Page 1

Type: TD25

Service manual

This service manual describes tumble dryer type TD25 and is a supplement to the general service manual

for the 700 series.

Contents

Introduction ................................................................................................................................................... 3

Product overview ..........................................................................................................................................

4

Programme ...................................................................................................................................................

5

Indication of programme sequence ...............................................................................................................

5

Options and settings .....................................................................................................................................6

Variant settings .............................................................................................................................................

7

Test programme ............................................................................................................................................

8

Troubleshooting ..........................................................................................................................................

10

Components and measurement values ......................................................................................................

12

Technical data .............................................................................................................................................

13

Wiring diagram

............................................................................................................................................14

Appendix: Timer diagram TD25 ......................................................................................................................

Page 2

Service manual TD25

2

Page 3

Service manual TD25

3

Introduction

You are holding the service manual for the TD25 generation of tumble dryer.

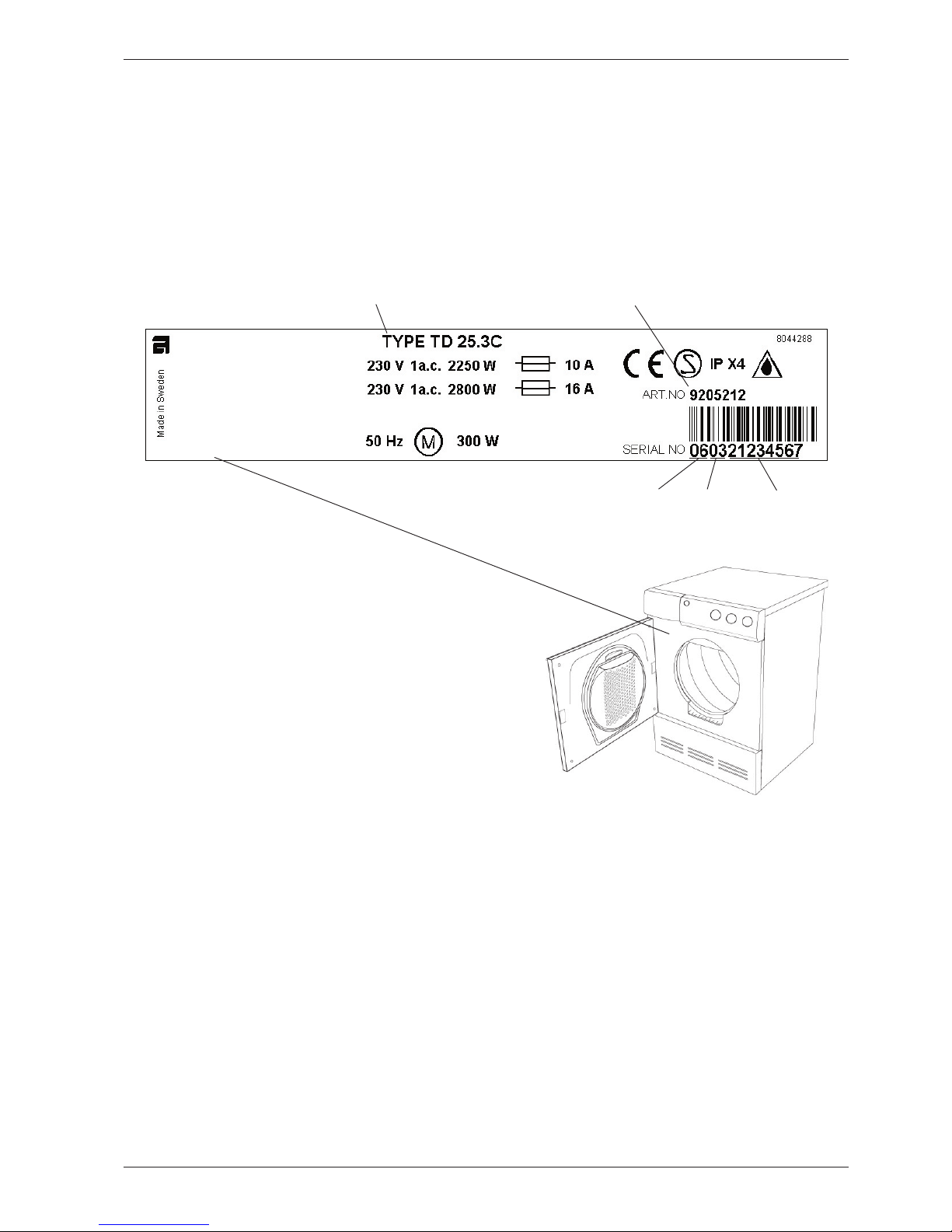

There are two types of tumble dryer in the TD25 series: TD25.1 and TD25.3. The following page presents

the different versions, to help you identify the machine types. The variants are named differently from mar

ket to market. The type designation is the most important factor for identifying the machine type. The type

designation can be found on the machine plate, which is located inside the machine’s door.

It should be easy to service a tumble dryer. It is important that you, as a service technician, are given the

conditions to be able to carry out work in an efficient and satisfactory way. Our hope is that this service

manual is a useful tool for your daily work.

Typbeteckning Produktnummer

Löpnummer

År Vecka

Type designa-

Product number

Week

Serial number

Page 4

Service manual TD25

4

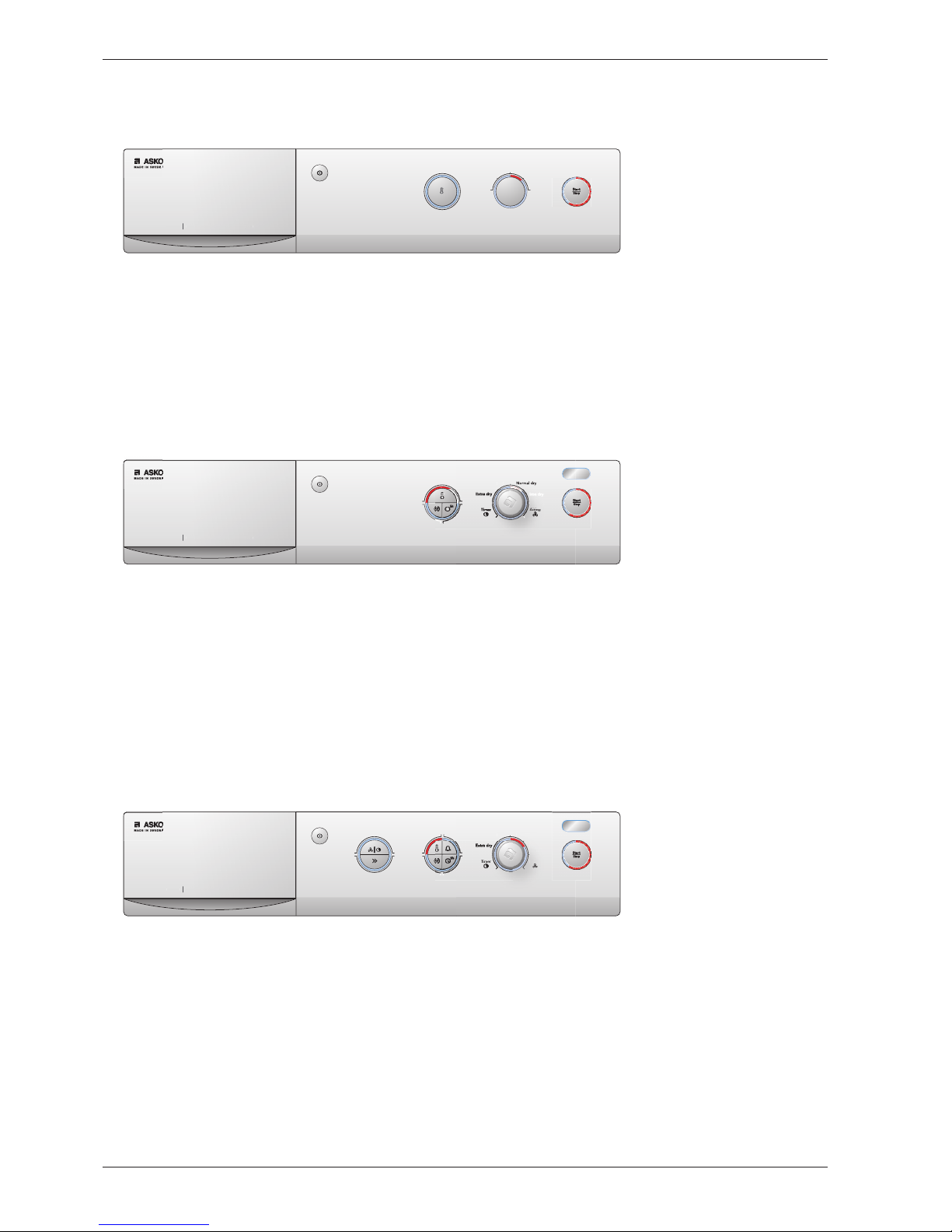

TD25.3

Programme: 4 automatic programmes, 1 timer programme and 1 airing programme (For further infor-

mation, see the timer diagram at the foot of the document.)

Options: 4 (designations differ depending on the market, see directions for use.)

Settings: Temperature.

2h

minm

in

Airin

g

Normal dr

y

Iron dr

y

Dr

y

T75 2

BUT T E R F L Y D R Y I N

G

Type overview

TD25.1

Programme: 4 automatic programmes (For further information, see timer diagram at the foot of the

document.)

Options None.

Settings: Temperature.

T 7 1 2

BUT T E R F L Y D R Y I N

G

Program

Temperature

Extra dry

Dry

Normal dr

y

Iron dr

y

TD25.3

Programme: 4 automatic programmes, 1 timer programme and 1 airing programme (For further infor-

mation, see the timer diagram at the foot of the document.)

Options: 2 (designations differ depending on the market, see directions for use.)

Settings: Temperature.

T73 2

BUT T E R F L Y D R Y I N

G

Dr

y

Page 5

Service manual TD25

5

Programme

When using tumble dryer TD25 it is possible to choose between four different programmes that automatically sense how damp the washing is. The machine dries to different levels depending on which of the four

programmes has been selected on the front panel. The machine only has one automatic programme that

runs for different lengths of time (and therefore dries to different levels) depending on which of the four programmes has been selected on the front panel. The automatic programme runs for a maximum of 3 hours.

The machine has a Timer programme that runs for the time that is set (20 minutes – 2 hours), regardless of

whether the washing is dry or not.

The machine has an Airing programme that blows cold air for the time that is set (5 minutes – 2 hours).

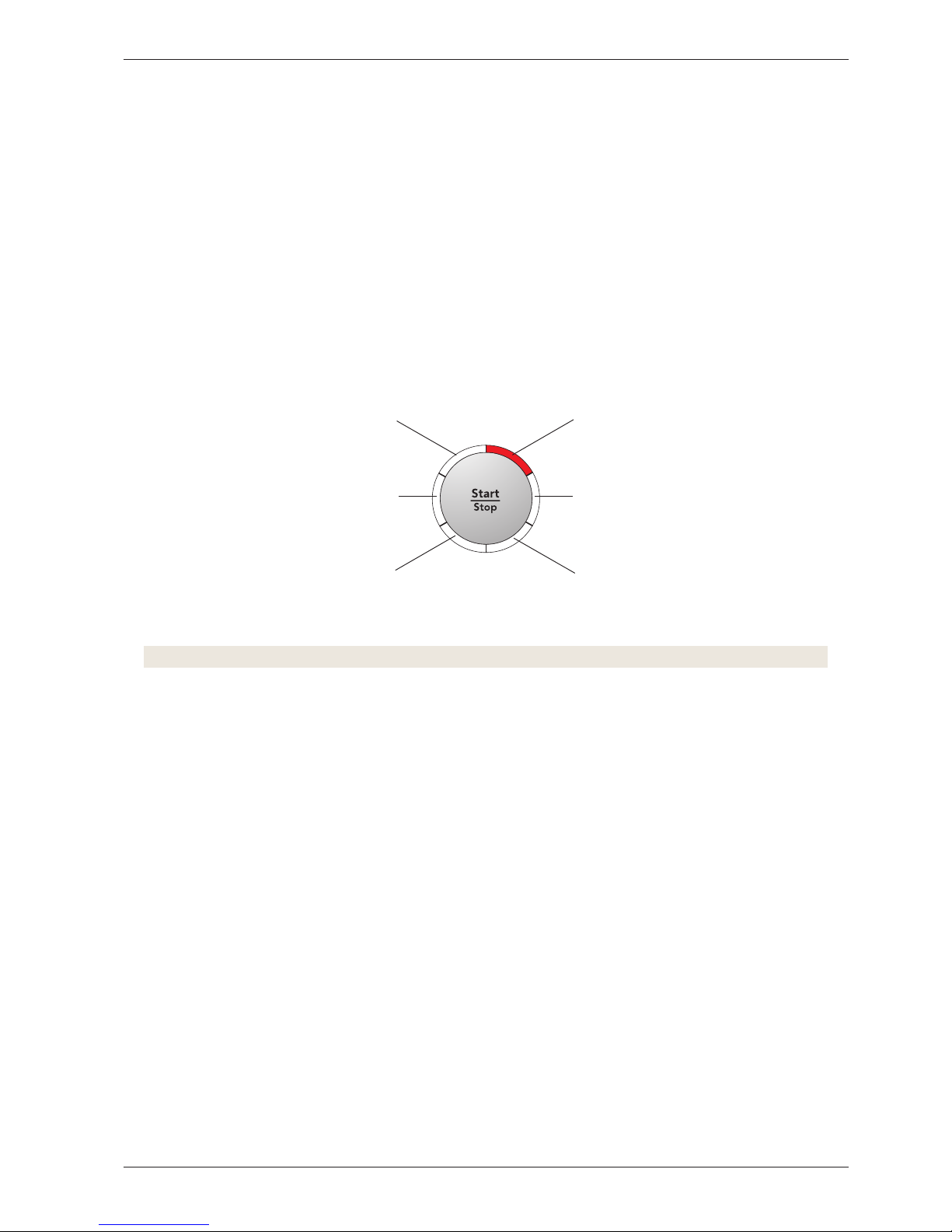

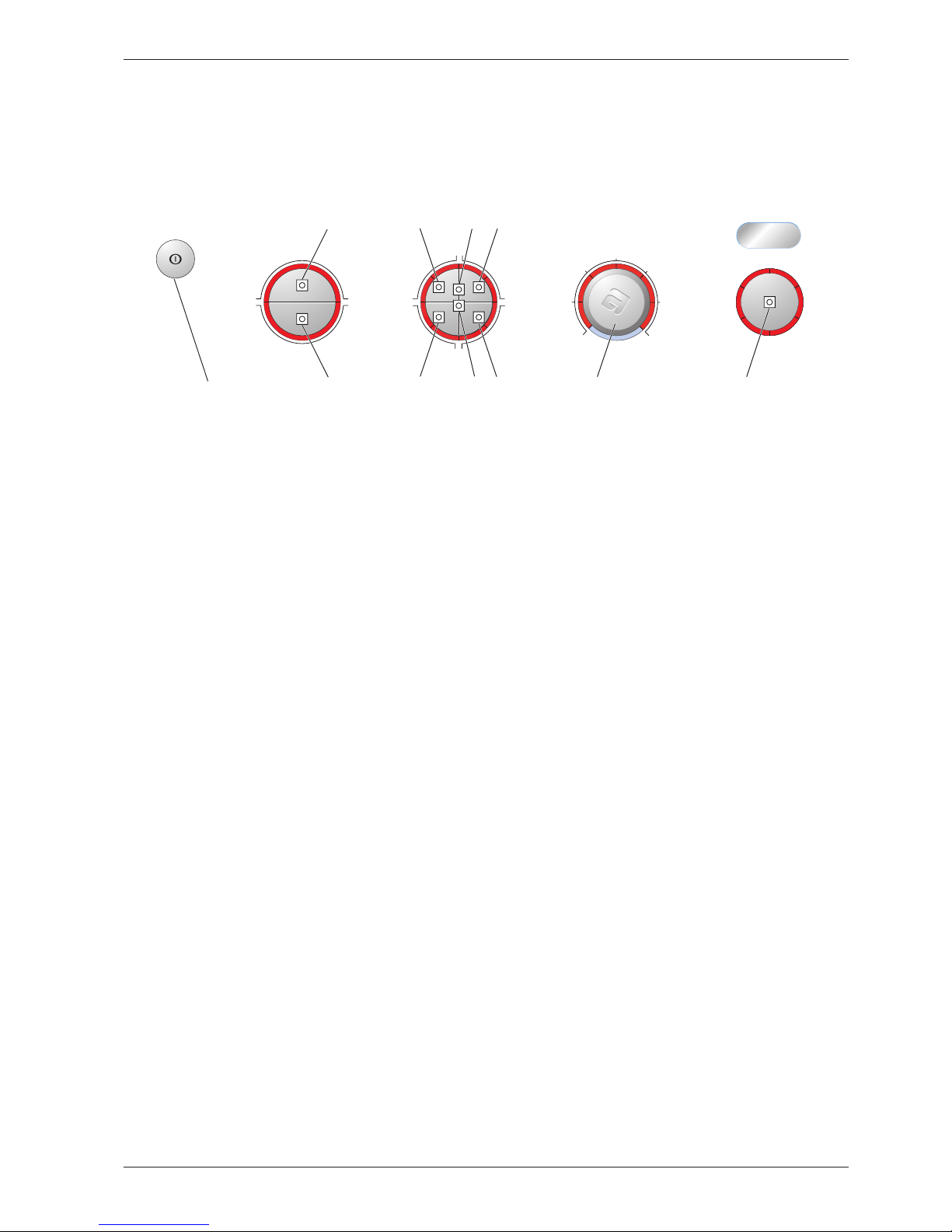

Indication of programme sequence

During the programme, the current programme sequence is indicated by a fixed light in the LEDs around

the start/stop button (see the image).

The cycle time is calculated during the start sequence.

Note!

If the door is opened whilst a programme is in operation, the programme will be interrupted and return to

the start position.

Start

End

Cooling

¼ cycle time

¾ cycle time ½ cycle time

Page 6

Service manual TD25

6

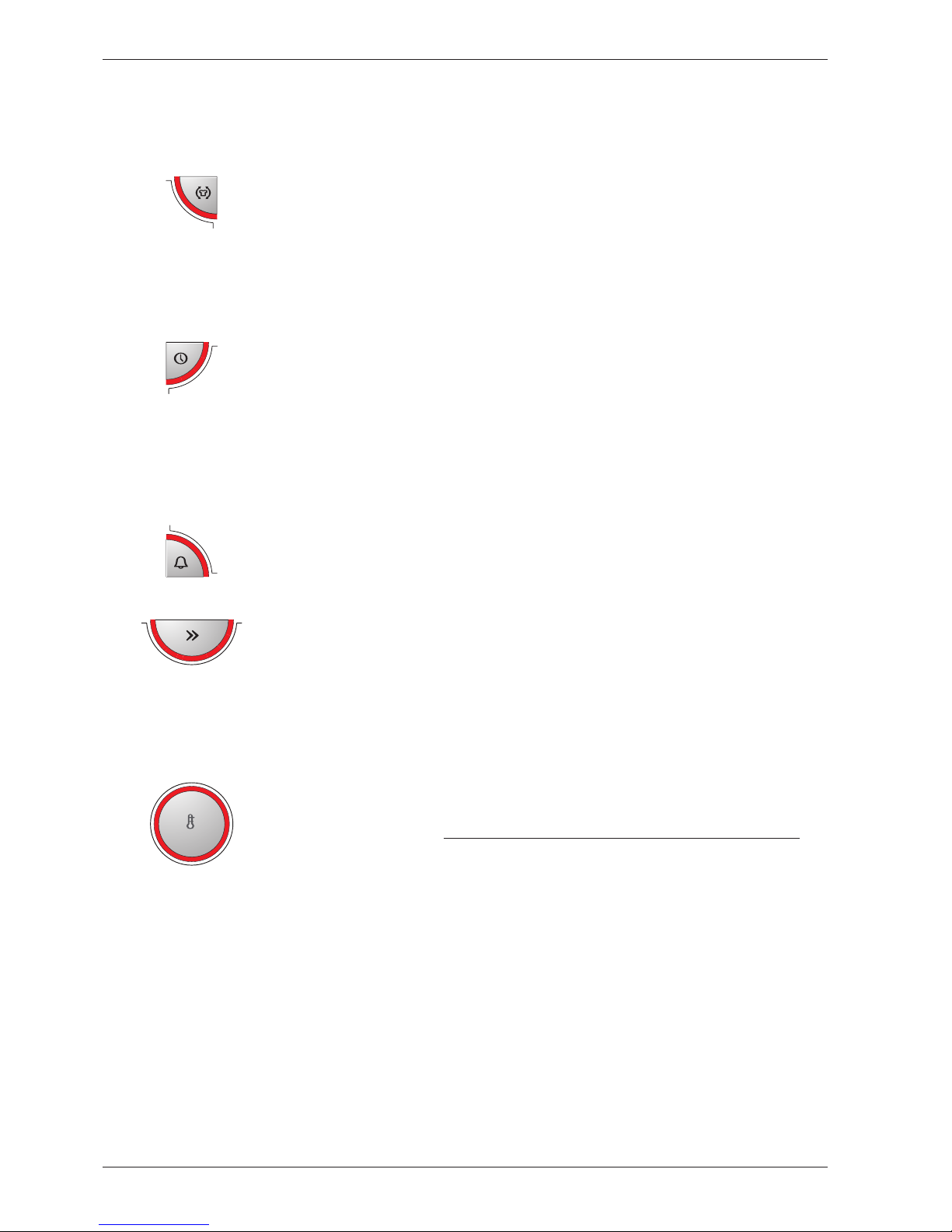

Options and settings

Options

2h

Means that the drum will rotate 3 seconds per minute for 2 hours once the drying

programme has finished. The option prevents the fabrics from remaining in the

same position and becoming creased, which is good if you are unable to remove

them immediately after tumble-drying has finished.

If the Buzzer is also activated

a signal will sound each time the drum rotates, as a reminder that the drying pro

-

gramme has finished.

5h

Delays the start of the machine by 5 hours.

Activated by pressing the Time-delayed start button and then the start/stop but

-

ton.

The number 5 in the display indicates that Time-delayed start has been activated.

The number of hours to start is displayed with a countdown from 5 to 1.

Deactivated by pressing the start/stop button for 3 seconds until the red field next to

Time-delayed start goes out.

This means that a buzzer will sound for 3 seconds when the drying programme

finishes.

Reduces cooling to 3 minutes.

Cannot be used in the Airing programme.

(In ”normal cases” when Short cooling is deselected, the machine cools for 15

minutes. )

Settings

Possible to set to a high or low temperature.

High temperature Low temperature

Airing dryer:

57°C 43°C

Condenser dryer:

73°C 50°C

Temperature setting cannot be carried out in the airing programme.

Page 7

Service manual TD25

7

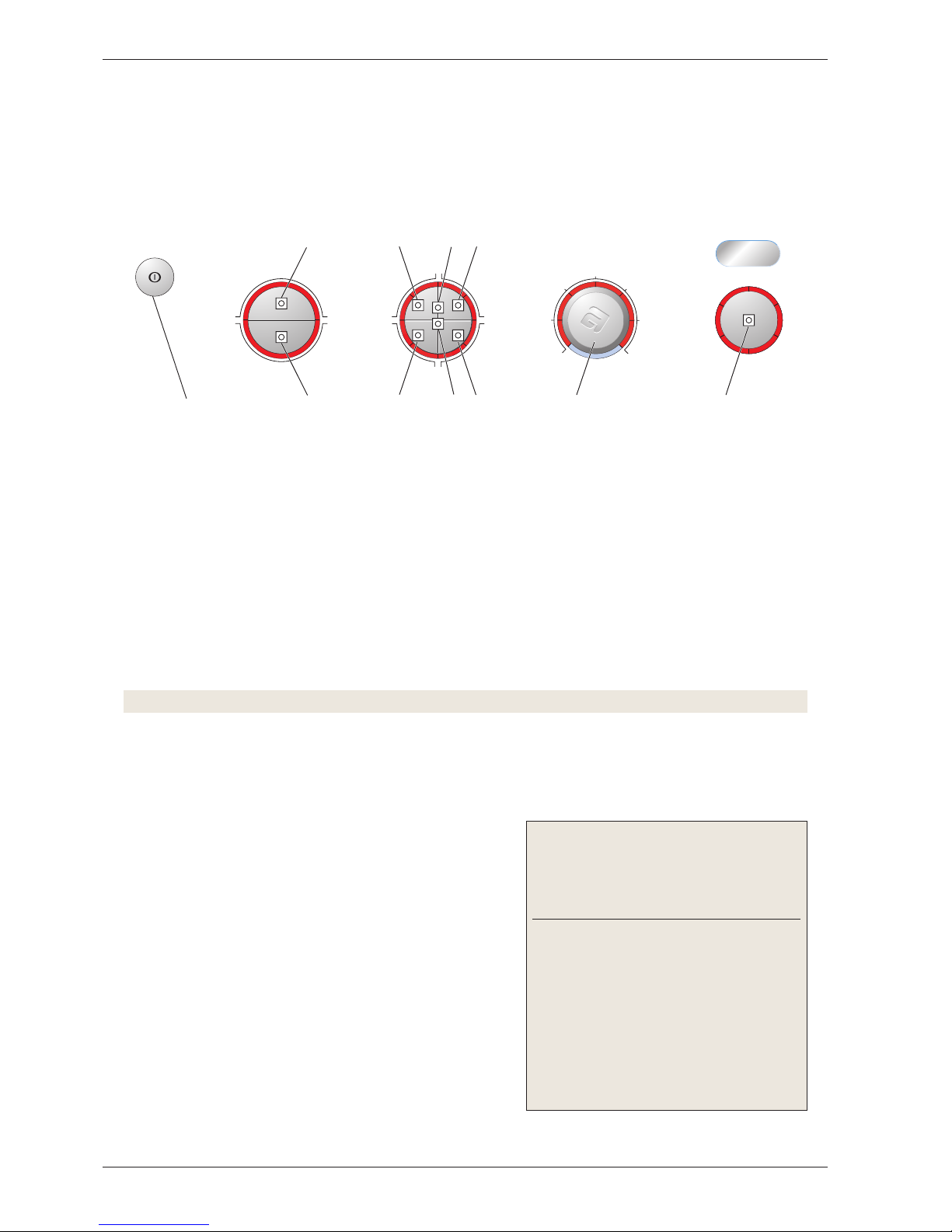

Variant settings

The following version settings can be made after replacing the control unit.

Total reset

1. Hold the start/stop button (S1) in, start the machine by pressing the main power switch and keep the

start/stop button depressed until one of the LEDs on the panel lights.

Buzzer

1. Hold S5 or S6 pressed in, start the machine by pressing the main power switch and keep S5/S6

pressed in until L1, L13 and L15 start to flash.

2. Change the setting by pressing J1/S2. L8 lights when the buzzer is activated.

3. Confirm your selection by pressing the start/stop button (S1).

10 A or 16 A

1. Hold the start/stop button (S1) in, start the machine by pressing the main power switch and keep the

start/stop button depressed until one of the LEDs on the panel lights.

2. Press the start/stop button (S1) 5 times. L1 starts to flash.

3. Change the setting by pressing S2 or J1. L8 lights when 16 A is activated.

4. Confirm your selection by pressing the start/stop button (S1).

Adjusting drying time

1. Hold the start/stop button (S1) in, start the machine by pressing the main power switch and keep the

start/stop button depressed until one of the LEDs on the panel lights.

2. Press the start/stop button (S1) for a further 5 seconds until L1 starts to flash.

3. Change the setting by pressing S2 or J1. The selected setting is indicated as follows:

No adjustment: no LED:

+ 5 minutes:

L8

+10 minutes: L9

+15 minutes:

L10

+20 minutes:

L11

4. Confirm your selection by pressing the start/stop button (S1).

The control unit detects and adjusts automatically to the panel layout and machine model when the option

buttons are pressed several times.

L19

L1

L2

L3

L6

L4

L5

L10

L11

L12

L9

L7

L13

L14

L15

a

a

a

a

b

b

b

b

L16

L17

L18

L8

S1

S8 S4S6

S10

S9 S3

S5

S7

J1/S2

Main power switch

S = Push button

L = LED

Page 8

Service manual TD25

8

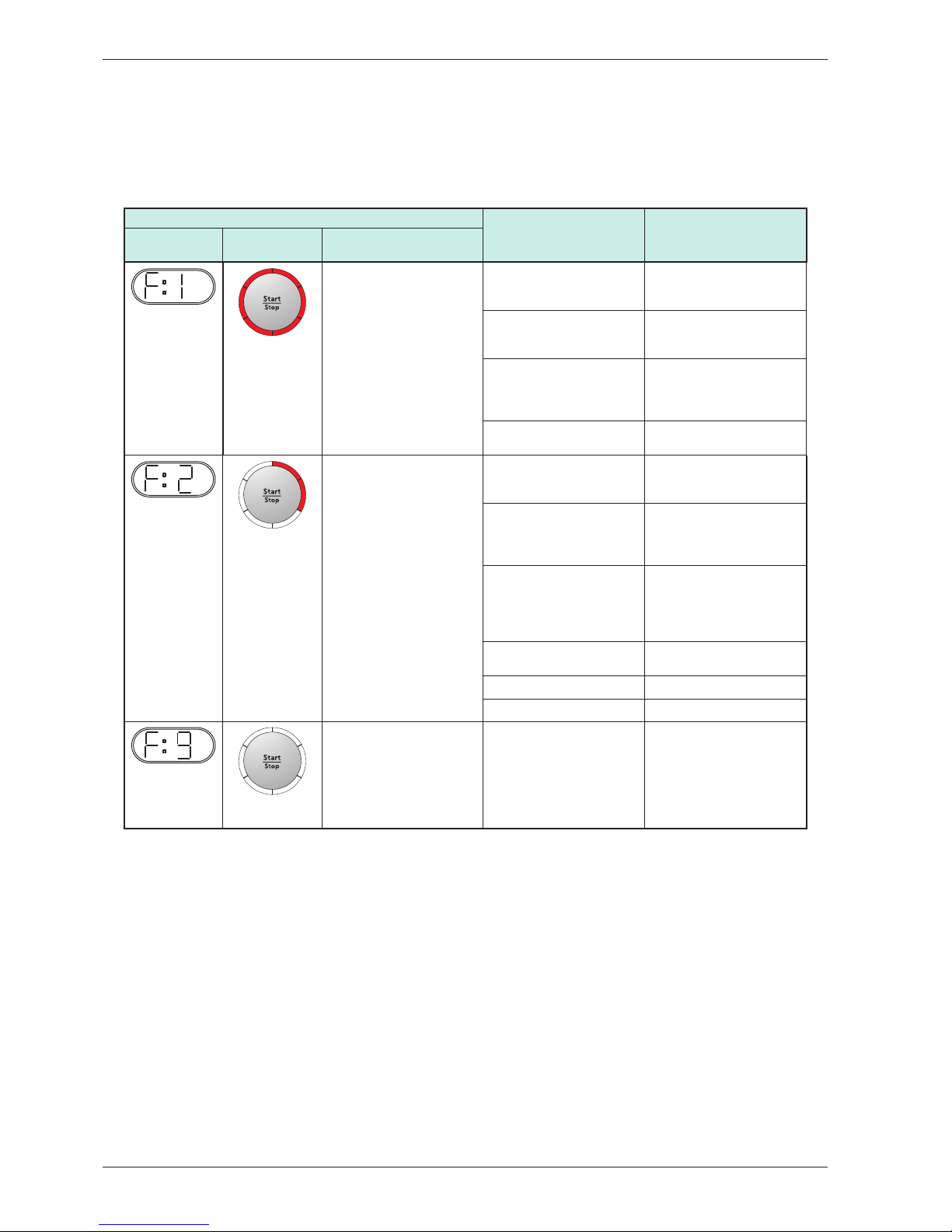

Total reset of programmes

To access the test programme, total reset of the programme must be carried out as follows:

1. Cancel the current programme and switch off the machine by pressing the main power switch.

2. Hold the start/stop button (S1) in and start the machine by pressing the main power switch.

3. Check that any of the LEDs around the programme knob (L7 – L12) lights. This indicates that total

reset has been carried out.

Starting the test programme

4. Press button S7 (left-hand button on divided options button) and keep it pressed for approximately 20

seconds.

Note! This must be done within 3 seconds after carrying out total reset.

• All LEDs except L17 and L18 light up continuously. This indicates that the test programme has been

activated.

Testing the motor and condensing waterpump

5. Press the start/stop button (S1).

• LED L6 lights up and is lit for the entire test program

-

me.

• Condenser dryer: LED L8 lights up.

• Airing dryer: LED L7 lights up.

• The motor and condensing waterpump starts.

• Water fills the housing for the water tank until the

machine stops (check that the switch for condensation

water works).

6. Press the start/stop button (S1) to start the motor and

pump out the condensation water.

• LED L 2 lights up and is lit for the remainder of the test

programme.

Indication of faults:

Fault indication/symptom

Cause

The condensing

waterpump pumps until

S1 is reactivated and

L7 lights up (applies to

airing dryers).

The rear thermistor

does not have any contact or is damaged.

The motor will not start. Motor or cable fault

The condensing water

-

pump does not start.

Switch or cable fault

Test programme

The entire test programme is run in a sequence as follows. You can cancel the test programme at any time

during the programme by opening the door or pressing the main power switch.

L19

L1

L2

L3

L6

L4

L5

L10

L11

L12

L9

L7

L13

L14

L15

a

a

a

a

b

b

b

b

L16

L17

L18

L8

S1

S8 S4S6

S10

S9 S3

S5

S7

J1/S2

Main power switch

S = Push button

L = LED

Page 9

Service manual TD25

9

Testing the element, thermistor and temperature regulation

7. Press the start/stop button (S1).

• LED L3 starts to flash and the large element loop acti

-

vates.

8. Press the start/stop button (S1).

• LED L3 lights continuously and the machine runs heat

regulation for 15 minutes.

• LED L4 starts flashing, which means that temperature

regulation is finished.

• Cooling runs for 5 minutes.

• The machine stops.

Indication of faults:

Fault indication/symptom

Cause

The element does not

start.

Element or cable fault

The programme stops.

F9 is shown in the dis

-

play (applies to machi

-

nes with a display).

The front thermistor is

not connected.

Testing the interval time and buzzer tone

9. Press the start/stop button (S1).

• LED L4 lights up.

• The motor starts and runs at intervals at the same time

as a buzzer sounds.

Indication of faults:

Fault indication/symptom

Cause

No buzzer tone Fault in control

Cancel the test programme.

10. Press the start/stop button (S1).

• The test programme stops and ”End” is shown in the display (applies to machines with a display).

Page 10

Service manual TD25

10

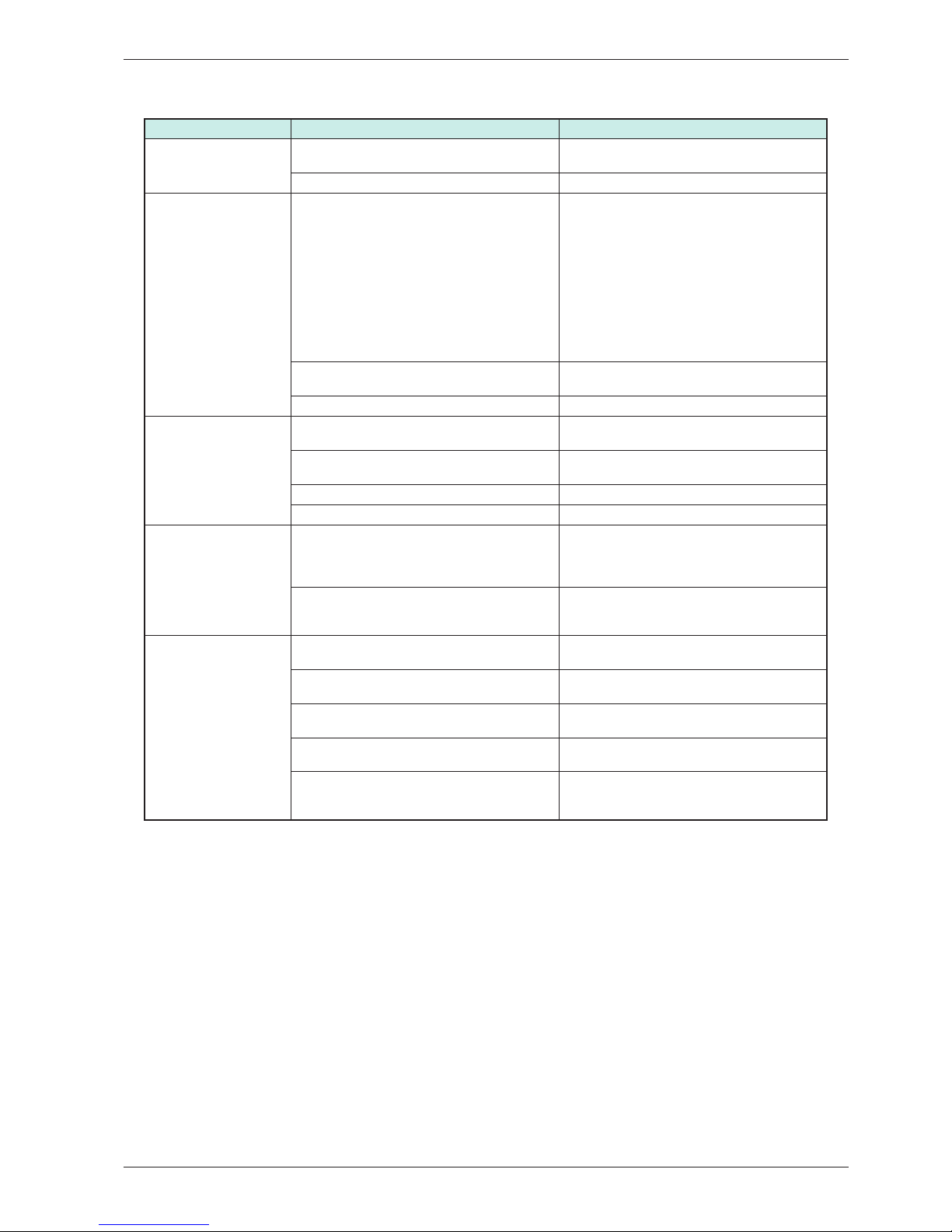

Troubleshooting

Fault indications

The following faults are indicated by a flashing red light in the start/stop button LEDs and as a trouble code

on the display (display not available on all machine versions).

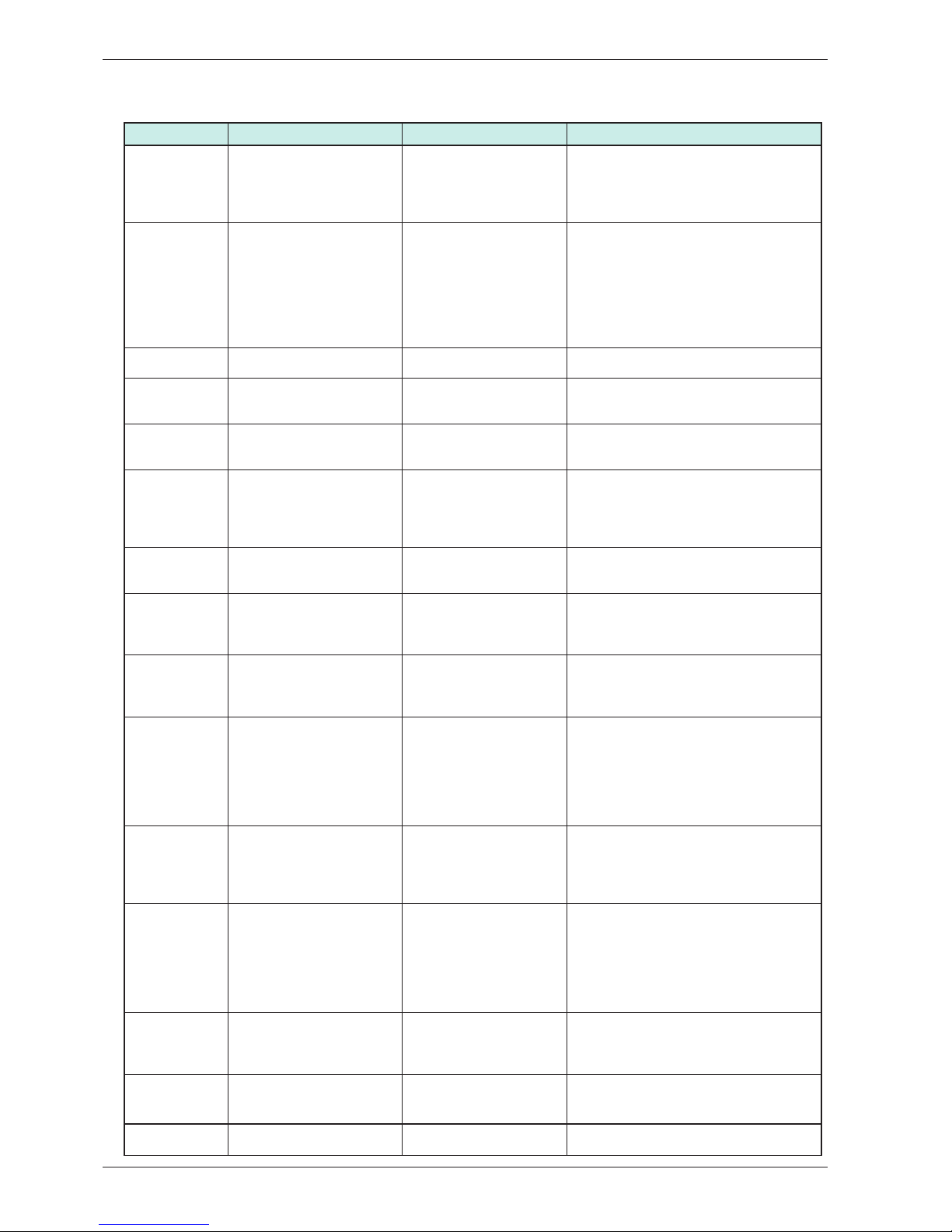

Fault indication Cause Action

Display

LEDs

(flashing)

Meaning

Overfilling

The machine stops.

(applies to condenser

dryers)

The condensation water tank

is full.

Check if the customer has:

• Emptied the tank and

restarted the machine

Condensing waterpump or

hoses blocked.

• Clean hoses and check

voltage and resistance in

the drain pump.

Float/float switch is defective. • Check that the float has

not got “stuck” and check

the function of the microswitch.

The control unit is faulty (the

pump does not start).

• Replace control unit.

Maximum permitted programme time

The machine stops after 3

hours.

The washing has been spun

at too low a speed, i.e. less

than 800 rpm.

Check if the customer has:

• Tried spinning at a higher

speed

The control unit did not have

chance to reset, but added

the time to the next drying

cycle.

Check if the customer has:

• Has the machine switched

off for 30 minutes before

restarting

High ambient temperature

combined with low element

output and low drying tempe

rature leads to condensation

formation.

Check if the customer has:

• Attempted to select an

-

other programme

• Good ventilation in the

room

Poor condensation due to

blocked external air

• Ensure that the external air

has free passage.

Defective thermistor. • Replace the thermistor.

Defective control unit • Replace control unit.

(no indication in

LEDs)

Thermistor fault

The machine stops.

The front thermistor is de

fective or the control is not in

contact with it.

• Replace the thermistor.

After carrying out corrective actions as above, reset the fault indications by switching off the machine using

the main power switch.

Page 11

Service manual TD25

11

Other faults

Fault symptom Cause Action

The machine will not start. The outer door is not properly closed. • Check that the door pin is activating the door

switch.

The machine is not supplied with power. • Check the fuses and connections.

The machine stops. The automatic overheating protection has tripped.

Check if the customer has:

• Opened the door and cleaned the filter and

condenser unit

• Left the door open long enough for the overheating protection to be reset

and the display and LEDs to light up

• Attempted to restart the programme

Service action:

• Clean internal fan wheel, condenser, air ducts

and element.

• Check the seals.

The overheat protection in the motor has been

tripped.

• Clean and check the motor.

• If necessary, replace the motor.

Defective control unit • Replace control unit.

The washing does not

get dry.

Air leakage at the door seals is affecting the

drying results. • Check the sealing strips.

Air leakage around the motor shaft affects the

drying result.

• Check the seal around the motor shaft.

Defective rear thermistor • Replace the thermistor.

Defective control unit • Replace control unit.

Drying is uneven. Mixing of various types of items can lead to une

-

ven drying results.

Customer information:

• Check that different types of items are not

mixed in the same machine. Remove the dry

items.

How full the machine is affects the drying results.

Customer information:

• Check that the machine is not overfilled. Remove some of the washing if necessary.

Tumble-drying takes too

long.

The lint filter is blocked.

Customer information:

• Cleaning the lint filter.

The condenser unit is blocked.

Customer information:

• Clean the condenser.

The washing machine’s spinning affects drying.

Customer information:

• Spin at a minimum of 800 rpm.

The machine is in a room with poor ventilation.

Customer information:

• Open doors to adjacent rooms.

The evacuation hose is too long, blocked or bent.

Customer information:

• Try to make the hose length as short as pos

-

sible with as gentle bends as possible.

Page 12

Service manual TD25

12

Components and measurement values

Item number Component Measurement value Comments

80 790 43 Motor 50 Hz,

220/240 V

Main winding: 23.8 Ω

Auxiliary winding: 28.1 Ω

Current: 1.1 A; 270 W;

2850 rpm

80 766 90 Motor 60 Hz, 220/240 V Winding resistance:

cable colour grey-blue

25.5 Ω

cable colour grey-red

16.0 Ω

Current: 0.9 A; 200 W;

3300 rpm

The motor is a 2-pin motor and is directly

connected to the fan for internal air and

gearing for driving the cylinder. The fan for

external air is also driven on condenser

dryers. All resistance values have toleran

-

ces of ±7 %.

80 801 19 Capacitor 8 μF, 400V The capacitor is mounted on the motor.

80 638 09 Condensing waterpump

25W

111 Ω

80 762 02 EMC filter with inductor The filter eliminates interference to and

from the machine.

80 762 24 Thermistor 40 – 60 kΩ (at room tem-

perature 20 – 30°C)

The thermistor controls temperature

regulation. If the thermistor is short-circuited or detaches from the control unit, the

programme is cancelled.

80 792 00 Thermostat (135°C) The thermostat automatically disconnects

the heating loop at too high temperatures.

80 773 85 Thermostat/Overheating

protection

(150°C automatic)

The thermostat

/overheating protection interrupts the

programme at too high temperatures.

80 797 37 Thermostat/Overheating

protection , 150°C (USA)

The thermostat/overheating protection

interrupts the programme at too high

temperatures.

80 761 04 Door switch The front door affects a door switch,

which interrupts the programme when

the door is opened. If the door has been

opened and closed during the programme

the machine must be restarted using the

start/stop button.

80 761 03 Microswitch float If both containers are overfilled the pro-

gramme is interrupted by a float switch

located on the lower holder. Overfilling is

indicated in the display.

Electrical connection The machine is delivered as single phase

and can be switched between 1950 W, 10

A and 2500 W, 16 A.

Adjustment between 1950 W / 10 A and

2500 W / 16 A is carried out using soft

-

ware via buttons.

80 771 30

80 771 32

Control Unit (TD25.1)

Control Unit (TD25..3)

The control unit contains microproces

sors for controlling programmes, motor,

element etc.

80 762 26 Heating Element 2500W

80 762 27 Heating Element 3000W

Page 13

Service manual TD25

13

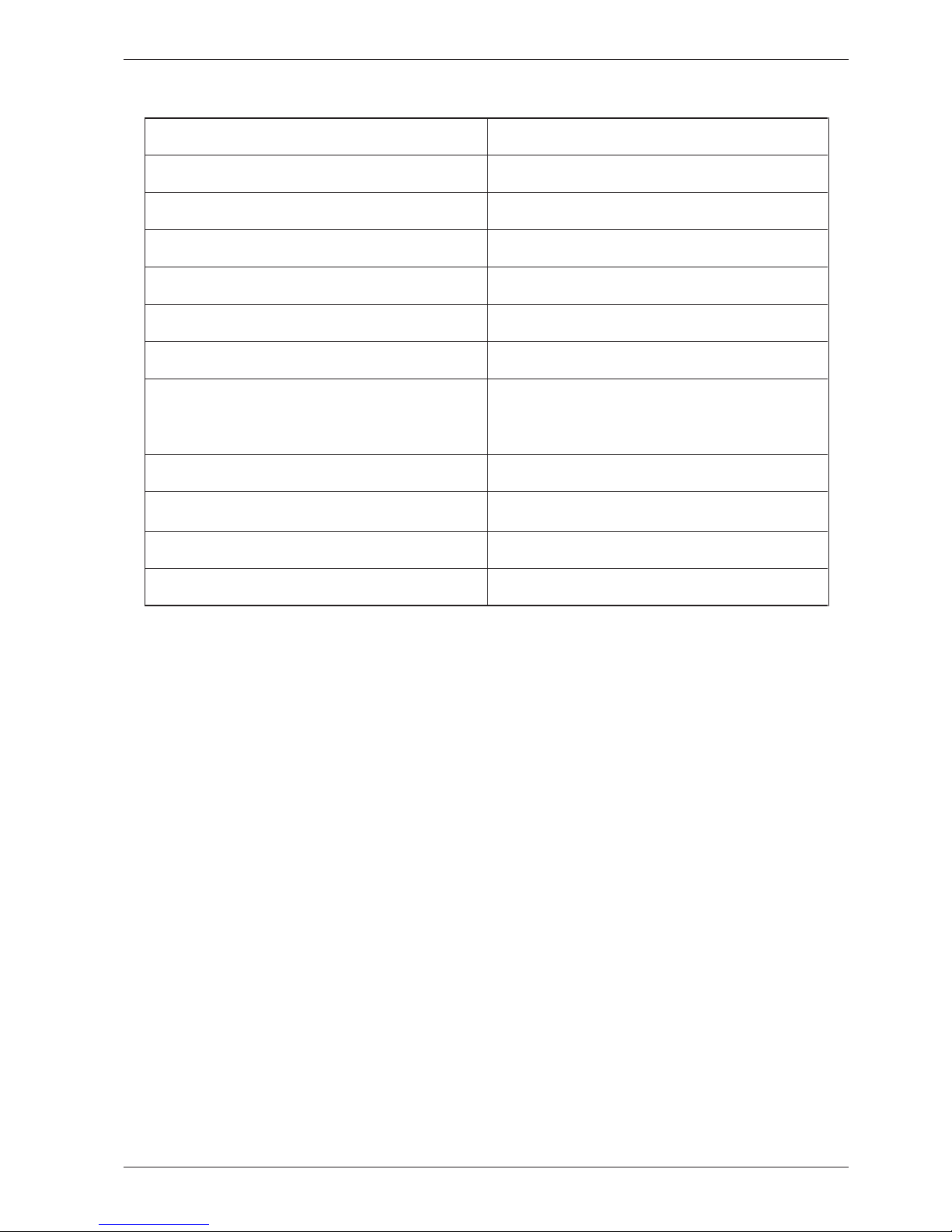

Technical data

Height: 850 mm

Width: 595 mm

Depth: 585 mm

Weight: 47 kg

Cylinder volume:

111 l

Max. washing capacity: 6.0 kg

RPM: 52 rpm

Rated power: 1950 W = 10 A

2500 W = 16 A

Adjustment between 10 and 16 A is carried out

using software via buttons.

Drying drum material:

Stainless steel

Outer casing material: Powder-coated and hot-galvanized sheet steel or

stainless steel

Set-up: Stacking or freestanding

Protection class:

IP X4

Page 14

Service manual TD25

14

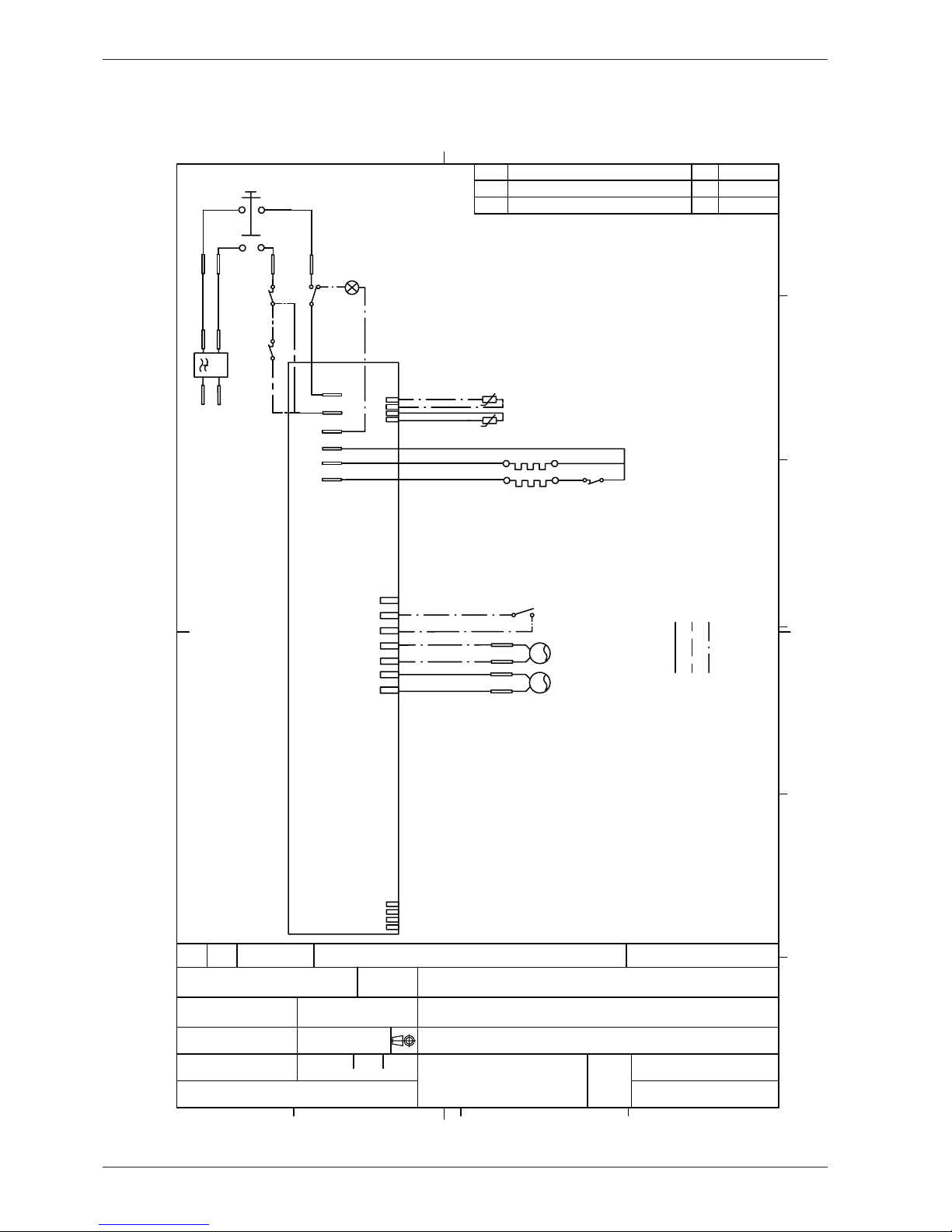

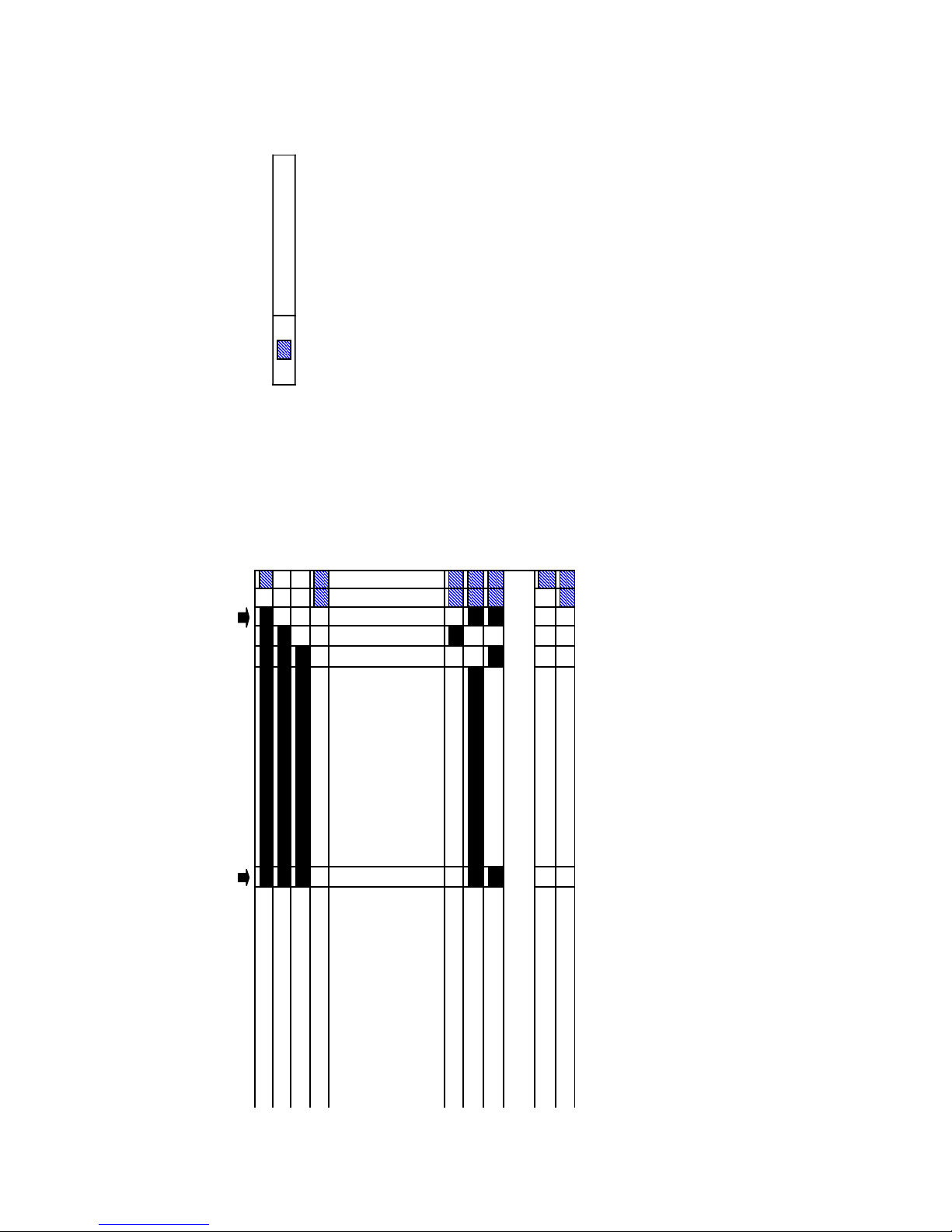

Wiring diagram

WIRES IN ALL MACHINES

INTERNAL CONNECTION

M

B

AP

550 / 1050 W

1950 W

AP: DRAIN PUMP

EL: HEATING ELEMENT

F: FILTER

NTC: THERMISTOR

TB: MAIN SWITCH

FB: FLOAT SWITCH

DO: DOOR SWITCH

T1: THERMOSTAT, OVERHEATING (HEATER)

T2: THERMOSTAT, FAN HOUSING

T3: THERMOSTAT (HEATER)

M: MOTOR

B: INTERIOR LIGHT

FB

T1

T3

TB

F

NTC 1

1

4

7

Home

L

N

E

L

T

B

3

4

5

6

4 23

FORMAT A4

1

A

F

C

Year Week

D

B

Revision

E

Appd

Rev ind

This document must not be copied without

our written permission, and the contents

thereof must not be imparted to a third party

nor be used for any unauthorized purpose.

Contravention will be prosecuted.

Asko Cylinda AB

Dimensions, Type, etc.

Pos.

Material

Name of item

Qty

Dens.Kg/dm3

Part No.

Material

ASKO CYLINDA

Description(ENG)

Gen.tolerance

Scale

Description(SE)

Replace

Gen.tol.Angle

Rev Ind

Designed by

Project

Week

Year

Iss by Dept

Released by

Pema

03 28

KOPPLINGSSCHEMA TD25

80 791 01-01

CIRCUIT DIAGRAM TD25

TD25

80 761 01

02

S:\U\WMD25\1_Tryckunderlag\Kopplingsschema\8076101 Kopplingsschema TD25\8076101 Circuit diagram TD25-02.dft , pema , 2005-11-10 15:00:44

UT

NTC 2

ALTERNATIVE WIRING

DB

*A

*B

*A

*A

*A CONDENSE DRYER

*B WITH INTERIOR LIGHT

T2

PM

PM 05 44

05 45

01

02

Drawing updated

Drawing updated

Page 15

Service manual TD25

15

Notes

80 800 48 Rev 1 Service maual

Page 16

Product information TD25

Пуск

Компоненты

Временные инт

Программа

Режимы

Предотвращение измятия

Охлаждени

е

Пояснения к таблице

По выбору

Зуммер

3 сек. вкл., 57 сек. В

ы

3 мин - 15 мин

3 сек

Проветривание

Автоматическая программа

Временная программа

Временная диаграмма (описание процесса выполнения программы) TD25

Электродвигатель

2'

Дренажный насос (30 сек. вкл., 210 сек.

Нагревательный элемент

Зуммер

Программа сушки (макс. 3 часа)

20 минут - 2 часа

5 минут - 2 часа

Appendix: Timer diagram Page 1

Loading...

Loading...