Page 1

ULTRASONIC FLAW DETECTOR

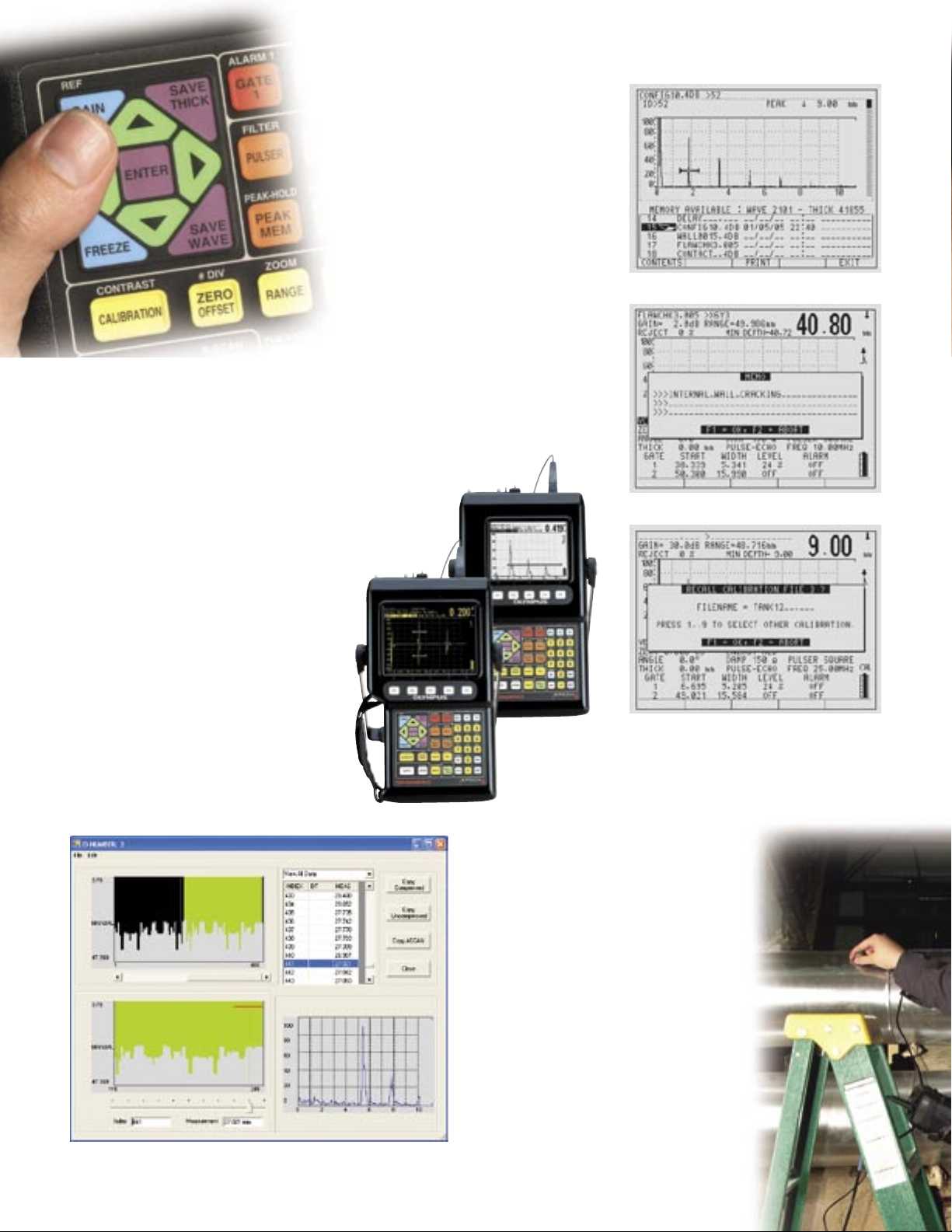

The Panametrics-NDT™ EPOCH 4 is

an advanced digital ultrasonic flaw

detector that combines powerful, fully

featured measurement capabilities, a

comprehensive internal datalogger, and

a wide range of software options to solve

many demanding inspection problems.

Signal processing features include a 25

MHz bandwidth to permit testing of

thinner materials, a selectable square

wave pulser to optimize penetration

on thick or attenuating materials, and

narrowband filters to improve signal-tonoise ratio in high gain applications. The

EPOCH 4 incorporates rugged packaging

and a conveniently organized directaccess keypad, and offers the choice

of high-resolution Liquid Crystal or

Electroluminescent displays.

A large capacity datalogger allows field

storage of test data that can then be

transferred to the PC via its versatile

GageView PRO Interface Program.

EASY AND FAST OPERATION

The EPOCH 4 with its robust packaging

design, large display, and functional

color-coded keypad provides easy and

fast operation in difficult inspection

environments.

Important keys such as Gain, Freeze,

Save Thickness, Save Waveform, Enter,

and Slewing Keys are grouped together

for easy thumb control and one-handed

operation of all critical parameter

settings.

The five Function keys allow quick access

to preset parameter values that can be

customized by the operator.

EPOCH 4

Flaw Detectors

FEATURES

• Customizable narrowband filtering

• Selectable, tunable square wave or negative

spike excitation pulser

• Light, ergonomically designed

(5.7 lbs / 2.6 Kg)

• Fast minimum 60 Hz display update rate

• High-power NiMH battery

• Large, bright, high-resolution ELD or LCD

with full/split screen views

• Automated transducer calibration

• 400” (10,000 mm) full screen range at

longitudinal velocity of steel

• Superior minimum range capability (0.038”

or 1 mm full scale at longitudinal velocity of

steel)

• Display Freeze holds waveform and

soundpath data

• Soundpath data viewable in inches,

millimeters, or microseconds

• Peak Hold and Peak Memory

• RF display mode

• Alarms, threshold positive/negative, or

minimum depth

• Dual Gate with Echo-to-Echo measurements

• Security Key enables remote upgrade of

software options

TUNABLE SQUARE WAVE

PULSER – STANDARD FEATURE

The EPOCH 4 set a new industry standard

in 2001 when it was introduced with both a

Tunable Square Wave Pulser and a Negative

Spike Pulser. These high voltage pulsers offer the

operator extensive application versatility and

ease of use. The Tunable Square Wave Pulser

along with Narrowband filtering produce classleading material penetration and signal-to-noise

ratios in difficult materials such as cast metals,

large forgings, composites, and plastics.

Both pulsers are standard equipment on the

EPOCH 4PLUS, EPOCH 4, and EPOCH 4B,

and optional on the EPOCH LT.

920-005B

Page 2

INTERNATIONAL VERSATILITY

The EPOCH 4’s keypad is available in

English or International Symbols. Display

languages are keypad selectable in

French, German, Spanish, Italian,

Russian, Japanese, English, and a

custom user defined language.

AN AWESOME DISPLAY OF

CHOICES

LCD or ELD: The EPOCH 4’s Liquid

Crystal Display provides cutting edge

brightness and optimum viewing of the

waveform in conditions from bright,

direct sunlight to complete darkness.

The Electroluminescent Display offers a

fast update rate, four brightness levels,

and a very high degree of sharpness.

SOPHISTICATED ALPHANUMERIC

INTERNAL DATALOGGER

The EPOCH 4’s sophisticated datalogger

is designed for ease of use while providing a wide range of features for virtually

all flaw detection and thickness gaging

applications. All saved data can be organized in alphanumeric file names and

identifier (ID) codes that can be scrolled

and reviewed on-screen. A Memo feature

permits entry of additional inspection

data and the Edit feature can be used to

add, delete, or clear file names and ID

numbers.

Save and recall inspection data sets in

any combination of 500 waveforms (or

instrument setups) or 10,000 thickness

readings. The expandable memory option

saves any combination of up to 2,000

waveforms or 40,000 thickness readings.

Datalogger File Menu

Memo Feature

ELD

GageView PRO Interface Program Viewing a B-Scan Data File

LCD

Quick Recall Feature

EXTENSIVE DOCUMENTATION

AND TRANSFER CAPABILITIES

The optional Windows-based GageViewTM

Pro Interface program adds practical

collection, editing, and review capabilities to

the EPOCH 4. GageView Pro is a powerful

tool that collects, manages, and formats

stored inspection data.

GageView Pro database tracking allows

setup of inspection plans with pre-loaded

calibrations, IDs, and memos. Data can be

printed or easily copied and pasted into word

processing and spreadsheet documents for

further reporting needs. GageView Pro is

compatible with the EPOCH 4, EPOCH LT,

EPOCH 4B and EPOCH 4PLUS flaw

detectors.

Page 3

DAC (Distance Amplitude Correction) TVG (Time Varied Gain)

STANDARD SOFTWARE

DAC (Distance Amplitude Correction)

Calculates signal amplitude as a

percentage or dB difference of the DAC

curve level (ASME, ASME-3, or JIS). Same

size reflectors peak along the curve

independent of their location. An alarm

can be activated when a gated signal

breaks the curve.

TVG (Time Varied Gain)

TVG with 40 dB dynamic range corrects

for distance/amplitude variations due to

material attenuation and beam spreading.

Reference echoes are brought to a

standard full screen level of 80%.

SOFTWARE OPTIONS

CSC (Curved Surface Correction)

Corrects sound path information when

using an angle beam transducer to

inspect a curved surface circumferentially.

Spotweld Overlay

The Weld Overlay feature allows onscreen comparison of the live waveform

with a stored reference waveform. The

Stamping feature permits stored weld

data to be stamped “good”, “undersized”,

“stick”, or two other operator defined

conditions. (PN: EP4/SPOTWELD)

Floating Gate

Automatically varies Gate Level by -6 dB

or -12 dB of the gated backwall echo.

Results in consistency of edge-depth

measurements by making readings at the

same relative amplitude. (PN: EP4/FG)

Interface Gate

Powerful tool for immersion applications

where the water path distance between

the transducer and front surface of the

part is continually changing. Maintains

the Interface Echo (between the water

and the front surface of the part) on the

left side of the EPOCH 4’s display.

(PN: EP4/IG)

AWS D1.1 and D1.5

Provides a dynamic reflector “indication

rating” for various AWS weld inspection

applications. This allows for a more

efficient inspection by eliminating

manual calculations. (PN: EP4/AWS)

Wave Analysis

Used to select particular points along

an RF waveform and then obtain a

timing/thickness measurement and also

a dB difference between the two points.

Applications include measuring the scale/

oxide buildup on the inner diameter of

boiler tubes. (PN: EP4/WAVE)

DGS/AVG – Now set-up on board!

Flaw sizing technique that permits echo

signals to be evaluated using DGS/AVG

diagram associated with a particular type

of probe and material. The DGS/AVG

diagram shows the relationship among

echo height, flaw size, and distance from

the transducer. (PN: EP4/DGS/AVG)

Expanded Memory

Increases datalogger capacity from 500

waveforms/10,000 thickness readings

to 2,000 waveforms/40,000 thickness

readings. (PN: EP4/ MEM)

High PRF (1,000 Hz)

Increases the PRF rate of the EPOCH 4

and is useful for higher scanning speed

inspections. The high PRF software fixes

the PRF at 1 KHz. (PN: EP4/HPRF)

Low PRF (30 Hz)

Reduces or eliminates “wrap-around”

noise by setting the PRF to a fixed 30

Hz. This feature is often necessary when

inspecting materials that are highly

attenuating or have long sound paths.

(PN: EP4/LPRF)

Auto-Freeze

Provides the ability to automatically

freeze the A-Scan waveform when a gate

alarm has been triggered.

(PN: EP4/AUTOFREEZE)

B-scan

Generates an easy to understand crosssectional profile view of an inspected

part. Excellent for corrosion mapping

of pipes, boilers, and storage tanks.

This view can be used to visually verify

acquired thickness measurements and

also highlight areas with critically thin

thickness values. Contact Olympus NDT

for a detailed brochure on the B-Scan

option. (PN: EP4/BSCAN)

GageView Pro

A powerful software that collects,

manages, and formats stored inspection

data. (PN: GAGEVIEWPRO-KIT-SERIAL)

API 5UE: Allows defect sizing according to API Recommended Practice 5UE.

Uses the Amplitude Distance Differential

Technique (ADDT) to measure the size

of potential defects during the prove-up

process of OCTG pipe. The measurement

process is simple and repeatable since all

ADDT variables are captured from a Peak

Memory envelope. (PN: EP4/API5UE)

Advanced DAC/TVG: Calculates

signal amplitude as a percentage or

dB level compared to a DAC curve

or a reference echo amplitude fixed

with Time Varied Gain. DAC versions

include ASME, ASME 3, JIS, and

Custom. Contains several key features

including: dynamically adjustable DAC

curves, switchable DAC & TVG

views, 80%-20% DAC/TVG, a flexible

TVG table, and custom DAC

warning curves. (PN: EP4/ADT)

Page 4

EPOCH 4 SPECIFICATIONS*

MEASUREMENTS

Sensitivity: 110 dB Max and Reference

level sensitivity feature with 6 dB or

0.1 dB selectable resolution

Auto Transducer Calibration: Automated

calibration of transducer Zero Offset

and/or Velocity.

Reject: 0% to 80% of full scale in

1% increments

Units: English, Metric, or Microseconds

Material Velocity: 0.025 to 0.6000 in/

μsec (635 to 15240 m/S)

Range: Standard 0.038 inch to 400 inch

(1 mm to 10,000 mm)

Refracted Angle: Fixed settings of 0°, 30°,

45°, 60°, 70°, or variable from 10° to 85°

in 0.1° resolution

Peak Memory: Simultaneous display of

live A-scan at 60 Hz update rate and

peak envelope of A-scan display.

Peak Hold: Freezes Peak Memory echo

envelope for waveform comparison with

live A-scan.

Pulser Type, User Selectable: Tunable

square wave, negative spike excitation.

Pulse Energy: Low (100 V), Medium

(200 V), High (300 V), and Max (400 V)

Damping: 50, 63, 150, and 400 ohms

Rectification: Full Wave, Half Wave

Positive or Negative, and unrectified RF

settings

Analog Bandwidth: 0.05 MHz to 25 MHz

at –3 dB

Filters: Broadband, Narrowband, or

Custom Selectable Low and High Pass

Filters

Test Modes: Pulse Echo, Dual, or Through

Transmission

Alarms: Selectable threshold positive/

negative or minimum depth modes

DISPLAY

Display: 320 pixels (W) X 240 pixels (H),

ELD or LCD screens

Display Update Rate: Minimum 60 Hz

POWER SUPPLY

Power Requirements: AC Mains: 100-120

VAC, 200-240 VAC, 50-60 Hz

Battery: Internal Rechargeable NiMH

battery pack rated at 12 V at 4000 mAH

Battery Operating Time: ELD, 7 hours

nominal. LCD, 10 hours nominal.

2 hour typical Recharge Time.

OUTPUTS

High Speed Parallel Port: Allows rapid

communication to external devices and

B-scan encoder communication.

Analog Output: Keypad selectable

voltage output of depth or amplitude data

VGA Output Port: Connects to standard

VGA monitor or A/V projector.

RS-232 Communications Port: Allows

interfacing with PCs and printers. Max

Baud Rate 38.4.

GENERAL

Keypad: English or International symbols

Languages: Available in keypad selectable

languages: English, French, German,

Spanish, Italian, Russian, Japanese, and a

user-defined custom language.

Transducer Cable Connectors:

Fits BNC or Number 1 Lemo

Dimensions:

(ELD) 11.15” H x 6.55” W x 2.6” T

(LCD) 11.15” H x 6.55” W x 2.4” T

Weight: 5.7 lbs. (2.6 Kg) with battery

Operating Temperature:

ELD/ -20°C to 50°C (-4°F to 122°F)

LCD/ 0°C to 50°C (32°F to 122°F)

Storage Temperature: -40°C to 70°C

(-40°F to 158°F) depending on battery

and display

®

PC Requirements: PC running minimum

Microsoft® Windows® XP®, Microsoft

Windows 2000

®

Warranty: One year warranty, battery not

included. Optional second year warranty

available.

STANDARD INCLUSIONS

EPOCH 4 Advanced MicroprocessorBased Ultrasonic Flaw Detector. Includes:

• EP4/MCA Mini Charger Adapter

• EP4/BAT Nickel Metal Hydride

Rechargeable Battery

• EP4/CAL-NIST NIST Calibration

Certificate

• EP4/MAN Instruction Manual

• EP4/TC Transport Case

• EP4/PS Stainless Steel Pipe Stand

• EP4/HS Hand Strap

OPTIONAL ACCESSORIES

EP4/SC Shipping Hard Shell Case

EP4/BAT-AA Alkaline Battery Pack

EP4/EC External Stand-Alone Charger

EP4/RPC Rubber Protective Carrying Case

EP4/PR Printer: 110-120 V

EP4/PRE Printer: 230-240 V

EP4/DP-E Display Protectors (ELD)

EP4/DP-L Display Protectors (LCD)

EP4/C-15VGA-6 VGA Cable

EP4/C-25PRL-6 Parallel Port Cable

EP4/C-9FAT-6 Serial Port Cable

GAGEVIEWPRO-KIT-SERIAL Interface

program including serial cable

Printed 9/2005

© 2005 Olympus NDT, All Rights Reserved.

*All specifications are subject to change without notice.

Panametrics, Panametrics-NDT and the Panametrics-NDT logo are trademarks of Panametrics Inc.

Other company or product names mentioned in this document may be trademarks or registered

trademarks of their respective companies

Olympus NDT, Inc.

48 Woerd Ave, Waltham, MA U.S.A.

TEL 781-419-3900 • 800 225-8330 in North America

e-mail: info@panametrics-ndt.com

WWW.PANAMETRICS-NDT.COM

Loading...

Loading...