Assa abloy SW100 User Manual

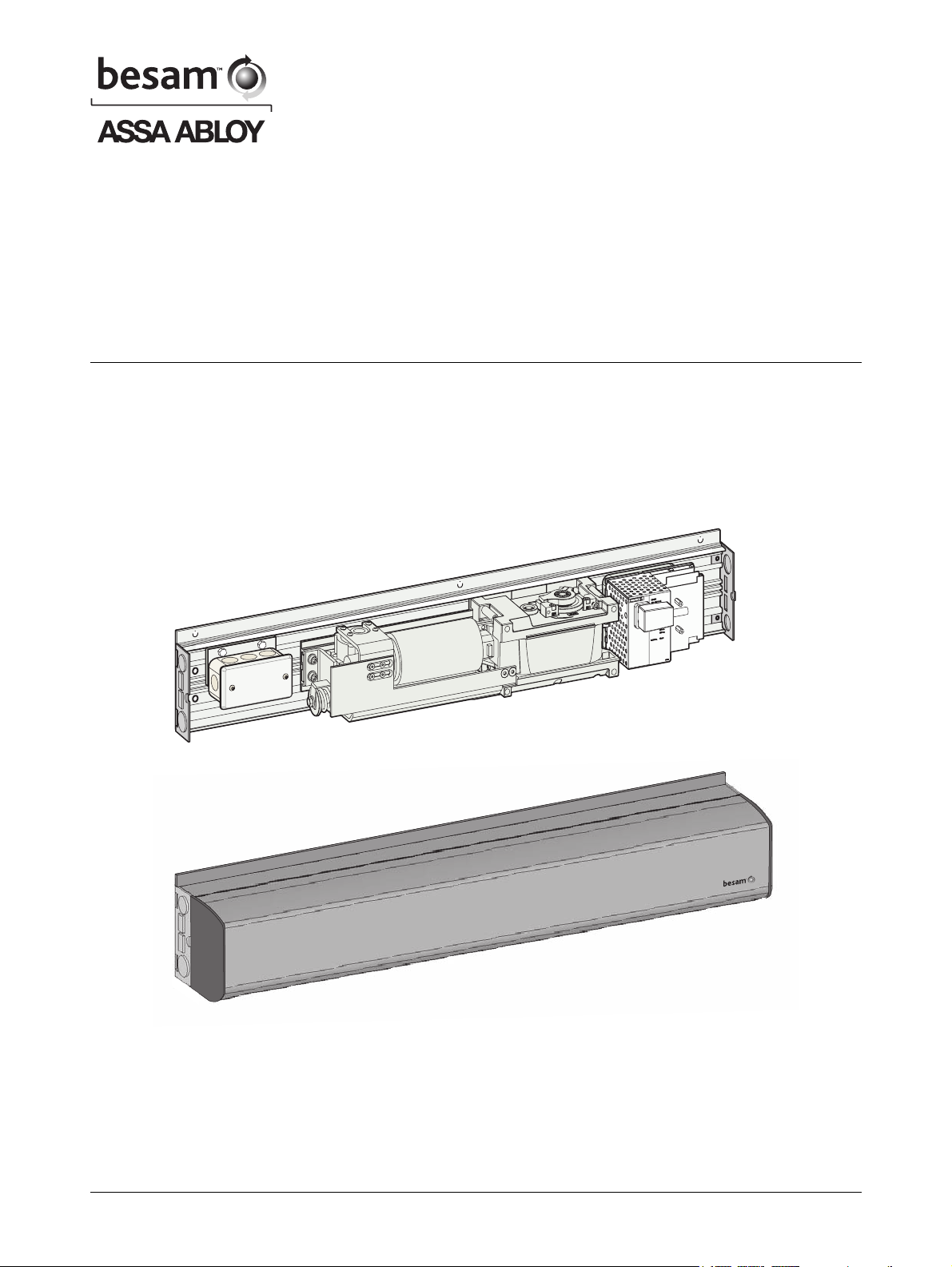

Besam Low Energy Swing Door Operator

SW100

Installation and Service Manual

1003680-US-4.0 – Issue 2007-10-11

ASSA ABLOY, the global leader in door opening solutions

© All rights in and to this material are the sole property of ASSA ABLOY Entrance Systems AB. Copying, scanning, alterations or modifications are expressly forbidden without the prior written consent of the applicable company within ASSA

ABLOY Entrance Systems AB. Rights reserved for changes without prior notice.

2 Issue 2007-10-11 1003680-US-4.0

Table of content

1 Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 Important information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

4 Technical specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

5 How the SW100 works. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

6 Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

7 Part identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

8 Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

9 Pre-installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

10 Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

11 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

12 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

13 Changing group of parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

14 Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

15 ANSI / BHMA A156.19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

16 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

17 Planned maintenance checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

1003680-US-4.0 Issue 2007-10-11 3

Revision

1Revision

The following pages have been revised:

Page Revision

5 2.3 Glazing materials added

7 Cover depth changed from 5 3/16” to 5 1/8”

4 Issue 2007-10-11 1003680-US-4.0

Important information

2 Important information

2.1 Important notice

To avoid bodily injury, material damage and malfunction of the product, the instructions contained in this manual must be strictly observed during installation, adjustment, repairs and service, etc. Only Besam-trained technicians should be allowed to

carry out these operations.

2.2 Radio and television reception

This equipment generates and uses radio frequency energy and if not installed and

used properly, that is, in strict accordance with the manufacturer's instructions, it may

cause interference to radio and television reception. It has been designed to comply

with the emission limits in accordance with EN 61000-6-3 and EN 61000-6-2 (US

market FCC 47 CFR Part 15B), which are designed to provide reasonable protection

against such interference in a residential installation. However, there is no guarantee

that interference will not occur in a particular installation. If this equipment does

cause interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference

by one or more of the following measures:

• Re-orient the receiving antenna.

• Relocate the receiver with respect to the equipment.

• Move the receiver away from the equipment.

• Plug the receiver into a different outlet so that equipment and receiver are on different branch circuits.

• Check that protective earth (PE) is connected.

If necessary, the user should consult the dealer or an experienced radio/television

technician for additional suggestions.

2.3 Glazing materials

The glazing material for swing doors shall comply with ANSI Z97.1

1003680-US-4.0 Issue 2007-10-11 5

Introduction

3 Introduction

This manual contains the necessary details and instructions for the installation, maintenance and service of the low energy swing door operator SW100, a universal electro-mechanical operator suitable for all low energy applications of swing doors.

The SW100 can be mounted on either side of the door header for pull or push action,

and is suitable for single or double doors fitted with butt hinges, offset or center

pivots.

The SW100 ensures all-around safety. The operator can be combined with a full

range of sensor products providing swing door safety, but meets also the requirements for a low energy operator without any sensors.

6 Issue 2007-10-11 1003680-US-4.0

Technical specification

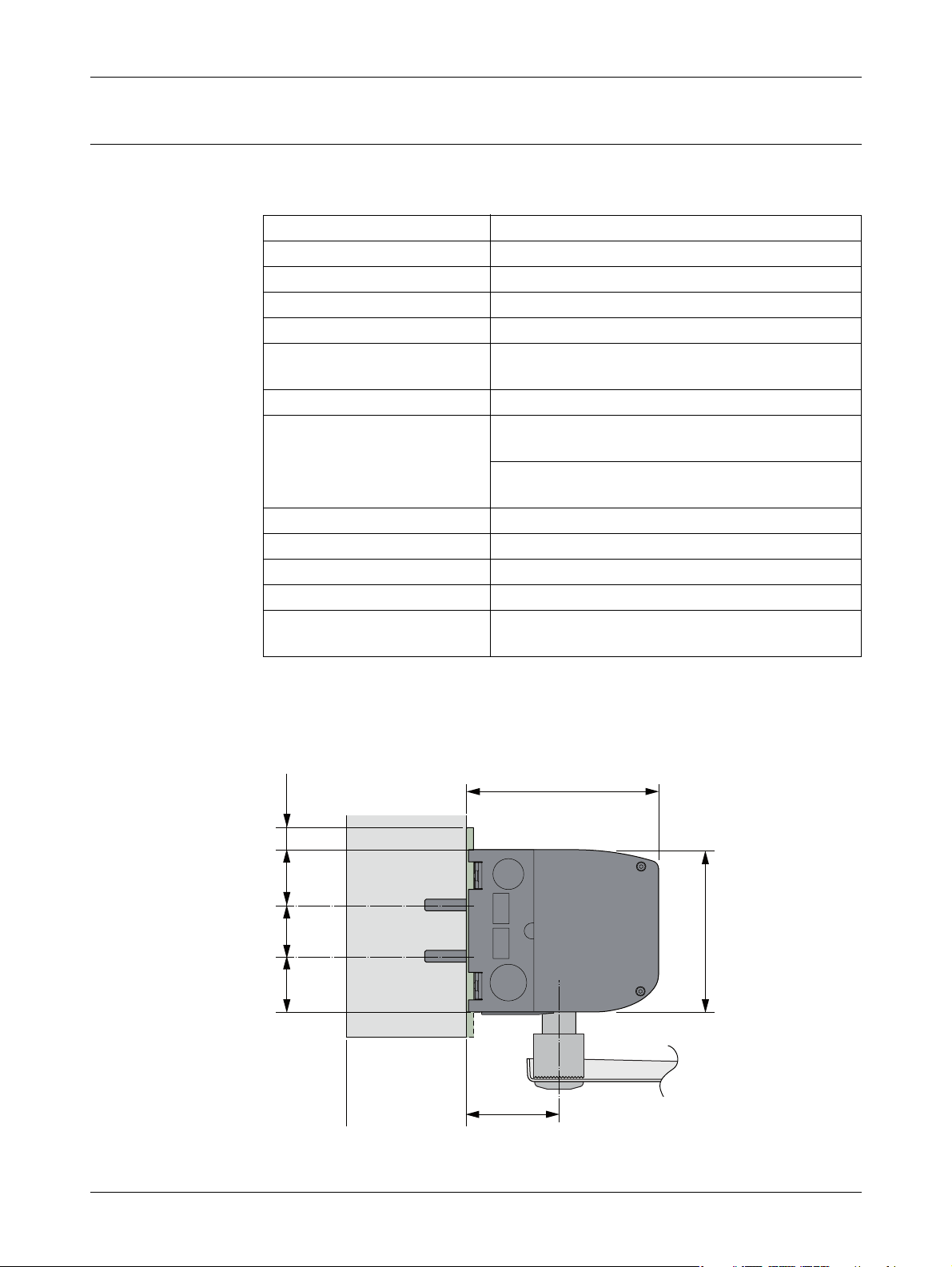

4 Technical specification

Power supply: 120 V AC +10/-15%, 50/60 Hz

Power consumption: max. 75 W

Auxiliary voltage: 24 V DC, max. 400 mA

Internal control fuse: 2 x T 6.3 AH 250 V

Door width: 36-48” (914-1219 mm)

Electro-mechanical locking

device

Door weight: 100-200 lb. (45-90 kg)

Door opening angle: Push arm: 80° - 110°, with reveal 0 - 11

Opening time (0° - 80°): variable between 3 - 6 seconds

Closing time (90° - 10°): variable between 3 - 6 seconds

Hold open time: 1.5-30 seconds

Ambient temperature: -4 °F to +113 °F (-20 °C to +45 °C)

Relative humidity

(non-condensing)

Selectable: 12V DC, max. 500 mA / 24 V DC,

max. 250 mA

13/16”

(0 - 300 mm)

Pull arm: 80° - 110°, with reveal 0 - 5

1/8”

(0 - 130 mm)

Max. 85%

This product is to be installed internally or externally with suitable weather protection.

Class of protection IP 20.

Complies with: IEC 335-1, ANSI/BHMA A156.19 and UL 325.

5 1/8’’

5/8’’

4 5/16’’

11/2’’ 11/2’’13/8’’

2 9/16’’

ILL-01658

1003680-US-4.0 Issue 2007-10-11 7

How the SW100 works

5 How the SW100 works

The low energy swing door operator SW100 uses a DC motor and a gear-reduction

system to drive an arm system, which opens the door. Closing power is provided by a

motor and a clock spring. An electronic control unit uses a motor encoder and a

microprocessor to control the door’s movement.

5.1 Opening

When an opening signal is received by the control unit, the door is opened at the

operator-adjusted opening speed. Before the door is fully open at back check, it slows

automatically to low speed. The motor stops when the selected door opening angle

has been reached. The open position is held by the motor.

If the door is obstructed while opening, it will either stall or stop which can be

selected with a DIP-switch (SOS).

• When stalling - the door will continue to try to open during the hold open time.

• When stopping - the door will, even if hold open time has not expired, close after

2 seconds.

5.2 Closing

When the hold open time has elapsed, the operator will close the door automatically,

using spring force and motor. The door will slow to low speed at latch check before it

reaches the fully closed position. The door is kept closed by spring power or

extended closing force by the motor.

8 Issue 2007-10-11 1003680-US-4.0

How the SW100 works

5.3 Functions on the basic control unit CU-ESD (see also page 32)

5.3.1 Power failure

During power failure the operator acts as a door closer with controlled closing speed.

5.3.2 Spring force

The operator is delivered with spring pre-tension factory set to 210°. If necessary, the

spring tension can be electronically adjusted with a potentiometer to required closing

force.

5.3.3 Extended closing force/torque (CLTQ)

If the potentiometer CLTQ is set to 0°, the door will close with normal spring power. If

the potentiometer is turned clockwise, the motor will increase the closing force/torque.

5.3.4 Power assist (POAS)

If the potentiometer POAS is set to 0°, the door gives no power assist. If the potentiometer is turned clockwise, the motor will give/increase power assist when the door

is opened manually.

5.3.5 Push and go (PAG)

DIP-switch to select “Push and Go” On or Off. “Push and Go” is available from any

door position.

5.3.6 Overhead presence detector (OPD), frame mounted

When an OPD sensor is mounted on the frame or operator header just above the

swing side of the door, it will–when activated–either keep the door open or closed.

The sensor is not active during opening and closing. Lock-out signal must be connected for proper function.

• a closed door will not open, if the OPD detects activity in the field

• an open door will not close, if the OPD detects activity in the field

• during opening, the door will continue to open, even if the OPD detects activity in

the field

• during closing, the door will continue to close, even if the OPD detects activity in

the field

• the OPD is not active in program mode OFF, manually opened door or during battery operation (Power Save Mode).

1003680-US-4.0 Issue 2007-10-11 9

How the SW100 works

5.3.7 Mat

Mat safety means that:

• a closed door will not open, if someone steps on the mat

• an open door will not close, if someone steps on the mat

• during opening, the door will continue to open, even if someone steps on the mat

• during closing, the door will continue to close, even if someone steps on the mat

• opening impulses are prevented during closing, if someone steps on the mat

• the mat is not active in program mode OFF, manually opened door or during battery operation (Power Save Mode).

5.4 Functions on the extension unit EXU-SI (see also page 34)

5.4.1 Kill function

• If kill circuit is closed, the control will ignore all signals and close door(s) at normal speed.

• When kill is no longer active, operator will resume normal operation.

• If kill function must have manual reset, jumper must be removed and reset button

connected to terminal No. 8 and Ground.

• The lock will lock when kill is active regardless of program selector setting.

• The function of the lock can be changed during Kill (see page 42).

5.4.2 Function of locks

• The control has an available output of DC for external locks

• DIP-switches to select 12 or 24 V DC, locked with or without power

• DIP-switch for lock release and potentiometer for opening delay

• DIP-switch for lock kick if door is not fully closed, to overcome binding in the

locking device during closing

• Input to unlock signal from lock. Potentiometer for opening delay is to be set to

max. As soon as unlock signal is received the door will start to open. The output

signal shall be active low.

5.4.3 Program selector

• Input for OPEN, EXIT and OFF (if no program selector, AUTO is default).

5.4.4 Impulses

• Input for Outer impulse, Key impulse and Open/Close impulse.

10 Issue 2007-10-11 1003680-US-4.0

How the SW100 works

5.4.5 Open / close impulse

The impulse will open the door and the door will stay open until a new impulse is

given. If no impulse is given the door will close after 15 minutes. This can be made

infinite by changing group of parameters (see page 42).

Open/close impulse works only in program selection “On”.

5.5 Functions on the extension unit EXU-SA (see also page 35) – optional

5.5.1 Presence impulse approach, door mounted

The presence impulse is active during fully open and closing. The sensor is mounted

to the approach side of the door. Once the door is closed, the sensor is ignored and

will not be active until the next impulse is received.

Note: When installed as a pair of doors, the presence impulse signal will re-open

both doors. The sensor is not active in program mode OFF, manually opened

door or during battery operation (Power Failure Mode).

5.5.2 Presence detection swingpath, door mounted

When a sensor that is mounted on the swing side of a door detects an object, it will

send a command to the control unit to stall the door. If the control unit has received a

short signal from the sensor and there is still hold open time left on the control unit,

the door will continue on its way open if the object has cleared. The inhibit/blanking

potentiometer can be adjusted so that the sensor will avoid detecting a wall or object

near the full open position. Presence detection has a higher priority than presence

impulse.

Note: When installed as a pair of doors the presence detection signal will stop both

doors, except for double egress doors. The behavior for double egress doors

can be changed (see page 42). The sensor is not active in program mode OFF,

manually opened door or during battery operation.

5.5.3 Monitored safety sensors

Both presence impulse and presence detection can be monitored. If a sensor becomes

defective, the operator will not accept any impulses and will then work as a manual

door closer.

5.5.4 Open door indication

A relay output is used to indicate an opening cycle or a specific position of the door.

The indication position is set by adjusting the inhibit/blanking potentiometer.

5.5.5 Error indication

A potential free contact COM/NO/NC for external error indication (see page 48).

1003680-US-4.0 Issue 2007-10-11 11

Models

6 Models

Two main models of the low energy swing door operator SW100 are available:

• Single operator

• Double operator

The operators are non-handed and not dependent on the hinges. The operators suit

both pushing and pulling arm systems.

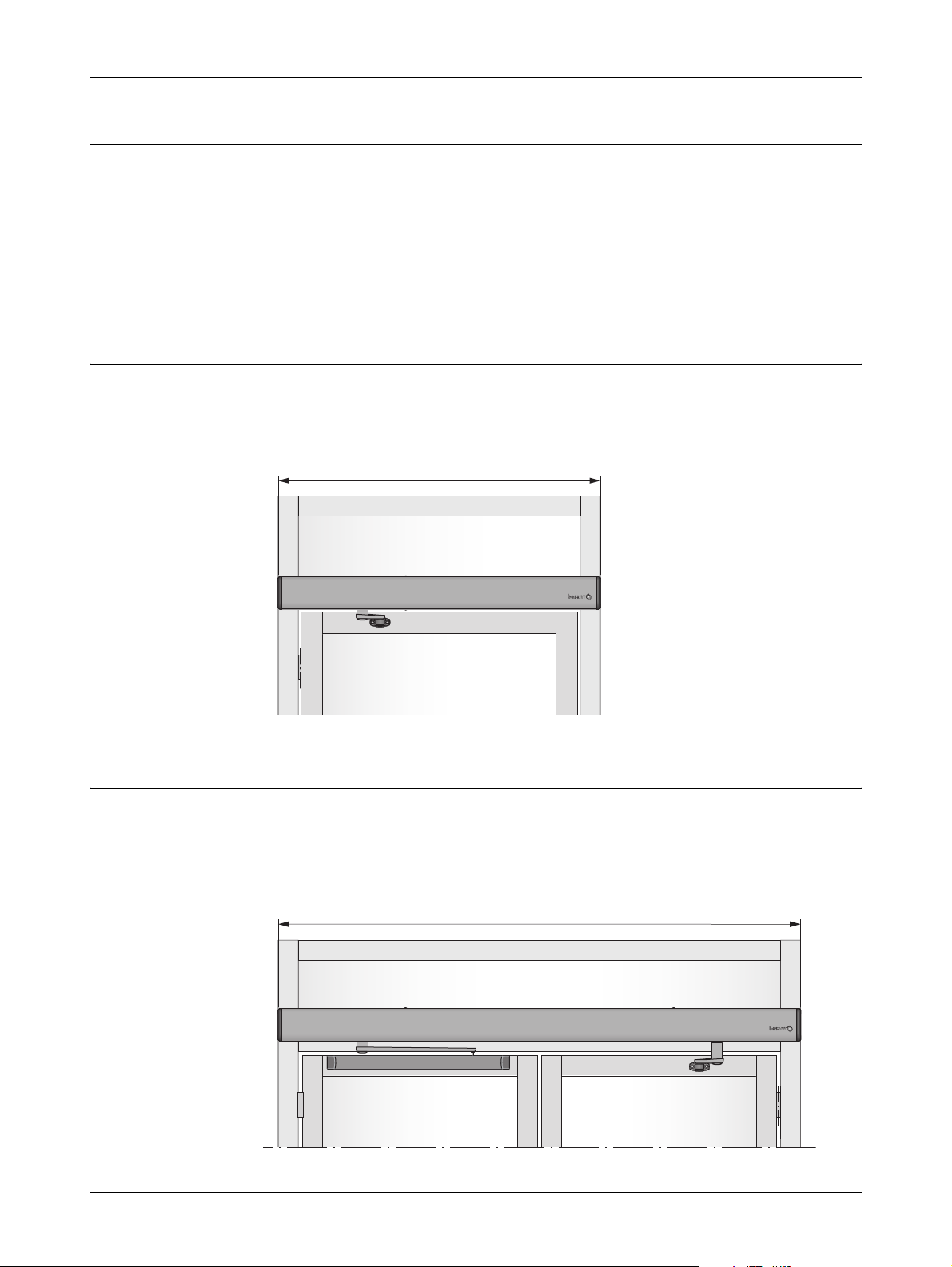

6.1 Single operator

The product is delivered complete with back plate, control unit, end plates and cover.

Length including end plates, L = 39.5” (1003 mm).

Pushing arm system shown.

L

6.2 Double operator (Consult Product Order form for availability)

The product is delivered complete with back plate, control unit, end plates and cover.

Cover length L is optional.

Two operators can be mounted under the same cover to open one door each.

Pushing and pulling arm system shown (double egress).

L

12 Issue 2007-10-11 1003680-US-4.0

Part identification

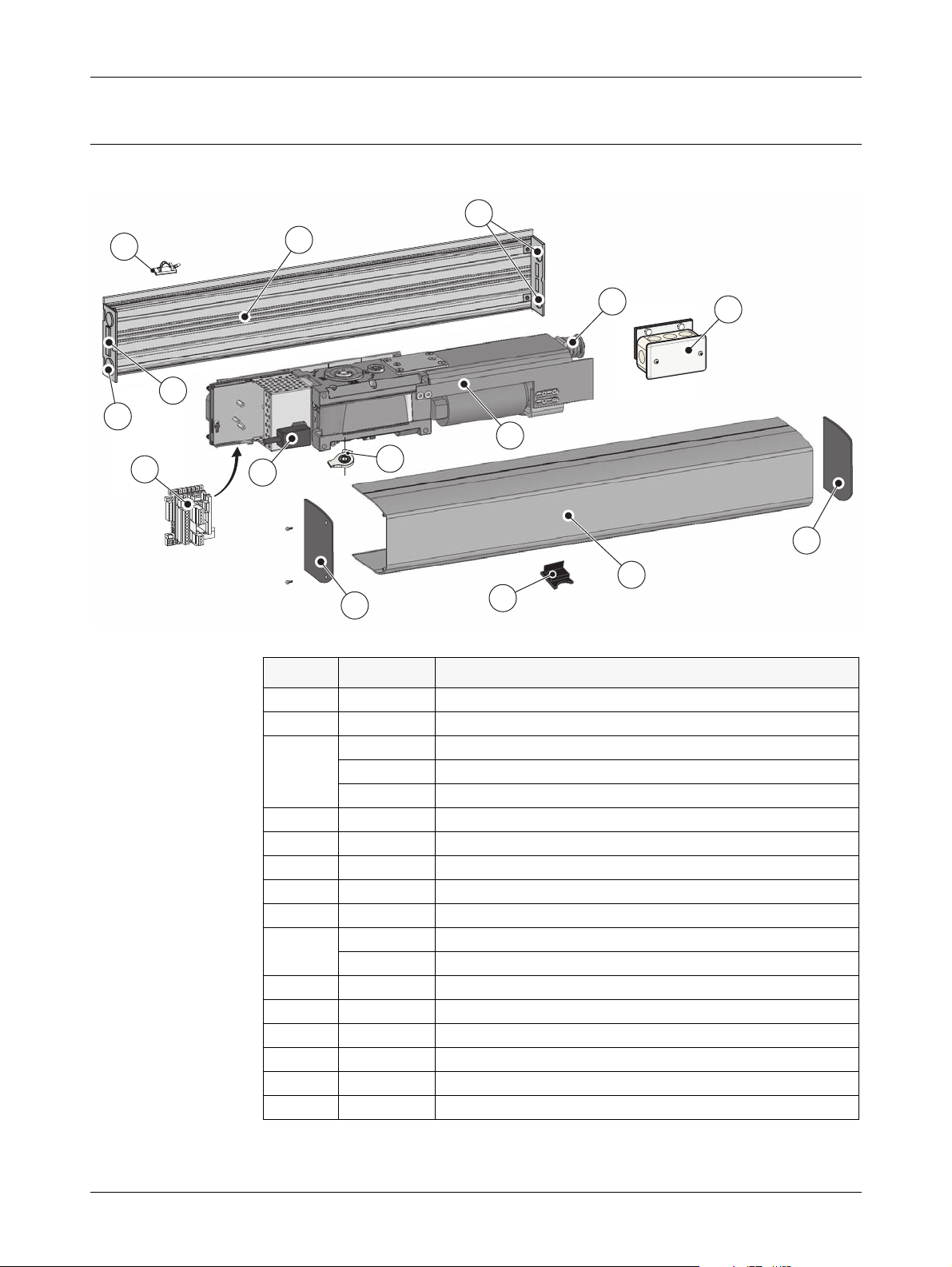

7 Part identification

11

10

1

12

9

7

2

3

4

Item No. P/N Description

1 1003547 Back plate (shorty)

2 1003498 Transmission unit/operator

3 1003532 Control unit CU-ESD

4 1700607 Mains contact

5 1003540 Door stop body

6 1003542 Top end plate

7 1003543 Bottom end plate

8 1003546 Main cover (shorty)

9 1003581 Power On/Off switch

10 1003578 Cable holder (50 pcs)

11 – Knockouts for cable inlet

12 – Belt tension device

13 1003545 Fill cover (output shaft)

14 1004437 Connection box

– 1003583 Sync cable – optional

5

8

6

1003554 EXU-SI (Kit to extend the security functions) – optional

1003557 EXU-SA (Kit to extend the safety functions) – optional

1003582 On/Off/Hold open switch – optional

13

14

6

1003680-US-4.0 Issue 2007-10-11 13

Options

8Options

8.1 Arm systems

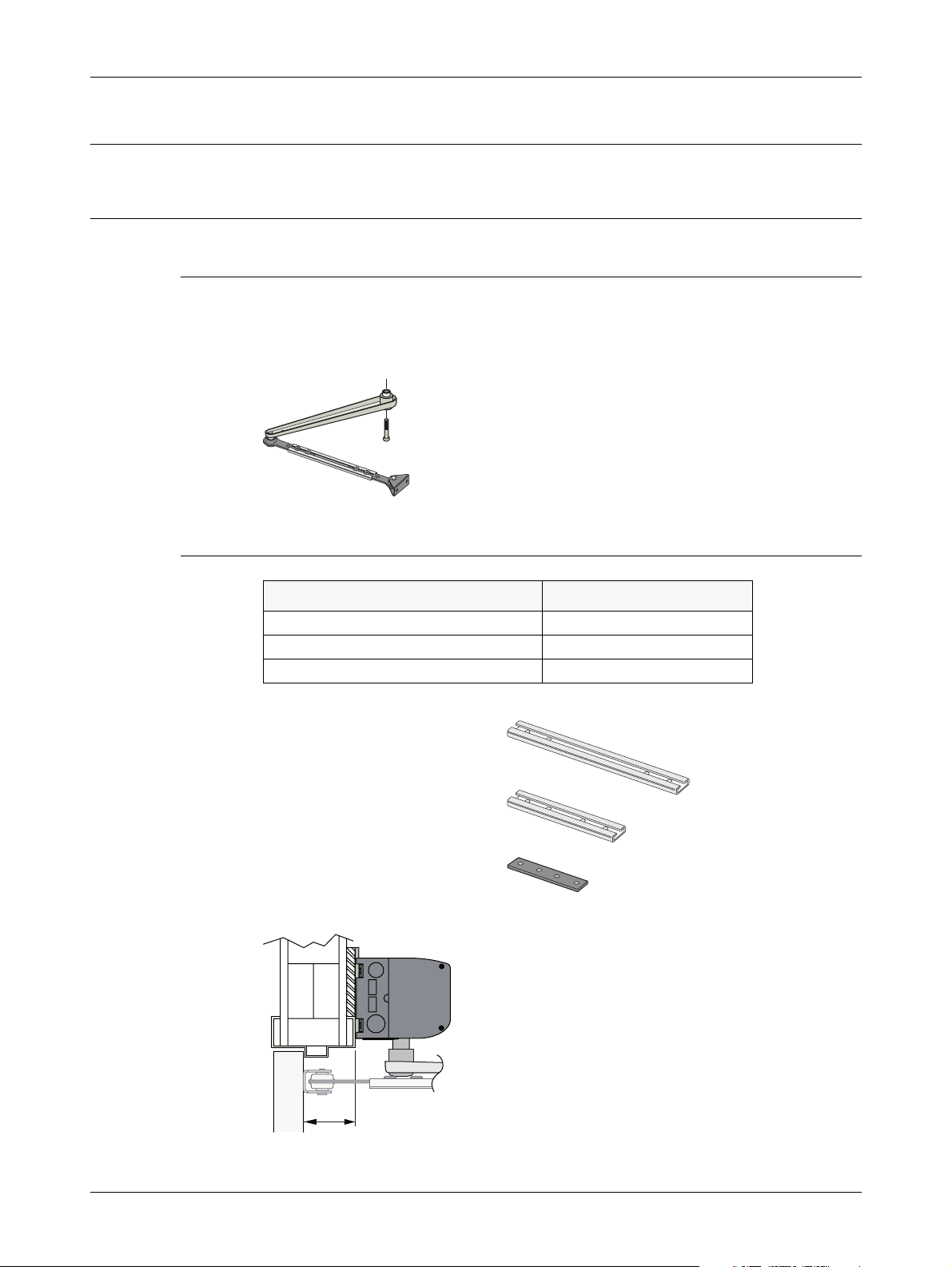

8.1.1 Arm system, PUSH P/N: 1003576

This arm system is delivered with drive arm, telescopic part and door fitting. It is

used if the operator is installed on the wall on the opposite side of the door swing, and

approved for fire door application.

PUSH

8.1.2 PUSH-arm extensions

Reveal = X Extension

Up to 4-1/8” (0-105 mm) None (standard arm)

4-1/8” to 8-11/16” (105-220 mm) 13-9/16” (345 mm)

8-11/16” to 11-13/16” (220-300 mm) 9-1/16” (230 mm) + Joint part

13-9/16” (345 mm) extension

P/N: 21-06-17305

9-1/16” (230 mm) extension

P/N: 21-06-17304

Joint part

P/N: 21-06-17319

X

14 Issue 2007-10-11 1003680-US-4.0

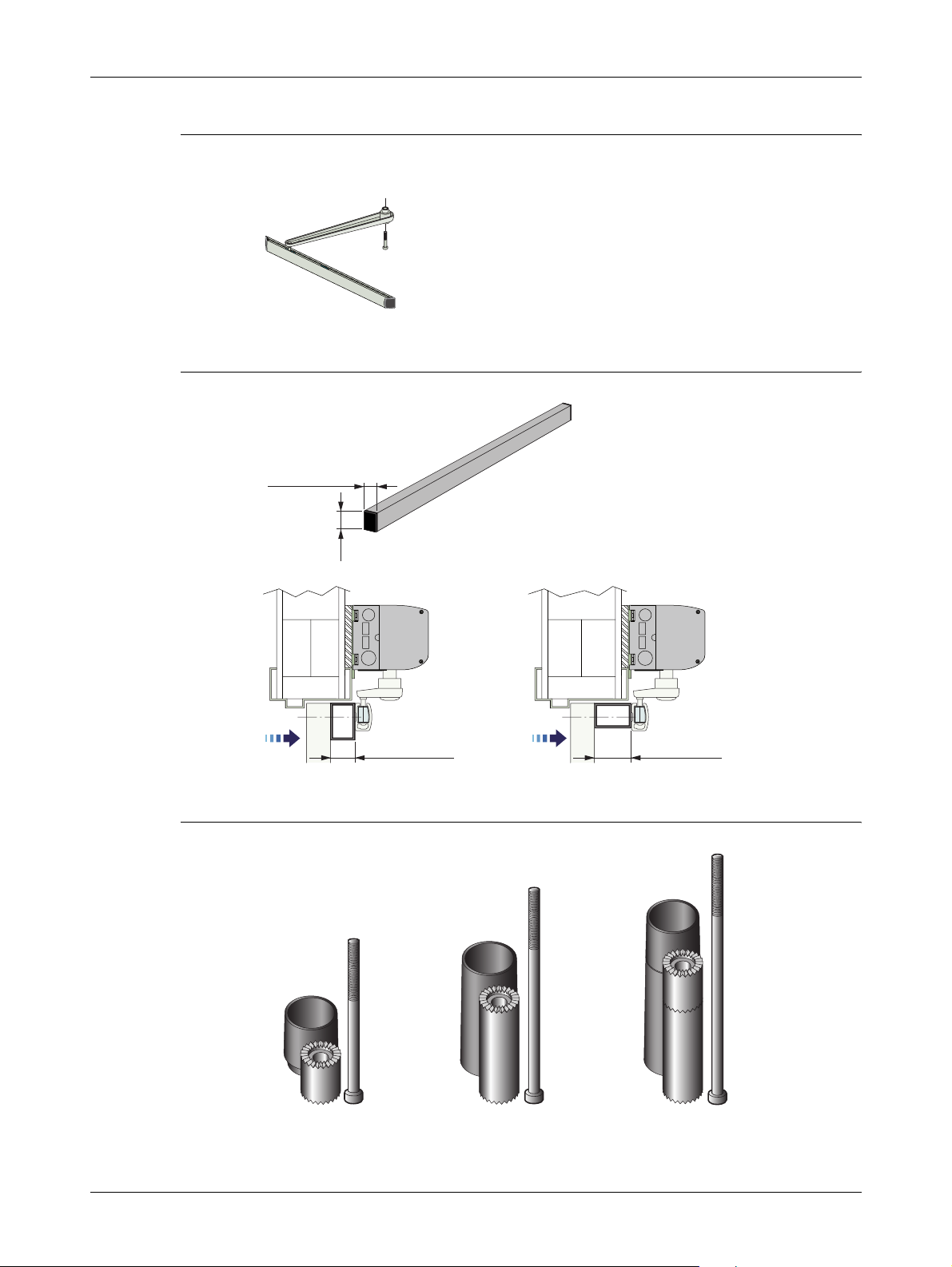

8.1.3 Arm system, PULL P/N: 1003577

This arm system is delivered with drive arm, guide shoe and door fitting.

PULL

8.1.4 Reveal spacer, PULL P/N: 173804BK

40 mm (1-9/16")

Options

60 mm

(2-3/8")

40 (1-9/16") 60 (2-3/8")

8.1.5 Drive shaft extension kits

20 mm

(3/4")

70 mm

(2-3/4")

50 mm

(2")

P/N: 21-03-205

1003680-US-4.0 Issue 2007-10-11 15

P/N: 21-03-206

P/N: 21-03-207

Options

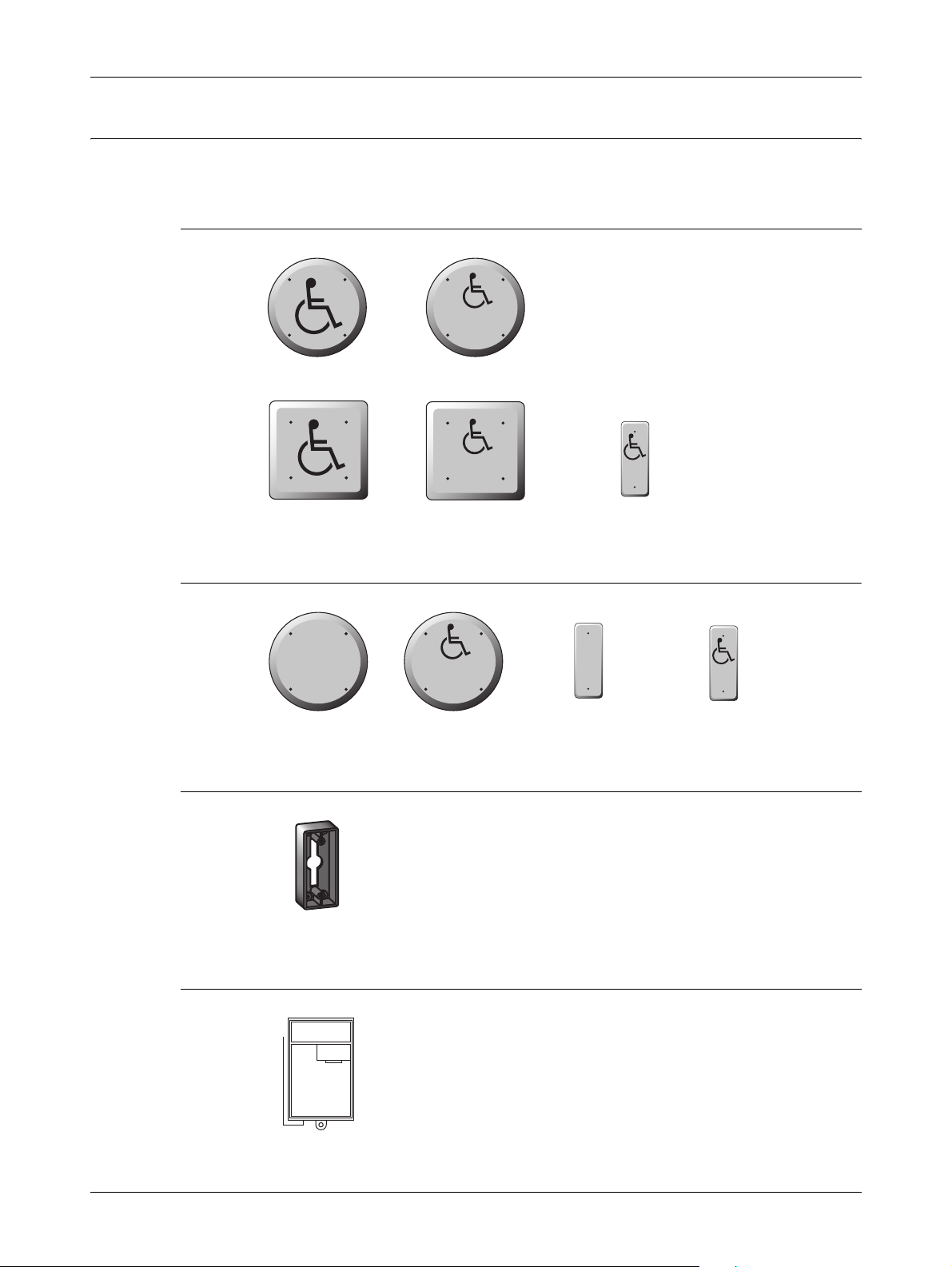

8.2 Push plates

For disable use, mount push plate 31” above floor level.

8.2.1 Push plates

PRESS

TO OPEN

P/N: 75-02-101

P/N: 75-02-107

P/N: 75-02-102

PRESS

TO OPEN

P/N: 75-02-108

8.2.2 Remote transmitter push plates

PUSH

TO OPEN

P/N: 75-02-273

PUSH

TO OPEN

P/N: 75-02-272

8.2.3 Installation box for narrow plates

P/N: 75-02-280

PUSH

TO

OPEN

P/N: 75-02-269

P/N: 75-02-270

PUSH

TO

OPEN

P/N: 75-21-002

8.2.4 Remote receiver

P/N: 75-02-271

16 Issue 2007-10-11 1003680-US-4.0

Loading...

Loading...