Page 1

Specifications and electrical requirements

SKF Dynamic Motor Analyzer EXP4000

Integrated testing

capabilities

The SKF Dynamic Motor Analyzer EXP4000 integrates a wide range of

monitoring capabilities which meet

high quality standards. Designed for

in-service monitoring of power circuit

issues, overall motor health, load, and

performance, it gives the user a

comprehensive look at overall motor

integrity. This instrument was

designed for remote monitoring from

the Motor Control Center (MCC) or

through the EP1000 connection. It is

a non-hazardous, low voltage,

battery operated unit, which makes it

highly portable and durable for use in

tight and rugged locations.

Continuous innovation

Continual design breakthroughs

demonstrate our on going

commitment to quality, reliability,

and competitive advantage. This

instrument provides data on degradation

of motor performance and the effects of

overheating on motor operation. Survey

plant wide efficiency, determine load

mismatches, oscillating load and transient

peak energy. Results are immediate,

showing operating efficiencies, thereby

allowing the user to determine the true

cost of wasted energy.

Comprehensive analysis

The S K F Dynamic M o t or Analyzer EXP4000 performs seven major

functions to enhance a P/PM program.

Within these functions evaluate the

incoming power, motor and load utilizing a

system wide approach to predictive

maintenance, troubleshooting and quality

assurance. This motor analyzer offers a

wide variety of capabilities for the

maintenance professional to understand

the condition of the rotating system. It is

programmed to supply information on

Page 2

voltage level, voltage balance, harmonic

and total distortion, rotor cage condition,

motor efficiency, effective service factor,

overcurrent, operating condition, torque

ripple, load history among others. This

wide range of tests allows exploration of

the true condition of motor integrity and

conditions related to motor performance.

Advanced data collection

and organization

Once testing is completed, results can be

saved and stored for each motor. This type

of documentation i s c r i t ical f or any m a i n t enance program. It allows the recalling of

information for true trending capabilities.

Test results are managed using standard

MS Access relational database file formats.

Reports can be quickly generated through

the main print console, allowing operators

visual confirmation of motor integrity.

The software and data transfer package

enables the creation of multiple databases

to organize collected data to specifications

set by users. This eases communication

channels by handling data in a manner

that is useful, complete and accessible.

Test domains

harmonics tests. These issues identify

improper tap settings on supply transformers, poorly distributed single phase

loads, overloading (saturating) supply

transformers, excessive VFDs on low

voltage busses, excessing non-harmonic

frequencies on a VFD, missing line

inductors on VFD applications, missing or

open power factor correction capacitors

along with high resistance connections.

Machine performance

Conclusively evaluate the operation of the

motor, identifying stressful operation and

its source with this domain. It looks at

Effective Service Factor, Load, Operation

Condition, Efficiency, and calculates

Payback Period. Commonly found

problems include: thermal overloading of

the motor, machine deterioration

recognition among other items that are

directly related to the motors health and

the energy wasted with ineff iciencies.

Current

Currrent level and current unbalance are

utilized to determine overall electrical

machine health. These parameters are

used to determine the following issues

overloading, connection issues, miss

connections, iron saturation and

improperly wound motors.

Power quality

This domain identifies non-optimal power

quality problems, which cause additional

motor stress. Flag frequent problems with

voltage level, voltage unbalance, harmonic

distor tion, total distortion, power and

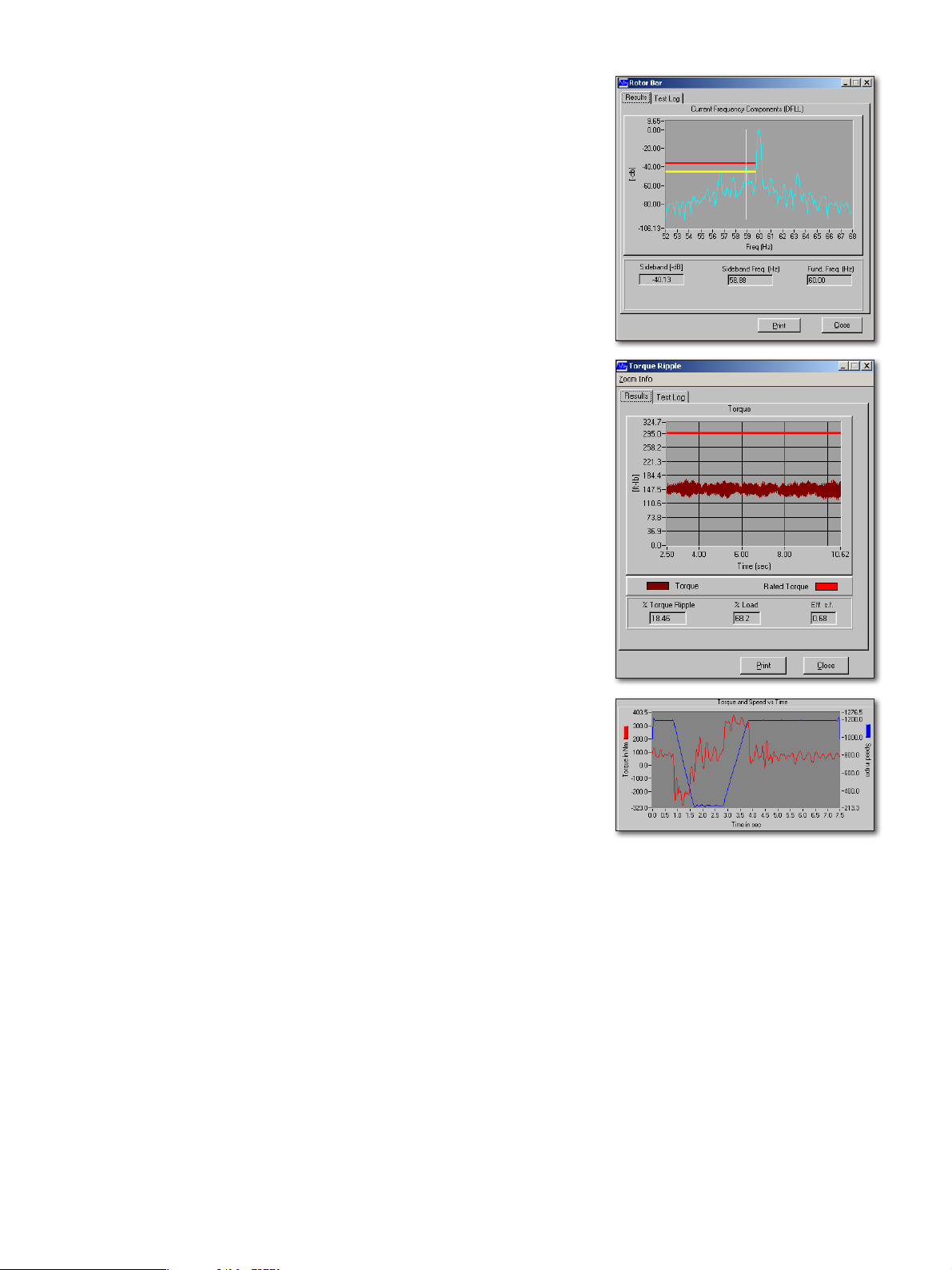

Spectrum

This domain has the rotor bar test along

with V/I spectrum, Demodulated

Spectrum, and Harmonics. It shows

current and voltage relationships with

regards to frequency. Electrically it will

find saturation problems, broken rotor

2

Page 3

bars, excessive VFD drives on low voltage

busses and mechanical problems.

Torque (Optional)

The torque domain is a substantial breakthrough by Baker Instrument Company,

an SKF Group Company. Torque Ripple and

Torque Spectrum enable the user to find

numerous problems quickly and

accurately. It specializes in diagnosing

mechanical issues, shows transient

overloading, finds mechanical imbalances

along with bearing problems, and

cavitation, among others.

Connections

This portion of the SKF Dynamic Motor

Analyzer - EXP4000 software offers

additional tools including phasor diagrams,

three currents and voltages, instantaneous voltage, and symmetrical components.

This data provides the operator with valuable power data as well as a way to make

sure the EXP4000 is correctly connected.

most important to their operation. This

software will also act as a power analyzer

to determine actual power quality.

Transient Analysis

The SKF Dynamic Motor Analyzer EXP4000 also performs a start up analysis

using the transient analysis tool. The traces

are the rms currents and voltages of all

three phases. This data can be zoomed,

panned, and the cursors allow reading of

levels and time within the graphs. Along

with this powerful analysis capability,

startup Torque versus Time can also be

evaluated. These tools allow the user to

visually see the amplitude of voltage,

current and torque at startup, along with

motor startup time. Only by monitoring all

three phases of the current, voltage and

torque can the maintenance professional

separate between a power, motor or load

issue on start up.

Efficiency

Efficiency assessment, pay-back period

and Motor Master+ identify motors

performing under par, and calculates the

pay-back period if replaced by a new motor.

The S KF Dynamic M oto r Analy z er EXP4000 exceeds the performance of

other instrumentation in both accuracy of

efficiency estimation and in ease of use for

field environments.

VFD monitoring (Optional)

Along with any three phase induction

motor and generator, the SKF Dynamic

Motor Analyzer - EXP4000 will monitor

the activities of VFD applications and AC

servo motors using the VFD4000 software

module. These types of drives have always

created problems for maintenance

professionals and for the first time

comprehensive diagnosis of motor

problems are facilitated even under the

most demanding VFD operation.

Continuous monitoring (Optional)

The continuous monitoring software

(CM4000) enables the user to monitor

41 data points real time. This real time and

continuous data gathering capability will

give immediate impact in finding

intermittent problems with motors such as

electrical tripping. This user customized

software enables the operator to collect

real time data on whatever is deemed the

3

Page 4

Technical specifications Benefits

Voltage Unbalance• Power Quality•

Voltage THD• Poorly performing transformers•

Current THD• Connection issues•

Negative Sequence Impedance• Rotor•

Speed calculation• -Cracked bars

% Load & % Efficiency• -Poor welds

Spectrum Voltage• -Broken bars

Spectrum Current• -Eccentricity

Current Level• Load Issues•

Effective Service Factor• -Over load

Power details• -Process

Continuous acquisition• Mechanical•

O-Scope• -Bearing faults

Auto Phasing• -Miss alignment

Auto testing including timer function• -Fan unbalances

One button testing• -Belt frequencies

Bearing check• -Worn Impellars

Startup Transient Voltage• -Gear mesh frequencies

Startup Current• VFD•

Startup Torque•

Torque Spectrum•

Torque Time Waveform•

Efficiency Estimation•

-Power quality

-Shorted IGBT’s

-Feedback loop

-Process information

-Tuning/Setup

Soft Start•

-Tuning/Setup

-Troubleshooting

Energy Assesment•

Specifications

Input Power 110-250 VAC, 50/60 Hz integrated power

supply

Maximum Rated

1,000 V AC, 500 V DC

Measurement/Testing

Voltage

Current Transformers

0-10 A, 0-150 A, 1-1,000 A, 0-3,000 A

(all portable)

Connections – Amphenol

military spec twist type

Power entry module (1)

Portable voltage connection (1)

Portable current connection (1)

EP Port (1)

Vibration sensor connection (1)

Computer specifications 40 GB – 4,200 rpm or better

512 MB - 2GB installed RAM

Battery or AC power operated

Software Platform: Microsoft Windows XP,

Professional, Windows 7 or better

USB 2.0

Weight 15 lbs

Industrial standards NEMA MG-1

The Power of Knowledge Engineering

Seals

Bearings

and units

Lubrication

systems

Drawing on five areas of competence and application-specific expertise amassed over 100 years,

SKF brings innovative solutions to OEMs and production facilities in every major industry worldwide.

These five competence areas include bearings and units, seals, lubrication systems, mechatronics

(combining mechanics and electro nics into intelligent systems), and a wide range of services, from 3-D

Mechatronics Services

computer modelling to advanced condition monitoring and reliability and asset management systems.

A global presence provides SKF customers uniform quality standards and universal product availability.

Baker Instrument Company, an SKF Group Company

4812 McMurry Avenue, Fort Collins, CO 80525

T: 970/282-1200 - 800/752-8272 F: 970/282-1010

www.bakerinst.com

® SKF is a registered trademark of the SKF Group.

® Baker is a registered trademark of the SKF Group.

Microsoft and Windows are either registered trademarks or trademarks of Microsoft Corporation in the United States and/or other

countries.

© SKF Group 2010

The contents of this publication are the copyright of the publisher and may not be reproduced (even extracts) unless permission is

granted. Every care has been taken to ensure the accuracy of the information contained in this publication but no liability can be

accepted for any loss or damage whether direct, indirect or consequential arising out of the use of the information contained herein.

Publication 6769 EN · July 2010

Printed in USA on environmentally friendly paper.

IEEE 519

EN61000-2-2

EN 61000-2-7

VDE 839-2-2

VDE 839 -2-2

skf.com bakerinst.com

Loading...

Loading...