Assa abloy DC3200, DC3210, DC3220 User Manual

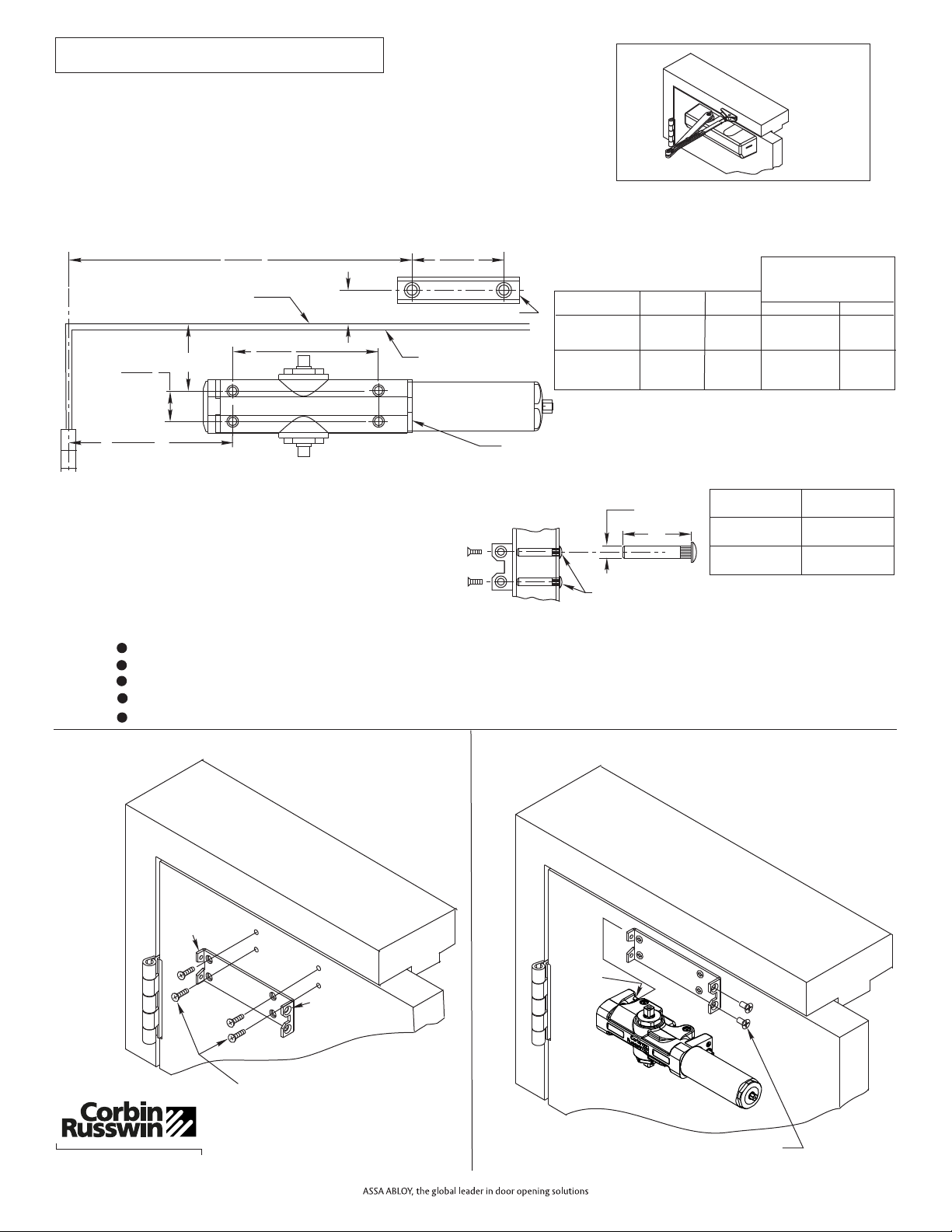

DC3200 Series

Multi-Sized 1 thru 6

Installation Instructions

ASSA ABLOY

Universal Door Closers

For Non-Hold Open or “A1”

Hold Open Arm Options

®

DC3200

IMPORTANT:

BEFORE

INSTALLING:

Regular Arm

See pages

2 & 3

An improperly installed or incorrectly adjusted door closer may cause property

damage or personal injury; and will void product warranty.

To avoid personal injury, DO NOT DISASSEMBLE THIS DOOR CLOSER BODY.

Door closers must be securely fastened to a properly reinforced door and frame

with fasteners provided.

Door closers with the “A1” HOLD OPEN ARM option are not permitted to be

installed in fire door assemblies.

The Americans with Disabilities Act (ADA) requires that doors having door closers

have an opening force not to exceed 5 lbf. for interior doors, 8.5 lbf exterior doors.

Use standard templating for regular arm and parallel arm applications. Jamb

mounted applications use the template for 140° door opening to achieve the

required opening force.

The door closer's power size adjustment feature may require adjustment to its

lowest setting to comply with ADA opening force guidelines.

ADA compliant closers are: DC3200, DC3210, DC3220

DC3210

Parallel Arm

See pages

4 & 5

Jamb Mount

See pages

6 & 7

DC3220

Size of Door & Door Closer

Type

of

Installation

Regular &

Top Jamb

Parallel

Arm

**NOTE: These forces are for standard templating with bearing type hinges and do not account for pressure differentials and draft.

80-9330-3000-152 Rev. 05/12

Interior

' "

2 4

' "

3 0

' "

3 6

' "

4 0

' "

4 6

' "

5 0

' "

2 4

' "

2 6

' "

3 0

' "

3 6

' "

4 0

' "

4 6

Exterior

In-swinging

' "

2 6

' "

3 0

' "

3 6

' "

*4 0

Exterior

Out-swinging

3 0

' "

3 6

' "

4 0

' "

*4 6

' "

' "

2 6

' "

3 0

' "

*3 6

' "

*4 0

Recommended

Closer Size

1

2

3

4

5

6

1

2

3

4

5

6

**Max.

Opening

Force

lbs/f

8

14

16

22

24

26

8

14

16

22

24

26

TO DETERMINE

HAND OF

YOUR DOOR:

RHR

LEFT

HAND

DOOR

RIGHT

HAND

DOOR

LHR

Installation Instructions

Regular Arm Application

DC3200 Series

1. Template

Mark Door and Jamb (for closer bracket and arm bracket)

1

"

"

*10-5/8

(270)

FRAME LINE

A

4-5/16

(109.5)

2-1/4

(57.2)

B

ARM BRACKET

TOP OF DOOR

MOUNTING DIMENSIONS

TOP RAIL

2-1/2 & OVER

"

(64mm)

"

1-3/4 MIN.

(44mm)

If top rail is 2-1/2 (64mm) or greater, use template FM131C provided.

If top rail is 1-3/4 (44mm) to 2-7/16 (62mm), see MOUNTING DIMENSIONS chart.

C

HINGE OR PIVOT

L

(25.4)

A

"

1

(25.4mm)

5/8

"

(16mm)

B

7/8

"

(23mm)

1-1/4

(32mm)

"

Regular Arm

MIN. CLEARANCE

REQUIRED OVER

DOOR

NHO

"

"

1-11/16

(43mm)

2-1/16

(53mm)

1-1/2

(39mm)

1-7/8

(48mm)

HO

"

"

*7-1/2

(191)

To obtain extra closing force add 3 (77mm) to dimensions marked.

*

This will limit degree of door opening to 110°.

MOUNTING SCREW SPECIFICATIONS

ARM AND CLOSER BRACKET

1/4-20 oval head machine screw

or 1/4-14 self-drilling screw.

3/16 (4.8) diameter pilot hole

required for Wood Applications.

NOTES:

}

or

{

Check hand of door, see page 1.

Right Hand Application Shown. Left Hand Opposite.

Dimensions given in inches (mm). Do Not Scale Drawing.

Closer must be installed in a true horizontal plane to ensure proper closer performance.

Door opening (up to 180°) is dependent upon door, frame, wall and hinge/pivot conditions permitting.

2. Install Closer Bracket

"

Option M54:

Sex nuts, furnished

when ordered

CLOSER BRACKET

3/8

(10)

L

1/4-20 THREAD

Drill thru 9/32 (7.1) Enlarge to

3/8 (9.5) Dia. This Side Only

(4 Places)

THICKNESS

1-3/8 (35mm)"

1-3/4 (44mm)

DOOR

"

& OVER

SEX NUT

LENGTH “L”

1-9/32 (33mm)"

1-21/32 (42mm)"

3. Mount Closer Body to Closer Bracket

Pin Hole

End

®

ASSA ABLOY

80-9330-3000-152 Rev. 05/12

Countersunk

Hole End

1/4-14 x 1-1/2 OH Self-Drilling (4)

or

1/4-20 x 3/4 OHMS w/ Sex Nuts (4)

(M54 Option)

Pins

(2)

1/4-20 x 1/2 OHMS (2)

Page 2

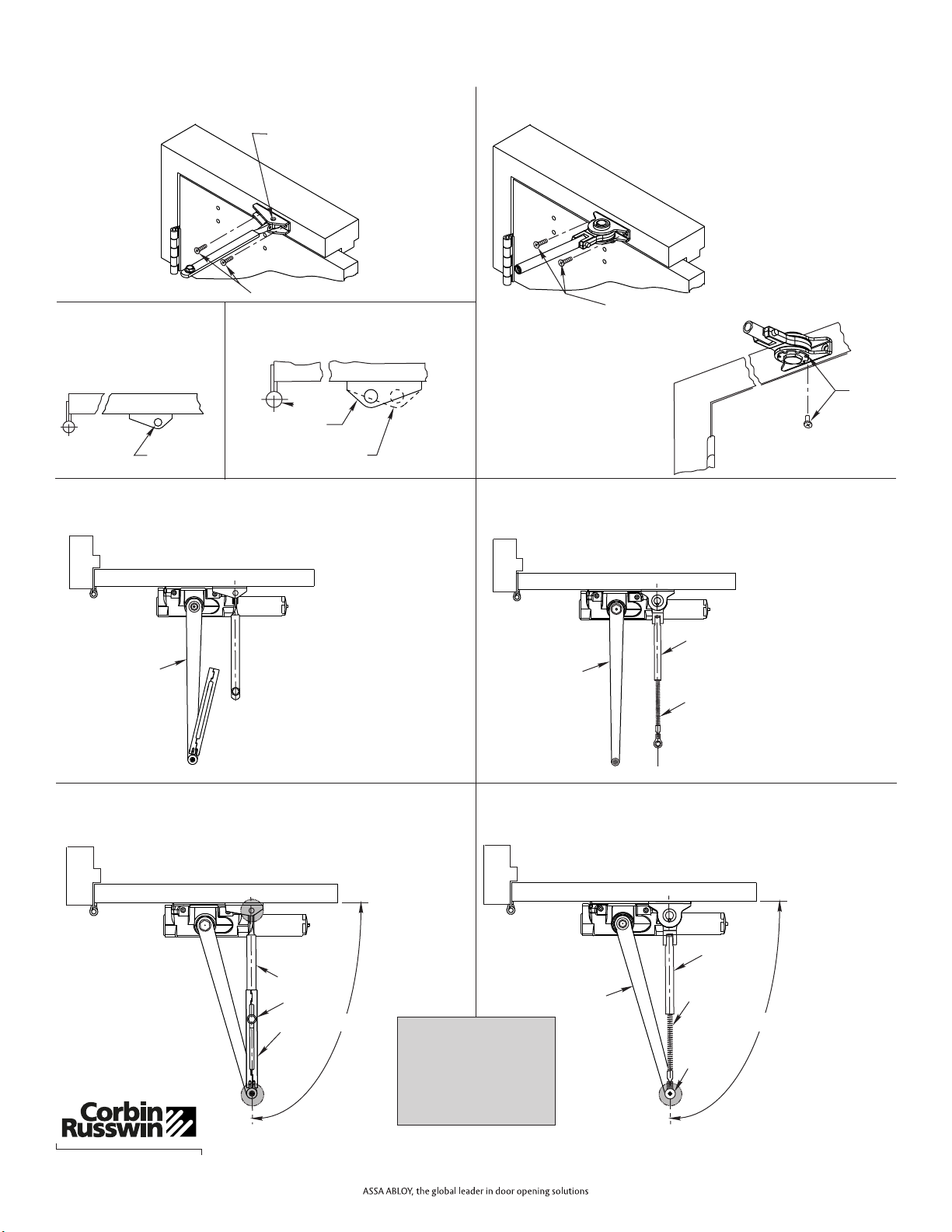

Regular Arm Application (Continued)

4a. Attach Arm Bracket to Frame

NON-HOLD OPEN ARM ONLY:

Pivot (away from hinge)

1/4-14 x 1-1/2 OH Self-Drilling (4)

Standard Position

Normal mounting position.

Position with pivot point

away from hinge.

Away from

hinge

For Additional 15% Closing Force

Reposition arm mounting bracket so that

pivot point is toward hinge.

Hinge

FOR MAXIMUM

POWER

FOR REGULAR

POWER

5a. Position Arm on Closer

NON-HOLD OPEN ARM ONLY:

Main arm projects straight out at 90° angle to door.

4b. Attach Arm Bracket to Frame

HOLD OPEN ARM (A1 OPTION ONLY):

1/4-14 x 1-1/2 OH Self-Drilling (4)

HOLD OPEN ARM:

Position so that dial

screw is on

UNDERSIDE of bracket

5b. Position Arm on Closer

HOLD OPEN ARM ONLY:

Main arm projects straight out at 90° angle to door. Remove main

arm screw from elbow joint and disassemble arm. Thread the rod

into the Arm Bracket as shown below.

DIAL

SCREW

MAIN ARM

6a. Preload and Adjust Arm

NON-HOLD OPEN ARM ONLY:

Open door and slide arm rod into arm loop. Close door, swing arms

so adjusting arm is 90° to frame. With 7/16 wrench INSTALL and

TIGHTEN SCREW SECURELY.

ARM ROD

SCREW

ARM

LOOP

®

"

90°

MAIN ARM

6b. Preload and Adjust Arm

HOLD OPEN ARM ONLY:

While door is closed, adjust the Threaded Arm in the Arm Bracket

until the bearing fits back onto the elbow joint on the Main Arm at 90°

as shown below. RE-INSTALL AND TIGHTEN SCREW SECURELY.

MAIN ARM

Extended Maintenance

Lubricate Arm periodically

shaded points with a drop or

two of appropriate lubricant.

NOTE: When lubricating a

Hold Open Arm, DO NOT

use any lubricant on the

Holding Surface components.

at

ARM

BRACKET

THREADED

ROD

ARM

BRACKET

THREADED

ARM

SCREW

90°

ASSA ABLOY

80-9330-3000-152 Rev. 05/12

For Adjustments See Page 8

Page 3

Loading...

Loading...