Page 1

FIP-400 FIBER INSPECTION PROBE

NETWORK TESTING—OPTICAL

Highly versatile probe to detect dirty/damaged connectors with unparalleled precision

KEY FEATURES

Easy back-panel connector inspection

Truly rugged and lightweight solution for the fi eld

Image-capture capability for report documentation

Ideal for all types of connectors: APC, UPC, MTP and more

Slim design for easy use in crowded patch panels

Compatible with EXFO test instruments

SPEC SHEET

2011

GLOBAL PORTABLE FIBER OPTIC

TEST EQUIPMENT MARKET

SHARE LEADERSHIP AWARD

Page 2

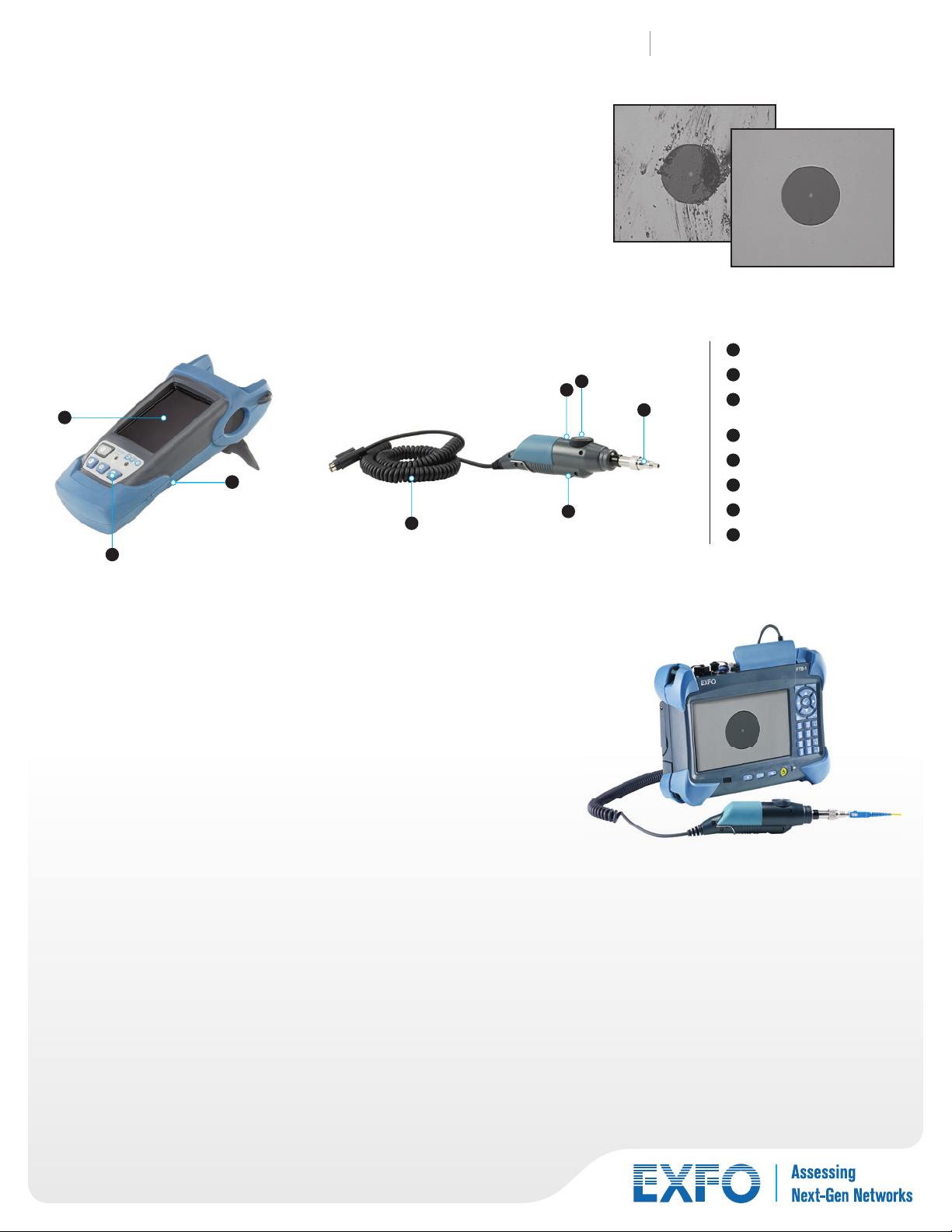

ZOOM IN ON CLARITY

It’s a known fact: optical network problems are often caused by dirty and/or

damaged connectors. Using a fiber inspection probe to ensure that connectors/

adapters are clean and exempt of any defect is where accurate testing starts.

Thanks to EXFO’s FIP-400 Fiber Inspection Probe, checking connectors and

other fiber terminations for polish quality and cleanliness has never been easier.

Benefit from the best optical resolution in the industry and see scratches and dirt

particles as small as 1 µm. Also, use a USB converter to send image captures to a

portable platform or a PC.

FIP-400 Fiber Inspection Probe

Dirty connector

Clean connector

Fiber Probe Viewer

1

72

3

Video Inspection Probe

4

CONNECTORMAX ANALYSIS SOFTWARE

Automatic pass/fail analysis with multiple-platform flexibility

Available on the portable FTB-1, FTB-200 and FTB-500 platforms

›

Save time and money

Lightning-fast results in seconds through simple one-touch operation

›

Complete test reports for future referencing

Stores images and results for record-keeping

›

3.5” TFT LCD screen

1

Rechargeable Li-ion battery

6

5

7

8

2

Adjustable brightness

3

and contrast

Probe connector (EXFO type)

4

Image capture button

5

Focusing device

6

Interchangeable tip

7

Magnification knob (dual model)

8

Delivering fast pass/fail assessment of connector endfaces, EXFO’s

ConnectorMax Analysis Software is designed to save both time and money in

the field. The industry’s first platform-based, automated inspection application,

ConnectorMax eliminates guesswork, instead providing clear-cut connector

endface analysis.

ConnectorMax enables field technicians to analyze defects and scratches and

measure their impact on connector performance. Results are then compared

against pre-programmed IEC/IPC standards or user-defined criteria, leading

to accurate pass/fail verdicts established right on-site.

ConnectorMax therefore helps avoid two time- and money-consuming situations:

undetected connector defects that force technicians to later return to the site,

and unnecessary replacement of connectors whose slight defects are not

enough to get a “fail” verdict.

Automatic pass/fail analysis in any FTB platform

Page 3

FIP-400 Fiber Inspection Probe

THE INDUSTRY’S MOST VERSATILE PROBE

With EXFO’s FIP-400, you have the choice—you can either use it with a PC, with one of our test sets or with our lightweight,

handheld monitor. Choose the way that works best for you.

APPLICATIONS

Patchcord inspection

Compatible with a wide range of connector types

›

Offers great optical performance for patchcord quality assurance

›

Use it as a stand-alone unit to perform fi eld applications or with a USB

›

adapter in a manufacturing environment

Patch panel bulkhead inspection

Get a clear view of both sides of an interconnection

›

Inspect hard-to-reach connecto rs without stressing

›

adjacent fi bers, thanks to the FIP-400’s slim design

Single-fiber connector inspection

Compatible with 1.25 mm and 2.5 mm angled-polished

›

and ultra-polished connectors (APC and UPC)

Multifiber connector inspection

Compatible with male and female ribbon connectors such as

›

MTP multifi ber APC and UPC connectors

Connection inspection through ConnectorMax Analysis

Software

Delivers clear-cut pass/fail verdicts, eliminating guesswork in the fi eld and

›

helping you save time and money

Lightning-fast: results in 4 seconds through simple one-touch operation

›

Full test reports for future referencing

›

Patchcord inspection in a manufacturing environment

Patch panel bulkhead inspection

Page 4

FIP-400 Fiber Inspection Probe

SPECIFICATIONS

Video Inspection Probe

Size (H x W x D) without tip cap

with tip cap

Weight 0.2 kg (0.44 lb)

Resolution Theoretical < 2 µm, detection capability < 1 µm

Field of view

Light source Blue LED

Lighting technique Coaxial

Capture button

Connector EXFO probe port type (8 pin mini-DIN)

Focus control Adjustable on the probe

Optical magnification Adjustable, low and high (dual model only)

Fiber Probe Viewer

Size (H x W x D) 50 mm x 99 mm x 190 mm (1 15/16 in x 3 7/8 in x 7 1/2 in)

Weight

LCD screen 3.5 in TFT active matrix (320 x 240 pixels)

Power Rechargeable Li-ion battery or AC adapter/charger

Battery life 3 hours (continuous use)

Charging time 4 hours

Connector EXFO probe port type (8 pin mini-DIN)

USB Converter USB 1.1 Model USB 2.0 Model

Size (H x W x D)

Connectors EXFO probe port type (8 pin mini-DIN)/USB

Capture button No Yes

b

c

38 mm x 32 mm x 170 mm (1 ½ in x 1 ¼ in x 6 11/16 in)

38 mm x 32 mm x 200 mm (1 ½ in x 1 ¼ in x 7 ¾ in)

625 µm x 464 µm (low magnification)

412 µm x 306 µm (high magnifi cation)

Present on all models

0.3 kg (0.66 lb)

20 mm x 36 mm x 90 mm

13

(

/16 in x 1 7/16 in x 3 9/16 in)

a

19 mm x 36 mm x 95 mm

7

(¾ in x 1

/16 in x 3 ¾ in)

GENERAL SPECIFICATIONS

Temperature operating

storage

Relative humidity 0 % to 95 % non-condensing

–10 oC to 50 oC

–40 oC to 70 oC

ACCESSORIES

Optional Standard

FIPT-BOX Plastic case divided into various compartments for tips Video inspection probe (single or dual magnification)

GP-1001 Rechargeable battery for handheld display FC-SC tip for bulkhead

GP-10-073 Soft carrying case for inspection probe, display and accessories U25M universal patchcord tip for 2.5 mm ferrule

Plastic case divided into various compartments for tips

Page 5

ORDERING INFORMATION

FIP-400-XX-XX

Model

FIP-400-P-SINGLE = Video inspection probe

FIP-400-P-D UAL = Video inspection probe

FIP-400-D = Handheld display

FIP-400-USB1 = USB1 converter with software,

FIP-400-USB2 = USB2 converter with software for PC

FIP-400-USB

Example: FIP-400-P-SINGLE-FIPT-400-LX5-APC

Single magnification

Dual magnification

compatible with FTB-400 and IQS-500

FTB-500 d and IQS-600

FIP-400 Fiber Inspection Probe

Extra Adapter Tips

00 = Without extra FIP-400 tip

FIPT-400-LC-K

FIPT-400-25A-K

FIPT-400-ADAPTER = Adapter tip

FIPT-400-D4 = D4 tip for bulkhead adapter

FIPT-400-E2000 = E-2000 tip for bulkhead adapter

e

,

FIPT-400-E2000-APC = E2000 APC tip for bulkhead adapter

FIPT-400-FC-SC-A6 = FC and SC angled tip for bulkhead (60 degree)

FIPT-400-FC-SC-APC = FC APC angled tip for bulkhead adapter

FIPT-400-LC = LC tip for bulkhead adapter

FIPT-400-LC-A6 = LC angled tip for bulkhead adapter (60 degree)

FIPT-400-LC-APC = LC/APC tip for bulkhead adapter

FIPT-400-LEMO = LEMO tip for bulkhead adapter

FIPT-400-LX5-APC = LX.5/APC tip for bulkhead adapter

FIPT-400-MTP2 = MTP2 tip for bulkhead adapter (extended, reversible)

FIPT-400-MTP2-K = MTP, APC and UPC tips for bulkhead adapter (extended, reversible)

FIPT-400-MTPA-TIP = MTPA replaceable nozzle for MTP2 (extended, reversible)

FIPT-400-MTPA2 = MTP/APC tip for bulkhead adapter (extended, reversible)

FIPT-400-MTP2-TIP = MTP2 replaceable nozzle for MTP2 (extended, reversible)

FIPT-400-MU = MU tip for bulkhead adapter

FIPT-400-MU-L = MU tip for bulkhead adapter (extended)

FIPT-400-ODC-S = ODC Socket (male) tip

FIPT-400-ODC-U = ODC Universal Guide tip

FIPT-400-ODC-2PIN-P = ODC 2 Pin Plug (female) Guide tip

FIPT-400-ODC-4PIN-P = ODC 4 Pin Plug (female) Guide tip

FIPT-400-ODC-2PIN-P-K = ODC 2 Pin Plug (female) Guide & Universal tip

FIPT-400-ODC-4PIN-P-K = ODC 4 Pin Plug (female) Guide & Universal tip

FIPT-400-ODC-2&4PIN-P-K = ODC 2 & 4 Pin Plug (female) Guides & Universal tip

FIPT-400-SC-APC = SC APC tip for bulkhead adapter

FIPT-400-OTAP-APC = OptiTap™ bulkhead adapter

FIPT-400-OTIP-MT-APC = MT/APC type OptiTip™ for male and female connectors

FIPT400-OTIP-MT-APC/M = Male adapter tube for FIPT-400-OTIP-MT-APC tip

FIPT-400-SC-L = SC tip for bulkhead adapter (extended)

FIPT-400-ST = ST tip for bulkhead adapter

FIPT-400-U12M = Universal patchcord tip for 1.25 mm ferrule

FIPT-400-U12MA = Universal patchcord tip for 1.25mm APC ferrule

FIPT-400-U20M2 = Universal patchcord tip for 2.0 mm ferrule (P4, LEMO)

FIPT-400-U25MA = Universal patchcord tip for 2.5 mm APC ferrule

d

Notes

a. Dual model only

b. Works with USB 2.0 adapter, FOT-930 and FTB-200

c. Without battery

d. FTB-500 minimum Toolbox software requirement: 6.28 or higher

e. May require USB1 or USB2 depending on user’s PC

EXFO Corporate Headquarters > 400 Godin Avenue, Quebec City (Quebec) G1M 2K2 CANADA | Tel.: +1 418 683-0211 | Fax: +1 418 683-2170 | info@EXFO.com

Toll-free: +1 800 663-3936 (USA and Canada)

EXFO America 3400 Waterview Parkway, Suite 100 Richardson, TX 75080 USA Tel.: +1 972 761-9271 Fax: +1 972 761-9067

EXFO Asia 100 Beach Road, #22-01/03 Shaw Tower SINGAPORE 189702 Tel.: +65 6333 8241 Fax: +65 6333 8242

EXFO China 36 North, 3

Room 1207, Tower C, Global Trade Center

EXFO Europe Omega Enterprise Park, Electron Way Chandlers Ford, Hampshire S053 4SE ENGLAND Tel.: +44 23 8024 6810 Fax: +44 23 8024 6801

EXFO Finland Elektroniikkatie 2 FI-90590 Oulu, FINLAND Tel.: +358 (0)403 010 300 Fax: +358 (0)8 564 5203

EXFO Service Assurance 270 Billerica Road Chelmsford, MA 01824 USA Tel.: +1 978 367-5600 Fax: +1 978 367-5700

EXFO is certified ISO 9001 and attests to the quality of these products. This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device may not cause

harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation. EXFO has made every effort to ensure that the information contained in

this specification sheet is accurate. However, we accept no responsibility for any errors or omissions, and we reserve the right to modify design, characteristics and products at any time without obligation. Units

of measurement in this document conform to SI standards and practices. In addition, all of EXFO’s manufactured products are compliant with the European Union’s WEEE directive. For more information, please

visit www.EXFO.com/recycle. Contact EXFO for prices and availability or to obtain the phone number of your local EXFO distributor.

For the most recent version of this spec sheet, please go to the EXFO website at www.EXFO.com/specs.

In case of discrepancy, the Web version takes precedence over any printed literature.

rd

Ring Road East, Dongcheng District Beijing 100013 P. R. CHINA Tel.: + 86 10 5825 7755 Fax: +86 10 5825 7722

|

www.EXFO.com

SPFIP400.9AN © 2011 EXFO Inc. All rights reserved.

2008

Printed in Canada 11/12

Loading...

Loading...