Page 1

Total Coordinator for EMC

Noise Laboratory Co., Ltd.

www.noiseken.co.jp

ESS-2000

ELECTROSTATIC

DISCHARGE SIMULATOR

ESS-2002

Page 2

Your products may

have passed the test

standards, but can

they survive in the real

world?

There are many ESD

standards for your

equipment.

Do those standards

really represent

the real world

phenomenon?

Reconsider your

testing program to

assure that your

products are really

ESD-immune.

Consider NoiseKen's

ESS series ESD

simulators to ensure

your products survival

in the real world.

The issue of product-level ESD (electrostatic discharge)

immunity has been attracting continued interest because it is

an important quality factor in equipment reliability, durability

and sometimes safety.

Generally, among the causes of equipment malfunction,

problems caused by ESD are the most diffi cult events against

which to incorporate protective measures, since the causal

relationship generally cannot be found easily. This often

makes ESD test programs extensive, complex, burdensome

and time-consuming. Thanks to the following benefi ts,

NoiseKen's ESS series ESD simulators are your best choice

whatever your requirements are, for design, qualifi cation,

production or diagnostic tests.

●

Meets and far exceeds the requirements in

EN/IEC61000-4-2

●

Up to 30kV output in both contact and air

discharges

●

A light weight discharge gun

●

Easily changeable capacitor and resistor units

●

A wide range of options

●

CE marked

Two models ESS-2000 and ESS-2002 are available.

The above-mentioned capabilities are common to them.

The ESS-2002 is the basic model with a built-in discharge

counter and time controller.

The ESS-2000 is the fully programmable menu-driven

simulator enabling users to carry out tests in a more automated

manner.

Page 3

Electrostatic Discharge Simulator

2

Computer-Controlled ESD Simulator

ESS-2000 & TC-815R

■

FEATURES

●

Fully programmable menu-driven simulator providing

four operation modes: IEC severity, Manual, Sweep, and

Program

●

A new level of ease of use and safety with the user

interface consisting of a 5-inch LCD, ten-key buttons,

rotary knob and others

●

Unique shape for operator's easy access to the control

and displays even when the unit is put on the fl oor level

(ground plane)

●

GP-IB interface

●

A wide variety of the dedicated options

(Gun stand in the photo is an optional accessory.)

■

CONTROLS, INDICATORS AND TERMINALS

Large LCD: Makes testing faster,

easier and more reliable

Start/Stop buttons

Cursor buttons

Infra-red reception

for Remote Controller and

Tem./Humidity Sensor

High Voltage Connector:

Used to connect discharge gun

Controls: Intuitive set-up can be done

Rotary Control

Warning Lamp:

Blinks when the HV circuitry is on.

Function keys

<Front Panel>

Printer terminal

GP-IB interface

AUX terminal

Warning Lamp

terminal

Power switch

AC Inlet

Earth terminal

<Rear Panel>

TC-815R

ESS-2000

Conforming to IEC61000-4-2

Page 4

Electrostatic Discharge Simulator

3

ESS-2000

●

MENU DISPLAY

■

DISPLAY EXAMPLES

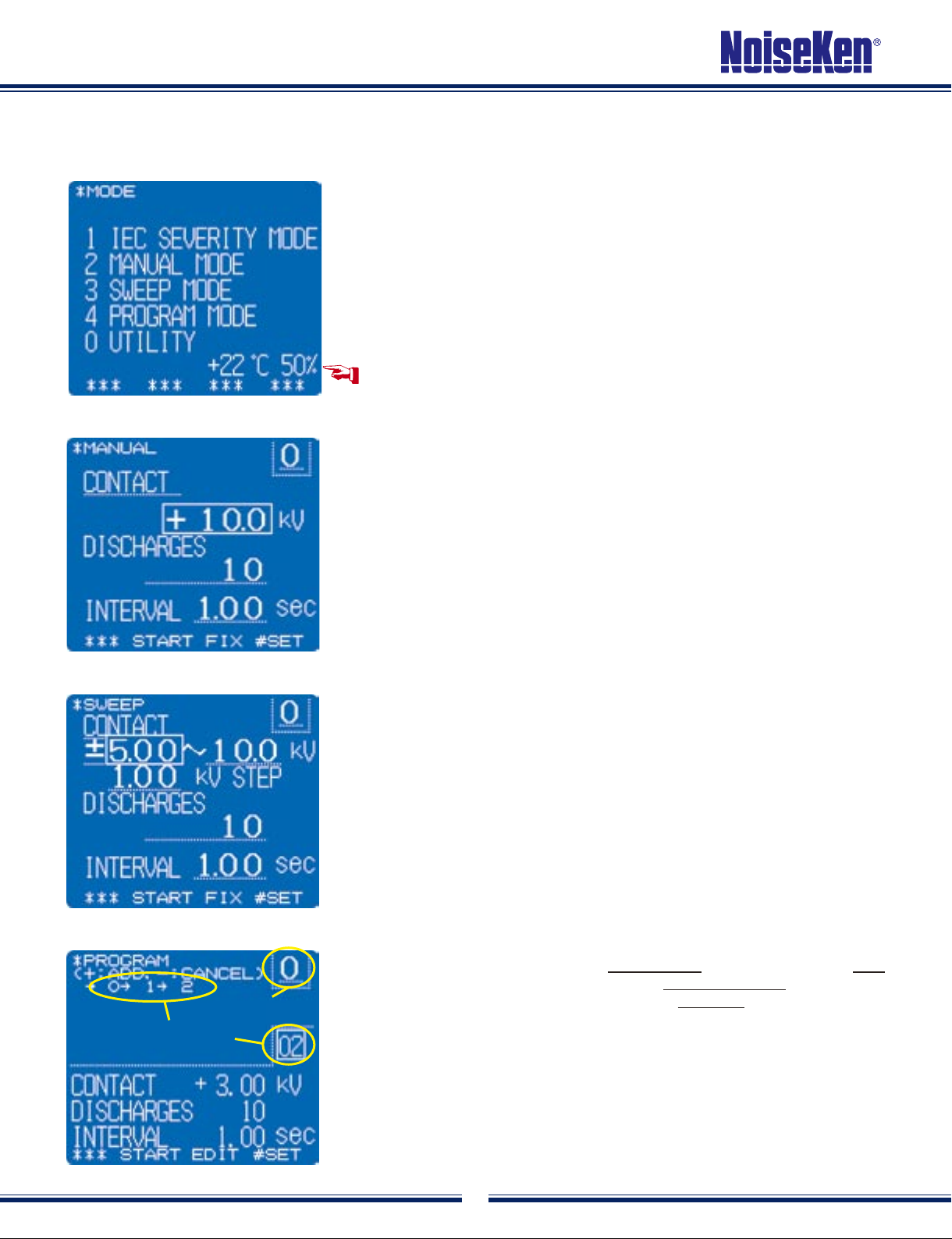

After pressing the main switch, press the mode button. This places the simulator

in the initial menu, which displays the four operational modes and utility mode.

The optional temperature/humidity sensor shows the current measured values.

●

MANUAL MODE

If you desire to operate the unit in the manual mode, press the corresponding tenkey, 2. Items to be set by the operator will appear. Discharge method (contact/air

discharge), discharge voltage, number of discharges and interval can be set. The

item in the cursor can be varied by using the ten-key or rotary knob.

Contact discharges:

For contact discharge testing, after completion of

required settings, press the START button and pull the trigger. The simulator will

then generate the required number of pulses at the required interval. Pulling the

trigger again will pause the unit. Pulling again will restart the unit .

Air discharges:

For air discharge testing, after completion of setting, press the

START key. To carry out air discharges,

keep pulling the trigger and approach the discharge tip to the EUT. Keep pulling

the trigger to maintain the HV relay in the on status.

●

SWEEP MODE

In this mode, the simulator generates discharges in an automatic ramp. Starting,

ending and step voltages can be freely set. In this mode, the number of

discharges set is that in each step. For example, when the simulator is set to

5kV for start voltage, 10kV for end voltage, 1kV for step voltage, in a way of 10

discharges at an interval of 1 second, it produces 10 pulses at 5kV at an interval

of 1 second and proceeds to 6kV pulses, also 10 discharges. These steps

continue until the simulator has completed 10 pulses of 10kV.

Two different ways of pulling the trigger:

When the trigger is pulled and

then released quickly, the simulator operates in a way that it pauses before it

proceeds to next step voltage. For continuous operation, pull the trigger for more

than 2 seconds. The message of "CONTINUOUS" is indicated on the upper right

side of the screen.

●

PROGRAM MODE

Test settings can be stored for 100 program units. Any combination of units

selected from those 100 units can consist of one test sequence, the longest is

up to 30 units. Here we call one test sequence a program. 50 programs can be

stored.

For program unit setting, press EDIT button. Settings of voltage, etc. can be

done in the same way as the other operation modes. The trigger functions in the

same ways as in the sweep mode. When pulled once and released instantly, the

simulator operation pauses before it goes to the next program unit. If pulled for

more than 2 seconds, the simulator operates continuously.

Program unit No.

Program No.

Page 5

Electrostatic Discharge Simulator

4

ESS-2000

■

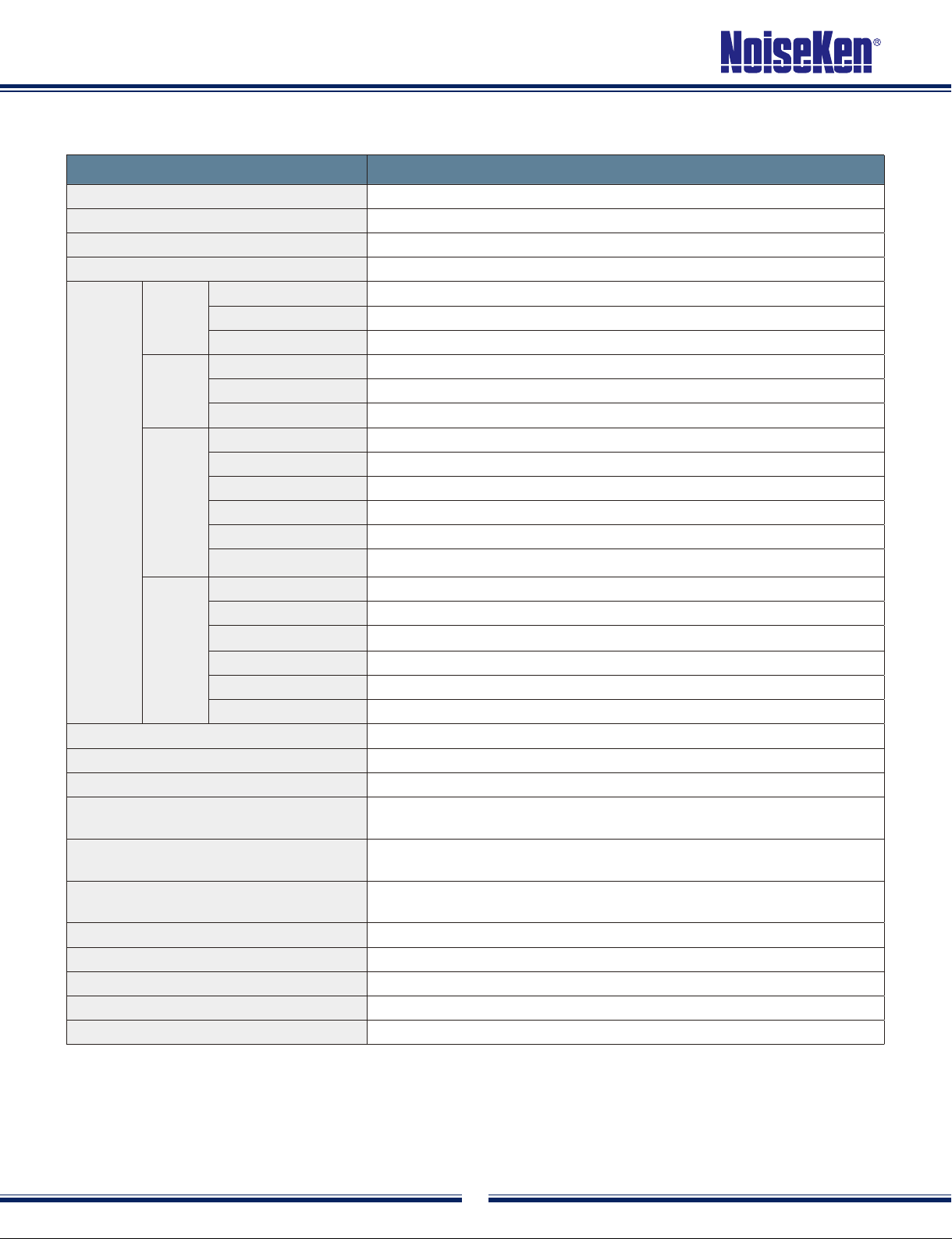

SPECIFICATIONS

Parameters ESS-2000 specifications

Output voltage 0.20 ~ 30.0kV ±5%

Polarity Positive or negative

Charging resistance 10MΩ(53MΩ for combination with TC-815R discharge gun)

Discharge mode Air discharge and contact discharge

Operation

mode

IEC

severity

level

Level setting 1, 2, 3, 4

Discharge interval 0.05 ~ 600.0 s

No. of times of discharge 1 ~ 60000 times

Manual

Discharge interval 0.05 ~ 600.0 s

No. of times of discharge 1 ~ 60000 times

Setting storage function Up to 10 conditions storable

Sweep

Starting voltage ±0.20 ~ 30.0 kV

Ending voltage ±0.20 ~ 30.0 kV

Step voltage 0.00 ~ 30.0 kV

Discharge interval 0.05 ~ 600.0 s

No.of times of discharge 1 ~ 60000 times

Setting storage function Up to 10 conditions storable

Program

Voltage setting ±0.20 ~ 30.0 kV

Discharge interval 0.05 ~ 600.0 s

No. of times of discharge 1 ~ 60000 times

No. of steps 30 steps maximum

No. of programs Up to 50 conditions storable

No. of program units Up to 100 conditions can be set.

Display element LCD with back light

Character display English or Japanese

Setting method Ten-key pad, Rotary control, Function keys

Auxiliary function

Upper limit voltage setting function / Trigger switch select function

Auto stop function / Inversion on the screen function

Memory function

Contents of each setting and last operation display are backed up for more than 3 months with battery

full charged.

External interface functions

GP-IP connecting I/F / Warning light connecting I/F

External trigger input I/F / Elimination probe connecting I/F

Printer interface Conforming to simple CENTRONIX I/F

Contents of print Currently applied voltage/ Contents of various settings / Current temperature and humidity(option)

Power supply 100 ~ 240 VAC 50/60 Hz

Operating temperature and humidity 15 ~ 35°C 25 ~ 75% (No dewing shall occur.)

Dimensions and weight (W)250 × (H)324 × (D)320 mm Approx. 8.0 kg

Page 6

Electrostatic Discharge Simulator

5

ESD Simulator

ESS-2002 & TC-815R

The NoiseKen's ESS-2002 is a further development from an award winning* ESD simulator ESS-2001. A completely new

design has made the product easier to use, more reliable and affordable. The major benefi ts provided by our best selling high

performance ESD simulator ESS-2000 are not sacrifi ced. The most signifi cant addition is RS232 interface. Remote control

Windows software package is optionally available.

* Evaluation Engineering 2001 Readers' Choice Award

(Gun stand in the photo is an optional accessory.)

■

CONTROL PANEL

■

FEATURES

●

Meets and far exceeds the requirements in EN/IEC61000-4-2

●

Up to 30kV output in both contact and air discharges

●

A lightweight discharge gun

●

Easily changeable capacitor and resistor units

●

A wide range of options

●

CE marked

●

Self-explanatory control panel

●

Optional remote control Windows software ESS-2002-PC offers

more comprehensive control than local operation.

■

SPECIFICATIONS

Parameters ESS-2002 specifi cations

Output voltage 0.20~30.0kV

Polarity Positive or negative

Charging resistance 10MΩ (53M ohm for combination with TC-815R Discharge Gun)

Discharge mode Air discharge and Contact discharge

Discharge interval 0.05~9.99s

Counter 1~999 discharges

Trigger Gun and main unit (controller)

External interface Optic RS232

Power supply 100~240VAC 50/60Hz, <50VA

Operating temperature and humidity 15~35°C, 25-75% (No dewing shall occur)

Dimensions (W)340×(H)200×(D)300mm (Projection excluded)

Weight Approx. 7.0kgs.

Conforming to IEC61000-4-2

Selects the parameter to be changed.

Locks the current settings

Increment and decreme nt for the sele cted

parameter

CLEAR button: reset the COUNT or other

setting.

Selects either of the preset IEC specifi ed test

voltage

Selects CONTACT or AIR discharge

POWER key

WARNING LAMP

Blinks during the time HV circuitry is on.

REMOTE control port

Output VOLTAGE indicator

POLARITY select button

Discharge INTERVAL indicator

Discharge COUNT indicator

CONTROLLER TRIGGER button

GUN TRIGGER button

STOP button

HV circuitry turns off

START button

HV circuitry turns on

Page 7

Electrostatic Discharge Simulator

6

ESD Simulator Options

■

OPTIONAL ACCESSORIES for ESS-2000

●

Tem./Humidity Sensor

Model: 07-00016A

●

Automatic ESD Eliminator

Model: 01-00013A

●

Wireless Remote Controller

Model: 08-00006B

●

Gun Holder

Model: 03-00040A

●

Warning Lamp

Model: 11-00008A

A gun holder can be screwed to the

left-side panel of ESS-2000.

■

OPTIONAL ACCESSORIES for ESS-2002

●

Fiber optic RS232 interface Model 07-00017A

●

Remote control Windows software ESS-2002-PC Model 14-00030A

Complete, comprehensive ready-made Windows software package to control the ESS-2002 simulator remotely from your PC.

All test parameters in ESD test can be controlled including discharge mode of either air or contact.

Manual mode offers operationality as if the operator directly controls the ESS-2002 simulator but with automatic preset voltage ramp.

IEC severity mode offers preprogrammed test setting as per IEC 61000-4-2 standard for instant use.

Program mode offers sequencing of user edited parameter settings.

Manual mode IEC severity mode Program mode

Dimensions: (W)85 × (H)60 × (D)150 mm

Page 8

Electrostatic Discharge Simulator

7

Discharge Gun

TC-815R

A lightweight and versatile discharge gun standard-supplied with the

both ESS series models.

(Gun stand in the photo is an optional accessory.)

■

FEATURES

●

200ps Fast Rise Time Adapter optionally available.

●

Easily changeable Capacitor and Resistor units: A discharge resistor

is placed in the capacitor unit and the resulting CR network can be

fi tted into the gun. This method ensures any desired combination of

a capacitor and resistor.

Capacitor unit Spring Discharge resistor Electrode

For the waveform integrity, the standard 150pF capacitor unit has a fi xed

combination with 330 ohm resistor only.

■

SPECIFICATIONS

Parameters TC-815R specifi cations

Output voltage 0.20 ~ 30.0kV

Discharge waveform

parameters

Compliant with EN/IEC61000-4-2

Standard energy storage

capacitor

150pF ±10%

Standard discharge resistor 330Ω±10%

Charging resistor

43MΩ

(53MΩfor combination with ESS main unit)

Cable length 2 m

Dimensions

(W)75 × (H)220 × (D)210 mm

(Discharge tip excluded)

Discharge mode Air discharge and contact discharge

Weight Approx. 1.4 kg

For automotive electronics ESD test to ISO 10605, a dedicated

discharge gun package including the relevant two CR networks is

also available.

■

STANDARD ACCESSORIES

●

150pF Capacitor unit

(with a 330 ohm resistor built-in)

●

Discharge tip

Model: 12-00001A (Conical)

Model: 12-00002A (Round)

●

Instruction manual

■

OPTIONAL ACCESSORIES

*)

Standard accessories for TC-815R

●

Discharge tip

Model: 12-00001A (Conical)*

Model: 12-00002A (Round)*

●

Discharge resistor

(100,150,200,250,300,330,400,

500,1k,1.5k,2k,5k,10kΩ)

Model: H-100,150,200,250,300,330,

400,500,1K,1.5K,2K,5K,10K

●

Extension cable

Model:05-00047A

2m length of TC-815R gun cable

can be extended to 5m.

●

Capacitor unit

(100,150,200,250,300pF)

(330, 400, 500pF)

Model: 06-00013A ~ 00017A

06-00032A/00018A/00019A

Conforming to IEC61000-4-2

Page 9

Electrostatic Discharge Simulator

8

TC-815R

Parameters Specifi cations

Current limiting resistor 15Ω

■

OTHER OPTIONAL ACCESSORY

●

Loading Resistor (Current Detector)

Model: 06-00001A

■

OPTIONAL ACCESSORIES

●

Free Arm Gun Stand

Model: 03-00022B

Dimensions: W180 × H760 × D70 mm

Weight: Approx. 5kg

●

Gun Stand

Model: PS-806

Dimensions: H300 mm

Diameter: 160mm

Weight: Approx. 1.6kg

●

Fast Rise Time Adapter

Model: 12-00003A

Enables a fast rise time.

Approx. 200ps (150ps~300ps)

●

Impulsive Magnetic Field Adapter Model: 03-00030B

●

Impulsive Electric Field Adapter Model: 03-00031B

Simulations of the electric and magnetic fi elds produced by an electrostatic discharge can be separately performed by the

Impulsive Magnetic Field Adaptor and Impulsive Electric Field Adaptor. These adaptors are designed to connect to the

Discharge Gun TC-815R.

03-00030B 03-00031B

Parameters Specifi cations

Discharge resistance 1.5kΩ

Electrode for generating

electric fi eld

80 mm in diameter

Maximum voltage applied 30kV

Parameters Specifi cations

Applied voltage 15kV max

Output impedance 50Ω

Conversion ratio

1V/1A (50Ω termination)

2V/1A (Open)

Output connector N-R type

Dimensions 70 x 39mm

The Loading Resistor (Model: 06-00001A) is used to

check, verify and calibrate the output waveforms of an

electrostatic simulator for conducting an electrostatic

discharge immunity test conforming to IEC61000-4-2.

Back drawing Elevation

8-φ3.2PCφ60

Coaxial connector (NR)

240Ωx5 51Ωx25

70

φ

(38)

Page 10

Electrostatic Discharge Simulator

9

ESD Test Environment

ESS-801/801GL

A complete package to easily build up the ESD test (laboratory test)

set-up called for in the IEC standard.

Test set-up example with ESS-801

■

CONSTITUTION OF ESS-801 (TABLE TYPE)

Description Model Dimensions Quantity

Testing table 03-00039A (W)1600 × (H)800 × (D)800 mm 1

Vertical coupling plane 03-00005A (W)500 × (H)500 × (t)1.5 mm 1

Ground plane 03-00007A (W)1800 × (H)1000 × (t)1.5 mm 3

Insulating sheet 03-00004A (W)1450 × (H)650 × (t)0.5 mm 1

Cable with discharge resistors 05-00054B 470kΩ× 2 2

Horizontal coupling plane 03-00020A (W)1600 × (H)800 × (t)1.5 mm 1

ESS-801GL

(Vertical coupling plane & Cable with resistors)

■

CONSTITUTION OF ESS-801GL (FLOOR TYPE)

Description Model Dimensions Quantity

Insulation pallet 03-00024A (W)1200 × (H)1200 × (t)100 mm 1

Vertical coupling plane base 03-00034A (W)540 × (H)1540 × (D)500 mm 1

Ground plane 03-00007A (W)1800 × (H)1000 × (t)1.5 mm 3

Cable with discharge resistors 05-00054B 470kΩ× 2 1

Conforming to IEC61000-4-2

Page 11

Electrostatic Discharge Simulator

10

IEC61000-4-2 Standard

■

TEST SET-UP

●

Ground reference plane: A copper or aluminum sheet of

0.25 mm minimum thickness: other materials may be used

but they shall have at least 0.65 mm minimum thickness.

The minimum size is 1 m2. The exact size depends on the

EUT. It shall project beyond the EUT or coupling plane

by at least 0.5 m on all sides. It shall be connected to the

protective earth.

●

Coupling planes: These planes shall be constructed from

the same material and thickness as that of the ground

reference plane and shall be connected to the ground

reference plane via a cable with a 470kΩ resistor located at

each end.

Typical position for

direct application

●

Test set-up for test performed in laboratories:

A ground reference plane shall be provided on the fl oor of

the laboratory.

The EUT shall be conne cted to the grounding system

and arranged and connected according to its installation

specifi cations. A distance of 1 m minimum shall be provided

between the EUT and any metallic structure.

The discharge return cable of the test generator shall

be connected to the ground referen ce plane, and this

connection shall be of low impedance.

In cases where the length of the cable exceeds the length

necessary to apply the discharges to the selected points,

the excess length shall be placed non-inductively off the

ground reference plane and shall not come closer than 0.2

m to other conductive parts in the test set-up.

■

TEST SET-UP EXAMPLE

●

Table top equipment

0.1m

Typical position for indirect

discharge to HCP

Isolation tranformer

ESD simulator

Typical position for

indirect discharge to VCP

Vertical Coupling Plane

(0.5m x 0.5m)

470kΩ resistor

Wooden table

Ground reference plane

Insulation sheet

Horizontal coupling plane

Test set-up for table-top equipment, laboratory tests

●

Floor-standing equipment

EUT

0.1m

0.8m

EUT

Typical position for

indirect discharge to VCP

Isolation tranformer

ESD simulator

Vertical Coupling Plane

(0.5m x 0.5m)

470kΩ resistor Insulation pallet

(h=0.1m)

Typical position for

direct application

Ground reference plane

ESD simulator

0.1m

0.1m

A wooden table of 0.8m height shall be set on the

ground plane. 1.6m x 0.8 m horizontal and 0.5m x

0.5 m vertical coupling planes shall be put on the

table. An insulating support of 0.5 mm thickness

shall be inserted between the EUT/cables and the

horizontal coupling plane.

An insulation support of 0.1m thickness shall be

used. 0.5m x 0.5m vertical coupling plane shall be

used for indirect application of discharges.

Page 12

Electrostatic Discharge Simulator

IEC61000-4-2 Standard

■

EXECUTION OF THE TEST

●

Direct application of discharges to the EUT

The test voltage shall be increased from the minimum to the

selected test level. The test shall be performed with single

discharges. On selected points at least ten discharges in the

most sensitive polarity shall be applied.

It may be necessary to carry out some investigatory or

preliminary testing to select the points at which discharges

are to be applied. This pretest may be done at a repetition

rate of 20 discharges per second or more.

The ESD gun shall be held perpendicular to the surface to

which the discharge is applied.

In the case of contact discharge, the tip of the discharge

electrode shall touch the EUT before the discharge switch is

operated.

In the case of air discharges, the round tip of the discharge

electrode shall be approached as fast as possible to touch

the EUT. Wh ile the di scha rge electr ode approaching,

the discharge switch shall be maintained closed until a

discharge occurs.

●

Indirect application of the discharge:

Discharges to objects placed or installed near the EUT shall

be simulated by applying the discharges to a coupling plane

in the contact discharge mode.

●

Horizontal coupling plane: At least 10 single discharges in

the most sensitive polarity shall be applied to the edge of the

plane opposite the center point of the EUT and 0.1m from

the front of the EUT. The ESD gun shall be kept horizontal

and perpendicular to the front edge line of the plane.

●

Vertical coupling plane: At least 10 single discharges in

the most sensitive polarity shall be applied to the center of

one vertical edge of the coupling plane. The coupling plane

shall be placed parallel to, and positioned at a distance of 0.1

m from, the EUT. Discharges shall be applied with sufficient

different positions such that the four faces of the EUT are

completely illuminated.

■

ESD GENERATOR SCHEMATIC AND REQUIRED PERFORMANCE

●

Circuit Diagram

NOISE LABORATORY CO., LTD.

1-4-4, Chiyoda, Sagamihara City,

Kanagawa Pref., 229-0037 Japan

Tel: +81(0)42-712-2051 Fax: +81(0)42-712-2050

http://www.noiseken.co.jp/

E-mail: sales@noiseken.com

Rch Rd

V

Cs

Capacitance Cs: 150pF

Discharge resistance Rd: 330Ω

Charging resistance Rch: 50-100MΩ

Output voltage V: Contact 8kV max.

Air 15kV max.

Holding time: at least 5 s

Discharge, mode of operation: Single discharge

(time between successive discharges at least 1 s)

●

ESD typical output waveform

I

Ipeak

100%

90%

Iat30ns

Iat60ns

10%

30ns

60ns

tr=0.7 to 1ns

I

1

I

2

t

●

Severity Level

Level

Contact Discharge

Air discharge

1 2kV 2kV

2 4kV 4kV

3 6kV 8kV

4 8kV 15kV

X

1)

Special Special

1)

X is an open level.

●

Designs and specifications are subject to change without notice.

●

Waveform parameters

Level

VoltagekVFirst peak current

(±10%)Ip

Rise timetrCurrent at 30ns

(±30%) I

1

Current at 60ns

(±30%) I

2

1 2 7.5A 0.7~1ns 4A 2A

2 4 15A 0.7~1ns 8A 4A

3 6 22.5A 0.7~1ns 12A 6A

4 8 30A 0.7~1ns 16A 8A

0407-07K

N

Loading...

Loading...