Page 1

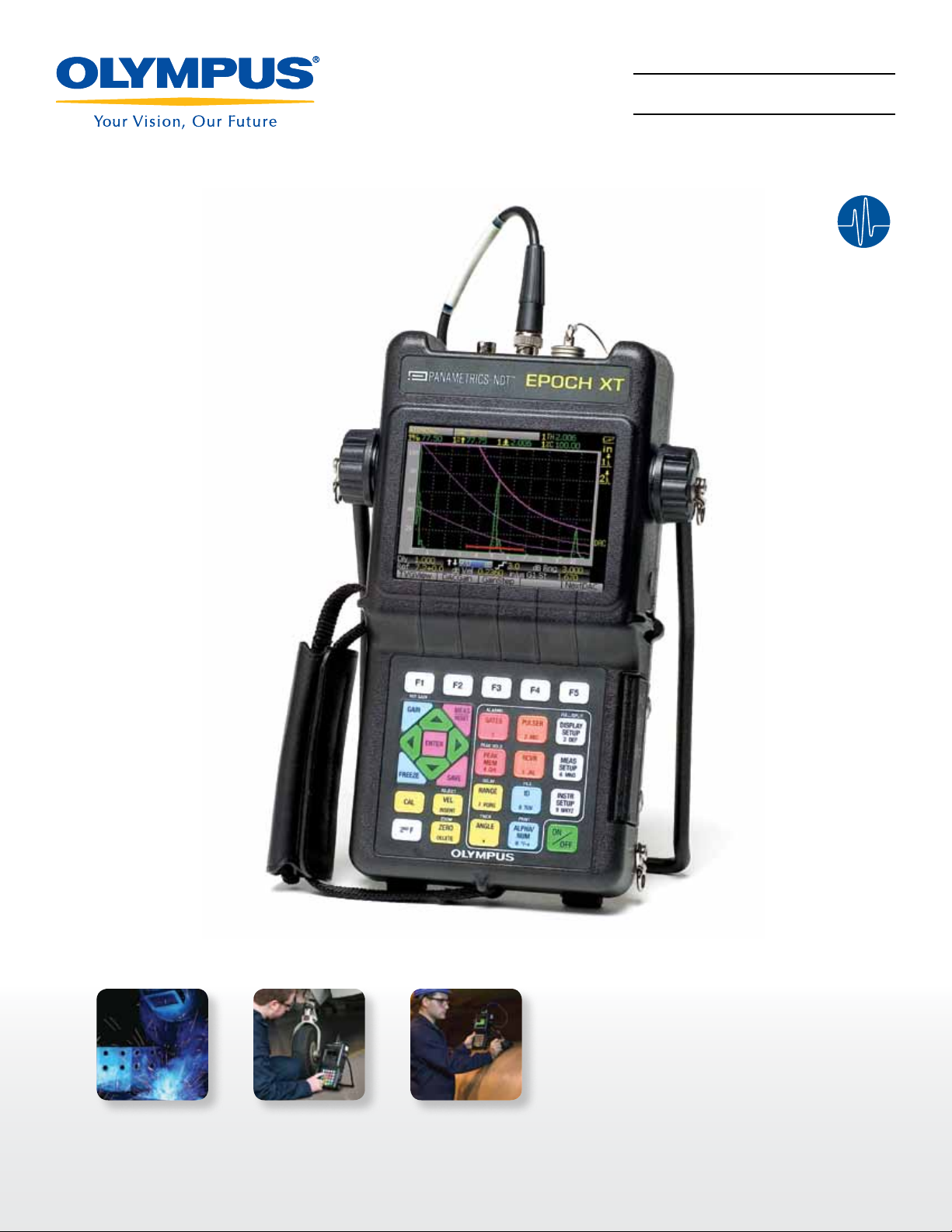

ULTRASONIC FLAW DETECTOR

EPOCH XT

• ProvenUltrasonicPerformance

• BroadApplicationUse

• DirectAccessInterface

• EN12668-1Compliant

920-105H-EN

Page 2

EPOCH XT

Advanced Ultrasonic Flaw Detector

Key Features

■ EN12668-1 compliant

■ Tested for explosive atmosphere, vibration

and shock

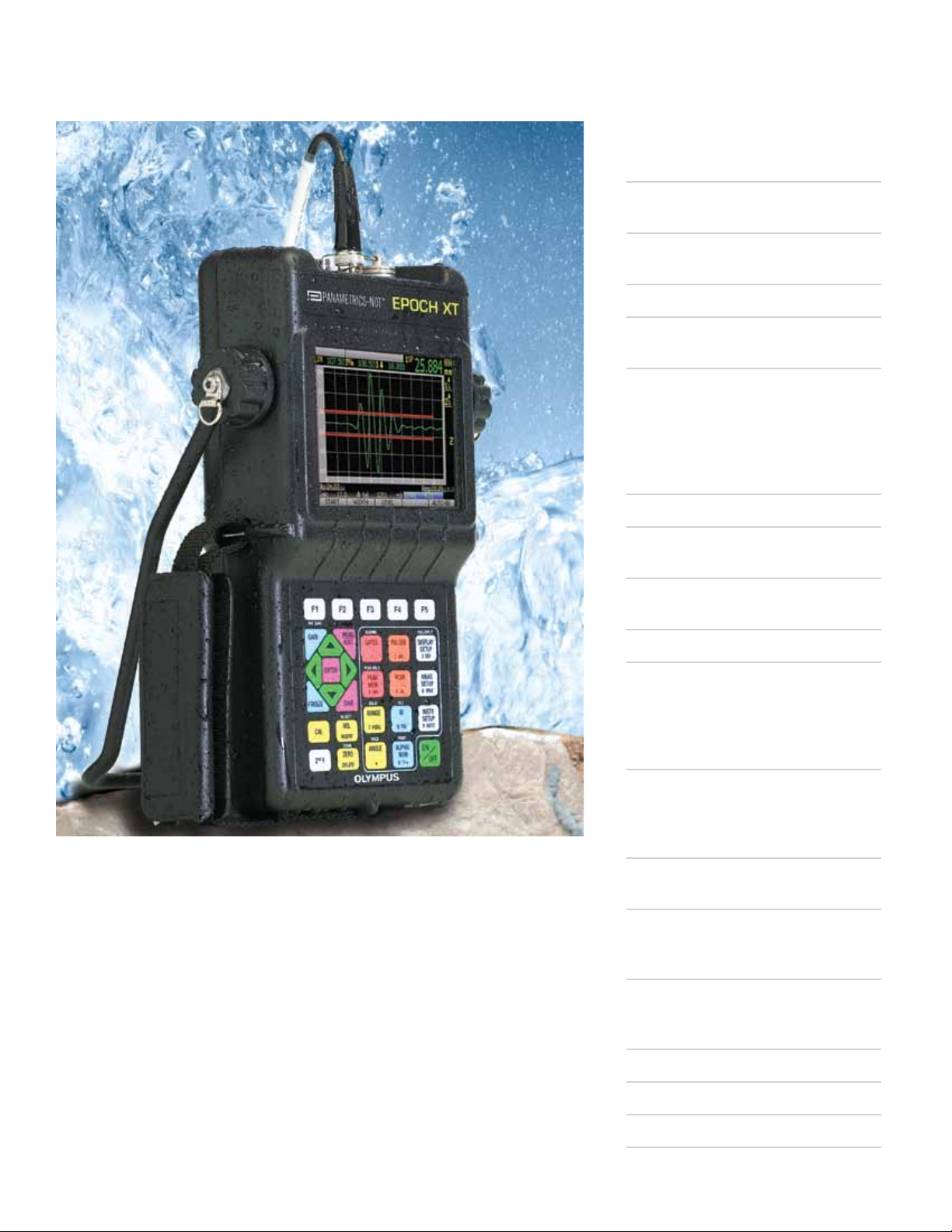

■ Designed to meet IP67 requirements to

withstand harsh environments

■ Direct access hand-held design

■ Split screen view of A-scan and param-

eters for fast calibration verification

■ Dynamic DAC/TVG Standard

– Dynamic DAC curves

– Custom warning

– Meets ASME requirements

– TVG table allows fully customized TVG

setups

■ Onboard DGS/AVG feature

The EPOCH XT Ultrasonic Flaw Detector is designed for great inspection

flexibility and for use in extreme environments. It combines a multitude

of enhanced flaw detection and measurement features, a bright multicolor

LCD, versatile battery options, powerful data management, and numerous

software features in a compact unit with a sealed case designed to meet IP67

requirements.

The EPOCH XT allows the operator access to a wide variety of standard pulser

and receiver features that make the unit flexible to a large number of flaw

detector applications. With up to 475V pulse energy combined with Olympus

NDT’s PerfectSquare

™

tunable square wave pulser, the EPOCH XT is capable of

high penetration applications beyond the standard flaw detector. And with an

arsenal of optional software features, the instrument can be enhanced to meet

the needs of nearly any conventional ultrasonic inspector.

■ Multiple battery options – can be used

with lithium-ion, NiMH, or C-cells

■ Host USB port for direct printing and storage

to USB drives

■ Client USB Port for PC communication

■ Perfect Square

electronically controlled on both the

leading and trailing edges to maximize

transducer performance and near-surface

resolution.

■ Digital receiver filtering

– 7 standard filters for excellent signal to

noise ratio

– 30 optional filters for expanded applications

■ Wide pulse voltage range from 50V to

475V

■ PRF adjustable from 10 Hz to 1 kHz in

10 Hz increments. All measurements

are taken “single shot.”

■ Powerful alphanumeric data logger:

Corrosion thickness gage file types can be

set up onboard.

■ Simple incremental and calibration files

■ Multicolor LCD

™

Technology: Pulse is

■ Lightweight – 2.1 kg (4.7 lb)

2

www.olympus-ims.com

Page 3

Loaded With Practical Measurement Features

The EPOCH XT incorporates many standard measurement features including a tunable square wave pulser, selectable narrow-band and

broadband digital filters, gain range from 0 dB to 110 dB, peak memory and peak hold, adjustable PRF, 0.01 mm (0.001 in.) measurement resolution, and two gates with programmable alarms. In addition, the unit offers many standard and optional application-specific

software features: Dynamic DAC/TVG (Distance Amplitude Correction/ Time Varied Gain), On-board DGS/AVG, AWS D1.1 and D1.5,

manual or encoded B-scan, Advanced Filter, and GageView Pro

• Standard tunable square wave pulser

with PerfectSquare™ Technology allows

the operator to adjust pulse width to

maximize transducer performance.

• Standard digital receiver filtering:

broadband, several narrow-band

settings, and a high-pass setting

• Five measurement displays that are

fully customizable to meet inspection

needs. Select any Gate 1 or Gate 2

measurement for each display box.

• Amplitude measurement resolution of

0.25% full-screen height

• Amplitude measurement from 0% to

110% full-screen height

• Gate measurement modes: Peak, Edge

and First Peak Mode for thickness

measurement applications

• Measurement rate adjustable from

10 Hz to 1kHz in 10 Hz increments on

live screen

• Peak Mem. and Peak Hold functions

in all rectified modes. Peak Hold also

functions in RF mode.

®

.

• Grid Display modes

– Standard 1 to 10

– Sound path

– Leg mode for angle beam inspection

– Selectable 100% or 110% vertical

display

• Leg indicator and measurement mode

indicator for each gate

• Alarm indicator for each gate

Direct-access Keypad

• Logical color-coded key organization

• Direct access to important instrument

setup parameters

• Direct entry of alphanumeric characters

• Five customizable function keys allow

the operator to quickly select preset

values.

• Available in English, Japanese, or

Chinese, or International symbols

3

Page 4

Powerful Software Capabilities

EPOCH XT ASME III DAC

Standard Software

Dynamic DAC/TVG

Calculates signal amplitude as a percentage or dB level compared

to a DAC curve or a reference echo amplitude fixed with Time

Varied Gain. DAC versions include ASME, ASME 3, JIS, and Custom. Contains several key features including: dynamically adjustable DAC curves, switchable DAC and TVG views, (20% to 80%)

DAC/TVG, a flexible TVG table, and custom DAC warning curves.

CSC (Curved Surface Correction)

Corrects sound path information when using an angle beam transducer to circumferentially inspect a curved surface.

DGS/AVG

Flaw sizing technique that permits echo signals to be evaluated

using a DGS/AVG diagram associated with a particular type of

probe and material. The DGS/AVG diagram shows the relationship

among echo height, flaw size, and distance from the transducer.

EPOCH XT B-scan and Floating Gate

Software Options

B-Scan

Single value (thickness) based B-scan that allows fully encoded

or manual scans for corrosion monitoring. Simultaneous viewing

of an A-scan and B-scan is available. Operates in all test modes

including: TVG, Echo-to-Echo, and Floating Gate. Includes Floating Gate option.

Floating Gate

Gate option, which allows the operator to “float” Gate 1 and/or

Gate 2 at a selected height compared to a gated echo (–1 dB to

–14 dB). This feature is intended to allow more consistent, precise

readings, especially in Edge Detection mode. This option is included in the B-scan option.

AWS D1.1 & D1.5

Provides a dynamic reflector “indication rating” for various AWS

weld inspection applications. This allows for more efficient inspection by eliminating manual calculations.

EPOCH XT DGS/AVG

The AVG/DGS Binder, contains

a DGS diagram and specification

sheets for each angle beam, dual

element, and protective face transducers from the Olympus NDT

Atlas Transducers series. These

diagrams are printed on splash

and tear proof paper and housed in a six-ring binder.

4

www.olympus-ims.com

www.olympus-ims.com

Page 5

Template Storage

Interface Gate

Template Storage

Allows on-screen comparison of a live waveform with a saved

reference waveform. Saved templates can be dynamically toggled

on and off with a single key press for fast waveform comparison.

Gain adjustment feature allows each saved template a unique

base gain for inspections requiring varying sensitivity levels. Excellent for spotweld analysis and other applications.

Advanced Filters

The Advanced Filters option takes advantage of the EPOCH XT’s

unique digital receiver design and allows unprecedented filtering

flexibility. This option allows the EPOCH XT operator to choose

from 37 different filter settings. Specific performance improvements

from this option include:

•Performanceimprovement with low- frequency probes com-

monly used for inspection of composites and plastics.

•ImprovedinitialpulserecoverywithnewDCcoupledsetups.

•

Optimized broadband response from mid- to high-frequency

transducers.

•Useofverylowfrequencytransducers(50kHzto100kHz

range) for specialized applications.

Interface Gate

This optional third measurement gate enables real-time tracking

of a variable interface echo in order to maintain consistent digital

measurements.

Backwall Echo Attenuator (BEA)

Attenuates the backwall echo of an inspected part using the

screen region defined by Gate 2. BEA is used to avoid screen saturation of the backwall echo to allow detailed flaw echo examination in the part region before the backwall while still monitoring

the backwall echo for drop-out or signal reduction.

API 5UE

Allows defect sizing according to API Recommended Practice

5UE. Uses the Amplitude Distance Differential Technique (ADDT)

to measure the size of potential defects during the proveup

process of OCTG pipe. The measurement process is simple and

repeatable since all ADDT variables are captured from a Peak

Memory envelope.

API 5UE

5

Page 6

Extensive Documentation and Data Management Capabilities

GageView Pro

The optional GageView Pro interface

program helps manage and format stored

inspection data. Data can be printed or easily copied and pasted into word processing

files and spreadsheets for further reporting

needs. The GageView Pro interface program

also allows the creation of a customized

database of identifier (ID) strings that can be

uploaded to the EPOCH XT. New features

include remote display of live EPOCH

XT screens on a PC, Live-Screen Capture

mode, database backup/restore, and multiview windows. The interface program is

fully compatible with the EPOCH LT, XT,

600 and 1000 Series.

• Export thickness or amplitude data

saved on the EPOCH to Excel, Word, or

similar programs

• Create, format, and manage test

databases

• View the live instrument display on a

PC with Remote Display

• Import real-time screen snapshots

• Import and export setups between the

EPOCH and a PC

• Create a custom DGS probe library

®

Data Logger and

Documentation

The EPOCH XT’s sophisticated data

logger is designed for ease of use while

providing a wide range of features

for many flaw detection and thickness gaging applications. Employing

Panametrics™ corrosion thickness gage

technologies, the EPOCH XT is ready

to meet your inspection and thickness

measurement survey requirements.

File types to meet your needs:

• Incremental

• Sequential

• 2-D, 2-D EPRI

• 2-D custom point

• 3-D

• Boiler

• CAL

The EPOCH XT offers onboard report generation. Operators can set up

custom report headers and print directly from the instrument using the

USB host port.

Export inspection data to MS Excel spreadsheet. Data is organized into worksheets

for waveforms, measurement data and instrument data.

Remote display allows the operator to view the live EPOCH XT display on a PC. Operator

can also control all instrument functions with the on-screen keypad or the PC keyboard.

6

GageView Pro Main File View

DGS Probe Library Management Screen

www.olympus-ims.com

Page 7

Built For Tough Environments

Physical Features

• Hand strap can be mounted for left or

right-hand operation

• Easy-to-use rubberized Pipe Stand that

can be folded in or removed

• Durable instrument-mounted D-rings

for chest harness use

• Sealed battery compartment—no tools

required for battery replacement

• Sealed I/O door for AC adaptor and

USB connections

Multiple Battery Options

The EPOCH XT offers three battery options

that provide long-lasting battery operating

time.

• Internal, rechargeable: NiMH, lithium-

ion, or alkaline C-cells

• Optional external smart battery charger

Environmental Ratings

IP rating

Explosive atmosphere

Shock tested EC 60068-2-27, 60 g, 6µs H.S., 3 axes, 18 total

Vibration tested

Operating temperature

Battery storage temperature –10 °C to 60 °C (–14 °F to 140 °F)

Designed to meet IP67 environmental seal requirements. The product design

was confirmed to meet the IP rating by means of Olympus NDT’s internal design

verification test process.

Approved for Explosive Atmosphere per MIL-STD-810F,

Procedure 1, NFPA 70E, Section 500, Class 1, Div. 2, Group D

Sine Vibration per IEC 60068-2-6, 50 Hz to 150 Hz at 0.03 in. DA or 2 g,

20 sweep cycles

Lithium-ion: –20 °C to 50 °C (–4 °F to 122 °F)

Nickel Metal Hydride: 0 °C to 50 °C (32 °F to 122 °F)

Alkaline: –10 °C to 50 °C (14 °F to 122 °F)

Recharge temperature: 0 °C to 40 °C (32 °F to 122 °F)

Optional Protective Case

The EPOCH XT is available with an optional rubber protective case that is intended

to protect the unit in harsh environments.

Operators have the choice of selecting the

rubber protective case in black or white

rubber. The white rubber case, along with

the optional white background keypad

(shown left) are designed to minimize

heat absorption in very hot climates with

intense sunlight.

Hardware Input/Output

Port Option

• Optional 16 Pin HW I/O port

– Alarm outputs

– Trigger input/output

– Encoder interface

• 16 Pin I/O cable available

VGA Output

The EPOCH XT comes standard with a

VGA output port which allows the display

to be viewed on most external monitors,

projectors and other display devices. The

instrument connects to VGA-compatible

devices with the EPOCH XT VGA cable.

Analog Output Option

The EPOCH XT features an optional

hardware port for analog output. This

option provides continuous output of depth

or amplitude information to an external

device, such as a strip chart recorder or

a PC outfitted with an Analog/Digital

converter card. The information is output

as a voltage, either on a 0 V to 1 V or 0 V to

10 V scale.

Dual USB Ports

• USB client port for high-speed data

transfer to computer

• USB host port to interface directly to

printers with USB ports and back up

critical inspection data to USB drives

USB connections and AC input adaptors

are sealed behind a thumb-screw accessible door.

7

Page 8

EPOCH XT Specifications*

General

Overall dimensions

(W x H x D)

Weight 2.1 kg (4.7 lb) with lithium-ion battery

Keypad English, International, Japanese, Chinese

Languages

Transducer connections BNC or Number 1 LEMO

Data storage 10,000 IDs onboard

Battery type Choice of lithium-ion, nickel metal hydride, and alkaline C-cells

Battery life Lithium-ion: 9 h to 10 h; NiMH: 5 h; C-cells: 1 h to 2 h

Power requirements AC Mains: 100 VAC to 120 VAC, 200 VAC to 240 VAC, 50 Hz to 60 Hz

Display type

Display dimensions

(W x H, Diag.)

Pulser

Pulser Tunable Square Wave

PRF User selectable or auto from 10Hz to 1kHz

Energy settings 50 V to 475 V in 25 V increments

Pulse width Adjustable from 40ns to 5,000ns (0.1 MHz) with PerfectSquare™ Technology

Damping 50 , 63 , 150 , 400

Receiver

Gain 0 to 110 dB

Maximum input signal 20 V p-p

Receiver input impedance 400 ± 5%

Receiver bandwidth 0.2 MHz to 26.5 MHz at –3 dB

Digital filter settings

Rectification Full-wave, Positive Half-wave, Negative Half-wave, RF

System linearity

Reject 0 to 80% FSH with Visual Warning

Amplitude measurement 0 to 110% full screen height with 0.25% resolution

Measurement rate Equivalent to PRF in all modes

Calibration

Automated calibration

Test modes Pulse Echo, Dual, or Through Transmission

Units Millimeters, inches, or microseconds

Range 1.86 mm to 13,409 mm (0.073 in. to 527 in.) @ longitudinal velocity in steel

Velocity 635 m/s to 15240 m/s (0.0250 in./µs to 0.6000 in./µs)

Zero offset 0 µs to 4950 µs

Display delay –59 mm to 12700 mm (–2.323 in. to 500 in.)

Refracted angle 0.1° to 85° in 0.1° increments

Measurements

Measurement gates 2 fully independent gates for amplitude and TOF measurements

Gates (1, 2)

Gate start Variable over entire displayed range

Gate width Variable from Gate Start to end of displayed range

Gate height Variable from 2 to 95% full screen height

Alarms Positive and Negative Threshold, Minimum Depth (Gate 1 and Gate 2)

Measurement display locations 5 locations available (manual or auto selection)

Echo-to-Echo Standard Gate 2-Gate 1

Other measurements

DAC/TVG Standard

DAC points Up to 50 points, 110 dB dynamic range

Special DAC modes 20-80% DAC, Custom DAC (up to 6 curves)

Curved surface correction Standard OD or Bar correction for Angle Beam measurements

277 mm x 150 mm x 51 mm (at hand), 71 mm (at display);

10.9 in. x 5.9 in. x 2 in. (at hand), 2.8 in. (at display)

English, Spanish, French, German, Italian, Japanese, Chinese, Russian, Korean,

Norwegian, Swedish

Color Liquid Crystal Display: With 60 Hz update, user-selectable color schemes

and brightness, and split-screen and full-screen modes.

320 pixels x 240 pixels color

101 mm (4 in.) x 75 mm (3 in.), 125 mm (5 in.)

Seven digital filter sets standard (0.2-10 MHz, 2.0-21.5 MHz, 8.0-26.5 MHz,

0.5-4 MHz, 0.2-1.2 MHz, 1.5-8.5 MHz, 5-15 MHz), additional filters optional

Horizontal: ± 0.2% FSW

Vertical: 0.25% FSH, amplifier accuracy ± 1dB

Velocity, Zero Offset

Straight Beam (First Backwall or Echo-to-Echo)

Angle Beam (Soundpath or Depth)

Thickness, Soundpath, Projection, Depth, Amplitude,

Time-Of-Flight, Min./Max. Depth, Min./Max. Amplitude

Overshoot (dB) value for DGS/AVG, ERS (equivalent reflector size) for DGS/

AVG, AWS D1.1/D1.5 rating (D), Reject Value

Instrument Inputs/Outputs

USB Client Port: For communication with

GageView Pro

USB Host Port: Allows direct printing to any PCL5

compatible laser or inkjet printer as well as data

storage on USB drives

LEMO® Hardware I/O (optional): Alarm outputs,

trigger in/out, encoder interface

VGA Output Port: Connects to standard VGA

monitor or projector

Analog Output Port (optional): Selectable voltage

output of depth or amplitude data

Data Storage

Up to 10,000 IDs with waveforms, measurements,

and setup parameters

Standard Package

EPOCH XT: Digital ultrasonic flaw detector

EP-MCA: AC adaptor

CASE-10009 (U8764102): Transport case

910-264: Operating manual

EPXT-BAT-L (U8760021): Lithium-ion or

EPXT-BAT-N (U8760038): Nickel metal hydride

battery

Optional Accessories

EPXT-EC (U8767043): External smart battery

charger

EP4/CH (U8140055): Chest harness

EPXT-RPC (U8764043): Rubber protective case

(black)

EPXT-RPC-W (U8764044): Rubber protective case

(white)

EPXT-DP (U8780047): Clear display protectors

(10)

EPXT-C-16HW-6 (U8840086): 16-pin hardware

I/O cable with diagram

EPXT-C-VGA-6 (U8779019): VGA Cable

Software Options

EPXT-AWS (U8140068): AWS D1.1/D1.5

EPXT-BSCAN (U8140025): B-scan software

EPXT-BSCAN-KIT-XX: B-scan kit including soft-

ware, encoder, and encoder cable

EPXT-FG (U8140073): Floating Gate

EPXT-FILTERS (U8140099): Advanced Filters

EPXT-BEA (U8140142): Backwall Echo Attenua-

tion software

EPXT-TEMPLATE (U8140143): Template Storage

software

EPXT-API5UE (U8140144): API RP-5UE software

EPXT-IG (U8140145): Interface Gate software

GAGEVIEWPRO-KIT-USB (U8140078):

GageView Pro

www.olympus-ims.com

info@olympusNDT.com

48 Woerd Avenue, Waltham, MA 02453, USA, Tel.: (1) 781-419-3900

12569 Gulf Freeway, Houston, TX 77034, USA, Tel.: (1) 281-922-9300

505, boul. du Parc-Technologique, Québec (Québec) G1P 4S9, Tel.: (1) 418-872-1155

1109 78 Ave, Edmonton (Alberta) T6P 1L8

Epoch_XT_EN_8p_201202• Printed in the USA • Copyright © 2012 by Olympus NDT.

*All specications are subject to change without notice.

All brands are trademarks or registered trademarks of their respective owners and third party entities.

isISO9001and14001certied.

Loading...

Loading...