during which current flows, the potential on pin 12 and hence the rotational speed also affects the function of load limiting. A current

proportional to the potential on pin 10 gives rise to a voltage drop across R

the current measured on pin 14 is smaller than the actual current through R

, via pin 14, so that

10

.

8

This means that higher rotational speeds and higher current amplitudes lead to the same current

integral. Therefore, at higher speeds, the power dissipation must be greater than that at lower

speeds before the internal threshold voltage on pin 15 is exceeded. The effect of speed on the

maximum power is determined by the resistor R

and can therefore be adjusted to suit each

10

individual application.

If, after load limiting has been turned on, the momentum of the load sinks below the “o-momentum” set using R

, V15 will be reduced. V12 can then increase again so that the phase angle is

10

reduced. A smaller phase angel corresponds to a larger momentum of the motor and hence the

motor runs up, as long as this is allowed by the load momentum. For an already rotating

machine, the effect of rotation on the measured “current integral” ensures that the power dissipation is able to increase with the rotational speed. The result is a current-controlled

acceleration run-up which ends in a small peak of acceleration when the set point is reached.

The load limiting latch is simultaneously reset. Then the speed of the motor is under control

again and is capable of carrying its full load. The above mentioned peak of acceleration depends

upon the ripple of actual speed voltage. A large amount of ripple also leads to a large peak of

acceleration.

The measuring resistor R

should have a value which ensures that the amplitude of the voltage

8

across it does not exceed 600 mV.

8

U211B

4752B–INDCO–09/05

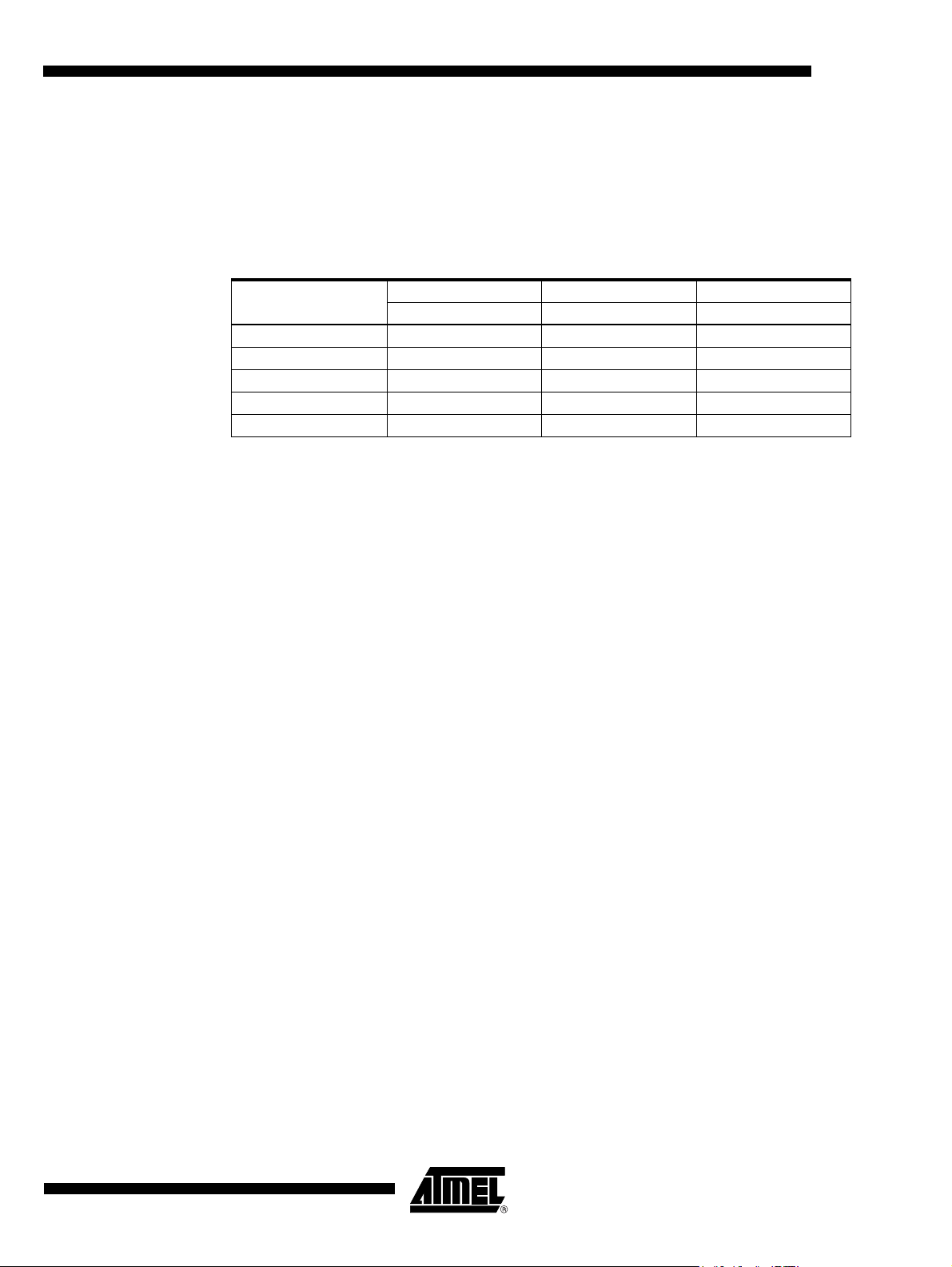

7.4 Design Hints

U211B

Practical trials are normally needed for the exact determination of the values of the relevant

components for load limiting. To make this evaluation easier, the following table shows the effect

of the circuitry on the important parameters for load limiting and summarizes the general

tendencies.

Table 7-1. Load Limiting Parameters

Component Component Component

Parameters

P

max

P

min

P

max/min

t

d

t

r

P

max

P

min

t

d

t

r

- Maximum continuous power dissipationP1 = f

- Power dissipation with no rotation P1 = f

- Operation delay time

- Recovery time

n.e. - No effect

R10 Increasing R9 Increasing C9 Increasing

Increases Decreases n.e.

Increases Decreases n.e.

Increases n.e. n.e.

n.e. Increases Increases

n.e. Increases Increases

n ≠ 0

(n)

n = 0

(n)

7.5 Pulse-output Stage

The pulse-output stage is short-circuit protected and can typically deliver currents of 125 mA.

For the design of smaller triggering currents, the function I

10-12 on page 18.

7.6 Automatic Retriggering

The variable automatic retriggering prevents half cycles without current flow, even if the triac has

been turned off earlier, e.g., due to a collector which is not exactly centered (brush lifter) or in the

event of unsuccessful triggering. If necessary, another triggering pulse is generated after a time

lapse which is determined by the repetition rate set by resistance between pin 5 and pin 3 (R

With the maximum repetition rate (pin 5 directly connected to pin 3), the next attempt to trigger

comes after a pause of 4.5 t

ishes. If pin 5 is not connected, only one trigger pulse per half cycle is generated. Since the

value of R

for a fixed value of C

= f(RGT) can be taken from Figure

GT

and this is repeated until either the triac fires or the half cycle fin-

p

determines the charging current of C2, any repetition rate set using R

5-3

.

2

is only valid

5-3

5-3

).

4752B–INDCO–09/05

9

7.7 General Hints and Explanation of Terms

To ensure safe and trouble-free operation, the following points should be taken into consideration when circuits are being constructed or in the design of printed circuit boards.

• The connecting lines from C

to pin 7 and pin 2 should be as short as possible. The

2

connection to pin 2 should not carry any additional high current such as the load current.

When selecting C

, a low temperature coefficient is desirable.

2

• The common (earth) connections of the set-point generator, the tacho generator and the final

interference suppression capacitor C

of the f/V converter should not carry load current.

4

• The tacho generator should be mounted without influence by strong stray fields from the

motor.

• The connections from R

and C5 should be as short as possible.

10

To achieve a high noise immunity, a maximum ramp voltage of 6 V should be used. The typical

resistance R

R

kΩ()

ϕ

can be calculated from Iϕ as follows:

ϕ

3

Tms()1.13 V()× 10

-------------------------------------------------------------=

CnF()6V()×

×

T = Period duration for mains frequency (10 ms at 50 Hz)

C

= Ramp capacitor, maximum ramp voltage 6 V and constant voltage drop at

ϕ

R

= 1.13 V

ϕ

A 10% lower value of R

(under worst case conditions) is recommended.

ϕ

Figure 7-2. Explanation of Terms in Phase Relationship

Mains

Supply

V

Trigger

Pulse

Load

Voltage

Load

Current

GT

V

I

L

V

π/2 π 3/2π 2π

t

p

L

tpp = 4.5 t

p

ϕ

Φ

10

U211B

4752B–INDCO–09/05

7.8 Design Calculations for Main Supply

The following equations can be used for the evaluation of the series resistor R1 for worst case

conditions:

–

V

MminVSmax

R

= R

1max

--------------------------------------

0.85

2 I

tot

1min

VMV

–

-----------------------------=

2 I

Smax

U211B

Smin

2

1

P

R1max()

V

----------------------------------------------=

–()

MmaxVSmin

2 R

where:

V

M

V

S

I

tot

I

Smax

I

p

I

x

R

can be easily evaluated from the Figure 10-14 on page 19, Figure 10-15 on page 19 and

1

= Mains voltage

= Supply voltage on pin 3

= Total DC current requirement of the circuit

+ Ip + I

= I

S

x

= Current requirement of the IC in mA

= Average current requirement of the triggering pulse

= Current requirement of other peripheral components

Figure 10-16 on page 20.

4752B–INDCO–09/05

11

8. Absolute Maximum Ratings

Reference point pin 2, unless otherwise specified

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress rating

only and functional operation of the device at these or any other conditions beyond those indicated in the operational sections of this

specification is not implied. Exposure to absolute maximum rating conditions for extended periods may affect device reliability.

Parameters Pins Symbol Value Unit

Current requirement 3 -I

t ≤ 10 µs 3 -i

Synchronization current 1 I

17 I

syncI

syncV

t < 10 µs 1 ±i

t < 10 µs 17 ±i

f/V Converter

Input current 8 I

t < 10 µs 8 ±i

Load Limiting

Limiting current,

negative half wave

14 I

t < 10 µs 14 I

Input voltage

14 ±V

15 -V

Phase Control

Input voltage 12 -V

Input current

12 ±I

6-I

Soft Start

Input voltage 13 -V

Pulse Output

Reverse voltage 4 V

Pulse Blocking

Input voltage 18 -V

Amplifier

Input voltage 11 V

Pin 9 open 10 -V

Reference Voltage Source

Output current 16 I

Storage temperature range T

Junction temperature T

Ambient temperature range T

S

s

I

I

I

I

I

I

i

I

I

I

I

I

R

I

I

I

o

stg

j

amb

30 mA

100 mA

5mA

5mA

35 mA

35 mA

3mA

13 mA

5mA

35 mA

1V

|V16| to 0 V

0 to 7 V

500 µA

1mA

|V16| to 0 V

VS to 5 V

|V16| to 0 V

0 to V

S

V

|V16| to 0 V

7.5 mA

-40 to +125 °C

125 °C

-10 to +100 °C

12

U211B

4752B–INDCO–09/05

U211B

9. Thermal Resistance

Parameters Symbol Value Unit

Junction ambient DIP18

SO16 on p.c.

SO16 on ceramic

R

thJA

R

thJA

R

thJA

120

180

100

10. Electrical Characteristics

-VS = 13.0 V, T

Parameters Test Conditions Pins Symbol Min. Typ. Max. Unit

Supply voltage for mains operation 3 -V

Supply voltage limitation

DC current requirement -V

Reference voltage source

Temperature coefficient 16 -TC

Voltage Monitoring

Turn-on threshold 3 -V

Turn-off threshold 3 -V

Phase-control Currents

Synchronization current

Voltage limitation ±IL = 5 mA 1, 17 ±V

Reference Ramp (see Figure 10-1 on page 15)

Charge current

R

-reference voltage α ≥ 180° 6, 3 V

ϕ

Temperature coefficient 6 TC

Pulse Output (see Figure 10-12 on page 18, Pin 4)

Output pulse current R

Reverse current I

Output pulse width Cϕ = 10 nF t

Amplifier

Common-mode signal range 10, 11 V

Input bias current 11 I

Input offset voltage 10, 11 V

Output current 12

Short circuit forward, transmittance

= 25° C, reference point pin 2, unless otherwise specified

amb

-I

= 4 mA

S

-I

= 30 mA

S

= 13.0 V 3 I

S

= 10 µA

-I

L

-IL = 5 mA

3-V

16 -V

1

17

= f(R6)

I

7

R6 = 50 kΩ to 1 MΩ

= 0, VGT = 1.2 V I

GT

I

= f(V

12

10-11

), (see

Figure 10-7 on page 17)

7I

12 Y

±I

±I

10

-I

+I

S

S

S

Ref

VRef

SON

SOFF

syncI

syncV

I

7

ϕRef

VϕRef

o

or

p

, V

IO

10

O

O

f

13.0 V

14.6

14.7

1.2 2.5 3.0 mA

8.6

8.9 9.2

8.3

0.5 mV/K

11.2 13.0 V

9.9 10.9 V

0.35 2.0 mA

1.4 1.6 1.8 V

120 µA

1.06 1.13 1.18 V

0.5 mV/K

100 155 190 mA

0.01 3.0 µA

80 µs

11

V

16

0.01 1 µA

10 mV

75

88

110

120

1000 µA/V

K/W

K/W

K/W

Limit

16.6

16.8

9.1

-1 V

145

165

V

V

V

V

V

µA

µA

4752B–INDCO–09/05

13

10. Electrical Characteristics (Continued)

-VS = 13.0 V, T

Parameters Test Conditions Pins Symbol Min. Typ. Max. Unit

Pulse Blocking, Tacho Monitoring

Logic-on 18 -V

Logic-off 18 -V

Input current

Output resistance 18 R

Frequency-to-voltage Converter

Input bias current 8 I

Input voltage limitation

Turn-on threshold 8 -V

Turn-off threshold 8 -V

Charge Amplifier

Discharge current

Charge transfer voltage 9 to 16 V

Charge transfer gain I

Conversion factor

Output operating range 10 to 16 V

Linearity ±1 %

Soft Start, f/V Converter Non-active (see Figure 10-2 on page 15 and Figure 10-4 on page 16)

Starting current V

Final current V

f/V Converter Active (see Figure 10-3 on page 15, Figure 10-5 on page 16 and Figure 10-6 on page 16)

Starting current V

Final current V

Discharge current Restart pulse 13 I

Automatic Retriggering (see Figure 10-13 on page 19, Pin 5)

Repetition rate R

Load Limiting (see Figure 10-9 on page 17, Figure 10-10 on page 18 and Figure 10-11 on page 18)

Operating voltage range 14 V

Offset current

Input current V

Output current V

Overload ON 15-16 V

= 25° C, reference point pin 2, unless otherwise specified

amb

V

= V

18

V18 = V

= -1 mA

I

I

II = +1 mA

(see Figure 10-7 on

TOFF

16

= 1.25 V

18 I

8

page 17)

= 1 nF, (see Figure

C

5

10-17 on page 21)

10/I9

C

= 1 nF, R6 = 100 kΩ

5

9I

9, 10 G

(see Figure 10-17 on

page 21)

= V16, V8 = V

13

= 0.5 13 I

13

= V

13

16

= 0.5 I

13

= 0 t

5-3

R

= 15 kΩ t

5-3

= V

V

10

16

2

V14 = V2 via 1 kΩ

= 4.5 V 14 I

10

= 300 mV 15-16 I

14

13 I

13 I

14

15-16

TON

TOFF

IB

-V

+V

TON

TOFF

dis

I

O

I

I

ch

i

3.7 1.5 V

1.25 1.0 V

0.3 1 µA

14.5

1.5 6 10 kΩ

0.6 2 µA

660

7.25

750

8.05

100 150 mV

20 50 mV

0.5 mA

6.50 6.70 6.90 V

7.5 8.3 9.0

K 5.5 mV/Hz

O

O

O

O

O

O

pp

pp

I

I

O

I

O

I

O

TON

20 45 55 µA

50 85 130 µA

247µA

30 55 80 µA

0.5 3 10 mA

34.56 t

-1.0 +1.0 V

5

60 90 120 µA

110 140 µA

7.05 7.4 7.7 V

0-6 V

20 t

12

0.1

1.0

µA

mV

V

p

p

µA

µA

14

U211B

4752B–INDCO–09/05

Figure 10-1. Ramp Control

)

°

(

α

e

l

g

n

A

e

s

a

h

P

240

200

160

120

U211B

Reference Point Pin 2

10nF 4.7nF

2.2nF

80

0

0 0.2 0.4 0.6 0.8

Rϕ (MΩ)

C

=1.5nF

/t

ϕ/t

1.0

Figure 10-2. Soft-start Charge Current (f/V Converter Non-active)

100

80

)

60

A

µ

(

3

1

I

40

20

Reference Point Pin 16

0

02 4 6 8

V13(V)

10

Figure 10-3. Soft-start Charge Current (f/V Converter Active)

4752B–INDCO–09/05

100

80

Reference Point Pin 16

)

60

A

µ

(

3

1

I

40

20

0

02 4 6 8

V13 (V)

10

15

Figure 10-4. Soft-start Voltage (f/V Converter Non-active)

10

8

)

6

V

(

3

1

V

4

2

Reference Point Pin 16

0

t = f

(C3)

Figure 10-5. Soft-start Voltage (f/V Converter Active)

10

8

Reference Point Pin 16

)

6

V

(

3

1

V

4

2

0

t = f

(C3)

Figure 10-6. Soft-start Function

16

U211B

10

Reference Point Pin 16

8

6

)

V

(

3

1

V

4

2

0

t = f

(C3)

Motor Standstill (Dead Time)

Motor in Action

4752B–INDCO–09/05

Figure 10-7. f/V Converter Voltage Limitation

500

250

U211B

)

A

µ

(

8

I

Reference Point Pin 2

0

-250

-500

-10 -8 -6 -4 -2

Figure 10-8. Amplifier Output Characteristics

100

50

)

A

µ

(

0

2

1

I

-50

Reference Point

-100

-300 -200 -100 0 200

for I

= -4 V

12

V

V8 (V)

10-11

(V)

02

100

4

300

4752B–INDCO–09/05

Figure 10-9. Load Limit Control

200

150

)

A

µ

(

100

6

1

2

1

I

-

50

0

024 6

V

(V)

15-16

8

17

Figure 10-10. Load Limit Control f/V Dependency

200

150

)

A

µ

(

100

2

4

1

I

50

0

024 6

Figure 10-11. Load Current Detection

250

200

)

150

A

µ

(

6

1

5

1

I

100

50

0

0 100 200 300 400

Figure 10-12. Pulse Output

100

V

10-16

I15 = f(V

V

V

14-2

(V)

= V

10

(mV)

Shunt

16

)

500 600

8

700

18

U211B

80

60

(mA)

GT

I

40

1.4 V

VGT = 0.8 V

20

0

0 200 400 600 800

R

GT

1000

(Ω)

4752B–INDCO–09/05

Figure 10-13. Automatic Retriggering Repetition Rate

20

15

)

Ω

k

(

3

10

5

R

5

0

0 6 12 18 24

tpp/t

p

U211B

30

Figure 10-14. Determination of R

1

50

40

)

30

Ω

k

(

1

R

20

10

0

04812

Figure 10-15. Power Dissipation of R

6

5

4

)

W

(

)

1

3

R

(

P

2

Mains Supply

230 V

16

I

(mA)

tot

1

Mains Supply

230 V

4752B–INDCO–09/05

1

0

0102030

(kΩ)

R

1

40

19

Figure 10-16. Power Dissipation of R1 According to Current Consumption

6

5

Mains Supply

4

)

W

(

)

1

3

R

(

P

2

1

230 V

0

03 6 912

I

(mA)

tot

15

20

U211B

4752B–INDCO–09/05

Figure 10-17. Speed Control, Automatic Retriggering, Load Limiting, Soft Start

U211B

L

1

D

1N4007

=

M

V

230 V ~

N

M

8

Ω

R

1

R

Ω

2 W

18 k

TIC

226

Ω

Ω

12

R

1 M

180

R

4

pulse

Output

5

Automatic

retriggering

4

R

470 k Ω

1 W

33 m

2

3.3 nF

7

6

2

C

3

Phase-

22 µF/

-V

Supply

control unit

25 V

1

C

S

2

voltage

limitation

)

12

ϕ = f (V

2.2 µF

11

C

GND

Reference

16

voltage

Voltage

monitoring

18

tacho

Pulse blocking

to-voltage

Frequency-

Soft start

monitoring

converter

-V

Speed sensor

4

C

220 nF

Ref

12 13 9 8

5

C

8

C

7

C

Ω

1 k

1 nF

2.2 µF/

3

C

220 nF

7

R

5

R

16 V

22 kΩ

detector

Control

amplifier

3

Ω

R

Voltage/current

17 1

-

+

controlled

speed/time

Load limitation

Controlled

current sink

R

10 µF/16V

11

2 MΩ

6

R

100 kΩ

220 k

15

9

R

9

C

1 MΩ

4.7 µF/16V

Actual speed

6

C

100 nF

voltage

Set speed

voltage

R

19

Ω

100 k

11

10

C

10

2.2 µF/16V

14

10

R

1 kΩ

4752B–INDCO–09/05

13

R

31

R

47 kΩ

100 kΩ

Ω

14

R

56 k

21

Figure 10-18. Speed Control, Automatic Retriggering, Load Switch-off, Soft Start

F

µ

V

2

0

.

1

2

F

n

0

1

C

6

R

Ω

k

0

0

1

8

C

F

µ

V

7

.

0

4

1

9

C

Ω

k

0

9

7

R

4

0

0

1

6

C

1

1

R

F

n

0

2

2

F

µ

2

.

2

Ω

k

4

1

0

R

1

d

e

1

3

R

3

C

V

0

1

e

Ω

e

g

p

k

a

s

t

l

0

t

o

5

e

v

2

S

7

C

Ω

M

1

3

Ω

1

k

R

7

4

V

0

1

/

F

µ

2

.

2

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

Ω

k

7

5

R

1

B

1

1

2

U

5

F

C

p

0

8

6

9

8

7

ϕ

R

6

2

Ω

R

M

5

1

4

S

V

-

3

D

N

G

2

2

1

1

R

F

n

0

4

2

2

C

Ω

k

5

1

R

t

/

ϕ

C

F

n

2

2

C

.

2

Ω

0

8

1

r

o

s

n

e

s

d

e

e

p

S

22

1

F

1

µ

C

2

.

2

5

5

X

Z

B

U211B

Ω

k

4

0

R

7

4

F

V

µ

5

2

2

2

1

C

Ω

W

m

1

1

1

x

3

=

8

R

N

T1

Ω

k

3

2

T

Ω

k

7

4

5

1

R

6

1

R

0

R

2

2

4

1

0

0

D

4

N

Ω

k

7

4

1

Ω

k

0

2

1

.

R

2

L

Ω

W

k

5

.

8

1

1

1

R

M

~

V

0

3

2

The switch-off level at maximum load shows in principle the same speed dependency as the

original version (see Figure 10-17 on page 21), but when reaching the maximum load, the motor

is switched off completely. This function is effected by the thyristor (formed by T

and T2) which

1

ignites when the voltage at pin 15 reaches typically 7.4 V (reference point pin 16). The circuit is

thereby switched to standby mode over the release Pin 18.

4752B–INDCO–09/05

Figure 10-19. Speed Control, Automatic Retriggering, Load Switch-down, Soft Start

d

F

µ

V

2

.

0

2

1

0

1

C

6

R

Ω

k

0

0

F

1

n

0

2

2

8

C

F

µ

V

7

.

0

4

1

9

C

1

µF

1

2

C

.

2

Ω

k

9

0

R

7

4

Ω

5

k

1

3

R

3

1

T

5

5

X

Z

B

1

3

R

F

n

0

0

1

6

C

1

1

R

3

C

F

µ

V

2

.

0

2

1

Ω

k

4

1

0

R

1

2

T

6

1

R

e

e

g

Ω

e

a

k

t

p

l

0

s

o

t

5

v

e

2

S

7

C

Ω

M

1

Ω

k

7

4

3

1

Ω

k

R

7

4

V

0

1

F/

µ

2

.

2

0

1

1

1

2

1

3

1

4

1

Ω

k

7

5

1

R

5

F

C

p

0

8

6

9

8

7

ϕ

R

6

2

B

1

1

2

5

Ω

R

M

1

U

5

1

6

1

7

1

8

1

Ω

k

3

0

R

2

2

4

0

1

0

D

4

N

1

Ω

k

0

2

1

.

R

2

L

4

S

V

-

3

D

N

G

2

1

Ω

W

k

5

.

8

1

1

1

R

R

Ω

k

4

0

R

7

4

M

~

V

0

3

2

The maximum load regulation shows in principle the same speed dependency as the original

version (see Figure 10-17 on page 21). When reaching the maximum load, the control unit is

turned to α

formed by T

, adjustable with R2. Then, only IO flows. This function is effected by the thyristor,

max

and T2 which ignites as soon as the voltage at pin 15 reaches approximately 6.8 V

1

(reference point pin 16). The potential at pin 15 is lifted and kept by R

ing threshold whereby the maximum load regulation starts and adjusts the control unit constantly

to α

(IO), inspite of a reduced load current. The motor shows that the circuit is still in operation

max

by produceing a buzzing sound.

U211B

F

n

0

2

4

2

C

Ω

k

5

R

1

t

/

ϕ

C

F

n

2

2

C

.

2

Ω

2

1

0

8

1

F

µ

2

2

r

o

s

n

e

s

d

e

e

p

S

V

5

2

1

C

Ω

m

W

1

1

1

x

3

=

8

R

N

over the internal operat-

14

4752B–INDCO–09/05

23

Figure 10-20. Speed Control, Automatic Retriggering, Load Limiting, Soft Start, Tacho Control

d

F

µ

V

2

.

0

2

1

F

n

0

1

C

6

R

Ω

k

8

6

8

C

9

R

9

C

1

1

C

0

0

1

6

C

1

1

R

F

n

0

2

2

Ω

M

1

F

µ

7

.

4

F

n

2

2

F

µ

2

.

2

e

1

3

R

e

e

Ω

g

p

k

a

s

t

l

0

t

o

5

e

v

2

S

7

C

Ω

M

5

.

1

3

C

V

0

1

3

Ω

1

k

R

7

4

V

0

1

/

µF

2

.

2

0

1

1

1

2

1

3

1

4

1

5

1

6

1

V

0

1

/

F

m

1

7

1

8

1

Ω

k

7

2

R

2

B

1

1

2

5

C

F

n

1

9

8

7

ϕ

6

5

R

2

Ω

R

M

1

F

n

0

4

2

2

C

Ω

k

5

1

R

t

/

ϕ

C

F

n

2

2

C

.

2

r

o

s

n

e

s

d

e

e

p

S

U

4

S

V

-

3

D

N

G

2

Ω

2

1

0

2

1

R

2

24

U211B

W

W

k

3

M

1

R

0

2

2

4

1

0

0

D

4

N

1

Ω

W

k

5

8

.

1

1

1

R

M

Ω

0

k

1

R

1

~

V

0

L

3

2

W

k

4

0

R

7

4

F

µ

V

5

2

2

2

1

C

Ω

W

m

1

1

1

x

3

=

8

R

N

4752B–INDCO–09/05

Figure 10-21. Speed Control with Reflective Opto Coupler CNY70 as Emitter

d

e

e

.

p

n

i

s

m

t

8

1

e

S

R

1

Ω

3

k

R

0

3

1

C

F

µ

V

7

0

.

1

4

F

n

0

4

2

C

2

Ω

k

8

7

R

4

0

1

Ω

k

0

7

4

7

R

3

C

F

µ

V

2

0

.

1

2

C

d

e

.

e

x

p

a

s

3

t

m

1

e

R

S

Ω

k

1

1

6

R

V

0

1

F

µ

0

1

1

1

1

F

n

0

7

7

8

C

F

n

2

2

Ω

k

0

2

2

4

C

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

4

R

4

0

0

4

N

1

1

D

B

1

1

2

U

0

7

Y

N

C

9

F

p

6

0

C

8

6

8

7

ϕ

R

6

2

Ω

R

M

1

5

6

R

4

W

S

0

V

0

-

1

3

D

N

G

2

1

Ω

k

5

0

R

Ω

W

k

5

.

8

1

1

1

R

7

4

U211B

Ω

0

7

4

6

1

R

7

1

R

5

1

5

V

X

Ω

0

0

1

5

F

C

n

0

7

4

Ω

k

0

2

2

R

t

/

ϕ

C

2

C

3

R

A

m

0

5

=

T

G

I

Ω

k

9

5

.

1

F

0

n

1

3

R

.

3

Ω

k

7

.

4

F

µ

V

7

5

2

4

1

C

9

Z

C

B

3

Z

F

µ

V

0

0

0

1

1

0

1

C

W

8

/

5

1

Ω

R

k

5

.

3

2

4

D

0

0

4

N

1

n

o

i

t

u

l

o

v

e

R

/

s

e

s

l

u

P

0

2

2

.

a

c

4752B–INDCO–09/05

3

8

W

Y

B

s

e

d

o

i

d

l

l

a

1

L

2

L

M

4

Ω

1

0

0

R

1

~

V

0

3

2

~

F

n

V

0

0

5

5

1

2

2

1

C

25

Figure 10-22. Speed Control, Maximum Load Control with Reflective Opto Coupler CNY70 as Emitter

V

d

e

.

e

n

p

i

s

m

t

4

e

1

S

R

1

3

Ω

k

R

0

0

1

C

F

V

µ

7

0

4

1

F

n

0

6

7

C

4

Ω

k

6

2

R

8

C

µF

V

7

0

.

1

4

9

C

Ω

k

0

2

2

9

R

2

2

Ω

k

0

2

8

1

1

R

3

F

µ

V

2

.

0

2

1

1

F

1

n

C

2

2

d

e

.

e

x

p

a

s

t

3

m

e

1

S

R

Ω

k

7

6

R

1

F

F

µ

0

7

1

C

n

0

7

8

4

C

0

1

1

1

2

1

3

1

4

1

B

0

7

Y

N

C

5

C

9

8

7

6

1

1

2

2

R

5

U

5

1

6

1

7

1

8

1

Ω

k

3

0

R

1

1

4

0

0

4

N

1

1

D

4

S

V

-

3

D

N

G

2

1

4

R

Ω

W

k

1

.

0

1

1

1

R

9

8

1

Ω

0

R

7

4

7

Ω

1

k

R

3

3

3

1

C

F

µ

1

Ω

6

1

k

R

0

1

F

p

0

8

6

F

t

n

/

ϕ

3

.

C

3

2

ϕ

C

R

Ω

M

1

2

1

R

Ω

0

0

1

A

m

0

5

=

T

G

Ω

I

k

0

2

2

F

n

1

4

C

5

Ω

R

k

2

.

2

F

V

µ

2

5

2

2

1

C

26

U211B

M

Ω

0

0

1

~

0

Ω

1

k

R

1

.

1

~

V

0

3

2

F

V

n

0

5

1

2

0

1

5

2

C

Ω

1

.

0

x

3

=

8

R

4752B–INDCO–09/05

U211B

The schematic diagram (see Figure 10-22 on page 26) is designed as a speed control IC based

on the reflection-coupled principle with 4 periods per revolution and a maximum speed of

30000 rpm. The separation of the coupler from the rotating aperture should be about approximately 1 mm. In the schematic diagram, the power supply for the coupler was provided

externally because of the relatively high current consumption.

Instructions for adjusting:

1. In the initial adjustment of the phase-control circuit, R

R

= 0 and R

14

are in minimum position, the motor just turns.

31

2. The speed can now be adjusted as desired by means of R

mined by R

and R14.

13

should be adjusted so that when

2

between the limits deter-

31

3. The switch-off power of the limiting-load control can be set by R

higher the switch-off power.

. The lower R9, the

9

4752B–INDCO–09/05

27

11. Ordering Information

Extended Type Number Package Remarks

U211B-xY DIP18 Tube

U211B-xFPY SO16 Tube

U211B-xFPG3Y SO16 Taped and reeled

12. Package Information

Package DIP18

Dimensions in mm

23.3 max

4.8 max

7.77

7.47

1.64

1.44

18 10

19

Package SO16

Dimensions in mm

0.4

1.27

20.32

10.0

9.85

8.89

0.58

0.48

2.54

0.5 min

1.4

0.25

0.10

3.3

technical drawings

according to DIN

specifications

6.4 max

0.36 max

9.8

8.2

5.2

4.8

3.7

0.2

3.8

6.15

5.85

28

U211B

16 9

technical drawings

according to DIN

specificati ons

18

4752B–INDCO–09/05

13. Revision History

Please note that the following page numbers referred to in this section refer to the specific revision

mentioned, not to this document.

Revision No. History

4752B-INDCO-08/05

U211B

• Put datasheet in a new template

• First page: Pb-free logo added

• Page 28: Ordering Information changed

4752B–INDCO–09/05

29

Atmel Corporation Atmel Operations

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 487-2600

Regional Headquarters

Europe

Atmel Sarl

Route des Arsenaux 41

Case Postale 80

CH-1705 Fribourg

Switzerland

Tel: (41) 26-426-5555

Fax: (41) 26-426-5500

Asia

Room 1219

Chinachem Golden Plaza

77 Mody Road Tsimshatsui

East Kowloon

Hong Kong

Tel: (852) 2721-9778

Fax: (852) 2722-1369

Japan

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shinkawa

Chuo-ku, Tokyo 104-0033

Japan

Tel: (81) 3-3523-3551

Fax: (81) 3-3523-7581

Memory

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

Microcontrollers

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

La Chantrerie

BP 70602

44306 Nantes Cedex 3, France

Tel: (33) 2-40-18-18-18

Fax: (33) 2-40-18-19-60

ASIC/ASSP/Smart Cards

Zone Industrielle

13106 Rousset Cedex, France

Tel: (33) 4-42-53-60-00

Fax: (33) 4-42-53-60-01

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Scottish Enterprise Technology Park

Maxwell Building

East Kilbride G75 0QR, Scotland

Tel: (44) 1355-803-000

Fax: (44) 1355-242-743

RF/Automotive

Theresienstrasse 2

Postfach 3535

74025 Heilbronn, Germany

Tel: (49) 71-31-67-0

Fax: (49) 71-31-67-2340

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Biometrics/Imaging/Hi-Rel MPU/

High Speed Converters/RF Datacom

Avenue de Rochepleine

BP 123

38521 Saint-Egreve Cedex, France

Tel: (33) 4-76-58-30-00

Fax: (33) 4-76-58-34-80

Literature Requests

www.atmel.com/literature

Disclaimer: The information in this document is provided in connection with Atmel products. No license, express or implied, by estoppel or otherwise, to any

intellectual property right is granted by this document or in connection with the sale of Atmel products. EXCEPT AS SET FORTH IN ATMEL’S TERMS AND CONDI-

TIONS OF SALE LOCATED ON ATMEL’S WEB SITE, ATMEL ASSUMES NO LIABILITY WHATSOEVER AND DISCLAIMS ANY EXPRESS, IMPLIED OR STATUTORY

WARRANTY RELATING TO ITS PRODUCTS INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR NON-INFRINGEMENT. IN NO EVENT SHALL ATMEL BE LIABLE FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL, PUNITIVE, SPECIAL OR INCIDENTAL DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF PROFITS, BUSINESS INTERRUPTION, OR LOSS OF INFORMATION) ARISING OUT

OF THE USE OR INABILITY TO USE THIS DOCUMENT, EVEN IF ATMEL HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. Atmel makes no

representations or warranties with respect to the accuracy or completeness of the contents of this document and reserves the right to make changes to specifications

and product descriptions at any time without notice. Atmel does not make any commitment to update the information contained herein. Unless specifically provided

otherwise, Atmel products are not suitable for, and shall not be used in, automotive applications. Atmel’s products are not intended, authorized, or warranted for use

as components in applications intended to support or sustain life.

© Atmel Corporation 2005. All rights reserved. Atmel®, logo and combinations thereof, Everywhere You Are® and others, are registered trade-

marks or trademarks of Atmel Corporation or its subsidiaries. Other terms and product names may be trademarks of others.

Printed on recycled paper.

4752B–INDCO–09/05

Loading...

Loading...